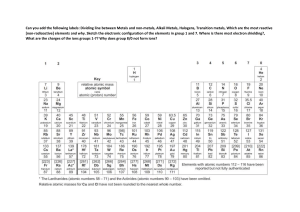

ЧАСТЬ ЭКРАНА ПОД ЗАПИСЬ (контентом не заполнять) Construction material technology Lecture 1. Basic concepts I would like to present you the first lecture in a series of lectures about technologies of structural materials our first lecture will be devoted to the basic concepts of the course Lyubov Bondarenko, assistant of department 903 "Advanced materials and technologies for aerospace purposes" Lecture content In the first lecture we will talk about we learn such a topic as • Introduction. • Classification of materials. Metallic, nonmetallic, composite materials. • Atomic-crystalline structure of metals. • Structural research methods. X-ray diffraction analysis. • Processing of XRD data lecture course and in more detail we will consider such a topic as in this lecture we will analyze the basic concepts of the entire course, which will be useful to us in the future 2 1. Introduction 3 Introduction Materials science is the science of the relationship between the structure of materials and their composition and physical and chemical properties. Materials are understood as substances used to manufacture something or used in the operation of other substances. We'll start with such a thing as materials science. The properties of technical materials are formed during the manufacturing process. Different structure and properties of materials can be formed even with the same chemical composition, but different manufacturing technology. fundamental importance we talked about such a concept as materials 4 Introduction Structural materials are materials intended for the manufacture of machine parts, devices, engineering structures that are exposed to mechanical stress. Machine parts differ in a wide variety of shapes, sizes, operating conditions. They operate under - static, - cyclic, - shock loads, - at low and high temperatures, - in contact with various fields. These use factors determine the requirements for the materials of construction. Basic requirements: operational, technological, economic. we are moving to functional purpose determining the name of the materials and name course. They are intended for use in various designs and are called structural casting, metal forming, welding, soldering, pressing see into In this definition, we mentioned a such thing as machine parts. A part is mechanism produced without the use of assembly operations it is the basis of the design, an indivisible part. bolt, shaft and others let's talk about them in more 5 detail Introduction Operational requirements. Structural strength is a set of mechanical properties that ensure reliable and long-term operation of the material under operating conditions. Operational requirements are paramount. The material should have a high structural strength - this will help ensure the performance of specific machines and devices. The working temperature range of modern materials is from -269 °C to 1000 °C (in some cases up to 2500 °C). To work at high temperatures, the material requires heat resistance, and at low temperatures, cold resistance. In some cases, it is important to require certain magnetic, electrical, thermal properties, high dimensional stability. 6 Introduction Technological requirements. Manufacturability is assessed by such concepts as -machinability, -cutting, -pressure, -weldability, -castability, -hardenability, -tendency to deform and warp during heat treatment. the goal of the Technological requirements is to make the part as little work as possible. In other words, production should meet a wide variety of requirements. Let's take a look at some of them There are strong, wear-resistant, elastic, lightweight, corrosion-resistant, heat-resistant structural materials. 7 Introduction Technological requirements. The principle of parallelism is the simultaneous execution of partial production processes and separate operations on similar parts and parts of the product at different workplaces. there are other principles that ensure the manufacturability of parts production processes. direct flow, flexibility, optimality, prevention The principle of automaticity - assumes the maximum execution of operations of the production process automatically, i.e. without direct participation of the worker or under his supervision and control. 8 Introduction Economic requirements. The economic requirements come down to the cost and availability of the material. especially these requirements are important when scaling production. I mean the transition from laboratory-scale production to fullfledged production of hundreds and thousands of parts in a factory. Naturally, production within a laboratory, when it comes to a small number of products, and a factory are different. For example, laboratory synthesis often uses inert media such as argon or nitrogen. Inert synthesis avoids oxidation. But such a synthesis is expensive, especially when producing a large batch of parts. It turns out that manufacturers should avoid such economically disadvantageous conditions as inert. 9 10 2. Classification of materials: metals 11 Classification of materials Metallic materials Ferrous metallurgy Non-metallic materials Composite materials In turn, metallic materials are divided into materials of ferrous and non-ferrous metallurgy. Non-ferrous metallurgy On the slide you can see examples of the listed material classes. Examples steels, cast irons, ferro-alloys and iron-based alloys non-ferrous metals aluminum, copper, zinc, lead, nickel, tin and their alloys As you can see, materials are categorized into metallic materials, non-metallic materials, and composite materials. rubber, ceramics, glass, plastics, sitalls fiberglass, carbon plastics, kevlar, damask So the materials of ferrous metallurgy include ... Now let's define each of the material classes 12 Classification of materials: metals Metals (from Latin metallum - mine) are a group of chemical elements that, under normal conditions*, have characteristic metallic properties, such as: - high heat and electrical conductivity, - positive temperature coefficient of resistance, - high plasticity, - malleability and metallic luster. *pressure p = 0.1013 MPa = 760 mm Hg. Art. (normal atmosphere) temperature of 273.15 K (0 ° C) We'll start with metals. As you can understand from the definition .. At the bottom of the slide, you can see…. 13 Classification of materials: metals Metals Let's talk about examples of metals. Where can you find metals? if we look at… locate There are metals in the blue cells of the table. For instance, its iron, aluminum, copper and others. 14 OpenStax, Chemistry. OpenStax CNX. Jun 20, 2016 Classification of materials: metals Metals filling procedure Let's take a look at the electronic formula of metals. You can see the structure of the aluminum atom on the slide. According to Mendeleev's periodic table, it has only three electron orbitals. is determined by On the one hand, it is in the third group, that is, it has only three electrons in the outer energy orbital. Great, we figured it out. Go ahead. The first level in any atom (except hydrogen, try to guess why) is filled with only two electrons. short electronic entry As we remember, there are eight electrons at the full electronic level. And three more on the outer level. As a result, there are thirteen 15 electrons in the aluminum atom. Classification of materials: metals Ferrous metals - iron and alloys based on it (steel, ferroalloys, cast irons). Cast irons are alloys of iron with carbon, with a carbon content of more than 2.14% (in some cast irons up to 6%). Cast irons are classified into white, gray, and malleable. Steels are alloys of iron with carbon with a carbon content of less than 2.14%. low carbon (less than 0.25%), carbonaceous (0.25-0.6%), high-carbon (more than 0.6%). Let's move on to ferrous metallurgy. Ferrous metals - iron and alloys based on it (steel, ferroalloys, cast irons). These metals are mainly used in the production of iron and steel. Ferrous metals account for more than 90% of the total volume of metals used in the economy, of which the bulk is various steels. The main element giving various properties to iron alloys is carbon. 16 Classification of materials: metals Ferrous metals In addition to carbon, cast irons and steels contain other components that are divided into alloying: to obtain cast irons and steels with the required properties - corrosion resistance, - elasticity, - ductility, - heat resistance; alloying components include silicon, aluminum, manganese, molybdenum, copper, nickel, chromium, vanadium, tungsten and others; harmful impurities: sulfur, phosphorus, arsenic, oxygen, nitrogen 17 Classification of materials: metals for example, let's analyze the composition of cast iron CAST IRON COMPOSITION Iron (Fe) The mine component of cast Carbon (C) Silica (Si) Manganese (Mn) Phosphorus (P) harmful impurities Sulfur (S) Chromium (Cr) Nickel (Ni) Molybdenum (Mo) alloying components consists of Classification of materials: metals now we turn to such a topic as Non-ferrous metallurgy is a branch of metallurgy that includes the extraction, processing of non-ferrous metal ores and the smelting of non-ferrous metals and their alloys. According to their physical properties and purpose, nonferrous metals can be conditionally divided into heavy (lead, zinc, tin, nickel) and light (aluminum, titanium, magnesium). On the basis of this division, a distinction is made between the metallurgy of light metals and the metallurgy of heavy metals. 19 20 3. Classification of materials: non-metals and composites so, in the third part of our lecture we will touch on such topics as 21 Classification of materials: nonmetals Nonmetals Metalloids Moving on to non-metals. As you can see from the definition, Nonmetals are chemical elements with typically nonmetallic properties that occupy the upper right corner of the Periodic Table. On the slide, you can see the already familiar periodic table, where non-metals are marked in blue. Unlike metals, there are much less non-metals, there are 22 elements in total. The metalloids are in purple these are several compounds: bork, silicon, arsenic, tellurium, germanium, antimony 22 OpenStax, Chemistry. OpenStax CNX. Jun 20, 2016 Let's recall what electronic levels are and how to understand how many electrons are on the outer level. Classification of materials: nonmetals Nonmetals Oxygen atoms This is important because the number of electrons in the external energy level will determine the oxidizing capacity of the element. Electron Electron That is, its ability to accept missing electrons. So let's break it down with oxygen. Let's go back to Mendelian's periodic table. Empty Oxygen is located in the second row, that is, it has two energy levels. At the same time, he is also in the sixth group, that is, on the external level, he has six electrons. as you remember, the level at which there are eight electrons is considered complete. That is, oxygen lacks two electrons, which it will take away from other elements, forming compounds. 23 Classification of materials: composites A (properties A) + B + (properties B) … (properties ….) AB.. = (properties C) A≠B≠C (properties A) ≠ (properties B) ≠ (properties C) Composite material or composite a multicomponent material made of two or more components with significantly different physical and/or chemical properties. Theirs combination, lead to the emergence of a new material with characteristics that differ from the characteristics of individual components connection of material a with material b these materials have phase boundaries, that is, they do not mix with each other until they completely dissolve or form a completely new material 24 Classification of materials: composites In the composition of the composite, it is customary to separate the matrix / matrices and reinforsement. matrix/matrices phase boundary composite reinforcement If we vary the composition of the matrix and reinforcement, their ratio, the orientation of the filler, we can obtain a wide range of materials with the required set of properties. let's take a closer look at the different types of composite materials 25 Classification of materials: composites Type of composites materials each of these fillers imparts different properties to the matrix. For example, such a filler can impart strength to the composite or, on the contrary, plasticity 26 Classification of materials: composites we can highlight in turn this classification was taken from Ibrahim ID et al (2015). Journal of Reinforced Plastics and Composites. DOI: 10.1177 / 0731684415591302 27 Classification of materials: composites Mineral fillers are natural or synthesized solid surface particles that do not contain metal or carbon black. Such fillers have a variety of shapes - from almost spherical particles to lamellar and needle-like. Mineral fillers for PVC historically include calcium carbonate (ground and precipitated), aluminum trihydrate, barite, talc, mica, kaolin, feldspar, nepheline syenite, and wollastonite. 28 29 4. Atomic-crystalline structure of metals 30 Atomic-crystalline structure of metals can be divided into In a solid state, a substance has a special crystalline structure called a crystal lattice. This is an auxiliary geometric image introduced to analyze the structure of a crystal. In the nodes of the imaginary lattice are metal ions, between the nodes - electrons. I would underline, that… 31 OpenStax, Chemistry. OpenStax CNX. Jun 20, 2016 Atomic-crystalline structure of metals 14 types of Bravais lattices: Primitive (atoms only at nodes), Base-centered (additional atoms at the centers of two opposite faces), Body-centered (additional node in the center of the cell), Face-centered (additional knot in the center of all faces), Rhombohedral - two additional nodes dividing the volumetric diagonal of a hexagonal cell into three equal parts. Depending on the values of the size and mutual orientation of the ribs, 14 types of Bravais lattices are distinguished: number 1 can be attributed to Atomic-crystalline structure of metals The interplanar distance in the crystal (d (hkl) is the distance between the planes of one family of parallel planes. A unique characteristic of the lattice of each substance. fingerprints The interplanar distance d (hkl) The distance between atoms in the crystal lattice of solids is ~ 0.1 nm - 1.5 nm. The orientation of the family of planes in the crystal is given by the Miller indices - h k l (x y z). the orientation of the crystal faces in space is described by Miller indices. Atomic-crystalline structure of metals Miller indices - h k l (x y z). Miller indices (h k l) - plane coordinates. X-axis - [1 0 0] Y-axis - [0 1 0] Z axis - [0 0 1] Miller's indices are a kind of address where you can find a crystal lattice site. How do you know which Miller index corresponds to a certain angle? For example, let's look at the picture. In order to determine the Miller indices, you need to mentally move the origin of coordinates to one of the nodes of the crystal lattice. Atomic-crystalline structure of metals Miller indices - h k l (x y z). Miller indices (h k l) - plane coordinates. X-axis - [1 0 0] Y-axis - [0 1 0] Z axis - [0 0 1] In the figure, as you can see, the origin is placed at one of the nodes and has coordinate 0. Next, you mentally draw the axes, which will be the crystal faces. Then the node lying on the x-axis will have coordinates 1 0 0. Indeed, because it belongs only to the x-axis, and does not belong to the other two axes - y and z. The node with coordinates 101 belongs directly to the x axis and the upward z axis. But it does not belong to the y-axis and has coordinate 0 in its direction. What coordinates do you think will have a node belonging to three axes at once? Atomic-crystalline structure of metals Miller indices - h k l (x y z). Miller indices (h k l) - plane coordinates. X-axis - [1 0 0] Y-axis - [0 1 0] Z axis - [0 0 1] in fact, not only the nodes, but also the crystal planes have their own coordinates. How to define them. It is very simple: the plane will have the coordinates that the line perpendicular to it has. And we have just learned to determine the coordinates of the line - these are the coordinates of the node that lies on this axis. Let's figure it out and look at the figure. The upper plane of the cube is intersected only by the z axis. What are the coordinates of this axis or the node of the crystal that lies on it? 001. The plane has the same coordinates. Ok, now let's deal with the right side of the cube. It is perpendicular to the y-axis. As you may have guessed, the coordinates of this plane are then 010. Atomic-crystalline structure of metals Miller indices - h k l (x y z). Miller indices (h k l) - plane coordinates. X-axis - [1 0 0] Y-axis - [0 1 0] Z axis - [0 0 1] let's complicate the task. Why do you think the shaded plane of the cube has coordinates 010? V ery simple: the axis perpendicular to it leaves the origin and belongs to two axes x and y at once. In fact, it perpendicular to the plane х0y Atomic-crystalline structure of metals Miller indices - h k l (x y z). Miller indices (h k l) - plane coordinates. X-axis - [1 0 0] Y-axis - [0 1 0] Z axis - [0 0 1] and one more task. You can see a plane that has coordinates 111. This plane is a perpendicular line that comes out of the origin of the coordinate system and does not lie on any plane. That is, it belongs to three axes at once –x y z. Therefore, the plane perpendicular to it has coordinates 111 Atomic-crystalline structure of metals Miller indices - h k l (x y z). you can practice and independently understand why this or that plane has certain coordinates. Atomic-crystalline structure of metals I think you have a good question. Why do we analyze in such detail what coordinates have the nodes of an invented crystal lattice? As I said, each substance has its own unique crystal lattice - with a unique interplanar distance and arrangement of atoms, that is, a unique set of Miller indices. On the slide you can see the graphical structure of iron oxide magnetite, built using the Vesta graphics program. Knowing the Miller indices, we can determine the position of each atom in the lattice and thus distinguish magnetite from other compounds. Vesta, #COD 9006920 In other words, we can identify the phase. 41 5. Structural research methods. X-ray diffraction analysis (XRD) Structural research methods Various methods are used to study structural materials. Macroanalysis: Study the structure of materials visually or with optical instruments. The most accessible is the study of kinks Microscopic analysis: performed using optical microscopes (useful magnification up to 950x) and electron microscopes X-ray analysis: The crystal lattice parameters are determined using X-ray structural analysis. As you already understood, the parameters of the crystal lattice, which we studied before, are used to identify a substance by X-ray phase analysis. Let's take a closer look at this method. 43 X-ray diffraction analysis The electromagnetic spectrum from the name of the method it is clear that it uses X-ray radiation. The electromagnetic spectrum is the aggregate of all frequency ranges of electromagnetic radiation wavelength λ= 10-11 – 10-8 нм ten to the minus eleven power area •0.1 nm - 0.01 nm - hard X-ray radiation. Sources: some nuclear reactions, cathode ray tubes. • 10 nm - 0.1 nm - soft X-ray. Sources: cathode-ray tubes, thermal radiation from plasma. X-ray diffraction has acted as the cornerstone of twentieth-century science. Its development has catalyzed the developments of all of the rest of solid-state science and much of our understanding of chemical bonding. Some 10000–20000 powder diffractometers are in use worldwide, and of the order of 160000 powder patterns are available in the Powder Diffraction File (PDF) electronic database. I would like to read you a quote about the method that we will now be studying from.. One of the important method XRD: Сapability of the method Qualitative analysis • identification of crystalline phases; • determine the state of a solid (crystalline, amorphous, amorphous with crystalline inclusions); • determine the parameters of the unit cell of an unknown substance; • make structural analysis of simple structures • determine the coordinates of atoms in a unit cell; Quantitative analysis • • • • • determination of the number of phases in the mixture; determination of average crystal sizes determination of their size distribution function study of internal stresses studying textures, i.e. nature of predominant orientation of crystallites. XRD: Аdvantages of the method • the drug is not destroyed during analysis; • analysis requires a small amount of substance; • relative simplicity of required settlement operations • the ability to distinguish between modifications and isomers of the same chemical compound XRD: The essence of the method Let us direct parallel X-rays at an angle φ on the crystal plane hkl, spaced from each other at a distance d. X-rays penetrate deep into the crystal and their reflection occurs not only from the surface, but also from the underlying planes. Reflection does not occur at every angle φ. The reflected reflex can occur only when the resulting amplitude is different from zero and sufficient in magnitude to be recorded. XRD: Wolfe-Bragg’s condition (law) in other words, only those rays will be registered that correspond to the Bragg equation, which is shown on the slide. This law describes the dependence of the wavelength of the incident radiation on the interplanar distance and the angle of inclination of the source at which the X-ray waves cross the sample. XRD: Wolfe-Bragg’s condition (law) The crystal is on a rotating platform. Under some of its provisions, the Wolfe-Bragg conditions are satisfied. Instead of one rotating crystal, you can take a crystalline powder, consisting of a huge variety of differently oriented crystals. Due to the disordered orientation of the crystals, it is obvious that among them there are always those for which the diffraction conditions are satisfied. 1. The cathode emits electrons when heated. XRD: X-ray source 2. Due to the large potential difference between the cathode and anode, the flow of electrons is accelerated and gains more energy. The resulting accelerated electron beam hits the positively charged anode. X-ray tube (Cu-anode) X-ray 3. Upon reaching the anode, the electrons experience a sharp deceleration, instantly losing most of the acquired energy. This produces X-ray bremsstrahlung. 4. During deceleration, only about 1% of the kinetic energy of an electron goes to X-rays, 99% of the energy is converted into heat. in the figure you see a source with a copper anode. The anode material is very important, since the position of the peaks in the diffractogram will depend on the anode material. The diffractometer records the intensity and scattering angle of X-rays. XRD: The diffractometer Let us examine in detail the operation of the diffractometer. as you can see, the rotating platform with the source emits X-rays. They pass through several monochromators to select a specific wavelength. In a diffractometer, a beam of X-rays strikes a crystalline material, producing an X-ray diffraction pattern that can be analyzed to determine the crystal structure. Then they pass through the source, which also rotates and hit the detector. And then the information goes to the computer. OpenStax, Chemistry. OpenStax CNX. Jun 20, 2016 53 6. Processing of X-ray diffraction analysis data XRD: Experimental data processing And we get a set of coordinates from the original spectrum (X-axis - scattering angle, Y-axis - intensity) Let's see exactly how the data received by the detector is processed. the original data is converted into a graph called a diffractogram. Based on the diffractogram, we can obtain information about the interplanar spacing, Miller indices - and, most importantly, the phase composition of the substance. That is, we can understand what kind of substance it is. Intensity, (a.u.) XRD: Information extracted from radiographs background (instrumental noise, amorphous phase) peak position - lattice parameter FWHMaverage crystal size Diractogram can be analyzed according to several key parameters. First, the presence of a small number of high narrow peaks demonstrates the crystallinity of the substance. If in the area up to 20 degrees there is a wide peak (the so-called halo), then it can be attributed either to the amorphous part, which is in the substance, or to the measurement features. XRD: Information extracted from radiographs the position of the peaks is described by Miller indices. Intensity, (a.u.) Each substance has its own unique set of Miller indexes with a unique position. background (instrumental noise, amorphous phase) peak position - lattice parameter FWHMaverage crystal size It is this set: the position of the peaks and their intensity make it possible to identify the substance. Finally, the position at half height allows the particle size to be calculated. XRD: ICDD Database Information on the ratio of interplanar distance and intensity for each substance is presented in the "X-ray card index", published before 1970 by the American Society for Testing and Materials (ASTM) (American Society for Testing and Materials). Subsequent issues are published by ICDD International Center for Diffraction Data. XRD: Determination of the phase composition by ICDD X-ray radiation crosses the crystal planes with certain Miller indices. As you can see, these indices can be labeled over the peaks of the diffractogram. Intensity, (a.u.) XRD: Determination of the phase composition by ICDD on this slide you can see a graphical representation of how material is identified. The program compares the obtained diffractogram with those in its database. The closest variants allow identifying the phase. However, what if the obtained diffractogram does not completely coincide with those in the database? then we can say that we are dealing with some intermediate phase variant. XRD: Determination of the phase composition by ICDD Let's take a look at this using the example of the scientific work of the research group to which I belong. We synthesize and modify magnetite nanoparticles. However, under certain conditions, magnetite nanoparticles can oxidize to another iron oxide - maghemite. Nucleus structural formula % Fe3O4 Particle size ± standard deviation, nm Fe3O4 Fe2,93O4 78.8 11.5±2.3 Fe3O4/APTES (I) Fe2,92O4 75.8 13.1±3.3 Fe3O4/APTES (II) Fe2,81O4 42.4 12.4±1.9 X-ray phase analysis allows you to determine the percentage of magnetite and maghemite in the resulting mixture. Reference 1. Fetisov G.P., Karpman M.G., Matyunin V.M. and other Materials science and technology of construction materials. - M .: Metallurgy, 2000, 2001. 2. Abraimov N.V., Eliseev V.S., Krymov V.V. Aviation materials science and metal processing technology / Ed. N.V. Abraimova. - M .: Higher school, 1998.444p. 3. Lakhtin Yu.M. Metallurgy and heat treatment. - M .: Metallurgy, 1993. 4. Kolachev B.A., Livanov V.A., Elagin V.I. Metallurgy and heat treatment of non-ferrous metals and alloys. - M .: MISIS, 1999. 5. Shishkin, A. V. Materials Science. Construction technology materials: textbook. for universities / A. V. Shishkin. - Novosibirsk: Publishing house of NSTU, 2004. 6. X-RAY METHOD OF DIAGNOSTICS AND QUALITATIVE PHASE ANALYSIS OF MINERALS, Kutsevol M.L., Dnepropetrovsk 7. Qualitative X-ray phase analysis. ICDD Database., Moscow, 2012. Course for FNM MSU. 8. Pavel Chizhov, X-ray radiation. Interaction of X-ray radiation with matter. General view of the diffractogram. Profile analysis. Laboratory of Inorganic Crystal Chemistry, Department of Inorganic Chemistry, Faculty of Chemistry, Moscow State University. Moscow 2010. Course for group 415 of the Chemical Faculty of Moscow State University. Lecture 3 9. Methods of crystal structure research. Powder diffraction. Lecture course 62 Thank you for help in creating the lectures of the professor of the department 912B MAI Gulzhian Dzhardimalieva. 63