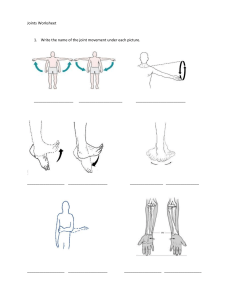

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/267412141 Characteristics of Sheathing-to-Timber Joints in Wood Shear Walls Article CITATIONS READS 8 356 2 authors, including: Ulf Arne Girhammar Luleå University of Technology 81 PUBLICATIONS 1,201 CITATIONS SEE PROFILE Some of the authors of this publication are also working on these related projects: Structural Robustness in Timber Buildings View project All content following this page was uploaded by Ulf Arne Girhammar on 31 January 2015. The user has requested enhancement of the downloaded file. Characteristics of Sheathing-to-Timber Joints in Wood Shear Walls Ulf Arne GIRHAMMAR Umeå University Sweden UlfArne.Girhammar@tfe.umu.se 1980 Dr. Eng.; 1981 Assoc. Prof.; 1987 Eng. Consultant, wood and building industry; 1989 Adjunct Prof. 1994 Senior Specialist, mechanics industry. Presently at Umeå University. Nils Ivar BOVIM Assistant Professor Agricultural University of Norway 1971 Civ.Eng, 1973-1982 at Norwegian Institute of Wood Technology. Since 1982 Consultant Eng. Since 1996 also at Agricultural University of Norway Bo KÄLLSNER Adjunct Professor Växjö University Sweden 1977 Dr in Civ Eng. Since 1975 at Trätek - Swedish Institute for Wood Technology Research in Stockholm. Since 2001 also at Växjö University. Summary The capacity of wood-framed shear walls is essentially governed by the characteristics of the sheathing-to-timber joints. Their characteristics and failure modes vary, e.g. with respect to loadingto-grain directions and edge distances of the fasteners. In this paper, results from an experimental study of sheathing-to-timber joints are presented and a parametric equation to model the entire load-slip relationship is proposed. Load-slip curves for different sheathing materials and load-to-grain directions are presented, and the influence of edge distance of fasteners in the sheets is illustrated. Key words: Sheathing-to-timber joint, load-to-grain direction, edge distance, analytical model. 1 Introduction 1.1 Background The behaviour and capacity of sheathed wood shear walls are essentially governed by the characteristics of the fasteners. In order to develop and apply accurate computerised design methods for such shear walls it is important to know in detail the characteristics and failure modes of the sheathing-to-timber joints, e.g. with respect to loading-to-grain directions and edge distances for the fasteners in the sheets and wood members. In non-linear finite element modelling of shear walls it is necessary to know the whole load-deformation curve of the joints including the different joint failure modes and to be able to model the successive joint failures and, therefore, the gradual failure of the shear wall as a whole. Also, in order to apply plastic design methods of the type presented in the companion paper [1], it is important to know the range of applicability with respect to the brittleness of the sheathing-totimber joints at failure. Due to economic reasons, it is desirable to use as few connectors as possible. Hence, large fastener diameters are often used and edge distances to the sheet and framing member become critical. This leads to brittle failure modes for the joints and the conventional elastic and plastic methods that are based on ductile failure modes are not applicable. 1.2 Objectives The purpose of this paper is to present the results of an experimental study and to give a mathematical model for the behaviour and characteristics of sheathing-to-timber joints. The study comprises of the following parts: (1) Tests of single joints with respect to different sheathing materials, load-to-grain directions, and edge distances; and (2) Development and application of a parameter equation modelling the entire load-slip behaviour of the joints. 1001 2 Testing Program 2.1 Test Specimens and Testing Procedure All test specimens were designed as follows: x Frame members: Pine (Pinus Sylvestris), C24, 45u120u300 mm. x Sheathing: 150u150 mm. x Nails: Annular ringed shank nails (Duofast), fy | 400-500 MPa, 50u2.1 mm. The joints were hand-nailed and the nail holes were pre-drilled, 1.7 mm, in case of hardboard. x Edge distances: For both frame member and sheet, 11.25 mm for parallel and 22.5 mm for perpendicular load-to-grain directions in timber, respectively. The test set-up is shown in Figure 1 for the single nailed sheathing-to-timber joints loaded parallel and perpendicular to grain, respectively. The testing procedure was designed to conveniently study the edge distance effect. P P 150 Free edge 150 Free edge 200 150 P 2 P 100+150+100 P 2 Figure 1. Test set-up for sheathing-to-timber joints subjected to tensile loads parallel and perpendicular to grain, respectively. All tests were performed under deformation control and with a deformation rate of 2 mm/min. For each test, the density and moisture content was determined and a choice of fasteners was tested. No adjustment of the test results was made with respect to these parameters. 2.2 Joints with Different Sheathing Materials at Different Load-to-Grain Directions Three types of materials were used: x Hardboard (wet process fibre board, HB.HLA2, Masonite AB): C40, 8 mm. x Particleboard (Byggelit AB): V100, 12 mm. x Plywood (Spruce, Picea Abies, Schauman Wood Oy): P30, 9 mm (3.2+2.6+3.2). The load directions were parallel (0q) and perpendicular (90q) to grain, respectively. 2.3 Joints with Hardboard at Different Load-to-Grain Directions and Edge Distances Only hardboard was used as sheathing material. The dimensions of the timber member were 45u95u300 mm and the sheet 150u230 mm in these tests. The edge distance of the fastener in the timber member was 22.5 mm in all tests. For load directions parallel to grain (0q), the following edge distances in the sheet were tested: x 1d and 2d, where d = 2.1 mm. And for load directions perpendicular to grain (90q): x 2d, 3d, 4d, and 5d, where d = 2.1 mm. 3 Test Results 3.1 Joints with Different Sheathing Materials at Different Load-to-Grain Directions 3.1.1 Hardboard The test results for parallel and perpendicular load-to-grain directions, respectively, are shown in Figure 2 (P = load, u = slip) [2]. In all parallel tests but one, a ductile type of failure took place (nail yielding followed by withdrawal of nail). The brittle type of failure, which occurred after the 1002 1600 1600 1400 1400 1200 1200 1000 1000 800 P [N] P [N] ultimate load-bearing capacity was reached, had reference to bending failure of nail in the sheet. All perpendicular tests exhibited a ductile type of failure (nail yielding followed by withdrawal of nail). Mean values are given in Table 1. Withdrawal 600 800 Withdrawal 600 400 400 Nail failure 200 200 0 0 0 5 10 15 20 (a) 25 30 35 40 45 50 0 5 10 15 u [mm] 20 25 30 35 40 45 50 u [mm] (b) Figure 2. Load-slip curves for hardboard: a) Parallel and b) perpendicular load-to-grain direction Table 1. Mean values of test results for joints with different sheathing materials. Sheathing material Hard0q board 90q Particle- 0q board 90q Ply0q wood 90q Displacement [mm] Dry density Moisture 3 [kg/m ] Content [%] At max. At failure load (1)* (2)* Timber Sheet Timber Sheet 5 50 382 896 10.5 7.1 6 33 388 884 10.4 6.9 10 14 44 462 595 9.7 6.7 12 16 37 466 582 9.8 7.6 10 19 459 428 9.2 6.3 12 19 41 442 419 10.4 6.8 Maximum load [kN] 1.03 1.05 1.30 1.21 1.32 1.39 Number of tests 10 10 10 12 10 12 * Displacement in case of (1) final brittle failure and (2) final ductile failure. 1600 1600 1400 1400 1200 1200 1000 Withdrawal P [N] P [N] 3.1.2 Particleboard The test results are shown in Figure 3 [3]. Due to a mistake, the slip is somewhat overestimated. Parallel tests: Three failures by withdrawal of nail, three by punching of nail head, and four by nail failure in timber member. Perpendicular tests: Five failures by withdrawal of nail, four by punching of nail head, and three by nail failure in timber member. Mean values are given in Table 1. 800 600 1000 Withdrawal 800 600 Punching 400 400 Nail failure 200 Nail failure 200 0 Punching 0 0 5 10 15 20 (a) 25 30 35 40 45 50 0 u [mm] 5 10 15 20 (b) 25 30 35 40 45 50 u [mm] Figure 3. Load-slip curves for particleboard: (a) Parallel and (b) perpendicular load-to-grain direction. For particleboard and plywood, the maximum values seem to have been influenced by the higher density of the timber members. Note also that the thickness of particleboard is 12 mm, about 50 % thicker than the one of hardboard and plywood. 1003 3.1.3 Plywood The test results are shown in Figure 4 [3]. Parallel tests: Nine failures by punching of nail head, and one by nail failure in timber. Perpendicular tests: Three failures by withdrawal of nail and nine by punching of nail head. The difference in failure characteristics between parallel and perpendicular directions is due to the grain direction of the surface layers. Mean values are given in Table 1. 1600 1600 1400 1400 1000 P [N] P [N] 1200 Punching 800 600 1200 1000 Withdrawal 800 600 400 400 200 0 0 5 10 Punching 200 0 Nail failure 15 20 (a) 25 30 35 40 45 50 0 5 10 15 20 u [mm] 25 30 35 40 45 50 (b) u [mm] Figure 4. Load-slip curves for plywood: (a) Parallel and (b) perpendicular load-to-grain direction. 1500 1500 1200 1200 900 900 P [N] P [N] 3.2 Joints with Hardboard at Different Load-to-Grain Directions and Edge Distances The maximum load versus the edge distance in the case of parallel and perpendicular load-to-grain direction, respectively, is shown in Figure 5 [4]. Parallel tests: 1d—One failure by withdrawal of nail and one by edge failure; and 2d —All failures by edge failure. Perpendicular tests: 2d and 3d— All failures by edge failure; and 4d and 5d—All failures by withdrawal of nail, except in one (for 4d) where nail yielding was followed by edge failure in a very late stage. Boundary for edge failure is 2d for parallel and 4d for perpendicular cases, respectively. The number of tests is yet too small to draw final conclusions. For details, see Table 2. 600 600 Edge failure Edge failure 300 300 0 0 0 1 2 (a) 3 4 5 0 Edge distance [d ] 1 (b) 2 3 4 5 Edge distance [d ] Figure 5. Max load vs edge distance: (a) Parallel and (b) perpendicular load-to-grain direction. Table 2. Mean values of test results at different load-to-grain directions and edge distances. Maximum load [kN] Parallel Perpendicular 1d 2d 2d 3d 4d 5d 971 1047 923 1212 1290 1162 Displacement [mm] Dry density Moisture 3 [kg/m ] Content [%] At max. At failure load (1)* (2)* Timber Sheet Timber Sheet 8 18 34 414 922 11.7 7.1 5 38 413 930 11.5 7.3 3 5 433 912 12.4 8.0 7 9 431 907 11.8 7.6 7 13 >30 423 904 11.0 7.4 6 >30 415 904 11.3 7.7 * Displacement in case of (1) final brittle failure and (2) final ductile failure. 1004 Number of tests 2 5 6 5 5 5 4 Analytical Evaluation 4.1 Analytical Description of Entire Load-Slip Relationship Foschi proposed a three-parameter function to model the load-slip behaviour of timber joints [5]. To include the softening behaviour of the joints, his equation is extended to a five-parameter function. Thus, the entire load-slip curve (P, u) for sheathing-to-timber joints can be approximated as P ( P0 K1u ) (1 e K0 u P0 D u E )e (1) where P0, K0, K1 = Foschi parameters, and D, E = additional parameters, see Figure 6. Evaluation of the five-parameter equation using ordinary non-linear regression analysis and special Load P statistical software program is not a straightK1 K0 forward procedure in the present case. Here, an evaluation procedure will be used as follows: (1) Pm The first on-loading part of the curve is forced to pass through the maximum horizontal tangent point, (um, Pm), where Pm is the mean failure load P0 occurring at the corresponding mean deflection, um, as found from the tests; and (2) The second Ep Pc unloading part of the curve could be fitted to the mean energy, Ep, consumed after the maximum uc um load is reached as found from the tests, see the Slip u hatched area in Figure 6. As an alternative procedure, other correlated parameters such as a defined point of total collapse, (uc, Pc), could more Figure 6. Load-slip curve modelled by a 5conveniently be used as the basis for the curve fit parameter equation. for this part of the curve. Load-slip data from tests is a set of (u, P)-coordinates usually registered at constant time intervals. The amount of data is dependent of time to failure and occasional variation in loading speed for each test specimen. Using this raw data for the curve fit gives more weight to the test series with a high number of curve points. The problem could be decreased by using a smoothed curve with reduced number of points for each test. Each point represents the mean value of the test data at a certain curvilinear distance in a normalized load-slip plot, where both the failure load and the slip at failure are set equal to 1. Forcing the five-parameter load-slip curve through the points, (um, Pm) and (uc, Pc), the non-linear curve fit is reduced to finding the best value of the three Foschi parameters K0, K1, and P0 from load-slip data of the on-loading phase. An Excel spread-sheet and the Excel Solver have proved to be excellent tools for finding the set of Foschi parameters giving the best value of the curve fit. In the solving process the parameters D and E are found by iteration for each set of Foschi parameters. 4.2 Example of Curve Fits to Test Results As examples of curve fits using this analytical equation, the load-slip relationships for particleboard in Figure 3 will be used. Three curves are presented in Figure 7 showing curve fits based on, (a) all curves, (b) curves with ductile type of failure mode, and (c) curves having brittle failure characteristics. The different parameters are given in Table 3. 5 Comments and Conclusions Load-slip curves for single sheathing-to-timber joints with different sheathing materials and loaded parallel and perpendicular to grain are presented. The type of fastener used gives the desired ductile failure mode for hardboard. In case of particleboard and plywood, the optimum type of fastener is still to be found. The head of the present type of fastener is too small for soft materials as particleboard and, especially, plywood. The influence of the edge distance of the fastener in sheets of hardboard is illustrated. Preliminary 1005 0 5 10 15 20 25 (a) u [mm] 30 35 40 45 1600 1400 1200 1000 800 600 400 200 0 50 P [N ] 1600 1400 1200 1000 800 600 400 200 0 P [N ] P [N ] results indicate that the minimum edge distance is 2d for parallel and 4d for perpendicular load-tograin direction, respectively. A 5-parameter equation to model the entire load-slip relationship is proposed and its application to joints with particleboard is illustrated. 0 5 10 15 20 25 (a) u [mm] 30 35 40 45 1600 1400 1200 1000 800 600 400 200 0 50 0 5 10 15 20 25 (c) u [mm] 30 35 40 45 50 Figure 7. Load-slip curves for sheathing-to-timber joints with particleboard: Curve fits based on (a) all curves, (b) curves with ductile failure, and (c) curves with brittle failure. Table 3. Parameter values in the analytical equation. P0 [N] 648 151 861 All curves Curves with ductile failure Curves with brittle failure * A measure of the accuracy of the estimation. 6 K0 [N/mm] 888 1277 731 K1 [N/mm] 102 462 55.3 D 3.08 0.860 10.3 E D [mm ] 5208 5.20 71.7 1010 R2 * [%] 92.3 91.5 88.5 Acknowledgement We gratefully acknowledge the assistance of Jonas Eltoft, B.Sc. and Samuel Palm, B.Sc., who performed the tests at Umeå University, Department of Applied Physics, Civil Engineering. This work is part of a Nordic Wood project on panel structures. 7 References [1] Källsner B. and Girhammar U.A., “A plastic lower bound method for design of wood-framed shear walls,” 8th World Conference on Timber Engineering, Lahti, Finland, 2004. Eltoft, J. and Palm, S., “Tests of Joints in Sheathing-to-Timber Walls with Masonite as Sheet Material” (in Swedish), Umeå University, Department of Applied Physics & Electronics, Civil Engineering, Report 2003:2, Umeå, Sweden, 2003. Eltoft, J. and Palm, S., “Tests of Joints in Sheathing-to-Timber Walls with Different Sheet Materials” (in Swedish), Umeå University, Department of Applied Physics & Electronics, Civil Engineering, Report 2002:4, Umeå, Sweden, 2002. Eltoft, J., “Tests of Sheathing-to-Timber Joints with Masonite at Different Edge Distances” (in Swedish), Umeå University, Department of Applied Physics & Electronics, Civil Engineering, Report 2003:4, Umeå, Sweden 2003. Foschi, R. O., “Load-slip characteristic of nails,” Wood Science, Vol. 7, No. 1, pp. 69 – 76, 1974. [2] [3] [4] [5] 1006 View publication stats