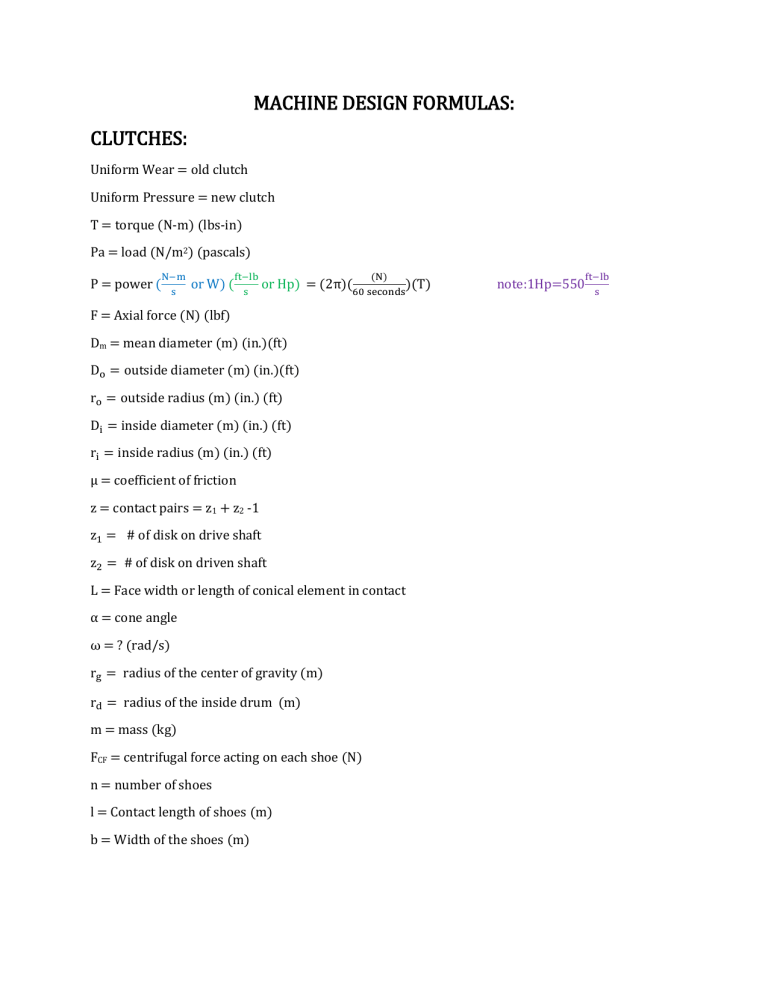

MACHINE DESIGN FORMULAS: CLUTCHES: Uniform Wear = old clutch Uniform Pressure = new clutch T = torque (N-m) (lbs-in) Pa = load (N/m2) (pascals) N−m s P = power ( or W) ( ft−lb or s (N) Hp) = (2π)(60 seconds)(T) F = Axial force (N) (lbf) Dm = mean diameter (m) (in.)(ft) Do = outside diameter (m) (in.)(ft) ro = outside radius (m) (in.) (ft) Di = inside diameter (m) (in.) (ft) ri = inside radius (m) (in.) (ft) μ = coefficient of friction z = contact pairs = z1 + z2 -1 z1 = # of disk on drive shaft z2 = # of disk on driven shaft L = Face width or length of conical element in contact α = cone angle ω = ? (rad/s) rg = radius of the center of gravity (m) rd = radius of the inside drum (m) m = mass (kg) FCF = centrifugal force acting on each shoe (N) n = number of shoes l = Contact length of shoes (m) b = Width of the shoes (m) ft−lb s note:1Hp=550 NEW PLATE CLUTCHES OLD PLATE CLUTCHES Use Uniform Pressure if not stated in problem which to use Use Uniform Wear if problem stated a mean diameter T= F= L= (z)(π)(μ)(Pa ) 12 (π)(Pa ) 4 (Do 3 − Di 3 ) T= (Do 2 − Di 2 ) F= Do −Di 2 L= 1(D 3 −D 3 ) Frictional Radius = 3(Do 2 −Di2 ) o (z)(μ)(π)(Pa )(Di ) 8 (π)(Pa )(Di ) 2 (Do 2 − Di 2 ) (Do − Di ) Do −Di 2 Frictional Radius = i Do +Di 4 Do +Di 2 Dm= NEW CONE CLUTCHES OLD CONE CLUTCHES Uniform Pressure Uniform Wear *assign X = other diameter in calculator* *assign X = other diameter in calculator* F= T= (π)(Pa ) 4 (F)(μ) 1(Do 3 −Di 3 ) [ ]× sin(α) 3(Do 2 −Di 2 ) D −D o i L = 2sin (α) Use Uniform Wear if problem stated a mean diameter (Do 2 − Di 2 ) z D 2 F = (π)(Pa )( i)(Do − Di ) (F)(μ) (Do +Di ) ]× 4 T = sin(α) [ D −D o i L = 2sin (α) (F)(μ) Dm ]× 2 z = sin(α) [ z CENTRIFUGAL CLUTCHES *Use (θ)(π) 180 to convert degrees to radians* ω1 = 2πN1 ω2 = 2πN2 T = (n)(μ)(m)(rg )(rd )(ω2 2 − ω1 2 ) FCF1 = (m)( ω1 2 )(rg ) FCF2 = (m)( ω2 2 )(rg ) F = (μ)(FCF2 − FCF1 ) l=[ (θ)(π) 180 ] (rd ) (Pa )(l)(b) = (m)(rg )(ω2 2 − ω1 2 ) BRAKES: m = mass (kg) v1 = initial velocity (m/s) v2 = final velocity (m/s) KE = kinetic energy (J) rad ) s ω = angular velocity ( I = mass moment of inertia (kg-m2) k = radius of gyration g = gravity (9.807 m/s2) E = energy that has dissipated through angular displacement (J) Mt = braking torque (N-m) θ = angle brake drum rotated or anglular displacement (rad) t = thickness d = diameter ρ = density(kg/m3) MECHANICAL BRAKES ENERGY DISSIPATION KE = 1 × m × (v1 2 − v2 2 ) 2 ∗ v2 = 0 when full stop ∗ KE = 1 × I × (ω1 2 − ω2 2 ) 2 KE = 1 × m × k 2 × (ω1 2 − ω2 2 ) 2 Radius of gyration = d D2 = 8 √8 = k2 PE = m × g × h E = Mt × θ m = A× t × ρ ρ= m volume volume = A× t ω= rpm × 60s 2π average velocity = ω1 + ω2 2 ω1 + ω2 θ=( )(time in seconds) 2