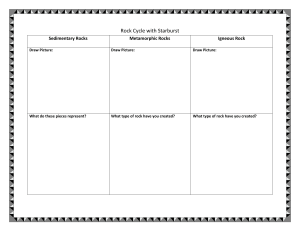

ANALYSIS OF LATERALLY LOADED PILES IN WEAK ROCK Downloaded from ascelibrary.org by MARRIOTT LIB-UNIV OF UT on 11/28/14. Copyright ASCE. For personal use only; all rights reserved. By Lymon C. Reese, l Honorary Member, ASCE ABSTRACT: The p-y method for the analysis of piles under lateral loading is extended here to the analysis of single piles in rock. Rational equations are presented for developing a solution, but the method is termed "interim" principally because of the meager amount of experimental data available to validate the equations. Nonlinearity, both in the p-y curves and in the bending stiffness of the pile, must be considered in solving ~or the loading that will cause a failure in bending, deflection, or buckling under combined loading. Two case studies are presented whereby the analytical method is shown to agree well with results from experiments. However, loading tests of full-sized piles are recommended at any site where a sizable number of piles are needed, to further improve the analytical method presented herein. INTRODUCTION Rock has received little attention by authors of papers on the lateral loading of piles. If rock is encountered in installing a deep foundation, overburden usually exists of sufficient thickness, that the computed deflection of a pile at the rock is so small that the resistance of the rock may be neglected, regardless of the stiffness of the rock. However, the combination of rock near or at the surface with a significant magnitude of lateral loading does occur, and lateral loading may dictate the penetration of the pile even though the axial load is substantial. The theory of elasticity has been used by Kulhawy and his coworkers (Carter and Kulhawy 1987, 1992), with useful results, and their ideas have influenced the development presented herein. A serious problem with regard to applying any analytical method to the response of rock is the dominant role played by the secondary structure of rock. The Canadian Foundation engineering manual (1978) has addressed secondary structure by basing the behavior of rock on the spacing and thickness of soil-filled cracks and joints, in addition to the compressive strength of intact specimens. SUBSURFACE INVESTIGATION The writer served on a panel to consider the foundations for a bridge at Northumberland Strait Crossing, Canada. The panel members included a number of experts on rock mechanics. The water depth was moderate, but rock existed at the floor of the strait. One of the schemes under consideration was to install piles into predrilled sockets. During winter, the columns, which were to be extensions of the piles, would be subjected to large lateral loads from moving sheets of ice. One of the panel members opined that each of the piles should be proof tested under lateral load because a soil-filled joint could exist near the surface of the rock. The weak joint would allow a mass of the rock to slide away from the pile with very low lateral resistance. The validity of the comment was apparent if, in fact, soil-filled joints existed at the site. The question was not resolved because the planning was abandoned for other reasons. (The bridge was under construction during 1996 with a different type of foundation.) For the design of piles under lateral loading in rock, special emphasis is necessary in the coring of the rock. Experience has shown that careful attention is required to establish procedures and specifications for field work. The values for the 'Professor Emeritus, The Univ. of Texas at Austin, TX; Prine., Lymon C. Reese & Associates, Inc. Note. Discussion open until April I, 1998. To extend the closing date one month, a written request must be filed with the ASCE Manager of Journals. The manuscript for this paper was submitted for review and possible publication on September 30, 1996. This paper is part of the Journal of Geotechnical and Geoenvironmental Engineering, Vol. 123, No. 11, November, 1997. ©ASCE, ISSN 1090-0241197/0011-10101017/$4.00 + $.50 per page. Paper No. 14234. Rock Quality Designation (RQD), percent of recovery, and compressive strength can probably be more seriously in error from improper procedures than are the corresponding properties of soil. The procedures that follow are based on results from field tests of piles in rock with differing characteristics. In neither case, however, did soil-filled joints influence the response of the piles. Methods of investigation should reveal detailed information, and designers must address the potential behavior of the rock in a site-specific manner. Therefore, the judgment of the geotechnical engineer is critical with respect to characterizing the rock and applying the technique shown herein. p-y METHOD OF ANALYSIS A model describing the method of analysis is shown in Fig. 1. An elevation view of a pile is shown in Fig. l(a), with a lateral load PIt an axial load Px , and a moment M applied at the pile head. The pile is shown as an elastic line "in Fig. l(b) in a coordinate system with deflection y and length x along the pile. The rock (soil, usually) is modeled according to the Winkler concept with a number of nonlinear, discrete mechanisms. The mechanisms, shown in the first quadrant for convenience, are characterized by a spring and sliding block merely to indicate nonlinearity, and they are described by the p-y curves in Fig. l(c), where p is the resistance of the rock and y is the local deflection. The parameter p refers to the line load from the rock resistance and is the integral of the unit stresses acting around the circumference of the pile. A number of authors have made recommendations for predicting p-y curves for different soils [for example, Matlock (1970); Welch and Reese (1972); O'Neill and Murchison (1983)]. The continuum is not modeled faithfully by the Winkler- P, M, pb P~ Pk=Y p1==y W x pC ~ y ~ FIG. 1. Model of Laterally Loaded Pile: (a) Elevation View; (b) As Elastic Line; (c) p-yCurves 1010/ JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING / NOVEMBER 1997 J. Geotech. Geoenviron. Eng. 1997.123:1010-1017. type curves; however, the recommendations for formulating Py curves are based strongly on results from field-load tests, as done herein, where the continuum effect is fully satisfied. The method is described in the technical literature [for example, McClelland and Focht (1956); Matlock and Reese (1960); Reese (1984)], and computer codes implementing the method are in use in many offices in the United States and abroad. The nonlinear differential equation to be solved for deflection, rotation, bending moment, shear, and soil resistance along the pile is d (d 2 2y d 2 Downloaded from ascelibrary.org by MARRIOTT LIB-UNIV OF UT on 11/28/14. Copyright ASCE. For personal use only; all rights reserved. y ) -dx 2 EI+P• -Pdx 2 dx 2 w-o - (1) where p. = axial load on pile, (F); y = lateral deflection of pile at point x, (L); P = soil resistance per unit length along pile, (F/L); EI = flexural rigidity (bending stiffness), (F - L 2); and W = distributed load along pile, (F/L). The equation is the standard beam-column equation where the value of EI may change along the length of the pile and may also be a function of the bending moment. The equation (1) allows a distributed load to be placed along the upper portion of a pile; (2) can be used to investigate the axial load at which a pile will buckle; and (3) can deal with a layered profile of soil or rock. Solutions may be developed readily using difference-equation techniques and Gaussian elimination. The usual method of developing a solution is to increment the loading, employing nonlinear p-y curves and a nonlinear EI curve, to find the failure loading from excessive deflection, a plastic hinge, or axial buckling. Analytical methods are available for computing the values of EI as a function of bending moment and axial load, and for computing the moment at which a plastic hinge will develop (Reese and Wang 1994). After finding the loading that will cause the governing type of failure, the loads may be factored to find the design loading. With input data at hand, various parameters may be investigated, and an acceptable solution can be found with computer codes that are relatively straightforward and easy to use. 3. The initial slope K lr of the p-y curves must be predicted because small lateral deflections of piles in rock can result in resistances of large magnitudes. For a given value of compressive strength, Klr is assumed to increase with depth below the ground surface. 4. The modulus of the rock Elro for correlation with Klro may be taken from the initial slope of a pressuremeter curve. Alternatively, the results of compressive tests of intact specimens may be used to obtain values of E lr • The data in Fig. 2 (Horvath and Kenny 1979; Peck 1976; Deere 1968) may be useful, but, as may be seen, the E lr values for samples of the same type of rock may vary by several orders of magnitude. Therefore, Fig. 2 can be expected to yield only approximate correlations between compressive strength and modulus. Fig. 3 (Bieniawski 1984) shows a correlation between Emus/Ecore and RQD. Values of Emus may be estimated if tests have been performed of cored specimens (Ems.. and E ir are assumed to be equivalent). Again, scatter is significant. The modulus for the mass of rock is assumed to be implemented in the expressions that follow. 5. The ultimate resistance Pur for the p-y curves will rarely, if ever, be developed in practice, but the prediction of Pur is necessary in order to reflect nonlinear behavior. 6. The component of the strength of rock from unit weight is considered to be small in comparison to that from compressive strength quro therefore, unit weight is ignored. 7. The compressive strength of the intact rock qur for computing a value of Pur may be obtained from tests of intact specimens. 8. The assumption is made that fracturing will occur at the surface of the rock under small deflections; therefore, the compressive strength of intact specimens is reduced by multiplication by a r to account for the fracturing. The value of a r is assumed to be 1/3 for RQD of 100 and to increase linearly to unity at RQD of zero. If RQD is zero, 0.1 FIELD TESTS Results from two programs of testing of full-scale, bored piles (drilled shafts) in rock are available for analysis (Nyman 1980; D. Speer, unpublished report, 1992). In both cases, data were available on the geometry of the piles, magnitude and point of application of loads, and characteristics of the rock. Curves showing deflection versus lateral load were reported for both of the programs. Comparisons of the results from analyses, using the procedures described herein, and results from the experiments are presented later. INTERIM RECOMMENDATIONS FOR COMPUTING p-yCURVES FOR ROCK Concepts An analysis of the results from the tests noted earlier, and a study of other information, formed the basis for the recommendations given here. The recommendations are termed "interim" for a number of reasons, and comments on their appropriate use in analysis and design are given. The following concepts and procedures establish the framework for the recommendations: 1. The secondary structure of rock, related to joints, cracks, inclusions, fractures, and any other zones of weakness, can strongly influence the behavior of the rock. 2. The p-y curves for rock and the bending stiffness EI for the pile must both reflect nonlinear behavior in order to predict loadings at failure. 10 100 I. 1x104 •I I,i 0.1 1 10 100 UNIAXIAL COMPRE88IVE STRENGTH - 1000 M'" FIG. 2. Engineering Properties for Intact Rocks [after Horvath and Kenney (1979); Peck (1976); Deere (1968)] JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING 1 NOVEMBER 1997/1011 J. Geotech. Geoenviron. Eng. 1997.123:1010-1017. p 1.0 (FILl Pur Jlj f Downloaded from ascelibrary.org by MARRIOTT LIB-UNIV OF UT on 11/28/14. Copyright ASCE. For personal use only; all rights reserved. o 0.6 I !l 0.8 YA Yrm 0.4 I o o FIG. 4. o _ 0.2 - - -_--D -..... ... -1- _1- _1- - - o n. "C;,lI 00 0 O.OL-....:...L_...L-_L-......L_...L-_L-......L_-'---IL--:t o 60 80 100 Rock Qu.1l1y D••llln.tlon, RQD, % FIG. 3. Modulu8 Reduction Ratio a8 Function of RQD [after Blenlaw8kl (1984)] the compressive strength may be obtained directly from a pressuremeter curve, or approximately from Fig. 2, by entering the value of the pressuremeter modulus. Ultimate Resistance of Rock The following expression for the ultimate resistance Pu, for rock is based on limit equilibrium and reflects the influence of the surface of the rock: Pu, = cx,qw,b Pur (1 + 1.4;); 0~ = 5.2cx,qw,b; Xr ~ x, ~ 3b 3b (2) Slope of Initial Portion of p-yCurves If one were to consider a strip from a beam resting on an elastic, homogeneous, and isotropic solid, the initial modulus K I (PI divided by YI) may be shown to have the following value (using the symbols for rock): (4) where E 1, = initial modulus of rock; and ki , = dimensionless constant. Eqs. (5) and (6) for ki , are derived from experiment and reflect the assumption that the presence of the rock 'surface will have a similar effect on kin as was shown for Pu, for ultimate resistance. o ~ x, ~ = 500; Xr > 3b Sketch of p-yCurve for Rock lower values of the K i , in relation to the modulus of rock or soil; however, the modulus of the rock at San Francisco, used principally in developing the correlations, was obtained by pressuremeter. The details employed in the pressuremeter test could well reveal a much lower value of the initial modulus of rock in comparison with that exhibited by a pile of large diameter deflected against the rock. Third, the increase in K 1, with depth in (5) is consistent with results obtained from the lateral loading of piles in overconsolidated clays. Formulas for Family of p-y Curves With guidelines for computing Pu, and Kin the equations for the three branches of the family of p-y curves for rock can be presented. The characteristic shape of the p-y curves is shown in Fig. 4. The equation for the straight-line, initial portion of the curves is given by (7) and, for the other branches, (8)(10) p =KI,y; Pu, Y P=- ( 2 Yrm (3) where qu, = compressive strength of rock, usually lower-bound as function of depth; cx, = strength reduction factor; b = diameter of pile; and x, = depth below rock surface. kl, r(l) 3b (5) (6) Eqs. (5) and (6), developed from experimental data, show that the initial portions of the P-Y curves are very stiff in order to model the relatively very low deflections observed during beginning loads. Some further comments are in order about the equations. First, the equations have no influence on solutions beyond the value of Y" and probably will have no influence on designs based on the ultimate bending moment of a pile. Second, available theory, while incomplete, shows much ) (7) y ~ y" O.2~ ; Y ~y,,; p ~ (8) Pur P =pw, Yrm = krmb (9) (10) where krm = constant, ranging from 0.0005 to 0.00005 (see case studies to follow), that serves to establish overall stiffness of curves. The value of y" is found by solving for the intersection of (7) and (8), and is shown by (11) Pu, ] 1.333 [ y" = 2(Yrml~KI' (11) COMMENTS ON EQUATIONS FOR PREDICTING p-y CURVES FOR ROCK The equations predict with reasonable accuracy the behavior of single piles under lateral loading for which experimental data are available. Because of the meager amount of data, the equations should be used with caution. An adequate factor of safety should be employed in all cases; preferably, field tests should be undertaken with full-sized piles, with appropriate instrumentation. If the rock contains joints that are filled with weak soil, the selection of properties of strength and stiffness must be sitespecific and will require a comprehensive geotechnical investigation. In those cases, the application of the method presented herein should proceed with even more caution than normal. The equations are based on the assumption that p is a linear function of y, an idea that appears to be valid if loading is static and if resistance is due only to lateral stresses. However, O'Neill points out that "in large-diameter drilled shafts, mo- 1012/ JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING I NOVEMBER 1997 J. Geotech. Geoenviron. Eng. 1997.123:1010-1017. ment is resisted in the push-pull resistance produced by the axial shears caused by the rotation of the pile. In rocks, this effect could be significant, especially for small deflections, if the diameter of the pile is large" (M. W. O'Neill, personal communication, 1996). COMPUTATION OF MUir AND EI AS FUNCTION OF BENDING MOMENT AND AXIAL LOAD The aim of the case studies that follow is to employ the Downloaded from ascelibrary.org by MARRIOTT LIB-UNIV OF UT on 11/28/14. Copyright ASCE. For personal use only; all rights reserved. p-y curves for rock for computing the pile-head deflection for comparison with experimental values. Experience and preliminary computations show the necessity of considering the nonlinear bending stiffness EI of a pile in order to make meaningful comparisons with experimental data. Methods of computing the value of EI as a function of the applied moment and axial load, as well as the ultimate bending moment Mol" are summarized here. The methods are implemented in the studies that follow. FIG. 5. Streaa-Straln Curve for Concrete Analytical Procedure Equations for the behavior of a slice from a beam or from a beam-column under bending and axial load are formulated. A reinforced-concrete section is assumed in the presentation, but the concepts can be applied to a steel shape. The EI of the concrete member will experience a significant change when cracking occurs. In the procedure described herein, the assumption is made that the tensile strength of concrete is relatively small and that cracks will be closely spaced when they appear. Actually, such cracks will initially be spaced at some distance apart, and the change in the EI will not be so drastic as computed. Therefore, the EI for a reinforced-concrete pile will change more gradually in practice than in the computations by the suggested analytical method. Because the nonlinear stress-strain curves for steel and concrete do not indicate a condition for collapse, values of the ultimate strain of these materials are selected to reflect their failure. For concrete, the ultimate value of strain is 0.003; for reinforcing steel, the ultimate value of strain is 0.015. These values appear to be consistent with those frequently used in practice. The curve for the deformational characteristics of concrete implemented in the procedure is shown in Fig. 5. The values of f~, the compressive strength, and E e , the modulus of elasticity, are found from standard tests of cylinders or from other appropriate tests. The following equations are for concrete of normal weight, and apply to the branches of the curve: fc = Eee; 0::5 fc fc =f~ [2 (t) - (t)1 fc =fe" ( 1 - ::5 J, (12) O::5fc 0.15£0) ; fe,,~ 0.0038 <? Je <? ::5f~ 0.8 5f"e (13) -----Jr--:L-----------'E FIG. 6. Streu.straln Curve for Steel from the American Concrete Institute (ACI) (1989) and is for concrete with normal weight. The stress-strain curve for steel is shown in Fig. 6, and there is no limit to the amount of plastic deformation. The curves for tension and compression are identical. The yield strength of the steel h is selected according to the material being used, and E is the initial modulus of the steel. The following equations apply: (19) E = 200,000 MPa (20) The derivation adopts the concept that plane sections in a beam or beam-column remain plane after loading. Thus, an axial load and a moment can be applied to a section with the result that the neutral axis will be displaced from the center of gravity of a symmetrical section. The equations to be solved are as follows: h (14) b f ' a dy = p. (21) ay dy =M (22) -h, where h f~ = 0.85f: (15) (16) J,= 19.7Vif (17) The approximate value of E e , in the absence of experimental data, may be taken from the following equation: Ee = 151,oooVif (18) The terms in (17) and (18) have units of kPa. Eq. (18) is b f ' -h, where b = depth of section; hit h2 = distance from neutral axis to extreme fibers; a = normal stress; y = distance from neutral axis; p. = axial load; and M = moment on section. The steps in a convenient procedure of computation are as follows: (1) Select the angle of rotation e for a section; (2) Estimate the position of the neutral axis; (3) Compute the strain across the section; (4) Use numerical methods to solve for the distribution of stresses across the cross section; (5) Compute the magnitude of the axial load by summing the forces across the JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING 1 NOVEMBER 1997/1013 J. Geotech. Geoenviron. Eng. 1997.123:1010-1017. section, as indicated in (20); (6) Modify the position of the neutral axis if the computed value of axial load does not agree with the applied load; (7) Repeat the computations until convergence is achieved; (8) Solve for the bending moment by numerical methods, implementing (22); and (9) Obtain the bending stiffness by use of (23) where p is equal to the radius of curvature of de divided by the length of the element dx. Downloaded from ascelibrary.org by MARRIOTT LIB-UNIV OF UT on 11/28/14. Copyright ASCE. For personal use only; all rights reserved. M EI 1 (23) P A computer code has been written to solve the relatively straightforward equations because of the iteration due to the nonlinear stress-strain characteristics of concrete and steel. The computations continue until the maximum strain selected for failure is reached. Then, the ultimate moment MUll can be found. Approximate Method The analytical procedure results in a sharp decrease in the value of EI because the mechanics predicts continuous cracking at a given tensile strain of the concrete. Observations of the behavior of reinforced-concrete sections have yielded an empirical equation that gives values of bending stiffness that reduce more gradually, as a function of the applied bending moment, than do the values from mechanics (ACI 1989). I. = (~:r Ig + [I - (~:r] Ier (24) where Mer =g (25) Ye f, = 19.7Vjf (for normal-weight concrete) (26) and where I. = effective moment of inertia for computation of deflection; I g = moment of inertia of gross concrete section about centroidal axis, neglecting reinforcement; Ye = distance from centroidal axis of gross section, neglecting reinforcement, to extreme fibers in tension; I er = moment of inertia of cracked section; and M a = maximum moment in pile. The value of I er may be computed by the analytical method, using standard mechanics. In computing bending stiffness, the value of E is assumed to remain constant. The absence of a term for axial load in (24) means that the approximate method or ACI method is limited in scope. However, a comparison of results from (24) with those from the analytical method with no axial load and with a specified axial load will reveal a trend that should prove useful in solving a practical problem. In applying the ACI method, the difference between the response of a beam and a pile to lateral loading may be great. For many practical cases, the computed bending-moment curve for a pile changes rapidly with depth, and the region of the maximum bending moment may be a small fraction of the length of the pile. Therefore, the engineer may wish to apply (24)-(26) point-by-point along the length of the pile rather than to the entire length. CASE STUDIES Islamorada The test was performed under sponsorship of the Florida Department of Transportation and was carried out in the Florida Keys (Nyman 1980). The rock was a brittle, vuggy, coral limestone, allowing a steel rod to be driven into the rock to considerable depths, apparently because the limestone would fracture and the debris would fall into the vugs. Cavities in the order of a third of a meter in the largest dimension existed in the limestone in some regions, but only the vugs were encountered at the test site. Two specimens were obtained for compressive tests. The small discontinuities at the outside surface of the specimens were filled with gypsum cement to minimize stress concentrations. The ends of the specimens were cut with a rock saw and lapped flat and parallel. The compressive strengths were found to be 3.34 and 2.60 MPa. The axial deformation was measured during testing, and the average value of the initial modulus of the rock was found to be 7,240 MPa. In the absence of additional data, the value from the cores is assumed to be equal to the modulus of the mass. The rock at the site was also investigated by in-situ-groutplug tests under the direction of Dr. John Schmertmann (unpublished report, 1977). A 140-mm-diameter hole was drilled into the limestone, a high-strength-steel bar was placed to the bottom of the hole, and a grout plug was cast over the lower end of the bar. The bar was pulled to failure and the hardened grout was examined to ensure that failure occurred at the interface of the plug and the limestone. Tests were performed at three locations, and the results are shown in Table I. Nyman (1980) studied all of the data, and a compressive strength of 3.45 MPa was selected as representative of the rock in the zone near the rock surface where the deflection of the pile was most significant. Values of RQD were not obtained. However, in view of the difficulty in obtaining intact specimens, RQD was assumed to be close to zero and a r was taken as unity. The bored pile was 1.22 m in diameter and penetrated 13.3 m into the limestone. A layer of sand over the rock was retained by a steel casing, and the lateral load was applied at 3.51 m above the surface of the rock. A maximum lateral load of 667 kN was applied, and the resulting curve of load versus deflection was nonlinear. Nyman (1980) recommended p-y curves for the vuggy rock at Islamorada. A key feature of the recommendations was that the rock was assumed to fracture and lose all strength after a small amount of deflection. Such a failure was not observed -only postulated. In the absence of other recommendations, Nyman's suggestions were used for other kinds of rock (Reese and Wang 1989). In the absence of details on the strengths of the concrete and steel and on the amount and placement of the rebars, the bending stiffness of the gross section was used for the initial solutions. The following values were used in the equations for p-y curves; qur = 3.45 MPa; a r = 1.0, ETI = 7,240 MPa; krm = 0.0005; b = 1.22 m; L = 15.2 m; and EI = 3.73 X 106 kN· m 2• The comparison of pile-head deflection for results from experiment and from analysis is shown in Fig. 7. The figure shows excellent agreement between the two methods up to about 350 kN, using unmodified values of the bending stiffness. A sharp change in the load-deflection curve occurs at a lateral load of about 350 kN. TABLE 1. Results of Grout-Plug Tests by Schmertmann (Unpublished Report, 19n) Depth range (m) (1 ) Ultimate resistance (MPa) (2) 0.76-1.52 0.76-1.52 0.76-1.52 2.44-3.005 2.44-3.005 2.44-3.005 5.49-6.10 5.49-6.10 2.28 1.31 1.15 1.74 2.08 2.54 1.31 1.013 10141 JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING 1NOVEMBER 1997 J. Geotech. Geoenviron. Eng. 1997.123:1010-1017. Downloaded from ascelibrary.org by MARRIOTT LIB-UNIV OF UT on 11/28/14. Copyright ASCE. For personal use only; all rights reserved. Computed curves giving deflection and bending moment as a function of depth are presented in Fig. 8 for a lateral load of 334 kN, one-half of the ultimate lateral load. Only depths of about 4.5 m for deflection and about 6 m for bending moment are plotted. The values to the full length are too small to plot. The stiffness of the rock, compared to the stiffness of the pile, is reflected by a total of 13 points of zero deflection over the length of the pile of 15.2 m. With an increase in the lateral loads, the deflections will increase and fewer points of zero deflection will result. However, for the data employed here, the pile will behave as a long pile through the full range of loading. With the use of nonlinear p-y curves, there can be no a priori decision about the classification of a pile under lateral loading as short, intermediate, or long. Such a decision can be made only after solution of (1), using nonlinear mechanics. As shown in Fig. 7, values of EI were reduced gradually in zones of large bending moments to find deflections that would agree fairly well with values from experiment. The plot of bending moment in Fig. 8 shows that the largest moment occurs in the zone of about 2.5 -4.5 m. The following combinations of values of load and bending stiffness were used in the analyses in units of kN and kN 'm2 , respectively: 350 and below 3.73 X 106 ; 400, 1.24 X 106 ; 467, 9.33 X 105 ; 534, 7.46 X lOS; 601, 6.23 X 105 ; and 667, 5.36 X 105 • In each case, the computed bending-moment curve was examined and the reductions were only made in the zone where the bending stiffness was expected to be in the nonlinear range. The lowest 700 -r--+----.,.------,.--..---..... 600 600 J 1 ) 400 - - - Araysls wi elastic EI Analysis wi reduced EI o Experimental 300 200 100 o 5 10 15 Oroundllne deflection, mm 20 FIG. 7. Comparison of Experimental and Computed Values of Pile-Head Deflection, Islamorada Test Bending moment, kN·m o -400 San Francisco The California Department of Transportation performed lateral-load tests of two bored piles near San Francisco (Speer, unpublished report, 1992), and the results of the tests, while unpublished, have been provided courtesy of Caltrans. Two borings were made into the rock, and the following statements describe the experimental techniques. "After bedrock was encountered, sampling was continued using a NWD4 core barrel in a 4-inch [102 mm] diameter cased hole. A three and seven eighth inch [98 mm] tricone rock bit was used to advance the casing and clean the borehole." The sandstone was found to be medium-to-fine grained (with grain sizes from 0.1 to 0.5 mm), well sorted, and thinly bedded (25 - 75 mm thick). Except in a few cases, recovery was 100%. Twenty values of RQD were reported, ranging from zero to 80, with an average of 45. In most of the corings, the sandstone was described as very intensely to moderately fractured with bedding joints, joints, and fracture zones. With respect to the selection of a value of an it was assumed that there was little chance of brittle fracture and a r was taken as unity. Pressuremeter tests were performed at the site, and the results, as might be expected, were scattered. The plotted results of the values obtained for the moduli of the rock are shown in Fig. 9. The averages that were used for analysis are shown as a function of depth by the dashed lines. The following values were estimated for the compressive strength of the rock: 0-3.9 m, 1.86 MPa; 3.9-8.8 m, 6.45 MPa; and below 8.8 m, 16.0 MPa. The right-hand curve in Fig. 2 was employed in developing the correlation between E jr from Fig. 9 and qur' Two piles, 2.25 m in diameter, with penetrations of 12.5 m and 13.8 m, were tested simultaneously. Lateral loading was accomplished by hollow-core rams, acting on high-strength steel bars, that were passed through tubes, transverse and perpendicular to the axes of the piles. The load was measured by load cells, and the piles were instrumented with slope indicators and strain bars. Deflection was measured by transducers, and slope and deflection of the tops of the piles were obtained by readings from the slope indicators. The load was applied in increments at 1.41 m above the ground line for pile A and 1.24 m for pile B. The pile-head deflection was measured at slightly different points above the 1200 BOO 400 value of EI that was used is believed to be roughly equal to that for the fully cracked section. The assumption that the decrease in slope of the curve of Y, versus P, at Islamorada can be explained by reduction in values of EI is reasonable. However, the Islamorada example gives little guidance to the designer of piles in rock, except for early loads. The example from San Francisco that follows is more instructive. O+-................-l,,......-'-.........l.-l,.........--..-'-"-T.......-j EJr,MPe o BOO 1200 1600 2000 o+-...,.........i--'-.........'-!-..............................."J...............-1 400 I 01 0 2 , ' °186 MFa , ooV----:-----, _ cJ 4-1-_°"':_ 3 .9 ......--r_ _ o 0: 5 8 6 - - - -: - -- 7 -0.5 0 0.5 1.5 2 2.5 .... 3 Deflection, mm 10 _0:' : I m: Q v6~5~F~ .- -b"--:- , _ .,_ --;-S.ifril- _:__ -0- __ ~_1: 00 MFa 12...L..------------'1'---...J FIG. 8. Plot of Computed Curves of Deflection and Bending Moment versus Depth, Islamorada Test, Lateral Load of 334 kN FIG. 9. Initial Moduli of Rock from Pressuremeter. San Francisco Test JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING / NOVEMBER 1997/1015 J. Geotech. Geoenviron. Eng. 1997.123:1010-1017. 1ססoo 40,...--.,..---,.--......--....,..--..., 30 ...... 25 .... -:'. .. .- ..... _ .. , --- .. ~ .. -- .. --- ------- ~ . ---- 35 8000 :G 1'! ~ ___ . L • • • • • _ . , , 8000 - .. - - ~ - . - . i .. - . - - - , j , - - - - - - Z .¥ ........ - l' --G__ 4000 2000 1:. lC Unmodlfled EI Anelytical ACI Expartmental 20 ' ._~~._ ..... , .. ..... ,,. .. , , .... ACI _ Experimental _ Analytical . , , -. - ": 15 r e . . .; ...... .............. ~ iii ;. .;.- , ........ ;. 10 ,.. ...... L .. ~ Downloaded from ascelibrary.org by MARRIOTT LIB-UNIV OF UT on 11/28/14. Copyright ASCE. For personal use only; all rights reserved. .. ~ • •• - . . , L .. 0 0 10 20 30 40 o-t-T""'T""T"'t"""........"T"",.............,...,.""T".,...,,.....,.."T"".......-1 o 4000 8000 12000 16000 20000 50 Qroundllne denectlon, mm FIG. 10. Comparison of Experimental and Computed Values of Pile-Head Deflection for Different Values of EI, San Francisco Test M, kN·m FIG. 11. Values of Elfor Three Methods, San Francisco Test 1ססoo rock line, but the results were adjusted slightly to yield equivalent values for each of the piles. In addition to the previously noted values, the following values were used in the analyses: k rm =0.ססOO5 and EI =35.15 6 2 6 4 X 10 kN· m (E = 28.05 X 10 kPa; I = 1.253 m ) for the beginning loads. The ultimate bending moment MUll was computed to be 17,740 m·kN. The values of EI and MUll were computed from the following properties of the cross section: compressive strength of the concrete was 34.5 MPa, tensile strength of the rebars was 496 MPa, there were 40 bars with a diameter of 43 mm, and cover thickness was 0.18 m. The curve for pile B (see Fig. 10) exhibited a large increase in pile-head deflection at the largest load, which suggests that a plastic hinge developed. Therefore, the assumption was made that the ultimate bending moment, 17,740 m . kN, was reached. Analysis of the previously reviewed Islamorada test showed that the bending stiffness of a reinforced-concrete member decreases significantly with increased bending moment; however, previous work showed that the computation of bending moment is not strongly dependent on the specific value of EI. Therefore, the beginning computations for the solution of (1) were based on the initial values of EI. Values of qu" from results from the pressuremeter (see Fig. 2), were found to predict MUll with reasonable accuracy. Then, attention was given to the probable reduction in the values of EI with increasing load, and three methods were used to predict the reduced values. The methods were the analytical method, the approximate method (or ACI method, used since no axial load was applied during the testing), and the experimental method. The three plots of the values of EI as a function of M are shown in Fig. 11. The experimental method employed the average of the observed deflections, the applied loading, and iteration to find the values of EI and the corresponding values of maximum bending moment that fitted the results. In these computations, and for those that follow, the value of EI was changed for the entire length of the pile for ease in computations. Errors in using constant values of EI in the regions of low values of M are thought to be small. All three curves exhibit a sharp decrease in the value of EI with increase in bending moment, but the analytical method yielded a precipitous drop, for the reason noted earlier. All of the values of EI start from 35.15 X 106 kN· m 2 , (the value of EI from the analytical method was slightly higher because of the presence of the steel). The values of I from ACI were multiplied by a constant value of E of 28.05 X 106 kPa to get the values of EI. Surprisingly, the values of I from the experiment and from ACI fall below the value from analysis for over half of the range of values. The concrete may be cracking 8000 ~ , , .. , , ,,, ,, .............. -: , , , , , ~ 6000 ··.·.·· ...,-------·r·.-·· e ~ 4000 ... 2000 ,, ,, '._._- .•••. ~ .. , , ,, .., .. "fi ~ :, - ~ •• ~ • - •••' • • • • - • - • & • - • • • • • • - - Unmodilled EI - K - Analytical : -e- ACI : .. , -lil- Experimental o.................-r-...............-r-..............-r-..............-r-...............-I 4000 6000 12000 18000 20000 o Maximum bending moment, kN-m FIG. 12. Comparison of Experimental and Computed Values of Maximum Bending Moments for Different Values of EI, San Francisco Test at a smaller strain than 0.003, there may be some crushing of the concrete in compression, or the analytical theory may not faithfully reflect the real behavior of the reinforced-concrete section in some other ways. The next step was to investigate the influence of the values of I (and El) on the computations of deflection and maximum bending moment. The computed pile-head deflections, using the values of I for the three cases in Fig. 11, are shown in Fig. 10. The experimental values agree well with computations, of course, because of the fitting noted earlier. The computations with the ACI equations fit the experimental values better than do the computations with the analytical method. However, if load factors of 2.0 and greater are selected, the computed deflections, taking into account the methods for reducing the value of EI, would be about 2 or 3 mm, with the experiment showing about 4 mm. The differences are probably not very important in the range of the service loading. Also shown in Fig. 10 is a curve showing deflection as a function of lateral load with no reduction in the values of EI. The necessity of employing a reduced value of EI is clear. The values of I in Fig. 11 were used to compute the maximum bending moment as a function of the applied load. The curves are given in Fig. 12, and the close agreement among all three methods is striking. Also shown in Fig. 12 is the plot of maximum bending moment using the gross EI. The curve is reasonably close to the curves from adjusted values of EI, indicating that the computation of bending moment is not very 1016/ JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING / NOVEMBER 1997 J. Geotech. Geoenviron. Eng. 1997.123:1010-1017. sensitive to the selected values of bending stiffness. The value of the ultimate bending moment Mult , computed by the analytical method, is shown in Fig. 12. Assuming Muir to be correct, all of the methods predict failure in bending with good accuracy. Downloaded from ascelibrary.org by MARRIOTT LIB-UNIV OF UT on 11/28/14. Copyright ASCE. For personal use only; all rights reserved. CONCLUSIONS 1. The p-y method for the analysis of piles under lateral loading, in wide use for the analysis and design for piles in soil, can be used for the analysis of piles installed in rock. 2. The subsurface investigation for the characteristics of rock at a particular site is critical because secondary structure can dictate the behavior of a pile under lateral loading. Special geotechnical studies are necessary for cases whereby joints are filled with weak soil. 3. The analytical method for computing the value of Muir is essential to the analysis of reinforced-concrete piles under lateral loading in order to compute the loading at which failure will occur in bending. 4. The interim method of computing p-y curves, employed in the solution of (1), using unadjusted values of EI, can be used to determine the combined loading that will develop the ultimate bending moment Muir in the pile. 5. Adjusted values of bending stiffness are necessary in computing pile-head deflection. The ACI equations are recommended for the computation of adjusted values of EI. 6. The computation of maximum bending moment is much less affected by the selection of appropriate values of EI than is the computation of deflection. 7. The deflection under service (unfactored) loads of the pile head for piles in rock, even for relatively soft rock, will be relatively small. 8. Field-load tests with instrumented piles in rock are strongly desirable for improving the design at a particular site, especially if a large number of piles are to be used, and to add to the experimental-data base. The method presented herein may be used in interpreting the results from the particular experiment. ACKNOWLEDGMENTS The writer wishes to acknowledge the contributions of the Florida Department of Transportation and the California Department of Transportation in performing the experiments that aIlowed for the development of the method presented herein. In particular, Tom PoIlack, acting chief, Division of Structures, Caltrans, is thanked for providing a copy of the first draft of an unpublished report (1996), entitled "Shaft lateral load test terminal separation." K. J. Nyman is acknowledged for the data acquisition and the preliminary analysis of the results of the experiment at Islamorada. Dr. Michael W. O'Neill, University of Houston, and Paul D. Passe, Florida Department of Transportation, read an early draft and made valuable suggestions. The writer's coIleagues, Dr. Shin-Tower Wang and Jos6 Arrel1aga, made significant contributions. Both read the drafts and offered useful suggestions about the method of analysis. Dr. Wang coded some of the techniques for solution by computer, and JostS Arr611aga prepared the drawings. APPENDIX I. Carter, J. P., and Kulhawy, F. H. (1992). "Analysis of lateral1y loaded shafts in rock." J. Geotech. Engrg., ASCE, 118(6), 839-855. Deere, D. V. (1968). "Chapter 1: geological considerations. Rock mechanics in engineering practice, K. G. Stagg and O. C. Zienkiewicz, eds., John Wiley & Sons, Inc., New York, N.Y., 1-20. Horvath, R. G., and Kenney, T. C. (1979). "Shaft resistance of rocksocketed drilled piers." Proc., Symp. on Deep Found., ASCE, New York, N.Y., 182-184. Matlock, H. (1970). "Correlations for design of laterally loaded piles in soft clay." Proc., 2nd Annu. Offshore Technol. Con/., Paper no. OTC 1204, 1,577-594. Matlock, H., and Reese, L. C. (1960). "Generalized solutions for laterally loaded piles.' J. Soil Mech. and Found. Div., ASCE, 86(5), 63-91. McClel1and, B., and Focht, J. A. Jr. (1956). "Soil modulus for laterally loaded piles." J. Soil Mech. and Found. Div., ASCE, 82(4). Nyman, K. J. (1980). "Field load tests of instrumented dril1ed shafts in coral limestone," MS thesis, Grad. School, The Univ. of Texas at Austin, Tex. O'Neill, M. W., and Murchison, J. M. (1983). "An evaluation of p-y relationships in sands." Rep. PRAC 82-41-1 Prepared for American Petroleum Institute, Univ. of Houston, University Park, Houston, Tex. Peck, R. B. (1976). "Rock foundations for structures." Proc., Spec. Con/. on Rock Engrg. for Found. and Slopes, ASCE, New York, N.Y. Reese, L. C. (1984). Handbook on design ofpiles and drilled shafts under lateral load. FHWA-1P-84-11, Fed. Hwy. Admin., U.S. Dept. of Transp., Washington, D.C. Reese, L. C., and Wang, S.-T. (1989). "Documentation of computer program LPILE." Ensoft, Inc. Reese, L. C., and Wang, S.-T. (1994). "Analysis of piles under lateral loading with nonlinear flexural rigidity." Proc., U.S. FHWA Int. Con/. on Des. and Constr. of Deep Found., Fed. Hwy. Admin., U.S. Dept. of Transp., Washington, D.C. Welch, R. C., and Reese, L. C. (1972). "Laterally loaded behavior of dril1ed shafts." Res. Rep. no. 3-5-65-89, Center for Highway Research. APPENDIX II. NOTATION The following symbols are used in this paper: Symbols Relating to p-yCurves b EI E tT kiT k rm L Pr Px p qUT = diameter of pile, (L); = flexural rigidity (bending stiffness), (F = initial modulus of rock, (FIL = dimensionless constant; XT y lXT L 2 ); ); = dimensionless constant, ranging from 0.0005-0.0005, that serves to establish overall stiffness of p-y curves; = length of pile (L); = lateral load on pile, (F); = axial load on pile, (F); = soil resistance per unit length along pile, (FIL); = compressive strength of rock, usually lower bound, as function of depth, (FIL = distributed load along pile, (FIL); = axial coordinate along pile, (L); = depth below rock surface, (L); = lateral deflection of pile at point x, (L); and = strength reduction factor. 2 W x 2 ); Symbols Relating to Bending Stiffness b f, hh h2 leT I. = depth of section, (L); = modulus of rupture of concrete, (F/L = distance from neutral axis to extreme fibers, (L); = moment of inertia of cracked section, (L4); = effective moment of inertia for computation of deflec2 ); tion, (L4 ); REFERENCES American Concrete Institute. (1989). "Building code requirements for reinforced concrete." ACI 318-89, Detroit, Mich. Bieniawski, Z. T. (1984). Rock mechanics design in mining and tunneling. A. A. Balkema, Rotterdam, The Netherlands. Canadian Foundation engineering manual. part 3. deep foundations. (1978). Can. Geoteeh. Soc., Montreal, Quebec, Canada. Carter, J. P., and Kukhawy, F. H. (1987). "Analysis and design of dril1ed shafts socketed into rock." Res. Rep. 1493-4, Geotech. Engrg. Group, Cornell Univ., Ithaca, N.Y. I, M M. MeT Px y Ye (J' = moment of inertia of gross concrete section, (L 4 ); = moment on section, (F - L); = applied maximum bending moment, (F - L); = cracking bending moment, (F - L); = axial load, (F); = distance from neutral axis, (L); = distance from centroidal axis of gross section, neglecting reinforcement, to extreme fibers in tension, (L); and = normal stress, (F/L 2 ). JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING 1 NOVEMBER 1997/1017 J. Geotech. Geoenviron. Eng. 1997.123:1010-1017.