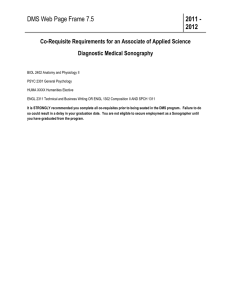

J. DRUG DEL. SCI. TECH., 23 (6) 577-581 2013 Recovery rate of rat skin micropores made by dissolving microneedles Y. Ito1*, N. Hamazaki1, H. Higashino1, N. Miyamoto1, Y. Murakami1, N. Inoue2, K. Takada1 Department of Pharmacokinetics, Kyoto Pharmaceutical University, Yamashina-ku, Kyoto, 607-8412, Japan 2 BioSerenTach Inc., Shimogyo-ku, Kyoto, Japan *Correspondence: yukako@mb.kyoto-phu.ac.jp 1 The physiological recovery rate of skin was studied using dissolving microneedles (DMs) made of chondroitin sulfate. Chips of two kinds were prepared having conical DMs as an array: (1) a 300 DM array chip having a sharp tip with mean diameter of 4.7 ± 0.2 μm, and a (2) 225 DM array chip having a less-sharp tip with mean diameter of 15.3 ± 0.3 μm. Under anesthesia, DMs were inserted into abdominal rat skin from which the hair had been removed. The kinetics of skin healing was studied by pathological and biochemical methods. At 5, 30, 45 min, and at 1 and 3 h after the removal of the DM array chip, the skin was stained with 0.25 % Evans blue solution before pathologic observations were performed. The skin physiology recovered to its normal state at 45 min with both DMs. Biochemical study was also performed by measuring the leaked amount of lactose dehydrogenase (LDH) activity. The maximum leaks, 199.3 ± 13.0 % (225 DMs) and 153.4 ± 23.2 % (300 DMs) appeared at 5 min. In both DMs, the micropores formed on the skin healed within 60 min. Pathological and biochemical examinations revealed that skin recovered to the pre-treatment level within 1 h. The effect of the adhesion length of the chips onto the skin on the skin’s recovery rate was studied by attaching two DMs to the rat skin for 6 h. Maximal leaks were detected at 5 min after administration, i.e., 157.8 ± 10.1 % for 300 DMs and 215.6 ± 5.4 % for 225 DMs. However, the leakage returned to the pretreatment level at 60 min. Therefore, DMs were found to be a low-invasive TDDS for drugs. Key words: Healing time - Dissolving microneedles (DMs) - Transdermal delivery - Skin - Rat. molecules are absorbed. MN TDDSs are classified into four categories [11]: (1) hollow-type MNs, which are extremely small needles through which a drug solution is injected into the skin [12]; (2) coating-type MNs, which are made of metallic and/or silastic substances onto which a surface drug is coated [13]; (3) pierce-type MNs, which are made of metallic or silastic microneedles that make microconduits in the skin, after which a drug solution or cream is applied following removal of the MNs [14]; and (4) dissolving microneedles (DMs), which are made of soluble polymers such as sodium chondroitin sulfate and sodium hyaluronic acid, where drug molecules are formulated into those base polymer as a solid dispersion [15]. Among them, coated MNs are the front-runner of MNs. Clinical phase II trials are underway in the USA, where parathyroid hormone (PTH) is formulated for the treatment of osteoporosis [16]. On the other hand, we have been studying two-layered DMs with water-soluble thread-forming biopolymers such as chondroitin sulfate, dextran, hyaluronic acid, and albumin used as the base. Chondroitin sulfate is a peptideglycan that exists in biological tissues [17-22]. Chondroitin sulfate is used as an injection preparation for the therapy of arthritis. Therefore, no safety problem exists when chondroitin sulfate is used as the pharmaceutical additive for dissolving microneedles. Drug molecules are formulated as a solid dispersion with the base polymer. After the insertion of DMs into the skin, the base polymer dissolves immediately. Then drug molecules are released into the skin tissue, producing high availabilities of peptide/protein. For example, 98 % relative physiological availability of insulin [23], 90.0-93.1 % bioavailability (BA) of desmopressin [24], 72.8-101.3 % BA of recombinant growth hormone [24], 65.9-69.0 % BA of erythropoietin [25], and 79.9-117.8 % relative BA of interferon [26] were obtained in our previous studies. In those studies, 225-300 DMs were formed on a chip made of cellulose acetate. To administer DMs into the skin, the chip was pressed to the skin with collision speed of 0.8-2.2 m/s followed by pressure of 7-22 N for 3 min when the polymer base dissolved within the skin and drug molecules were released from DMs and absorbed into systemic circulation. After the chip was removed from the skin, The hurdle of developing new molecular entities as pharmaceuticals is becoming higher each year [1]. Therefore, R&D activity for life-expansion of active pharmaceutical ingredients (APIs) has an important role in pharmaceutical industries. Most clinically used dosage forms are oral and injection preparations. New dosage forms, including drug delivery systems (DDSs) for oral and injection preparations, are studied intensively. Although injection preparation provides high bioavailability (BA) of drugs, e.g., BA is 100 % in the case of IV injection preparation, injection preparation demands high costs of both production and clinical treatment in clinics. In addition, patients, especially infants and child patients, often suffer from pain. In contrast, oral preparations such as tablets and capsules are convenient dosage forms, although drugs classified as class II and IV compounds, as described by Amidon et al. [2], invariably suffer from low-BA problems and high inter-subject variation of BA. As an alternative to those preparations, percutaneous preparations have attracted the interest of pharmaceutical scientists because they are patient-friendly preparations. However, the percutaneous preparation approved by the FDA as of 2007 amounted to only nine preparations [3]. Because the barrier function of skin is very strong, only a limited amount of a given drug is absorbed into systemic circulation. In fact, human skin comprises three layers: the stratum corneum, epidermis, and dermis. [4] The first is the 10-15-μm-thick outer layer, although it is dead tissue. The stratum corneum has a strong primary barrier function against drugs. The second barrier is the viable epidermis, which has a 100-150 μm thickness and which contains tissues such as living cells. However, no blood vessels exist in the epidermis [5]. To increase the skin permeability of drugs, numerous approaches using chemical enhancers, electric fields, ultrasound, and thermal methods have been attempted [6-10]. However, the success of those transdermal drug delivery systems (TDDSs) is limited because the skin has a strong barrier function, which leads to low membrane permeability of drugs through the skin. However, microneedles (MNs) present the possibility of cutting edge technology for the transdermal delivery of drugs. MNs produce micropores on the skin stratum corneum into which drug 577 J. DRUG DEL. SCI. TECH., 23 (6) 577-581 2013 Recovery rate of rat skin micropores made by dissolving microneedles Y. Ito, N. Hamazaki, H. Higashino, N. Miyamoto, Y. Murakami, N. Inoue, K. Takada the micropores that were produced by DMs disappeared gradually and the skin returned to its normal physiology. If the micropores do not close for a long time, the possibility of the skin infection would increase. Therefore, the kinetics of the skin healing, resealing, is an important research project. To evaluate the skin damage in this study, a pathological method using dye staining was used for the physical assessment. In addition, a biochemical method was also used. Namely, to evaluate skin irritation by cosmetics like shampoo and surfactants, lactate dehydrogenase (LDH), leakage from skin tissue was measured as a specific marker of cutaneous irritation [27-30]. Therefore, in this report, the kinetics of skin healing was studied by both pathological and biochemical approaches in rats. the skin was recorded using a digital camera, (Nikon D-200; Nikon Corp., Tokyo, Japan) under normal light. In the other groups of rats, skin images were recorded at 30 min, 45 min, 1 h, and 3 h after application of the DM array chips. In another group of rats, the LDH leakage was measured. At 5, 30, 45 min, and at 1 h and 3 h after the removal of DM array chip from the abdominal rat skin, tissue paper, 2.0 × 2.0 cm, soaked with 10 μL of phosphate buffered saline (PBS) was adhered to the skin for 1 min. Then the leaked interstitial fluid was absorbed to tissue paper. LDH was extracted from the tissue paper with 500 μL of PBS by shaking for 5 min (recipro shaker SR-1; Taitec Corp., Saitama, Japan). After the tube was centrifuged at 12,000 rpm for 15 min at 4 °C, the supernatant was obtained and used for LDH assay using a microplate reader (MTP-300; Corona Electric Co. Ltd., Ibaraki, Japan) at an absorption wavelength of 490 nm. I. MATERIALS AND METHODS 1. Materials Sodium chondroitin sulfate and cellulose acetate were obtained from Wako Pure Chemical Industries Ltd. (Osaka, Japan). Evans blue and brilliant blue (BB) were obtained from Nacalai Tesque Inc. (Kyoto, Japan). Hydroxypropyl cellulose was obtained from Nippon Soda Co. Ltd. (Tokyo, Japan). A lactate dehydrogenase (LDH) assay kit was obtained (Cytotoxicity Detection Kit; Roche Diagnostics Corp., Manheim, Germany). Male Wistar-Hannover rats used in the study and standard solid-meal commercial food were purchased (Japan SLC Inc., Hamamatsu, Japan). All other materials were of reagent grade. They were used as received. 6. Statistics All values are expressed as their mean ± S.D. Statistical differences were assumed to be significant when p < 0.05 (Student’s unpaired t-test). II. RESULTS DM array chips of two kinds prepared in this study are presented in Figure 1. Although the angle of their tip was the same (30°), the sharpness of their tips differed. Table I shows the physical properties of the two DMs. The 300 DM array chip had 300 microneedles; where the mean length was 491.9 ± 5.5 μm, the mean diameter of the basement was 288.8 ± 5.2 μm and the mean diameter of the tip was 4.7 ± 0.2 μm. However, the 225 DM array chip had 225 microneedles and a mean length of 489.6 ± 4.2 μm. The mean diameter of the basement was 290.6 ± 5.1 μm. The mean diameter of the tip was 15.3 ± 0.2 μm. No significant difference was found in the sizes of the two 2. Preparation of DM array chips To 40 mg of sodium chondroitin sulfate, 0.5 mg of BB was added if necessary, then 100 µl of 0.1 M phosphate buffered saline (PBS, pH 7.4) was added and chondroitin glue was obtained by mixing well. After the glue was degassed under reduced pressure, it was dispensed into a mold containing 225 or 300 inverted cone-shaped wells with an area of 1.0 cm2. Each well had 500 µm depth and 300 µm diameter at its top. The mold was covered with a 300 g steel plate. Then the glue was filled into the wells and was dried at 40 °C for 2 h. A chip was made of the mixture of cellulose acetate and hydroxypropyl cellulose (10:1) using a tabletting machine, (Handtab-100; Ichihashi Seiki, Kyoto, Japan). The chip, having a 2.0-mm thickness and 17-mm diameter, was painted with the glue consisting of 15 mg of chondroitin sulfate and 25 mL of distilled water by dipping into the glue solution. After the plate was removed, the glue was painted over the chip and covered on the mold. After drying under the pressure of a stainless steel plate for 3 h, the chip was removed and DMs were obtained as arrays on a chip. 3. Preparation of staining dye solution Evans blue, 25 mg, was dissolved with 10 mL of saline. 4. Microscopic observation of DMs A DM array chip of which the acral portion was stained with BB was observed using a digital videomicroscope (VH-5500; Keyence Co., Osaka, Japan) under normal light. 5. Recovery rate of micropores made on rat skin Male Wistar-Hannover rats, 329 ± 21 g, were anesthetized with sodium pentobarbital, 50 mg/kg. Body temperature was controlled to 37 °C by warming during the experiment. Hair on the abdominal region of each rat was removed using a shaver (ES7111; Panasonic Inc., Osaka, Japan). The DM array chip was administered to the rat skin using an applicator with collision speed of 2.0 m/s, followed by secondary pressure of 2.5 N for 3 min. At 5 min after the DM array chip was removed from the abdominal skin, soft tissue paper soaked with 0.25 % Evans blue solution was attached to the skin for 30 s to stain the micropores. After the soft tissue paper was removed, the skin surface was wiped carefully with soft tissue paper. Then an image of Figure 1 - Dissolving microneedle (DM) array chips of two kinds prepared for this study: (1) 300 DM array chip having a sharp tip and (2) 225 DM array chip having less sharpness. To clarify the shape of the acral portion of DMs, brilliant blue was added to the base polymer. 578 Recovery rate of rat skin micropores made by dissolving microneedles Y. Ito, N. Hamazaki, H. Higashino, N. Miyamoto, Y. Murakami, N. Inoue, K. Takada J. DRUG DEL. SCI. TECH., 23 (6) 577-581 2013 Table I - Physical properties of the two dissolving microneedle array chips (mean ± SD, n = 10). Type Number of MN on a chip Length (µm) Diameter of the basement (µm) Diameter of the top (µm) 300 DM 225 DM 300 225 491.9 ± 5.5 489.6 ± 4.2 288.8 ± 5.2 290.6 ± 5.1 4.7 ± 0.2 15.3 ± 0.3* *p < 0.05 compared to type (1) MN. DMs. However, 300 DMs had a sharper tip than 225 DMs. Figure 1 also shows an image of two types of DMs obtained using electron microscopy. As shown in those photos, sharpness of the tip of 300 DM was suggested. Figure 2 portrays images of the stained micropores on the skin formed by the insertion of DMs into the rat abdominal skin. At the initial stage of this experiment, methylene blue was used to stain the skin tissue. As methyl blue is a oxidation-reduction dye, it lost color by oxidation-reduction enzymes that existed in the skin tissue. Instead, Evans blue was used in this study, because it is nontoxic and used as a diagnostic in the estimation of blood volume after its intravenous injection; it is also used as a vital stain for following diffusion through blood vessel walls. At 5 min after insertion, the micropores were detected clearly on the rat skin in both DMs. However, the micropores stained with blue color became smaller as time passed. There was not a great difference in the recovery rate between the two DMs. At 45 min after the administration, the stained micropores by both DMs disappeared, which was ascribed to the recovery of the skin tissue to its normal physiology. As a result, the skin of the two groups rats healed within 60 min after insertion. Figure 3 presents results of the LDH leakage from the rat skin through micropores. At 5 min after the insertion of 225 DMs to the rat skin, the leaked amount of LDH increased to twice the pretreatment level. However, 300 DMs showed about 1.5-times higher LDH leakage than the pretreatment level. A significant difference was found in LDH leakage between 225 DMs and 300 DMs. At 30 and 45 min, LDH leakage amounts were about 151.5 ± 14.4 % and 124.5 ± 8.2 % in 225 DMs. The 300 DMs also showed 122.0 ± 17.0 % and 113.8 ± 16.6 % LDH increases. Significant differences were found for LDH leakage at 30 and 45 min between the two DMs. At 60 min after the DM insertion, no significant difference in LDH leakage was found as compared to the pretreatment levels. Therefore, skin physiology reverted to pretreatment levels in both DMs. To assess the effects of long-term adhesion of DMs to the skin, DMs of both types were attached to the rat skin continuously for 6 h. Thereafter, both pathological and biochemical studies were performed. Figure 4 shows the time course of the recovery of stained micropores. The micropores were stained with Evans blue until 45 min after the insertion of DMs into rat skin. Thereafter, staining was not detected, which showed the recovery of the skin tissue to the normal physiology. Figure 5 presents results elucidating LDH leakage after DMs were attached to the skin for 6 h. The maximum leaks were detected at 5 min after administration, 215.6 ± 5.4 % for 225 DMs and 157.8 ± 10.1 % for 300 DMs. The LDH leakage returned to the pretreatment level at 60 min. Comparison to the results in Figure 3 reveals no significant difference in the recovery rates of the skin between the adhesive lengths of DMs to the skin. Figure 2 - Time course of the image of the stained micropores made on rat skin at 5 min after inserting 300 DM and 225 DM array chips. At the predetermined time, the skin was stained with 2.5 % Evans blue solution and was recorded using a digital camera. Figure 3 - Time course of the leaked amount of LDH from the rat skin through micropores made by 5 min adhesion of two kinds of DMs: black, 225 DM array chip; white, 300 DM array chip. Each point represents the mean ± SD of 4-5 experiments. *Shows significant difference from the control value (p < 0.05). **Shows significant difference from LDH value of DM 300 (p < 0.05). by which microconduits are made on the skin, after which a drug solution or cream is applied. Because those microneedles are made of metal or plastic, they belong to the category of medical devices. When metal is used as the microneedle source material, microneedles having a complex figure can be prepared. Prausnitz et al. prepared arrow-shaped microneedles made of a stainless steel sheet and studied the recovery rate of the micropores made on the skin by measuring the skin impedance [31]. According to their results, microneedletreated skin sites had recovered barrier properties within 2 h, which is a longer time than the results obtained in our study. To explain the III. DISCUSSION DMs are TDDS that offer particularly high safety because DMs are made of water-soluble biopolymer such as sodium chondroitin sulfate, dextran and hyaluronic acid. However, microneedles of three kinds exist: (1) hollow microneedles connected to an infusion syringe, (2) coated microneedles, and (3) metallic and/or silastic microneedles 579 J. DRUG DEL. SCI. TECH., 23 (6) 577-581 2013 Recovery rate of rat skin micropores made by dissolving microneedles Y. Ito, N. Hamazaki, H. Higashino, N. Miyamoto, Y. Murakami, N. Inoue, K. Takada The second reason is the shape of microneedles. Prausnitz et al. used arrow-shaped stainless steel microneedles the surface of which was treated by electropolishing [31]. However, the shape of our DMs was conical, where the diameter of the tip portion was less and linearly increased forward to the basement, the damage done to the skin was thought to be less. The shape of our microneedle was conical, where the theoretical height and diameter of the basement were 500 μm and 300 μm. We compared the recovery rate of the micropores produced by two kinds of DM array chips having 225 and 300 DMs. The mean diameter of 300 DMs was 4.7 ± 0.2 μm and that of 225 DMs was 15.3 ± 0.3 μm. The diameter of the tip of 225 DMs was about three times greater than 300 DMs. When the tip portion of DM is inserted into the skin, micropores are made physically. As the area of the tip increased, the damage to the skin stratum corneum was thought to be increased. As a result, the recovery rate of the micropores produced by 300 DMs was faster than that made by 225 DMs. Those results suggest the importance of the shape and size of microneedles on the damage given to the inserted skin site. The third reason is the different species examined in the safety study. Prausnitz used human volunteers. In the present study, rats were used. Because the growth rate of the body differs between humans and rats [32], the skin healing rates are expected to differ between these species. Matsuo et al. studied skin irritation caused by the insertion of DMs made of sodium hyarulonic acid [33]. They studied skin irritation by measuring the electric impedance in rats. They reported that the electric impedance values recovered within 2 h after the insertion. We also studied the effect of the prolongation of DM adhesion to the rat skin on the recovery rate of micropores on the skin. In our previous report, the systemically absorbed amount of hydrophilic drug was dependent on the period of adhesion of the DM array chip to the rat skin [34]. The absorbed amount of sodium fluorescein (FL), which is a hydrophilic drug and which is used as a diagnostic drug in ophthalmology, from the DM array chip was increased from 0.18 ± 0.02 mg to 5.38 ± 1.99 mg by increasing the adhesive period from 3 min to 6 h. At that time, the damage of the rat skin was thought to be increased by the adhesion of DM array chip for a long period. As a result, the absorbed amount of FL was increased. However, our study based on pathology and biochemistry suggests that no significant difference exists in the recovery rates of rat skin between 3 min adhesion and 6 h adhesion. Therefore, we might state that the skin damage caused by DMs is tentative and the recovery of the skin occurred within 1 h after the removal of DM array chip. Figure 4 - Time course of the image of the stained micropores made on rat skin by 6 h adhesion of 300 DM and 225 DM array chips. At the predetermined time, the skin was stained with 2.5 % Evans blue solution and was recorded using a digital camera. * In conclusion, the resealing time of skin surface micropores created by the collision of DMs was studied using both pathological and biochemical methods. For a 300 DM array chip and 225 DM array chip having the mean tip diameter of 4.7 ± 0.2 μm and 15.3 ± 0.3 μm, skin physiology recovered to a normal state within 60 min. By increasing the adhesion time from 3 min to 6 h, no significant difference was found in the resealing time of the skin micropores. From those results, DMs were found to be a low-invasive TDDS for drugs. Figure 5 - Time course of the leaked amount of LDH from the rat skin through micropores made by 6 h adhesion of two kinds of DMs: black, 225 DM array chip; white, 300 DM array chip. Each point represents the mean ± SD of 4-6 experiments. *Denotes a significant difference from the control value (p < 0.05). **Denotes a significant difference from the LDH value of 300 DM (p < 0.05). discrepancy in the results, we might state that three reasons are possible. One is the difference of the material used to prepare microneedles. In the earlier study, microneedles were prepared using a laser cutting method and their surface cleaned by electropolishing. In contrast, the sodium chondroitin sulfate used in our experiment is used clinically as an injection preparation for arthritis therapy, where the clinical dose is 20-300 mg. In other words, the material of DM is safety and the amount of sodium chondroitin sulfate prepared in DM was too far below the clinical dose. Therefore, the differences of material for microneedles lead to the difference of the time for skin recovery. REFERENCES 1. 2. 3. 580 Pammolli F., Magazzini L., Riccaboni M. - The productivity crisis in pharmaceutical R&D. - Nature, 10, 428-439, 2011. Amidon G.L., Lennernas H., Shah V.P., Crison J.R. - A theoretical basis for a biopharmaceutic drug classification: the correlation of in vitro drug product dissolution and in vivo bioavailability. Pharm. Res., 12, 413-420, 1994. Birchall J.C. - Stratum corneum bypassed or removed. - In: Enhancement in Drug Delivery, E. Touitou, B.W. Barry Eds., CRC Press, New York, 2007, p. 337-351. Recovery rate of rat skin micropores made by dissolving microneedles Y. Ito, N. Hamazaki, H. Higashino, N. Miyamoto, Y. Murakami, N. Inoue, K. Takada 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. Kim Y.C., Park J.H., Prausnitz M.R. - Microneedles for drug and vaccine delivery. - Adv. Drug Deliv. Rev., 64, 1547-68, 2012. Park J., Allen M. G., Prausnitz M. R. Polymer - Microneedles for controlled-release drug delivery. - Pharm. Res., 23, 1008-1019, 2006. Barry B., Williams A. - Penetration enhancers. - Adv. Drug. Deliv. Rev., 56, 603-618, 2004. Cevc G. - Lipid vesicles and other colloids as drug carriers on the skin. - Adv. Drug. Deliv. Rev., 56, 675-711, 2004. Preat V., Vanbever R. - Skin electroporation for transdermal and topical delivery. - Adv. Drug. Deliv. Rev., 56, 659-674, 2004. Doukas A. - Transdermal delivery with a pressure wave. - Adv. Drug. Deliv. Rev., 56, 559-579, 2004. Mitragotri S., Kost J. - Low-frequency sonophoresis: a review. - Adv. Drug. Deliv. Rev., 56, 589-601, 2004. Prausnitz M.R., Mitragotri S., Langer R. - Current status and future potential of transdermal drug delivery. - Nat. Rev. Drug Discov., 3, 115-24, 2004. Teo M.A.L., Shearwood C., Ng K.C., Lu J., Moochhala S. - In vitro and in vivo characterization of MEMS microneedles. - Bio­ med. Microdevices, 7, 47-52, 2005. Matriano J.A., Cormier M., Johnson J., Young W.A., Buttery M., Nyam K., Daddona P.E. - Macroflux microprojection array patch technology: a new and efficient approach for intracutaneous immunization. - Pharm. Res., 19, 63-70, 2002. Henry S.D., McAllis V., Prausnitz M.G. - Microfabricated microneedles: A novel approach to transdermal drug delivery. - J. Pharm. Sci., 87, 922-925, 1998. Takada K. - Microfabrication derived DDS: from batch to individual production. - Drug Discov. Ther., 2, 140-155, 2008. Cosman F., Lane N.E., Bolognese M., Zanchetta J., GarciaHernandez P.A., Sees K., Matriano J.A., Gaumer K., Daddona P.E. - Effect of transdermal teriparatide administration on bone mineral density in postmenopausal women -. J. Clin. Endocrin. Metab., 95, 151-158, 2010. Morawski M., Alpár A. Brückner G., Fiedler A., Jäger C., Gati G., Stieler J.T., Arendt T. - Chondroitin sulfate proteoglycan-based extracellular matrix in chicken (Gallus domesticus) brain. - Brain Res., 1275, 10-23, 2009. Faissner A., Clement A., Lochter A., Streit A., Mandl C., Schachner M. - Isolation of a neural chondmitin sulfate proteoglycan with neurite outgrowth promoting properties. - J. Cell. Biol., 126, 783-799, 1994. Umehara Y., Yamada S., Nishimura S., Shioi J., Robakis N.K., Sugahara K. - Chondroitin sulfate of appican, the proteoglycan form of amyloid precursor protein, produced by C6 glioma cells interacts with heparin-binding neuroregulatory factors. - FEBS Lett., 557, 233-238, 2004. Wilson T.M., Snow D.M. - Chondroitin sulfate proteoglycan expression pattern in hippocampal development: potential regulation of axon tract formation. - J. Comp. Neurol., 424, 532-546, 2000. Sintov A., Di-Capua N., Rubinstein A. - Cross-linked chondroitin sulfate: characterization for drug delivery purposes. - Biomaterials., 16, 473-478,1995. Tsai F.M., Chiang L.Y., Wang F.L., Huang W.G., Wu C.P. - Oral sustained delivery of diclofenac sodium using calcium chondroitin sulfate matrix. - J. Biomater. Sci. Polym. Ed., 16, 1319-l331, 2005. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. J. DRUG DEL. SCI. TECH., 23 (6) 577-581 2013 Ito Y., Nakahigashi T., Yoshimoto N., Ueda Yu., Hamasaki N., Takada K. - Transdermal insulin application system with dissolving microneedles. - Diabetes. Technol. Ther., 14, 891-899, 2012. Fukushima K., Ise A., Morita H., Hasegawa R., Ito Y., Sugioka N., Takada K. - Two-layered dissolving microneedles for percutaneous delivery of peptide/protein drugs in rats. - Pharm. Res., 28, 7-21, 2011. Ito Y., Hasegawa R., Fukushima K., Sugioka N., Takada K. Self-dissolving microarray chip as percutaneous delivery system of protein drug. - Biol. Pharm. Bull., 33, 683-690, 2010. Ito Y., Saeki A., Shiroyama K., Sugioka N., Takada K. - Percutaneous absorption of interferon-α by self-dissolving micropiles. - J. Drug. Target., 16, 243-249, 2008. Augustin C., Collombel C., Damour O. - Use of dermal equivalent and skin equivalent models for in vitro cutaneous irritation testing of cosmetic products: comparison with in vivo human data. - Cutan. Ocul. Toxicol., 17, 5-17, 1998. Ponec M., Kempenaar J. - Use of human skin recombinants as an in vitro model for testing the irritation potential of cutaneous irritants - Skin Pharmacol., 8, 49-59, 1995. Van de Sandt J.J.M., Maas W.J.M., Doornink P.C., Rutten A.A.J.J.L. - Release of arachidonic and linoleic acid metabolites in skin organ cultures as characteristics of in vitro skin irritancy. - Fundam. Appl. Toxicol., 25, 20-28, 1995. Koschier F.J., Roth R.N., Stephens T.J., Spence E.T., Duke M.A. - In vitro skin irritation testing of petroleum-based compounds in reconstituted human skin models. - Cutan. Ocul. Toxicol., 13, 23-37, 1994. Gupta J., Gill H.S., Andrews S.N., Prausnitz M.R. - Kinetics of skin resealing after insertion of microneedles in human subjects. - J. Cont. Rel., 154, 148-155, 2011. Dedrick R.L., Bischoff K.B., Zaharko D.S. - Inter-species correction of plasma concentration history of methotrexate. - Cancer. Chemother. Rep., 54, 95-102, 1970. Matsuo A., Yokota Y., Zhai Y., Quan Y., Kamiyama F., Mukai Y., Okada N., Nakagawa S. - A low-invasive and effective transcutaneous immunization system using a novel dissolving microneedle array for soluble and particulate antigens. - J. Con. Rel., 161, 10-17, 2012. Ito Y., Hamazaki N., Takada K. - Method to increase the systemically delivered amount of drug from dissolving microneedles. - Chem. Pharm. Bull., 61, 8-15, 2013. ACKNOWLEDGMENTS This study was supported by a Ministry of Education, Culture, Sports, Science and Technology (MEXT)-Supported Program for the Strategic Research Foundation at Private Universities, 2008-2013. This study was also supported by a grant-in-aid for scientific research provided by MEXT, 2010-2013. MANUSCRIPT Received 8 February 2013, accepted for publication 7 August 2013. 581