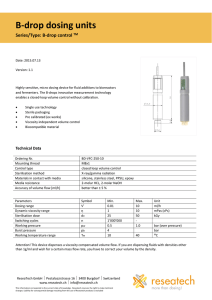

No. Name / purpose Unit rev. Qty Specifications/Requirements Automatic material application system. PCS. one - Overall dimensions: 740x852x630 mm; p/n one - Weight: 105 kg; Designed to work with complex electronic components. Can be used for both prototyping and serial applications - Working field: 500x500x100 mm; - Power supply: AC 220V 50/ 60Hz 10A 0.8 kW; - Three- axis platform; - H-bridge; - Industrial CCD camera 1.3 MP for reading fiducial marks and programming; - Field of view 7x9 mm (adjustable); - Repeatability/accuracy: ±0.01 mm; - Travel speed: XY 500mm/ s , Z 300 mm/s; - Drive: servo motor + high precision module; - Maximum load: 15 kg; - Maximum load on the tool: 7 kg; - Resolution: 0.01x0.01 mm; - Types of drawing along three axes: point / arc / straight line / circle / fill; - Acceleration: 0.45g ; - Dosing of solder paste; - Dosing of materials with fluid pressure control ( FluidPressureControl ); - Sealing and coating; - Pasting and isolation of corners and edges of products; - Podzalivka (applying material under the body of the component); - Automatic calibration; - Visual inspection; - Scanning of a barcode and fiducial points; Z axis ; - Intelligent dosing head control system; - Ring LED illumination (coaxial - optional); - Management and programming using a PC; - SSD disk with a memory capacity of 120Gb; - Valve Auger V-8000s - 1 piece ; - Valve controller Auger C-191 B - 1 pc ; - Piezo valve APJ-1000S (heating unit and controller included) - 1 pc ; - Low liquid level sensor in the syringe - 2 pcs ; - Laser sensor for adjusting the dosing height 30±4 mm - 1 pc ; - Module for automatic needle calibration - 1 pc ; - A set of spare parts - 1 pc.