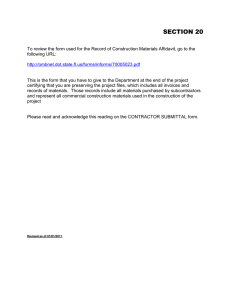

19.2. SITE LAYOUT A contractor must consider many factors when laying out a site to support construction operations: 1. Site size compared with the footprint and configuration of constructed structures. 2. Location of adjacent roads, buildings, and utilities—pedestrian traffic must be kept at a safe distance from the construction site; fencing and barricades may be necessary to block off all or part of a road during construction operations. 3. Soil conditions and excavation requirements—it is important to consider how soil conditions and excavation of a site will change over the duration of a project. What are the excavation shoring needs and how will water be controlled. The bearing capacity of soils in areas where a mobile crane will operate should be verified. The proximity of the crane to the edge of an excavation or foundation wall must be considered. 4. Construction sequence and schedule. 5. Location of utilities—the impact of overhead obstructions such as power or communication lines must be considered; what precautions are needed if machines operate over underground utilities. 6. Equipment requirements—the size and location of hoisting equipment are determined based on both the physical hoisting requirements and the project schedule. 7. Material quantity, delivery, and storage. 8. Temporary facilities and trailers to assist the jobsite work. Health and employee regulations may require sanitary facilities on a job site. The site layout in terms of construction activities, material storage, office trailer, and sanitary facilities can be sketched on a project plan sheet (Figure 19.4). 9. Tool and equipment storage. 10. Worker parking—parking availability on and around a jobsite will typically be addressed in the project bid package. Workers may have to be bused to the site. Figure 19.4 Site layout plan sketch on a project plan sheet 19.2.1. Early Coordination While preparing bids, the general contractor (GC) or construction manager (CM) will define subcontract work packages and © McGraw-Hill Education. All rights reserved. Any use is subject to the Terms of Use, Privacy Notice and copyright information. seek subcontractor prices. On building construction projects it is common for many parts of the work to be subcontracted—on CM-led projects it can be 100% subcontracted—so early interaction between the GC or CM and the selected subcontractors is important. The subcontractors will, in turn, seek lower-tier subcontractors to perform even more specialized work. As an example, in the case of a steel-frame building, a GC will normally have a steel subcontractor. The steel subcontractor, typically the fabricator, will seek lower-tier subcontractors for (1) steel erection, (2) shear studs, (3) metal deck supply and installation, and (4) special fabrications. Typically, the GC will require the major subcontractors, such as the steel subcontractor, to provide input for the preliminary project schedule and jobsite layout. The jobsite layout affects subcontractor efficiency. 19.2.2. Bid Package The bid package given to each contractor by the project owner normally includes information related to: Scope of work as defined by applicable specifications Jobsite conditions and site layout Space limitations Allowable temporary facilities A pre-bid meeting may be held to address questions related to the bid package. During this pre-bid stage, the GC and the major subcontractors will make a preliminary determination of the equipment requirements necessary for constructing the work. A steel subcontractor would be primarily interested in lifting requirements and the location of on-site laydown space to accommodate steel deliveries (Figure 19.5). A concrete subcontractor will consider lifting requirements and storage space for forming systems and reinforcing steel (Figure 19.6). Figure 19.5 Steel stored at the project site for erection Figure 19.6 Reinforcing steel ready to be lifted The subcontractors will need information from the GC and have to provide information to the GC about: © McGraw-Hill Education. All rights reserved. Any use is subject to the Terms of Use, Privacy Notice and copyright information. Schedule Sequence of other trades (subcontractors) Crane size and provider Placement of crane, job trailers, storage areas, and laydown areas Mutual equipment use. Subcontractors often look to use the general contractor's forklift or other lifting equipment for handling their material deliveries. The jobsite layout and equipment will be controlled by site constraints. For lower-tier contractors with lifting requirements, such as the steel and concrete subcontractors, a primary consideration will be crane size and positioning. The two other critical pieces of information are (1) laydown area size and (2) laydown area location. The goal of site layout is to optimize operational processes—steel erection, concrete forming, and placement of the concrete in the forms. The GC and the subcontractors seek to keep the number of crane locations at a minimum. Laydown areas are located as close as possible to the structure. But the decisions are all dependent on project-site size and lifting requirements (Figure 19.7). Figure 19.7 Project lifting solutions Occupational Safety & Health Administration (OSHA) Standard 1926.752 places specific duties on the General Contractor (termed “controlling contractor” by OSHA). 1926.752(c) Site layout. The controlling contractor shall ensure that the following is provided and maintained: 1926.752(c)(1) Adequate access roads into and through the site for the safe delivery and movement of derricks, cranes, trucks, other necessary equipment, and the material to be erected and means and methods for pedestrian and vehicular control. Exception: this requirement does not apply to roads outside of the construction site. 1926.752(c)(2) A firm, properly graded, drained area, readily accessible to the work with adequate space for the safe storage of materials and the safe operation of the erector's equipment. As stated in the OSHA standard, the GC is responsible for providing access points into the construction “site for the safe delivery” of materials. The subcontractors are responsible for communicating to the GC any necessary special access requirements. The GC usually provides access for workers into a project or into the structure on a building project; however, movement of subcontractor employees from floor to floor on a building project may be the responsibility of the subcontractors (Figure 19.8). © McGraw-Hill Education. All rights reserved. Any use is subject to the Terms of Use, Privacy Notice and copyright information. Figure 19.8 Personnel hoist provided for moving materials and crews The relationship between a building's footprint and the size of the site has a significant impact on the planning and sequencing of construction operations and equipment selection. Space is necessary for delivery vehicles and for storage of construction materials. Material laydown areas may have to change as construction progresses and this will impact construction operations. The GC must carefully coordinate all construction processes and the activities of the subcontractors if it is necessary to position the crane within the footprint of the building being constructed, as such a situation often impacts the installation of other building systems (Figure 19.9). © McGraw-Hill Education. All rights reserved. Any use is subject to the Terms of Use, Privacy Notice and copyright information. Figure 19.9 Crane positioned in the field area of a stadium rehab project The overall project schedule and construction sequencing are dependent on crane location and size (dimensions) of the building being constructed. OSHA Standard 1926.753(d) is specific about worker safety in relation to working under lifted loads. 19.2.3. 1926.753(d) Working Under Loads Routes for suspended loads shall be preplanned to ensure that no employee is required to work directly below a suspended load except for: Employees engaged in the initial connection of the steel; or Employees necessary for the hooking or unhooking of the load. When working under suspended loads, the following criteria shall be met: Materials being hoisted shall be rigged to prevent unintentional displacement; Hooks with self-closing safety latches or their equivalent shall be used to prevent components from slipping out of the hook; and All loads shall be rigged by a qualified rigger. OSHA Standard 1926.550(a)(19), Cranes and Derricks, further states: All employees shall be kept clear of loads about to be lifted and of suspended loads. © McGraw-Hill Education. All rights reserved. Any use is subject to the Terms of Use, Privacy Notice and copyright information. Because of this OSHA Standard and sound safety practices a lack of planning can result in restrictions on work activities of other trades during erection of steel or placement of concrete. © McGraw-Hill Education. All rights reserved. Any use is subject to the Terms of Use, Privacy Notice and copyright information.