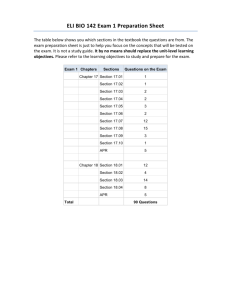

@AIRBUS A350-900 AIRCRAFT CHARACTERISTICS AIRPORT AND MAINTENANCE PLANNING AC The content of this document is the property of Airbus. It is supplied in confidence and commercial security on its contents must be maintained. It must not be used for any purpose other than that for which it is supplied, nor may information contained in it be disclosed to unauthorized persons. It must not be reproduced in whole or in part without permission in writing from the owners of the copyright. Requests for reproduction of any data in this document and the media authorized for it must be addressed to Airbus. © AIRBUS S.A.S. 2005. All rights reserved. AIRBUS S.A.S. Customer Services Technical Data Support and Services 31707 Blagnac Cedex FRANCE Issue: Jun 01/13 Rev: Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING HIGHLIGHTS Revision No. 2 - Apr 01/15 LOCATIONS CHAPTER 2 Section 2-1 Subject 2-1-0 General Aircraft Characteristics Data Section 2-3 Subject 2-3-0 Ground Clearances FIGURE Ground Clearances FIGURE Ground Clearances FIGURE Ground Clearances FIGURE Ground Clearances FIGURE Ground Clearances FIGURE Ground Clearances FIGURE Flap Tracks - Retracted FIGURE Ground Clearances Section 2-7 Subject 2-7-0 CHG CODE DESCRIPTIONS OF CHANGE R R DESCRIPTION TITLE UPDATED R R N N N N N N ILLUSTRATION ILLUSTRATION ILLUSTRATION ILLUSTRATION ILLUSTRATION ILLUSTRATION N ILLUSTRATION ADDED FIGURE Forward Passenger/Crew Doors R FIGURE Aft Passenger/Crew Doors R FIGURE Nose Landing Gear Doors R FIGURE Main Landing Gear Doors R ADDED ADDED ADDED ADDED ADDED ADDED Section 2-8 Subject 2-8-0 Escape Slides R FIGURE Escape Slides N Section 2-9 Subject 2-9-0 ILLUSTRATION ADDED R Landing Gear R FIGURE Main Landing Gear R HIGHLIGHTS Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING LOCATIONS FIGURE Nose Landing Gear Subject 2-9-1 CHG CODE R DESCRIPTIONS OF CHANGE N Landing Gear Maintenance Pits N FIGURE Maintenance Pit Envelopes N ILLUSTRATION ADDED FIGURE NLG/MLG Extension/Retraction Pit FIGURE NLG/MLG Shock Absorber Removal Pit FIGURE NLG/MLG Removal Pit N ILLUSTRATION ADDED N ILLUSTRATION ADDED N ILLUSTRATION ADDED Section 2-14 Subject 2-14-1 Jacking for Maintenance R FIGURE Jacking for Maintenance R Subject 2-14-2 R CHAPTER 3 Section 3-1 Subject 3-1-0 N N N General Information Section 3-3 Subject 3-3-0 N N N Take-Off Weight Limitation FIGURE ISA Conditions FIGURE ISA + 15 ˚C (+59 ˚F) Conditions Section 3-4 Subject 3-4-0 N N N N N Landing Field Length N FIGURE Landing Field Length N Section 3-5 Subject 3-5-0 Final Approach Speed ILLUSTRATION ADDED ILLUSTRATION ADDED ILLUSTRATION ADDED N N N HIGHLIGHTS Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING LOCATIONS CHAPTER 5 Section 5-4 Subject 5-4-1 Grounding (Earthing) Points CHG CODE DESCRIPTIONS OF CHANGE R R Subject 5-4-2 Hydraulic System R Subject 5-4-3 Electrical System Subject 5-4-10 R N Cargo Control Panels N FIGURE Forward Cargo Control Panels N ILLUSTRATION ADDED FIGURE Aft Cargo Control Panels N ILLUSTRATION ADDED R NOTE AMENDED Section 5-6 Subject 5-6-0 Ground Pneumatic Power Requirements Section 5-8 Subject 5-8-0 R Ground Towing Requirements R DESCRIPTION TITLE UPDATED CROSS REFERENCED MANUAL(S) ADDED/REVISED/DELETED FIGURE Ground Towing Requirements R ILLUSTRATION REVISED CHAPTER 6 Section 6-1 Subject 6-1-0 Engine Exhaust Velocities and Temperatures Subject 6-1-1 Engine Exhaust Velocities - Ground Idle Power FIGURE Ground Idle Power - TRENT XWB Engine Subject 6-1-2 R N N N N N N ILLUSTRATION ADDED N HIGHLIGHTS Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING LOCATIONS Engine Exhaust Temperatures - Ground Idle Power FIGURE Ground Idle Power - TRENT XWB-84 Engine Subject 6-1-3 CHG CODE N N DESCRIPTIONS OF CHANGE ILLUSTRATION ADDED N Engine Exhaust Velocities - Breakaway Power FIGURE Breakaway Power (11% MTO Thrust) - TRENT XWB-84 Engine N N ILLUSTRATION ADDED FIGURE Breakaway Power (22% MTO Thrust) - TRENT XWB-84 Engine N ILLUSTRATION ADDED Subject 6-1-4 N Engine Exhaust Temperatures Breakaway Power N FIGURE Breakaway Power (11% MTO Thrust) - TRENT XWB-84 Engine N ILLUSTRATION ADDED FIGURE Breakaway Power (22% MTO Thrust) - TRENT XWB-84 Engine N ILLUSTRATION ADDED Subject 6-1-5 N Engine Exhaust Velocities - Max Take-Off Power FIGURE Max Take-Off Power - TRENT XWB-84 Engine (Single) N N ILLUSTRATION ADDED FIGURE Max Take-Off Power - TRENT XWB-84 Engine (Twin) N ILLUSTRATION ADDED Subject 6-1-6 Engine Exhaust Temperatures - Max Take-Off Power FIGURE Max Take-Off Power - TRENT XWB-84 Engine Section 6-3 Subject 6-3-1 Danger Areas of the Engines - Ground Idle Power N N N ILLUSTRATION ADDED N N N HIGHLIGHTS Page 4 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING LOCATIONS FIGURE Ground Idle Power - TRENT XWB-84 Engine Subject 6-3-3 Danger Areas of the Engines - Max TakeOff Power FIGURE Max Take-Off Power - TRENT XWB-84 Engine CHG CODE N DESCRIPTIONS OF CHANGE ILLUSTRATION ADDED N N N ILLUSTRATION ADDED CHAPTER 7 Section 7-1 Subject 7-1-0 General Information Section 7-2 Subject 7-2-0 R Landing Gear Footprint R FIGURE Landing Gear Footprint R Section 7-3 Subject 7-3-0 Maximum Pavement Loads FIGURE Maximum Pavement Loads Section 7-4 Subject 7-4-0 R R Landing Gear Loading on Pavement R FIGURE Landing Gear Loading on Pavement FIGURE Landing Gear Loading on Pavement Section 7-5 Subject 7-5-0 NOTE AMENDED R N ILLUSTRATION ADDED R Flexible Pavement Requirements - US Army Corps of Engineers Design Method R FIGURE Flexible Pavement Requirements R FIGURE Flexible Pavement Requirements N DESCRIPTION TITLE UPDATED NOTE AMENDED ILLUSTRATION ADDED Section 7-6 HIGHLIGHTS Page 5 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING LOCATIONS CHG CODE DESCRIPTIONS OF CHANGE Subject 7-6-0 Flexible Pavement Requirements - LCN Conversion Section 7-7 Subject 7-7-0 R Rigid Pavement Requirements - Portland Cement Association Design Method R FIGURE Rigid Pavement Requirements R FIGURE Rigid Pavement Requirements N Section 7-8 Subject 7-8-0 R Rigid Pavement Requirements - LCN Conversion Subject 07-08-01 R D Subject 07-08-02 D Section 7-9 Subject 7-9-0 R R NOTE AMENDED ILLUSTRATION ADDED ACN/PCN Reporting System - Flexible and Rigid Pavements R DESCRIPTION TITLE UPDATED NOTE AMENDED FIGURE ACN/PCN Reporting System WV000, MRW 268 900 kg, CG 33% R ILLUSTRATION REVISED FIGURE ACN/PCN Reporting System WV001, MRW 275 900 kg, CG 33.2% N ILLUSTRATION ADDED N D ILLUSTRATION ADDED FIGURE ACN Table Subject 07-09-01 CHAPTER 10 Section 10-0 Subject 10-0-0 Aircraft Rescue and Fire Fighting R FIGURE Front Page R FIGURE Highly Flammable and Hazardous Materials and Components R HIGHLIGHTS Page 6 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING LOCATIONS FIGURE Emergency Evacuation Devices CHG CODE R FIGURE FWD and AFT Lower Deck Cargo Doors R FIGURE APU Compartment Access R FIGURE Batteries Location and Access R DESCRIPTIONS OF CHANGE HIGHLIGHTS Page 7 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING LIST OF EFFECTIVE CONTENT Revision No. 2 - Apr 01/15 CONTENT CHG CODE LAST REVISION DATE CHAPTER 1 Subject 1-1-0 Introduction Jun 01/13 Subject 1-2-0 Glossary Jun 01/13 CHAPTER 2 Subject 2-1-0 General Aircraft Characteristics Data R Apr 01/15 Subject 2-2-0 General Aircraft Dimensions Jun 01/13 FIGURE General Aircraft Dimensions Sep 01/14 Subject 2-3-0 Ground Clearances R Apr 01/15 FIGURE Ground Clearances R Apr 01/15 FIGURE Ground Clearances N Apr 01/15 FIGURE Ground Clearances N Apr 01/15 FIGURE Ground Clearances N Apr 01/15 FIGURE Ground Clearances N Apr 01/15 FIGURE Ground Clearances N Apr 01/15 FIGURE Flap Tracks - Retracted N Apr 01/15 FIGURE Ground Clearances N Apr 01/15 Subject 2-4-0 Interior Arrangements - Plan View Jun 01/13 FIGURE Standard Configuration Jun 01/13 Subject 2-5-0 Interior Arrangements - Cross Section Jun 01/13 L.E.C. Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING CONTENT CHG CODE FIGURE Typical Configuration LAST REVISION DATE Jun 01/13 Subject 2-6-0 Cargo Compartments Jun 01/13 FIGURE Cargo Compartments Jun 01/13 Subject 2-7-0 Door Clearances and Location Sep 01/14 FIGURE Door Identification and Location Sep 01/14 FIGURE Forward Passenger/Crew Doors R Apr 01/15 FIGURE Aft Passenger/Crew Doors R Apr 01/15 FIGURE Forward Cargo Compartment Door Sep 01/14 FIGURE Aft Cargo Compartment Door Sep 01/14 FIGURE Bulk Cargo Compartment Door Sep 01/14 FIGURE Nose Landing Gear Doors R Apr 01/15 FIGURE Main Landing Gear Doors R Apr 01/15 Escape Slides R Apr 01/15 FIGURE Escape Slides N Apr 01/15 Landing Gear R Apr 01/15 FIGURE Main Landing Gear R Apr 01/15 FIGURE Nose Landing Gear R Apr 01/15 Landing Gear Maintenance Pits N Apr 01/15 FIGURE Maintenance Pit Envelopes N Apr 01/15 FIGURE NLG/MLG Extension/Retraction Pit N Apr 01/15 FIGURE NLG/MLG Shock Absorber Removal Pit N Apr 01/15 FIGURE NLG/MLG Removal Pit N Apr 01/15 Subject 2-8-0 Subject 2-9-0 Subject 2-9-1 Subject 2-10-0 Exterior Lighting Jun 01/13 L.E.C. Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING CONTENT CHG CODE FIGURE Exterior Lighting LAST REVISION DATE Jun 01/13 FIGURE Exterior Lighting Jun 01/13 FIGURE Exterior Lighting Jun 01/13 FIGURE Exterior Lighting Jun 01/13 FIGURE Exterior Lighting Jun 01/13 Subject 2-11-0 Antennas and Probes Location Jun 01/13 FIGURE Antennas and Probes Location Jun 01/13 Subject 2-12-0 Engine and Nacelle Jun 01/13 FIGURE Engine and Nacelle Jun 01/13 Subject 2-12-1 APU Jun 01/13 FIGURE APU Jun 01/13 Subject 2-13-0 Levelling, Symmetry and Alignement Jun 01/13 FIGURE Location of Leveling Points Jun 01/13 Subject 2-14-1 Jacking for Maintenance R Apr 01/15 FIGURE Jacking for Maintenance R Apr 01/15 Subject 2-14-2 Jacking for wheel change Jun 01/13 FIGURE Nose Landing Gear Jacking Point Heights Jun 01/13 FIGURE Main Landing Gear Jacking Point Heights Jun 01/13 CHAPTER 3 Subject 3-1-0 General Information N Apr 01/15 N Apr 01/15 Subject 3-3-0 Take-Off Weight Limitation L.E.C. Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING CONTENT CHG CODE N LAST REVISION DATE Apr 01/15 N Apr 01/15 Landing Field Length N Apr 01/15 FIGURE Landing Field Length N Apr 01/15 N Apr 01/15 FIGURE ISA Conditions FIGURE ISA + 15 ˚C (+59 ˚F) Conditions Subject 3-4-0 Subject 3-5-0 Final Approach Speed CHAPTER 4 Subject 4-2-0 Turning Radii Jun 01/13 FIGURE Turning Radii Jun 01/13 Subject 4-3-0 Minimum Turning Radii Jun 01/13 FIGURE Minimum Turning Radii Jun 01/13 Subject 4-4-0 Visibility from Cockpit in Static Position Jun 01/13 FIGURE Visibility from Cockpit in Static Position Jun 01/13 Subject 4-5-0 Introduction Jun 01/13 Subject 4-5-1 90˚ Turn - Runway to Taxiway Jun 01/13 FIGURE 90˚ Turn - Runway to Taxiway Jun 01/13 Subject 4-5-2 135˚ Turn - Runway to Taxiway Jun 01/13 FIGURE 135˚ Turn - Runway to Taxiway Jun 01/13 Subject 4-5-3 180˚ Turn on a Runway Jun 01/13 FIGURE 180˚ Turn on a Runway Jun 01/13 Subject 4-5-4 L.E.C. Page 4 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING CONTENT 90˚ Turn - Taxiway to Taxiway FIGURE 90˚ Turn - Taxiway to Taxiway CHG CODE LAST REVISION DATE Jun 01/13 Jun 01/13 Subject 4-5-5 135˚ Turn - Taxiway to Taxiway Jun 01/13 FIGURE 135˚ Turn - Taxiway to Taxiway Jun 01/13 Subject 4-6-0 Runway Holding Bay (Apron) Jun 01/13 FIGURE Runway Holding Bay (Apron) Jun 01/13 Subject 4-7-0 Minimum Line-Up Distance Corrections Sep 01/14 FIGURE 90˚ Turn on Runway Entry Sep 01/14 FIGURE 180˚ Turn on Runway Turn Pad Sep 01/14 FIGURE 180˚ Turn on Runway Width Sep 01/14 Subject 4-8-0 Aircraft Mooring Jun 01/13 FIGURE Aircraft Mooring Sep 01/14 CHAPTER 5 Subject 5-1-0 Aircraft Servicing Arrangements Jun 01/13 Subject 5-1-1 Typical Ramp Layout (Open Apron) Sep 01/14 FIGURE Typical Ramp Layout (Open Apron) Sep 01/14 Subject 5-1-2 Typical Ramp Layout (Gate) Sep 01/14 FIGURE Typical Ramp Layout (Gate) Sep 01/14 Subject 5-2-0 Terminal Operations - Full Servicing Turn Round Time Sep 01/14 FIGURE Full Servicing Turn Round Time Chart Sep 01/14 Subject 5-3-0 L.E.C. Page 5 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING CONTENT CHG CODE Terminal Operations - Transit Turn Round Time FIGURE Transit Turn Round Time Chart LAST REVISION DATE Sep 01/14 Sep 01/14 Subject 5-4-0 Ground Service Connections Layout Sep 01/14 FIGURE Ground Service Connections Layout Sep 01/14 Subject 5-4-1 Grounding (Earthing) Points R Apr 01/15 FIGURE Grounding (Earthing) Point - NLG Sep 01/14 FIGURE Grounding (Earthing) Point - MLG Sep 01/14 Subject 5-4-2 Hydraulic System R Apr 01/15 FIGURE Green Ground Service Panel Sep 01/14 FIGURE Yellow Ground Service Panel Sep 01/14 Subject 5-4-3 Electrical System R Apr 01/15 FIGURE Electrical Service Panel Jun 01/13 FIGURE RAT Sep 01/14 Subject 5-4-4 Oxygen System Sep 01/14 FIGURE Oxygen System Jun 01/13 FIGURE Crew Oxygen Storage - Location Sep 01/14 Subject 5-4-5 Fuel System Sep 01/14 FIGURE Refuel/Defuel Control Panel Sep 01/14 FIGURE Refuel/Defuel Couplings Sep 01/14 FIGURE Overpressure Protectors and NACA Vent Intake Sep 01/14 Subject 5-4-6 Pneumatic System Sep 01/14 FIGURE Low Pressure Ground Connectors Sep 01/14 L.E.C. Page 6 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING CONTENT CHG CODE FIGURE High Pressure Ground Connectors LAST REVISION DATE Sep 01/14 Subject 5-4-7 Engine Oil Servicing Sep 01/14 FIGURE Engine Oil Servicing Sep 01/14 VFG Oil Servicing Sep 01/14 FIGURE VFG Oil Servicing Sep 01/14 Starter Oil Servicing Sep 01/14 FIGURE Starter Oil Servicing Sep 01/14 APU Oil Servicing Sep 01/14 FIGURE APU Oil Servicing Sep 01/14 Subject 5-4-8 Potable Water System Sep 01/14 FIGURE Potable-Water Ground Service Panel Sep 01/14 FIGURE Forward Drain Port Sep 01/14 FIGURE Potable-Water Tanks Location Sep 01/14 Subject 5-4-9 Waste Water System Sep 01/14 FIGURE Waste-Water Ground Service Panel Sep 01/14 FIGURE Waste Tanks Location Jun 01/13 Subject 5-4-10 Cargo Control Panels N Apr 01/15 FIGURE Forward Cargo Control Panels N Apr 01/15 FIGURE Aft Cargo Control Panels N Apr 01/15 Subject 5-5-0 Engine Starting Pneumatic Requirements Sep 01/14 FIGURE Example for Use of the Charts Sep 01/14 FIGURE Engine Starting Pneumatic Requirements Sep 01/14 Subject 5-6-0 Ground Pneumatic Power Requirements R Apr 01/15 L.E.C. Page 7 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING CONTENT CHG CODE FIGURE Ground Pneumatic Power Requirements LAST REVISION DATE Jun 01/13 Subject 5-7-0 Preconditioned Airflow Requirements Jun 01/13 FIGURE Preconditioned Airflow Requirements Jun 01/13 Subject 5-8-0 Ground Towing Requirements R Apr 01/15 FIGURE Ground Towing Requirements R Apr 01/15 Subject 5-9-0 De-icing and External cleaning Jun 01/13 CHAPTER 6 Subject 6-1-0 Engine Exhaust Velocities and Temperatures N Apr 01/15 Engine Exhaust Velocities - Ground Idle Power N Apr 01/15 FIGURE Ground Idle Power - TRENT XWB Engine N Apr 01/15 Engine Exhaust Temperatures - Ground Idle Power N Apr 01/15 FIGURE Ground Idle Power - TRENT XWB-84 Engine N Apr 01/15 Engine Exhaust Velocities - Breakaway Power N Apr 01/15 FIGURE Breakaway Power (11% MTO Thrust) - TRENT XWB-84 Engine N Apr 01/15 FIGURE Breakaway Power (22% MTO Thrust) - TRENT XWB-84 Engine N Apr 01/15 Engine Exhaust Temperatures - Breakaway Power N Apr 01/15 FIGURE Breakaway Power (11% MTO Thrust) - TRENT XWB-84 Engine N Apr 01/15 FIGURE Breakaway Power (22% MTO Thrust) - TRENT XWB-84 Engine N Apr 01/15 Subject 6-1-1 Subject 6-1-2 Subject 6-1-3 Subject 6-1-4 L.E.C. Page 8 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING CONTENT CHG CODE LAST REVISION DATE Engine Exhaust Velocities - Max Take-Off Power N Apr 01/15 FIGURE Max Take-Off Power - TRENT XWB-84 Engine (Single) N Apr 01/15 FIGURE Max Take-Off Power - TRENT XWB-84 Engine (Twin) N Apr 01/15 Engine Exhaust Temperatures - Max Take-Off Power N Apr 01/15 FIGURE Max Take-Off Power - TRENT XWB-84 Engine N Apr 01/15 Danger Areas of the Engines - Ground Idle Power N Apr 01/15 FIGURE Ground Idle Power - TRENT XWB-84 Engine N Apr 01/15 Danger Areas of the Engines - Max Take-Off Power N Apr 01/15 FIGURE Max Take-Off Power - TRENT XWB-84 Engine N Apr 01/15 Subject 6-1-5 Subject 6-1-6 Subject 6-3-1 Subject 6-3-3 Subject 6-4-0 APU Exhaust Velocities and Temperatures Jun 01/13 FIGURE APU Exhaust Velocities and Temperatures Jun 01/13 CHAPTER 7 Subject 7-1-0 General Information R Apr 01/15 Landing Gear Footprint R Apr 01/15 FIGURE Landing Gear Footprint R Apr 01/15 Maximum Pavement Loads R Apr 01/15 FIGURE Maximum Pavement Loads R Apr 01/15 Landing Gear Loading on Pavement R Apr 01/15 FIGURE Landing Gear Loading on Pavement R Apr 01/15 FIGURE Landing Gear Loading on Pavement N Apr 01/15 Subject 7-2-0 Subject 7-3-0 Subject 7-4-0 L.E.C. Page 9 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING CONTENT CHG CODE LAST REVISION DATE Flexible Pavement Requirements - US Army Corps of Engineers Design Method R Apr 01/15 FIGURE Flexible Pavement Requirements R Apr 01/15 FIGURE Flexible Pavement Requirements N Apr 01/15 R Apr 01/15 Rigid Pavement Requirements - Portland Cement Association Design Method FIGURE Rigid Pavement Requirements R Apr 01/15 R Apr 01/15 FIGURE Rigid Pavement Requirements N Apr 01/15 R Apr 01/15 ACN/PCN Reporting System - Flexible and Rigid Pavements R Apr 01/15 FIGURE ACN/PCN Reporting System - WV000, MRW 268 900 kg, CG 33% FIGURE ACN/PCN Reporting System - WV001, MRW 275 900 kg, CG 33.2% FIGURE ACN Table R Apr 01/15 N Apr 01/15 N Apr 01/15 Subject 7-5-0 Subject 7-6-0 Flexible Pavement Requirements - LCN Conversion Subject 7-7-0 Subject 7-8-0 Rigid Pavement Requirements - LCN Conversion Subject 7-9-0 CHAPTER 8 Subject 8-0-0 Scaled Drawings Jun 01/13 FIGURE Scaled Drawings Jun 01/13 CHAPTER 10 Subject 10-0-0 Aircraft Rescue and Fire Fighting R Apr 01/15 FIGURE Front Page R Apr 01/15 FIGURE Highly Flammable and Hazardous Materials and Components R Apr 01/15 L.E.C. Page 10 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING CONTENT CHG CODE FIGURE Crew Rest Compartments Location LAST REVISION DATE Jun 01/13 FIGURE Wheel/Brake Overheat Jun 01/13 FIGURE Composite Materials Location Jun 01/13 FIGURE Ground Lock Safety Devices Jun 01/13 FIGURE Emergency Evacuation Devices R Apr 01/15 FIGURE Pax/Crew Doors and Emergency Exits Jun 01/13 FIGURE Cockpit Emergency Exit Jun 01/13 FIGURE FWD and AFT Lower Deck Cargo Doors R FIGURE Control Panels FIGURE APU Compartment Access Apr 01/15 Jun 01/13 R Apr 01/15 FIGURE Aircraft Ground Clearances Jun 01/13 FIGURE Structural Break-in Points Jun 01/13 FIGURE Batteries Location and Access R Apr 01/15 L.E.C. Page 11 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING TABLE OF CONTENTS 1 1-1-0 1-2-0 SCOPE INTRODUCTION Glossary 2 AIRCRAFT DESCRIPTION 2-1-0 General Aircraft Characteristics Data 2-2-0 General Aircraft Dimensions 2-3-0 Ground Clearances 2-4-0 Interior Arrangements - Plan View 2-5-0 Interior Arrangements - Cross Section 2-6-0 Cargo Compartments 2-7-0 Door Clearances and Location 2-8-0 Escape Slides 2-9-0 Landing Gear 2-9-1 Landing Gear Maintenance Pits 2-10-0 Exterior Lighting 2-11-0 Antennas and Probes Location 2-12-0 Engine and Nacelle 2-12-1 APU 2-13-0 Levelling, Symmetry and Alignement 2-14-1 Jacking for Maintenance 2-14-2 Jacking of the Landing Gear 3 3-1-0 3-3-0 3-4-0 3-5-0 AIRCRAFT PERFORMANCE General Information Take-Off Weight Limitation Landing Field Length Final Approach Speed 4 4-2-0 4-3-0 4-4-0 4-5-0 4-5-1 GROUND MANEUVERING Turning Radii Minimum Turning Radii Visibility from Cockpit in Static Position Runway and Taxiway Turn Paths 90˚ Turn - Runway to Taxiway T.O.C. Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 4-5-2 4-5-3 4-5-4 4-5-5 4-6-0 4-7-0 4-8-0 135˚ Turn - Runway to Taxiway 180˚ Turn on a Runway 90˚ Turn - Taxiway to Taxiway 135˚ Turn - Taxiway to Taxiway Runway Holding Bay (Apron) Minimum Line-Up Distance Corrections Aircraft Mooring 5 TERMINAL SERVICING 5-1-0 Aircraft Servicing Arrangements 5-1-1 Typical Ramp Layout (Open Apron) 5-1-2 Typical Ramp Layout (Gate) 5-2-0 Terminal Operations - Full Servicing Turn Round Time 5-3-0 Terminal Operations - Transit Turn Round Time 5-4-0 Ground Service Connections Layout 5-4-1 Grounding (Earthing) Points 5-4-2 Hydraulic System 5-4-3 Electrical System 5-4-4 Oxygen System 5-4-5 Fuel System 5-4-6 Pneumatic System 5-4-7 Oil System 5-4-8 Potable Water System 5-4-9 Waste Water System 5-4-10 Cargo Control Panels 5-5-0 Engine Starting Pneumatic Requirements 5-6-0 Ground Pneumatic Power Requirements 5-7-0 Preconditioned Airflow Requirements 5-8-0 Ground Towing Requirements 5-9-0 De-icing and External cleaning 6 6-1-0 6-1-1 6-1-2 6-1-3 6-1-4 6-1-5 OPERATING CONDITIONS Engine Exhaust Velocities and Temperatures Engine Exhaust Velocities - Ground Idle Power Engine Exhaust Temperatures - Ground Idle Power Engine Exhaust Velocities - Breakaway Power Engine Exhaust Temperatures - Breakaway Power Engine Exhaust Velocities - Max Take-Off Power T.O.C. Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 6-1-6 6-3-1 6-3-3 6-4-0 Engine Exhaust Temperatures - Max Take-Off Power Danger Areas of the Engines - Ground Idle Power Danger Areas of the Engines - Max Take-Off Power APU Exhaust Velocities and Temperatures 7 7-1-0 7-2-0 7-3-0 7-4-0 7-5-0 7-6-0 7-7-0 7-8-0 7-9-0 PAVEMENT DATA General Information Landing Gear Footprint Maximum Pavement Loads Landing Gear Loading on Pavement Flexible Pavement Requirements - US Army Corps of Engineers Design Method Flexible Pavement Requirements - LCN Conversion Rigid Pavement Requirements - Portland Cement Association Design Method Rigid Pavement Requirements - LCN Conversion ACN/PCN Reporting System - Flexible and Rigid Pavements 8 8-0-0 SCALED DRAWINGS Scaled Drawings 10 AIRCRAFT RESCUE AND FIRE FIGHTING 10-0-0 Aircraft Rescue and Fire Fighting T.O.C. Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING SCOPE 1-1-0 INTRODUCTION **ON A/C A350-900 Introduction 1. General The A350 AIRCRAFT CHARACTERISTICS AIRPORT AND MAINTENANCE PLANNING (AC) manual is issued for the A350-900 series aircraft to provide necessary data to airport operators and airlines for airport facilities planning. The data given in this issue of the A350 AIRCRAFT CHARACTERISTICS AIRPORT AND MAINTENANCE PLANNING (AC) can be subject to change pending completion of the design and flight test phase. It is given for guidance only and does not constitute a contractual commitment. This document is not customized and must not be used for training purposes. The A350 XWB is a new family of mid-size medium to long range new technology aircraft that will deliver superior fuel efficiency, passenger comfort, environmental characteristics and economics, with a global market coverage. The aircraft is designed to offer multiple payload capabilities with a consistant range ability across the family. The A350 XWB is equipped with two Rolls-Royce Trent XWB engines. This engine will incorporate the most advanced technologies to provide the best aircraft performance, maintainability, lowest fuel consumption and environmental impact. Reflecting market needs, the A350 XWB offers a high level of cargo hold capability and flexibility. Two wide cargo doors and a Cargo Loading System (CLS) compatible with most lower deck cargo containers and pallet standards, allowing interlining operations, ease the loading. The A350 XWB provides easy and cost effective ground handling minimizing aircraft turn round time. The innovative A350 XWB design increases planning flexibility to perform maintenance during the aircraft scheduled downtime. Correspondence concerning this publication should be directed to: AIRBUS S.A.S. Customer Services Technical Data Support and Services 1 Rond Point Maurice BELLONTE 31707 BLAGNAC CEDEX FRANCE 1-1-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 1-2-0 Glossary **ON A/C A350-900 Glossary 1. List of Abbreviations Aircraft A/C ACN Aircraft Classification Number APU Auxiliary Power Unit Business Class B/C California Bearing Ratio CBR CC Cargo Compartment CG Center of Gravity E Young’s Modulus ESWL Equivalent Single Wheel Load FAA Federal Aviation Administration FDL Fuselage Datum Line FR Frame FSTE Full Size Trolley Equivalent FWD Forward GPU Ground Power Unit Ground Support Equipment GSE ICAO International Civil Aviation Organisation International Standard Atmosphere ISA L Radius of relative stiffness LCN Load Classification Number LD Load Device LD Lower Deck LH Left Hand LP Low Pressure LPS Last Pax Seating MAC Mean Aerodynamic Chord MAX Maximum MIN Minimum MLG Main Landing Gear NLG Nose Landing Gear Outside Air Temperature OAT PAX Passenger PBB Passenger Boarding Bridge 1-2-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING PCA PCN PRM RH ULD US VFG WV Y/C 2. Portland Cement Association Pavement Classification Number Passenger with Reduced Mobility Right Hand Unit Load Device United States Variable Frequency Generator Weight Variant Economic Class Design Weight Terminology Maximum Design Ramp Weight (MRW): Maximum weight for ground maneuver (including weight of taxi and run-up fuel) as limited by aircraft strength and airworthiness requirements. It is also called Maximum Design Taxi Weight (MTW). Maximum Design Landing Weight (MLW): Maximum weight for landing as limited by aircraft strength and airworthiness requirements. Maximum Design Takeoff Weight (MTOW): Maximum weight for takeoff as limited by aircraft strength and airworthiness requirements. (This is the maximum weight at start of the take-off run). Maximum Design Zero Fuel Weight (MZFW): Maximum permissible weight of the aircraft without usable fuel. Maximum Seating Capacity: Maximum number of passengers specifically certified or anticipated for certification. Usable Volume: Usable volume available for cargo, pressurized fuselage, passenger compartment and cockpit. Water Volume: Maximum volume of cargo compartment. Usable Fuel: Fuel available for aircraft propulsion. 1-2-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING AIRCRAFT DESCRIPTION 2-1-0 General Aircraft Characteristics Data **ON A/C A350-900 General Aircraft Characteristics Data 1. The following table provides characteristics of A350--900 Models, these data are specific to each Weight Variant: Aircraft Characteristics WV000 WV001 Maximum Taxi Weight (MTW) Maximum Ramp Weight (MRW) Maximum Take-Off Weight (MTOW) Maximum Landing Weight (MLW) Maximum Zero Fuel Weight (MZFW) 2. WV002 268900 kg (592824 lb) 275900 kg (608256 lb) 272900 kg (601642 lb) 268000 kg (590839 lb) 205000 kg (451948 lb) 192000 kg (423288 lb) 275000 kg (606272 lb) 207000 kg (456357 lb) 195700 kg (431445 lb) 272000 kg (599658 lb) 207000 kg (456357 lb) 194000 kg (427697 lb) The following table provides characteristics of A350--900 Models, these data are common to each Weight Variant: Standard Seating Capacity Usable Fuel Capacity (density = 0.785 kg/l) Pressurized Fuselage Volume Cockpit Volume Passenger Compartment Volume Usable Volume, FWD CC (Based on LD3) Usable Volume, AFT CC (Based on LD3) Aircraft Characteristics 315 (2 class) 138000 l (36456.4 USgal) 108330 kg (238827.0 lb) 971 m3 (34291.0 ft.3) 8.23 m3 (291.0 ft.3) 473.7 m3 (16729.0 ft.3) 89.4 m3 (3157.0 ft.3) 71.5 m3 (2525.0 ft.3) 2-1-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING Usable Volume, Bulk CC Water Volume, FWD CC Water Volume, AFT CC Water Volume, Bulk CC Aircraft Characteristics 9.12 m3 (322.07 ft.3) 113.4 m3 (4004.7 ft.3) 95.8 m3 (3383.16 ft.3) 11.4 m3 (402.59 ft.3) 2-1-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 2-2-0 General Aircraft Dimensions **ON A/C A350-900 General Aircraft Dimensions 1. This section provides general aircraft dimensions. 2-2-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 66.61 m (218.54 ft) 9.09 m (29.82 ft) 6.09 m (19.98 ft) 3.04 m (9.97 ft) 9.42 m (30.91 ft) 4.63 m (15.19 ft) 7.79 m (25.56 ft) 28.66 m (94.03 ft) 65.26 m (214.11 ft) 64.75 m (212.43 ft) 18.79 m (61.65 ft) 1.74 m (5.71 ft) 0.75 m (2.46 ft) 10.60 m (34.78 ft) 12.87 m (42.22 ft) NOTE: RELATED TO AIRCRAFT ATTITUDE AND WEIGHT. P_AC_020200_1_0010001_01_02 General Aircraft Dimensions (Sheet 1 of 2) FIGURE-2-2-0-991-001-A01 2-2-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 66.80 m (219.16 ft) 2.46 m (8.07 ft) 6.21 m (20.37 ft) 13.47 m (44.19 ft) 7.86 m 10.50 m (25.79 ft) (34.45 ft) 12.75 m (41.83 ft) 5.96 m (19.55 ft) 17.02 m (55.84 ft) 9.62 m (31.56 ft) 21.97 m (72.08 ft) 5.18 m (16.99 ft) 2.88 m (9.45 ft) 46.68 m (153.15 ft) NOTE: RELATED TO AIRCRAFT ATTITUDE AND WEIGHT. P_AC_020200_1_0010001_02_02 General Aircraft Dimensions (Sheet 2 of 2) FIGURE-2-2-0-991-001-A01 2-2-0 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 2-3-0 Ground Clearances **ON A/C A350-900 Ground Clearances 1. This section provides the heights of various points of the aircraft, above the ground, for different aircraft configurations. Dimensions in the tables are approximate and will vary with tire type, weight and balance and other special conditions. The dimensions are given for: - A light weight, for an A/C in maintenance configuration with FWD CG and a AFT CG, - An aircraft at MRW with a FWD CG and a AFT CG, - Aircraft on jacks, FDL at 6.50 m (21.33 ft.). NOTE : Passenger and cargo door ground clearances are measured from the center of the door sill and from floor level. 2-3-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 CP1 RD1 D1 D2 D3 W2 W1 C3 D4 AP N1 VT HT C2 F2 BF3 F4 BF1 MRW A/C CONFIGURATION C1 F1 F3 140 000 kg (308 647 lb) BF2 FWD CG (26%) AFT CG (33.2%) D5 A/C JACKED FDL = 6.5 m FWD CG (20%) AFT CG (40%) (21.33 ft) m m m ft ft ft 5.16 16.93 5.38 17.65 6.37 20.91 5.22 17.14 5.34 17.51 6.37 20.91 5.33 17.47 5.27 17.28 6.37 20.91 5.40 17.73 5.21 17.10 6.37 20.90 7.33 24.05 7.61 24.97 8.59 28.18 3.20 10.50 3.38 11.08 4.39 14.40 3.43 11.25 3.29 10.78 4.43 14.52 3.43 11.25 3.26 10.70 4.41 14.47 3.71 12.18 2.52 8.27 8.88 2.71 3.71 12.18 2.70 8.85 2.59 8.48 8.61 28.26 8.78 28.82 9.80 32.14 8.59 28.17 8.45 27.71 9.58 31.45 2.57 8.44 2.67 8.75 3.71 12.17 3.16 10.37 2.08 6.81 2.08 6.82 8.80 2.59 8.51 2.68 3.71 12.18 5.94 19.49 6.21 20.36 7.18 23.55 4.07 13.35 4.35 14.27 5.32 17.45 9.57 31.41 9.44 30.96 10.57 34.69 7.14 23.44 7.05 23.12 8.17 26.80 7.88 25.84 7.56 24.80 8.77 28.77 6.82 22.38 6.52 21.38 7.72 25.34 17.38 57.03 17.06 55.99 18.27 59.96 0.87 0.94 3.08 6.54 2.87 1.99 m m ft ft 5.11 16.76 5.06 16.60 D1 5.13 16.82 5.10 16.74 D2 5.17 16.96 5.16 16.91 D3 5.22 17.13 5.18 16.98 D4 DOORS 7.25 23.79 7.31 23.98 D5 3.09 10.15 3.13 10.27 C1 10.58 3.26 10.68 3.22 C2 3.21 10.54 3.25 10.67 C3 2.45 7.92 8.05 2.41 F1 2.53 2.50 8.30 8.22 F2 28.02 8.50 27.90 8.54 F3 8.38 27.50 8.41 27.60 F4 8.03 8.09 2.45 2.47 FUSELAGE BF1 6.34 1.93 6.34 1.93 BF2 2.52 2.50 8.20 8.27 BF3 19.38 5.85 19.19 5.91 CP1 13.26 3.98 13.06 4.04 RD1 30.74 9.40 30.85 9.37 W1 WINGS 6.96 6.98 22.90 22.83 W2 7.60 7.67 25.16 24.92 HT 6.62 21.71 6.55 21.48 TAILPLANE AP 56.11 17.17 56.34 17.10 VT 0.74 0.76 2.43 2.48 N1 ENGINE/ N1 WITH NACELLE 0.59 1.93 0.60 1.97 0.72 2.36 0.78 2.55 1.84 6.02 DRAIN MAST NOTE: PASSENGER AND CARGO DOOR GROUND CLEARANCES ARE MEASURED FROM THE CENTER OF THE DOOR SILL AND FROM FLOOR LEVEL. P_AC_020300_1_0010001_01_03 Ground Clearances FIGURE-2-3-0-991-001-A01 2-3-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A B C D E F G H J LEADING EDGE SLATS EXTENDED 140 000 kg (308 647 lb) MRW DESCRIPTION DN* INBD DN* OUTBD SLAT 1 INBD SLAT 1/2 SLAT 2/3 SLAT 3/4 SLAT 4/5 SLAT 5/6 SLAT 6 OUTBD FWD CG (26%) AFT CG (33.2%) FWD CG (20%) AFT CG (40%) A B C D E F G H J m 3.41 4.58 4.60 4.98 5.33 5.67 5.98 6.28 6.62 ft 11.20 15.01 15.10 16.33 17.48 18.59 19.63 20.61 21.71 m 3.43 4.58 4.61 4.98 5.33 5.66 5.97 6.27 6.60 ft 11.25 15.03 15.12 16.33 17.47 18.57 19.59 20.56 21.64 m 3.55 4.71 4.74 5.12 5.48 5.82 6.14 6.44 6.78 NOTE: * DN − DROOP NOSE ft 11.63 15.47 15.56 16.80 17.97 19.09 20.13 21.13 22.24 m 3.61 4.74 4.77 5.13 5.46 5.79 6.09 6.37 6.69 ft 11.85 15.56 15.64 16.82 17.93 18.99 19.97 20.91 21.95 P_AC_020300_1_0020001_01_00 Ground Clearances Leading Edge Slats - Extended FIGURE-2-3-0-991-002-A01 2-3-0 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 G F E D C B A FLAPS EXTENDED 140 000 kg (308 647 lb) MRW DESCRIPTION FLAP 1 INBD FLAP 1/2 FLAP 2 OUTBD FLAP 3 INBD FLAP 3/4 FLAP 4/5 FLAP 5 OUTBD FWD CG (26%) AFT CG (33.2%) FWD CG (20%) AFT CG (40%) A B C D E F G m 2.54 3.26 4.06 4.12 4.86 5.40 5.65 ft 8.32 10.71 13.34 13.51 15.96 17.72 18.52 m 2.53 3.25 4.05 4.11 4.85 5.38 5.63 ft 8.29 10.67 13.30 13.47 15.91 17.67 18.46 m 2.69 3.42 4.22 4.27 5.02 5.56 5.81 ft 8.82 11.21 13.84 14.01 16.47 18.24 19.05 m 2.65 3.37 4.17 4.23 4.96 5.49 5.73 ft 8.69 11.07 13.69 13.86 16.28 18.01 18.79 P_AC_020300_1_0030001_01_00 Ground Clearances Trailing Edge Flaps - Extended FIGURE-2-3-0-991-003-A01 2-3-0 Page 4 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 J H G F E D C B A SPOILERS EXTENDED 140 000 kg (308 647 lb) MRW DESCRIPTION SPOILER 1 INBD SPOILER 1/2 SPOILER 2 OUTBD SPOILER 3 INBD SPOILER 3/4 SPOILER 4/5 SPOILER 5/6 SPOILER 6/7 SPOILER 7 OUTBD FWD CG (26%) AFT CG (33.2%) FWD CG (20%) AFT CG (40%) A B C D E F G H J m 5.00 5.46 5.91 6.06 6.30 6.51 6.69 6.87 7.04 ft 16.39 17.91 19.40 19.87 20.66 21.34 21.96 22.54 23.11 m 4.99 5.45 5.91 6.05 6.29 6.49 6.68 6.86 7.03 ft 16.37 17.89 19.38 19.84 20.63 21.31 21.92 22.49 23.06 m 5.15 5.61 6.07 6.21 6.45 6.66 6.85 7.03 7.20 ft 16.89 18.41 19.90 20.36 21.16 21.85 22.47 23.05 23.63 m 5.12 5.58 6.03 6.17 6.41 6.61 6.80 6.97 7.13 ft 16.78 18.30 19.79 20.26 21.03 21.70 22.30 22.86 23.40 P_AC_020300_1_0040001_01_00 Ground Clearances Spoilers - Extended FIGURE-2-3-0-991-004-A01 2-3-0 Page 5 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 D C B A AILERONS DOWN 140 000 kg (308 647 lb) MRW DESCRIPTION AILERON 1 INBD AILERON 1 OUTBD AILERON 2 INBD AILERON 2 OUTBD FWD CG (26%) AFT CG (33.2%) FWD CG (20%) AFT CG (40%) A B C D m 5.91 6.32 6.31 6.80 ft 19.38 20.73 20.69 22.30 m 5.89 6.30 6.29 6.77 ft 19.32 20.66 20.62 22.22 m 6.07 6.48 6.47 6.96 ft 19.91 21.27 21.23 22.84 m 5.99 6.39 6.38 6.85 ft 19.65 20.97 20.93 22.49 P_AC_020300_1_0050001_01_00 Ground Clearances Ailerons - Down FIGURE-2-3-0-991-005-A01 2-3-0 Page 6 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 D C B A AILERONS UP 140 000 kg (308 647 lb) MRW DESCRIPTION AILERON 1 INBD AILERON 1 OUTBD AILERON 2 INBD AILERON 2 OUTBD FWD CG (26%) AFT CG (33.2%) FWD CG (20%) AFT CG (40%) A B C D m 6.92 7.16 7.17 7.45 ft 22.72 23.50 23.54 24.43 m 6.91 7.14 7.15 7.42 ft 22.66 23.43 23.47 24.35 m 7.08 7.33 7.34 7.61 ft 23.24 24.04 24.07 24.98 m 7.01 7.23 7.24 7.50 ft 22.99 23.74 23.77 24.62 P_AC_020300_1_0060001_01_00 Ground Clearances Ailerons - Up FIGURE-2-3-0-991-006-A01 2-3-0 Page 7 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 C B A FLAP TRACKS RETRACTED 140 000 kg (308 647 lb) MRW DESCRIPTION FLAP TRACK 1 FLAP TRACK 2 FLAP TRACK 3 FWD CG (26%) AFT CG (33.2%) FWD CG (20%) AFT CG (40%) A B C m 3.72 4.53 5.17 ft 12.22 14.87 16.96 m 3.72 4.52 5.16 ft 12.19 14.84 16.92 m 3.87 4.68 5.33 ft 12.71 15.37 17.47 m 3.84 4.64 5.27 ft 12.61 15.24 17.30 P_AC_020300_1_0070001_01_00 Flap Tracks - Retracted FIGURE-2-3-0-991-007-A01 2-3-0 Page 8 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 C B A FLAP TRACKS EXTENDED 140 000 kg (308 647 lb) MRW DESCRIPTION FLAP TRACK 1 FLAP TRACK 2 FLAP TRACK 3 FWD CG (26%) AFT CG (33.2%) FWD CG (20%) AFT CG (40%) A B C m 2.82 3.34 4.00 ft 9.26 10.95 13.11 m 2.81 3.32 3.98 ft 9.23 10.90 13.06 m 2.98 3.49 4.16 ft 9.77 11.46 13.63 m 2.93 3.43 4.08 ft 9.62 11.27 13.40 P_AC_020300_1_0080001_01_00 Ground Clearances Flap Tracks - Extended FIGURE-2-3-0-991-008-A01 2-3-0 Page 9 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 2-4-0 Interior Arrangements - Plan View **ON A/C A350-900 Interior Arrangements - Plan View 1. This section gives the standard configuration. 2-4-0 Page 1 Apr 01/15 A G L S A L PASSENGER DOOR 1 LH L G PASSENGER DOOR 1 RH ITEM G L A S G DESIGNATION (12) GALLEY (9) LAVATORY ATTENDANT SEAT (8) (1) STOWAGE PASSENGER DOOR 2 LH A A PASSENGER DOOR 2 RH 2-4-0 SEAT PITCHES: ECONOMY 32 in. BUSINESS 60 in. G A A G G G G G G PASSENGER DOOR 4 LH L L PASSENGER DOOR 4 RH 48 BUSINESS CLASS (6−ABREAST) 267 ECONOMY CLASS (9−ABREAST) PASSENGER SEATS (315 TOTAL) PASSENGER DOOR 3 LH L A L L L A PASSENGER DOOR 3 RH @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_020400_1_0010001_01_01 Standard Configuration FIGURE-2-4-0-991-001-A01 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 2-5-0 Interior Arrangements - Cross Section **ON A/C A350-900 Interior Arrangements - Cross Section 1. This section gives the typical configuration. 2-5-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 BUSINESS CLASS / FIRST CLASS 6 ABREAST 1.50 m (59 in) 0.55 m (21.5 in) 0.18 m (7 in) 0.57 m (22.5 in) 0.09 m (3.5 in) BASELINE ECONOMY CLASS 9 ABREAST 1.53 m (60.11 in) 0.04 m (1.5 in) 0.46 m (18 in) 0.46 m (18.1in) NOTE: AISLE WIDTH MAY VARY DEPENDING ON ACTUAL CABIN CONFIGURATION SELECTED BY CUSTOMER P_AC_020500_1_0010001_01_01 Typical Configuration FIGURE-2-5-0-991-001-A01 2-5-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 2-6-0 Cargo Compartments **ON A/C A350-900 Cargo Compartments 1. This section gives cargo compartments : - Locations and dimensions, - Loading combinations. 2-6-0 Page 1 Apr 01/15 2.90 m (114.55 in) FR19 16.221 m (638.62 in) LOWER DECK FORWARD CARGO COMPARTMENT FR44 2-6-0 13.578 m (535.57 in) 2.85 m (112.34 in) LOWER DECK AFT CARGO COMPARTMENT FR61 FR85 0.95 m (37.4 in) 1.91 m (75.20 in) LOWER DECK BULK CARGO COMPARTMENT FR82 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_020600_1_0020001_01_00 Cargo Compartments Locations and Dimensions (Sheet 1 of 2) FIGURE-2-6-0-991-002-A01 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING STANDARD: 20 LD3 CONTAINERS STANDARD: 6 PALLETS 88 in / 96 in X 125 in STANDARD: 16 LD3 CONTAINERS STANDARD: 5 PALLETS 88 in / 96 in X 125 in **ON A/C A350-900 P_AC_020600_1_0020001_02_00 Cargo Compartments Loading Combinations (Sheet 2 of 2) FIGURE-2-6-0-991-002-A01 2-6-0 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 2-7-0 Door Clearances and Location **ON A/C A350-900 Door Clearances and Location 1. This section provides door clearances and location. 2-7-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 DOOR 1L DOOR 3L DOOR 2L DOOR 4L BULK CARGO DOOR DOOR 4R DOOR 1R DOOR 3R DOOR 2R AFT CARGO DOOR COCKPIT ESCAPE HATCH FWD CARGO DOOR P_AC_020700_1_0010001_01_02 Door Identification and Location (Sheet 1 of 2) FIGURE-2-7-0-991-001-A01 2-7-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 52.55 m (172.41 ft) 37.93 m (124.44 ft) 18.86 m (61.88 ft) 6.82 m (22.38 ft) 49.99 m (164.01 ft) 4.12 m (13.52 ft) 11.68 m (38.32 ft) 47.30 m (155.18 ft) P_AC_020700_1_0010001_02_02 Door Identification and Location (Sheet 2 of 2) FIGURE-2-7-0-991-001-A01 2-7-0 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 PASSENGER/CREW DOOR 1LH, 1RH 0.73 m (2.40 ft) 0.86 m (2.82 ft) 2.46 m (8.07 ft) FWD 1.26 m (4.13 ft) 2.16 m (7.09 ft) 0.06 m (0.20 ft) SEE CHAPTER 2−3 FWD P_AC_020700_1_0020003_01_01 Forward Passenger/Crew Doors (Sheet 1 of 2) FIGURE-2-7-0-991-002-C01 2-7-0 Page 4 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 PASSENGER/CREW DOOR 2LH, 2RH 0.84 m (2.76 ft) 0.69 m (2.26 ft) 2.47 m (8.10 ft) FWD 2.16 m (7.09 ft) 1.26 m (4.13 ft) 0.06 m (0.20 ft) SEE CHAPTER 2−3 FWD P_AC_020700_1_0020003_02_01 Forward Passenger/Crew Doors (Sheet 2 of 2) FIGURE-2-7-0-991-002-C01 2-7-0 Page 5 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 PASSENGER/CREW DOOR 3LH, 3RH 0.84 m (2.76 ft) 2.47 m (8.10 ft) 0.69 m (2.26 ft) FWD 2.11 m (6.92 ft) 1.26 m (4.13 ft) 0.06 m (0.20 ft) SEE CHAPTER 2−3 FWD P_AC_020700_1_0030001_01_01 Aft Passenger/Crew Doors (Sheet 1 of 2) FIGURE-2-7-0-991-003-A01 2-7-0 Page 6 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 PASSENGER/CREW DOOR 4LH, 4RH 0.87 m (2.85 ft) 0.74 m (2.43 ft) FWD 2.39 m (7.84 ft) 1.26 m (4.13 ft) FWD 0.06 m (0.20 ft) 2.16 m (7.09 ft) SEE CHAPTER 2−3 P_AC_020700_1_0030001_02_01 Aft Passenger/Crew Doors (Sheet 2 of 2) FIGURE-2-7-0-991-003-A01 2-7-0 Page 7 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A 2.91 m (9.55 ft) FWD A 2.55 m (8.37 ft) 1.76 m (5.77 ft) 0.27 m (0.89 ft) SEE CHAPTER 2−3 2.40 m (7.87 ft) 0.74 m (2.43 ft) A A P_AC_020700_1_0040001_01_00 Forward Cargo Compartment Door FIGURE-2-7-0-991-004-A01 2-7-0 Page 8 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A FWD 2.85 m (9.35 ft) A 2.53 m (8.30 ft) 2.40 m (7.87 ft) 1.75 m (5.74 ft) 0.27 m (0.89 ft) SEE CHAPTER 2−3 0.75 m (2.46 ft) A A P_AC_020700_1_0050001_01_00 Aft Cargo Compartment Door FIGURE-2-7-0-991-005-A01 2-7-0 Page 9 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A 0.95 m (3.12 ft) FWD 1.76 m (5.77 ft) A 0.76 m (2.49 ft) SEE CHAPTER 2−3 A A P_AC_020700_1_0060001_01_00 Bulk Cargo Compartment Door FIGURE-2-7-0-991-006-A01 2-7-0 Page 10 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A B 1.06 m (3.48 ft) 61.8° R 0.78 m (2.56 ft) R 1.06 m (3.48 ft) 0.77 m (2.53 ft) 2.93 m (9.61 ft) 2.00 m (6.56 ft) A P_AC_020700_1_0070001_01_01 Nose Landing Gear Doors Forward Nose Landing Gear Doors (Sheet 1 of 2) FIGURE-2-7-0-991-007-A01 2-7-0 Page 11 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 0.76 m (2.49 ft) 69.8° R 0.71 m (2.33 ft) R 0.72 m (2.36 ft) 0.59 m (1.94 ft) 2.15 m (7.05 ft) 2.03 m (6.66 ft) B P_AC_020700_1_0070001_02_01 Nose Landing Gear Doors Aft Nose Landing Gear Doors (Sheet 2 of 2) FIGURE-2-7-0-991-007-A01 2-7-0 Page 12 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A 2.75 m (9.02 ft) 1.63 m (5.35 ft) 81.3° R 2.43 m (7.97 ft) 0.13 m 0.19 m (0.43 ft) (0.62 ft) A P_AC_020700_1_0080001_01_01 Main Landing Gear Doors FIGURE-2-7-0-991-008-A01 2-7-0 Page 13 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 2-8-0 Escape Slides **ON A/C A350-900 Escape Slides 1. General This section provides location of escape facilities and related clearances. 2. Location Escape facilities are provided at the following locations: - One cockpit escape rope is kept in a dedicated stowage compartment adjacent to the escape hatch, - One slide-raft at each passenger/crew door (total eight). 2-8-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 CABIN DUAL−LANE SLIDE/RAFT CABIN DUAL−LANE SLIDE/RAFT CABIN DUAL−LANE SLIDE/RAFT COCKPIT ESCAPE ROPE CABIN SINGLE−LANE SLIDE/RAFT NOTE: RH SHOWN, LH SYMMETRICAL P_AC_020800_1_0020001_01_00 Escape Slides (Sheet 1 of 2) FIGURE-2-8-0-991-002-A01 2-8-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING NOTE: RH SHOWN, LH SYMMETRICAL GRID EQUALS 1 m (3.28 ft) IN REALITY 0 3 6 9 12 15 18 21 24 27 30 33 EMERGENCY DESCENT THROUGH THE ESCAPE HATCH WITH THE ESCAPE ROPE **ON A/C A350-900 P_AC_020800_1_0020001_02_00 Escape Slides (Sheet 2 of 2) FIGURE-2-8-0-991-002-A01 2-8-0 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 2-9-0 Landing Gear **ON A/C A350-900 Landing Gear 1. MLG System Description The two MLGs are mounted in the LH and RH wing just outboard of the wing root within the trailing edge. The MLGs retract sideways into bays in the fuselage. Each MLG has a four wheel twin-tandem bogie. Each MLG has one related main door operated by a single door actuator. Each MLG has a gear uplock and a door uplock. The MLG has a double side stay arrangement to improve load distribution on the composite wing. Each side stay has a separate lock stay assembly to provide a positive means to lock the landing gear in the extended position for landing and ground manoeuvres. Each MLG leg contains a single-stage oleo shock strut consisting of a sliding piston and a main fitting that is supported by the two folding side stays and pivots on the top of the main fitting for extension/retraction. In flight, the MLGs are retracted and locked up. The MLG doors are closed and locked to enclose the MLG bay in flight and on the ground, only opening when the landing gear is extending or retracting. Hydraulic power for the MLG extension/retraction comes from the Green Hydraulic System. 2. NLG System Description The NLG is located in the forward lower fuselage on the aircraft centerline below the cockpit. It is forward retracting and consists of a twin wheel axle mounted on a main fitting that incorporates a single-stage oleo shock strut supported by a forward drag stay. The NLG main fitting accommodates the steering assembly for the NWS system. In flight, the NLG is retracted and locked up while the four sideways opening NLG Doors are closed and locked to enclose the NLG bay. The two forward doors are each operated by two independent door actuators. When retracted, the NLG is held by an uplock and the two main NLG doors are held by a single door uplock assembly, containing an uplock hook for each door. The hydraulically powered Forward NLG Doors are also closed after the NLG is extended. The aft doors are mechanically driven and remain open when the NLG is extended. Hydraulic power for the NLG extension/retraction comes from the Yellow hydraulic system. 3. Landing Gear Extension and Retraction System The Landing Gear Extension and Retraction System is made up of three sub-systems: - Normal extension and retraction system, for normal extension and retraction - Alternate extension system, for extension in flight if the normal system is unavailable - Ground door opening system, to allow on-ground access to the landing gear bays for maintenance purposes. 2-9-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 FIXED FAIRING DOOR HINGE DOOR C B A D FREE−FALL RAMP HINGE ACTUATOR MAIN DOOR HINGE A LH SHOWN RH SYMMETRICAL F MECHANICAL LINKAGE FREE−FALL RAMP UP−LOCK FITTING FREE−FALL ROD B C P_AC_020900_1_0010001_01_01 Main Landing Gear Doors Overview (Sheet 1 of 3) FIGURE-2-9-0-991-001-A01 2-9-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 FORWARD LOCK STAY ACTUATOR RETRACTION ACTUATOR FORWARD LOCK STAY G MAIN FITTING FORWARD SIDE STAY SLIDING PISTON E FORWARD DOWNLOCK SPRINGS BOGIE AFT LOCK STAY ACTUATOR AFT LOCK STAY G BOGIE PITCH TRIMMER ACTUATOR D AFT DOWNLOCK SPRINGS AFT SIDE STAY UPPER TORQUE LINK LOWER TORQUE LINK E P_AC_020900_1_0010001_02_01 Main Landing Gear Overview (Sheet 2 of 3) FIGURE-2-9-0-991-001-A01 2-9-0 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 SAFETY PIN SAFETY COLLAR WARNING FLAG LOCK STAY SAFETY PIN F SAFETY PIN WARNING FLAG G 01 TYPICAL NOTE: 01 FORWARD LOCK STAY SHOWN, AFT SIMILAR P_AC_020900_1_0010001_03_01 Main Landing Gear Safety Devices (Sheet 3 of 3) FIGURE-2-9-0-991-001-A01 2-9-0 Page 4 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A FORWARD DOOR B ACTUATOR C E AFT DOOR HINGE A HINGE PROTECTIVE PLATE DOOR STOP INTER DOOR STOP ROD FITTING B RH SHOWN LH SYMMETRICAL P_AC_020900_1_0020001_01_01 Nose Landing Gear Doors Overview (Sheet 1 of 4) FIGURE-2-9-0-991-002-A01 2-9-0 Page 5 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 RETRACTION ACTUATOR F LOCK STAY ACTUATOR UPPER DRAG STAY FORWARD/ AFT LOCK STAYS LOWER DRAG STAY MAIN FITTING DOWNLOCK SPRINGS D G STEERING ASSEMBLY TOWING FITTING C UPPER TORQUE LINK SLIDING PISTON LOWER TORQUE LINK D P_AC_020900_1_0020001_02_01 Nose Landing Gear Overview (Sheet 2 of 4) FIGURE-2-9-0-991-002-A01 2-9-0 Page 6 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 SAFETY COLLAR WARNING FLAG SAFETY PIN E SAFETY PIN LOCK STAY WARNING FLAG F P_AC_020900_1_0020001_03_01 Nose Landing Gear Safety Devices (Sheet 3 of 4) FIGURE-2-9-0-991-002-A01 2-9-0 Page 7 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 H J 2GN 1GN G WARNING FLAG H FWD J FWD P_AC_020900_1_0020001_04_01 Nose Landing Gear Service Panels (Sheet 4 of 4) FIGURE-2-9-0-991-002-A01 2-9-0 Page 8 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 2-9-1 Landing Gear Maintenance Pits **ON A/C A350-900 Landing Gear Maintenance Pits 1. General The minimum maintenance pit envelopes for landing gear shock absorber maintenance are shown in Figures FIGURE 2-9-1-991-001-A, FIGURE 2-9-1-991-002-A, FIGURE 2-9-1-991-003-A and FIGURE 2-9-1-991-004-A. The landing gears are shown with simplified gear structure. The three envelopes show the minimum dimensions for these maintenance operations: - Extension and retraction - Gear removal - Piston removal. Pit envelopes shown represent minimum sizing required to accommodate landing gear tires and removal tooling. Dimensions for the below cases are to be added in the shown envelopes: - Clearance allowances for working area - Operator access - Functional clearances - Tooling - Civil engineering considerations. The maintenance pits are symmetrical about the aircraft centerline and all dimensions shown are minimum dimensions with zero clearances. The dimensions for the pits have been determined as follows: - The aircraft starting condition is with weight on wheels supported by jacks over the pits. - The pit depths are then based on the shock absorbers lowering to the fully extended position plus allowances for tooling. - The length and width of the pits allow the gear to rotate after the weight is taken off the landing gear - The landing gear tires are in the maximum grown condition - The MLG wheels, brakes and bogie beams are removed before the piston is removed - The NLG wheels are removed before the piston is removed - Both the MLG and the NLG pistons are removed vertically. The pit depth for the MLG piston removal is based on the removal pallet support leg being installed at its maximum length (upper pin hole position). The landing gear piston trolley for MLG and NLG may be positioned FWD or AFT of the landing gears depending on the chosen removal orientation (rotation FWD or AFT). Dimensions for elevators and associated mechanisms must be added to those in Figures FIGURE 2-9-1-991-001-A, FIGURE 2-9-1-991-002-A, FIGURE 2-9-1-991-003-A and FIGURE 2-9-1-991-004-A. 2-9-1 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING A. Elevators These can be either mechanical or hydraulic. They are used to: - Permit easy movement of persons and equipment around the landing gears - Lift and remove landing gear assemblies out of the pits. B. Jacking The aircraft must be in position over the pits to put the gear on the elevators. The jack must be installed and engaged with all the jacking points, AC 2-14-1 for aircraft maintenance jacking. When lowering the elevators, the aircraft weight will be transferred from the wheels to the jacks. The landing gears must not be in contact with the elevators during retraction/extension tests. The aircraft must not bend when it is jacked and when its weight is off the wheels. When tripod support jacks are used, the tripod-base circle radius must be limited because the locations required for positioning the columns are close to the sides of the pits. 2-9-1 Page 2 Apr 01/15 2-9-1 1.73 m (5.68 ft) 3.14 m (10.30 ft) 1.63 m (5.35 ft) 0.91 m (2.99 ft) NLG REMOVAL PIT OUTLINE 2.26 m (7.42 ft) FWD 3.85 m (12.63 ft) 3.41 m (11.19 ft) 2.57 m (8.43 ft) WING 2.30 m (7.55 ft) JACKING POINT MLG REMOVAL PIT OUTLINE MLG SHOCK ABSORBER REMOVAL PIT MLG EXTENSION/RETRACTION PIT OUTLINE 4.16 m (13.65 ft) WING JACKING POINT AIRCRAFT CENTER LINE NLG EXTENSION/RETRACTION PIT OUTLINE NLG SHOCK ABSORBER REMOVAL PIT OUTLINE NOTE: ENVELOPES SHOWN WITH ZERO CLEARANCE TO OUTSIDE EDGE OF TIRES. FWD JACKING 1.14 m POINT (3.74 ft) 0.38 m (1.25 ft) 10.11 m (33.17 ft) 1.52 m (4.99 ft) 1.16 m (3.81 ft) A/C DATUM X = 0 38.56 m (126.51 ft) 2.05 m (6.73 ft) 8.71 m (28.58 ft) 2.22 m (7.28 ft) 3.50 m (11.48 ft) 1.84 m (6.04 ft) @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_020901_1_0010001_01_00 Maintenance Pit Envelopes FIGURE-2-9-1-991-001-A01 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 0.38° REF AIRCRAFT JACKED AT 20% MAC FUSELAGE DATUM LINE FWD NLG FULLY EXTENDED NLG WEIGHT ON WHEELS 0.44 m (1.44 ft) NLG TIRES RETRACTION SWEEP GROUND PLANE 0.11° REF AIRCRAFT JACKED AT 41% MAC NLG EXTENSION/RETRACTION PIT 2.25 m (7.38 ft) FUSELAGE DATUM LINE MLG TIRES RETRACTION SWEEPS FWD MLG FULLY EXTENDED MLG WEIGHT ON WHEELS 0.90 m (2.95 ft) GROUND PLANE MLG EXTENSION/RETRACTION PIT P_AC_020901_1_0020001_01_00 NLG/MLG Extension/Retraction Pit FIGURE-2-9-1-991-002-A01 2-9-1 Page 4 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 0.38° REF AIRCRAFT JACKED AT 20% MAC FUSELAGE DATUM LINE FWD NLG FULLY EXTENDED 0.09 m (0.30 ft) NLG WEIGHT ON WHEELS CLEARANCE BETWEEN BOTTOM OF MAIN FITTING AND TOP OF PISTON EXTENT OF PIT TO ALLOW REMOVAL OF THE NLG SHOCK ABSORBER WITH TROLLEY POSITIONED AFT OF NLG SLIDING TUBE GROUND PLANE 1.85 m (6.07 ft) NLG SHOCK ABSORBER REMOVAL PIT 2.03 m (6.66 ft) NLG SHOCK ABSORBER REMOVAL TROLLEY 2.03 m (6.66 ft) 0.11° REF AIRCRAFT JACKED AT 41% MAC FUSELAGE DATUM LINE FWD MLG FULLY EXTENDED CLEARANCE BETWEEN BOTTOM OF MAIN FITTING AND TOP OF PISTON MLG WEIGHT ON WHEELS 2.25 m (7.38 ft) EXTENT OF PIT TO ALLOW ROTATION OF THE SLIDER FWD OF MLG MLG SHOCK ABSORBER REMOVAL PIT MLG REMOVAL TOOL TRANSPORTATION PALLET 0.09 m (0.30 ft) GROUND PLANE MLG SLIDER TRANSPORTATION PALLET 2.40 m (7.87 ft) 2.80 m (9.19 ft) P_AC_020901_1_0030001_01_00 NLG/MLG Shock Absorber Removal Pit FIGURE-2-9-1-991-003-A01 2-9-1 Page 5 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 0.38° REF AIRCRAFT JACKED AT 20% MAC **ON A/C A350-900 FUSELAGE DATUM LINE NLG LOWERED UNTIL ZERO CLEARANCE BETWEEN TOP OF NLG AND NOSE FUSELAGE PROFILE FWD EXTENT OF PIT TO ALLOW REMOVAL OF THE NLG AND TROLLEY TO GROUND LEVEL WITH ZERO CLEARANCE TO THE NOSE FUSELAGE NLG WEIGHT ON WHEELS EXTENT OF PIT WITH NLG TROLLEY TOWING HANDLE EXTENDED 0.94 m (3.08 ft) NLG PISTON NLG TROLLEY GROUND PLANE NLG REMOVAL PIT 3.52 m (11.55 ft) 4.60 m (15.09 ft) 0.63 m (2.07 ft) 7.66 m (25.13 ft) 8.74 m (28.67 ft) 0.11° REF AIRCRAFT JACKED AT 41% MAC FUSELAGE DATUM LINE FWD MLG LOWERED UNTIL ZERO CLEARANCE BETWEEN TOP OF MLG AND LOWER WING O/S SKIN LINE MLG PISTON MLG WEIGHT ON WHEELS MLG REMOVAL PIT MLG TROLLEY GROUND PLANE 1.36 m (4.46 ft) 1.12 m (3.67 ft) EXTENT OF PIT WITH MLG TROLLEY TOWING HANDLE EXTENDED 4.06 m (13.32 ft) 5.55 m (18.21 ft) P_AC_020901_1_0040001_01_00 NLG/MLG Removal Pit FIGURE-2-9-1-991-004-A01 2-9-1 Page 6 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 2-10-0 Exterior Lighting **ON A/C A350-900 Exterior Lighting 1. This section gives the location of the aircraft exterior lighting. EXTERIOR LIGHTING ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 DESCRIPTION RIGHT NAVIGATION LIGHT (GREEN) LEFT NAVIGATION LIGHT (RED) TAIL NAVIGATION LIGHT (WHITE) UPPER ANTI-COLLISION LIGHT/BEACON (RED) LOWER ANTI-COLLISION LIGHT/BEACON (RED) LOGO LIGHTS ENGINE SCAN LIGHTS WING SCAN LIGHTS WING STROBE LIGHT (HIGH INTENSITY, WHITE) TAIL STROBE LIGHT (HIGH INTENSITY, WHITE) TAXI CAMERA LIGHTS (NLG) TAXI CAMERA LIGHTS (MLG) LANDING LIGHTS RUNWAY TURN-OFF LIGHTS TAXI LIGHTS TAKE-OFF LIGHTS CARGO COMPARTMENT FLOOD LIGHTS LANDING GEAR BAY/WELL LIGHTS (DOME) 2-10-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 9 3 6 1 6 4 9 2 7 8 7 8 11 12 5 12 10 P_AC_021000_1_0010002_01_00 Exterior Lighting FIGURE-2-10-0-991-001-B01 2-10-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 13 13 16 15 16 14 6 6 P_AC_021000_1_0020001_01_00 Exterior Lighting FIGURE-2-10-0-991-002-A01 2-10-0 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 3 5 1 2 4 8 7 11 11 14 14 15 P_AC_021000_1_0030002_01_00 Exterior Lighting FIGURE-2-10-0-991-003-B01 2-10-0 Page 4 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 10 12 12 9 9 16 13 13 P_AC_021000_1_0040001_01_00 Exterior Lighting FIGURE-2-10-0-991-004-A01 2-10-0 Page 5 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 18 17 17 18 EXAMPLE FOR LIGHT N° 17 CEILING LIGHT SPOT LIGHT P_AC_021000_1_0050001_01_00 Exterior Lighting FIGURE-2-10-0-991-005-A01 2-10-0 Page 6 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 2-11-0 Antennas and Probes Location **ON A/C A350-900 Antennas and Probes Location 1. This section gives the location of antennas and probes. 2-11-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 15 1 2 3 4 5 6 7 23 28 24 27 26 25 8 9 10 11 12 13 14 17 22 21 20 19 18 16 29 30 31 32 40 1 − LOC 2 − SSA 1 3 − TAT PROBE 1, 2 4 − ICE PROBE 5 − GNSS 1 6 − GNSS 2 7 − TCAS 2 (TOP) 8 − WACS 9 − SATCOM 10 − VHF 1 11 − ADF 1 12 − ADF 2 13 − VHF 3 14 − ELT 15 − HF 16 − MARKER 17 − ISP LH 18 − DME 2 19 − RADIO ALT R2 20 − RADIO ALT E2 39 38 37 36 35 34 33 21 − DME 1 22 − TCAS 1 (BOTTOM) 23 − PITOT 24 − MFP 1 25 − AOA 26− ICE PROBE DETECTOR 27 − GLIDE 28 − WEATHER RADAR 29 − VOR 30 − ISP RH 31 − TCAS 1 (TOP) 32 − SSA 2, 3 33 − ICE PROBE PROTECTOR 34 − MFP 2, 3 35 − RADIO ALT E1 36 − RADIO ALT R1 37 − RADIO ALT R3 38 − RADIO ALT E3 39 − TCAS 2 (BOTTOM) 40 − VHF 2 NOTE: LOCATION DEPENDING OF AIRCRAFT CONFIGURATION P_AC_021100_1_0010001_01_00 Antennas and Probes Location FIGURE-2-11-0-991-001-A01 2-11-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 2-12-0 Engine and Nacelle **ON A/C A350-900 Engine and Nacelle 1. Power Plant The A350--900 has two main power plants, one installed under each wing on a pylon. Each power plant can be lowered for removal from its pylon. The power plant comprises the: - Nacelle, - Engine. 2. Nacelle The nacelle comprises the following assemblies: - Air intake, - Fan cowls, - Thrust reverser, - Exhaust system. 3. A. Fan Cowl A power door opening system is installed to assist in opening the cowls. The cowls have access doors for fan case-mounted components. B. Thrust Reverser The engine thrust reverser consists primarily of a inner fixed structure and an outer translating sleeve. The fan exhaust stream is reversed by the cascades and blocker doors, which form part of the translating sleeve actuated by an electrical Thrust Reverser Actuation System (TRAS). A power door opening system is used to assist thrust reverser cowl opening. The thrust reverser latching system is designed so that the remote latches close only when the hooks are engaged. Means are provided to latch and secure a thrust reverser in the stowed position. Means are provided to permit actuation of the thrust reversers without engine operation, for maintenance purposes, either using the TRAS powered by the aircraft or by manual drive with external Ground Support Equipment (GSE). C. Exhaust System The exhaust system consists of a primary nozzle and a center body plug. The exhaust system is designed to optimize aerodynamics and acoustic performance. Engine A. Ignition Each engine is equipped with a dual ignition system controlled by the FADEC. Each engine is equipped with an automatic flame-out protection. 2-12-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING B. Cooling System A nacelle cooling and ventilating system automatically provides the airflow required for cooling engine and nacelle accessories and associated structure. C. Power Control Forward thrust of each engine is controlled by a throttle control lever mounted on the center pedestal in the cockpit. Thrust reverser control is by means of a separate lever for each engine. D. Engine Master Control Engine fuel shutoff is controlled by switches installed on the center pedestal. E. Emergency Shutdown Actuation of the fire controls closes the associated LP valves. F. Indicating Indications for each engine are displayed on the Control and Display System (CDS). G. Oil The propulsion system has an independent integral oil system that is able to provide the appropriate quantity of oil, at the temperature necessary for continuous propulsion system operation, for all achievable conditions within the propulsion system operating envelope. Means are provided for gravity filling. It is possible to visually check and replenish the engine oil level without opening the fan cowl door. Magnetic chip detectors are installed in the lubrication system. H. Starting The engine is equipped with a pneumatic air turbine starter. The starter can be supplied with air either from the APU, or the other engine, or an Air Start Unit (AS). Standard types of GSE can be used. 2-12-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 5.09 m (16.70 ft) 0.72 m (2.39 ft) 11.10 m (36.42 ft) 2.03 m (6.66 ft) 1.53 m (5.02 ft) 1.68 m (5.51 ft) 1.94 m (6.36 ft) 2.09 m (6.86 ft) 1.40 m (4.59 ft) 6.40 m (21 ft) 1.65 m (5.41 ft) 3.94 m (12.93 ft) 3.17 m (10.40 ft) 3.52 m (11.55 ft) 1.48 m (4.86 ft) 0.89 m (2.92 ft) REFER TO SECTION 2−3−0 NOTE: APPROXIMATE DIMENSIONS DEPENDING ON AIRCRAFT CONFIGURATION P_AC_021200_1_0010001_01_00 Engine and Nacelle (Sheet 1 of 3) FIGURE-2-12-0-991-001-A01 2-12-0 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 C A FC A D TR B B 5.50 m (18.04 ft) 1.01 m (3.31 ft) C D 6.39 m (20.96 ft) 1.28 m (4.20 ft) NOTE: APPROXIMATE DIMENSIONS DEPENDING ON AIRCRAFT CONFIGURATION. FC: FAN COWL AND TR: THRUST REVERSER P_AC_021200_1_0010001_02_00 Engine and Nacelle (Sheet 2 of 3) FIGURE-2-12-0-991-001-A01 2-12-0 Page 4 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 C A FC A TR=45° D TR B B 6.42 m (21.06 ft) 1.51 m (4.95 ft) FC=50° C D 7.13 m (23.40 ft) 1.81 m (5.94 ft) NOTE: APPROXIMATE DIMENSIONS DEPENDING ON AIRCRAFT CONFIGURATION. FC: FAN COWL AND TR: THRUST REVERSER P_AC_021200_1_0010001_03_00 Engine and Nacelle (Sheet 3 of 3) FIGURE-2-12-0-991-001-A01 2-12-0 Page 5 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 2-12-1 APU **ON A/C A350-900 APU 1. The APU is installed at the rear part of the fuselage in the tail cone. An air intake system with a flap-type door is installed in the top right area of the tail cone. The exhaust gases pass overboard at the end of the fuselage cone. 2-12-1 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 Z315, Z316 ENGINE A FR112 EXHAUST SYSTEM AIR SYSTEM B IGNITION AND STARTING SYSTEM FR104 A ENGINE FUEL AND CONTROL SYSTEM AIR SYSTEM FR104 FR109 B OIL SYSTEM P_AC_021201_1_0010001_01_00 APU FIGURE-2-12-1-991-001-A01 2-12-1 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 2-13-0 Levelling, Symmetry and Alignement **ON A/C A350-900 Levelling, Symmetry and Alignement 1. Quick Leveling There are three alternative procedures to level the aircraft: - Quick leveling procedure with Air Data/Inertial Reference System (ADIRS), - Quick leveling procedure with a spirit level in the passenger compartment, - Quick leveling procedure with a spirit level in the FWD cargo compartment. 2. Precise Leveling For precise leveling, it is necessary to install sighting rods in the receptacles located under the fuselage (points 10 and 17 for longitudinal leveling) and under the wings (points 1 LH and 1 RH for lateral leveling) and use a sighting tube. With the aircraft on jacks, adjust the jacks until the reference marks on the sighting rods are aligned in the sighting plane (aircraft level). 3. Symmetry and Alignment Check Possible deformation of the aircraft is measured by photogrammetry. 2-13-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 RIB5 RIB4 FR92 1RH 17 RIB5 RIB4 10 1LH FR22 FR23 P_AC_021300_1_0010001_01_00 Location of Leveling Points FIGURE-2-13-0-991-001-A01 2-13-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 2-14-1 Jacking for Maintenance **ON A/C A350-900 Jacking for Maintenance 1. 2. Aircraft Jacking Points for Maintenance A. The A350-900 can be jacked: - At not more than 164000 kg (361558 lb), - Within the limits of the permissible wind speed when the aircraft is jacked outside a closed environment. B. Primary Jacking Points The aircraft is provided with three primary jacking points: - One located on the forward lower left fuselage (FR12), - Two located under the wings (one under each wing, RIB9). C. Auxiliary Jacking Point (Safety Stay) - When the aircraft is on jacks, a safety stay is placed under the fuselage at FR98 to prevent tail tipping caused by accidental displacement of the aircraft center of gravity. - The safety point must not be used for lifting the aircraft. Jacks and Safety Stay A. Jack Design - The maximum eligible static load given in table (FIGURE 2-14-1-991-001-A) are the maximum loads applicable on jack fittings. - In fully retracted position (jack stroke at minimum), the height of the jacks is such that the jack may be placed beneath the aircraft under the most adverse conditions, namely, tires deflated and shock absorbers depressurized, with a sufficient clearance between the aircraft jacking point and the jack upper end. - The jacks stroke enables the aircraft to be jacked up so that the Fuselage Datum Line (FDL) may be positioned up to 7.30 m (23.95 ft.) from the ground to allow all required maintenance procedure and in particular, the removal/installation of the landing-gear shock absorbers. B. Safety Stay The stay stroke enables the aircraft tail to be supported up to the Fuselage Datum Line (FDL) positioned at 7.30 m (23.95 ft.) from the ground. 2-14-1 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 RIB9 WING JACKING POINT B FUSELAGE DATUM LINE SAFETY POINT FR12 A FR98 C Y X FWD JACKING POINT B’ WING JACKING POINT RIB9 X MAXIMUM LOAD ELIGIBLE Y m ft m ft daN FORWARD FUSELAGE JACKING POINT A 4.77 15.65 −1.72 −5.64 18630 WING JACKING POINT B 33.22 108.99 8.71 28.58 76600 B’ 33.22 108.99 −8.71 −28.58 76600 SAFETY STAY C 58.75 192.75 0 0 7650 NOTE: SAFETY STAY IS NOT USED FOR JACKING. P_AC_021401_1_0010001_01_00 Jacking for Maintenance Jacking Points Location (Sheet 1 of 5) FIGURE-2-14-1-991-001-A01 2-14-1 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 FUSELAGE DATUM LINE L N M CONFIGURATION AIRCRAFT ON WHEELS, SHOCK−ABSORBER DEFLATED, TIRES DEFLATED (RH) A/C ON JACKS, FDL AT 6.50 m (21.33 ft), A/C FUSELAGE PARALLEL TO THE GROUND, SHOCK−ABSORBER RELAXED, CLEARANCE OF MAIN GEAR WHEELS = 1.17 m (3.84 ft) (STANDARD TIRES *), CLEARANCE OF NOSE GEAR WHEELS = 1.38 m (4.53 ft) (STANDARD TIRES *) AIRCRAFT ON WHEELS (STANDARD TIRES *) MAXIMUM JACKING WEIGHT = 164 000 kg (361 558 lb) AIRCRAFT ON WHEELS (STANDARD TIRES *) A/C WEIGHT = 142 000 kg (313 056 lb) CG POSITION (% MAC) HEIGHT L M m ft m N ft 4.70 LH 15.42 LH 4.00 RH 13.12 RH 4.68 LH 15.35 LH 4.00 RH 13.12 RH m ft 4.71 15.45 4.48 14.70 20 3.12 10.24 41 3.36 20 4.32 14.17 5.66 18.57 6.12 20.08 41 4.32 14.17 5.66 18.57 6.12 20.08 20 3.06 10.04 4.58 15.03 5.15 16.90 41 3.29 10.79 4.57 14.99 4.91 16.11 20 3.09 10.14 4.62 15.16 5.19 17.03 41 3.34 10.96 4.60 15.09 4.93 16.18 11.02 NOTE: * STANDARD TIRES: NOSE LANDING GEAR = 1 050 x 395 R16 MAIN LANDING GEAR = 1 400 x 530 R23 P_AC_021401_1_0010001_02_01 Jacking for Maintenance Jacking Dimensions (Sheet 2 of 5) FIGURE-2-14-1-991-001-A01 2-14-1 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A Z120 FR11 FR12 FR12 FR13 FR13 FR14 NOSE JACK ADAPTOR A P_AC_021401_1_0010001_03_00 Jacking for Maintenance Forward Jacking Point (Sheet 3 of 5) FIGURE-2-14-1-991-001-A01 2-14-1 Page 4 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 RIB9 REAR SPAR A 571FB (671FB) A Z571 (Z671) PLATE COVER PROTECTOR A WING JACK ADAPTOR A A A P_AC_021401_1_0010001_04_01 Jacking for Maintenance Wing Jacking Point (Sheet 4 of 5) FIGURE-2-14-1-991-001-A01 2-14-1 Page 5 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 FR98 BEAM5 Z310 FR98 A B A AFT JACK ADAPTOR FR98 B FWD P_AC_021401_1_0010001_05_01 Jacking for Maintenance Auxiliary Jacking Point - Safety (Sheet 5 of 5) FIGURE-2-14-1-991-001-A01 2-14-1 Page 6 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 2-14-2 Jacking of the Landing Gear **ON A/C A350-900 Jacking for wheel change 1. General To replace either the wheel or brake unit assemblies on any of the landing gears, it is necessary to lift the landing gear with a jack. The landing gear can be lifted by a pillar jack or with a cantilever jack. NOTE : You can lift the aircraft at Maximum Ramp Weight (MRW). 2. Nose Landing Gear (NLG) To lift the NLG axle with a jack, a dome shaped pad is installed between the wheels. The reaction loads at the jacking position are shown in FIGURE 2-14-2-991-002-A. NOTE : The maximum load at NLG jacking point is 33758 daN. 3. Main Landing Gear (MLG) To lift the MLG bogie with jacks, a dome shaped pad is installed below the FWD and AFT ends of each bogie beam. Each pair of wheels and brake units can be replaced on the end of the bogie that is lifted. Both FWD and AFT ends of the bogie beam can be lifted together, but the bogie beam must be kept level during the lift to prevent damage. The reaction loads at the jacking position are shown in FIGURE 2-14-2-991-003-A. NOTE : The maximum load at each MLG jacking point is 83892.5 daN. 2-14-2 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A A B FWD A − A : DOME HEIGHT − B : DISTANCE BETWEEN TYRES A350−900 NLG (1 050 x 395 R16) CONFIGURATION (ASSUME ALL OTHER TYRES ON THE A/C ARE INTACT) WEIGHT (T) 2 TYRES (NORMAL) MRW 1 FLAT TYRE CG (% MAC) DIM A DIM B mm in mm in 26.2 291 11.45 261 10.27 MRW 26.2 227 8.93 214 8.42 2 FLAT TYRES & 50% RIM FLANGE DAMAGE MLW 20 75 2.95 191 7.51 2 FLAT TYRES & NO RIM FLANGE DAMAGE MLW 20 97 3.81 191 7.51 P_AC_021402_1_0020001_01_00 Nose Landing Gear Jacking Point Heights FIGURE-2-14-2-991-002-A01 2-14-2 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A A C B FWD − A : DOME HEIGHT − B : DISTANCE BETWEEN TYRES − C : DISTANCE BETWEEN BRAKE RODS AND GROUND A A350−900 MLG (1 400 x 530 R23) CONFIGURATION DIM A DIM A DIM B DIM B (ASSUME ALL OTHER WEIGHT CG AFT FWD AFT FWD TYRES ON THE A/C (T) (% MAC) mm in mm in mm in mm in ARE INTACT) 4 TYRES (NORMAL) 33.2 378 14.88 378 14.88 1 029 40.51 1 036 40.78 MRW FWD INNER TYRE 33.2 304 11.96 381 15.00 981 38.62 1 041 40.98 MRW UNSERVICEABLE FWD OUTER TYRE 33.2 285 11.22 374 14.72 974 38.34 1 033 40.66 MRW UNSERVICEABLE AFT INNER TYRE 33.2 381 15.00 304 11.96 1 032 40.62 983 38.70 MRW UNSERVICEABLE AFT OUTER TYRE 33.2 374 14.72 285 11.22 1 025 40.35 975 38.38 MRW UNSERVICEABLE 2 FLAT FWD TYRES 42 129 5.07 404 15.90 967 38.07 1 071 42.16 MLW & 50% RIM DAMAGE 2 FLAT AFT TYRES 42 404 15.90 129 5.07 1 060 41.73 967 38.07 MLW & 50% RIM DAMAGE 4 FLAT TYRES & 42 136 5.35 136 5.35 967 38.07 967 38.07 MLW 50% RIM DAMAGE 2 FLAT FWD TYRES 42 159 6.25 403 15.86 967 38.07 1 071 42.16 MLW & NO RIM DAMAGE 2 FLAT AFT TYRES 42 403 15.86 159 6.25 1 059 41.69 967 38.07 MLW & NO RIM DAMAGE 4 FLAT TYRES & 42 166 6.53 166 6.53 967 38.07 967 38.07 MLW NO RIM DAMAGE TYRE CHANGE FWD MAX GROWN TYRE 25 mm 33.2 541 21.29 378 14.88 1 113 43.81 1 029 40.51 MRW FROM GROUND AFT MAX GROWN 33.2 378 14.88 541 21.29 1 029 40.51 1 113 43.81 MRW TYRE 25 mm FROM GROUND 8 FLAT TYRES & 26.2 118 4.64 118 4.64 967 38.07 967 38.07 MRW 50% RIM DAMAGE 8 FLAT TYRES & 26.2 149 5.86 149 5.86 967 38.07 967 38.07 MRW NO RIM DAMAGE DIM C FWD mm in DIM C AFT mm in 267 10.51 267 10.51 194 7.63 271 10.66 175 6.88 264 10.39 271 10.66 193 7.59 264 10.39 175 6.88 18 0.70 293 11.53 293 11.53 18 0.70 26 1.02 1.02 48 1.88 293 11.53 26 293 11.53 48 1.88 55 2.16 2.16 55 431 16.96 268 10.55 268 10.55 430 16.92 7 0.27 7 0.27 39 1.53 39 1.53 P_AC_021402_1_0030001_01_00 Main Landing Gear Jacking Point Heights FIGURE-2-14-2-991-003-A01 2-14-2 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING AIRCRAFT PERFORMANCE 3-1-0 General Information **ON A/C A350-900 General Information 1. Standard day temperatures for the altitudes shown are tabulated below: FEET 0 2 4 6 8 000 000 000 000 Standard Day Temperatures for the Altitudes Standard Day Temperature Altitude METERS ?C ?F 0 59.0 15.0 610 51.9 11.1 44.7 1 220 7.1 1 830 37.6 3.1 2 440 30.5 -0.8 3-1-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 3-3-0 Take-Off Weight Limitation **ON A/C A350-900 Take-Off Weight Limitation 1. This section provides the take-off weight limitation at ISA conditions and ISA + 15 ˚C (+59 ˚F) conditions on a dry runway. 3-3-0 Page 1 Apr 01/15 3-3-0 MTOW 130 1 500 150 170 190 210 230 250 270 2 000 6 920 2 500 8 920 3 500 RUNWAY LENGTH (m) 3 000 RUNWAY LENGTH (ft) 10 920 14 920 4 000 4 500 0 ft 2 000 ft 4 000 ft 6 000 ft 8 000 ft AIRPORT PRESSURE ALTITUDE 12 920 NOTE: THESE CURVES ARE GIVEN FOR INFORMATION ONLY. THE APPROVED VALUES ARE STATED IN THE "OPERATING MANUALS" SPECIFIC TO THE AIRLINE OPERATING THE AIRCRAFT. TAKE−OFF WEIGHT (x 1 000 kg) 4 920 290 286.6 5 000 336.6 386.6 436.6 486.6 536.6 586.6 636.6 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_030300_1_0010001_01_01 ISA Conditions FIGURE-3-3-0-991-001-A01 Page 2 Apr 01/15 TAKE−OFF WEIGHT (x 1 000 lb) 3-3-0 MTOW 130 1 500 150 170 190 210 230 250 270 2 000 6 920 2 500 8 920 3 500 RUNWAY LENGTH (m) 3 000 RUNWAY LENGTH (ft) 10 920 14 920 4 000 4 500 0 ft 2 000 ft 4 000 ft 6 000 ft 8 000 ft AIRPORT PRESSURE ALTITUDE 12 920 NOTE: THESE CURVES ARE GIVEN FOR INFORMATION ONLY. THE APPROVED VALUES ARE STATED IN THE "OPERATING MANUALS" SPECIFIC TO THE AIRLINE OPERATING THE AIRCRAFT. TAKE−OFF WEIGHT (x 1 000 kg) 4 920 290 286.6 5 000 336.6 386.6 436.6 486.6 536.6 586.6 636.6 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_030300_1_0020001_01_01 ISA + 15 ˚C (+59 ˚F) Conditions FIGURE-3-3-0-991-002-A01 Page 3 Apr 01/15 TAKE−OFF WEIGHT (x 1 000 lb) @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 3-4-0 Landing Field Length **ON A/C A350-900 Landing Field Length 1. This section provides the landing field length on a dry runway. 3-4-0 Page 1 Apr 01/15 3-4-0 1 200 130 1 400 1 600 1 800 2 000 2 200 2 400 326.6 140 150 386.6 180 LANDING WEIGHT (x 1 000 kg) 160 170 366.6 LANDING WEIGHT (x 1 000 lb) 346.6 VALID FOR ALL TEMPERATURES 306.6 426.6 446.6 190 8 000 ft 6 000 ft 4 000 ft 2 000 ft 0 ft 200 AIRFIELD ELEVATION 406.6 NOTE: THESE CURVES ARE GIVEN FOR INFORMATION ONLY. THE APPROVED VALUES ARE STATED IN THE "OPERATING MANUALS" SPECIFIC TO THE AIRLINE OPERATING THE AIRCRAFT. REQUIRED LANDING DISTANCE (m) 286.6 2 600 210 4 280 4 780 5 280 5 780 6 280 6 780 7 280 7 780 8 280 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_030400_1_0010001_01_01 Landing Field Length FIGURE-3-4-0-991-001-A01 Page 2 Apr 01/15 REQUIRED LANDING DISTANCE (ft) @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 3-5-0 Final Approach Speed **ON A/C A350-900 Final Approach Speed 1. This section provides the final approach speed. It is defined as the indicated airspeed at threshold in the landing configuration, at the certificated maximum flap setting and maximum landing weight, in standard atmospheric conditions. The approach speed is used to classify the aircraft into an Aircraft Approach Category, a grouping of aircraft based on the indicated airspeed at threshold. 2. The final approach speed is 140 kt at a MLW of 205000 kg (451948 lb) and classifies the aircraft into the Aircraft Approach Category C. NOTE : This value is given for information only. 3-5-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING GROUND MANEUVERING 4-2-0 Turning Radii **ON A/C A350-900 Turning Radii 1. This section gives the turning radii. 4-2-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 R5 R3 R1 70° 65° 60° R2 R4 R6 NOTE: FOR TURNING RADII VALUES, REFER TO SHEET 2 P_AC_040200_1_0010001_01_00 Turning Radii (Sheet 1 of 2) FIGURE-4-2-0-991-001-A01 4-2-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A350−900 TURNING RADII TYPE OF STEERING EFFECTIVE TURN ANGLE (deg) STEERING ANGLE (deg) 2 20 19.6 2 25 24.5 2 30 29.4 2 35 34.2 2 40 39.1 2 45 43.8 2 50 48.6 2 55 53.1 2 60 57.5 2 65 61.5 2 70 65.0 2 72 (MAX) 66.1 1 50 49.3 1 55 54.1 1 60 58.7 1 65 63.2 1 70 67.5 1 72 (MAX) 69.2 R1 R2 RMLG LMLG R3 NLG R4 WING R5 NOSE R6 TAIL m ft m ft m ft m ft m ft m ft m ft m ft m ft m ft m ft m ft 76.3 250 58.7 193 46.7 153 38.0 125 31.1 102 25.7 84 21.1 69 17.4 57 14.1 46 11.4 37 9.2 30 8.5 28 86.9 285 69.3 227 57.3 188 48.6 159 41.7 137 36.3 119 31.7 104 28.0 92 24.7 81 22.0 72 19.8 65 19.1 63 86.0 282 69.6 228 58.9 193 51.5 169 45.9 151 41.8 137 38.6 127 36.2 119 34.3 113 32.9 108 31.9 105 31.6 104 113.6 373 96.2 316 84.3 277 75.7 248 68.9 226 63.7 209 59.2 194 55.5 182 52.4 172 49.8 163 47.7 156 47.0 154 87.1 286 71.2 233 60.8 199 53.7 176 48.5 159 44.7 147 41.8 137 39.6 130 38.0 125 36.7 121 35.9 118 35.6 117 96.0 315 79.7 262 69.0 226 61.5 202 55.9 183 51.7 170 48.3 158 45.7 150 43.5 143 41.9 137 40.6 133 40.2 132 m ft m ft m ft m ft m ft m ft 20.5 67 16.6 54 13.3 43 10.3 34 7.7 25 6.7 22 31.1 102 27.2 89 23.9 78 20.9 69 18.3 60 17.3 57 38.2 125 35.7 117 33.8 111 32.4 106 31.2 103 30.9 101 58.6 192 54.8 180 51.6 169 48.7 160 46.2 152 45.3 149 41.4 136 39.2 129 37.6 123 36.3 119 35.3 116 35.0 115 47.8 157 45.1 148 43.0 141 41.2 135 39.8 130 39.2 129 NOTE: ABOVE 50°, AIRLINES MAY USE TYPE 1 OR TYPE 2 TURNS DEPENDING ON THE SITUATION TYPE 1 TURNS USE: ASYMMETRIC THRUST DURING THE WHOLE TURN; AND DIFFERENTIAL BRAKING TO INITIATE THE TURN ONLY TYPE 2 TURNS USE: SYMMETRIC THRUST DURING THE WHOLE TURN; AND NO DIFFERENTIAL BRAKING AT ALL IT IS POSSIBLE TO GET LOWER VALUES THAN THOSE FROM TYPE 1 BY APPLYING DIFFERENTIAL BRAKING DURING THE WHOLE TURN. P_AC_040200_1_0010001_02_00 Turning Radii (Sheet 2 of 2) FIGURE-4-2-0-991-001-A01 4-2-0 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 4-3-0 Minimum Turning Radii **ON A/C A350-900 Minimum Turning Radii 1. This section gives the minimum turning radii. 4-3-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 R5 R3 X Y R4 A (MINIMUM TURNING WIDTH) R6 NOTE: TYPE 1 TURNS USE: ASYMMETRIC THRUST DURING THE WHOLE TURN; AND DIFFERENTIAL BRAKING TO INITIATE THE TURN ONLY TYPE 2 TURNS USE: SYMMETRIC THRUST DURING THE WHOLE TURN; AND NO DIFFERENTIAL BRAKING AT ALL A350−900 MINIMUM TURNING RADII TYPE OF STEERING EFFECTIVE TURN ANGLE (deg) STEERING ANGLE (deg) 1 72 (MAX) 69.2 2 72 (MAX) 66.1 m ft m ft X Y A R3 NLG R4 WING R5 NOSE R6 TAIL 28.7 94 28.7 94 10.9 36 12.7 42 48.5 159 51.1 168 30.9 101 31.6 104 45.3 149 47.0 154 35.0 115 35.6 117 39.2 129 40.2 132 NOTE: IT IS POSSIBLE TO GET LOWER VALUES THAN THOSE FROM TYPE 1 BY APPLYING DIFFERENTIAL BRAKING DURING THE WHOLE TURN. P_AC_040300_1_0010001_01_00 Minimum Turning Radii FIGURE-4-3-0-991-001-A01 4-3-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 4-4-0 Visibility from Cockpit in Static Position **ON A/C A350-900 Visibility from Cockpit in Static Position 1. This section gives the visibility from cockpit in static position. 4-4-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 NOT TO BE USED FOR LANDING APPROACH VISIBILITY DIMENSIONS ARE APPROXIMATE 27° VISUAL ANGLES IN VERTICAL PLANE THROUGH PILOT EYE POSITION. 20° 3.04 m (9.97 ft) 14.20 m (46.59 ft) 105.5° 120° FIRST OFFICER FIELD OF VIEW 4.63 m (15.19 ft) MAX AFT VISION WITH HEAD TURNED AROUND SPINAL COLUMN. WING TIP CAN BE SEEN WHEN HEAD IS MOVED TO THE SIDE. VISUAL ANGLES IN HORIZONTAL PLANE THROUGH PILOT EYE POSITION. CAPTAIN FIELD OF VIEW 105.5° 120° 0.53 m (1 ft 8.88 in) VISUAL ANGLES IN PLANE PERPENDICULAR TO LONGITUDINAL AXIS. 32° 32° 15° 15° NOTE: PILOT EYE POSITION WHEN PILOT’S EYES ARE IN LINE WITH THE RED AND WHITE BALLS. ZONE THAT CANNOT BE SEEN P_AC_040400_1_0010001_01_00 Visibility from Cockpit in Static Position FIGURE-4-4-0-991-001-A01 4-4-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 4-5-0 Runway and Taxiway Turn Paths **ON A/C A350-900 Introduction 1. This section gives the runway and taxiway turnpaths for the following configurations: - 90˚ Turn --- Runway to Taxiway - 135˚ Turn --- Runway to Taxiway - 180˚ U-Turn on Runway - 90˚ Turn --- Taxiway to Taxiway - 135˚ Turn --- Taxiway to Taxiway The turnpaths Runway to Taxiway and Taxiway to Taxiway are defined using 2 methods: - Oversteering method, - Cockpit over centerline method. The 180 U-Turn on runway is defined using the following method: - U-Turn using edge of runway method. 4-5-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 4-5-1 90˚ Turn - Runway to Taxiway **ON A/C A350-900 90˚ Turn - Runway to Taxiway 1. This section gives the 90˚ turn - runway to taxiway. 4-5-1 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 FAA LEAD−IN FILLET L=75 m (250 ft) APPROX 10.9 m (36 ft) 23 m (75 ft) APPROX 13.3 m (44 ft) TAXIWAY CENTERLINE FILLET R = 25.5 m (85 ft) TURN R = 45 m (150 ft) NLG PATH MLG PATH RUNWAY CENTERLINE 45 m (150 ft) P_AC_040501_1_0010001_01_02 90˚ Turn - Runway to Taxiway Oversteering Method (Sheet 1 of 2) FIGURE-4-5-1-991-001-A01 4-5-1 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 FAA LEAD−IN FILLET L=75 m (250 ft) APPROX 5 m (16 ft) 23 m (75 ft) TAXIWAY CENTERLINE FILLET R = 25.5 m (85 ft) TURN R = 45 m (150 ft) NLG PATH MLG PATH RUNWAY CENTERLINE 45 m (150 ft) P_AC_040501_1_0010001_02_02 90˚ Turn - Runway to Taxiway Cockpit over Centerline Method (Sheet 2 of 2) FIGURE-4-5-1-991-001-A01 4-5-1 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 4-5-2 135˚ Turn - Runway to Taxiway **ON A/C A350-900 135˚ Turn - Runway to Taxiway 1. This section gives the 135˚ turn - runway to taxiway. 4-5-2 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 APPROX 5.8 m (19 ft) FAA LEAD−IN FILLET L=75 m (250 ft) APPROX 7.6 m (25 ft) FILLET R = 25.5 m (85 ft) TURN R = 45 m (150 ft) TAXIWAY CENTERLINE 23 m (75 ft) NLG PATH RUNWAY CENTERLINE MLG PATH 45 m (150 ft) P_AC_040502_1_0010002_01_02 135˚ Turn - Runway to Taxiway Oversteering Method (Sheet 1 of 2) FIGURE-4-5-2-991-001-B01 4-5-2 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 RUNWAY CENTERLINE TURN R = 45 m (150 ft) FAA LEAD−IN FILLET L=75 m (250 ft) APPROX 1.6 m (5 ft) FILLET R = 25.5 m (85 ft) ADDITIONAL FILLET TO MEET 4.5 m (15 ft) EDGE CLEARANCE TAXIWAY CENTERLINE 23 m (75 ft) NLG PATH MLG PATH 45 m (150 ft) P_AC_040502_1_0010002_02_02 135˚ Turn - Runway to Taxiway Cockpit over Centerline Method (Sheet 2 of 2) FIGURE-4-5-2-991-001-B01 4-5-2 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 4-5-3 180˚ Turn on a Runway **ON A/C A350-900 180˚ Turn on a Runway 1. This section gives the 180˚ turn on a runway. 4-5-3 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 RUNWAY CENTERLINE R4 = 45.3 m (149 ft) R3 = 30.9 m (101 ft) 4.5 m (15 ft) R5 = 35 m (115 ft) 4.5 m (15 ft) APPROX 48.5 m (159.12 ft) NLG PATH NOSE TIP PATH MLG PATH WING TIP PATH NOTE: TYPE 1 VALUES. IT IS POSSIBLE TO GET LOWER VALUES THAN THOSE FROM TYPE 1 BY APPLYING DIFFERENTIAL BRAKING DURING THE WHOLE TURN. P_AC_040503_1_0010001_01_01 180˚ Turn on a Runway FIGURE-4-5-3-991-001-A01 4-5-3 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 4-5-4 90˚ Turn - Taxiway to Taxiway **ON A/C A350-900 90˚ Turn - Taxiway to Taxiway 1. This section gives the 90˚ turn - taxiway to taxiway. 4-5-4 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 FAA LEAD−IN FILLET L=75 m (250 ft) APPROX 10.5 m (34 ft) 23 m (75 ft) APPROX 12.9 m (42 ft) TAXIWAY CENTERLINE FILLET R = 25.5 m (85 ft) TURN R = 45 m (150 ft) NLG PATH TAXIWAY CENTERLINE MLG PATH 23 m (75 ft) P_AC_040504_1_0010001_01_02 90˚ Turn - Taxiway to Taxiway Oversteering Method (Sheet 1 of 2) FIGURE-4-5-4-991-001-A01 4-5-4 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 FAA LEAD−IN FILLET L=75 m (250 ft) APPROX 3.9 m (13 ft) 23 m (75 ft) ADDITIONAL FILLET TO MEET 4.5 m (15 ft) EDGE CLEARANCE TAXIWAY CENTERLINE FILLET R = 25.5 m (85 ft) TURN R = 45 m (150 ft) TAXIWAY CENTERLINE NLG PATH MLG PATH 23 m (75 ft) P_AC_040504_1_0010001_02_02 90˚ Turn - Taxiway to Taxiway Cockpit over Centerline Method (Sheet 2 of 2) FIGURE-4-5-4-991-001-A01 4-5-4 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 4-5-5 135˚ Turn - Taxiway to Taxiway **ON A/C A350-900 135˚ Turn - Taxiway to Taxiway 1. This section gives the 135˚ turn - taxiway to taxiway. 4-5-5 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 APPROX 6.9 m (23 ft) FAA LEAD−IN FILLET L=75 m (250 ft) APPROX 8.8 m (29 ft) FILLET R = 25.5 m (85 ft) TURN R = 45 m (150 ft) TAXIWAY CENTERLINE TAXIWAY CENTERLINE 23 m (75 ft) NLG PATH MLG PATH 23 m (75 ft) P_AC_040505_1_0010002_01_02 135˚ Turn - Taxiway to Taxiway Oversteering Method (Sheet 1 of 2) FIGURE-4-5-5-991-001-B01 4-5-5 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 TURN R = 45 m (150 ft) FAA LEAD−IN FILLET L=75 m (250 ft) APPROX 2.5 m (8 ft) FILLET R = 25.5 m (85 ft) ADDITIONAL FILLET TO MEET 4.5 m (15 ft) EDGE CLEARANCE TAXIWAY CENTERLINE TAXIWAY CENTERLINE 23 m (75 ft) NLG PATH MLG PATH 23 m (75 ft) P_AC_040505_1_0010002_02_02 135˚ Turn - Taxiway to Taxiway Cockpit over Centerline Method (Sheet 2 of 2) FIGURE-4-5-5-991-001-B01 4-5-5 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 4-6-0 Runway Holding Bay (Apron) **ON A/C A350-900 Runway Holding Bay (Apron) 1. This section gives the runway holding bay (Apron). 4-6-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 6.1 m (20 ft) MAIN LANDING GEAR PATH 90 m (300 ft) 102 m (335 ft) 12.2 m (40 ft) 6.1 m (20 ft) HOLDING POINT 190 m (625 ft) TAXIWAY CENTERLINE RUNWAY CENTERLINE 23 m (75 ft) 45 m (150 ft) NOTE: COORDINATE WITH USING AIRCRAFT FOR SPECIFIC PLANNED OPERATING PROCEDURES. P_AC_040600_1_0010001_01_00 Runway Holding Bay (Apron) FIGURE-4-6-0-991-001-A01 4-6-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 4-7-0 Minimum Line-Up Distance Corrections **ON A/C A350-900 Minimum Line-Up Distance Corrections 1. The ground maneuvers were performed using asymmetric thrust and differential braking only to initiate the turn. TODA: Take-Off Distance Available ASDA: Acceleration-Stop Distance Available 2. 90˚ Turn on Runway Entry This section gives the minimum line-up distance correction for a 90˚ turn on runway entry. This maneuver consists in a 90˚ turn at minimum turn radius. It starts with the edge of the MLG at a distance of 4.5 m (15 ft.) from the taxiway edge, and finishes with the aircraft aligned on the centerline of the runway. During the turn, all the clearances must meet the minimum value of 4.5 m (15 ft.) for this category of aircraft as recommended in ICAO Annex 14. 3. 180˚ Turn on Runway Turn Pad This section gives the minimum line-up distance correction for a 180˚ turn on the runway turn pad. This maneuver consists in a 180˚ turn at minimum turn radius on a runway turn pad with standard ICAO geometry. It starts with the edge of the MLG at a distance of 4.5 m (15 ft.) from the pavement edge, and it finishes with the aircraft aligned on the centerline of the runway. During the turn, all the clearances must meet the minimum value of 4.5 m (15 ft.) for this category of aircraft as recommended in ICAO Annex 14. 4. 180˚ Turn on Runway Width This section gives the minimum line-up distance correction for a 180˚ turn on the runway width. For this maneuver, the pavement width is considered to be the runway width, which is a frozen parameter (45 m (150 ft) and 60 m (200 ft)). As per the standard operating procedures for the ”180˚ turn on runway” (described in the Flight Crew Operating Manual), the aircraft is initially angled with respect to the runway centerline when starting the 180˚ turn. The value of this angle depends on the aircraft type, and is mentioned in the FCOM. During the turn, all the clearances must meet the minimum value of 4.5 m (15 ft.) for this category of aircraft as recommended in ICAO Annex 14. 4-7-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 4.5 m (15 ft) TODA TAXIWAY CENTERLINE ASDA > 4.5 m (15 ft) RUNWAY CENTERLINE ASDA: ACCELERATION−STOP DISTANCE AVAILABLE TODA: TAKE−OFF DISTANCE AVAILABLE 90° TURN ON RUNWAY ENTRY MAX AIRCRAFT STEERING TYPE ANGLE A350−900 72° 60 m (200 ft) WIDE RUNWAY 45 m (150 ft) WIDE RUNWAY MINIMUM LINE−UP MINIMUM LINE−UP DISTANCE CORRECTION DISTANCE CORRECTION ON TODA ON ASDA ON TODA ON ASDA 25.7 m 84 ft 54.3 m 178 ft 21.8 m 72 ft 50.5 m 166 ft P_AC_040700_1_0010001_01_01 90˚ Turn on Runway Entry FIGURE-4-7-0-991-001-A01 4-7-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 MINIMUM PAVEMENT WIDTH 4.5 m (15 ft) TODA > 4.5 m (15 ft) 4.5 m (15 ft) ASDA RUNWAY CENTERLINE ASDA: ACCELERATION−STOP DISTANCE AVAILABLE TODA: TAKE−OFF DISTANCE AVAILABLE 180° TURN ON RUNWAY TURN PAD MAX AIRCRAFT STEERING TYPE ANGLE A350−900 72° 45 m (150 ft) WIDE RUNWAY 60 m (200 ft) WIDE RUNWAY MINIMUM LINE−UP MINIMUM LINE−UP DISTANCE CORRECTION DISTANCE CORRECTION ON TODA ON ASDA ON TODA ON ASDA 37.2 m 122 ft 65.9 m 216 ft 35.7 m 117 ft 64.4 m 211 ft REQUIRED MINIMUM PAVEMENT WIDTH 62.9 m 206 ft P_AC_040700_1_0020001_01_01 180˚ Turn on Runway Turn Pad FIGURE-4-7-0-991-002-A01 4-7-0 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 4.5 m (15 ft) > 4.5 m (15 ft) TODA ASDA 4.5 m (15 ft) 25° RUNWAY CENTERLINE ASDA: ACCELERATION−STOP DISTANCE AVAILABLE TODA: TAKE−OFF DISTANCE AVAILABLE 180° TURN ON RUNWAY WIDTH MAX AIRCRAFT STEERING TYPE ANGLE A350−900 72° 60 m (200 ft) WIDE RUNWAY 45 m (150 ft) WIDE RUNWAY MINIMUM LINE−UP MINIMUM LINE−UP DISTANCE CORRECTION DISTANCE CORRECTION ON TODA ON ASDA ON TODA ON ASDA 47.5 m 156 ft 76.2 m 250 ft NOT POSSIBLE P_AC_040700_1_0030001_01_01 180˚ Turn on Runway Width FIGURE-4-7-0-991-003-A01 4-7-0 Page 4 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 4-8-0 Aircraft Mooring **ON A/C A350-900 Aircraft Mooring 1. This section provides information on aircraft mooring. 4-8-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 TOWING FITTING STRAP A QUICK RELEASE PIN MOORING KIT TENSIONER SAFETY LEVER WARNING FLAG HOOK MOORING POINT A P_AC_040800_1_0010001_01_01 Aircraft Mooring FIGURE-4-8-0-991-001-A01 4-8-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING TERMINAL SERVICING 5-1-0 Aircraft Servicing Arrangements **ON A/C A350-900 Aircraft Servicing Arrangements 1. This section provides typical ramp layouts, showing the various GSE items in position during typical turn round scenarios. These ramp layouts show typical arrangements only. Each operator will have its own specific requirements/regulations for the positioning and operation on the ramp. This table gives the symbols used on servicing diagrams. Ground Support Equipment AC AIR CONDITIONING UNIT AS AIR START UNIT BULK BULK TRAIN CAT CATERING TRUCK CB CONVEYOR BELT CLEAN CLEANING TRUCK FUEL FUEL HYDRANT DISPENSER or TANKER GPU GROUND POWER UNIT LDCL LOWER DECK CARGO LOADER LV LAVATORY VEHICLE PBB PASSENGER BOARDING BRIDGE PS PASSENGER STAIRS TOW TOW TRACTOR ULD ULD TRAIN WV POTABLE WATER VEHICLE 5-1-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-1-1 Typical Ramp Layout (Open Apron) **ON A/C A350-900 Typical Ramp Layout (Open Apron) 1. This section provides the typical ramp layout (open apron). The Stand Safety Line delimits the Aircraft Safety Area (minimum distance of 7.5 m (25 ft.) from the aircraft). No vehicle must be parked in this area before complete stop of the aircraft (wheel chocks in position on landing gears). 5-1-1 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 TOW AS GPU PS CAT ULD AC LDCL CAT PS FUEL LDCL BULK CLEAN STAND SAFETY LINE ULD CB WV CAT LV FEET 0 10 20 30 40 50 60 0 4 8 12 16 METERS 20 P_AC_050101_1_0010001_01_02 Typical Ramp Layout (Open Apron) FIGURE-5-1-1-991-001-A01 5-1-1 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-1-2 Typical Ramp Layout (Gate) **ON A/C A350-900 Typical Ramp Layout (Gate) 1. This section provides the baseline ramp layout (gate). The Stand Safety Line delimits the Aircraft Safety Area (minimum distance of 7.5 m (25 ft.) from the aircraft). No vehicle must be parked in this area before complete stop of the aircraft (wheel chocks in position on landing gears). 5-1-2 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 TOW AS GPU PBB CAT ULD AC LDCL CAT PBB FUEL LDCL BULK CLEAN STAND SAFETY LINE ULD CB WV CAT LV FEET 0 10 20 30 40 50 60 0 4 8 12 16 METERS 20 P_AC_050102_1_0010001_01_02 Typical Ramp Layout (Gate) FIGURE-5-1-2-991-001-A01 5-1-2 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-2-0 Terminal Operations - Full Servicing Turn Round Time **ON A/C A350-900 Terminal Operations - Full Servicing Turn Round Time 1. This section provides a typical turn round time chart showing the typical time for ramp activities during aircraft turn round. Actual times may vary due to each operator’s specific practices, resources, equipment and operating conditions. 2. Assumptions used for full servicing turn round time chart A. PASSENGER HANDLING 315 pax: 48 B/C + 267 Y/C. All passengers deplane and board the aircraft. 2 Passenger Boarding Bridges (PBB) used at doors L1 and L2. Equipment positioning + opening door = +3 min. Closing door + equipment removal = +3 min. No Passenger with Reduced Mobility (PRM) on board. Deplaning: - 158 pax at door L1 - 157 pax at door L2 - Deplaning rate = 25 pax/min per door - Priority deplaning for premium passengers. Boarding: - 158 pax at door L1 - 157 pax at door L2 - Boarding rate = 15 pax/min per door - Last Pax Seated allowance (LPS) + headcounting = +4 min. B. CARGO 2 cargo loaders + 1 belt loader. Opening door + equipment positioning = +2.5 min. Equipment removal + closing door = +2.5 min. 100% cargo exchange: - FWD cargo compartment: 8 containers/4 pallets - AFT cargo compartment: 4 containers/4 pallets - Bulk compartment: 1000 kg (2205 lb). Container unloading/loading times: - Unloading = 1.2 min/container - Loading = 1.4 min/container. Bulk unloading/loading times: 5-2-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING - Unloading = 110 kg/min (243 lb/min) - Loading = 95 kg/min (209 lb/min). Pallet unloading/loading times: - Unloading = 2.4 min/pallet - Loading = 2.8 min/pallet. C. REFUELLING 100000 L (26418 USgal), 4 hoses, 40 psig (2.76 bars-rel). Dispenser positioning + connection = +8 min. Disconnection + dispenser removal = +8 min. D. CLEANING Cleaning is performed in available time. E. CATERING 3 catering trucks for servicing galleys simultaneously at doors R1, R2 and R4. Equipment positioning + opening door = +5 min. Closing door + equipment removal = +3 min. Full Size Trolley Equivalent (FSTE) to unload and load: 40 FSTE - 10 FSTE at door R1 - 7 FSTE at door R2 - 23 FSTE at door R4. Time for trolley exchange = 1.5 min per FSTE. F. GROUND HANDLING/GENERAL SERVICING Start of operations: - Bridges/Stairs: t0=0 - Other equipment: t = t0 +1 min. Ground Power Unit (GPU): up to 2 × 90 kVA. Air Conditioning: up to 2 hoses. Potable water servicing: 100% uplift, 1060 L (280 USgal). Waste water servicing: draining + rinsing. 5-2-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 TRT: 61 min 0 10 20 30 40 50 60 70 DEPLANING/BOARDING AT L1 DEPLANING/BOARDING AT L2 HEADCOUNTING CATERING AT R1 CATERING AT R2 CATERING AT R4 CLEANING AVAILABLE TIME CARGO FWD CC CARGO AFT CC BULK REFUELING POTABLE WATER SERVICING WASTE WATER SERVICING GSE POSITIONING/REMOVAL ACTIVITY CRITICAL PATH P_AC_050200_1_0010001_01_02 Full Servicing Turn Round Time Chart FIGURE-5-2-0-991-001-A01 5-2-0 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-3-0 Terminal Operations - Transit Turn Round Time **ON A/C A350-900 Terminal Operations - Transit Turn Round Time 1. This section provides a typical turn round time chart showing the typical time for ramp activities during aircraft turn round. Actual times may vary due to each operator’s specific practices, resources, equipment and operating conditions. 2. Assumptions used for transit turn round time chart A. PASSENGER HANDLING 315 pax: 48 B/C + 267 Y/C. 50% passengers deplane and board the aircraft. 1 Passenger Boarding Bridge (PBB) used at door L1. Equipment positioning + opening door = +3 min. Closing door + equipment removal = +3 min. No Passenger with Reduced Mobility (PRM) on board. Deplaning: - 158 pax at door L1 - Deplaning rate = 25 pax/min per door. Boarding: - 158 pax at door L1 - Boarding rate = 15 pax/min per door - Last Pax Seated allowance (LPS) + headcounting = + 4 min. B. CARGO 1 cargo loader + 1 belt loader. Opening door + equipment positioning = +2.5 min. Equipment removal + closing door = +2.5 min. 50% cargo exchange: - AFT cargo compartment: 2 containers/2 pallets - Bulk compartment: 500 kg (1102 lb). Container unloading/loading times: - Unloading = 1.2 min/container - Loading = 1.4 min/container. Bulk unloading/loading times: - Unloading = 110 kg/min (243 lb/min) - Loading = 95 kg/min (209 lb/min). Pallet unloading/loading times: - Unloading = 2.4 min/pallet 5-3-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING - Loading = 2.6 min/pallet. C. REFUELING No refueling. D. CLEANING Cleaning is performed in available time. E. CATERING One catering truck for servicing the galleys as required. F. GROUND HANDLING/GENERAL SERVICING Start of operations: - Bridges: t0 = 0 - Other equipment: t = t0 + 1 min. Ground Power Unit (GPU): up to 2 × 90 kVA. Air conditioning: up to 2 hoses. No potable water servicing. No waste water servicing. 5-3-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 TRT: 30 min 0 5 10 15 20 25 30 35 DEPLANING/BOARDING AT L1 HEADCOUNTING CATERING AVAILABLE TIME CLEANING AVAILABLE TIME CARGO AFT CC BULK ACTIVITY GSE POSITIONING/REMOVAL P_AC_050300_1_0010002_01_02 Transit Turn Round Time Chart FIGURE-5-3-0-991-001-B01 5-3-0 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-4-0 Ground Service Connections Layout **ON A/C A350-900 Ground Service Connections Layout 1. This section provides the ground service connections layout. 5-4-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 12 11 10 7 8 9 6 1 2 4 5 3 7 8 9 15 14 17 13 10 11 12 16 18 1 − NLG GROUNDING (EARTHING) POINT 2 − GROUND ELECTRICAL POWER CONNECTORS 3 − OXYGEN SYSTEM 4 − LOW PRESSURE AIR PRE−CONDITIONING 5 − HIGH PRESSURE AIR PRE−CONDITIONING 6 − YELLOW HYDRAULIC−SYSTEM SERVICE PANEL 7 − ENGINE OIL SERVICING 8 − STARTER OIL SERVICING 9 − VFG OIL SERVICING 10 − REFUEL/DEFUEL COUPLINGS (OPTIONAL−LH WING) 11 − OVERPRESSURE PROTECTOR 12 − NACA FLAME ARRESTOR 13 − MLG GROUNDING (EARTHING) POINT 14 − GREEN HYDRAULIC−SYSTEM SERVICE PANEL 15 − REFUEL/DEFUEL CONTROL PANEL 16 − POTABLE WATER SERVICING PANEL 17 − WASTE WATER SERVICING PANEL 18 − APU OIL SERVICING P_AC_050400_1_0010001_01_02 Ground Service Connections Layout FIGURE-5-4-0-991-001-A01 5-4-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-4-1 Grounding (Earthing) Points **ON A/C A350-900 Grounding (Earthing) Points 1. Grounding (Earthing) Point Locations AFT OF NOSE On Nose Landing Gear leg On left Main Landing Gear leg On right Main Landing Gear leg 4.42 m (14.5 ft.) 32.95 m (108.1 ft.) 32.95 m (108.1 ft.) DISTANCE FROM AIRCRAFT CENTERLINE LH SIDE RH SIDE 0.07 m (0.23 ft.) 5.59 m (18.34 ft.) 5.59 m (18.34 ft.) MEAN HEIGHT FROM GROUND 1.06 m (3.48 ft.) 1.55 m (5.09 ft.) 1.55 m (5.09 ft.) A. The grounding (earthing) stud on each landing gear leg is designed for use with a clip-on connector (such as an Appleton TGR). B. The grounding (earthing) studs are used to connect the aircraft to an approved ground (earth) connection on the ramp or in the hangar for: - Refuel/defuel operations - Maintenance operations - Bad weather conditions. NOTE : In all other conditions, the electrostatic discharge through the tire is sufficient. 5-4-1 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A B A C GROUNDING (EARTHING) POINT B C P_AC_050401_1_0010001_01_00 Grounding (Earthing) Point - NLG FIGURE-5-4-1-991-001-A01 5-4-1 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 B A A A C LH SHOWN RH SYMMETRICAL GROUNDING (EARTHING) POINT B C P_AC_050401_1_0020001_01_00 Grounding (Earthing) Point - MLG FIGURE-5-4-1-991-002-A01 5-4-1 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-4-2 Hydraulic System **ON A/C A350-900 Hydraulic System 1. Hydraulic System The nominal operating pressure is 5000 psi (345 bar). A. Access ACCESS Green Hydraulic System: Access Door 197LB Yellow Hydraulic System: Access Door 194KB 2. AFT OF NOSE 36.37 m (119.32 ft.) DISTANCE FROM AIRCRAFT CENTERLINE LH SIDE RH SIDE 0.61 m (2.0 ft.) 30.35 m (99.57 ft.) MEAN HEIGHT FROM GROUND 2.39 m (7.84 ft.) 1.51 m (4.95 ft.) B. Reservoir Pressurization - One 1/4 in. ISO 4570 connector. C. Reservoir Filling Centralized filling capability is on the Green ground service panel. Filling: Ground pressurized supply or hand pump. D. Ground Test On each ground service panel: - One self-sealing connector (suction) - One self-sealing connector (delivery). 2.24 m (7.35 ft.) Technical Specifications A. The hydraulic ground equipment must be able to start with the aircraft hydraulic circuit not pressurized. B. The hydraulic ground equipment must be able to permanently operate with the aircraft reservoir pressures varying between 2.0 bar and 5.0 bar (29.0 psi and 72.51 psi). C. After ground equipment shutdown, no further fluid exchange must occur between the aircraft reservoir and the ground equipment. 5-4-2 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 Z190 A 197LB GROUND TEST PRESSURE CONNECTION GROUND TEST SUCTION CONNECTION GROUND SUPPLY A P_AC_050402_1_0010001_01_01 Green Ground Service Panel FIGURE-5-4-2-991-001-A01 5-4-2 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A Z190 194KB GROUND TEST PRESSURE CONNECTION GROUND TEST SUCTION CONNECTION A P_AC_050402_1_0020001_01_01 Yellow Ground Service Panel FIGURE-5-4-2-991-002-A01 5-4-2 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-4-3 Electrical System **ON A/C A350-900 Electrical System 1. A/C External Power ACCESS AFT OF NOSE DISTANCE FROM AIRCRAFT CENTERLINE LH SIDE RH SIDE A/C External 6.63 m Power: (21.75 ft.) Access Door 122AR 2. 3. 0.91 m (2.99 ft.) MEAN HEIGHT FROM GROUND 2.58 m (8.46 ft.) Technical Specifications A. External Power Receptacle: - Two standard ISO 461 Style3 -- 90 kVA each. B. Power Supply: - Three-phase, 115 V, 400 Hz. C. Electrical Connectors for Servicing: - AC outlets: HUBBELL 5258 - DC outlets: HUBBELL 7472. A/C Emergency Generation ACCESS RAT Safety-Pin Installation: Access Panel 198VR AFT OF NOSE 39.48 m (129.53 ft.) DISTANCE FROM AIRCRAFT CENTERLINE LH SIDE RH SIDE 2.50 m (8.2 ft.) 5-4-3 MEAN HEIGHT FROM GROUND 2.91 m (9.55 ft.) Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 122AR A ELECTRICAL POWER RECEPTACLES 925VU A FWD P_AC_050403_1_0010001_01_01 Electrical Service Panel FIGURE-5-4-3-991-001-A01 5-4-3 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 198VR A 198QR B 198PR SAFETY PIN Z190 A RAT RETRACTED B RAT EXTENDED P_AC_050403_1_0030001_01_01 RAT FIGURE-5-4-3-991-003-A01 5-4-3 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-4-4 Oxygen System **ON A/C A350-900 Oxygen System 1. General The crew oxygen system has two isolated subsystems: - The left-hand side oxygen subsystem supplies oxygen to the captain and one observer. - The right-hand side oxygen subsystem supplies oxygen to the F/O and one observer. Each subsystem has a compartment with a HP gaseous cylinder assembly (one more cylinder assembly for each oxygen compartment is optional). 2. Access Get access to the forward lower-deck cargo-compartment. The access panel to the crew oxygen servicing point is located on the rear triangular area of the FWD cargo door. 3. Technical Specifications - One 3/8 in. MIL-DTL 7891 standard service connection. 5-4-4 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 FR20 A FR30 B Z130 FR29 A FR28 CREW OXYGEN FILLING PORT CREW OXYGEN FILLING GAGE B P_AC_050404_1_0010001_01_00 Oxygen System FIGURE-5-4-4-991-001-A01 5-4-4 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 FR32 FR33 FR20 C FR21 A B Z130 A OXYGEN COMPARTMENT−CAPT B OXYGEN COMPARTMENT−F/O C P_AC_050404_1_0020001_01_00 Crew Oxygen Storage - Location FIGURE-5-4-4-991-002-A01 5-4-4 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-4-5 Fuel System **ON A/C A350-900 Fuel System 1. Refuel/Defuel Control Panel ACCESS AFT OF NOSE Refuel/Defuel 36.2 m Control Panel: (118.77 ft.) Access Door 197KB 2. DISTANCE FROM AIRCRAFT CENTERLINE LH SIDE RH SIDE MEAN HEIGHT FROM GROUND 2.18 m (7.15 ft.) On centerline Refuel/Defuel Connectors ACCESS AFT OF NOSE Refuel/Defuel Coupling, Left (Optional): Access Door 523EB Refuel/Defuel Coupling, Right: Access Door 623EB A. DISTANCE FROM AIRCRAFT CENTERLINE LH SIDE RH SIDE MEAN HEIGHT FROM GROUND 32.57 m (106.86 ft.) 15.83 m (51.94 ft.) - 5.5 m (18.04 ft.) 32.57 m (106.86 ft.) - 15.83 m (51.94 ft.) 5.5 m (18.04 ft.) Refuel/defuel couplings: (1) Two standard ISO 45, 2.5 in. on right wing. (2) Two standard ISO 45, 2.5 in. on left wing (optional). B. Refuel pressure: (1) Max. pressure: 3.45 bar (50 psi). 3. Overpressure Protector and NACA Intake for Vent Tank ACCESS Overpressure Protector NACA Intake for Vent Tank AFT OF NOSE 38.24 m (125.46 ft.) 38.69 m (126.94 ft.) FROM AIRCRAFT CENTERLINE LH SIDE RH SIDE 22.33 m 22.33 m (73.26 ft.) (73.26 ft.) 23.07 m 23.07 m (75.69 ft.) (75.69 ft.) 5-4-5 MEAN HEIGHT FROM GROUND 6.13 m (20.11 ft.) 6.19 m (20.31 ft.) Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 Z190 197KB A TYPICAL LAYOUT 11QU A P_AC_050405_1_0010001_01_01 Refuel/Defuel Control Panel FIGURE-5-4-5-991-001-A01 5-4-5 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 01 A 523EB 623EB Z500 Z600 RIB16 RIB15 REFUEL/DEFUEL COUPLING A NOTE: 01 LH OPTIONAL RH SHOWN LH SYMMETRICAL P_AC_050405_1_0020002_01_01 Refuel/Defuel Couplings FIGURE-5-4-5-991-002-B01 5-4-5 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A 543DB (643DB) 543CB (643CB) RIB27 Z500 (Z600) RIB25 NACA INTAKE NACA DUCT PANEL TANK OVERPRESSURE DISC OVERPRESSURE PANEL A LH SHOWN RH SYMMETRICAL P_AC_050405_1_0030001_01_01 Overpressure Protectors and NACA Vent Intake FIGURE-5-4-5-991-003-A01 5-4-5 Page 4 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-4-6 Pneumatic System **ON A/C A350-900 Pneumatic System 1. Low Pressure Connectors ACCESS AFT OF NOSE Low Pressure 23.58 m Connector: (77.36 ft.) Access Door 193CB Low Pressure 23.58 m Connector: (77.36 ft.) Access Door 194CR A. 2. DISTANCE FROM AIRCRAFT CENTERLINE LH SIDE RH SIDE MEAN HEIGHT FROM GROUND - 1.05 m (3.44 ft.) 2.59 m (8.5 ft.) - 1.87 m (6.14 ft.) 2.87 m (9.42 ft.) Connectors : Two standard SAE AS4262 type B, 8 in. High Pressure Connectors ACCESS AFT OF NOSE High Pressure 26.81 m Connectors: (87.96 ft.) Access Door 193KB A. DISTANCE FROM AIRCRAFT CENTERLINE LH SIDE RH SIDE MEAN HEIGHT FROM GROUND 2.06 m (6.76 ft.) On centerline Connectors: Two standard ISO 2026, 3 in. 5-4-6 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 194CR A 193CB Z190 LP CONNECTOR A P_AC_050406_1_0010001_01_01 Low Pressure Ground Connectors FIGURE-5-4-6-991-001-A01 5-4-6 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 193KB Z190 A HP CONNECTOR A P_AC_050406_1_0020001_01_01 High Pressure Ground Connectors FIGURE-5-4-6-991-002-A01 5-4-6 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-4-7 Oil System **ON A/C A350-900 Engine Oil Servicing 1. Engine Oil Servicing ACCESS AFT OF NOSE 24.7 m Engine 1: Access Door 415BR (81.04 ft.) 24.7 m Engine 2: Access Door 425BR (81.04 ft.) DISTANCE FROM AIRCRAFT CENTERLINE LH SIDE RH SIDE 8.6 m (28.22 ft.) 12.29 m (40.32 ft.) 5-4-7 MEAN HEIGHT FROM GROUND 3.23 m (10.6 ft.) 3.23 m (10.6 ft.) Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 415BR (ENGINE 1) 425BR (ENGINE 2) A OIL TANK OIL LEVEL SIGHT GLASS OIL FILLER CAP A TYPICAL P_AC_050407_1_0040001_01_00 Engine Oil Servicing FIGURE-5-4-7-991-004-A01 5-4-7 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 VFG Oil Servicing 1. VFG Oil Servicing ACCESS Engine 1: Fan Cowl 415AL Engine 2: Fan Cowl 425AL AFT OF NOSE 24.3 m (79.72 ft.) 24.3 m (79.72 ft.) DISTANCE FROM AIRCRAFT CENTERLINE LH SIDE RH SIDE 11.02 m (36.15 ft.) 9.86 m (32.35 ft.) 5-4-7 MEAN HEIGHT FROM GROUND 1.22 m (4.0 ft.) 1.22 m (4.0 ft.) Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 B B A A DISCONNECT RESET HANDLE PRESSURE FILL C DRAIN FILTER BOWL SIGHT GLASS OVERFLOW/STANDPIPE B C TYPICAL P_AC_050407_1_0090001_01_00 VFG Oil Servicing FIGURE-5-4-7-991-009-A01 5-4-7 Page 4 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 Starter Oil Servicing 1. Starter Oil Servicing ACCESS Engine 1: Fan Cowl 415AL Engine 2: Fan Cowl 425AL AFT OF NOSE 24.6 m (80.71 ft.) 24.6 m (80.71 ft.) DISTANCE FROM AIRCRAFT CENTERLINE LH SIDE RH SIDE 10.57 m (34.68 ft.) 10.31 m (33.83 ft.) 5-4-7 MEAN HEIGHT FROM GROUND 1.08 m (3.54 ft.) 1.08 m (3.54 ft.) Page 5 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A PRESSURE FILL PORT PRESSURE SPILL PORT OIL DRAIN PLUG/ MAGNETIC CHIP DETECTOR A P_AC_050407_1_0100001_01_00 Starter Oil Servicing FIGURE-5-4-7-991-010-A01 5-4-7 Page 6 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 APU Oil Servicing 1. APU Oil Servicing ACCESS AFT OF NOSE 62.52 m APU: Access Door 316BR (205.12 ft.) - DISTANCE FROM AIRCRAFT CENTERLINE LH SIDE RH SIDE 0.48 m (1.57 ft.) 5-4-7 MEAN HEIGHT FROM GROUND 6.45 m (21.16 ft.) Page 7 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A Z310 B 316BR FR104 A FILL CAP PRESSURE OVERFILL PORT C SIGHT GLASS PRESSURE FILL PORT B C FWD P_AC_050407_1_0110001_01_00 APU Oil Servicing FIGURE-5-4-7-991-011-A01 5-4-7 Page 8 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-4-8 Potable Water System **ON A/C A350-900 Potable Water System 1. Potable Water System ACCESS AFT OF NOSE Potable-Water 50.2 m Ground Service (164.7 ft.) Panel: Access Door 164AR 2. DISTANCE FROM AIRCRAFT CENTERLINE LH SIDE RH SIDE - 1.6 m (5.25 ft.) MEAN HEIGHT FROM GROUND 3.3 m (10.83 ft.) Technical Specifications A. Connectors: (1) Fill/drain nipple 3/4 in. (ISO 17775). B. Capacity: (1) Standard configuration - two tanks (530 l (140 USgal) each): 1060 l (280 USgal). (2) Optional - two tanks (750 l (198 USgal) each): 1500 l (396 USgal). C. Filling pressure: (1) Max filling pressure: 8.6 bar (125 psi). 5-4-8 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 Z160 FR71 A 164AR FR84 FR85 FR86 POTABLE WATER INDICATION PANEL FILL STOP OVERFLOW NIPPLE DRAIN A FILL/DRAIN PORT FWD P_AC_050408_1_0050001_01_00 Potable-Water Ground Service Panel FIGURE-5-4-8-991-005-A01 5-4-8 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A Z120 FR12 FR13 DRAIN PORT A P_AC_050408_1_0060002_01_00 Forward Drain Port FIGURE-5-4-8-991-006-B01 5-4-8 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A Z170 POTABLE WATER TANKS FR93 FR89 FR86 A P_AC_050408_1_0070001_01_00 Potable-Water Tanks Location FIGURE-5-4-8-991-007-A01 5-4-8 Page 4 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-4-9 Waste Water System **ON A/C A350-900 Waste Water System 1. Waste Water System ACCESS AFT OF NOSE Waste-Water 52.21 m Ground Service (171.29 ft.) Panel: Access Door 171AL 2. DISTANCE FROM AIRCRAFT CENTERLINE LH SIDE RH SIDE MEAN HEIGHT FROM GROUND 3.69 m (12.11 ft.) On centerline Technical Specifications A. Connectors: (1) Draining - 4 in. (ISO 17775). (2) Flushing and Filling - 1 in. (ISO 17775). B. Usable waste tank capacity: (1) Two tanks (595 l (157 USgal) each): 1190 l (314 USgal). C. Waste tank - Rinsing: (1) Operating pressure: 3.45 bar (50 psi). D. Waste tank - Precharge: (1) Precharge per tank (two tanks): 23 l (6 USgal). 5-4-9 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 WASTE DRAIN CONNECTION FILL AND RINSE CONNECTION CONTROL LEVER P_AC_050409_1_0010001_01_00 Waste-Water Ground Service Panel FIGURE-5-4-9-991-001-A01 5-4-9 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A Z170 FR93 FR89 FR86 WASTE TANK A P_AC_050409_1_0020001_01_00 Waste Tanks Location FIGURE-5-4-9-991-002-A01 5-4-9 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-4-10 Cargo Control Panels **ON A/C A350-900 Cargo Control Panels 1. Cargo Control Panels DISTANCE ACCESS FWD Cargo Door Control Panel: Access Door 132AR FWD CLS* Panel: Access Door 132BR AFT Cargo Door Control Panel: Access Door 152AR AFT CLS* Panel: Access Door 152BR AFT OF NOSE FROM AIRCRAFT CENTERLINE LH SIDE RH SIDE MEAN HEIGHT FROM GROUND 9.59 m (31.46 ft.) 2.48 m (8.14 ft.) 3.87 m (12.7 ft.) 9.59 m (31.46 ft.) 2.77 m (9.09 ft.) 4.50 m (14.76 ft.) 45.18 m (148.23 ft.) 2.46 m (8.07 ft.) 3.80 m (12.47 ft.) 45.37 m (148.85 ft.) 2.84 m (9.32 ft.) 4.71 m (15.45 ft.) NOTE : * CLS - CARGO LOADING SYSTEMS 5-4-10 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 A FR22 FR21 Z130 B C FWD CARGO DOOR PWR ON/OFF SWITCH SYST ON LAMP 132BR A 132AR INDICATOR LIGHT "CARGO DOOR FULLY OPEN AND ARRESTED" TOGGLE SWITCH OPEN OR CLOSE CARGO DOOR JOYSTICK B 01 MANUAL OPERATING DEVICE FWD C NOTE: 01 OUTSIDE CARGO LOADING SYSTEM CONTROL PANEL 02 02 FWD CARGO DOOR CONTROL PANEL P_AC_050410_1_0030001_01_00 Forward Cargo Control Panels FIGURE-5-4-10-991-003-A01 5-4-10 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 FR77 FR76 A AFT CARGO DOOR B Z150 PWR ON/OFF SWITCH SYST ON LAMP C A 152BR 152AR INDICATOR LIGHT "CARGO DOOR FULLY OPEN AND ARRESTED" TOGGLE SWITCH OPEN OR CLOSE CARGO DOOR JOYSTICK B 01 MANUAL OPERATING DEVICE FWD C NOTE: 01 OUTSIDE CARGO LOADING SYSTEM CONTROL PANEL 02 02 FWD CARGO DOOR CONTROL PANEL P_AC_050410_1_0040001_01_00 Aft Cargo Control Panels FIGURE-5-4-10-991-004-A01 5-4-10 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-5-0 Engine Starting Pneumatic Requirements **ON A/C A350-900 Engine Starting Pneumatic Requirements 1. The purpose of this section is to provide the minimum air data requirements at the aircraft connection, needed to start the engine within no more than 90 seconds, at sea level (0 feet), for a set of Outside Air Temperatures (OAT). ABBREVIATION A/C ASU HPGC OAT DEFINITION Aircraft Air Start Unit High Pressure Ground Connection Outside Air Temperature A. Air data (discharge temperature, absolute discharge pressure) are given at the HPGC. B. For the requirements below, the configuration with two HPGC is used. Using one connector only (for a given mass flow rate and discharge pressure from the ASU) will increase the pressure loss in the ducts of the bleed system and therefore lower the performances at the engine starter. C. For a given OAT the following charts are used to determine an acceptable combination for air data: discharge temperature, absolute discharge pressure and mass flow rate at the HPGC. D. This section is addressing requirements for the ASU only, and is not representative of the start performance of the aircraft using the APU or engine cross bleed procedure. E. To protect the A/C, the charts feature, if necessary: - The maximum discharge pressure at the HPGC - The maximum discharge temperature at the HPGC. 5-5-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 ROLLS ROYCE TRENT 1000/SEA LEVEL STARTING TIME: LESS THAN 90 s AIR DATA AT AIRCRAFT CONNECTION (TWO CONNECTORS) 180 390 170 AIRFLOW (kg/min) 350 150 330 140 310 130 290 120 270 110 250 230 100 ABSOLUTE PRESSURE (psia) 90 AIRFLOW (lb/min) 370 160 210 40 45 50 ABSOLUTE PRESSURE (psia) 55 55 50 45 ASU DISCHARGE TEMPERATURE: 70° C (158° F) 140° C (284° F) 260° C (500° F) MAX 40 35 −45 −35 −25 −15 −5 5 15 25 35 45 OUTSIDE AIR TEMPERATURE OAT (° C) 55 −40 −20 0 20 40 60 80 100 120 OUTSIDE AIR TEMPERATURE OAT (° F) EXAMPLE: FOR AN OAT OF 15° C (59° F) AND AN ASU PROVIDING A DISCHARGE TEMPERATURE OF 260° C (500° F) AT HPGC: − THE REQUIRED PRESSURE AT HPGC IS 41 psia − THE REQUIRED AIRFLOW AT HPGC IS 102 kg/min. NOTE: IN CASE THE ACTUAL DISCHARGE TEMPERATURE OF THE ASU DIFFERS SUBSTANTIALLY FROM THE ONES GIVEN IN THE CHARTS, A SIMPLE INTERPOLATION (LINEAR) IS SUFFICIENT TO DETERMINE THE REQUIRED AIR DATA. EXAMPLE: FOR AN OAT OF 15° C (59° F) AND AN ASU PROVIDING A DISCHARGE TEMPERATURE OF 200° C (392° F) AT HPGC, INTERPOLATING BETWEEN THE LINES 140° C (284° F) AND 260° C (500° F) RESULTS IN: − A REQUIRED PRESSURE AT HPGC OF 42.5 psia − A REQUIRED AIRFLOW AT HPGC OF 114 kg/min. P_AC_050500_1_0010001_01_00 Example for Use of the Charts FIGURE-5-5-0-991-001-A01 5-5-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 ROLLS ROYCE TRENT 1000/SEA LEVEL STARTING TIME: LESS THAN 90 s AIR DATA AT AIRCRAFT CONNECTION (TWO CONNECTORS) 180 390 170 AIRFLOW (kg/min) 350 150 330 140 310 130 290 120 270 110 250 230 100 90 AIRFLOW (lb/min) 370 160 210 45 40 50 55 ABSOLUTE PRESSURE (psia) ABSOLUTE PRESSURE (psia) 55 50 45 40 35 −45 −35 −25 −15 −5 5 15 25 35 45 55 OUTSIDE AIR TEMPERATURE OAT (° C) −40 −20 0 20 40 60 80 100 120 OUTSIDE AIR TEMPERATURE OAT (° F) ASU DISCHARGE TEMPERATURE: 70° C (158° F) 140° C (284° F) 260° C (500° F) MAX P_AC_050500_1_0020001_01_00 Engine Starting Pneumatic Requirements FIGURE-5-5-0-991-002-A01 5-5-0 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-6-0 Ground Pneumatic Power Requirements **ON A/C A350-900 Ground Pneumatic Power Requirements 1. General This section describes the required performance for the ground equipment to maintain the cabin temperature at 27 deg.C (80.6 deg.F) for the cooling or 21 deg.C (69.8 deg.F) for the heating cases after boarding (Section 5.7 - steady state), and provides the time needed to cool down or heat up the aircraft cabin to the required temperature (Section 5.6 - dynamic cases with aircraft empty). ABBREVIATION A/C AHM GC GSE IFE LP OAT PCA A. DEFINITION Aircraft Aircraft Handling Manual Ground Connection Ground Service Equipment In-Flight Entertainment Low Pressure Outside Air Temperature Pre-Conditioned Air The air flow rates and temperature requirements for the GSE, provided in Sections 5.6 and 5.7, are given at A/C ground connection. NOTE : The cooling capacity of the equipment (kW) is only indicative and is not sufficient by itself to ensure the performance (outlet temperature and flow rate combinations are the requirements needed for ground power). An example of cooling capacity calculation is given in Section 5.7. B. The air flow rates and temperature requirements for the GSE are given for the A/C in the configuration ”2 LP ducts connected”. NOTE : The maximum air flow is driven by Pressure limitation at ground connection. C. 2. For temperature at ground connection below 2 deg.C (35.6 deg.F) (Subfreezing), the ground equipment shall be compliant with the Airbus document ”Subfreezing PCA Carts -- Compliance Document for Suppliers” (contact Airbus to obtain this document) defining all the requirements with which Subfreezing Pre-Conditioning Air equipment must comply to allow its use on Airbus aircraft. These requirements are in addition to the functional specifications included in the IATA AHM997. Ground Pneumatic Power Requirements This section provides the ground pneumatic power requirements for: 5-6-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING - Heating (pull up) the cabin, initially at OAT, up to 21 deg.C (69.8 deg.F) (FIGURE 5-6-0-991-001-A --- Sheet 1). Cooling (pull down) the cabin, initially at OAT, down to 27 deg.C (80.6 deg.F) (FIGURE 5-6-0-991-001-A --- Sheet 2). 5-6-0 Page 2 Apr 01/15 AIR FLOW AT GC (kg/s) 2.5 2.7 2.9 3.1 3.3 3.5 3.7 3.9 4.1 4.3 4.5 5-6-0 35 40 45 50 55 TIME TO HEAT CABIN TO +21°C (+69.8°F) ON GROUND (min) 60 65 PU1 "ISA −38°C (−36.4°F )" PU2 "ISA −45°C (−49°F )" PU1: OAT ISA −38°C (−36.4°F); GC OUTLET +70°C (+158°F); A/C EMPTY; IFE OFF; NO SOLAR LOAD; LIGHTS ON; RECIRCULATION FANS ON PU2: OAT ISA −45°C (−49°F); GC OUTLET +70°C (+158°F); A/C EMPTY; IFE OFF; NO SOLAR LOAD; LIGHTS ON; RECIRCULATION FANS ON PULL UP CASES: 30 MAX AIR FLOW PULL UP PERFORMANCE (+70°C (+158°F) GC OUTLET) @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_050600_1_0010001_01_02 Ground Pneumatic Power Requirements Heating (Sheet 1 of 2) FIGURE-5-6-0-991-001-A01 Page 3 Apr 01/15 AIR FLOW AT GC (kg/s) 2.5 2.7 2.9 3.1 3.3 3.5 3.7 3.9 4.1 4.3 4.5 20 5-6-0 30 40 50 60 70 TIME TO COOL CABIN TO +27°C (+80.6°F) ON GROUND (min) PD1 "ISA +23°C (+73.4°F) / GC OUTLET +2°C (+35.6°F)" PD2 "ISA +23°C (+73.4°F) / GC OUTLET −10°C (+14°F)" PD3 "ISA +23°C (+73.4°F) / GC OUTLET −20°C (−4°F)" PD1: OAT ISA +23°C (+73.4°F); GC OUTLET + 2°C (+35.6°F); A/C EMPTY; IFE OFF; SOLAR LOAD; LIGHTS ON; RECIRCULATION FANS ON PD2: OAT ISA +23°C (+73.4°F); GC OUTLET −10°C (+14°F); A/C EMPTY; IFE OFF; SOLAR LOAD; LIGHTS ON; RECIRCULATION FANS ON PD3: OAT ISA +23°C (+73.4°F); GC OUTLET −20°C (−4°F); A/C EMPTY; IFE OFF; SOLAR LOAD; LIGHTS ON; RECIRCULATION FANS ON PULL DOWN CASES: 10 MAX AIR FLOW PULL DOWN PERFORMANCE 80 90 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_050600_1_0010001_02_01 Ground Pneumatic Power Requirements Cooling (Sheet 2 of 2) FIGURE-5-6-0-991-001-A01 Page 4 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-7-0 Preconditioned Airflow Requirements **ON A/C A350-900 Preconditioned Airflow Requirements 1. This section provides the necessary information for the design of a ground unit; it gives the air flow rate and temperature combinations needed to maintain the cabin temperature at 27 deg.C (80.6 deg.F). These settings are not intended to be used for operation (they don’t substitute to the settings given in the AMM): They are issued from theoretical simulations and give the picture of a real steady state. For the air conditioning operation, Airlines will refer to the AMM that details the procedure and the PCA settings to maintain the cabin temperature below 27 deg.C (80.6 deg.F) during boarding (therefore it is not a steady state). 5-7-0 Page 1 Apr 01/15 5-7-0 −10 C2 C1 −5 C3 0 5 10 MAX AIR FLOW 15 20 25 30 GC OUTLET TEMPERATURE (°C) 35 40 H1 45 H2 50 OAT ISA−38°C (−36.4°F); A/C EMPTY; IFE OFF; NO SOLAR LOAD; LIGHTS ON; RECIRCULATION FANS ON OAT ISA−45°C (−49°F); A/C EMPTY; IFE OFF; NO SOLAR LOAD; LIGHTS ON; RECIRCULATION FANS ON OAT ISA−55°C (−67°F); A/C EMPTY; IFE OFF; NO SOLAR LOAD; LIGHTS ON; RECIRCULATION FANS ON OAT ISA+30°C (86°F); 446 PASSENGERS AND CREW; IFE ON; LIGHTS ON; SOLAR LOAD; RECIRCULATION FANS ON OAT ISA+23°C (73.4°F); 446 PASSENGERS AND CREW; IFE ON; LIGHTS ON; SOLAR LOAD; RECIRCULATION FANS ON OAT ISA; 446 PASSENGERS AND CREW; IFE ON; LIGHTS ON; SOLAR LOAD; RECIRCULATION FANS ON 1,8 2,3 2,8 3,3 3,8 4,3 COOLING/HEATING PERFORMANCE EXAMPLE: COOLING CAPACITY CALCULATION: FOR THE CONDITIONS C3, THE COOLING CAPACITY OF 4.25 kg/s x 1kJ/(kg.°C) X (27−2) = 106 kW IS NEEDED TO MAINTAIN THE CABIN TEMPERATURE BELOW 27°C (86°F) (4.25 kg/s AT GC OUTLET OF 2°C (35.6°F)). AIRFLOW FROM GC (kg/s) 4,8 H3 55 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_050700_1_0010001_01_01 Preconditioned Airflow Requirements FIGURE-5-7-0-991-001-A01 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-8-0 Ground Towing Requirements **ON A/C A350-900 Ground Towing Requirements 1. This section provides information on aircraft towing. The A350 is designed with means for conventional or towbarless towing. Information/procedures can be found in chapter 9 of the Aircraft Maintenance Manual. Status on towbarless towing equipment qualification can be found in ISI 09.11.00001. It is possible to tow or push the aircraft, at maximum ramp weight with engines at zero or up to idle thrust, using a towbar attached to the NLG. One towbar fitting is installed at the front of the leg (optional towing fitting for towing from the rear of the NLG available). The main landing gears have attachment points for towing or debogging (for details, ARM 7). This section shows the chart to determine the drawbar pull and tow tractor mass requirements as a function of the following physical characteristics: - Aircraft weight, - Number of engines at idle, - Slope. 2. Towbar design guidelines The A350 towbar requirements are identical to the towbar requirements of the long range aircraft. - ISO 8267-1, ”Aircraft - Towbar Attachment Fitting - Interface Requirements - Part 1: Main Line Aircraft”, - ISO 9667, ”Aircraft Ground Support Equipment - Towbars”, - IATA Airport Handling Manual AHM 958, ”Functional Specification for an Aircraft Towbar”. A conventional type towbar is required which should be equipped with a damping system (to protect the NLG against jerks) and with towing shear pins: - A traction shear pin calibrated at 28 620 daN (64 340 lbf), - A torsion pin calibrated at 3 130 m.daN (27 7028 lbf.in). The towing head is designed according to ISO 8267--1, cat. III. 5-8-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 DRAWBAR PULL ( x 1000 kg ) 25 =0 .8 BREAKWAY RESISTANCE 4% # OF ENGINES ON FOR PB: 1 ENGINE THRUST 811 daN 17.0 15 D AR 280 2% SLOPE 1 ENGINE ON 250 255 230 205 .2 =0 180 155 W O SN 130 H WE 10 DR YC ON CR ETE TC ON CR ET E =0 .57 20 A/C WEIGHT ( x 1000 kg ) 5 ICE = 0.05 29.8 0 0 10 20 30 40 50 60 70 80 TOTAL TRACTION WHEEL LOAD ( x 1000 kg ) 0 1 2 No. OF ENGINES AT IDLE 0 0.5 1.0 1.5 2.0 SLOPE ( % ) EXAMPLE HOW TO DETERMINE THE MASS REQUIREMENT TO TOW A A350 AT 250 000 kg, AT 2% SLOPE, 1 ENGINE AT IDLE AND FOR WET TARMAC CONDITIONS: − − − − − − − ON THE RIGHT HAND SIDE OF THE GRAPH, CHOOSE THE RELEVANT AIRCRAFT WEIGHT (250 000 kg), FROM THIS POINT DRAW A PARALLEL LINE TO THE REQUIRED SLOPE PERCENTAGE (2%), FROM THIS POINT OBTAINED DRAW A STRAIGHT HORIZONTAL LINE UNTIL No. OF ENGINES AT IDLE = 2, FROM THIS POINT DRAW A PARALLEL LINE TO THE REQUESTED NUMBER OF ENGINES (1), FROM THIS POINT DRAW A STRAIGHT HORIZONTAL LINE TO THE DRAWBAR PULL AXIS, THE Y−COORDINATE OBTAINED IS THE NECESSARY DRAWBAR PULL FOR THE TRACTOR (17 000 kg), SEARCH THE INTERSECTION WITH THE "WET CONCRETE" LINE. THE OBTAINED X−COORDINATE IS THE RECOMMENDED MINIMUM TRACTOR WEIGHT (29 800 kg). P_AC_050800_1_0010001_01_00 Ground Towing Requirements FIGURE-5-8-0-991-001-A01 5-8-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 5-9-0 De-icing and External cleaning **ON A/C A350-900 De-icing and External cleaning 1. De-Icing and External Cleaning on Ground. The mobile equipment for aircraft de-icing and external cleaning must be capable of reaching heights up to approximately 17 m (56 ft.). 2. De-Icing Wing Top Surface (Both Sides) AIRCRAFT TYPE 354 m2 (3810 ft.2) A350--900 AIRCRAFT TYPE A350--900 Wingtip Devices HTP Top Surface (Both Inside and (Both Sides) (Outside Surfaces) (Both Sides) 25 m2 69 m2 (269 ft.2) (743 ft.2) Fuselage Top Surface (Top Third - 120? Arc) 357 m2 (3843 ft.2) VTP (Both Sides) 102 m2 (1098 ft.2) Nacelle and Pylon Total De-Iced Area (Top Third - 120? Arc) (All Engines) 56 m2 962 m2 (603 ft.2) (10355 ft.2) NOTE : Dimensions are approximate 3. External Cleaning Wing Top Surface (Both Sides) AIRCRAFT TYPE A350--900 354 m2 (3810 ft.2) AIRCRAFT TYPE A350--900 Wing Lower Wingtip Devices HTP Top Surface (Both Inside Surface (Including Flap and (Both Sides) Track Fairing) (Outside (Both Sides) Surfaces) (Both Sides) 384 m2 25 m2 69 m2 (4133 ft.2) (269 ft.2) (743 ft.2) VTP (Both Sides) 102 m2 (1098 ft.2) Fuselage and Belly Fairing 1073 m2 (11550 ft.2) HTP Lower Surface (Both Sides) 69 m2 (743 ft.2) Nacelle and Pylon Total Cleaned Area (All Engines) 166 m2 2242 m2 (1787 ft.2) (24133 ft.2) NOTE : Dimensions are approximate 5-9-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING OPERATING CONDITIONS 6-1-0 Engine Exhaust Velocities and Temperatures **ON A/C A350-900 Engine Exhaust Velocities and Temperatures 1. General This section provides the estimated engine exhaust-efflux velocity and temperature contours for Maximum Take-Off (MTO), Breakaway 11% MTO, Breakaway 22% MTO and Ground Idle conditions for the A350 engines. The contours are available for the Rolls-Royce Trent XWB-84 engine. The Maximum Take-Off data are presented at the maximum thrust rating. The Breakaway data are presented at a rating that corresponds to the minimum thrust level necessary to start the movement of the A350-900 at its maximum ramp weight, from a static position or when on an uphill surface with a slope of 1.5%. Breakaway thrust corresponds to 11% MTO when applied on both engines and 22% MTO when applied on a single engine (Idle thrust on the other engine). The Idle data are directly provided by the engine manufacturer. In the charts, the longitudinal distances are measured from the inboard engine core-nozzle exit section. The lateral distances are measured from the aircraft fuselage centerline. The estimated efflux data are shown at ISA +15K (+15˚C), Sea Level Static and no headwind conditions. The analysis assumes that the core and the bypass streams are fully mixed by the nozzle exit plane. The effects of on-wing installation or ground proximity are not taken into account and the ambient air is assumed to be still. The velocity contours are presented at 50 ft/s (15 m/s), 100 ft/s (30 m/s) and 150 ft/s (46 m/s). The temperature contours are shown at ambient temperature +10K (+10˚C), ambient temperature +20K (+20˚C) and ambient temperature +30K (+30˚C). In the case of the velocity contours for the Maximum Take-Off operating condition, there is some coalescence of the jet plumes from the port and starboard engines, hence the contours are presented with both a plan view and a side view for twin-engine operation. An axisymmetric view is also provided for this case, to be applied only for single engine operation. For the other figures, there is no interference between the two engine plumes in the operating conditions studied and hence the efflux can be adequately described by the axisymmetric contours of a single plume. 6-1-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 6-1-1 Engine Exhaust Velocities - Ground Idle Power **ON A/C A350-900 Engine Exhaust Velocities - Ground Idle Power 1. This section provides engine exhaust velocities at ground idle power. 6-1-1 Page 1 Apr 01/15 RADIAL CO−ORDINATE (ft) −100 −80 −60 −40 −20 0 20 40 0 6-1-1 40 60 80 100 120 AXIAL CO−ORDINATE (ft) 140 160 180 200 TRENT XWB 84000 lbf THRUST ENGINE − ESTIMATED EXHAUST EFFLUX VELOCITY CONTOURS AT GROUND IDLE AXISYMMETRIC VIEW 20 ICN−TRENTXWB−A−710000−R−K0680−02140−A−001−01 220 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_060101_1_0020001_01_00 Ground Idle Power - TRENT XWB Engine FIGURE-6-1-1-991-002-A01 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 6-1-2 Engine Exhaust Temperatures - Ground Idle Power **ON A/C A350-900 Engine Exhaust Temperatures - Ground Idle Power 1. This section provides engine exhaust temperatures at ground idle power. 6-1-2 Page 1 Apr 01/15 −40 0 40 6-1-2 20 40 60 100 120 AXIAL CO−ORDINATE (ft) 80 Tamb +10K 140 160 180 200 TRENT XWB 84000 lbf THRUST ENGINE − ESTIMATED EXHAUST EFFLUX TEMPERATURE CONTOURS AT GROUND IDLE SIDE VIEW 0 Tamb +30K Tamb +20K ICN−TRENTXWB−A−710000−R−K0680−02294−A−001−01 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_060102_1_0010001_01_00 Ground Idle Power - TRENT XWB-84 Engine (Sheet 1 of 2) FIGURE-6-1-2-991-001-A01 Page 2 Apr 01/15 VERTICAL CO−ORDINATE (ft) RADIAL CO−ORDINATE (ft) 6-1-2 0 20 40 80 100 AXIAL CO−ORDINATE (ft) 60 ICN−TRENTXWB−A−710000−R−K0680−02141−A−001−01 120 140 160 TRENT XWB 84000 lbf THRUST ENGINE − ESTIMATED EXHAUST EFFLUX TEMPERATURE CONTOURS AT GROUND IDLE AXISYMMETRIC VIEW −100 −80 −60 −40 −20 0 20 40 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_060102_1_0010001_02_00 Ground Idle Power - TRENT XWB-84 Engine (Sheet 2 of 2) FIGURE-6-1-2-991-001-A01 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 6-1-3 Engine Exhaust Velocities - Breakaway Power **ON A/C A350-900 Engine Exhaust Velocities - Breakaway Power 1. This section provides engine exhaust velocities at breakaway power. 6-1-3 Page 1 Apr 01/15 −100 −80 −60 −40 −20 0 20 40 6-1-3 20 40 60 50 ft/sec AXIAL CO−ORDINATE (ft) 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 100 ft/sec TRENT XWB 84000 lbf THRUST ENGINE − ESTIMATED EXHAUST EFFLUX VELOCITY CONTOURS AT 11% MTO THRUST AXISYMMETRIC VIEW 0 150 ft/sec ICN−TRENTXWB−A−710000−R−K0680−02138−A−001−01 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_060103_1_0010001_01_00 Breakaway Power (11% MTO Thrust) - TRENT XWB-84 Engine FIGURE-6-1-3-991-001-A01 Page 2 Apr 01/15 RADIAL CO−ORDINATE (ft) −100 −80 −60 −40 −20 0 20 40 0 200 100 ft/sec 300 AXIAL CO−ORDINATE (ft) 50 ft/sec 400 500 TRENT XWB 84000 lbf THRUST ENGINE − ESTIMATED EXHAUST EFFLUX VELOCITY CONTOURS AT 22% MTO THRUST AXISYMMETRIC VIEW 100 150 ft/sec ICN−TRENTXWB−A−710000−R−K0680−02136−A−001−01 600 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_060103_1_0020001_01_00 Breakaway Power (22% MTO Thrust) - TRENT XWB-84 Engine FIGURE-6-1-3-991-002-A01 6-1-3 Page 3 Apr 01/15 RADIAL CO−ORDINATE (ft) @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 6-1-4 Engine Exhaust Temperatures - Breakaway Power **ON A/C A350-900 Engine Exhaust Temperatures - Breakaway Power 1. This section provides engine exhaust temperatures at breakaway power. 6-1-4 Page 1 Apr 01/15 6-1-4 −40 0 40 20 40 60 100 120 AXIAL CO−ORDINATE (ft) 80 Tamb +10K 140 160 180 200 TRENT XWB 84000 lbf THRUST ENGINE − ESTIMATED EXHAUST EFFLUX TEMPERATURE CONTOURS AT 11% MTO THRUST SIDE VIEW 0 Tamb +30K Tamb +20K ICN−TRENTXWB−A−710000−R−K0680−02292−A−001−01 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_060104_1_0010001_01_00 Breakaway Power (11% MTO Thrust) - TRENT XWB-84 Engine (Sheet 1 of 2) FIGURE-6-1-4-991-001-A01 Page 2 Apr 01/15 VERTICAL CO−ORDINATE (ft) RADIAL CO−ORDINATE (ft) −100 −80 −60 −40 −20 0 20 40 6-1-4 20 40 60 100 120 AXIAL CO−ORDINATE (ft) 80 Tamb +10K 140 160 180 200 TRENT XWB 84000 lbf THRUST ENGINE − ESTIMATED EXHAUST EFFLUX TEMPERATURE CONTOURS AT 11% MTO THRUST AXISYMMETRIC VIEW 0 Tamb +30K Tamb +20K ICN−TRENTXWB−A−710000−R−K0680−02139−A−001−01 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_060104_1_0010001_02_00 Breakaway Power (11% MTO Thrust) - TRENT XWB-84 Engine (Sheet 2 of 2) FIGURE-6-1-4-991-001-A01 Page 3 Apr 01/15 −40 0 40 6-1-4 20 40 60 100 120 AXIAL CO−ORDINATE (ft) 80 Tamb +10K 140 160 180 200 TRENT XWB 84000 lbf THRUST ENGINE − ESTIMATED EXHAUST EFFLUX TEMPERATURE CONTOURS AT 22% MTO THRUST SIDE VIEW 0 Tamb +30K Tamb +20K ICN−TRENTXWB−A−710000−R−K0680−02290−A−001−01 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_060104_1_0020001_01_00 Breakaway Power (22% MTO Thrust) - TRENT XWB-84 Engine (Sheet 1 of 2) FIGURE-6-1-4-991-002-A01 Page 4 Apr 01/15 VERTICAL CO−ORDINATE (ft) RADIAL CO−ORDINATE (ft) −100 −80 −60 −40 −20 0 20 40 6-1-4 20 40 60 100 120 AXIAL CO−ORDINATE (ft) 80 Tamb +10K 140 160 180 200 TRENT XWB 84000 lbf THRUST ENGINE − ESTIMATED EXHAUST EFFLUX TEMPERATURE CONTOURS AT 22% MTO THRUST AXISYMMETRIC VIEW 0 Tamb +30K Tamb +20K ICN−TRENTXWB−A−710000−R−K0680−02137−A−001−01 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_060104_1_0020001_02_00 Breakaway Power (22% MTO Thrust) - TRENT XWB-84 Engine (Sheet 2 of 2) FIGURE-6-1-4-991-002-A01 Page 5 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 6-1-5 Engine Exhaust Velocities - Max Take-Off Power **ON A/C A350-900 Engine Exhaust Velocities - Max Take-Off Power 1. This section provides engine exhaust velocities at max take-off power. 6-1-5 Page 1 Apr 01/15 −100 0 100 0 400 100 ft/sec 800 AXIAL CO−ORDINATE (ft) 600 50 ft/sec 1000 1200 1400 TRENT XWB 84000 lbf THRUST ENGINE − ESTIMATED EXHAUST EFFLUX VELOCITY CONTOURS AT MTO AXISYMMETRIC VIEW FOR SINGLE ENGINE OPERATION 200 150 ft/sec ICN−TRENTXWB−A−710000−R−K0680−02134−A−001−01 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 RADIAL CO−ORDINATE (ft) P_AC_060105_1_0030001_01_00 Max Take-Off Power - TRENT XWB-84 Engine (Single) FIGURE-6-1-5-991-003-A01 6-1-5 Page 2 Apr 01/15 −40 0 40 0 400 100 ft/sec 800 AXIAL CO−ORDINATE (ft) 600 50 ft/sec 1000 1200 1400 TRENT XWB 84000 lbf THRUST ENGINE − ESTIMATED EXHAUST EFFLUX VELOCITY CONTOURS AT MTO SIDE VIEW FOR TWIN−ENGINE OPERATION 200 150 ft/sec ICN−TRENTXWB−A−710000−R−K0680−02133−A−001−01 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 6-1-5 VERTICAL CO−ORDINATE (ft) P_AC_060105_1_0040001_01_00 Max Take-Off Power - TRENT XWB-84 Engine (Twin) (Sheet 1 of 2) FIGURE-6-1-5-991-004-A01 Page 3 Apr 01/15 −100 0 100 0 400 800 AXIAL CO−ORDINATE (ft) 600 1000 1200 1400 TRENT XWB 84000 lbf THRUST ENGINE − ESTIMATED EXHAUST EFFLUX VELOCITY CONTOURS AT MTO PLAN VIEW FOR TWIN − ENGINE OPERATION 200 ICN−TRENTXWB−A−710000−R−K0680−02132−A−001−01 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 LATERAL CO−ORDINATE (ft) P_AC_060105_1_0040001_02_00 Max Take-Off Power - TRENT XWB-84 Engine (Twin) (Sheet 2 of 2) FIGURE-6-1-5-991-004-A01 6-1-5 Page 4 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 6-1-6 Engine Exhaust Temperatures - Max Take-Off Power **ON A/C A350-900 Engine Exhaust Temperatures - Max Take-Off Power 1. This section provides engine exhaust temperatures at max take-off power. 6-1-6 Page 1 Apr 01/15 −40 0 40 0 6-1-6 300 AXIAL CO−ORDINATE (ft) 200 Tamb +10K 400 TRENT XWB 84000 lbf THRUST ENGINE − ESTIMATED EXHAUST EFFLUX TEMPERATURE CONTOURS AT MTO SIDE VIEW 100 Tamb +30K Tamb +20K ICN−TRENTXWB−A−710000−R−K0680−02288−A−001−01 500 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 VERTICAL CO−ORDINATE (ft) P_AC_060106_1_0030001_01_00 Max Take-Off Power - TRENT XWB-84 Engine (Sheet 1 of 2) FIGURE-6-1-6-991-003-A01 Page 2 Apr 01/15 −100 −80 −60 −40 −20 0 20 40 0 6-1-6 300 AXIAL CO−ORDINATE (ft) 200 Tamb +10K 400 TRENT XWB 84000 lbf THRUST ENGINE − ESTIMATED EXHAUST EFFLUX TEMPERATURE CONTOURS AT MTO AXISYMMETRIC VIEW 100 Tamb +30K Tamb +20K ICN−TRENTXWB−A−710000−R−K0680−02135−A−001−01 500 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 RADIAL CO−ORDINATE (ft) P_AC_060106_1_0030001_02_00 Max Take-Off Power - TRENT XWB-84 Engine (Sheet 2 of 2) FIGURE-6-1-6-991-003-A01 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 6-3-1 Danger Areas of the Engines - Ground Idle Power **ON A/C A350-900 Danger Areas of the Engines - Ground Idle Power 1. This section provides danger areas of the engines at ground idle power conditions. 6-3-1 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 R 4.6 m (15 ft) 1.6 m (5 ft) 45° UPTO 67 m (220 ft) AFT OF EXHAUST NOZZLES 30° INTAKE SUCTION DANGER AREA ENTRY CORRIDOR EXHAUST DANGER AREA P_AC_060301_1_0010001_01_00 Ground Idle Power - TRENT XWB-84 Engine FIGURE-6-3-1-991-001-A01 6-3-1 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 6-3-3 Danger Areas of the Engines - Max Take-Off Power **ON A/C A350-900 Danger Areas of the Engines - Max Take-Off Power 1. This section provides danger areas of the engines at max take-off power conditions. 6-3-3 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 R 9.1 m (30 ft) UPTO 442 m (1 450 ft) AFT OF EXHAUST NOZZLES 30° INTAKE SUCTION DANGER AREA EXHAUST DANGER AREA P_AC_060303_1_0010001_01_00 Max Take-Off Power - TRENT XWB-84 Engine FIGURE-6-3-3-991-001-A01 6-3-3 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 6-4-0 APU Exhaust Velocities and Temperatures **ON A/C A350-900 APU Exhaust Velocities and Temperatures 1. This section gives APU exhaust velocities and temperatures. 6-4-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 [m] [ft] 40 15 m/s 10 46 m/s 30.5 m/s 61 m/s 30 20 FD 5 10 [m] [ft] 0 0 5 0 10 10 20 30 15 40 50 0 20 60 [m] [ft] 40 93°C 427°C FD 10 315.5°C 204°C 20 149°C 5 260°C [m] [ft] 10 0 0 0 5 10 10 20 30 30 15 40 50 0 20 60 P_AC_060400_1_0010001_01_00 APU Exhaust Velocities and Temperatures FIGURE-6-4-0-991-001-A01 6-4-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING PAVEMENT DATA 7-1-0 General Information **ON A/C A350-900 General Information 1. A brief description of the pavement charts that follow will help in airport planning. To aid in the interpolation between the discrete values shown, each aircraft configuration is shown with a minimum range of five loads on the MLG. All curves on the charts represent data at a constant specified tire pressure with: - The aircraft loaded to the maximum ramp weight (MRW), - The CG at its maximum permissible aft position. Pavement requirements for commercial aircraft are derived from the static analysis of loads imposed on the MLG struts. Landing Gear Footprint: Section 7-2-0 presents basic data on the landing gear footprint configuration, MRW and tire sizes and pressures. Maximum Pavement Loads: Section 7-3-0 shows maximum vertical and horizontal pavement loads for certain critical conditions at the tire-ground interfaces. Landing Gear Loading on Pavement: Section 7-4-0 contains charts to find these loads throughout the stability limits of the aircraft at rest on the pavement. These MLG loads are used as the point of entry to the pavement design charts which follow, interpolating load values where necessary. Flexible Pavement Requirements - US Army Corps of Engineers Design Method: Section 7-5-0 uses the procedures in Instruction Report No S-77-1 ”Procedures for Development of CBR Design Curves”, dated June 1977 and modified according to the methods described in ICAO Aerodrome Design Manual, Part 3. Pavements, 2nd Edition, 1983, Section 1.1 (The ACN-PCN Method), and utilizing the alpha factors approved by the ICAO in October 2007. The report was prepared by the ”U.S. Army Corps Engineers Waterways Experiment Station, Soils and Pavement Laboratory, Vicksburg, Mississippi”. The line showing 10 000 coverages is used to calculate Aircraft Classification Number (ACN). Flexible Pavement Requirements - LCN Conversion Method: 7-1-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING The Load Classification Number (LCN) curves are no longer provided in section 7-6-0 since the LCN system for reporting pavement strength is obsolete, having been replaced by the ICAO recommended ACN/PCN system in 1983. For questions regarding the LCN system, contact Airbus. Rigid Pavement Requirements - PCA (Portland Cement Association) Design Method: Section 7-7-0 gives the rigid pavement design curves that have been prepared with the use of the Westergaard Equation. This is in general accordance with the procedures outlined in the Portland Cement Association publications, ”Design of Concrete Airport Pavement”, 1973 and ”Computer Program for Airport Pavement Design”, (Program PDILB), 1967 both by Robert G. Packard. Rigid Pavement Requirements - LCN Conversion: The Load Classification Number (LCN) curves are no longer provided in section 7-8-0 since the LCN system for reporting pavement strength is obsolete, having been replaced by the ICAO recommended ACN/PCN system in 1983. For questions regarding the LCN system, contact Airbus. ACN/PCN Reporting System: Section 7-9-0 provides ACN data prepared according to the ACN/PCN system as referred to in ICAO Annex 14, ”Aerodromes”, Volume 1 ”Aerodrome Design and Operations” Fourth Edition July 2004, incorporating Amendments 1 to 6. The ACN/PCN system provides a standardized international aircraft / pavement rating system replacing the various S, T, TT, LCN, AUW, ISWL, etc., rating systems used throughout the world. ACN is the Aircraft Classification Number and PCN is the corresponding Pavement Classification Number. An aircraft with an ACN less than or equal to the PCN can operate without restriction on the pavement. Numerically, the ACN is two times the derived single wheel load expressed in thousands of kilograms. The derived single wheel load is defined as the load on a single tire inflated to 1.25 MPa (181 psi) that would have the same pavement requirements as the aircraft. Computationally, the ACN/PCN system uses the PCA program PDILB for rigid pavements and S-77-1 for flexible pavements to calculate ACN values. The Airport Authority must decide on the method of pavement analysis and the results of their evaluation shown as follows: PCN SUBGRADE TIRE PRESSURE EVALUATION PAVEMENT TYPE CATEGORY CATEGORY METHOD R - Rigid A - High W - No pressure limit T - Technical F - Flexible B - Medium X - High pressure limited U - Using Aircraft to 1.75 MPa (254 psi) 7-1-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING PCN PAVEMENT TYPE SUBGRADE CATEGORY C - Low D - Ultra Low TIRE PRESSURE CATEGORY Y - Medium pressure limited to 1.25 MPa (181 psi) Z - Low pressure limited to 0.5 MPa (73 psi) EVALUATION METHOD For flexible pavements, the four subgrade categories (CBR) are: - A. High Strength B. Medium Strength C. Low Strength D. Ultra Low Strength CBR CBR CBR CBR 15 10 6 3 For rigid pavements, the four subgrade categories (k) are: - A. High Strength B. Medium Strength C. Low Strength D. Ultra Low Strength k k k k = = = = 150 MN/m 3 (550 pci) 80 MN/m 3 (300 pci) 40 MN/m 3 (150 pci) 20 MN/m 3 (75 pci) 7-1-0 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 7-2-0 Landing Gear Footprint **ON A/C A350-900 Landing Gear Footprint 1. This section provides data about the landing gear footprint in relation with the aircraft MRW and tire sizes and pressures. The landing-gear footprint information is given for all the operational weight variants of the aircraft. 7-2-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 28.665 m (94.045 ft) 10.600 m (34.777 ft) 0.748 m (2.454 ft) 1.735 m (5.692 ft) 2.040 m (6.693 ft) WEIGHT VARIANT MAXIMUM RAMP WEIGHT A350−900 268 900 kg (592 825 lb) WV000 A350−900 275 900 kg (608 250 lb) WV001 A350−900 272 900 kg (601 650 lb) WV002 PERCENTAGE OF WEIGHT ON MAIN GEAR GROUP NOSE GEAR TIRE SIZE NOSE GEAR TIRE PRESSURE WING GEAR TIRE SIZE WING GEAR TIRE PRESSURE 93.7% 1050x395R16 28PR 12.2 bar (177 psi) 1400x530R23 42PR 16.6 bar (241 psi) 93.7% 1050x395R16 28PR 12.2 bar (177 psi) 1400x530R23 42PR 16.8 bar (244 psi) 94.8% 1050x395R16 28PR 12.2 bar (177 psi) 1400x530R23 42PR 16.6 bar (241 psi) P_AC_070200_1_0010001_01_02 Landing Gear Footprint FIGURE-7-2-0-991-001-A01 7-2-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 7-3-0 Maximum Pavement Loads **ON A/C A350-900 Maximum Pavement Loads 1. This section provides maximum vertical and horizontal pavement loads for some critical conditions at the tire-ground interfaces. The maximum pavement loads are given for all the operational weight variants of the aircraft. 7-3-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 H V V (MG) (NG) V (NG) MAXIMUM VERTICAL NOSE GEAR GROUND LOAD AT FORWARD CG V MAXIMUM VERTICAL MAIN GEAR GROUND LOAD AT AFT CG (MG) H 1 MAXIMUM HORIZONTAL GROUND LOAD FROM BRAKING 2 3 4 V (NG) MAXIMUM WEIGHT RAMP VARIANT WEIGHT STATIC LOAD AT FWD CG STATIC BRAKING AT 10 ft/s² DECELERATION 5 V (MG) (PER STRUT) STATIC LOAD AT AFT CG 6 H (PER STRUT) AT STEADY BRAKING INSTANTANEOUS AT 10 ft/s² BRAKING DECELERATION COEFFICIENT = 0.8 23.4 % A350−900 268 900 kg 23 450 kg MAC WV000 (592 825 lb) (51 700 lb) (b) 37 500 kg (82 675 lb) 125 960 kg 33 % MAC (277 700 lb) (a) 41 790 kg (c) (92 125 lb) 100 770 kg (c) (222 150 lb) 23.4 % A350−900 275 900 kg 23 450 kg MAC WV001 (608 250 lb) (51 700 lb) (b) 37 500 kg (82 675 lb) 129 330 kg 33.2 % 42 880 kg MAC (c) (285 125 lb) (a) (94 525 lb) 103 460 kg (c) (228 100 lb) % A350−900 272 900 kg 23 450 kg 23.4 MAC WV002 (601 650 lb) (51 700 lb) (b) 37 500 kg (82 675 lb) 129 310 kg 36.39 % 42 410 kg MAC (c) (285 075 lb) (a) (93 500 lb) 103 450 kg (c) (228 075 lb) NOTE: (a) LOADS CALCULATED USING AIRCRAFT AT MRW (b) LOADS CALCULATED USING AIRCRAFT AT 250 200 kg (551 600 lb) (c) BRAKED MAIN GEAR P_AC_070300_1_0010001_01_02 Maximum Pavement Loads FIGURE-7-3-0-991-001-A01 7-3-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 7-4-0 Landing Gear Loading on Pavement **ON A/C A350-900 Landing Gear Loading on Pavement 1. This section provides data about the landing gear loading on pavement. The MLG loading on pavement graphs are given for the weight variants that produce (at the MRW and maximum aft CG and standard tire pressure) the lowest ACN (and LCN) and the highest ACN (and LCN) for each type of aircraft. Example, see FIGURE 7-4-0-991-001-A, calculation of the total weight on the MLG for: - An aircraft with a MRW of 268 900 kg (592 825 lb), - The aircraft gross weight is 210 000 kg (462 975 lb), - A percentage of weight on the MLG of 93.68 % (percentage of weight on the MLG at MRW and maximum aft CG). The total weight on the MLG group is 196 730 kg (433 725 lb). NOTE : The CG in the figure title is the CG used for ACN/LCN calculation. 7-4-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 300 300 MTOW − 268 000 kg 290 25.46% MAC 280 270 260 260 250 250 240 240 230 230 MLW 210 200 200 190 190 180 180 170 170 160 160 450 400 350 150 MZFW TAKE OFF 140 500 220 210 150 550 (x 1 000 lb) 220 600 AIRCRAFT GROSS WEIGHT 270 (x 1 000 kg) 280 WEIGHT ON MAIN LANDING GEAR (x 1 000 kg) 650 CG FOR ACN/LCN CALCULATION 33% MAC 290 140 300 LANDING 130 130 120 120 84 86 88 90 92 94 96 98 PERCENTAGE OF WEIGHT ON MAIN GEAR 100 P_AC_070400_1_0010001_01_01 Landing Gear Loading on Pavement WV000, MRW 268 900 kg, CG 33% FIGURE-7-4-0-991-001-A01 7-4-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 300 300 MTOW − 275 000 kg 290 26.2% MAC 280 270 260 260 250 250 240 240 230 230 MLW 550 500 220 210 210 200 200 190 190 180 180 170 170 160 160 MZFW 150 450 (x 1 000 lb) 220 600 AIRCRAFT GROSS WEIGHT 270 (x 1 000 kg) 280 WEIGHT ON MAIN LANDING GEAR (x 1 000 kg) 650 CG FOR ACN/LCN CALCULATION 33.2% MAC 290 400 350 150 TAKE OFF 140 140 300 LANDING 130 130 120 120 84 86 88 90 92 94 96 98 PERCENTAGE OF WEIGHT ON MAIN GEAR 100 P_AC_070400_1_0020001_01_00 Landing Gear Loading on Pavement WV001, MRW 275 900 kg, CG 33.2% FIGURE-7-4-0-991-002-A01 7-4-0 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 7-5-0 Flexible Pavement Requirements - US Army Corps of Engineers Design Method **ON A/C A350-900 Flexible Pavement Requirements - US Army Corps of Engineers Design Method 1. This section provides data about the flexible pavement requirements. The MLG loading on pavement graphs are given for the weight variants that produce (at the MRW and maximum aft CG and standard tire pressure) the lowest ACN and the highest ACN for each type of aircraft. They are calculated with the US Army Corps of Engineers Design Method. To find a flexible pavement thickness, you must know the Subgrade Strength (CBR), the annual departure level and the weight on one MLG. The line that shows 10 000 coverages is used to calculate the Aircraft Classification Number (ACN). The procedure that follows is used to develop flexible pavement design curves: - With the scale for pavement thickness at the bottom and the scale for CBR at the top, a random line is made to show 10 000 coverages, - A plot is then made of the incremental values of the weight on the MLG, - Annual departure lines are made based on the load lines of the weight on the MLG that is shown on the graph. Example, see FIGURE 7-5-0-991-001-A, calculation of the thickness of the flexible pavement for: - An aircraft with a MRW of 268 900 kg (592 825 lb), - A ”CBR” value of 10, - An annual departure level of 3 000, - The load on one MLG of 110 000 kg (242 500 lb). The required flexible pavement thickness is 711 mm (28 in.). NOTE : The CG in the figure title is the CG used for ACN calculation. 7-5-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 SUBGRADE STRENGTH − CBR 3 6 10 15 20 30 40 60 80 WEIGHT ON ONE MAIN LANDING GEAR 125 960 kg (277 700 lb) 110 000 kg (242 500 lb) 100 000 kg (220 450 lb) 90 000 kg (198 425 lb) 80 000 kg (176 375 lb) MAXIMUM POSSIBLE MAIN GEAR LOAD AT MAXIMUM RAMP WEIGHT AND AFT CG 10 000 COVERAGES USED FOR ACN CALCULATIONS ALPHA FACTOR = 0.8 ANNUAL DEPARTURES* 1 200 3 000 6 000 15 000 25 000 *20 YEAR PAVEMENT LIFE 3 10 6 10 15 20 15 (in) 30 40 (cm) 20 30 60 80 40 60 80 100 120 150 180 FLEXIBLE PAVEMENT THICKNESS 1400x530R23 42PR TIRES TIRE PRESSURE CONSTANT AT 16.6 bar (241 psi) P_AC_070500_1_0010001_01_02 Flexible Pavement Requirements WV000, MRW 268 900 kg, CG 33% FIGURE-7-5-0-991-001-A01 7-5-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 SUBGRADE STRENGTH − CBR 3 6 10 15 20 30 40 60 80 WEIGHT ON ONE MAIN LANDING GEAR 129 330 kg (285 125 lb) 110 000 kg (242 500 lb) 100 000 kg (220 450 lb) 90 000 kg (198 425 lb) 80 000 kg (176 375 lb) MAXIMUM POSSIBLE MAIN GEAR LOAD AT MAXIMUM RAMP WEIGHT AND AFT CG 10 000 COVERAGES USED FOR ACN CALCULATIONS ALPHA FACTOR = 0.8 ANNUAL DEPARTURES* 1 200 3 000 6 000 15 000 25 000 *20 YEAR PAVEMENT LIFE 3 10 6 10 15 20 15 (in) 30 40 (cm) 20 30 60 80 40 60 80 100 120 150 180 FLEXIBLE PAVEMENT THICKNESS 1400x530R23 42PR TIRES TIRE PRESSURE CONSTANT AT 16.8 bar (244 psi) P_AC_070500_1_0020001_01_00 Flexible Pavement Requirements WV001, MRW 275 900 kg, CG 33.2% FIGURE-7-5-0-991-002-A01 7-5-0 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 7-6-0 Flexible Pavement Requirements - LCN Conversion **ON A/C A350-900 Flexible Pavement Requirements - LCN Conversion 1. The Load Classification Number (LCN) curves are no longer provided in section 7-6-0 since the LCN system for reporting pavement strength is obsolete, having been replaced by the ICAO recommended ACN/PCN system in 1983. For questions regarding the LCN system, contact Airbus. 7-6-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 7-7-0 Rigid Pavement Requirements - Portland Cement Association Design Method **ON A/C A350-900 Rigid Pavement Requirements - Portland Cement Association Design Method 1. This section provides data about the rigid pavement requirements for the PCA (Portland Cement Association) design method. The MLG loading on pavement graphs are given for the weight variants that produce (at the MRW and maximum aft CG and standards tire pressure) the lowest ACN and the highest ACN for each type of aircraft. They are calculated with the PCA design method. To find a rigid pavement thickness, you must know the Subgrade Modulus (k), the permitted working stress and the weight on one MLG. The procedure that follows is used to develop rigid pavement design curves: - With the scale for pavement thickness on the left and the scale for permitted working stress on the right, a random load line is made. This represents the MLG maximum weight to be shown, - A plot is then made of all values of the subgrade modulus (k values), - More load lines for the incremental values of weight on the MLG are made based on the curve for k = 80 MN/m3 , already shown on the graph. Example, see FIGURE 7-7-0-991-001-A, calculation of the thickness of the rigid pavement for: - An aircraft with a MRW of 268 900 kg (592 825 lb), - A k value of 80 MN/m3 (300 lbf/in3), - A permitted working stress of 35.15 kg/cm2 (500 lb/in2), - The load on one MLG of 110 000 kg (242 500 lb). The required rigid pavement thickness is 290 mm (11 in.). NOTE : The CG in the figure title is the CG used for ACN calculation. 7-7-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 1400x530R23 42PR TIRES TIRE PRESSURE CONSTANT AT 16.6 bar (241 psi) 1000 15 38 70 MAXIMUM POSSIBLE MAIN GEAR LOAD AT MAXIMUM RAMP WEIGHT AND AFT CG 36 14 k = 20 MN/m³ 65 900 k = 40 MN/m³ 34 60 k = 80 MN/m³ 13 k = 150 MN/m³ 800 55 50 700 30 28 26 11 600 10 500 9 400 24 18 40 35 30 22 20 (lb/in²) 45 (kg/cm²) ALLOWABLE WORKING STRESS 12 (in) RIGID PAVEMENT THICKNESS (cm) 32 8 WEIGHT ON ONE MAIN LANDING GEAR 125 960 kg (277 700 lb) 110 000 kg (242 500 lb) 100 000 kg (220 450 lb) 90 000 kg (198 425 lb) 80 000 kg (176 375 lb) 7 25 300 200 20 15 NOTE: THE VALUES OBTAINED BY USING THE MAXIMUM LOAD REFERENCE LINE AND ANY VALUES FOR k ARE EXACT. FOR LOADS LESS THAN MAXIMUM, THE CURVES ARE EXACT FOR k = 80 MN/m³ BUT DEVIATE SLIGHTLY FOR ANY OTHER VALUES OF k. REFERENCE: "DESIGN OF CONCRETE AIRPORT PAVEMENTS" AND "COMPUTER PROGRAM FOR AIRPORT PAVEMENT DESIGN − PROGRAM PDILB" PORTLAND CEMENT ASSOCIATION. P_AC_070700_1_0010001_01_01 Rigid Pavement Requirements WV000, MRW 268 900 kg, CG 33% FIGURE-7-7-0-991-001-A01 7-7-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 1400x530R23 42PR TIRES TIRE PRESSURE CONSTANT AT 16.8 bar (244 psi) 1000 15 38 70 MAXIMUM POSSIBLE MAIN GEAR LOAD AT MAXIMUM RAMP WEIGHT AND AFT CG 36 14 k = 20 MN/m³ 65 900 k = 40 MN/m³ 34 60 k = 80 MN/m³ 13 k = 150 MN/m³ 800 55 50 700 30 28 26 11 600 10 500 9 400 24 18 40 35 30 22 20 (lb/in²) 45 (kg/cm²) ALLOWABLE WORKING STRESS 12 (in) RIGID PAVEMENT THICKNESS (cm) 32 8 WEIGHT ON ONE MAIN LANDING GEAR 129 310 kg (285 075 lb) 110 000 kg (242 500 lb) 100 000 kg (220 450 lb) 90 000 kg (198 425 lb) 80 000 kg (176 375 lb) 7 25 300 200 20 15 NOTE: THE VALUES OBTAINED BY USING THE MAXIMUM LOAD REFERENCE LINE AND ANY VALUES FOR k ARE EXACT. FOR LOADS LESS THAN MAXIMUM, THE CURVES ARE EXACT FOR k = 80 MN/m³ BUT DEVIATE SLIGHTLY FOR ANY OTHER VALUES OF k. REFERENCE: "DESIGN OF CONCRETE AIRPORT PAVEMENTS" AND "COMPUTER PROGRAM FOR AIRPORT PAVEMENT DESIGN − PROGRAM PDILB" PORTLAND CEMENT ASSOCIATION. P_AC_070700_1_0020001_01_00 Rigid Pavement Requirements WV001, MRW 275 900 kg, CG 33.2% FIGURE-7-7-0-991-002-A01 7-7-0 Page 3 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 7-8-0 Rigid Pavement Requirements - LCN Conversion **ON A/C A350-900 Rigid Pavement Requirements - LCN Conversion 1. The Load Classification Number (LCN) curves are no longer provided in section 7-8-0 since the LCN system for reporting pavement strength is obsolete, having been replaced by the ICAO recommended ACN/PCN system in 1983. For questions regarding the LCN system, contact Airbus. 7-8-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING 7-9-0 ACN/PCN Reporting System - Flexible and Rigid Pavements **ON A/C A350-900 ACN/PCN Reporting System - Flexible and Rigid Pavements 1. This section provides data about the Aircraft Classification Number (ACN) for an aircraft gross weight in relation to a subgrade strength value for flexible and rigid pavement. The MLG loading on pavement graphs are given for the weight variants that produce (at the MRW and maximum aft CG and standard tire pressure) the lowest ACN and the highest ACN for each type of aircraft. To find the ACN of an aircraft on flexible and rigid pavement, you must know the aircraft gross weight and the subgrade strength. NOTE : An aircraft with an ACN equal to or less than the reported PCN can operate on that pavement, subject to any limitation on the tire pressure (Ref: ICAO Aerodrome Design Manual Part 3 Chapter 1 Second Edition 1983). For example, see FIGURE 7-9-0-991-001-A (sheet 1), calculation of the ACN for flexible pavement for: - An aircraft with a MRW of 268 900 kg (592 825 lb) - An aircraft gross weight of 210 000 kg (462 975 lb) - A medium subgrade strength (code B). The ACN for flexible pavement is 51. For example, see FIGURE 7-9-0-991-001-A (sheet 2), calculation of the ACN for rigid pavement for: - An aircraft with a MRW of 268 900 kg (592 825 lb) - An aircraft gross weight of 210 000 kg (462 975 lb) - A medium subgrade strength (code B). The ACN for rigid pavement is 52. 2. Aircraft Classification Number - ACN Table The table (FIGURE 7-9-0-991-003-A) provides ACN data in tabular format similar to the one used by ICAO in the ”Aerodrome Design Manual Part 3, Pavements - Edition 1983” for all the operational weight variants of the aircraft. As an approximation, use a linear interpolation in order to get the ACN at the required operating weight using the following equation: - ACN = ACN min + (ACN max -- ACN min) x (Operating Weight - 142 000 kg)/(MRW - 142 000 kg) As an approximation, also use a linear interpolation in order to get the aircraft weight at the pavement PCN using the following equation: - Operating Weight = 142 000 kg + (MRW -- 142 000 kg) x (PCN -- ACN min)/(ACN max -ACN min) With ACN max: ACN calculated at the MRW in the table and with ACN min: ACN calculated at 142 000 kg. NOTE : The CG in the figure title is the CG used for ACN calculation. 7-9-0 Page 1 Apr 01/15 7-9-0 20 120 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 SUBGRADE STRENGTH D − CBR 3 (ULTRA LOW) C − CBR 6 (LOW) B − CBR 10 (MEDIUM) A − CBR 15 (HIGH) ALPHA FACTOR = 0.8 300 190 200 (x 1 000 kg) (x 1 000 lb) 210 220 230 500 240 250 260 270 600 280 ACN WAS DETERMINED AS REFERENCED IN ICAO AERODROME DESIGN MANUAL PART 3 CHAPTER 1. SECOND EDITION 1983. AIRCRAFT GROSS WEIGHT 180 400 1400x530R23 42PR TIRES TIRE PRESSURE CONSTANT AT 16.6 bar (241 psi) @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 AIRCRAFT CLASSIFICATION NUMBER (ACN) P_AC_070900_1_0010001_01_01 ACN/PCN Reporting System - WV000, MRW 268 900 kg, CG 33% Flexible Pavement (Sheet 1 of 2) FIGURE-7-9-0-991-001-A01 Page 2 Apr 01/15 7-9-0 20 120 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 400 190 200 (x 1 000 kg) (x 1 000 lb) 210 220 230 500 240 250 260 270 600 280 ACN WAS DETERMINED AS REFERENCED IN ICAO AERODROME DESIGN MANUAL PART 3 CHAPTER 1. SECOND EDITION 1983. AIRCRAFT GROSS WEIGHT 180 SUBGRADE STRENGTH D − k = 20 MN/m³ (ULTRA LOW) C − k = 40 MN/m³ (LOW) B − k = 80 MN/m³ (MEDIUM) A − k = 150 MN/m³ (HIGH) 300 1400x530R23 42PR TIRES TIRE PRESSURE CONSTANT AT 16.6 bar (241 psi) @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 AIRCRAFT CLASSIFICATION NUMBER (ACN) P_AC_070900_1_0010001_02_00 ACN/PCN Reporting System - WV000, MRW 268 900 kg, CG 33% Rigid Pavement (Sheet 2 of 2) FIGURE-7-9-0-991-001-A01 Page 3 Apr 01/15 7-9-0 20 120 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 SUBGRADE STRENGTH D − CBR 3 (ULTRA LOW) C − CBR 6 (LOW) B − CBR 10 (MEDIUM) A − CBR 15 (HIGH) ALPHA FACTOR = 0.8 300 190 200 (x 1 000 kg) (x 1 000 lb) 210 220 230 500 240 250 260 270 600 280 ACN WAS DETERMINED AS REFERENCED IN ICAO AERODROME DESIGN MANUAL PART 3 CHAPTER 1. SECOND EDITION 1983. AIRCRAFT GROSS WEIGHT 180 400 1400x530R23 42PR TIRES TIRE PRESSURE CONSTANT AT 16.8 bar (244 psi) @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 AIRCRAFT CLASSIFICATION NUMBER (ACN) P_AC_070900_1_0020001_01_00 ACN/PCN Reporting System - WV001, MRW 275 900 kg, CG 33.2% Flexible Pavement (Sheet 1 of 2) FIGURE-7-9-0-991-002-A01 Page 4 Apr 01/15 7-9-0 20 120 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 400 190 200 (x 1 000 kg) (x 1 000 lb) 210 220 230 500 240 250 260 270 600 280 ACN WAS DETERMINED AS REFERENCED IN ICAO AERODROME DESIGN MANUAL PART 3 CHAPTER 1. SECOND EDITION 1983. AIRCRAFT GROSS WEIGHT 180 SUBGRADE STRENGTH D − k = 20 MN/m³ (ULTRA LOW) C − k = 40 MN/m³ (LOW) B − k = 80 MN/m³ (MEDIUM) A − k = 150 MN/m³ (HIGH) 300 1400x530R23 42PR TIRES TIRE PRESSURE CONSTANT AT 16.8 bar (244 psi) @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 AIRCRAFT CLASSIFICATION NUMBER (ACN) P_AC_070900_1_0020001_02_00 ACN/PCN Reporting System - WV001, MRW 275 900 kg, CG 33.2% Rigid Pavement (Sheet 2 of 2) FIGURE-7-9-0-991-002-A01 Page 5 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 ACN FOR ACN FOR LOAD RIGID PAVEMENT FLEXIBLE PAVEMENT ALL UP ON ONE TIRE SUBGRADES − MN/m³ SUBGRADES − CBR WEIGHT MASS MAIN PRESSURE VARIANT (kg) (MPa) GEAR HIGH MEDIUM LOW ULTRA−LOW HIGH MEDIUM LOW ULTRA−LOW LEG (%) 80 10 150 40 20 15 6 3 A350−900 WV000 A350−900 WV001 A350−900 WV002 268 900 46.8 142 000 275 900 46.9 272 900 142 000 70 82 95 65 69 79 109 32 33 36 41 31 32 34 41 65 73 85 98 68 72 82 113 32 33 36 41 31 32 34 41 65 73 85 98 67 72 82 113 33 33 36 41 31 32 34 42 1.68 142 000 47.4 63 1.66 1.66 P_AC_070900_1_0030001_01_00 ACN Table FIGURE-7-9-0-991-003-A01 7-9-0 Page 6 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING SCALED DRAWINGS 8-0-0 Scaled Drawings **ON A/C A350-900 Scaled Drawings 1. This section provides the scaled drawings. NOTE : When printing this drawing, make sure to adjust for proper scaling. 8-0-0 Page 1 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 0 0 10 4 20 FEET 30 40 8 12 METERS 50 16 60 20 0 0 10 4 20 FEET 30 40 8 12 METERS 50 16 60 20 NOTE: WHEN PRINTING THIS DRAWING, MAKE SURE TO ADJUST FOR PROPER SCALING P_AC_080000_1_0010001_01_00 Scaled Drawings FIGURE-8-0-0-991-001-A01 8-0-0 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING AIRCRAFT RESCUE AND FIRE FIGHTING 10-0-0 Aircraft Rescue and Fire Fighting **ON A/C A350-900 Aircraft Rescue and Fire Fighting 1. This sections provides data related to aircraft rescue and fire fighting. The figures contained in this section are the figures that are in the Aircraft Rescue and Fire Fighting Charts poster available for download on AIRBUSWorld and the Airbus website. 10-0-0 Page 1 Apr 01/15 10-0-0 REVISION DATE: APRIL 2015 REFERENCE : P_RF_000000_1_A350900 SHEET 1/2 AIRBUS S.A.S. 2012 . All rights reserved. AIRBUS S.A.S CUSTOMER SERVICES TECHNICAL DATA SUPPORT AND SERVICES 31707 BLAGNAC CEDEX FRANCE THIS CHART GIVES THE GENERAL LAYOUT OF THE A350−900 STANDARD VERSION. THE NUMBER AND ARRANGEMENT OF THE INDIVIDUAL ITEMS VARY WITH THE CUSTOMERS. FIGURES CONTAINED IN THIS POSTER ARE AVAILABLE SEPARATELY IN THE CHAPTER 10 OF THE "AIRCRAFT CHARACTERISTICS − AIRPORT AND MAINTENANCE PLANNING" DOCUMENT. @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_100000_1_0010001_01_03 Front Page FIGURE-10-0-0-991-001-A01 Page 2 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_100000_1_0030001_01_02 Highly Flammable and Hazardous Materials and Components FIGURE-10-0-0-991-003-A01 10-0-0 Page 3 Apr 01/15 10-0-0 EMERGENCY EXIT ACCESS DOOR NOTE: THE CREW REST COMPARTMENT INSTALLATION IS OPTIONAL AND RELATED TO AIRCRAFT CONFIGURATION. ACCESS DOOR EMERGENCY EXIT FLIGHT CREW REST COMPARTMENT CABIN CREW REST COMPARTMENT @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_100000_1_0040001_01_01 Crew Rest Compartments Location FIGURE-10-0-0-991-004-A01 Page 4 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_100000_1_0050001_01_00 Wheel/Brake Overheat Wheel Safety Area (Sheet 1 of 2) FIGURE-10-0-0-991-005-A01 10-0-0 Page 5 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_100000_1_0050001_02_00 Wheel/Brake Overheat Recommendations (Sheet 2 of 2) FIGURE-10-0-0-991-005-A01 10-0-0 Page 6 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING TITANIUM QUARTZ, GLASS CFRP SANDWICH CFRP MONOLITHIC COMPOSITE MATERIALS ALU ALLOY **ON A/C A350-900 P_AC_100000_1_0060001_01_00 Composite Materials Location FIGURE-10-0-0-991-006-A01 10-0-0 Page 7 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING NOSE LANDING GEAR MAIN LANDING GEAR TYPICAL INSTALLATION **ON A/C A350-900 P_AC_100000_1_0070001_01_00 Ground Lock Safety Devices FIGURE-10-0-0-991-007-A01 10-0-0 Page 8 Apr 01/15 10-0-0 COCKPIT ESCAPE ROPE GRID EQUALS 1 m (3.28 ft) IN REALITY CABIN SINGLE−LANE SLIDE/RAFT 10.25 m (33.63 ft) EMERGENCY DESCENT THROUGH THE ESCAPE HATCH WITH THE ESCAPE ROPE NOTE: − RH SHOWN, LH SYMMETRICAL. − DIMENSIONS ARE APPROXIMATE. 0 3 6 9 12 15 CABIN DUAL−LANE SLIDE/RAFT 9.38 m (30.77 ft) CABIN DUAL−LANE SLIDE/RAFT 9.43 m (30.94 ft) CABIN DUAL−LANE SLIDE/RAFT 9.35 m (30.68 ft) @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_100000_1_0080001_01_02 Emergency Evacuation Devices FIGURE-10-0-0-991-008-A01 Page 9 Apr 01/15 10-0-0 MECHANICAL DOOR−LOCKING INDICATORS TO OPEN: 1 − MAKE SURE THAT RESIDUAL CABIN−PRESSURE WARNING LIGHTS DOES NOT FLASH. 2 − PUSH FLAP TO GRASP HANDLE. 3 − LIFT HANDLE FULLY UP TO HORIZONTAL POSITION (GREEN LINE). 4 − PULL THE DOOR OUT AND MOVE IT FORWARD. OUTER HANDLE SLIDE ARMED WARNING−LIGHT AND BUZZER (SLIDE WILL BE DISARMED AUTOMATICALLY IF DOOR IS OPEN FROM OUTSIDE) RESIDUAL CABIN−PRESSURE WARNING−LIGHT PASSENGER/CREW DOORS AND EMERGENCY EXITS EXTERIOR CONTROL HANDLES @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_100000_1_0090001_01_00 Pax/Crew Doors and Emergency Exits FIGURE-10-0-0-991-009-A01 Page 10 Apr 01/15 10-0-0 TO OPEN: 1 − PUSH ON THE HANDLE. THE HANDLE IS EJECTED FROM ITS HOUSING. 2 − TURN THE HANDLE COUNTERCLOCKWISE TO DESENGAGE THE LATCHES. 3 − PUSH ON THE ESCAPE HATCH. IT OPENS INSIDE THE COCKPIT. NOTE: THE ESCAPE HATCH IS THE COCKPIT EMERGENCY EXIT. MAKE SURE THAT NO PERSON IN THE COCKPIT IS BELOW THE ESCAPE HATCH. ESCAPE ROPE @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_100000_1_0100001_01_00 Cockpit Emergency Exit FIGURE-10-0-0-991-010-A01 Page 11 Apr 01/15 INDICATOR WINDOWS MANUAL OPERATION TWO OPERATORS ARE NECESSARY FOR THIS OPERATION. 1 − DO OPERATIONS 1 AND 2 OF THE "NORMAL OPERATION" PROCEDURE. 2 − ON THE YELLOW GROUND SERVICE−PANEL, DO STEP (A) OR (B): (A) CONNECT A DRILLING MACHINE (WITH SOCKET DIA 1/2 in (12.7 mm)). (B) ATTACH THE HYDRAULIC AUXILIARY−PUMP GEARBOX TO THE HYDRAULIC AUXILIARY PUMP. CONNECT THE HANDLE (STORED ON 194KB ) AND THE EXTENSION HANDLE (STORED ON 197LB) WITH THE HYDRAULIC AUXILIARY−PUMP GEARBOX. 3 − OPERATE THE HYDRAULIC AUXILIARY−PUMP GEARBOX (AT NOT MORE THAN 100 RPM). 4 − TURN THE MANUAL OPERATING DEVICE TO THE "OPEN" POSITION (CLOCKWISE) AND HOLD IT UNTIL THE GREEN INDICATOR LIGHT COMES ON (CARGO DOOR FULLY OPEN AND LOCKED). 5 − RELEASE THE MANUAL OPERATING DEVICE. 6 − STOP THE OPERATION OF THE HYDRAULIC AUXILIARY PUMP. NOTE: WARNING: MAKE SURE THAT THE RESIDUAL PRESSURE WARNING−LIGHT DOES NOT FLASH. WARNING: ENSURE THAT ALL PERSONNEL AND EQUIPMENT ARE CLEAR OF CARGO DOOR AREA. LATCH HANDLE HANDLE EXTENSION HANDLE YELLOW GROUND SERVICE−PANEL NORMAL OPERATION HYDRAULIC AUXILIARY−PUMP GEARBOX DRILLING MACHINE 194KB 1 − PUSH THE LOCK HANDLE FLAP IN AND PULL THE LOCK HANDLE TO THE "UNLOCKED" POSITION (OUT AND UP). 2 − QUICKLY AND FULLY PULL THE LATCH HANDLE DOWN WITH A CONTINUOUS MOVEMENT (OUT AND DOWN). 3 − MAKE SURE THAT THE INDICATOR FLAG COMES OUT AND YOU CAN SEE THE RED INDICATION THROUGH THE EIGHT INDICATOR WINDOWS. 4 − PUSH THE TOGGLE SWITCH ON THE DOOR OPERATION PANEL TO THE "OPEN" POSITION AND HOLD IT UNTIL THE GREEN INDICATOR LIGHT COMES ON (CARGO DOOR FULLY OPEN AND LOCKED). 5 − RELEASE THE TOGGLE SWITCH. MANUAL OPERATING DEVICE HYDRAULIC AUXILIARY PUMP 197LB CARGO COMPARTMENT DOOR TOGGLE SWITCH GREEN INDICATOR LIGHT 194KB INDICATOR FLAG LOCK HANDLE FLAP LOCK HANDLE FWD AND AFT CARGO−COMPARTMENT DOOR−CONTROLS RESIDUAL PRESSURE WARNING−LIGHT @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_100000_1_0110001_01_01 FWD and AFT Lower Deck Cargo Doors FIGURE-10-0-0-991-011-A01 10-0-0 Page 12 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING INSTALLED ON NLG **ON A/C A350-900 P_AC_100000_1_0120001_01_00 Control Panels FIGURE-10-0-0-991-012-A01 10-0-0 Page 13 Apr 01/15 10-0-0 316AR HOOK LATCH PIN LATCH 315AL SAFETY LEVER A 316BR 1 − OPEN THE OVERPRESSURE DOOR 316BR TO RELEASE UNWANTED AIR PRESSURE. 2 − TURN THE SAFETY LEVER AND BLOCK IT. 3 − RELEASE THE HOOK LATCHES ON RIGHT ACCESS DOOR 316AR. 4 − OPERATE PIN LATCHES (FORWARD AND AFT). 5 − OPEN RIGHT ACCESS DOOR 316AR AND LOCK MANUALLY THE FIXED ROD WHEN DOOR IS FULLY OPEN. 6 − OPERATE PIN LATCHES (FORWARD AND AFT) ON LEFT ACCESS DOOR 315AL . 7 − OPEN LEFT ACCESS DOOR 315AL AND LOCK MANUALLY THE FIXED ROD WHEN DOOR IS FULLY OPEN. OPERATION: A FIXED ROD FIXED ROD APU ACCESS DOORS @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_100000_1_0150001_01_01 APU Compartment Access FIGURE-10-0-0-991-015-A01 Page 14 Apr 01/15 10-0-0 FT3 WL1 FT1 D3 BF3 RAT BF2 BF1 N1 D2 HT F3 C1 D1 D5 F1 AP BF1 BF2 BF3 C1 C2 C3 CP1 D1 D2 D3 D4 D5 m 6.52 2.66 2.08 2.59 3.37 3.29 3.26 6.20 5.37 5.33 5.27 5.21 7.61 ft 21.39 8.73 6.82 8.50 11.06 10.79 10.70 20.34 17.62 17.49 17.29 17.09 24.97 A/C (142 000 kg) CONFIGURATION AFT CG (40%) F1 F2 F3 F4 FT1 FT2 FT3 HT N1 RAT RD1 VT WL1 WL2 m 2.70 2.58 8.78 8.45 3.84 4.64 5.27 7.56 0.93 1.25 4.34 17.07 9.44 7.04 ft 8.86 8.46 28.81 27.72 12.60 15.22 17.29 24.80 3.05 4.10 14.24 56.00 30.97 23.10 A/C (142 000 kg) CONFIGURATION AFT CG (40%) DIMENSIONS ARE RELATED TO AIRCRAFT WEIGHT AND CG CONFIGURATION FT2 D4 C3 C2 F2 F4 AP NOTE: PASSENGER AND CARGO DOOR GROUND CLEARANCES ARE MEASURED FROM THE CENTER OF THE DOOR SILL AND FROM FLOOR LEVEL. VT WL2 RD1 CP1 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_100000_1_0160001_01_01 Aircraft Ground Clearances FIGURE-10-0-0-991-016-A01 Page 15 Apr 01/15 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING = = = = CUT HERE IN EMERGENCY NOT MARKED ON ALL AIRCRAFT COLORED **ON A/C A350-900 P_AC_100000_1_0170001_01_01 Structural Break-in Points FIGURE-10-0-0-991-017-A01 10-0-0 Page 16 Apr 01/15 10-0-0 Z120 BAT 1 A ELT BAT EMER 1 ACCESS VIA FWD CARGO COMPARTMENT DOOR FR19 ACCESS VIA ACCESS DOOR 811 A C FR87 B C B ELT ANTENNA FR88 NOTE: MAIN BATTERIES: THE BATTERY CASE AND THE EXHAUST SYSTEM CAN CONTAIN AND ISOLATE AN INTERNAL BATTERY EVENT. IF THERE IS A BATTERY CELL VENTING EVENT, THE GASES WILL BE RELEASED OUT OF THE AIRCRAFT THROUGH A PIPE CONNECTED TO THE AIRCRAFT SKIN AND CLOSED BY A BURST DISK. WHEN A CELL VENTING EVENT OCCURS, THE GROUND PERSONNEL MUST STAY AWAY FROM THE E/E BAY AND THE EXHAUSTED GASES. YOU MUST NOT DISCONNECT THE POWER CONNECTOR OR CUT OFF THE BATTERY POWER WIRES TO DISCONNECT THE BATTERIES FROM THE ELECTRICAL NETWORK. BAT 2 BAT EMER 2 FR0 @A350-900 AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING **ON A/C A350-900 P_AC_100000_1_0180001_01_01 Batteries Location and Access FIGURE-10-0-0-991-018-A01 Page 17 Apr 01/15