Hydrometallurgy, 29 ( 1992 ) 173-189

173

Elsevier Science Publishers B.V., Amsterdam

Acidic dissolution of zinc ferrite

F. Elgersma, G.F. Kamst, G.J. Witkamp and G.M. van Rosmalen

Delft University of Technology, Laboratory for Process Equipment, Leeghwaterstraat 44, 2628 CA

Delft, The Netherlands

(Revised version accepted December l 0, 1991 )

ABSTRACT

Elgersma, F., Kamst, G.F., Witkamp, G.J. and Van Rosmalen, G.M., 1992. Acidic dissolution of zinc

ferrite. In: W.C. Cooper and D.B. Dreisinger (Editors), Hydrometallurgy, Theory and Practice.

Proceedings of the Ernest Peters International Symposium. Hydrometallurgy, 29: 173-189.

The dissolution of synthetic and industrial zinc ferrite was studied in HNOs, HCIO4 and H2504

solutions, at temperatures ranging from 75°C to 95°C and in the presence of an excess of Fe 2+, Fe 3+

or Zn 2÷ ions. The rate constant describing this dissolution process was obtained by using a surfacereaction controlled, shrinking core model, which yielded good results.

The dissolution rate of zinc ferrite depends on the square root ofthe hydrogen ion activity in H2SO4

and HCIO4 solutions. The apparent activation energy for the dissolwtion equals 74 + 2 kJ/mol in H2504,

47 + 22 kJ/mol in HCIO4 and 37 + 16 kJ/moi in HNOs. The order of the rate constant was 0.6 in the

Fe 2+ and - 0 . 5 in the Fe s+ concentration. The rate constant for the dissolution of industrial zinc

ferrite was 20-50% lower than for synthetic zinc ferrite. The presence of 85 g/i Zn 2+ in the leach

solution retarded the dissolution rate of zinc ferrite. A dissolution mechanism is proposed which

qualitatively explains the results obtained.

INTRODUCTION

Hydrometallurgical zinc winning plants frequently use ZnS concentrates

which contain up to 10% Fe. During roasting, iron combines with zinc to

form the spinel ZnO'Fe203 (zinc ferrite). In order not to lose zinc incorporated in ZnO'Fe203, acidic leaching (pH 1, 90°C) is required to dissolve it.

The dissolution yields a Zn/Fe solution from which iron has to be removed.

This is mostly done by operating a jarosite, goethite or haematite process.

This paper aims at studying the factors that affect the dissolution rate of

ZnO'Fe203. Such information is useful for optimizing the current leaching

process and is essential for the design of a simultaneous jarosite precipitation/zinc ferrite dissolution process, which may have considerable advanCorrespondence to: F. Elgersma. Delft University of Technology, Laboratory for Process Equipment, Leeghwaterstraat 44, 2628 CA Delft, The Netherlands.

0304-386X/92/$05.00 © 1992 Elsevier Science Publishers B.V. All rights reserved.

174

E ELGERSMAETAL.

tages compared to the current, subsequent, zinc ferrite dissolution-jarosite

precipitation process.

The dependence of the dissolution rate of ZnO.Fe203 o n the composition

of the leach solution was studied because the solution composition influences

the solution potential, which is one of the rate-determining factors in the dissolution process. The solution composition was varied by choosing different

initial concentrations of Fe 2+ and Fe 3+. Furthermore, the dependency on the

hydrogen activity was determined in H 2 S O 4 and HCIO4 leaching and the kinetics were determined, by varying the leach temperature between 75 °C and

95°C in HNO3, HCIOa and n 2 s o 4. The Z n 2+ and the HSO4- concentration

were varied independently in order to study complexation effects in the leach

solution, which indirectly affect the solution potential. Finally, the dissolution rates of synthetic and industrial ZnO. Fe203 were compared.

Although earlier work [ 1-7 ] on the dissolution rate of ZnO.Fe203 has been

published, no systematic study on the relationship between the solution composition and the dissolution rate, as provided in this paper, was available yet.

EXPERIMENTAL

Synthetic ZnO. F e 2 0 3 w a s prepared in a m o u n t s of 5 or 10 g by the following

procedure: In deionized, distilled water, stoichiometric amounts of

ZnSO4.7H20 (72 g/I) and FeSO4.7H20 (139 g/l) were dissolved at 75°C

after addition of l wt% H2SO4. Upon mixing with a solution containing

(NH4)~C~O4 in 10% excess at 90°C, ZnFe2(C204 ).~ was formed. The precipitate was filtered, washed and subsequently dried for 3 h at l l0°C. It was

calcined at 700°C for 20 h to yield ZnO. Fe.,O3. A sample of 0.25 g ZnO.Fe203

was leached for 2 h at 25°C in 50 ml of a solution, containing 20 g NH4C! and

600 ml 25% NHs per liter, for determining the residual ZnO content of the

synthetic product [ 8 ]. Industrial ZnO. Fe203 was isolated from industrial calcine. This was formed in a 9.5 m diameter fluid bed roaster at 910°C using a

ZnS concentrate containing about 52 wt% Zn and 8 wt% Fe. The isolation

procedure included the dissolution of ZnO in 0.1 M H2SO4 at 20°C until no

t~rther increase in the pH was measured. All chemicals used were analytically

pure.

The synthetic and the industrial ZnO.Fe203 were characterized by scanning electron microscopy (SEM) to establish the crystal size and shape and

by X-ray diffraction (XRD) to confirm the crystal structure. Kryptonporosimetry was applied to determine the specific surface area. The particle

size distribution was determined using a Coulter Counter Multisizer. A sample of 0.1 g ZnO'Fe203 was leached for 15-30 min in l0 ml of 36% HCI at

25 °C. This "total" leach provided the total amount of zinc and iron in the

product.

For determination of the dissolution rate, 0.25 g or 0.5 g ZnO'Fe203 was

175

ACIDIC DISSOLUTION OF ZINC FERRITE

leached by either HNO3, HCIO4 o r H 2 S O 4 at temperatures between 75 °C and

95°C in a 250 ml round-bottomed flask, stirred at 610 rpm. Each 3, 5, 10 or

15 min a liquid sample was taken and the zinc and iron contents of the solution were determined by AAS and/or ICP. I f F e 2+ had been added, the flask

was operated under a N2 atmosphere. The flask was immersed in a thermostatically controlled water bath with a terr,perature accuracy of _ 0.2 ° C. The

experiments lasted between 20 rain and 3 h.

H 2 S O 4 w a s used as the leachant because this reflects industrial practice.

HNO3 and HCIO4 w e r e used, in order to avoid complexation between the

acid anion and Zn 2÷ and Fe 3+. Fe(NO3)3"9H20, ZnSO4"TH20,

Zn (NO3)'6H20, FeCI2.4H20 and FeSO4.7tt20 were used as sources for Fe 3+,

Zn 2+ and Fe 2+ ions, respectively. NaHSO4.H/O was added as a source of

excess H S O 4 - ions in an H2SO4 leach solution.

DATA ANALYSIS

The conversion data for each experiment were characterized by a rate constant for dissolution obtained from a surface reaction controlled shrinking

core model given by:

l - ( l - x ) l / 3 = l /3kSo t

(1)

where: x = t h e conversion; k = t h e rate constant (g/m2.min); So=the specific surface area of the solids (m2/g) at t = 0 ; t = t h e time (min).

In deriving eq. ( 1 ) the following assumptions were made:

( 1 ) the particles dissolve isomorphically;

(2) the number of particles remain constant throughout the process;

(3) the dissolution rate per unit surface area is constant, thus a constant

driving force tbr the dissolution process is required.

The conversion x is defined as the ratio of dissolved iron per gram

ZnO. FeaO3 in a sample over dissolved iron per gram ZnO. Fe203 as obtained

0

~is

•

s

i

lo

20

~m

~'o

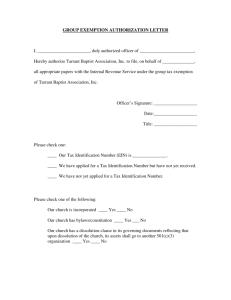

Fig. !. A representative volume-based panicle size distribution of synthetic zinc ferrite.

176

F. ELGERSMA ET AL.

Fig. 2. A representative SEM photograpii of a synthetic zinc ferrite particle (a) before and (b)

acidic leaching.

after

during the "total leach". The zinc concentration is used for calculating the

conversion in cases where iron ions were added.

ACIDIC DISSOLUTION OF ZINC FERRITE

177

RESULTS

Characterization of zinc ferrite

Synthetic ZnO. Fe203 was prepared in small charges of 5 or I 0 g, in order

to attain a 100% yield. The free ZnO content varied between 2.5 and 5 wt%

and the free Fe203 content between 2 and 7 wt%. Thus, the purity of zinc

ferrite samples was about 90 wt%. A typical volume-based particle size distribution of the synthetically obtained product is given in Fig. 1. No crystalline

phases apart from zinc ferrite were detected. The specific surface area of the

charges varied between 2 and 7 m2/g (accuracy _+2%). Figure 2 shows representative ZnO. Fe203 particles before and after leaching.

In industrial samples, ZnO'Fe203, Zn2SiO4 and PbSO4 were detected as

crystalline phases. Cd and Cu were detected chemically and are assumed to

be present as CdO.Fe203 (0.4 wt%) and CuO'Fe203 ( 1.4 wt%). The resulting purity of ZnO.Fe203 is about 70%. A good particle size analysis could not

be obtained because the industrial samples coagulated during the size analysis. Figure 3a, however, gives a representative view of industrial ZnO. Fe203,

which consists of even smaller particles than partly leached synthetic

ZnO. Fe203 (Fig. 3b).

Applicability of the shrinking core model

The shrinking core model adequately describes the dissolution process as

long as the conversion increases with time. The model yields a straight line

over the whole time range and the slope of this line yields the rate constant k.

In Fig. 4a the measured conversion data are properly fitted by a conversion

curve which is computed with the k value obtained from the shrinking core

model in Fig. 4b. In Fig. 5a the conversion time plot for a typical experiment

carried out in the presence of initially added Fe 3+, Fe 2+ or Zn 2+ is given.

The shrinking core model no longer yields a straight line when the conversion

becomes practically constant (Fig. 5b) and, therefore, the drawn straight line

was used as the best fit for the period of progressing conversion.

Table 1 shows the results of three experiments carried out to check the reproducibility (which was _+2.5% ) using three different charges. The rate constant is calculated assuming the significant internal surface area of ZnO. Fe203

to be fully wetted. This assumption was checked by comparing the results

obtained with this method with results obtained by rotating disc experiments

with a well-defined exposed surface area [ 3 ]. Since the deviation in the rate

constant for two experiments performed under similar conditions was within

5%, this assumption is justified.

Dependence of the rate constant on the temperature

The dependence of the rate constant on the temperature was determined in

0.5 M H2SO4, 1 M HNO3 and 1 M HCIO4 from experiments performed at

178

F. ELGERSMAET AL.

Fig. 3. A representative SEM photograph of industrial zinc ferrite (a) before leaching, compared to (b) synthetic zinc ferrite after leaching.

temperatures between 75 ° and 95°C. The results are listed in Table 2. Plots

of In k versus 1/ T are shown in Fig. 6. The apparent activation energies calculated from the slope of the drawn straight line equal 74_+2 kJ/mol for

H2SO4, 47 _+22 kJ/mol for HCIO4 and 37 +_16 kJ/mol for HNO3.

179

ACIDIC DISSOLUTION OF ZINC FERRITE

O.t, 1-II-X}

0.8 conversion

0

0

0

0

0.6

1/3

O

O

0

0

0.2

OJ,

0.2

(a)

0.0

0.o

0

50

100

150

200

Ib)

II

200

'

' 150

'

s"

time in minutes

time in minutes

Fig. 4. The measured conversion and the conversion predicted by (a) the shrinking core model

and (b) the linear dependency of the model value with time.

conversion

(-1

(a)

1

~ . / ~ ~ , , , ~

0.8

0.6

0.6¸

1-(1-Xl

I/3

(b)

O.l,,

0,2

- model

0,0

,,

o

lo

'

2'o

'

3'o

'

~'o'

s'o

.

0

.

.

.

20

/,0

6o

time in minutes

time in minutes

Fig. 5. The dissolution grade ofzinc ferrite in 2 M HCIO4at 90°C in the presence of (a) 20 g/i

Fe 3+ and (b) the corresponding shrinking core model value.

TABLE 1

Zinc ferrite dissolution experiments I: reproducibility of the results

Temperature

( °C )

Acid

Acid strength

( mol/! )

Added

ions

Rate constant

(g/m'-. rain )

90

90

90

H2SO4

0.5

0.5

0.5

-

0.0128

0.0133

0.0127

H2SO4

H2504

180

F. ELGERSMA ET AL.

TABI,E 2

Zinc ferrite dissolution experiments II: dependence on the temperature

Temperature

(°C)

Acid

Acid strength

(mol/l)

75

80

85

90

95

80

85

90

95

75

80

90

95

H2SO 4

H2SO 4

H2SO 4

H2SO 4

H2SO 4

HNO3

HNOa

HNO3

HNO3

HCIO4

HCIO4

HCIO4

HCIO4

0.5

0.5

0.5

0.5

0.5

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

-3

Added

ions

Rate constant

(g/m2.min)

0.0043

0.0065

0.0091

0.0133

0.0174

0.0011

0.0013

0.0013

0.0020

0.O004O

0.00095

0.00091

0.00123

tn k

-5

H2S04

•

-'7

.q

0.0030

1/T (l/K)

Fig. 6. The Arrhenius plot for the dissolution of zinc ferrite in 0.5 M sulfuric acid, 1 M nitric

acid and 1 M perchloric acid.

Dependence o f the rate constant on the H + and H S 0 4 - ion activity

The dependence of the rate constant on the H + activity was determined for

dissolution in H 2 S O 4 and HCIO4 solutions, from the experiments described

in Table 3. The H + ion activity was calculated using Pitzer's method [ 9 ]. The

required data were obtained from [ l 0 ]. The dissolution of Fe and Zn ions

during the experiment was neglected in the calculation of the activity coefficients. Fig. 7 shows the plots of log k as a function of log [H + ] obtained. For

both acids, an order of 0.50 in the H + activity was found. The activity cal-

181

ACIDIC DISSOLUTION OF ZINC FERRITE

TABLE 3

Zinc ferrite dissolution experiments !11: dependence on H ÷ activity

Temperature

(° C )

Acid

90

90

90

90

90

90

90

90

85

85

85

85

H2SO4

H2SO4

H2SO4

H2SO4

HCIO4

HCIO4

HCIO4

HCIO4

H2SO4

H2SO4

H2SO4

H2SO4

Acid strength

( mol/! )

Added ion

(g/!)

Rate constant

(g/m2. min )

0.25

0.5

1.0

2.0

0.25

0.5

1.0

2.0

0.5

0.5

0.5

0.5

24.3

48.6

72.9

145.8

0.0078

0.0 i 28

0.0172

0.0249

0.0004

0.0006

0.0009

0.0015

0.01 i 6

0.01 ! 3

0.0112

0.0109

HSO~

HSO~

HSO~

HSO~"

TABLE 4

Zinc ferrite dissolution experiments IV: dependence on the Fe 3+ concentration

Temperature

Acid

(° C )

85

85

85

85

90

t)0

90

90

90

H2SO4

H2SO4

H,SO4

1-12SO4

HCIO4

HCIO4

I-ICIO4

HCIO4

HCIO4

Acid strength

( mol/! )

Added ion

Rate constant

(g/i)

(g/m2. min )

0.5

0.5

0.5

0.5

2.0

2.0

2.0

2.0

2.0

3.8

3.9

5.5

6.4

2.0

4.5

10.0

15.0

20.0

Fe 3÷

Fe ~÷

Fe ~÷

Fe a÷

Fe ~+

Fe 3÷

Fe ~+

Fe "~+

Fe 3+

0.0076

0.0067

0.0066

0.0052

0.0015

0.0017

0.0013

0.00095

0.00080

culations showed that the SO4 2- activity was, surprisingly, independent of

the H E S O 4 concentration. Four experiments were carried out where NaHSO4.HzO was added, in concentrations ranging from 0.25 to 1.5 M. The

addition caused an increase in the rate constant of about 20%, compared to a

similar experiment without HSO4- addition.

Dependence o f the rate constant on the Fe 3+ concentration

The dependence of the rate constant on the Fe 3+ concentration was established for H2SO4 and HCIO4 solutions from the experiments listed in Table

4. The results of the experiments are shown in Fig. 8a, where log k versus the

initial Fe 3+ concentration in log(ppm) is plotted. In 0.5 M H2SO4, the order

182

F. ELGERSMA ET AL.

-2.8

log k

-).C

-3.2

{z)

-3.4

-0.8

-1./,,

•

'

'

_~.l,'

'

'

6

'

'

'

log all+

Io9 k

-1.6-1.8

-2.0

-2.2

(b)

.o',e-d,6-o',~,-o,2

o

o~

o~,

Inq i,i *

Fig. 7. The order of the rate constant for zinc fcrrite dissolution in the hydrogen activity (a) in

HCIO., at 90°C and (b) in aaso4 at 90°C.

in the Fe 3+ concentration equals -0.5+_0.2. in 2 M HCIO4, the order is

-0.50_+0.06. For calculating the order in 2 M HCIO4, the results from the

experiment with 2 g/I Fe 3+ were not used.

Dependence o f the rate constant on the Fe z + concentration

The dependence of the rate constant on the Fe 2+ concentration was determined for dissolution in H2SO4 and HCIO4 solutiens (Table 5). Six experiments were carried out with initial Fe 2+ concentrations between 0 and 800

ppm in a 0.5 M H 2 5 0 4 solution. The rate constants did not differ significantly. The addition of 4 g/l Fe 2+ as FeSO4"7H20, however, increased the

rate constant by 80% compared to a similar experiment in the absence of Fe 2+.

ACIDIC DISSOLUTION OF ZINC FERRITE

-2.0

183

tog k (a)

0

0

-3.2

3.0

tog

-1.0

si0

EFe3,

tog k (b)

t

0

-1.5

-25

3.:

'

316

'

,

,

~.0

---4--

,

,

tog

--, ........

T

4.,4.

CFe2+

Fig. 8. The orderof the rateconstant for ZnO.Fe203 dissolution for (a) Fe3+ concentrationand

(b) Fe2+ concentration in 2 M HCIO4at 90°C and 0.5 M H2SO4at 85°C.

Four experiments were carried out to determine the influence of the

FeCI2.4H20 addition on the rate constant in 2 M HCIO4. The results are shown

in Fig. 8b, where log k is plotted against the initial Fe 2+ concentration in log

(ppm). The order of the rate constant in the Fe 2÷ concentration equals

0.62 _+0.25, if the results are fitted with a straight line.

Dependence o f the rate constant on the

Zn 2+

concentration

The rate constant was measured in a 1.8 M H2504 solution in the presence

of 1.3MZn 2+, added either as Zn(NO3)2 or as ZnSO4. Table 6 shows that, in

the presence of NO3-, the addition of 85 g / l Z n 2 + decreases the rate constant

184

F. ELGERSMAETAL.

TABLE 5

Zinc ferrite dissolution experiments V: dependence on the Fe z+ concentration

Temperature

(-C)

Acid

Acid strength

(mol/l)

Added ion

(g/l)

Rate constant

(g/m-'.min)

85

85

85

85

85

85

90

90

90

90

H2504

H2504

H2SO4

H2SO4

0.5

0.5

0.5

0.5

0.5

0.5

2.0

2.0

2.0

2.0

0.073 Fe 2+

0.164 Fe -'+

0.240 Fe -'+

0.421 Fe 2+

0.806 Fe -'+

4.0 Fe -'+

!.8 Fe -'+

3.9 Fe-"+

8.9 Fe-"+

! 7.6 Fe-"+

0.0080

0.0072

0.0066

0.0075

0.0076

0.0166

0.0104

0.0102

0.0148

0.0455

H2SO4

H.,SO4

HCIO4

HCIO4

HCIO4

HCIO4

TABLE 6

Zinc ferrite dissolution experiments Vl: dependence on the Zn-' ÷ concentration

"i'cmpcrature

( ~(')

Acid

Acid strength

(mol/l)

Added ion

(g/l)

Rate constant

(g/m2,min)

00

~)()

~)()

H:SO4

H:SO,~

H:SO,~

1.8

1.8

1,8

85 Zn-' ÷

85 Zn ~'÷

0.0243"

0.0109 !'

0.0140"

" Estimated value,

"Zinc nitrate was used as zinc source,

' Zinc sulfate was used as zinc source,

by 55%. In the presence of an equivalent amount of

SO42- the rate constant

reduces by 42%.

D(['ferences between synthetic and industrial zinc ferrite

In a 4 M HCIO4 solution the rate constant of industrial ZnO.Fe203 was

about 80% of that of synthetic ZnO. Fe203, as follows from Table 7. In a 0.5

M H 2 5 0 4 solution, the ratio of the rate constants was about 0.5. Thus, the

rate constant for the dissolution of industrial ZnO.Fe,O~ is lower than for

synthetic ZnO. Fe203 which is leached under similar conditions. Since the purity of industrial ZnO'Fe203 is only about 70%, part of the specific surface

should be regarded as "non-active", which partly explains the difference.

An attempt to measure the dissolution kinetics of synthetic ZnO.Fe203 in

an industrial hot acid leach solution was not successful. This was because the

increase in zinc or iron concentration, upon leaching, could not be measured

185

ACIDIC DISSOLUTION OF ZINC FERRITE

TABLE 7

Zinc ferrite dissolution experiments VII: comparison with industrial ferrite

Temperature

( °C )

Acid

Acid strength

( mol/! )

Ferrite type

Rate constant

(g/m 2.min )

80

80

90

90

HCIOa

HCIO4

H2SO4

4.0

4°0

0.5

0.5

synthetic

industrial

synthetic

industrial

0.0026

0.0021

0.0133

0.0066

H2SO4

against the high background values of the iron ( 10 g/l) and zinc ( > 40 g/l)

concentration in the solution.

DISCUSSION AND CONCLUSIONS

It is still unknown whether the dissolution kinetics of ZnO. Fe203 in acidic

media can be fully explained by the dissolution mechanism proposed for haematite by Warren and Devuyst [ 11 ], as suggested by Lu and Muir [2 ]. In

this mechanism two options for desorption are distinguished:

Step 1: surface hydroxylation

I--sFe~lO + H20~b-sFe~ll (OH)2

(2 )

Step 2: surface protonation

t--sFelll-OH + H30 + ~-*[--sFelIIOH2 + + H20

(3 )

Step 3a: direct desorption

I--~FeIIIOH+ ~1--~+ FeIIIOH~,.+

(4)

Step 3b: anion adsorption and subsequent desorption

b-~FeUlOH2 + + X- ~l--s FelllOH2 X

(5)

I--sFelllOH2 X ~b--s+ FeUlOH2X 2+

(6)

Dependence o f the rate constant on the H + and HSO4- activity

The order of the rate constant in the H + activity equals 0.50 in both the

HCIO4 and H2SO4solutions. This is in accordance with a theoretical relationship for the acidic dissolution of a metal hydroxide derived by Vermilyea [ 12 ].

This relation may only be applied when H + is the only complexing agent on

the particle surface. Since metal oxides at pH values below that corresponding

to the zero point of charge (ZnO.Fe203, pHzpc= 3.5 [ 13 ] ) are hydroxylated

(step 1 in the model), the same relationship may also be applied for describing the acidic dissolution of metal oxides:

186

F. ELGERSMA ET AL.

( { n _ k T n _ C } ~ '~+z+~/~'~+l+-°~-z-~

r = n +k + \ {--'ffg-~r-;~ }

(7)

where:C=the H + concentration (tool/l); a + and t~- =the electrochemical transfer coefficients (which are usually equal to 0.5 [ 14 ] ); n = the number ofions/cme; z=the charge number of H +; kr ÷ and kr- =constants; r=the

dissolution rate (mol/l.cm 2 ).

With z+ = 1 for H ÷ and z_ = - 1 for the transferred electron, it becomes

clear that the dissolution rate depends upon the square root of the H +

concentration.

Additions of 0.25-1.5 M HSO4- to 0.5 M H2SO4 solutions all increase the

rate constant for dissolution by 20%; probably as a consequence of the excess

of HSO4- already present.

The dependence of the rate constant on the potential of the solution

The presence of F e 2 + and Fe 3+ directly influences the potential of the solution and, thereby, the dissolvtion rate of ZnO. Fe2Oa, which is determined

by the potential difference between the surface of the particles and the bulk

of the solution. The reductive dissolution, here in the presence of Fe 2+ in

solution, has been described by Lieser [ 15] for the dissolution of anhydrous

Fe2(SO4)3. The rate-determining step was the reduction of a Fe a+ ion in the

surface layer by a hydrogen atom, which, it is claimed, is formed in the double

layer due to the oxidation of a dissolved Fe 2+ ion. If Fe 2+ is present in the

leach solution, in the absence of other reductants it becomes the ion determining the solution potential. The lower solution potential, due to the presence of Fe 2÷, increases the direct desorption rate (step 3a in the model),

because Fe 3+ desorbs more easily from the surface layer, after being indirectly reduced by dissolved Fe 2+. Upon entering the solution the valency of

the desorbed species becomes determined by the solution potential.

Nil and Hisamatsu [ 7 ] presented the dependence of the rate constan~t for

ZnO. Fe203 dissolution, on the addition of 0-1 g/l Fe 2+ as FeSO4.7H20 to a

9 wt% H2SO4 solution at 50°C. The order of the rate constant in the Fe 2+

concentration was 0.5. Our results, however, show that, at 85°C in a 0.5 M

H2SO4solution, the addition of0-1 g/l Fe 2÷ did not change the rate constant,

as is shown in Table 5. This is probably due to the fact that, at higher temperatures, the dissolution proceeds so much faster that a small decrease in solution potential, due to a small Fe 2+ addition, is no longer significant.

In 2 M HCIO4 at 90°C using FeCl2.4H20 the order of the dependency on

the Fe 2+ concentration equals 0.62 _+0.25. It is, however, questionable whether

a linear fit is applicable. In the presence of Cl- and Fe 2+ the direct desorption

rate is increased by the presence of Fe 2+, but indirect desorption via CI- ad-

ACIDIC DISSOLUTION OF ZINC FERRITE

187

sorption (step 3b in the model) may also occur. Since FeCI2.4H20 was used

as the Fe 2+ source, both the Cl- concentration and the Fe 2+ concentration

increased. This probably caused the deviation from the straight line. Further

research on the separate influence of Fe 2+ is, therefore, still to be done.

No experiments have been reported in the literature in which ZnO'Fe203

was dissolved in the presence of Fe 3+. The above results show that the order

of the rate constant in the Fe 3+ concentration equals -0.5. No activities for

the Fe-'+ or Fe 3+ addition experiments were calculated because no appropriate data for Pitzer's models were available. Our experimental results, are in

reasonable agreemerit with a theoretically derived equation, presented by

Gorichev and Kipriyanov [ 16 ], for the dependency of the rate constant for

the dissolution of magnetite (Fe304) on the Fe 2+/Fe 3+ concentration:

0 5

0.5

--0 5

k = k o a f-i + a Fe2 + a Fe3";

(8)

The model of Gorichev and Kipriyanov [ 16 ] contains the same rate-determining step as the model by Lieser [ 15 ] and additionally includes the influence of the presence of Fe 3+ for determining the solution potential.

The solution potential is indirectly influenced by the presence of Zn2+,

SO 4- or CI-. Zn 2 + ions compete with Fe 3+ ions for complex formation with

SO4::-. The decelerating influence of Zn 2+ can be understood by assuming

that the free Fe 3+ concentration increases, and thereby the solution potential,

causing a reduction of the dissolution rate.

Both SO42- and Cl- play a similar role. By complexation of Fe 3+ with either

Cl- or SO42-, the free Fe 3+ concentration decreases, which decreases the solution potential. The complexation stimulates desorption via anion adsorption (step 3b). This explains the considerably lower leaching rate in HNO3

and HCIO4 solutions, when no complexation is expected, compared to the

rate in H2SO4 and HCi solutions. Surprisingly, the apparent activation energies of the dissolution in H2SO4 (74-+ 2 kJ/mol) and HCI (83 kJ/mol [ 4 ] )

are higher than the corresponding values in HNO3 (37_ 16 kJ/mol) and

HCIO4 (47_+22 kJ/mol), which fact points at a less favorable reaction path.

For this apparent discrepancy no explanation is currently available.

The reason for the large degree of uncertainty in the values for the activation energy in HNO3 and HCIO4 is unknown. Thus, further research is required in order to obtain these data with a higher accuracy. Despite the limited accuracy, the experiments clearly show the significant difference in

activation energy for the dissolution of zinc ferrite in H2SO4, compared to the

values in HNO3 and HCIO4.

CONSEQUENCES FOR INDUSTRIAL PRACTICE

The above results indicate that high Fe 3+ concentrations decelerate the dissolution of ZnO.Fe:O3~ However, by dissolving ZnO.Fe203, Fe 3+ is released.

188

F. ELGERSMAETAL.

It is, therefore, desirable to introduce a sink for Fe 3+. A suitable sink for Fe 3+

is jarosite (NHaFe3 (SO4)2 ( O H ) 6 . By simultaneously dissolving Z n O ' F e 2 0 3

and precipitating jarosite, the dissolution of zinc ferrite will not be retarded

by the presence of Fe 3+. Meanwhile, the precipitation of jarosite is taking

place under controlled conditions because the supersaturation for the precipitation is determined by the dissolution of Fe 3+ from ZnO'Fe203. This is beneficial for the produced crystal size and shape and, consequently, improves

the filterability of the solids. A better filterability reduces the zinc losses in

the jarosite residue. Experiments where this simultaneous conversion is studied will be reported in a subsequent paper.

ACKNOWLEDGEM ENTS

The Dutch Ministry of Housing, Physical Planning and the Environment is

acknowledged for sponsoring this reseach. F. van der Ham is thanked for his

contribution to this study.

REFERENCES

I

2

3

4

5

6

7

8

9

I()

I!

Pi.illenberg, R., Hydromet,~ilurgische Verarbeitung eisenreicher Zinkkonzentrate nach

tllcrnlischer Teilreduktion des R6stgutes. Ph.D. Thesis, Rhein-Westf~ilische Technische

Hochscl~ulc, Aachen, Germany ( 1981 ).

Lu, Z.Y. and Muir, L., Dissolution ofmetal ferrites and iron oxides by HCI underoxidising

and reducing conditions. Hydrometallurgy, 21 ( 1988): 9-2 I.

Ramachandra Sarma, V.N., Deo, K. and Biswas, A.K., Dissolution of zinc ferrite samples

in acids. Hydrometallurgy, 2 ( 1976)' ! 7 I- 184.

Nt.,~cz.

' C. and Vinals, J., Kinetics of leaching of zinc ferrite in aqueous hydrochloric acid

solutions. Metall. Trans. B, ! 5B ( 1984)' 221-228.

(iramatikov, M.V. and lvanovskii, M.D., Kinetics of zinc fcrrite dissolution in sulfuric

acid under the influence of ultrasonic vibrations. Russ. J. Appl. Chem., 45 ( 1972 ): 12201223.

Ryczaj, K. and Riesenkampf, W., Kinetics ofthe dissolution of zinc-magnesium ferrites in

sulphuric acid solutions related to zinc leach processes. HydrometaUurgy, I 1 ( 1983 ): 363370.

Nii, K. and Hisamatsu, Y., Study on zinc ferrite (V): The promotion ofacid dissolution of

zinc ferrite. Trans. Nat. Res. Inst. Metals, 8 (5) (1966): 193-199.

Chalyi, V.P. and Lukachina, E.N., Study of the kinetics and mechanism of ferrite formation in the aging of systems of metal hydroxides (1). lzv. Akad. Nauk SSSR Neorg. Mater.,

! (1965): !14-117.

Pitzer, K.S., Theoretical considerations ofsolubility with emphasis on mixed aqueous electrolytes. Pure Appl. Chem., 58 (1986): 1599-1610.

Pitzer, K.S., Theory: ion interaction ag,proach, in: R.M. Pylkowicz (Editor), Activity

CoeMcients in Electrolyte Solutions. CRC Press Boca Raton, Fla., USA, Vol. 1 (1979),

pp. 157-208.

Warren, I.H. anO Devuyst, E., Leaching of metal oxides. In: D.J.I. Evans and R.S. Shoemaker (Editors), Proc. Int. Symp. on Hydrometallurgy. TMS-AIME, Port City Press, Baltimore, Md., USA ( 1973 ), pp. 229-264.

ACIDIC DISSOLUTION OF ZINC FERRITE

189

12 Vermilyea, D.A., The dissolution c,f ionic compounds in acidic media. J. Electrochem. Soc.,

113 ( 1966): 1067-1070.

13 Kittaka, S. and Morimoto, T., Iso-electric point of metal oxides and binary metal oxides

have spinel structure. J. Colloid Interface Sci., 75 ( 1980): 398-403.

14 Atkins, P.W., Physical Chemistry. Oxford University Press, Oxford, UK, 2nd Ed. (1983),

p. 1047.

15 Lieser, K.H., Die AufliSsung des wasserfreien Eisen(lll)DSulfats in Gegenwart von verschiedenen Reduktionsmitteln in H20 und in D20. Z. Electrochem., 66 ( 1962): 23-29.

16 Gorichev, I.G. and Kipriyanov, N.A., Kinetics of the dissolution of oxide phases in acids.

Russ. J. Phys. Chem., 55 (1981): 1558-1568.