Complete-Hire-Sydney-Clarke-Bobcat-track-loader-T650-Operation-Manual

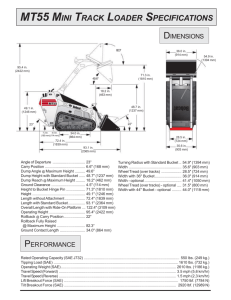

advertisement