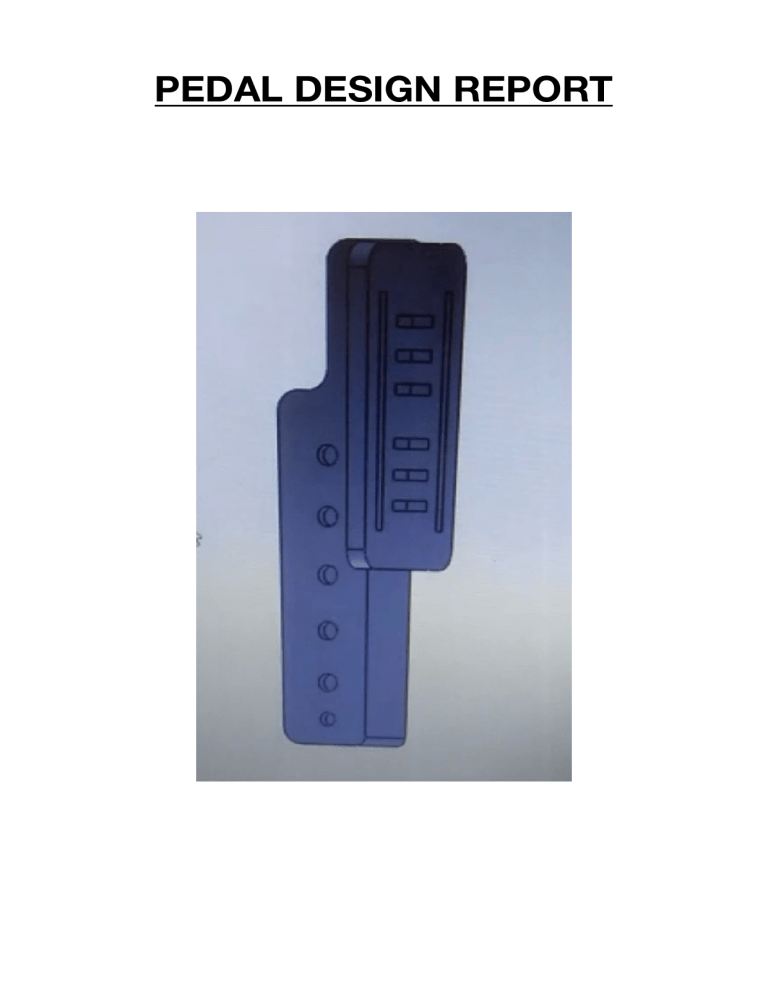

PEDAL DESIGN REPORT DESIGN GOALS Our design goal for our current season was to ensure the accuracy of all the components. To reduce the cost of production and machining time. More importantly to overcome the drawbacks of last year’s design. We also kept in mind the weight of the pedal and made attempts for weight reduction. THINGS WE KEPT IN MIND BEFORE DESIGNING OUR PEDAL - Should withstand a force of 1500N. - Throttle cable connection. A 6mm diameter at 50mm from top. - Pedal box dimensions. The pedal must fit in the pedal box so it is important to know dimensions of pedal box. - Dimension of pedal. Length of the pedal should be average foot size of an Indian men. MATERIAL SELECTION MILD STEEL ALUMINIUM STAINLESS STEEL TENSILE STRENGHT 420 MPa 276 MPa 505 MPa YIELD STRENGHT 240 MPa 145 MPa 215 MPa DENSITY 7.8 gcm-3 2.81gcm-3 8 gcm-3 HARDNESSS 110 HRB 60 HRB 70 HRB COST PER KG 40/- 260/- 180/- WELDABLE Less than ss Less than both More than others CORROSION RESISTANT POOR LESS THAN SS VERY HIGH MALIABLE MORE LESS MORE -After considering all the above aspects, we decided to choose stainless steel as our material to make pedal. -The key consideration were cost and strength of the material. -Why SS over Aluminium? Although aluminium is lighter than SS, the yield and tensile strength of SS is more so a smaller amount of SS can gives us a strength equivalent to a heavier/larger amount of aluminium. So this in a way does help us in weight reduction. -Composition of 304 SS Chromium 18% - is added to steel to increase resistance to oxidation. Nickel 8% - is responsible for a great toughness (impact strength) and high strength at both high and low temperatures. Nickel also greatly improves resistance to oxidation and corrosion. Carbon 0.08% - is present in all steels and is the principal hardening element. It raises tensile strength, hardness, resistance to wear and abrasion. Manganese 2% - strength and hardness; decreases ductility and weldability; effects hardenability of steel. Sulphur 0.03% - decreases ductility and notch impact toughness. Weldability decreases. Found in the form of sulfide inclusions. Silicone 1% - one of the principal deoxidizers used in steel making. In low-carbon steels, silicon is generally detrimental to surface quality. Phosphorus 0.04% - increases strength and hardness and decreases ductility and notch impact toughness of steel. Therefore, the material of our pedal is 304 Stainless steel. DESIGN CONCEPT After many iterations as shown below, our pedal design was selected ITERATION 1:Rejected because it was too heavy ITERATION 2:Rejected because it couldn’t withstand a force of 1500N ITERATION 3:Selected since it checked in all our current goals. - Here the two 6mm diameter holes are for throttle cable connections. - The bottom 8mm diameter hole is for mounting the pedal. - The other reductions are made for weight reduction. MANUFACTURING PROCESS - Laser cutting of all the three parts ie two side plates and one foot pedal were done individually. - Drilling was done in-house for all the weight reduction holes. - Welding of all the three finished parts was done in-house as well.