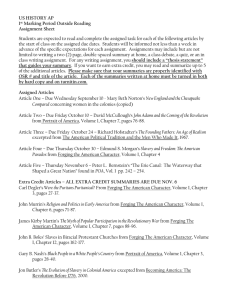

Metal Forming FORGING Prof. S.K.Sahoo Forging • It can be defined as the controlled plastic deformation of metals or alloys to a desired size or shape using compressive force exerted through some type of die by hammer, a press or upsetting machine. • Principle of working: A bar or billet or blank is compressed by the application of impact force or squeezing pressure to flow plastically in between two flat dies or inside the impression of the desired shapes. – The oldest metal forming operation (called blacksmithing). – Forging is generally a hot working operation though cold forging is used sometimes. – In forging, the shape of the raw material is changed by repositioning material rather than removing it. Examples – high-strength parts for automotive and aircrafts like engine crank shafts and connecting rods, gears, aircraft structural components, & jet engine turbine, etc. Advantages of Forging • Better mechanical properties , when the grain flow direction are properly directed for the specific application . • Forgings can be held to within fairly close dimensional tolerance. • Forgings products offer great resistance to impact & fatigue loads due to extra working during the process. • It allows material to be displaced / moved where it needed thus reduction in weight, wastages & cost. • Coarse or columnar grain are refined (as most forging are hot worked). • Impunities in the metal in the form of inclusion are broken up & distributed throughout the metal. • Internal porosity and cracks welded up giving high reliability to parts. • High production rate and Relatively smooth surface. Limitation of Forging • Tooling & handling cost is high. • In hot forging , due to high temperature of metal , there is rapid oxidation or scaling of the surface resulting in poor surface finish . • Forging operation is limited to simple shapes & has limitation for parts having under cuts , reentrant surface etc. • Some materials are not readily worked by forging. • Usually forgings cost more than castings. Metal Forming Grain flow characteristics in Forging Forging Machining Casting Uninterrupted, multi directional Broken grain flow No grain flow Maximum strength poor strength at critical section uncertain Properties Major advantages of the forging process is its ability to closely control the grain flow in the specific direction , so as to obtained best mechanical properties based on the specific application, i.e., shear stress should act at right angles to it where as the compressive & tensile stress should be act along the direction of the fibers. The influence of grain flow direction is of great importance particularly in parts like crank shaft, gear, crane hooks etc. So the direction of impact or squeezing pressure is important in forging to control the direction of grain flow for the specific application Type of Forging Operations • According to the direction of applied force: Drawing out- This is the operation in which the metals gets elongated with the reduction of the cross-sectional area. The force is applied in a direction, perpendicular to the length of axis. Upsetting- This is the operation of increasing the cross section at the expense of length. Force is applied parallel to the length axis. 6 •According to the shape of the die, the striking surface: a) Open die forging –In in this type the work is compressed between two flat dies, allowing metal to flow laterally with minimum constraint. b) Closed die or Impression die forging: In this type the work piece is compressed between two die halves which carry the impressions of the desired final shape that is imparted to workpart. Metal flow is constrained so that flash is created. c) Flashless forging: workpart is completely constrained in die. No excess flash is created. •According to the Work Temperature a) Cold forging –– advantage: increased strength that results from strain hardening . Twork<Tr (0.3Tm ) b) Hot or Warm forging: most common, as more amount of deformation can be done increasing ductility and reducing strength of work metal. T >T (0.5T ) work r m •According to the Application of Force a) Impact forging: Forge hammer is used to apply an impact load b) Press forging: Forge press used to apply gradual pressure • According to the Equipment/Machine used to apply Force • Smith forging- Impact force is given by manual or power hammer, where the work piece is kept in between two flat dies. • Drop forging- The work piece is given a series of blows in between closed impression dies. • Press forging-It is done keeping the work in closed impression dies by the application of continuous squeezing force supplied through a hydraulic press. • Machine forging or Upset forging- The material is only upset (force is applied parallel to length of billet to increase the cross-sectional area/diameter) to get the desired shape. Smith forging • This is the traditional forging operation involves heating the in the black smith’s hearth and then hammering it over the anvil. The operator manipulates the component in between the blows to get the final shape. The different operations carried out are fullering , flattening, bending , upsetting & swaging. • Fullering the heated work is hammered in between two fuller by a sledge hammer to decrease the cross-section & increase the length. • Flattening: The uneven mark of fuller is made flat /smooth by this process • Swaging: To obtained specific shape like round, hexagon, square, different swages are used. • Smith forging is used for small lots or for trial production & requires lot of skill. Metal Forming Open Die for Smith Forging a)Cogging operation on a rectangular bar. Blacksmiths use a similar procedure to reduce the thickness of parts in small increments by heating the workpiece and hammering it numerous times along the length of the part. (b) Reducing the diameter of a bar by open-die forging; note the movements of the die and the workpiece. (c) The thickness of a ring being reduced by opendie forging. Drop Forging In drop forging the desired shape of the component is obtained by repeated blows given by drop hammers keeping in between the close impression die cavity. The lower half of the die is fixed to the anvil of the machine where as the upper die is fixed to the ram. Complex shape can be obtained due to the impression of die, i.e. crank shaft, crane hook, connecting rod etc. The various passes used to get final shape are: •Fullering operation- It reduces the cross section at desired location to desired size. •Edging operation: The exact amount of material is gathered at each cross section of the finished product. •Drawing out: Reducing cross section area with increase in length. •Swaging operation: To get specific shapes swages are used. •Bending operation- This is required to those parts which have bent shape. This is done after edging to maintain the grain flow direction. •Blocking operation: It is the semi-finishing operation that makes the component close to the final shape. •Finishing operation: It is the final operation. To get the actual shape some extra metal has already been added from the beginning of the operations for complete fill up of the die cavity. At this stage it will come out and form the flash around the forging in the parting line (surface where upper and lower dies meets). •Trimming: It is the cutting operation to cut the extra flash that present around the forging. Press forging In press forging the final shape of the component is obtained by means of a single continuous squeezing action to it by hydraulic press in between the close impression die cavity .The capacity of the press vary from 5MN-150MN. Advantages of press forging• Because of continuous squeezing action the materials gets uniformly deformed through its entire depth. • The force of the press is fully absorbed by the stock, so less vibration & less chance of misalignment. • The impression obtained are clearer than that of drop forging. • As material flow smoothly by compression force, less draft & less corner radius is provided to impression. • Large size forging can be obtained. • An extra tong is not required in press forging to hold the part which is required in drop forging to manipulate the stock. Machine forging or Upset forging • As it involves the upsetting operation, it is also called as upset forging. Though drop & press forging are also done by machine, historically, only upset forging is called the machine forging. It is applied to get components like shafts gear blanks, axles, bolt, etc. • Upsetting machines are horizontal acting type. It consists of one stationary gripper die fixed to the machine frame, one movable gripper die, which move with ram /punch /header & a corresponding or heading tool. • The desired shape is obtained as per the impression engraved in stationary & movable dies. The forging cycle start with the movable die & stationary die grip the stock in closed position .Then the punch or heading tools advances against the stock & upset it to completely fill the die cavity similar to drop forging , the final shape is obtained by number of stages. Upset Forging (hot or cold) Bolt manufacture Closed Die for Drop, Press and upset Forging •The workpiece is deformed between two die halves which carry the impressions of the desired final shape. • The workpiece is deformed under high pressure in a closed cavity. • The process provide precision forging with close dimensional tolerance. •The line or plane separately the top & bottom dies is called parting line .It can be flat or multidirectional. Formation of a flash, or excess material that subsequently has to be trimmed off. Start of stroke End of stroke Product Metal Formingload-stroke Typical curve for closed/impression-die forging Note the sharp increase in load when the flash begins to form because requirement of more load for radial flow of material through constricted passage. Flash & gutter • Flash is that portion of excess metal which is adjoining the forging at the parting line. That portion is removed by trimming to get the product. In addition to the flash extension a further provision is made in the die in for any excess material. This is called gutter. These are provided in finishing dies The flash serves theses functions: • Act as a safety valve for excess metal in the closed die cavity. • It builds up pressure to ensure that metal can fills the far corner & intricate parts. • Striking surface between cavities is reduced. • The flash is designed so that the flow of metal through narrow flash is more difficult than filling of most intricate part of the die. Sequence of Forging operations Fullering Reducing cross section at desired location Bending Bend the specimen if required Edging Gathering exact amount of material is at each cross section Drawing out Reducing cross section area with increase in length Swaging Getting specific shapes using wages Trimming blocking Getting semifinish shape Finishing Getting final shape. Flash and gutter used in this stage Cutting out flash and gutter Stages in Impression-die (Closed-Die) Forging Connecting rod Crankshaft Forging Die Materials Die materials should have following properties • Thermal shock and fatigue resistance • High temperature strength, wear resistance, toughness and ductility • High hardenability, dimensional stability during hardening & machinability Material Used • Tool Steel, Die steel • High carbon alloy steel (with Cr, Mo, W, V, Ni) • Heat treatments such are nitriding or chromium plating are required to improve die life. • Carbon steels with 0.7-0.85% C are appropriate for small tools and flat impressions. • Medium-alloyed tool steels for hammer dies. Metal Forming Other Forging Processes Roll Forging Tapered leaf springs and knives can be made by this process using specially designed rolls. Required shapes are engraved on the roller. Rollers are rotated in both direction to impart the desired shapes on the blank/billet. Cold heading It is used to force metal to cold flow into enlarged sections by endwise squeezing. The process is used to make rivet head, bolt heads Forging Die Allowances • Appropriate Fillet & corner radius should be given to assure both smooth material flow & reasonable die life. Without fillet & corner radius Fillet With fillet & corner radius • Shrinkage allowances. (Cavity is made larger so that the product is larger in size, but will come to required size after shrinkage, for hot forging). • Die wear allowances (Cavity is made small so that after repeated use and wear it will come to required size). Forging Die Allowances • Sufficient draft on vertical wall for easy removal of forging from the die cavity .The internal draft is kept more than external draft because the forging tends to stick to dies due to shrinkage. • Machining allowances.( Extra material provided for finishing) • Flash & gutter (Usually Flash = 3% of max. thickness). Forging Machines Forging machines, wrt to principle of operation, are two types. 1. Forging hammers: In this type the force is applied by a falling weight attached to ram. It is an energy restricted machine since the deformation results from dissipating the potential energy of the ram that is converted to kinetic energy on striking. It can be two types: •Board and Drop hammer-In the board hammer the upper die & ram are raised by friction rolls gripping the board or by belt drive. When the board falls under gravity force it produces the blow energy . Then it is raised immediately for next blow. The strike rate varies from 60 to 150 blows per minute. The energy supplied by the blow is depending on the weight of ram & height of fall. In this type the deformation process until the total kinetic energy is dissipated by plastic deformation of work piece. •Power hammer: The ram is accelerated on the down stroke by steam /gas /air pressure in addition to the gravity .The main advantage is that energy of the blow can be controlled. It is available with power range 5 to 250 KN. 1. Forging hammers Steam or air Total energy supplied: Power hammer Board hammer Drop hammer The energy supplied by the blow is equal to the potential energy due to the weight of the ram and the height of the fall. Potential energy = mgh Where, m = mass v = velocity of ram at start of deformation g = acceleration of gravity p = air or steam pressure acting on ram cylinder on downstroke A = area of ram cylinder H = height of the ram drop 2. Forging presses These presses supply continually squeezing action. These press rated on the basis of the force developed at the end of the stroke. Broadly of two types: a. Mechanical press: Most mechanical press utilizes an eccentric crank to translate rotary motion into reciprocating motion of the crank slide. It is available with load capacity between 300-12,000 tones. Since each blow is of equal force, a press may be less suitable for carrying out preliminary shaping & finishing operations in the same piece of equipment. These mechanical forging presses are stroke restricted machine. Usually maximum load is attained when the ram is about 3mm of the bottom dead center position. Knuckle-joint press Screw press Crank press b. Hydraulic press: These are load restricted machines since their capability for carrying out forming operation is limited chiefly by the maximum load capacity .In this type the hydraulic pressure moves a piston which in turn connected to upper die gives the squeezing action .The important advantage is that the full press load is available at any point during the full stroke of the ram. The ram velocity can be controlled and even varied during the stroke. Hydraulic presses are available in rating from 500 to 18,000 tones even up to 50,000 tones are available .It gives very close tolerance forging, but relatively a slow speed machine. Forging Presses Hydraulic press Forging defects Defects may cause due to poor quality of the stock, incorrect die design, improper heating, wrong forging methods, incorrect forging conditions, uneven cooling of stock after forging etc. The common forging defects are founds are: •Incomplete dies filling: It may be occur due to less amount of stock material, in sufficient pressure, too low temperature of stock, internal die & forging design etc. •Cold shuts & lap: This defect is a discontinuously produced when two surface of metal fold against each other without welding completely. It can occur due to too small die radius, excessive chilling or high friction etc. •Wrong dimension: It is due to worn out dies, incorrect dies or mismatching both dies etc. •Pitting: Pitting of the forging surfaces caused by scale, which if not removed thoroughly from the die cavity is worked into the surface of the forging. When these are cleaned, pits are marked. Forging defects 5. Die shift- due to the mismatching of the two half of the dies. 6. Cracks: Cracks either longitudinal or transverse direction, at flash point can occur due to bad ingot, low temperature of forging, improper heating, incorrect of cooling etc. 7. Internal cracks: It can occur due to drastic change of shape at a first rate that causes internal stress. 8. Flakes: These are internal brakes or rupture occurs in some type of alloy steel due to too rapid cooling of forging. 9. Rupture fiber structure- It is the discontinuously in the flow of grain lines , caused due to working too rapidly , improper die design , or inadequate stock size . 10. Decarburization –If the stock is subjected to high temperature for long time it produce decarburized surface. 11. Fins & rags: These are small projection or loose metal driven into the surface of the forging. Design considerations in forging •Parting line, draft, fillet and corner radii chosen to permit smooth flow of material and easy removal of forging. •Parting line should be at largest cross section for symmetrical parts. Mirror imaging for non- symmetrical parts •Deep holes, high projection, thin section should be avoided. •All forging allowances, ie, machining, allowance, die wear allowances should be provided. Parting Line This Not This Parting Line Not This Parting Line This Forging load calculation Assumption: 1. Homogenous deformation, ie., stresses are uniform across the section •No friction Let initial conditions are: A0, h0, D0 Final states are: Af, hf, Df For a height decrease of ‘dh’ at a particular time , when Area is ‘A’ and height= ‘h’ External work supplied=p · A · dh where, p=forging pressure Same work is used internally for metal deformation, V=volume dh Y Y Internal work done= f ·dε ·V = f · h ·V dh V pAdh=Y f · h ·V (as A= h ) Giving Forging Load requirements, F =p · Af So, p= Y f or F = Y f · Af Example: A cylindrical workpiece of diameter 30mm & height also of 30 mm is to be compressed to 20mm. Forging press has capacity of 1,000 kN. True stress- strain curve follow σ = 400ɛ0.2 MPa, µ = 0, Find whether it is possible to press or not? Answer: Load required is F =Y f Af Initial volume=Final volume Af = V (volume)/hf = [(π/4)(30.0)2x30.0]/20.0=1060.287mm2 ɛb = ln (30/20) = ln (1.5) and ɛa = 0 1 Yf b a b K 1 n a n 1 Given, σ = 400 ɛ0.2MPa ln(1.5 ) 400 0.21 1 Yf ln(1.5) 0 1 0.2 0 278.27 MPa Putting values, Load required for forging, F = 278.27x103×1060.287x10-6 =295 kN (Capacity of press is more) So Forging is possible.