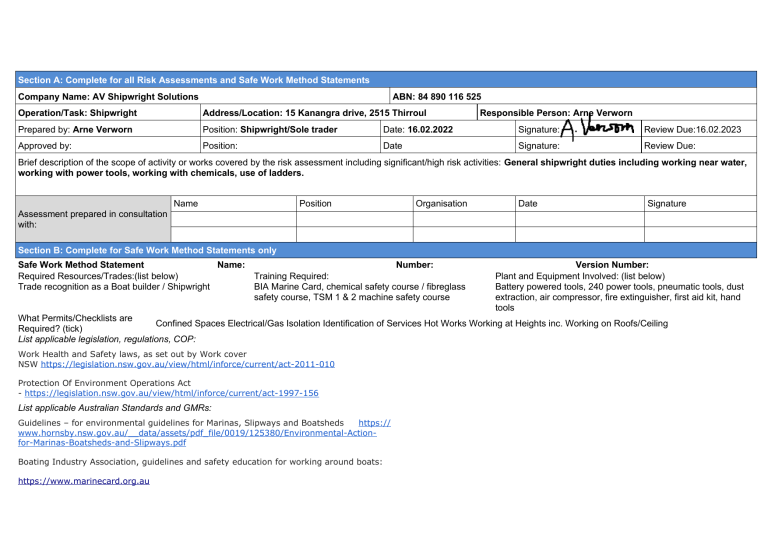

Section A: Complete for all Risk Assessments and Safe Work Method Statements Company Name: AV Shipwright Solutions ABN: 84 890 116 525 Operation/Task: Shipwright Address/Location: 15 Kanangra drive, 2515 Thirroul Responsible Person: Arne Verworn Prepared by: Arne Verworn Position: Shipwright/Sole trader Date: 16.02.2022 Signature: Review Due:16.02.2023 Approved by: Position: Date Signature: Review Due: Brief description of the scope of activity or works covered by the risk assessment including significant/high risk activities: General shipwright duties including working near water, working with power tools, working with chemicals, use of ladders. Name Position Organisation Date Signature Assessment prepared in consultation with: Section B: Complete for Safe Work Method Statements only Safe Work Method Statement Name: Number: Required Resources/Trades:(list below) Training Required: Trade recognition as a Boat builder / Shipwright BIA Marine Card, chemical safety course / fibreglass safety course, TSM 1 & 2 machine safety course Version Number: Plant and Equipment Involved: (list below) Battery powered tools, 240 power tools, pneumatic tools, dust extraction, air compressor, fire extinguisher, first aid kit, hand tools What Permits/Checklists are Confined Spaces Electrical/Gas Isolation Identification of Services Hot Works Working at Heights inc. Working on Roofs/Ceiling Required? (tick) List applicable legislation, regulations, COP: Work Health and Safety laws, as set out by Work cover NSW https://legislation.nsw.gov.au/view/html/inforce/current/act-2011-010 Protection Of Environment Operations Act - https://legislation.nsw.gov.au/view/html/inforce/current/act-1997-156 List applicable Australian Standards and GMRs: Guidelines – for environmental guidelines for Marinas, Slipways and Boatsheds https:// www.hornsby.nsw.gov.au/__data/assets/pdf_file/0019/125380/Environmental-Actionfor-Marinas-Boatsheds-and-Slipways.pdf Boating Industry Association, guidelines and safety education for working around boats: https://www.marinecard.org.au Communication Method: Contractual agreement with individual employees Adjacent works that may be affected Yes No Subcontractors used Yes No Coordination of work activity: Arne Verworn Communication to other parties: Process and frequency of review to ensure work complies with SWMS: Once a year, or sooner if circumstances have changed Emergency Response: PPE: (tick) where applicable document specific type Section C: Complete for all Risk Assessments and SWMS Initial Risk Rating Consequences Item No. Activity Description (Describe the sequence of work or the broad areas of activity) Aspects & Hazards (See last page for typical hazards) (See over page for categories) Controls (To bring the risk to as low as is reasonably (Describe what can go wrong based on hazard) Impact s (Note: Impacts describe how serious the consequences are) Likelih ood (vsmall to vlarge) (v.low to v.high) Ri sk R ati n g 1 being requested to leave site, unfamiliar with site conditions/ being overlooked during an lay-out, marina unaware that evacuation, no-one checking up works is being carried out on employee Injury, invalid insurance, 4 5 20 2 Boarding a motor or sailing vessel Slipping, falling, tripping, drowning Injury, death. 5 3 15 3 Working near water Falling into the water, drowning Injury, death 5 2 10 practicable ideally ‘eliminate’ risk, see over page for hierarchy of controls. Where a GMR risk event is identified, there must be at least one preventative (engineering or above) and one mitigative controls sign-in and sign-out each time you arrive onsite, first initial site introduction Resi dual Risk Rati ng Very low Move / pull the boat closer, enter at areas with Low slipping protection (non skid), set-up a gangway Wear a life jacket (if you can’t swim), move the boat closer to the wharf to reduce the gap between Low wharf and boat (reset lines). 4 Running 240v power leads Electrocution, tripping Injury, death 5 2 10 5 Operating 240v power tools electrocution Injury, death 5 2 10 6 Cutting and drilling of GFK / fibreglass Inhalation of GFK, environmental pollution Injury, environmental damage 3 2 6 7 Operating battery powered tools Inflicting an injury (cut, inhalation, shaving into eyes) Injury 3 2 6 Ensure all power outlets are fitted with a working RCD. Check power leads for any obvious defects Become familiar with and comprehend the manufacturer’s Safe Operating instructions. Keep extension leads away from the water’s edge. Ensure that the plug connecting to the marina power pedestal is a 15Amp “captive plug” (with a screw collar on the plug to connect securely to the outlet). Ensure all power outlets are fitted with a working RCD Check power tools for any obvious defects Understand the manufacturer’s Safe Operating instructions Only experienced/trained staff to use electrical equipment Ensure all appropriate guards are fitted/used Keep tools away from the water’s edge. Ensure that the plug connecting to the marina power pedestal is a 15Amp “captive plug” (with a screw collar on the plug to connect securely to the outlet) Prevent any shavings, dust etc from entering the water. Use dust extraction where possible. Use appropriate PPE Prevent any shavings, dust etc from entering the water. Use dust extraction where possible. Use appropriate PPE Check battery powered tools for any obvious defects Understand the manufacturers Safe Operating instructions Only experienced/trained staff to use tool equipment Ensure all appropriate guards are fitted/used Keep tools away from the water’s edge. Prevent any shavings, dust etc from entering the water. Use dust extraction where possible. Use appropriate PPE Low Low Low Low Ensure adequate ventilation Understand MSDS Bring small quantities to site Use sealed containers, spray bottles instead of open cans where practical Keep all chem’s in secondary spill-proof container Have fire fighting equipment nearby Ensure that an exclusion zone around your immediate work area is established Prevent any chemical or other type of contaminants to enter the waterways, or become airborne Use appropriate PPE Ensure adequate ventilation Understand MSDS Bring small quantities to site Use sealed containers, spray bottles instead of open cans where practical Keep all chemicals in secondary spill-proof container Have firefighting equipment nearby Ensure that an exclusion zone around your immediate work area is established Prevent any chemical or other type of contaminants to enter the waterways, or become airborne Use appropriate PPE Prevent any shavings, dust etc from entering the water. Use dust extraction where possible. Use appropriate PPE Clean up immediate Potentially wearing a life jacket, reducing the gap between boat and wharf, setting up a sanding tent / tarp to ensure no environmental pollution occurring, use of appropriate PPE Ensure adequate ventilation, setup a spray tent with filtration, Ensure no environmental damage is occurring Ensure that an exclusion zone around your immediate work area is established Prevent any chemical or other type of contaminants to enter the waterways, or become airborne Use appropriate PPE 8 Transportation of chemicals Spill, environmental pollution, skin contact Injury, environmental damage 5 4 20 9 Operation / handling / mixing of chemicals Spill, environmental pollution, skin contact Injury, environmental damage 5 4 20 10 Cutting and drilling of metal Inflicting an injury (cut, inhalation, shaving into eyes) Injury 4 3 12 11 Working on the boat hull (sanding, polishing) Falling into the water, environmental pollution, electrocution Injury, death, environmental damage 5 2 10 12 Spray painting environmental pollution, inhalation of fumes, over spray Injury, environmental damage 4 2 12 13 Sanding 2 6 Dust extraction, sanding tent, PPE Low Tool storage Tool transportation Working outdoors Injury, environmental damage Injury Injury Injury/illness, death 3 14 15 16 environmental pollution, inhalation of particles tripping Lifting heavy weights Sunburn, dehydration 3 3 4 2 3 2 6 9 8 Keep tools neat and organised Use trolley, don’t overload toolbags Sunscreen, sunglasses, hat, if possible sunsail Low Low Low Low Low Low Low 17 Working at height falling Injury, death 5 2 10 18 Working around / with 12v or 240v systems electrocution Injury, death 5 2 10 19 Working in confined spaces Getting stuck, insufficient ventilation Injury, death 5 2 10 20 Working on/with ladders Falling, tripping, crushing 5 2 10 Injury, death Wear a safety harness and use appropriate anchor points Isolate the system (turning off the circuit breaker), tag out (other people don’t turn it on again, communicate clearly) Get a second person to assist and monitor, ensure sufficient airflow Ensure stable, flat ground space/base selected for ladder location Seek second person to act as spotter/steadier if indicated. Understand MSDS and use according to safety instructions. Do not climb ladder if feeling unwell or dizzy. Low Low Low Low 21 Working in a public area Shipwright activities might impact other people / trades around as well as the general public Injury and illness of others 4 3 12 keep tools, cart and electrical leads confined to a small area immediately alongside the vessel, Low create and exclusion zone around the immediate work area if there is a potential risk to passer-by 22 Disposal of waste Incorrect disposal might cause an environmental damage and or a fine Environmental damage, fines 3 3 9 You the proper bins for the disposoal of waste products. If uncertain contact the Marina office for further information Very Low FALLS Fall on same level (trip/slip) Fall from any height Fall into trench Fall of materials PEDESTRIANS, TRAFFIC AND PARKING Car and heavy vehicle interaction Increased local traffic and/or reduced parking spaces (eg events) People and vehicle interaction e.g. car parks, driveways, loading docks, wharf Goods/material delivery hours and infrastructure Pedestrian access routes ASBESTOS AND HAZARDOUS BUILDING MATERIALS Work in areas where asbestos, synthetic minerals fibres, Polychlorinated biphenyls, ozone depleting substances are in existence including removal, disposal and encapsulation ELECTRICAL Electrical work inc live works Temporary power boards Tool or equipment potential faults Overhead power lines LONE WORKING Lone working WORK RELATED STRESS Excessive hours Fatigue Unrealistic deadlines MANUAL TASKS Repetitive/awkward tasks Office and sedentary work Active works inc maintenance, cleaning, kitchen and gardening NOISE AND VIBRATION Long term exposure to sound PLANT AND MAINTENANCE Use and maintenance of plant and equipment including exacavators, cranes etc Registered plant WATER BODIES Water body management CONSTRUCTION SITE COMPOUND Compound establishment including pedestrian and vehicle access/segregation Control and access Welfare and facilities INGROUND SERVICES Service strikes HIGH RISK WORKS (not covered elsewhere) Hot Works Confined Spaces EMERGENCY MANAGEMENT Potential emergency situations Emergency preparedness FIRST AID MANAGEMENT Potential first aid situations First aid preparedness SECURITY Inadequate lighting incl. site and surrounds Unauthorised access at operating assets Section E: Worker Acknowledgement (SWMS) Only YACHT SERVICES Refuelling Waste/ effluent pump-out Maintenance USE OF WORK BOAT Lone operation of work boat Travel to external sites Using work boat after dark EVENT MANAGEMENT Event set up Large crowd control EXTERNAL STAKEHOLDERS/NEIGHBOURHOOD Complaints re. site related activities Media interest Operating hours inc noise and public amenity Exposure to mechanical vibration WATER QUALITY Creation of dust from construction, demolition works Emissions from construction plant and traffic HAZARDOUS CHEMICALS Storage/segregation and use of hazardous chemicals Hazardous chemical spills STORMWATER AND EROSION Disposal of collected stormwater Generation of runoff/sediment from assets, sites and roadways Runoff and potential erosion from stockpiles/excavations areas. Uncontrolled stormwater/sediments entering receiving environments Water body management TEMPERATURE Working outdoors WASTE MANAGEMENT Generation of solid/liquid waste from construction or demolition Waste disposal and/or transportation Liquid and solid waste spills from concrete/paint wash-out CONSERVATION, HABITAT, FLORA AND FAUNA Environmental protection Dangerous animals and fauna OTHER By signing this SWMS, you are acknowledging that you have read and understand the steps involved in the work activity, the known hazards, level of risk and controls that must be implemented to mitigate the risks Name Signature Date Arne Verworn 16/2/2022 Section F: Review All broad risk assessments and SWMS must be reviewed when there is a change in the work environment that requires a change in the work methodology or at least every 6 mths. The review will be undertaken by the responsible person with relevant workers. All workers must re-sign on if there has been a material change in the way duties are managed. Review details Name Signature Date Appendix 1: Risk Management Definitions, matrix and heirarchy of controls Consequences Likelihood 5 Very High 4 High 3 Med 2 Low 1 Very Low Almost certain to occur in identified circumstances without controls Number and regularity of report incidents or risks indicates trend, expecting with near certainty it will occur again Quantified very high exposure without controls Strong anecdotal evidence that it is likely to occur in identified circumstance without any controls Number and regularity of report incidents or risks indicates trend, but not expecting with near certainty it will occur again Quantified high exposure without controls May occur in identified circumstances without controls Number and regularity of incidents from risk is infrequent Quantified moderate exposure without controls Could occur in identified circumstances without controls 1 or 2 incidents arising from the risk Quantified low exposure without control Highly unlikely to occur in identified circumstances without controls No evidence of incidents No quantified or known exposure to the risk without controls Consequences [Rated by impact] Risk Matrix Lik eli ho od Very High 5 High 4 Medium 3 Low 2 Very Low 1 Critical = 21-25 Significant = 15-20 Moderate = 9-14 Minor = 3-8 Negligible = 1-2 Very Small Small Medium Large Very Large 1 2 3 4 5 5 4 3 2 1 10 8 6 4 2 15 12 9 6 3 20 16 12 8 4 25 20 15 10 5 5 Very Large 4 Large 3 Medium Health and Safety Fatality due to injury or occupational illness; kidnapping of employee; evacuation of employees due to threat of fatality Permanent disabling injury or occupational illness Lost time injury or occupational illness 2 Small Offsite medical treatment 1 Very Small Onsite first aid treatment Environment/Corporate Social Responsibility Irreversible and/or offsite damage; clean up or remedy from damage result is remediation work lasting >12 months; regulatory notification compulsory with public investigation likely; impact on local community leads to community outrage Long term environmental damage, pollution or degradation; discovery of environmental risk with limited offsite impacts; clean up, remediation or rehabilitation will require <36 months Medium term environmental damage; discovery of environmental risk with limited onsite impacts; clean up, remediation or rehabilitation will require <12 months Short term environmental damage, pollution or degradation event; discovery of environmental risk with limited onsite impacts clean up, remediation or rehabilitation will require up to 1 month Minor onsite environmental damage, pollution, or degradation event; clean up, remediation or rehabilitation will require <24 hrs Hierarchy of Risk Control Consider the Hierarchy of Risk Control when selecting control actions to ensure the most effective control possible is used rather than the lower level control actions