4-

Contents

CLASSIFICATION OF

MATERIALS

;PageNo.

Ckapl(r •

c1assification of Materials

:tt 1'lof~-

CHAPTER

1-9

t '-«'

Conducting Materials-#- l\!ol-e.lS(For this chapter also see Appendix page no.119-121)

10-3!

Semiconducting Materials:#= No~

32-40

Insulating Materials. ;ff:

Magnetic Materials

.boo'\<

I 1.1. lntroductron

The main aim of any engineering works is the practical application of right material to

/ manufacture the electrical machines and appliances. While selecting the material for the required

application one should keep in ~iew the h'.gest degree of ~con~my and to meet the requirements

perfectly. Before selecting tt1e nght matenal for the requ1red JOb deep and thorough knowledg~

about the material should be attained. If there is lack of knowledge about the material then it will

be a big cause of br~kdown in the appliances and durability of the appliances also get affected.

There are many factors that o~e should ~onside~ before the selection o~ material. Physical,

mechanical, chemical and electncal properties are important factors but besides these followmg

are the main factors that must be kept in mind :

j

I

80-89

,pecial Pwpose Materials #book

For this chapter also see Appendix page no.122-124)

I

90-110

!

/

errous and Non-ferrous Materials #-

opendix

amioatioo Paper

ko h

ii 2

ttt

•

j

41-79

# back

et

I

lll-118

119-124

(i)

Cost

(ii) Availability

.

(iii) Ease of fabrication

(i) Cost : Cost of a material is a very important factor while selecting an engineering

material. Material should be chosen in such a way that highest degree of economy is achieved. For

/ example silver is the best conductor of electricity but it can not be used as conductor of electricity

j because of its high cost. And on the other hand, copper is not as good conductor as silver. But it is

/ widely used iis conductor in many engineering applications. Because copper is cheaper than silver.

/ Hence by using copper as a conductor in the required application overall cost is reduced.

I

/

(ii) Availability : Availability of materials and their continuous supply are also important

/ factors. If the material is easily available then the manufacturing process will be continuous. For

I example, many a time aluminium is preferred over copper, although it is an inferior material than

I copper. It has _lower c~nd~~tivity than_~at o~ copper. Because in India a!uminium is available in

, large amount 1.e, availab1hty of alummmm 1s more than copper, so due to many considerations

aluminium is used as a conductor in many applications like transformer windings, inductive

chokes for fluorescent tube lights and in overhead transmission lines.

I

I

Electrical and Electronics Engineering Materials

. -~ ~

c~fication

~----------...:..) ;

of Materials

(i v) It should have high mechanical strength

Anothe, example is that in earlier days mica is used as an insulating material worldwid~.

On the b i

(v) Free from atmospheric and chemical effects

But after the development of PVC and plastic materials, mica is replaced by PVC a nd plasttc

_

as follows :

(vi) It should have good electrical properties as per the requirement.

materials because these are the easily available materials having low cost. So in _present time P~C

th

@iMaterii

·

t rials for the plug top. 1n e same ·

and other plastic materials are used as an insulating material in many apphcauons like ~Ire

The above was a particular example of selecting

ma e

purpos,

b

t d

,

.

.

•

·

g

products

can

I

e

se

ec

e

.

insulation, switch board, switch outlets, panels, casing and to make the outer body of electncal , anner materials for the manufactunng

of vanous engmeenn

.

known

.th .

jl11

·

·

·

·

L

mber

appliances.

of

matenals

along WI their

.

The field of electrical engineenng 1s very wide. arge nu

.

f

t . fi th

&ateri:

Ease of fabrication : Last but not the least, ease of fabrication is also an important fact~r l · 0 us types are being used in the electrical engineering field. Right sel~cllon _ma enf al1 . otnr. el

extem2

jva0

.

·

·

ca

while selecting right material for the required application. In pres~nt a~e, s~eed of p~oductton is 'required

application is a tough task. Before selectmg

engm~enng m atenals funcllon o e ec

·

@,tateri,

very important. Many materials have restricted electrical applicattons, insp1te of having smta~le !engineering material should be known. These functions are hsted below.

anothe

properties because of having low fabrication speed. For example, ceramic is used to make h~e

(i) To carry the electric current from one place to another place.

insulators over a long period of time. But in present time ceramic is replaced by ~o~y resm.

@Mate~

(ii) To prevent the flow of electric current.

Although ceramic has favourable electrical and mechanical properties _for being a_ line insulator

@Maten

(iii) To control the flow of electric current.

.

·

but it has low fabrication speed. On the other side, ·epoxy resin has high fabncatton speed that

station

(iv) To allow the flow of electric current in one direction and obstruct the flow m another

tends high production speed.

To understand the above factors let us take an example : Consider a two pin or three pin direction.

1.2. Atomic

(v) To store electrical energy.

plug which is used to connect the many electrical appliances (like electric iron, i_table fan ,

,

Atomic

television) to the· supply mains. To manufacture the plug we need conducting matenal so that

(vi) To provide the easy path to the magnetic flux .

A ; ! ma1

appl i"! nces·can draw the electric supply from the supply mains and insulating material to prot_e ct

(vii) To convert the electrical energy into neat and light energy.

small pa ·lei

the h• ,nan beings from accidents and to avoid short circuit. Pins of.plug is made of conductmg

The above functions are performed by means of following, written in the same order as the

as elemen ai

mater, 11, conducting material of pin should be of such type that it has good electrical properties

functions written above.

An ·o

and h,gh mechanical strength as well. Because electric plugs are used in variety of applications

~opper and aluminium used to carry electric current from one place to another plac~.

where plugs have to bear different mechanical stress. So pins are made of brass to work as

types of parti•

Alumiruum is used as a conductor in overhead transmission line. Copper is used as a conductor m

conductors. Because brass has good mechanical strength, suitable electrical properties, high

charged parti

domestic wiring.

resistance against chemicals and atmospheric effects. These pins are ·embedded in an insulating

The neutron i

0.Plastic

materials,

ceramic,

~or~elain

obstruct

the

flo"'. of_electric curre~t. In overhead

body. It is required that there should not be any flow of current between the pins to avoid short

Nuclei

transnussion

lines

ceramic

and porcelam 1s used to manufacutre lme msul~tors o~ different shapes. \

circuit and to protect human being from electric shocks. Insulating material of plug top should

spinning aro,

have suitable electrical properties and good mechanical strength. The plug should have sufficient Plastic materials are used to manufacture the external body of electnc appliances and many

different orb

·mechanical strength to withstand stress during thousands of insertions and it should be moisture electrical products.

and chemical resistant because plugs are handled by wet and greasy hands and are used in open

Carbon, mang~ and constantan are used to manufacture different types of wrre

the order of

atmosphere where it is affected by moisture, humidity and gases present in the atmosphere. wound resistors of different shapes and rheostat which are used to control flow of electric current

diameter of :

Ceramic materials meet these requirements but its fabrication process takes too much time. Ease in electrical and electronic circuits.

space betwe

of fabrication of a material is an_ essential factor. It is difficult to give appropriate shape of plug to

Semiconducting materials such as silicon and germanium are used to convert I\

ceramic material in less time. So plastic material is mostly used as insulating material in place of jaltemating current (A.C.)

order i.e, h

into direct current (D.C.).

ceramic material because plastic materials meet the requirements of ease of production and also

valence ort

Mica,

paper,

polythene

etc.

are

used

as

dielectric

material

ii;i.

the

manufacturing

of

has low cost.

electrons o 1

capacitors which are used to store electrical energy.

From the above example we can understand the importance of various factors to be

negative ch

@steel and silicon alloys are used to manufacture magnetic core for transformers, electric ,

;onsidered while selecting right materials for the required job. These factors may be summarized

nucleus hai

/g~nerators

and

electric

motors.

These

magnetic

core materials provide easy path to the magnetic \

s listed below :

!flux.

has low attJ

(i) It should be of low cost

°

@

,

@

'

I

'fp

I

i

(ii) It should be easily available from local source

(iii) It should be easily moulded in different shapes

@Tungsten and nichrome are used to make electric bulb/lamp filaments and heating

1element of electric irons, heaters, electric ovens etc. These materials convert electrical energy into

lheat energy and light energy.

I

electrons c

Now this e

Electrical and Electronics Engineering Materials

Classification of Materials

According to modem electron theory. each element has different a1< 111i c lllllll hC! .-\n

analysis· we can functionally classify electrical engineering materials atomic number of element represents the number of electrons present m the atom. 11 enc.: 11 1,

above

f

.

Onthe basis o

clear that all elements have different number of electrons and valency i.e. number of valence

as follows ·

t in a particular atom are different. Each material has different properties has

~Materials which are used to allow _the electnc current to pass through them for vanous ' I t

d I 1ng wire in domestic wmng filaments of electric lamps are I e ec rans presen

~

, different ro erties on the basis of number of electrons. Atomic structure of aluminium and

'

'

purpose such as ~on uc •

.

p p .

'

known as conducting matenals.

copper has been 11lustrated m fig. 1.1

. .

.

fl ow of electric current used m lme insulators, !

the

obstruct

to

used

are

which

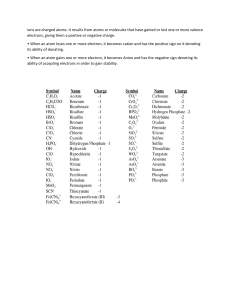

Cu(29) = 2, 8, 18, 1

1

. ,,

.

...

kn

atena1s

,

external body of electric apphances are own as msulatmg matenals.

0

®'1

.

t rials used to allow the flow of electric current in one direction and prevent the flow in

rr::...,

.

. d .

~nae

A1(13) = 2, 8, 3

another direction are known as "semi con uctmg materials."

@Materials which are used to store electrical energy are classified as •:dielectric materials."

@Materials which are used to provide easy path to magneltc flux m many rotatmg and

stationary electrical devices are known as "magnetic materials."

1.2. Atomic Theory and Classification of Materials on the Basis of

Atomic Structure

AII matters consist of minute particles called molecules which are further made by very

small pa •Jes known as atoms. Those substances whose molecules have similar atoms are known

Fig. 1.1 : Atomk structure of aluminium and copper

as elemen and substances whose molecules have dissimilar atoms are known as compounds.

An ·om consists a hard central core which is known as nucleus. A nucleus cons\sts two

Atomic number of aluminium is 13. It has three orbits namely K ,L,M. Electrons in the

types of particles, one is known as proton and another is known as neutron. Proton is a positively

2

) where n = No. of orbits from centre of atom.

charged particle whereas neutron does not consist any charge i.e., neutron is electrically neutral. orbit can ~e found out by applying the formula (2n

The neutron is as heavy as proton. Weight of both particles are equal to weight of hydrogen atom. So accordi.ng to this formula, no. of electrons in aluminium's three different orbits will be 2, 8 and

Nucleus is surrounded by a number of tiny particles called ~lectrons. The electrons are 3 in the successive orbits. It has three electrons in the valence orbit i.e. aluminium's valency is

spinning around themselves and also revolving around the nucleus. These electrons are placed in three. When external energy is applied to aluminium then all the atoms of aluminium relase their

different orbits (K ,L, M,N) having different energy levels. The effective diameter of an atom is of electrons and get three positive charges.

In same manner copper has 29 electrons. It has four orbits K ,L,M ,N (2, 8, 18, )) and in

the order of 10-8 cm and diameter of nucleus is of the order of 10- 13 cm. Hence we can·say that

diameter of an atom is approximately I05 times greater than that of nucleus. It means there is large valence orbit it has one electron i.e. valency of copper is one.

In the case of co nducting materials, there are l, 2, or 3

space between electron orbits and nucleus. The energy levels of different orbits ai:e in increasing

order i.e, higher order orbit has higher energy level. The outermost orbit of an atom i s, ~alled electrons present in the v"i<!nce orbit i.e.materials having l, 2 or ,

valence orbit and electrons present in the valence orbit are called valence electrons..All the 3 velency are categorized as conducting material and in the case

electrons of an atom are lightly held by nucleus. Nucleus has positive charge and electro~ has ! of insulating materials all atoms are fully stable. All the

negative charge so an attraction .force acts between the nucleus and electrons. Electrons nearer the electrons present in the atom are tightly held with nucleus. And

nucleus has highest attraction force and having low energy whereas electrons far from the nucleus in the case of semiconducting materials there are 4 electrons

has low attraction force and high energy. When external energy like, heat is given to the atom then present in the valence orbit i. e. materials having 4 valency are

electrons of valence orbit break the attraction force of nucleus and atom releases the electrons. categorized as semiconducting material. Atomic structure of

silicon semiconductor has been shown in the fig. 1.2.

Now this electron moves all around the matter. This electron is called free electron.

1

"• U '

l

j

"'".,,. ,...-J

'A<~"'"~'"°""'f

.>7

Electrical and Electronics Engineering Materials

~C~la~ss~i~fic~a~l•~·o~n~o:!._f~M!..'.!a~lc:'._!:r:!_:ia~ls~--- - - - -- -- - - - - : - - - - -- - -- - -

Sil i.:un has 1-1 ekctrons and its electron distribution is 2. 8, 4 in K, L, M orbits. II has 4

ekctrons in the outern1ost orbit i.e. its value of valency is 4. According to no. of electrons present,

in the atomic structure each material shows different properties. For example, in conducting)

material it is easy to loose its valence e- electrons so they are good conductor of electricity and!'

insulating material resists the flow of current because number of free electrons are almost zero.

And in the case of semiconductors valency is four. So in ordirary condition they behave like anj

insulator and when temperature gets increased they behave like a conductor.

I

j

Inter Atomic Bonds

The bond between atoms gives the solid shape to the metal. These bonds are of three types~

as given below :

(i) Metallic bond

(ii) Covalent bond

Fig, 1.3 : Covalent Bond of Germanium Atoms

(iii) Ionic bond

I/iii) Ionic bond : An ionic bond is formed between the atoms of two different eleme,

Bond 'tietween sodium and chlorine atom is an ideal example of ionic bond. Here the sodium at,

has one valence electron, due to this'sodium atom is more unstable. It has tendency to release 1

electron to get stable state. On the other side, chlorine has seven valence electrons, due to·u

chl~rine atom is. more st~ble. It has t~ndency to accept t_he electron to get stable .stat§ Wh

sodium reacts with chlonne then sodmm atom releases its electron and gets positive char§

whereas chlorine atom accepts this electron and gets negative charge. This kind of bond is cal11

@> Metallic bond : Elements which have one, two or three valence electrons are very ionic

bond and hence the atoms formed are called "donor ion" and "acceptor ion " respective!}

unstable because as we know that an atom requires eight electrons to get stable. In such case

r11•

.~X-ERCISE .

atoms of these elements give up their electrons to another atom to complete its octajHence an

electron cloud is formed throughout the space occupied by the atoms.

1. Explain the calssification of materials in three parts based on their atomic structure. ·- ✓

After releasing the electrons the atoms get positive charge. An electrostatic force acts

(BTE1005

2. Write short note on covalent bond.

(BTE1005

between the electron cloud and positive charge due to this the metal crystals remain in solid

3. List the name of groups in which the electrical engg. materials can be categorized. Ex~lai;

shapes] This type of bond is characteristic of elements having small number of valence electrons

how conduction of electricity takes place in conductor and semiconductor.

i e. metals, hence this kind of bond is called metallic bond. Due to metallic bond metals remain in

(BTE 2006, 2009)

4. On the basis of atomic structure explain how metals are good conductors of electricity.

solid st.ate and because of having less valence electrons these materials show the property o

The attraction force in all the three types of bonds are due to valence electrons present in th

outennost orbit of an atom. Unstable atom wants to complete 8 electrons in the valence orbit to get

slabilized. To complete its octal, atom can acquire more electrons or lose all its electrons to

another atom.

(BTE 2007)

5. On the basis of atomic structure explain the conductor, insulator and semiconductor.

(BTE 2008)

e-0nductivity, ductility, positive temperature coefficient etc.

g,ovalent bond : Elements which have four electrons in the outermost orbits have atoms

neither e-0mpletly st.able nor astable. In such cases atoms do sharing of electrons with the nearby

atom

to get

st.able state.]

.

Referring to figure J .3 which shows the e-0valent bonding between the germanium atom. I

,erma.nium has four valence electrons in the outermost orbit. Germanium atoms have no power of

•leasing of electrons. So each atom of germanium share electron with the neighbouring atom. ;

iis kind of sharing is called "e-0valency" and bond is called covalent bond.

6. Describe classification of materials on the basis of atomic structure- Li 5t th e names of any

two materials and their application from each group.

.

rare 20J2J

. wh.1ch matena

. 1s can be class1.fi ed• Explam how rnsuJ .

7. List the name of groups m

atmg

· ·

materials are bad conductors of eIectnc1ty.

b d (BT£ 20J3)

.1

. f perg)' an s. (BT£ 20

8. Discuss classification of electrical engg. matena

s on the basrs o e . mic structu

14)

.1

h

. f th elf ato

re

9. Explain electrical and electronics engg. matena

s on t e basis o

(BT. ·

E 20Js;

Electrical and Electronics Engineering Matcri~

l)

Classification of Materials

♦ Multiple Choice Questions -

. .1

- .

•

([)n the manufacniririg of line insulators epoxy resm is preferred over ceramic materials\ ♦ Fill in the Blanks

. 1s 1.s base d upon _c_J_.,> r:•) il S: } ; 1~ ( J VS\ (

. matena

.

I. Classification of electrical engmeenng

-.

because of :

_

~ .i.ly_~;n is best known conductor.

~

(b) availability

~

(a ) cost

Q) Because of low cost Cap.p 0ns used over silver. .

(d) none of these

.

~ase of fabrication

_

4 _ Ionic bond is formed between tw~1fferent tle~;J-~

s. Semiconducting materials have . .-:-r. .... electrons m the outennost orbi t.

2. According to atomic theory. the maximum number of electrons can be there in outermostn

orbit is :

6. Germanium semiconductor has atomic number of

~8

7. Because of its .. . . . . .. . epoxy resin is used over ceramics.

(a) I

(d) any number

@ \?,.n~~- is used to make pins of two pin plug. .

(c) 18

9. Insulating materials are used to prevent . (.\~c;.,b.1, c. S-f..o c k1;

3. An atomic number of an element represents the number of:

To store electrical energy . . . ... . . . materials are used.

10.

protons

(b)

W,Clectrons

11. Tungsten is used to make .. ... . . . . of electric bulb.

(d) electrons and protons

(c} neutrons

12. Materials which provide easy path to magnetic flux are called .

@Anion is :

13 . . . .. . . . .. is formed between the atoms of semiconductors.

(b) a free neutron

(a) a free electron

Answers

~ari atom with unbalanced electric chp.rge

(c) a free proton.

1. Atomic structure, 2. Silver, 3. Copper, 4. elements 5. 4 , 6. 32, 7 . ease of fabrication ,

@Bond fonped between the atoms of semiconducting material is called :

8. Brass, 9. electric shocks, 10. dielectric materi.als, 11. filament, 12. magnetic material ,

®,.covalent bond

(a) metallic bond

13. covalent bond.

(d) none of these

(c) ionic bond

@aond'formed between the atoms of two different elements is called:

(b) covalent bond

(a) metallic bond

(d) none ofthese(8,ionic bond

@Materials used to store the electric energy are called :

~Dielectric materials

(a) Insulating materials

(d) Magnetic materials

(c) Conducting materials

Materials which provide path to the magnetic flux are classified ·a s :

(b) Semiconducting materials

(a) Insulating materials

(d) Dielectric materials

(s),Magnetic materials

I

.32. ....

•

@

@To convert A.C. into D.C. which kind of materials are used?

(&Semiconducting materials

(c) Magnetic materials

(b) Conducting materials

(d) Insulating materials

@ In the manufacturing of electric bulb filament material used is :

(b) Copper

(d) Mica

~Tungsten

(c) Aluminium

1. (c)

2. (b)

9. (a)

10. (a)

3.(d)

Answers

S. (b)

4. (d)

6. (c)

7. (b)

8. (c)

l

I

.

•·

.

..

1D1t:· >"S 1--

-....~

?

er ..,.:ri:eMkds,..» sa-- y

Gritt?

m · i"l!Ci'w-Wet cftMz± ,~,-er·& MC&srair< .ffk+t'\rcrit

z£ tr: • "➔

- -=,;1 4

CON DUC TING MAT ERI ALS

I V=IR I

V = Applied voltage across th_e terminals (in volts)

I= Current-flowing through the conductor (in amperes)

where

Thus

p = resistivity of a material in ohm-metre

R =resistance of material in ohm

p=T

R oc!_

a

l

If

a can be written as

.

t

.

Assume that at 09 C temperature resistance of a conductor be Ro

and this conductor is

heated up to t°C temperature then expression for resistance at t°C tempera

ture can be written as :

R1 =R 0 (l+a. t)

... (3)

0

"\

Temperature is themost important tad& which affects the value ofresis

tivity. The value

of resistance increases by increasing the value of temperature. If

we draw a' graph between I

temperature and value of resistance for a given matetrial, then we get

a straight line. Increase .in

resistance depends on the following factors :

(i) Initial resistance of a material

(ii) Increase in temperature of a material

(iii) Nature of a material

Above relation can be written as :

I

R1 -R 0 ocR0 t

R, - Ro =a. Rot

... (I)

where a is a constant which is kn~as

own

temperature coefficient of resistance.

2.3. (i) Effect of Temperature on Resistivity

• Resistivity of a material does noi;emain constant. Value of resistiv

ity of material gets j

aff~c~e~ by the various factors. Following are the three main factors

that affect the value of

res1st1v1ty :

(a) Temperature

(b) Alloying

(c) Mechanical deformation.

2.3. Factors AffectinQ Resistivity

\

2.4 .

valu

d

t

a

if va

coeffi

coeffi

1

II

If

then

R =p

So resistivity can be difined as at 0°C temperature the reistance

of a material per unit

volume is known as resistivity or specific resistance.

1

I= length of a conducting material in metre

a =I metre 2 and I =I metre

a= cross-sectional area of a material in metre

2

t = 1°c, Ro = 1n

a.=R 1 -Ro

With the help of above expression a can be defined as : by increasi

ng the temperature of

R = pl

any conducting material from 0°C to 1°C change in resistance is known

as

temperature coefficient

a

j of that material at 0°C.

where 'p' is the coefficient of proportionality and it is called the

resistivity or specific

Equation (1) can be written as R = R (1 + a. t)

resistance of the material in ohm-metre.

1

0

0

... (2)

Ra

2.3. (ii) Value of Temperature Coefficient (a) at Different Temperatures

Hence

and

R = Resistance of the conductor (in ohms)

The resistance R of any material is directly proportional to its lenght

'/' and inversely

proportional to its cross-sectional area 'a'.

where

In simple words, resistivity of a material can be defined as "proper

ty of a material which

offers resistance in the path of electricity is called resistivity".

We all know the Ohm's law which can be written as :

2.2. Resistivity

Materials which are used for conduciing electricity in the field of electric

al engineering are

known as conducting materials and materials which are used for prevent

ing the flow of electricity

are known as insulating or non-conducting materials.

Conducting materials have very low value of resistivity and on the

other hand, insulating

materials have very high value .of resistivity. To determiue which materia

l is conducting material

and which material is insulating material we· should understand the

term resistivity and should

know the value of their resistivity. On the basis of resistivity, conduc

ting materials are further

subclassified into low resistivity materials and high resistivity materia

ls.

2.1. Introduction

etr:w5:er:1:ittS

:1 •., :

~'-~~

~ .~ -~....-

CHAPTER

- ~~' ,

r

,conduc ting Materia ls

1~

t

~

--

:70·

,. , --

65

60

55

50

45

40

35

-• --

.

I

I

We know the relation,

Ithe ~ is ·40Mm.

~!

coefficient of'copper af different value o temperature is shtJWn in the table :

1•

.

For any mate~~!-value ?f t~~pera~~~ coeffic'.ent can be _cal~ulat~d, various temp!ratw;es

tf value of temperature cdeffictent at zero degree celcius 1s- known'.' Value of temperature

1

coefficient o coppei'(Cu) at zero degree cefoius (cx 0 ) is 0.00427 per°C. ' he value of temperature

0.00328

R6o

R 60

0,0038 X 40

1

=4S6.SlQ

=400[ 1+ -l+-0.-00_3_8_x_2_0

·

R 60 =R 20 [1+

t)1

a

(60-20)1

l+ a. x 20

= R6o• R, = R20

t 1 =6D°C,

R,I

R 11 =R 1 [1+-a- (t 1 l+a t

t=2D°C

Putting all the values in the above equation, we get

temperatures

-

0.00333

0.00339

0.00339

0.00352

0.00358

0.00364

0.00371

E ~ A coil is made of sopper wire. .t\t a temperature of 20°C the resis.t ance of

Calculate the resistance of the _coil at a temperature of 60°C.

Temperature coefficient of copper at 0°C is 0.0038 ohm per degree C.

Solution : Given R 20 = 400 ohm, a O = 0.0038

I

I

.

.

0.00385

25

0.00378

0.00393

20

30

0,00401

0,00409

10

15

0,004 I 8

5

2.4. Value of Temperature Coefficient (a) of copper (Cu) at different

...(7)

--

~ --

lJ,UU427

0

Here

or

_

~

13

Value of temperature coefficient of copper at various temperatures

. ature in °c

Value of temperature coefficient (a) in /°C

Temper

-- -

Hence value of temperature coefficient can be calculated at various values of temperature if

value oftemper~ture coefficient at 0°C, ~ .O· is kn,oVl'.fl_.

Clo

at 1= - I+a.ot,

1+~ 0 t 2 -l-a_0 t 1

O+,a 0 f 1)(t2 -t 1)

at1

[ 1+aot1

I+aot2]-1=a t 1 U2 -t,)

or

or

l+a.ot2] =R [l+at,(t2-t1)]

R 1 ----=--=1

! [ l+a.ot,

i

Comparing Eq. (6) with Eq. (7)

R 12 =R1I [l+a.t1(t2 -t 1)]

R -R [ l+a.ot2]

'2 '1 l+a.ot1

a 0 (t2 -t 1 )

(l+a 0t 1)(t 2 -t 1)

. .. (5)

... (6)

... (4)

R11

Equation (5) divided by equation (4)

Rt2 can be written as :

I RaO'C

Fig. 2.1

~

;I

li§ i

,-

R, t' C

=Ro(l+aot1)

Ar

,§1

8

-

Rt2 =R 0(1+a 0t 2 )

Now assume that a conductor is heated up from 0°e to t°C and its

in'.tial temperature at 0°e be point A and temperature at t 0 e be point B . Now

this conductor is again cooled down from t0 e to ooe. Now it is clear that

when this condudor is heated up from 0°e to t0 e then its initial temperature

at 0°e be point A . But when this conductor is cooled down from t 0 e to ooe

then its initial temperature at 1°C be point B which has been shown in the

diagram_ According to equation (3),

8

Electrical and Electronics Engineering Materials1 Conducting Materials

Here a O is temperature coefficient at 0°e. Here assume that a

conductor has resistance R I at 1°C. Now this conductor is cooled down from

.

t0e to 0°C. (However practically it is not possible).

12

Elertrkal and Electronics Engineering Materials

C

(,

~~

(.~ '-

d--. 6

=0.2s[1+

R40 =0.301.Q

R40

0.004x20 ]

I+ (1.004) x 20

-,,(of\.--

(40-20)]

ao

I+(a 0 x20)

=0.28.Q

R20

R40 =R20[l+

=2.8 X 10-8 X IO 7

6

CXo =0.004

20xl0-

=2.8 X 10-8 X ~

R20

R20

R20 =P20 a

a = 20mm 2

20°C = 2.8 ~ I o-8 0-m,

.

We.know

l2

1+ 0.0042 X 12

l+0.084

= 71.61°C

1.2

60 l+0.0042x t2

-=-----=50 1+ 0.0042 X 20

R 2 l+a 0 12

-=---'-~

R 1 l+a 0 11

a 0 =0.0042/"C

Change in temp.= t2 - t1 = 71.61- 20

= 51.61"C

New resistance=R2 =60.Q

Intial resistance R 1 = 50 .Q

C,

g

R9.)

-

,,-

S'o

ld

(

z_(J ;>}

/4-6"<1L

~ ?,,o

\ \

6.o(l4

- ~ 2-3. At 20°C resistance of a machine's coil is SO ohm. After working few

h o u ~r~istance becomes 60 ohm. If temperature coefficient at 0°C oJ.qiif material is

0.0042 per degree C, then find the increase in temperature.

Sol: Given, Initial temperature 11 =20"C

~

\2- ~~-

,.,,d,oi-;\

X. / \>(

(Ay..\')

of.-1/

~

Solution : Given / = 200 m

\2- ,.

Q/Oc.

~ l e 2 ·2 · Calculate the resistance of a wire at 40°C which is ZOO m long a nd its

cross-sectional area is 20 mm 2. The wire is made of aluminium. Resistivity of aluminium at

zooc is 2· 8 x I o-8 0-m and its value of temperature coefficient of resistance at ooc is O.oo4

14

--!i

= 2D°C,

for copper a

~ I .0 /\

R1

R2

-::

= 230 = 230'2

I

1.2

l+Uo/ 2

l+u 0 i 1

/2

= Vz

I

= 0.00427

230

V

R = = - : : l9166H

Rz

O

I2

1.0854

J+0.00427

X

11

After substituting the values

R =40

I = 400metre

(i) For copper, p = 1.7 x I0- 8 0-m

4=

a

1.7 X IO-S X 400

rJ

As we know > R = pl

Example 2.5. Consider a copper wire having length of 400 metre. This "in 1s 11-sed·•

the manufacturi';)g of D.C. machine coil. The res.i stance of this tota l wir, is 40 .

(i) Find the diameter of the wire.

(ii) Also find the diameter of wire if it Is made of aluminium

'1 = 70. 25°C

1.30- I = 0.00427 11

0.03

'1 = - - - = 70 25°C

0 .00427

l.2x 1.0854= l+0.00427 11

1.2

_2_7_x_1-=2

1. = _I+_0_._004

2

l+0.0854

After putting the values, we get

I+ 0.00427 x 12

230

I 91.66 = I+ 0 .00427 x 20

t1

temperature of the field coil.

Sol. V = 230 V, t 1 = 1.2 A

Example 2.4. A shunt field coil of a I).<.. . 111 11cbinc i3 ta kin~ l . l a rnpt'.rt! ln1111 2 \IJ , ~

D.C. line. The temperature of 11,i~ coil Is 20"('. Afte r workln~ fur ~•11nc hour\ a1 full 1,~

current reduced upto 1.0 amr,crc. If coil b miadc of copper, !he n find t he in c r ea,i~ al

c·unducling Marerlul•

rtd:

. 1=-4

d=

. -a

2.8 X 10- ~ X 400

2 .8 X 10- S X 400

4= - - - - - -

3.142

I

75 to 98

10 to 14

Carbon steel

(upto 4.% carbon)

Iron (cast)

15 to 45

7

50 to 60

1.60

Brass

Carbon steel (high carbon)

1.77

Silver

Silicon steel

1.72

Copper (Hard drawn)

= 1.89 mm

Alloying is another ·factor which affects the resistivity of a material. By mixing some

impurities (some other material in small extent) to a metal its resistivity can be increased. Value of

rcistii,ity of an alloy is always higher than the value of resistivity of a pure base m~tal. The

structure of an alloy is not homogeneous compare to pure metal. Alloy metal acquires properties

like higher mechanical strength which are needed for the required applications. For example, by

adding ,:inc into pure copper we get an alloy called brass (60% coppei:, .40% zinc). The resistivity

of alloy metal brass is higher (about 4 times) than the value of resistivity of pure copper. And the

1cn, ile strength of brass is much more than that of copper. Because of'these properties brass is

" "'ti in such as : plug points, socket outlets, knife switches, heavy plates, shafts, rods etc. where

11 1gh tensile strength and hardness is required.

d

2.4.1. Effect of alloyinli on resistivity

2 .8

20°cx10:-

8

Resistivity

. (oh_m-µi) at

Aluminium (Cast soft)

. Material

2.9

d=~=.j3.56

1t

d= ✓ax4 = ✓2: 8x4

a = 2.8 mm 2

a=2.8x10-6 m

a = -----4

⇒

(,,,2

=v2.16=1.47mm

I

I

17

I

-

40 to 50

2 to 40

-

15 to 20

40

39

39

35

35

Temperature

coefficient per <\egree

cat 20°c xfo:-4

I

780

780

-

7.70

8.40 to

8.70

10.50

8.89

8.89

2.71

2.68

Density

1350

I 1500 (O 1530

I

I

-

-

960

1084

1084

630

655

C)

I Melting

point

(degree

, .4.2 . Effect ~s.!J,rutic~}..Deformation on Re~ vity .

. . .

2

:

Ir;;chanical force is applied on the conductor, then its _v alue of res1 s1Jv1ty gets changed

i. T

f

1· d mechaincal force influences the change in res1s11v1ty.

ype o app 1e

If tensile force is applied, then

(i) Length of conductor increases

~

(ii) Cross-sectional area decreases

Hence resistivity of conductor increases.

If in place of tensile force compressive force is applied on the conductor, then effects will

; be reverse as compared to above effects, that is

~

(i) Length of conductor decreases

(ii) Cross-sectional area increases

Hence resistivity of conductor decreases.

Now it is clear that value of resistivity changes due to changes in length and cross-section

area of the conductor. (Because of applying mechanical force/deformation).

Values of resistivity, temperature coefficient, density and melting point for different

materials.

•

•

Following table gives the comparative study of the value of resistivity, temperature

coefficient, density and melting point of different materials by which right material for the

required application can be selected.

Table2.1

Conducting Materials

Aluminium (hard drawn)

=

R= pl

a

2

~

l

a x 4 - ~ -x7

d= - - -4

l rt

3.142

p=2.8x10- 8 and / =400m, R=4 O

(ii) For aluminium

1 Jl'(';J

4

1. 7 x IO - x x 400

·-

=1.7 x 10- 6 m = 1.7 mm 2

a=

Elccl.-icul and Electrunic~ ~. ngineering Materiah

Copper (Annealed)

16

I:

f:

\·\ , ~~- ; rnt~C\ ( . \\\•1\ '\

in d ·, ,.,;"l

~ !~~.~Ltt..~~!l~ls and Thei r t\ReJicagont :

Cond uctin g Materials

.

~

-

At prese nt abou t 30 super cond uctor meta

ls (soft superconductors) and more than 600

supe rcond uctor alloy s (hard super cond uctor

s) are already know n.

Many meta ls and comp ound s show the

property of superconductivity at very low

temp eratu re. Good conductors of electricity

like copper, silver and aluminium do not get the

state

of super cond uctiv ity at lowe r temperature,

it shows that it is not necessary that only

good

cond uctor s of elect ricity can be supercondu

ctors. Superconductivity has been observed to

occur in

poor er meta llic cond uctor s such as tin, lead

and tenta\um rather than good conductors. It

is clear

that super -cond uctor s may not only be pure

metals but various alloys and chemical comp

ound

s as

well.

8

t

2 5 2 Aluminium :

.cal

• • • Alumm1

. •um is widely available in India and

used

exten sivelgy in the field of elect n

.

.

.

.

1

. eenn

.

. g. t -is n ext best to copper. Value ofres1shv1 . ..,,_

ty 1s__

2.8 x__

10-_ ohm- m whic h is 1.6 times

engmt r as compared to copper. Its density is

2.68 that 1s 1/3

.

grea1 _e g point is....:6::.:5::.:S=-=d-=::egr~e~e....centigrade. Like- - - - 1 . . time less than that of copp er.. Its

~oppehr, a urruftnium can be easil y draw n into

wtres,

me tm

.

d rods. Its resistivity and density c ange a

er the meta l is mech ainca lly drawn.

sheets, SlnP

an·

·um

is ·a soft metal

h alumm1

. but: when ith is . alloy

I ed With some other mate rials like

Althou~ um rro

. n or silico

n, it acquires highe

rhigh

mec an1ca· strength_ Alum inium fonn s an

·

h

oxide

magnesi '. 1 is exposed to atmosphere. It a~

corrosion resistance like copp er. ·It is diffic

ult

\aye~'lw

dA~

~re

a:ih

~,nu ~niu

.

tos~

This is the great disadvantage of aluminium again

st its use in dome stic

wiring.

.

. . .

.

Low resis tivity meta ls are follo wing whic

f

.incre ase m

t ls increases with

.

h are main ly used m elt:ct n cal engineerin

lt has been studied earlier thal the res1s11v1ty O

g field •

me• a compounds h

.

. .

l, Copper ,\ ;) &'le\

w ose res1stw1ty

temperature and vice-versa. There are some metal

1

4. Merc ury 35 1s and chemica

·

O

oo kelvin (- 273 C). At this• stage

2. Alum inium b '.).;

becomes zero when their temperature is decreased

~- Plati num i -:/I: • ;

h

(brou

g

t

near

·

·

d · ·ty for example, mercury beco mes ·.

3.Ste el

1~ 3L

such metals or chemical compounds attain

s the supercon uct1v1 •

__

super-conducting at approximately 4.5 kelvin

2.5.1. Cop per

(-268.5°C). Hence super-conductwity can be

defined as : "Stag e at which the value of resist

ivity of a metal becomes zero, is calle d supe

Amo ngst al\ the cond uctor s copp er is most

r- ·

wide ly used in the fi~ld o f elect rical engin

conductivity ." Superconducting material was

eering

due to its high cond uctiv ity and low resist ivity.

disconverd by Heike Kamerlingh Onne s at

Silve

r has lowe st res1sliv1ty but beca use of its high

the

_

University of Leiden in the Netherlands in 1911.

lt is an important research for the mode rn

~ cost it is not used as a cond uctin g material.

science. Heike Karner\ingh Onnes found that at

Copp er is reddi sh in colour. It has fine phys

4.5°K resistivity of mercury becomes zero. In

ical, chem ical and elect ric al prope rties. It

this

condition when electric current was flowing in

is a

non-magnetic material whic h is found in natur

the mercury ring, then it continuously was flow

e in the form of ores (mai nly copp er pyrit

ing

e

(Cu

without any power losses. lt shows the state of

'i"nd

cupri

2S)

te (Cu 2 C)). It can be avail able in hard drow

super-conductivity.

n or anne aled form . Mech anica l properti~

i

are different for hard draw n copp er and anne

(!be transition from normal conductivity to super

aled copp er. Anne aled copp er is soft, flexib

-conductivity takes place almost sudd enly.

le and has

less tensile strength than hard draw n copp er.

It occurs over a very narow range of temperature

Hard draw n copp er is obtai ned by drawing

about 0.05°K. The temperature at whic h the

copper

bars in cold condition. Anne aling proce ss invol

transition takes place from normal conductivit

ves heali ng at a speci fic temp erature than

y to super-conductivity is called "tran sition

coolin

g.

Resistivity of copp er is l.72xlO-s ohrn-m

temperature'

at 20 degre e C. Copp er can be draw n into

very thin

wires, sheets and bars of various thicknesS'

can be made . Its corro sion resistance is

2.5. Typ es of Superconductors

very high.

When it is exposed in atmosphere copp er oxide

layer form ed on it. Dens ity & melti ng point

There are two types of superconductors. First

of.

copper is 8.93 and 1084 degree centigrade. Tens

is soft super-conductors which are usual ly

ile stren gth varie s from 8.15 to 4 .72 tonne

made up of pure metals their range of transi

s/cm

2.

tion temperature is 0.01°K to 9.15°K. It has

Copp er can be easily soldered & weld ed. Copp

less

er joint s offer low conta ct resis tance. Coppe

technical uses.

r

has following applications :

On the either hand, another type is known as

I . In domestic wirin g

hard super-conductors they are usually made

up of alloy metals with high value of resist

2.

Transformer winding and moto r wind ing

ivity in normal state. Their value of transistion

temp eratu re is comparatively large. Their

_

value of transition temperature is high, it mean

3 Overhead transmission inductor

s as

comp ared to soft super-conductor, they get the

4 Bus-bars

state of super-conductivity in much time. Thes

e are

very usefu l as compared to type l supercondu

ctors.

5·_High voltage underground cables

6 _ Contact material for control relays

2.5.1. Superconducting Materials

Supe r-con ducti vit)'

18

Electrical and Electronics Engineering Mate rials

a

/\ lu,11i11rum is extensively used

.1,

a conduclPr \i•irl, in overhead lransmission lines, bus bars.

Ell'l'lrirnl 1111<1 Ell'l'tronks Engineering M1lll•rinls

-~

12.5 g/cm 3 . In the field of electrical engineering it has some specific applications such as mercury

switches, mercury vapour lamps, fluorescent tube lights, mercury arc rectifiers and in the

manufacturing of many electronic equipments.

2.5.4. Mercury

It is an important metal for electrical engineering field. It is the only metal which remains in

liquid form at -38.87"C temperature. It is a heavy metal. It is white and bright like silver so it is

6

also known as 'liquid silver'. Resistivity of mercury is 0.95 x 10- !2-m and value of temperature

coefficient of resistance is 2. 7 x 10-6 per°C. It ha5Imelhng poiniJ~i51°~and having density o(

copper. Its melting point is l 530°C because of high resistivity steel is not used as a conductor. But

it is used in the overhead transmission lines to reinforce the aluminium conductor. Zinc coated

steel wire is used as earth wire in overhead lines and as an ann-our wire around the conductors of

power cable and underground cables. The silicon steel alloy is used as magnetic core in electrical

machines such as AC/DC generators, motors and transformers.

4·

____

/

_

9 x J0 - 6

125-240

105

71.6

19 77

2 1 45

3li2'\

17(,li l

Value/Rang~

- ---- -

_ _ _ _ _ Z_I

2.6. Properties of Conductjng Materials

Platinum has various applications in the field of electrical engineering as follows :

J. In electrical electrodes

2. Elecrrical contacts

3•. Platinum resistance thermometers

4. As ignitor in mercury arc rectifier

5. For rust resistant surface

6. Used as a catalyst in chemical reactions

Tensile strength (MPa)

Thermal coefficient of expansion (per°C)

Resistivity at 2ff'C (in !2-m)

Thermal conductivity W/(m-k)

Density (g/cm )

3

Density when liquid al melting point (g/cm )

3

l3oiling poinl ( °C)

Melling roin' ( °C )

-- ~ e ! t_t .

('ondncling 1\1:tlcrials

(iii) Ductility : It is a property of metal due to which it can be drawn into wires and rolled

into sheets. bepenctmg upon the required application conducting material is drawn into wires of

various size and sheets of different width. So the ductility of metal should b,e high so 11 can be

easily drawn into wires and sheets.

Mechanical strength : In overhead transmission lines, line conductors have to bear \vind

pressure, stress due to ice and their own weight too. So the mechamcal strength of !me conductor

should be high so that it e_asily face these stress and strokes.

(v) Flexibility : In many applications conductor wire is used m the shape oi cod I.Ike in the

motor wmdmg and m the same way in the transmission distribution lines at the termmatmg end

ti!lliperature

(i) Resistivity : Resistivity of the conducting material should be low. We know that rn

electrical transmission and distribution lines voltage drop= IR and power losses = J 2 R.

Hence to minimize voltage drop and to keep power losses low resisti vity of the conducting

material should be low.

(ii) T.emperature coefficeint of resistance : The change in resistance with respect to

coefllc1ent of resistance for the given conducting material.

temperature 1s detmeu §§

of resistance should be low. Because if temperature of

coefficient

The value of temperature

transmission line changes there should not be any change in the resistivity of the conducting

material so that parameters of the transmission line remain constant at all temperature.

Steel is an alloy of iron. Steel is obtained by adding small percentage of carbon into iron

Iron is a soft metal when carbon is added into it acquires good mechanical properties and fi

increased tensile strength but at the same time its ductility decreases. If the percentage of carbon is f

high, then it becomes brittle. On the basis of carbon percentage, steel can be classified into !

following catogories :

~ Mild steel containing carbon about 0. 15% to 0.25%

~i) Medium steel containing carbon about 0.45% to 0.70%

Jiii) High carbon steel containing carbon about 0. 70% and above

8

The resistivity of steel is 9.8 xl0- .Q.m (at 20°C) i.e. 8 to 9 times higher than that of

2.5.3. Steel

squirrel cage inductor, motor rotor bars and in many othcr application. However the important

application ufaluminium is in winding of electrical 111achincs and large rating transfonner because

of bei ng low density material. Since resistivity of aluminium is much higher than that of copper.

So to keep / 2 R losses low cross-section has to have thicker. The total winding occupies more

space and the size of machine also increases. But because of lower density of aluminium,

aluminium winding has less weight as compare;:u to copper.

Zfl

2.5.5. Platinum

Platinum is an element represented by the symbol Pt and it has atomic number 78. It is a

dense, malleable, ductile, highly non-reactive, precious, gray white metal.

Platinum is one of the least reactive metals. It has remarkable resistance to corrosion, even

at high temperatures. It has great physical an_d-chemical properties which make it more suitable for

the industrial applications.

Other properties of platinum are given in the table.

er

2

in

h.

of

per

ng.

has

2S)

ies

IS

ring .

high

t'ld :

~

v

H1~P., CD'lc!.ul.J-iv~

l

--·•- -

l.\

- - -- - ---- - ·-

-

.

PP

lications

_

•

2.8.1. Carbon

Carbon is available i~ nature in different forms such as : graphite, diamond, charcoal.

Carbon materials used in the field of electrical engineering are manufactured from graphite and

other forms of carbon. These carbon graphite and other form of carbon ma terial powder are mixed

up with binding material (e. g . coal-tar, liquid, gases etc.) and this mixture is moulded in different

shapes then baked in electric ovens. To increase the conductivity of carbon material copper or

bronze powder_are mixed into the carbon mixture before the moulding process.

resistance.

of

coefficient

temperature

negative

Carbon is a high resistivity material. It has

Its melting point is-3'S'50°C. It is sensitive against pressure.

Carbon is used m making carbon brushes fo~-DC machines, as electrodes in arc lamps, in

dry cell, non-wire resistance, sliding contact in rheostafefo-:-·-· -· -

2.8. High Resistivity

atena

pre-he~ters at nuclear af!d .fossil fuel power plants.

. Is And Their A

l!)LD 4J() clyc.}-iu,~

m akL· <;on1rol ,pn ng'> fi,r c k<:1ri, al

.

•

•

.

•

.

In the fie ld ol electrical engmecnng 11 1s u,ct1 1O

vane! ~ ol

. . . gaug e · bean nl!- plate and wide

.

.

.

F"

.

. struments electrical contacts, diaphragm for pressure.:

· . th. use of mon: expensive c,ery 111um

.

.

'

1n

wire fo nns where the dcs1red properties do not require.: e ·

r.

II

.

.

.

, copper.

· ke I (a Iso known as .copper-nickel) 1s an a oy o copper

(iv) Cugronickel Bronze: Cupromc

;

_

~ that contains nickel and other strengthening elemerits, such as iron _a nd manganese. .

Cupronickel is a metal having silver color. It is high ly resistant to corroswn m sea-water

. b cause its electrode potential is adjusted to be neutral with regard to sea-water. It has good tensile

good

. . when annealed, therrna I cond uc t.ivi·1Y and them1al expansion.

.

.

te ength excellent ducllhty

11

y

easil_

b~

c~n

alloy

this

in

::ennal 'conductivity and ductility. By mixing 7.5% aluminium

verted into thin sheets by cold and hot rolling process. In the fie ld of_electn cal engmeenng it is

cond to make condenser tubes, heat exchanger tubes. In power generation cuprornc~el alloys are

~:: d in steam turbine condensers, oil coders, auxiliary cooling systems and high pressure

conducting Materia ls

Phosphor Bronze : Phosphor bronze is an alloy of copper with 3.5-10% of tin and

upto I% phosphorus. The phosphorus is added as deoxidizing agent dtlritig melting.

(ill)

Brgnze :

excellent formability and solderability.

4--

q...

drawn

1

Manganin is an alloy of copper. Wh£P 86% cop pfu, ' 12% maganese and 2% nickel are

into wires Its

added together then we get an alloy called manganin. It can be coldiy

working temperature is 60°C to 10°C and melting poi~t is 120°C. At higher value of temperature

its value of temperature coefficie nt of resistance increases. Due to this at higher temperature its

5

resistance varies. So it is not used at higher temperature. Manganin has 4 .55 xl0- ohm-cm

2.8.3. Manganin

When 60% of copper is mixed with 40% of zinc, we get an alloy called brass. It

(i)

has higher value of resistivity than copper but has higfl tensile strength. It can be easily converted

into rods, wire, sheets and tube. It can be easily soldered and welded. It has high resistance against

corrosion. Brass is used in making knife switches, plug tops, ceiling rose, lamp holder, contactors,

brush holders for DC machines and sliprings for AC generators and motors.

·.'

When copper (82-90%) and tin (8-16%) are mixed together with third element 2.s.2. Tungsten

(ii)

like cadmium, phosphorus, beryllium or silicon etc., then we get an alloy called Bronze-Bronzes

It is a very hard metal. Its resistivity is approximately twice that of aluminium i.e. 5.65

are given their name based on the third element which is added. For example, when the third

8

Q-m. It has great tensile strength. Its melting point is the highest of all metals i.e. 3422°C. It

oi

x

element is phosphorus, the alloy is called phosphor bronze. If the third element is silicon or

ps,

e.asily .drawn .into thin wires required for making filaments used in elec~

be

can

cadmium, the alloy is called silicon bronze or cadmium bronze respectively. All bronzes have high

tubes and electronic valves etc. It can work up to 2000°C when used in presence of

fluorescent

mechaincal strength and highly resistant to corrosion. Cadmium bronze is used for making

inert gares like: nitrogen, argon etc. or in vacuum. Even at few hundred degree temperature it can

commutator sagments and contacting conductors: Other applications of bronze are in si iding

easily ovidizes in the presence of oxygen.

contacts, knife switch blades and in current carrying springs.

Brass :

2.7. Low Resistivity Copper Alloys

and weather,,; effects :

These alloys have properties of toughness, strength, low coefficient of friction and fine

grain. It is a hard metal having good tolerance. It is a non-ferrous metal having high electrical

conductivity, high resistance to chemical and ·corrosion, high wear resistance, non-magnetism,

.

(mm

Electrical and Electronics Engineering Materials

•

f . .

·

• th d .

w here c irect10n o 1me 1s to be changed, conductor has to bend. If the conducting material -is

. ..

.

.

.

.

.

b

·

h d t h en II

can e broken at the ttme ofbendmg. So conducung matenal should contam flex1b1hty

ar

.

.

property sothat 11 can easily bend and turned into shape of coil.

gxida$iM : Many metals form oxide layer when placed into an open

(vi) .fEGG

· open atmosphere, there

·

·

· ·

m

where conductor exists

Ime

a Imosph ere. In overh ead transm1ss10n

aryg_c~n be oxidized

moisture

and

)

(0

con_ductor can be easily affected by the atmospheric gases 2

oxidation shoul be

against

resistance

its

e.

i.

oxidation

from

free

be

should

e~sily. So the conductor

high.

•

·

· placed mto

· : When conductor 1s

·

·

··) Res1stance

( vn

an open atmosphere 11

corrosion

agamst

should ~ot fiave the cor:roMon . p~o~erty. Corrosion degrades the mechanical efficiency of the

conductmg metal and its res1stiv1ty also gets affected. Hence the overall efficiency and

performance of the transmission line or electrical machine decreases. So the resistance against

corrosion should be high for the conducting material.

and weldin : In many applications where length of conductor

(viii) Easiness i

needs to be extended, soldering an we mg 1s to be done on the conductor to join the one

conductor to the another. So the conducting should be of such type that it can be soldered and

'

.

welded easily.

The conductor used in

(ix) Resistance against chemical

transmission line and in electrical machme are placed into open atmosphere where it has to face

many weather conditions and also affected by the chemicals. So the conducting material should

have high resistance ag_ainst chemicals and atmospheric effects.

22

rn-an

ure its

:-rature

e~ - Its

el are

.

5.65

zoc. It

.ps,

nee of

it can

nps, in

stance.

1arcoaL"

ite and

mixed

ifferent

pper or

ea-wate r

d tensile

. good

e easily

ring it is

Joys are

ressure

f copper

elec1nc<1 I

,a, iety of

ery ll1um

ZJ

't->"·-

1

3

,

0.39

455-860

19.5

8

5x10-7

1210

500

8.9 x10 3

·Value/Range

~

.

Nichrmna,

·•;:- r ;,

3

Melting point("C)

Density (lcg/m )

l40Q

g apparatu s li ke hea ter,

(i) Resistivity : High resistivity materials are used in heat producin

2

So to produce large

Rt.

1

=

H

etc. We know that for specific length produced heat

2.9. Pro erties of Hi h Res1stivit Materials

27

Applications

wi1.k , an ~1 y "' tk , 1ct·,

In the field of electrical engineering nichrome is used in a , 1.cry

rn it ,, 11 sed 10 mak e:

wire,

thin

into

drawn

easily

be

can

It

.

where electric healing is required

and electric "'•<.:n l"lc.

elements of heating devices such as kitc~en heater, geaser, elcctnc iron

C

'1

t1(lll0-l

CC

low

Conducting Matef'ial s

-- --

_1O. ..G6r

.

to a more stable form, such as

~ o s i o n is a natural process, which converts a pure metal

material s (usually metals) by

of

tion

~ oxide, hydroxid e or sulphide . It is the gradual deteriora

.

medium

ing

surround

their

chemical or electroch emi~al reaction with

with an oxidant such as

reaction

in

metal

of

n

oxidatio

Corrosio n means electroch emical

-known example of

well

a

is

oxides,

oxygen or sulphur. Rusting, the formation of iron

salts of the original

or

oxides

s

produce

electroch emical corrosio n. This type of damage ·typically

· d. · • orange co1ouration .

ta! d

me an resu 1ts m a 1stJnctJve

as ceramic s o r po lymers,

Corrisio n can also occur in material s other than metals, such

of corrosio n process in

Theory

.

common

more

is

tion"

"degrada

term

the

although in this context,

do not oc-:ur in the

metals

,

metals can be understo od as; apart from gold, platinum and few others

2

n of Metals

~~

ffim

electric iron

amount of heat resistivity should be high .

temperat ure. It should be

(ii) Melting point : High resistivity material has to bear high

high melting point.

have

should

It

capable to work at high temperat ure and not to be melt. So

are used generall y in

(iii) Low Temperature Coeffici ent : High resistivity materials

material s should be of

these

electrical riteasuring instruments, resistance box and rheostat etc. So

stance should not be

resi

of

value

such type that if value of their temperat ure changes, then their

low.

be

should

;°t

changed much. It means their value of temperat ure coefficie

g devices in the

(iv) Ductili : High resistivity material s are used in many heat producin

co.nverti ng th e

For

metal.

y

form of eating element. Heating element is a coil ofthin high resistivit

that metal has

essential

is

it

material

e

thick diameter wire in thin diamete r wire of high resistanc

wires.

thin

into

property of ductility so that metal can be easily drawn

applicat ions such as : in

(v). Free from oxidatio n : High resistivit y materials have many

in the element is not

used

electric ovens, kitchen heater, hot plate or room heater etc. If material

the material also

of

strength

and

free from oxidatio n then there should be less heat transfer

y.

efficienc

better

for

degrades . Hence material should be free from oxidatio n

resisti vity material s are

(vi) High mechan ical strength : In variety of applicati ons high

diameter for shunt resistanc e of measuri ng instrume nts

used to make the resistanc e wrre of

tensile strength so that they

and resistance boxes. So it required that material should have high

subsequ ent operatio n

and

y

may not break during the drawing of the wire or during the assembl

l

75~78% and chro~um is

"iHs an alloy of nickel and chromiu m in which ratio of_nick~I is

O

mto this alloy. Properties

29-30%,. ~n. and manganese in small quantity is often ID1Xed

nichrome 1s given below in the table.

Table : Propert ies of Nichrom e

s--~~ ~f?~ .v;iue/R iinge ,-:,,8 · ..,~•.. •. ,

.

Brope _· t · ,·

"·

--6

--6

·

,.

/

·'·

rty

. . .

10

5

10

x

- 1.

1.0 x

,

ResJStJvity at room temp. (ohm-m)

11.3

"C)

Thermal conductivity (W/m

13 4

.

.

Thermal ex

·

pans1on coefficient

-'

"C

(at 20°C to JOO'C) per

S400

.

2.8.5.

turing ofrheost at fo '

Applications : It is used to measure tempera ture. It is used in manufac

the formation o

for

used

also

is

It

meters.

ampere

of

e

resistanc

laboratories and shunt

Its value o

chrome.

and

iron

copper,

thennocouple, along with the wires of other metals such as

is used fo

it

this

to

due

ture,

tempera

its

in

change

the

with

much

resistance does not change

for this

resistant

of

nt

coefficie

ture

resistance purpose. It is used for DC shunts value of tempera

nts.

instrume

n

precisio

more

in

used

is

it

reason

this

to

due

n

metal is higher than rnangani

Tensile strength (MPa)

Specific heat capacity J/(g.K)

Temperature coeffi~ient at 20°C (in 1°C)

Thermal conductivity (W/m-K ) at23°C

Resistivity (at room temp. in .Q-m)

Melting temperature (°C)

Density (kg/m )

0

Highest working temperat ure ( C)

Property

r:;;;;,

·e box and slandard resistanc

_

·siivity. !Is melting pomt

.

N

~

C.....

eter shunts. res1slam

res1

~

~

resistors, amm

t

consistin g of 55¾_copper and'

Eureka. It is a coppe r-nic~ y us~a

2.8.4. ConS antgp

constant over a wide range o~

1s

which

ty,

res1st1v1

its

is

metal

s

i

h

t

~

as

known

It is also

45

coefficient, easily ductile.a

ture

tempera

le

% nickel. Important feae~r;co heat resistanc e, negligib

properties of constanto ' i

other

moulded

and

soldered

easily

be

has highncsp

effects, can

Properties. Ittmosphe

table.

the

.

resistant to a

·

Table : Propert ies of Constan ton

has been shown m

4

-~

. - 1.-5~96~0=o=c~_-:;E~le:c~tr~ic:a~l-:a:p:p~li:ca~t~io:n:s~o~f~m::a:ng:a:n~i:n~ar:e~;~w~i~re~~~

2 - - - -- -- - e coil etc.

Electrica l and Electron ics Engineer ing MateriaJ

··..

,

·

t .

proce ss

'1f::::::t

'Blast furnac e

Energ y

Level

y-

Fig. 1.2 : Energy slate of Metal in various forms

◄----

temperature

High pressu rn

and

/Energy

Output)

Corrosion

/~

~

~...,......,..,.,...,=-- -

('5 '--st~f ~

9.

8·

7.

5.

6.

Co

er

As cableJungs

winding

In

transformer from

kVA to 1000 kVA

In power wiring

In domesting wiring

Underground cable

Mostly used

Aluminium

Steei

_

in

Used

ACSR

conductor

_as centre

core for tncreas'

the tensile stren ~ng

aluminium · g of

conductor.

of / Less used

25

Mostly used

Not used

Not used

Not unsed

Not used

Not used

Rarely used

Not used

Not used

Rarely used

Mostl y used

Used as under- Mostl y used as Not used as cable

conductor but used as

ground telephone underground

distribution

armour for cab!

cable

e

safety

cable

Not used

Used

Used

Not used

Not used

Used

In winding of trans- / Mostl y used

former more than 1000

kVA

. _

s

3

/ AinCs~tdor ~mdm g of ~ I Mo tly used

m uction motor

· m armature and field I Mostl y used

DC

of

winding

1

lication

In overhead electrical Rarely used

and

transmission

distribution lines

A

ti

, --'-=-'=::..::..:==--- --- -....I...-- ___ __

machines

· commonly known as

· number 80. It 1s

. an eIement w1'th sym boI Hg and atomic

/ Rarely used

Mercu ry 1s

Not used

Mostl y used

industries' offices and

In

0.

I

2

.

h

.

.

h

heavy,

A

.

g/cm

13.55

1s

t

eart

.

weigh

c

.

as

specifi

Its

.

ouses

gyrurn

quick silver and was formerly named hydrar

_

electrode

is liquid at standard conditions for

.J__ _ _ _ ___J_ __ _ _ __

silver y d-bloc k element, mercury is the only metal that

good

a

i~

ury

]Merc

-39°C°

is

point

g

meltin

and

357°C

is

tempe rature and-pressure.ffi_s boiling point

3

6

Used in Manufacturing of Electric Lamp

Its electrical resistivity is 0 · 96 x 10- · •1 · Material

condu ctor of electricity but bad conductor of heat.

electric lamp :

Following materials are used in the manufacturing of

Its thermal

C.

degree

per

7

0.0002

is

nce

resista

of

ient

coeffic

ohm-m etre and temperature

ng of filaments of electric lamps

(i) Carbon, tantalum and tungsten : Used for manuf acturi

K)

µml(m

60.4

is

ion

expans

l

thenna

and

)

Wl(mK

8.30

is

condu ctivity

This meltin g points are 3900, 2800 and 3400° respec tively.

es, relays, fluorescent tubes,

In the field of electrical engineering mercury is used in switch

coveri ng.

(ii) Quartz Glass : Used for manuf acturi ng of outer glass

ents, liquid electrolytes,

instrum

and

ents

equipm

nic

electro

rs,

rectifie

arc

y

alarm circuits, mercur

caps.

(iii) Aluminium and brass : Used for manuf acturi ng of bulb

of mercury being used for making and

Hg-oxide batteries, alkaline batteries etc. An important use

als.

(iv) Copper : Used as a conne cting wire betwe en termin

breakins contact in Buchholz relay used for transfonner protection.

in the glass envelope to preven

(v) Nitrogen and Argon : These are inert gases, filled

oxidat ion ·of filament.

2.11. Uses of Mercury as Conducting Material

I

3.

2.

J.

4.

'

•

_s. No.

for Vario us~

i~ ~ a r i s o n of Copp er, Alum inium and Steel

uctor

!0A ~at ion s as Electrical Cond

,Condu cting Materi als

Electri cal and Electronics Engine ering Materi als

bound to other substances in ores, such as

nature in their pure form. They are normally chemically

a blast furnace) to extract the metals from

sulphi des, oxide s etc. Energ y must be exllended (e.g., in

the sulphi des, oxides etc. to obtain pure metals.

higher energy state than that found

Pure metals contai n more bound energy, representing a

in the nature as oxides or sulphides.

energy state, pure metals also

As all materi als in the universe strive to return to its lowest

as sulphides or oxides. Energy state of

strive to revert to their lowest energy state which they had

low

in which metals can revert to their

..

metal in variou s fonns has been shown in Fig. 2.2. The way

.

des.

sulphi

or

oxides

often

metals are

energ y level is by corrosion. The products of corrosion of

24

--

I

.

ICII lllld Flt•ctr

·11111cs

-

Ekctr·

me llng pom1

. is a

Elec1ro-graphi1e is used as brush contact material. Its · I .

- - - -

.

7

ni.: M:it(•ri~\

n

(ii) Two diffrrnet semi-conducting materials such as :

6 9

For P-type semi-conductor lead telluride (Pb T

and 38 1% (Te) and fc

(e) 21.), %

manufacturing ofN-type semi-cond uctor di- iod"d

bismuth te;itell un·ct·e (Ta

I

Pb

e

t

Tel

etc.

(BTTE 2010, 12, I

4. What . do you understand by supercond uctivity? List the names of supercond uctin

(BTE 2010, 1~, ~3,_ 15, I

matenals and their possible applicatio ns.

1ty.

5. What do you understand by resistivity ? Discuss the effect of temperatu re on·res1sttv

(2011,.13, 14, 1

3. Define the term hard and soft solder and also write the names of soldering materials.

(BTE 201

materia

2. List the names of high resistivity materials and write any two applicatio ns of each

(BTE201

resistivity.

1. What do you understand by the term resistivity ? Explain ilie various factors which affe

--E}(-ER_<:;I_SE ·

(i) Soft solder : It is used for joining the copper or brass wires together. It is an alloy off

and lead.in which the ratio oflead is 50% each. Its melding point is 400°C.

60% an

(ii) Hard solder : It is an alloy of copper and zinc and ratio of copper and zinc is

bra

and

steel

mild

of

sheets

thin

and

wires

steel

70%. It is used for joining the brass, copper and

etc. Its melting point is higher than that of soft solder.

V" Soldering materials are classified into two categorie s :

~Sold ering Materials

(vi) Tin 232°C

(vii) Indium 1564°C

(i) Copper l 884°C

(ii) Aluminium 659°C

(iii) Lead 327°C

(iv) Cadmium 321°C

(v) Bismuth 271 °C

:

Following are the materials used as fuse element and their respective melting point

2.16. Materials Used in Manufacturing of Fuse Elemen t

....,,_

6. Write ihc general properties o l low 1c~1st1 v11y malcria l.

7. Write the properties of" high n.:sistiv1ty 111ateriab: L>i~rn~~ 1hc rncia l u~cd

·

111

II , I 5 J

hcalt:r and

(lf/1 I J

29

(201 3)

1

(d) 4 .9 K

(b) 4.3 K

(d) 8.33

{l>r8.93

(9}-coppe r

(d) steel

6. Copper is widely used as conducto r over silver because of :

(b) high conducllvi.ty

W,ow cost

(d) easy fabricatio n

(c) availabili ty

S. Density of copper is :

(a) 8.83

(c) 8.63

(a) aluminium

(c) brass

@ l .72 x 1o-8 ohm-m is the resistivity of :

3. At present how many supercond uctor metals are known?

~ 30

(a) 20

(d) SO

(c) 40

0)-4.5 K

(c) 4 .6 K

@Mercu ry becomes supercond uctor at :

1. If length of conductin g wire increases, then its resistivity :

"8,-increa ses

(a) decreases

(d) none of these

(c) remains constant

Multiple Choice Questio ns

16. Write the names and properties, of materials used in(ii) Soldering

(i) Brush contact