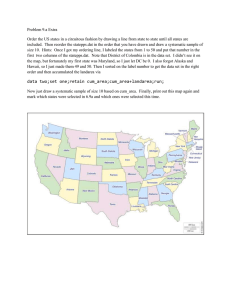

ANALYSIS OF RATES

2006

WORKS DEPARTMENT

CONTENTS

Sl. No.

DESCRIPTION

Page No.

(I)

Earth Work

1

(ii)

Special Item for Irrigation Work

11

(iii)

Concrete

43

(iv)

R.C.C. Work

49

(v)

Reinforced Brick Work

69

(vi)

Masonry Brick Work

71

(vii)

Masonry Stone Work

75

(viii)

Flooring

84

(ix)

Painting

93

(x)

Plastering

102

(xi)

Roofing

115

(xii)

Wood Work

132

(xiii)

Road Work

140

(xiv)

Site Clearance

195

(xv)

Pile Foundation

209

(xvi)

Dismantling

214

(xvii)

Iron Work

224

(xviii)

Well Sinking

228

(xix)

Other Building Items.

235

(xx)

Bridge Works

258

I EARTH WORK

Sl.

No.

Quantity

required

Description

Unit

1

2

3

4

1(a) Earth work in oridinary soil within 50m, initial lead

and 1.5m, initial lift including rought dressing and

breaking clods to maximum 5cm to 7cm and laying in

layers not exceeding 0.3m in depth and as per direction

of the Engineer-in-charge

per 100 cum.

i) Labour

Man Mulia

16 nos Each

16 nos Each

Female Mulia

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries and T & P etc. on (i)

Total (i + ii+ iii)

Rate

Rs. P

Amount

Rs. P

Remarks

5

6

7

55.00

55.00

Or Say

(b) Earth work in ordinary soil in embankments, roads, etc.

wtihin 50m initial lead and 1.5m initial lift including

rough dressing and breaking clods to maximum 5cm to

7cm and laying in layers not exceeding 0.3m in depth

and as per specification approved by the department

along with proper compaction with P.R.R. including

hire and running charges of P.R.R. (Measurement to be

taken on the finished compacted section of the fill).

per 100 cum

i) rate as per item (a)

Out turn of PRR

Earth work compaction considered 708.00 cum per day

ordinarily

880.00

880.00

176.00

35.20

1971.20

1971.20 / 100 cum

1971.20

Hire and running charges of PRR as per mechanical

wings comes to Rs 269.00 / Hr

For 708 cum Rs 269.00 x 8 = 2152.00

ii) For 100 cum = 2152.00x100/708 = 303.95

iii) Overhead Charges @ 10 % on (ii)

Total (i + ii+ iii)

-

-

Or Say

303.95

30.40

2305.55

2305.60

/ 100cum

Or Say

1971.20

271.99

2243.20 / 100 cum

2243.20 /100 Cum

-

( c ) Earth work in ordinary soil in embankments, roads, etc.

wtihin 50m initial lead and 1.5m initial lift including

rough dressing and breaking clods to maximum 5cm to

7cm and laying in layers not exceeding 0.3m in depth

and as per specification approved by the department

including proper compaction with H.R.R. (section

measurement to be taken on the finished compacted

section of the fill).

per 100 cum.

i) Rate as per item no 1 (a)

ii) Compaction by HRR as per item No 9 (a)

Total (i+ii)

-1-

Sl.

No.

Quantity

required

Description

1

2

( d) Earth work in ordinary soil in embankments, roads, etc.

maximum laboratory dry density not less than

1.44Gm/1.52Gm/1.65Gm per cubic centimeter in road

embankments respectively upto 3m/more than 3m high

and top 0.5m below sub-grade level within 50m initial

lead and 1.5m initial lift from approved borrow pits

away from the toe of the final section of the road

embankment bottom of the pit not being cut by an

imaginary line having a slope 1:4 projected from the

edge of the final section of the bank including rough

dressing and breaking clods maximum 5cm. to 7cm and

laying in layers each layer not exceeding 23cm in depth

upto required level including removal of roots, shrubs,

bushes and all foreign debris from the earth and

benching the old embankment, sectioning and

cambering the earth work and coveyance of all

material. T & P articles required for the work complete

in all respect as per specification of work and direction

of the Engineer-in-charge and to be measured on

section measurement after compaction under O.M.C.

conditon (100cum) including cost of controlled

compaction with P.R.R. watering upto O.M.C. and

confirming to approved specification including hire and

running charges of PRR.

i) rate as per item 1 (a)

Out turn for controlled specification of and PRR as per

NH standard =425 cum /day

ii) Hire and running charges of PRR and cost of labour for

compaction at OMC as per item no 9(b)I

3

Rate

Rs. P

Amount

Rs. P

Remarks

4

5

6

7

1971.20

-

Total(i+ii)

Unit

Or Say

2(a) Earth work in hard soil or gravelly soil within 50m.

Initial lead and 1.5m initial lift including rough

dressing and breaking clods to maximum 5cm to 7cm

and laying in layers not exceeding 0.3m in depth and as

per the direction of the Engineer-in-charge.

i) Labour

Man Mulia

21.5 nos Each

Woman Mulia

21.5 nos Each

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries and T & P etc.on (i)

Total (i + ii+ iii)

55.00

55.00

Or Say

-2-

2422.60

4393.80 / 100 cum

4393.80 / 100 cum

1182.50

1182.50

236.50

47.30

2648.80

2648.80 / 100 cum

Sl.

No.

Quantity

required

Description

1

2

( b) Earth work in hard soil or gravelly soil in embankment,

roads etc. within 50m initial lead and 1.5m initial lift

including rough dressing and breaking clods to

maximum 5cm to 7cm and laying in layers not

exceeding 0.3m in depth and as per specification

approved by the Department alongwith proper

compaction with P.R.R. including hire and running

charges of P.R.R. (section measurement to be taken on

the finished compacted section of the fill)

i) Rate as per item no 2(a)

ii) compaction by PRR as per item no 9(b)ii

Total(i+ii)

3

Unit

Rate

Rs. P

Amount

Rs. P

Remarks

4

5

6

7

Or Say

2648.80

334.40

2983.20

2983.20 / 100 cum

Or Say

2648.80

271.99

2920.79

2920.80 / 100 cum

( c) Earth work in hard soil or gravelly soil in embankment,

roads etc. within 50m initial lead and 1.5m initial lift

including rough dressing and breaking clods to

maximum 5cm to 7cm and laying in layers not

exceeding 0.3m in depth and as per specification

approved by the Department alongwith proper

compaction with H.R.R. (section measurement to be

taken on the finished compacted section of the fill)

i) Rate as per item no 2(a)

ii) compaction by PRR as per item no 9(a)

Total(i+ii)

( d) Earth work in hard soil or gravelly soil in embankment, roads

etc. maximum laboratory dry density not less than

1.44Gm/1.52Gm/1.65Gm per cubic centimeter in road

embankment respectively upto 3m./more than 3m. high and

top 0.5m below sub-grade level within 50m. initial lead and

1.5m initial lift from approved borrow pit 5m. away from the

toe of final section of the road embankment bottom of the pit

not being cut by an imaginary line having a slope 1:4 projected

from the edge of the final section of the bank including rough

dressing and breaking clods maximum 5cm to 7cm and laying

in layers each layer not exceeding 23cm in depth upto

requireed level inlcuding removal of roots, shrubs, bushes and

all foreign debris from the earth and benching the old

embankment, sectioning and cambering the earth work, cost

and conveyance of all materials. T & P articles etc required

for the work complete in all respect as per specification of

work and direction of the Engineer-in-charge and to be

measured on section measurement after

compaction under O.M.C. condition (100 cum) including cost

of controlled compaction with P.R.R. watering upto O.M.C.

and confirming to approved specification including hire and

i) Rate as per item no 2(a)

-3-

2648.80

Sl.

No.

Quantity

required

Description

1

2

ii) cost of labour charges for compaction for OMC and

hire and running charges of PRR as per item no 9(b) I

Total(i+ii)

3

Unit

Rate

Rs. P

Amount

Rs. P

Remarks

4

5

6

7

Or Say

3

2422.60

5071.40

5071.40 / 100 cum

Earth work in stoney earth and gravels mixed with

stone and boulder not exceeding 0.014cum in volume

within 50m. Initial lead and 1.5m initial lift including

rough dressing and breaking clods to maximum 5cm to

7cm and laying in layer not exceeding 0.3m in depth

and as per specification approved by the department

i) Labour

Man Mulia

Woman Mulia

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries and T & P etc.on ( i)

Total (i + ii+ iii)

33.53 nos Each

33.53 nos Each

-

55.00

55.00

Or Say

4

1844.15

1844.15

368.83

73.77

4130.90

4130.90 / 100 cum

Earth work in slushy soil (in water upto 0.6m depth

requiring the aid of pans and vessels) within 50m.

Initial lead and 1.5m initial lift as per the direction and

specification of the Deparment.

i) Labour

Man Mulia

Woman Mulia

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries and T & P etc.on ( i)

Total (i + ii+ iii)

-

21 nos Each

23 nos Each

-

55.00

55.00

Or Say

Cutting in disintegrated rock not requiring blasting to

be removed by pick axes and crow bars and depositing

materials within 50m initial lead and 1.5m initial lift

including rough dressing as per direction and

specification of the department including stacking the

useful materials separately as ordered.

i) Labour

Man Mulia

Woman Mulia

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries and T & P etc.on ( i)

Total (i + ii+ iii)

1155.00

1265.00

242.00

48.40

2710.40

2710.40 / 100 cum

5

55 nos Each

54 nos Each

-

55.00

55.00

Or Say

-4-

3025.00

2970.00

599.50

119.90

6714.40

6714.40 / 100 cum

Sl.

No.

Quantity

required

Description

1

2

6 Blasting hard and compacted sheet rock excluding sand

3

Unit

Rate

Rs. P

Amount

Rs. P

Remarks

4

5

6

7

85.00

55.00

75.00

65.00

85.00

110.00

150.00

130.00

80.60

55.56

11.11

622.27

219.88 /1 cum

219.90 / 1 cum

stone measured in solid including jumping holes cost of

explosive fuse, detonator, etc and stacking the blasted

i)

ii)

iii)

iv)

debris clear of work within 50m lead.

Date for 2.83 cum

Labour

Blaster

Man Mulia

Stone cutter

Sangi mulia

cost of explosive fuse, detonator L.S.

Overhead Charges @ 10 % on (i+ii)

2% Sundries T & P etc.on (i+ii)

Total (i + ii+ iii+iv)

For 1 cum = 622.27/2.83 =Rs. 219.88

1

2

2

2

-

no

nos

nos

nos

Each

Each

Each

Each

-

-

Or Say

7

Extra lead of 25m or part there of over the initial lead

of 50m for earth work in all kinds of embankment and

road works and ordinary earth work in general.

a) 50m to 75m

i) Labour

Man Mulia

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries and T & P etc.on ( i)

Total (i + ii+ iii)

-

3 nos Each

-

55.00

Total=

Or Say

b) 75m to 100m

i) Labour

Man Mulia

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries and T & P etc.on ( i)

Total (i + ii+ iii)

-

3.5 nos Each

-

55.00

Or Say

c) 100m to 125m

i) Labour

Man Mulia

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries and T & P etc.on ( i)

Total (i + ii+ iii)

-

4 nos Each

-

55.00

Or Say

d) 125m to 150m

i) Labour

Man Mulia

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries and T & P etc.on ( i)

Total (i + ii+ iii)

-

4.5 nos Each

-

55.00

Or Say

e) 150m to 175m

-5-

165.00

16.50

3.30

184.80 /100 cum

184.80 /100 cum

192.50

19.25

3.85

215.60 /100 cum

215.60 /100 cum

220.00

22.00

4.40

246.40 /100 cum

246.40 /100 cum

247.50

24.75

4.95

277.20 /100 cum

277.20 /100 cum

Sl.

No.

Quantity

required

Description

1

2

i) Labour

Man Mulia

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries and T & P etc.on ( i)

Total (i + ii+ iii)

3

-

Unit

Rate

Rs. P

Amount

Rs. P

Remarks

4

5

6

7

55.00

275.00

27.50

5.50

308.00 /100 cum

308.00 /100 cum

5 nos Each

-

Or Say

8

Extra lift of 1.5m or part there of over the initial lift of

1.5m in all kinds of embankments and road works and

ordinary earth work in general.

1st Extra lift of 1.5m (upto 7.5m)

i) Labour

Man Mulia

4.1 nos Each

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries and T & P etc.on ( i)

Total (i + ii+ iii)

55.00

Or Say

(a) Ramming or rolling eath work with light H.R.R. in

embankment in layers not exceeding 0.3m

Data for 28.31 cum

i) Labour

Man Mulia

0.75 nos Each

woman mulia

0.5 nos Each

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries and T & P etc.on ( i)

Total (i + ii+ iii)

For 100 cum = Rs.77.00 X 100/28.31 = Rs. 272.02

225.50

22.55

4.51

252.56 /100 cum

252.60 /100 cum

9

9

55.00

55.00

-

Or Say

(b) (i) Compacting and watering upto O.M.C. rolling

earth work with P.R.R. in embankment in layers not

exceeding 0.23m by power road roller including hire

and running charges of the roller (measurement to be

taken on the finished compacted section of the fill

under O.M.C. condition)

1. Hire and running charges of P.R.R. Rs. 269.00/hr

(considering a roller will compact 425 cum/day)

(Rs269.00 X 8 X 100) / 425

for 100 cum

2. Cost of watering with an av. Lead of 5km by truck

(considering carrying water 20Nos. Of maxphalt drums

in each trip) 5 trips of water required for 390cum of

earth

506.35

5 × 100

390

For 100 cum of earth

1.28

-6-

41.25

27.50

6.88

1.38

77.00

271.99 /100 cum

272.00 /100 cum

1.28 trips

trip

775.00

992.00

Sl.

No.

1

Quantity

required

Description

2

3. Labour charges for sprinkling water, labour required

for 390 cum 50 Nos.

Unit

Rate

Rs. P

Amount

Rs. P

Remarks

4

5

6

7

3

50 × 100

390

For 100 cum of earth

Man mulia

Overhead Charges 10 %

Total

12.80

-

Each

-

12.8 nos

55.00

Or Say

9

704.00

220.24

2422.59 /100 cum

2422.60 /100 cum

(b) (ii) for ordinary compaction by P.R.R. per day

(Ordinary compaction by P.R.R.) 708 cum

269.00×8×100

708

So for 100cum

303.95

Overhead Charges @10%

Total

30.40

334.35

334.40

/100 cum

Say

10 Fine dressing of earth work in ordinary or hard soil in

road formaton according to the direction of the

department including cutting or filling earth upto

0.15m depth of surface.

i) Labour

Man Mulia

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries & T & P etc. on (i)

Total (i + ii+ iii)

1 no

Each

-

55.00

Or Say

55.00

5.50

1.10

61.60 /100 sqm

61.60 /100 Sqm

11 Triangular or square section of 0.15m trench cutting for

alignment and demarcation purpose of dug belling

10cm to 15cm (Data for 304.80 R.M.)

i) Labour

Man Mulia

Female mulia

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries & T & P etc. on (i)

Total (i + ii+ iii)

For 1 RM = Rs308.00/304.80 = Rs 1.01

-

3 nos Each

2 nos Each

-

55.00

55.00

-

165.00

110.00

27.50

5.50

308.00

Say Rs1.00 per 1RM

12 Puddle filling of good clay including initial lead 50m

and 1.5m initial lift

-7-

Sl.

No.

Quantity

required

Description

1

2

3

i) Labour

Man Mulia for digging stiff clay and sand if required

15

female mulia for carrying

15

Man mulia for weathering pulversing, etc

15

Female mulia for weathering, pulversing etc.

10

laying

20

female mulia for carrying and for trodding

18

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries & T & P etc. on (i)

Total (i + ii+ iii)

nos

nos

nos

nos

nos

nos

Unit

Rate

Rs. P

Amount

Rs. P

Remarks

4

5

6

7

Each

Each

Each

Each

Each

Each

-

55.00

55.00

55.00

55.00

55.00

55.00

Or Say

825.00

825.00

825.00

550.00

1100.00

990.00

511.50

102.30

5728.80 /100 cum

5728.80 /100 cum

13 Sectioning and cambering earth work in road formation

to proper specification approved by the department

i) Labour

Female mulia

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries & T & P etc. on (i)

Total (i + ii+ iii)

0.75 no

-

Each

-

55.00

Or Say

14 Filling in foundation and plinth with excavated

materials including watering and ramming as directed

by the Engineer-in-charge for 100 cum

15 Filling in foundatin and plinth with sand watered and

rammed (Labour only)

i) Labour

Man Mulia

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries & T & P etc. on (i)

Total (i + ii+ iii)

41.25

4.13

0.83

46.20 /100 cum

46.20 /100 cum

2/3 rate of respective item of work

12.36 nos Each

-

55.00

Or Say

679.80

67.98

13.60

761.38 /100 cum

761.40 /100 cum

16 Fine dressing and turfing with initial lead of 50m and

1.5m initial lift as per direction of Engineer-in-charge

i) Labour

Female mulia for dressing

0.4 no

Man mulia for cutting turf

1 no

Female mulia for carrying

0.8 no

Man mulia for placing turfing in posting and ramming

with thapies

0.74 no

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries & T & P etc. on (i)

Total (i + ii+ iii)

Each

Each

Each

55.00

55.00

55.00

Each

-

55.00

Or Say

17 Extra lead of 50m or part there of over the initial lead

of 50m turfing

-8-

22.00

55.00

44.00

40.70

16.17

3.23

181.10 /100 Sqm

181.10 /100 Sqm

Sl.

No.

Quantity

required

Description

1

2

i) Labour

Man mulia

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries & T & P etc. on (i)

Total (i + ii+ iii)

3

0.95 no

-

Unit

Rate

Rs. P

Amount

Rs. P

Remarks

4

5

6

7

Each

-

55.00

Or Say

18 Extra lift of 1.5m or part thereof overinitial lift of 1.5m

for turfing

i) Labour

Man mulia

0.42 no

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries & T & P etc. on (i)

Total (i + ii+ iii)

Each

-

55.00

Or Say

52.25

5.23

1.05

58.52 /100 Sqm

58.50 /100 Sqm

23.10

2.31

0.46

25.87 /100 Sqm

25.90 /100 Sqm

19 Excavation of founation in hard rock (granite) removed

by chiselling including dressing and levelling the bed

not exceeding 1.5m in depth and depositing the soil

within initial lead of 50m and as per specification

approved by the Department

i) Labour

Man mulia

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries & T & P etc. on (i)

Total (i + ii+ iii)

-

5.68 nos Each

-

55.00

Or Say

20 Excavation of founation in laterite rock or any hard

rock (other than granite or disintigrated rock) removed

by chiselling including dressing and levelling the bed

not exceeding 1.5m in depth and depositing the soil

within initial lead of 50m and as per specification

approved by the Department

i) Labour

Man mulia

3.74 nos Each

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries & T & P etc. on (i)

Total (i + ii+ iii)

55.00

Or Say

21 Shoring and shuttering foundation trenches, pits etc.

with close wooden planks or sheets shuttering etc.

excluding cost of planks and sheets (labour only)

i) Labour

Carpenter (2nd class)

0.5 no

ii) Overhead Charges @ 10 % on (i)

iii) 2% Sundries & T & P etc. on (i)

Total (i + ii+ iii)

Each

-

75.00

Or Say

-9-

312.40

31.24

6.25

349.89 /1 cum

349.90 /1 cum

205.70

20.57

4.11

230.38 /1 cum

230.40 /1 cum

37.50

3.75

0.75

42.00 /Sqm

42.00 /Sqm

Sl.

No.

Quantity

required

Description

Unit

Rate

Rs. P

Amount

Rs. P

Remarks

1

2

3

4

5

6

7

22 Earth work in open well excavation with lead upto 50m

for 100cum

.

a) 1st depth of 1.5m initial rateof foundation same nature of soil

b) 2nd depth of 1.5m –1½ times initial rate + 1½ times lift

c) 3rd depth of 1.5m –2 times initial rate + 2½ times lift

d) 4th depth of 1.5m –2½ times initial rate + 3½ times liftt

e) 5th depth of 1.5m –3 times initial rate + 4½ times lift

f) 6th depth of 1.5m –3½ times initial rate + 5½ times lift

g) 7th depth of 1.5m –4 times initial rate + 6½ times lift

h)8th depth of 1.5m –4½ times initial rate + 7½ times lift

(and so on for further depth)

Notes :

(i) Oridinary soil - light black cotton, sandy earth, sandy loam, dry silt, fragile, red earth, soft earth,

and soft moorum.

(ii) Hard soil - Hard stiff clay, stiff black cotton,hard red earth, shales, moorum, ordinary gravels.

(iii) Stoney earth- earth mixed with gravel and boulders not exceeding 0.014 cum in volume

(iv) Slushy soil - A soil having the characteristics of liquid mud with negligible bearing capacity which can be

removed with the aid of pans and vessels only.

(v) For excavation of foundation including dressing and levelling the bed and depositing the soil with initial lea

of 50m and initial lift of 1.5m add 20 percent extra over the respectiv rates of earth work in excavation

(vi) Dewatering during excavation to be paid as per actuals.

(vii) The rate for extra lead and lift for blasted stone work will be double of the respective rates of leads

and lifts for earth work.

(viii) In the event of any difference in opinion regarding classification of soil the decision of the

Engineer-in-charge (E.E.) is final and binding.

(ix) 10 per cent excess on the above rates will be allowed for the works being executed inside jail premises.

-10-

II. SPECIAL ITEMS FOR IRRIGATION WORKS

1.

Excavation of any approved type of soil in approved borrow area by

mechanical means loading into and transportation by mechanical means and

unloading the soil within initial lead of 1km on properly prepared and

scientifically approved surface including spreading and levelling the earth in

22.5 cm layers to make ready for watering and compaction with sheep foot

rollers and dozers but excluding watering and compaction in dams and dykes

for all heights including construction, maintenance, watering and lighting of

haul road and borrow area etc. complete as per the direction of Engineer-incharge. (measurement of the fill to be taken on the finished compacted

section under OMC condition.)

Per 1 cum

(A) Excavation by Mechanical means :

---------------------------------------------- ---------------- --Considering Hitachi Excavator of the following specification :

Capacity of bucket =

Cycle time for one bucket excavation =

Bucket fill factor =

Overall efficiency =

Considering effective working of 50 min./ hour

Production per hour (loose earth) =

(50 x 60 x 0.91 x 0.9 x 0.83)/16 =

0.91 cum

16.00 sec

0.90

83.00 %

127.46 cum

Hire charge excluding supervision charge per hour =

Cost of mechanical excavation per 1 cum =

(B) Trasportation cost :

---------------------------------------------Capacity of Tipper (loose soil) =

Taking 80% carrying capacity, the

capacity of Tipper =

Lead

=

1717.64

Rs13.48

5.70 cum

4.56 cum

1.00 km

a) Loading time = (Body capacity/Excavator output per min)

=

2.15 min

b) Loaded haul @ 25km/hr =

2.40 min

c) Empty haul @ 25km/hr =

2.40 min

d) Spotting, turning and

unloading time

=

1.40 min

------------Total cycle time

=

8.35 min

Say

8.00 min

Quantity to be carried per hour =

(50 / 8.00 x 4.56) =

Hire charge of TATA Tipper excluding supervision charge/hr :

Depriciation of tyres & tubes :(6 x 6000 )/(2 x 2000) =

28.50 cum

Rs498.31

Rs9.00

--------------------

-11-

Hire charge of Tipper per hour =

Rs507.31

Cost of transportation of loose earth within

initial lead of 1km =

(507.31/28.50) =

Rs17.80

Add construction & maintenance of haul roads (L.S.)=

Add for spreading earth (L.S.)=

Rs1.50

Rs4.00

----------------Rs36.78

Total prime cost =

Add overhead charges (10% of prime cost) =

Total =

Rs3.68

----------------Rs40.46

For an average soil 120 cum of loose earth when compacted

to 95% Proctor density under O.M.C. condition will measure

100 cum.

So rate per 1 cum of compacted earth = Rs.40.46X120/100

Or say

2.

Rs48.55

Rs48.60 /cum

Watering earthwork upto OMC condition and compaction by sheepfoot rollers

and dozer in layers not exceeding 22.5 cm to 95% dry density including hire

and running charges of all the machineries complete as per direction of

Engineer-in-charge. (measurement to be taken on the finished compacted

section of the fill under OMC condition.)

A. Machines used B. Out turn -

Dozer and two pairs of sheepfoot rollers of total

weight 20 tonnes

100 cum of earthwork per working hour of machine

Hire charge of Dozer(D-80/A-12) excluding supervision

charge per hour =

Hire charge of sheepfoot roller excluding supervision

charge per hour =

Rs2,141.79

Total hire charge =

Hence cost for 100 cum of compacted earth =

Add towords watering (3 % of cost of compaction)=

Rs77.86

----------------Rs2,219.64

Rs2,219.64

Rs67.00

----------------Rs2,286.64

Prime cost per 1 cum of watering and compaction =

2286.64/100 =

Overhead charges 10% =

Or say

3.

Fine dressing and turfing the slopes of the dam or dyke with compact Dub

grass with initial lifts and lead and as per the direction of the Engineer-incharge.

Unit - 1 sqm.

A) Fine dressing of earthwork :

-12-

Rs22.87

Rs2.29

----------------Rs25.16 /cum

Rs25.20 /cum

Male Worker

0.01 nos.

@

Rs55.00

Rs0.55

B) Cutting Turf :

Male Worker

0.01 nos.

@

Rs55.00

Rs0.55

C) Male worker required to place turf and

ramming with thapies

0.007 nos.

@

Rs55.00

Rs0.41

D) Watering Charges

L.S.

Rs0.30

----------------Rs1.81

(A+B+C)

i) Overhead charges @ 10% (A+B+C) =

ii) Sundries and T&P @ 2% on labour charge=

Rs0.18

Rs0.04

Rs2.03

Rs2.00 /Sqm.

Or Say

4.

Supplying and spreading sand of approved specification on compacted

surfaces of earth dam or dykes for filter blanket and other horizontal filter zone

to proper thickness including surface dressing within initial lead complete as

directed by the Engineer-in-charge. (Cost of transportation to be added)

Unit - 1 cum.

A. Cost of Sand

1.00 cum

@

Rs29.00

Rs29.00

B. Labour charges

Dressing surface

Considering sand to be laid in layers of 0.2m,

Spreading area /cum =

1/ 0.2 =

Male Worker

0.20 m

5.00

sqm

0.05 nos.

@

Rs55.00

Rs2.75

0.40 nos.

@

Rs55.00

Rs22.00

Spreading within 50m lead from stacks

Male Worker

(A+B )=

Overhead charges @ 10% on (A+B) =

Or Say

5.

Supplying and spreading 20mm down graded chips satisfying filter criteria in

horizontal filter zones and filter blankets to proper thickness including surface

dressing within an initial lead complete as directed by the Engineer-in-charge.

(Cost of transportation to be added)

Unit - 1 cum.

A.Materials

Cost of Chips

-13-

Rs53.75

Rs5.38

----------------Rs59.13 /cum.

Rs59.10 /cum.

20mm to 10mm

10mm to 6mm

0.50 cum

0.50 cum

@

@

Rs638.00

Rs671.00

Rs319.00

Rs335.50

----------------Rs654.50

0.50 nos.

@

Rs55.00

(A+B )=

Rs27.50

----------------Rs682.00

Or Say

Rs68.20

----------------Rs750.20 /cum.

Rs750.20 /cum.

B. Labour charges

Labour for spreading & levelling

Male Worker

Overhead charges @ 10% on (A+B) =

6.

Supplying and spreading 40mm to 20mm size granite metal filter in horizontal

filter zones and filter blankets including levelling etc complete within initial lead

as directed by the Engineer-in-charge. (Cost of transportation to be added)

Unit - 1 cum.

A.Materials

Cost of Metal

40mm

20mm

B. Labour charges

0.50 cum

0.50 cum

@

@

Rs464.00

638.00

Rs232.00

319.00

Male Worker

0.55 nos.

@

Rs55.00

(A+B )=

Rs30.25

----------------Rs581.25

Or Say

Rs58.13

----------------Rs639.38 /cum.

Rs639.40 /cum.

Overhead charges @ 10% on (A+B) =

7.

Supplying and spreading sand of approved specification for filter in rock toe

riprap and filter drains in earth dam and dyke to proper slope and level within

an initial lead as directed by the Engineer-in-charge. (Cost of transportation to

be added)

Unit - 1 cum.

A.Materials

Cost of sand

1.00 cum

@

Rs29.00

Rs29.00

Rs55.00

Rs1.82

B. Labour charges

Considering thickness of filter as 0.3m

Spreading area per cum =

1 / 0.3 =

Male Worker

0.033 nos.

-14-

3.33

sqm

@

Filling & levelling

Male Worker

0.50 nos.

@

Rs55.00

(A+B )=

Overhead charges @ 10% on (A+B) =

Or Say

8.

Rs27.50

----------------Rs29.32

Rs58.32

Rs5.83

----------------Rs64.15 /cum.

Rs64.20 /cum.

Supplying and spreading granite chips of size 20mm down graded in filter in

rock toe riprap and filter drains in earth dam or dyke to proper slope and level

within initial lead as directed by the Engineer-in-charge. (Cost of

transo\portation to be added)

Unit - 1 cum.

A.Materials

Cost of Chips

20mm to 10mm

10mm to 6mm

0.50 cum

0.50 cum

@

@

Rs638.00

Rs671.00

Rs319.00

Rs335.50

----------------Rs654.50

0.625 nos.

@

Rs55.00

(A+B )=

Rs34.38

----------------Rs688.88

Or Say

Rs68.89

----------------Rs757.77 /cum.

Rs757.80 /cum.

B. Labour charges

Labour for site conveyance & filling

Male Worker

Overhead charges @ 10% on (A+B)=

9.

Supplying and spreading 40mm to 20mm size granite metal in filter in rock toe

riprap and filter drains in earth dam or dyke to proper slope and level within

initial lead as directed by the Engineer-in-charge. (Cost of transportation to be

added)

Unit - 1 cum.

A.Materials

Cost of metal

40mm

20mm

0.50 cum

0.50 cum

B. Labour charges

-15-

@

@

Rs464.00

Rs638.00

Rs232.00

Rs319.00

Male Worker

0.69 nos.

@

Rs55.00

(A+B )=

Overhead charges @ 10% on (A+B)=

10.

Or Say

Supplying and filling sand of approved specification in vertical chimny to

proper line & level using removable sheet metal separators upto designed

height of filter chimny within initial lead lead as directed by the Engineer-incharge. (Cost of transportation to be added)

Rs37.79

----------------588.79

Rs58.88

Rs647.67 /cum.

Rs647.70 /cum.

Unit - 1 cum.

A.Materials

Cost of sand

1.00 cum

@

Rs29.00

Male Worker

0.55 nos.

Add for depriciation charges of metal separators

@

Rs55.00

L.S.

Rs29.00

B. Labour charges for raising & spreading

(A+B )=

Rs30.25

Rs1.00

----------------Rs60.25

Or Say

Rs6.03

----------------Rs66.28 /cum.

Rs66.30 /cum.

Overhead charges @ 10% on (A+B)=

11.

Providing dry rubble rock toe with blasted and quarried granite boulders of

sizes 30cm and above with all leads and lifts including dumping with packing

interstices properly and surface packing to proper line and level complete as

directed by the Engineer-in-charge. ( No deduction to be made towords voids

in finished section.) (Cost of transportation to be added)

Unit - 1 cum.

A.Materials

Blasted R R stone

1.00 cum

@

Rs148.00

Rs148.00

B. Labour charges for lifting & laying etc.

i) Stone packer

0.20 nos.

ii)Male Worker

0.35 nos.

iii)Hammer Man

0.10 nos.

@

@

@

Rs65.00

Rs55.00

Rs65.00

(A+B )=

Rs13.00

Rs19.25

Rs6.50

----------------Rs186.75

Or Say

Rs18.68

----------------Rs205.43 /cum.

Rs205.40 /cum.

Overhead charges @ 10% on (A+B)=

-16-

12.

Providing stone riprap to the slopes of earthdam and dyke with quarried and

blasted granite stone boulders of size 0.30m and above including dumping on

slopes filling interstices with small stones & wedges and packing surface to

proper line and levels including fixing wave breakers complete with all leads &

lifts complete as directed by the Engineer-in-charge. (No deduction towords

voids in finished section.) (Cost of transportation to be added)

Unit - 1 cum.

A.Materials

Blasted R R stone

1.00 cum

@

Rs148.00

Rs148.00

0.32 nos.

0.45 nos.

0.10 nos.

@

@

@

Rs65.00

Rs55.00

Rs65.00

(A+B )=

Rs20.80

Rs24.75

Rs6.50

----------------Rs200.05

Or Say

Rs20.01

----------------Rs220.06

Rs220.10 /cum.

B. Labour charges

i) Stone packer

ii)Male Worker

iii)Hammer Man

Overhead charges @ 10% on (A+B)=

13.

Excavation in all kinds of soil including moorum, stoney earth, gravel etc.

excepting all kinds of rock & boulders exceeding 0.014cum in volume for dam

base stripping, cut-off trenches, outfall drains and stripping in borrow areas

including rough dressing and dumping the excavated materials away from

work site manually within 50m initial lead and 1.5m initial lift as per the

direction of Engineer-in-charge including stacking of useful materials as

directed.

Per 1 cum.

A) Labour Charge

Male Worker

Female Worker

0.237 nos.

0.237 nos.

@

@

Rs55.00

Rs55.00

Prime cost =

B) Other Charges

i) Overhead charges @10% of prime cost=

Rs2.61

Or Say

14.

Excavation of foundation in Disintegrated rock not requiring blasting to be

removed by pick axes and crow bars and depositing excavated materials

manually within 50m. initial lead and 1.5m. initial lift including stacking useful

materials separately as per direction of Engineer-in-charge.

Per 1 cum.

A) Labour Charge

-17-

Rs13.04

Rs13.04

Rs26.08

Rs28.69 /cum

Rs28.70 /cum

Male Worker

Female Worker

0.55 nos.

0.54 nos.

@

@

Rs55.00

Rs55.00

Prime cost =

B) Other Charges

i) Overhead charges @10% of prime cost=

Rs6.00

Or Say

15.

Rs30.25

Rs29.70

Rs59.95

Rs65.95 /cum

Rs66.00 /cum

Excavation of foundation in hard rock of all toughness and boulders above

0.03 cum in volume within 50 m. initial lead and 1.5 m. initial lift including

rough dressing as per specification of the department including stacking

useful stones and disposal of muck manually as directed by the Engineer-incharge.

Per 1 cum.

A) Drilling and blasting charge :

(a) Compressor Charges

Hire charge of 400 cfm compressor per hour =

Rs.766.35

3 Jack hammer can be operated at a time and

outturn of jack hammer = 5 holes drilling.

Blasted Rock out turn per 1.0 m hole is 1.00 cum.

Total out turn of blasted rock/hr= ( 3 x 5 x 1.00 )

Hire charge of compressor per cum =

15.00 cum.

Rs.51.09

(b) Jack hammer charges

Hire charge of jack hammer per hour =

Out turn per hour =(5 x 1.0)=

Hire charge of jack hammer per cum =

Rs.7.93

5.00 cum.

Rs.1.59

(c) Consumables

Rs.1,650.00

Cost of drill rod 2'6" (c1)=

Cost of drill rod 5'0" (c2)=

Rs.2,450.00

Avg. cost of drill rod (c3)=(c1+c2)/2 Rs.2,050.00

Life of one drill rod =

150.00 r.m.

Cost of drill rod per cum (c3 /(150 x 1.0)) =

Cost of air line per cum (L.S.) =

(d) Labour Charges

Driller 3 nos. @

75.00

Male Worker 4 nos. @

55.00

Blaster 1 no. @

85.00

Add for hidden cost of labour @10% of

direct labour charges =

/day =

/day =

/day =

Rs.13.67

Rs.5.00

Rs.225.00

Rs.220.00

Rs.85.00

Rs.53.00

-------------------Rs.583.00

Labour charges for drilling/cum taking 7hrs/shift =

(e) Explosives (Data for 2.4 m hole)

2/7th kg of Gelatine @

1 no. of Electric Detonator =

Lead wire (L.S.) =

Ammonium Nitrate 0.8 kg @

75.00

12.00

/kg =

/no.

25.00

/kg =

-18-

Rs.5.55

Rs.21.43

Rs.12.00

Rs.5.00

Rs.20.00

--------------------

Total on explosives =

Cost of explosive per cum =(cost of explosive/(2.4 x 1.0))=

Rs.58.43

Rs.24.35

DRILLING AND BLASTING COST (Q1) =

ADD FOR SECONDARY BLASTING (Q2) = 20% OF Q1 =

B) Labour charge

Hammer man

Male Worker

0.10 nos.

0.50 nos.

Rs.101.25

Rs.20.25

Rs.121.50

@

@

Rs65.00

Rs55.00

(A + B) =

Rs6.50

Rs27.50

Rs155.50

Or Say

Rs15.55

Rs171.05 /cum

Rs171.10 /cum

Overhead charges @ 10% of (A+B)

16.

Excavation, loading, unloading and carriage by mechanical means of all kinds

of soil, including stoney earth, gravel and moorum etc interspread with

boulders upto 1/2 cum size with all lifts and delifts including trimming of

slopes and bed to design section and depositing the the excavated materials

away from work site as per the specification and as directed by the Engineerin-charge within an initial lead of 1km from the place of excavation complete.

Per 1 cum.

(A) Excavation by Mechanical means

Considering Hitachi Excavator of the following specification :

Capacity of bucket =

Cycle time for one bucket excavation =

Bucket fill factor =

Overall efficiency =

0.91 cum

16.00 sec

0.90

83.00 %

Taking effective working per hr = 50 min,

Production per hour (loose earth) =

(50 x 60 x 0.91 x 0.9 x 0.83)/16 =

127.46 cum

Considering a swell factor of 0.86 for all kinds of soil,

Quantity of land excavation per hour =

109.62 cum

Hire charge of excavator

excluding supervision charges =

1717.64

Cost of excavtion per 1 cum = 1717.64/109.62 =

Rs15.67

(B) Trasportation cost

Capacity of Tipper (loose soil) =

5.70 cum

Taking 80% carrying capacity, the

capacity of Tipper =

Lead

=

4.56 cum

1.00 km

a) Loading time = (Body capacity/Excavator output per min)

=

2.15 min

-19-

b) Loaded haul @ 20km/hr =

c) Empty haul @ 20km/hr =

d) Spotting, turning and

unloading time

=

Total cycle time

=

3.00 min

3.00 min

1.40 min

9.55 min

Quantity to be carried per hour =

23.88 cum

Considering a swell factor of 0.86 for all kinds of soil,

Quantity of land excavation per hour =

20.54 cum

Hire charge of Tipper excluding

supervision charge / hr =

Depriciation of tyres & tubes :(6 x 9500/4000)

Hire charge of Tipper per hour =

Rs498.31

Rs14.25

Rs512.56

Cost of transportation of all kinds of soil within

initial lead of 1km =

(512.56/20.54) =

Total of excavation and transportation = 15.67+24.95 =

Add for trimming of slope and bed manually

Rs24.95

L.S.

(A + B) =

Rs40.62

Rs1.00

Rs41.62

Total =

Or Say

Rs4.16

Rs45.78 /cum

Rs45.80 /cum

Overhead charges @ 10% of (A+B)

17.

Excavation, loading and carriage by mechanical means in D.I. rock, laterite

and soft rock not requiring blasting interspread with boulders upto 1/2 cum

size with all lifts and delifts including trimming of slopes and bed to design

section and depositing the excavated materials away from work site as per the

specification and as directed by the Engineer-in-charge within an initial lead of

1km from the place of excavation complete.

Per 1 cum.

A. Excavation by Mechanical means

Capacity of excavator for

excavation of loose earth =

127.46 cum

Considering a swell factor of 0.715 for D.I. rock,

Quantity of soil excavation per hour =

Hire charge of excavator

excluding supervision charges =

91.13 cum

1717.64

Cost of excavation per 1 cum = 1717.64/91.13 =

Rs18.85

B. Trasportation cost

Capacity of Tipper (loose soil) =

Taking 80% carrying capacity, the

capacity of Tipper =

Lead

=

5.70 cum

4.56 cum

1.00 km

-20-

a) Loading time = (Body capacity/Excavator output per min)

=

2.15 min

b) Loaded haul @ 20km/hr =

3.00 min

c) Empty haul @ 20km/hr =

3.00 min

d) Spotting, turning and

unloading time

=

2.23 min

Total cycle time

=

10.38 min

Quantity to be carried per hour =

21.97 cum

Considering a swell factor of 0.715 for D.I. rock

Quantity of soil excavation per hour =

15.71 cum

Hire charge of Tipper per hour =

(As per Item No.16)

Rs512.56

Cost of transportation of D.I. rock earth within

initial lead of 1km =

(512.56/15.71) =

Total of excavation and transportation = 18.85+32.63 =

Add for trimming of slope and bed manually =

Rs32.63

L.S.

(A + B) =

Rs51.48

Rs2.00

Rs53.48

Total =

Or Say

Rs5.35

Rs58.83 /cum

Rs58.80 /cum

Overhead charges @ 10% of (A+B)

18.

Excavation of hard rock of all toughness in canal and cutoff trench of earth

dam and other deep cutting sections by mechanical drilling and appropriate

blasting with all lifts and delifts, loading into and transportation by transport

vehicle within 1 km of initial lead and depositing the excavated materials

neatly in specified dump yard as directed by Engineer-in-charge and trimming

of bed and slope to the design finished section by manually, if necessary

complete. (Recovery of useful materials of all sizes will normally be 0.7 cum

per cum of excavation measured in dump condition. In case of change of

recovery due to rock condition, percentage is to be fixed by Chief Engineer-incharge).

Per 1 cum.

Operations involved :

i) Rock is to be blasted continuously.

ii) The blasted materials is to be heaped.

iii) The heaped rock are to be loaded on Tipper

by excavator.

iv) The loaded materials is to be carried

within a lead of 1 km.

v) Trimming of bed and slope.

A. Cost of Drilling and blasting per 1 cum =

(As per Item of Hard Rock)

B. Loading by excavator /cum= 1717.64/72 =

(Taking outturn in rock as 72 cum/hr)

-21-

Rs101.25

Rs23.86

C. Trasportation by Tipper

Capacity of Tipper (loose soil) =

Taking 80% carrying capacity, the

capacity of Tipper =

Lead

=

1.00km

a) Loading time = (Body capacity/Excavator output per min)

=

3.80 min

b) Loaded haul @ 20km/hr =

3.00 min

c) Empty haul @ 20km/hr =

3.00 min

d) Spotting, turning and

unloading time

=

1.40 min

Total cycle time

=

11.20 min

5.70 cum

4.56 cum

Quantity to be carried per hour =

Considering a swell factor of 0.715

Quantity carried per hour =

20.36 cum

14.56 cum

Hire charge of Tipper per hour =

(As per Item No.16)

Cost of transportation within

initial lead of 1km =

Rs512.56

(512.56/14.56) =

Rs35.20

D. Hire charge of Dozer per hour

(excluding supervision charge)

Rs2,141.79

Cost of spreading by Dozer = 2141.79/120 =

(A+B+C+D)=

Overhead charges @10% of (A+B+C+D)=

Total =

Or Say

19.

Rs17.85

Rs178.16

Rs17.82

Rs195.98 /cum

Rs196.00 /cum

Preparation of bed of foundation by wedging and barring in hard rock including

removal of loose rock complete and disposal of muck by mechanical means

within initial lead & lift as directed by Engineer-in-charge.

Per 1 cum.

A. Labour Charge

Stone Cutter

Hammer man

Male Worker

1.00 nos.

1.00 nos.

2.00 nos.

@

@

@

Rs75.00

Rs65.00

Rs55.00

(A) =

i) Overhead charges @10% of (A)=

Rs25.00

Or Say

20.

Rs75.00

Rs65.00

Rs110.00

Rs250.00

Clearance of slush and muck from foundation pit by manual means including

removal of debris within 50 m. initial lead and initial lift of 1.5m as directed by

the Engineer-in-charge.

Per 1 cum.

-22-

Rs275.00 /cum

Rs275.00 /cum

A. Labour Charge

Male Worker

Female Worker

0.22 nos.

0.44 nos.

@

@

Rs55.00

Rs55.00

(A) =

i) Overhead charges @10% of (A)=

Rs3.63

Or Say

21.

Rs12.10

Rs24.20

Rs36.30

Rs39.93 /cum

Rs39.90 /cum

Preparation of foundation bed in hard rock requiring chieselling, hammering

and tampering; wire brushing and air & water jetting etc including hire charges

of all equipments and T & P etc. complete for dams, barrages and power

house etc. over rock foundation as directed by Engineer-in-charge.

Per 1 sqm.

A. Chipping

Stone Cutter

Male Worker

0.20 nos.

0.10 nos.

@

@

Rs75.00

Rs55.00

Rs15.00

Rs5.50

B. Brushing and removal of debris

Female Worker

0.10 nos.

@

Rs55.00

Rs5.50

@

Rs324.79

L.S.

Rs16.24

Rs1.00

L.S.

Rs65.00

Rs65.00

(A + B + C) =

Rs1.50

Rs0.65

Rs0.65

Rs46.04

Or Say

Rs4.60

Rs50.64 /sqm

Rs50.60 /sqm

C. Air and Water jetting in three operations

i) Air compressor / one

point supply charges

0.05 hr.

ii) Water charges

iii) Air hose, water

hose & fittings and

jet point charges

iv) Jet operator

0.01 nos.

v) Helper

0.01 nos.

@

@

Overhead charges @10% of (A+B+C)=

22.

Fixing 25 mm. dia anchor bars in foundation rock including drilling 35 mm. dia

holes, fixing wedged anchor and grouting with cement mortar 1:4 complete as

per the direction of Engineer-in-charge excluding cost of M.S. rods for dams,

barrages and power house structures including pull testing of 30% of anchors.

(Depth of hole only to be measured for payment purpose).

Per 1 r.m.

A. Drilling Hole

i) 400cfm Compressor

with crew

ii) Jack Hammer

iii) Labour for drilling holes -

0.145 hr.

0.435 hr.

Driller

Male Worker

0.07 nos.

0.07 nos.

-23-

@

@

Rs766.35

Rs7.93

Rs111.12

Rs3.45

@

@

Rs75.00

Rs55.00

Rs5.25

Rs3.85

iv) Cost of drill rod

1/150 nos.

@

Rs2,050.00

Rs13.67

Fitter Special

Male Worker

ii) Fixing anchors into holes -

0.10 nos.

0.10 nos.

@

@

Rs85.00

Rs55.00

Rs8.50

Rs5.50

Hammer man

Male Worker

iii) Cost of wedge

iv) Grouting with cement mortar

including materials and labours

Add for pull testing

0.05 nos.

0.05 nos.

@

@

Rs65.00

Rs55.00

L.S.

Rs3.25

Rs2.75

Rs2.50

L.S.

L.S.

(A+B) =

Rs6.00

Rs2.50

Rs168.34

Or Say

Rs16.83

Rs185.17 /1R.M.

Rs185.20 /1R.M.

B. Making wedged anchors and fixing

i) Cutting & splitting upto 10 cm. -

Overhead charges @10% of (A+B)=

23.

Random rubble stone masonry in dams, barrages and weirs etc. with cement

mortar 1:3 with quarried stone boulders of approved quality including providing

all materials, machineries and labour etc complete as per the direction of

Engineer-in-charge including construction of necessary ramps, cat ways etc.

for all lifts and delifts upto 10m of dam from average N.S.L. of block. (Cost of

transportation to be added)

For 1 cum

A. Materials:

i) Rubble stones including bond

stones, spalls and wedges 1cum

1.00 cum

ii) Sand of approved quality 0.45 cu

0.45 cum

iii)Cement

2.15 qtl

iv) Water cost (not allowed if supply mains

provided by department)

v) Admixtures (if used add extra)

@

@

@

Rs122.90

Rs29.00

Rs354.00

L.S.

L.S.

Total =

Rs122.90

Rs13.05

Rs761.10

Rs2.50

Rs0.00

Rs899.55

B. Labour charges for feeding mixer, carrying materials from

stock piles, laying masonry, curing etc. including cleaning.

Labour charges for 7.86 cum of masonry constructed per day

with the following labour for +/- 10m lift.

Mason Special

Mason Ordinary

Hammer man

Sangi mulia

Male Worker

Female worker

1.00

1.00

0.50

5.00

5.00

9.00

nos.

nos.

nos.

nos.

nos.

nos.

For lift/delift upto 20m add 20 % extra on labour =

-24-

@

@

@

@

@

@

Rs85.00

Rs75.00

Rs65.00

Rs65.00

Rs55.00

Rs55.00

Rs85.00

Rs75.00

Rs32.50

Rs325.00

Rs275.00

Rs495.00

Rs1,287.50

Rs257.50

Rs1,545.00

Quantity done in cum =

7.86

Rate/cum =

Rs196.56

C. Hire charge of mixer

A 10/7 concrete mixer can produce Mortar @4cum/hour

For 0.45 cum time = 1/4 x 0.45 =

Hire charges @

0.1125 hr.

Rs126.96 /hr =

Rs14.28

D. Cost of providing Ramps & Scaffolding and catways etc.

@ 10 % cost of materials (A)

(A+B+C+D)=

Rs89.96

Rs1,200.35

Or Say

Rs120.04

Rs1,320.39 /cum

Rs1,320.40 /cum

Overhead charges @10% of (A+B+C+D)=

24.

Random rubble stone masonry in dams, barrages and weirs etc. with cement

mortar 1:4 with quarried stone boulders of approved quality including providing

all materials, machineries and labour etc complete as per the direction of

Engineer-in-charge including construction of necessary ramps, catways etc.

for all lifts and delifts upto 10m of dam from average N.S.L. of block. (Cost of

transportation to be added)

For 1 cum

A. Materials:

i) Rubble stones including bond

stones, spalls and wedges

1.00 cum

ii) Sand of approved quality

0.45 cum

iii) Cement

1.60 qtl

iv) Water cost (not allowed if supply mains

provided by department)

v) Admixtures (if used add extra)

@

@

@

Rs122.90

Rs29.00

Rs354.00

L.S.

L.S.

Total =

Rs122.90

Rs13.05

Rs566.40

Rs2.50

Rs0.00

Rs704.85

C. Labour charges for feeding mixer, carrying materials from

stock piles, laying masonry, curing etc. including cleaning.

(As per Item R.R.stone Masonry with C:M 1:3)

Rs196.56

D. Hire charge of mixer

(As per Item R.R.stone Masonry with C:M 1:3)

Rs14.28

E. Cost of providing Ramps & Scaffolding and catways etc.

@ 10 % cost of materials (A)

(A+B+C+D)=

Overhead charges @10% of (A+B+C+D)=

-25-

Rs70.49

Rs986.18

Rs98.62

Rs1,084.80 /cum

Or Say

25.

Rs1,084.80 /cum

Cement concrete M10 grade with crushed granite coarse aggregate of size

40mm down graded mixed in batching and mixing plant including cost of all

materials, machineries and labour for materials up to mixing yard and

transportation of mixed concrete within initial lead of 1km by mechanical

means and laying in dams, barrages, power house and pen stock with all

lifts/delifts upto 1.5m height above average ground level as per direction of

Engineer-in-charge. (Cost of transportation of materials to be added)

For 1 cum

A. Materials

i) Cost of 40mm down graded aggregate for 0.93 cum :

40 mm down graded metal will contain

40mm

50.00%

20mm

25.00%

10mm

25.00%

Rate/cum =(464x0.50+638x0.25+671x0.25)=

Rate for 0.93 cum

0.93 cum

ii) Sand

iii) Cement

iv) Admixtures (to be added if used)

v) Water cost (to be added if supply

mains not provided by the department)

0.37 cum

2.07 qtl

@

@

@

Rs464.00

Rs638.00

Rs671.00

@

Rs559.25

@

@

Rs29.00

Rs354.00

L.S.

L.S.

Total =

Rs232.00

Rs159.50

Rs167.75

Rs559.25

Rs520.10

Rs10.73

Rs732.78

Rs0.00

Rs2.50

Rs1,266.11

B. Labour charges

i) Feeding batching plant :

Male Worker

0.20 nos.

@

Rs55.00

Rs11.00

ii) Placement and laying :

Mason Special

Male/Female worker

0.05 nos.

0.67 nos.

@

@

Rs85.00

Rs55.00

Rs4.25

Rs36.85

iii) Cleaning surface and green cutting and curing :

Jet Operator

0.10 nos.

Female worker

0.20 nos.

@

@

Rs65.00

Rs55.00

Total =

Rs6.50

Rs11.00

Rs69.60

C. Hire charge of machineries

i) Hire charge of transport vehicle :

(Conveyance of Green concrete from batching plant to

work site)

Transportation up to 1km by Tipper

One Tipper can carry 1.8 cum per trip, which is

manufactured by Batching Plant in two batches of

3 minutes each i.e. in 6 minutes.

Loading time

6.0 min

-26-

Loaded haul (@ 20 kmph)

Empty haul (@ 30 kmph)

Unloading, turning,

dumping etc.

Total cycle time =

3.0 min

2.0 min

3.3 min

14.30 min

No. of trips / hr considering

time = (50/14.30)

50.00 min effective

3.50 trips

Quantity of concrete transported considering

80% efficiency =

5.04 cum

Use rate of Tiper / hr without P.O.L. =

Cost of P.O.L. & lubricants a) Diesel

b) Lubricant @20% of Diesel

221.47

2.00 lt

@

Rs34.00

Hire charge of Tipper / cum =

Rs68.00

Rs13.60

303.07

Rs60.13

ii) Hire charge of Batching and Mixing Plant :

Out turn per hour =

Hire charge of Batching Plant/hr =

15.00 cum

468.70

Hire charge of Batching Plant / cum =

Rs31.25

iii) Hire charge of compressor for washing, cleaning

and green cutting :

Hire charge of 400cfm compressor/hr =

766.35

Compressor can supply air to 3 points and time

for cleaning in 3 phases is considered to be

0.03 hr each for 1 cum of concrete.

Hire charge of Compressor / cum =

Rs22.99

iv) Hire charge of vibrator :

Considering working conditions, one vibrator

can consolidate 5.04 cum concrete in 1 hr.

Use rate of Vibrator / hr =

Hire charge of Vibrator / cum =

94.90

Total =

(A + B + C ) =

Rs1,468.91

Or Say

Rs146.89

Rs1,615.80 /cum

Rs1,615.80 /cum

Overhead charges @10% of (A+B+C)

-27-

Rs18.83

Rs133.20

26.

Cement concrete M15 grade with crushed granite coarse aggregate of size

40mm down graded mixed in batching and mixing plant including cost of all

materials, machineries and labour and transportation of mixed concrete within

initial lead of 1km by mechanical means and laying in dams, barrages, power

house and pen stock with all lifts/delifts upto 1.5m height above average

ground level as per direction of Engineer-in-charge. (Cost of transportation of

materials to be added)

Unit - Per 1 cum

A. Materials

i) Cost aggregates

40mm

20mm

10mm

ii) Sand

iii) Cement

iv) Admixtures (to be added if used)

v) Water cost (to be added if supply

mains not provided by the department)

0.54

0.27

0.09

0.45

2.70

cum

cum

cum

cum

qtl

@

@

@

@

@

Rs464.00

Rs638.00

Rs671.00

Rs29.00

Rs354.00

L.S.

L.S.

Total =

Rs250.56

Rs172.26

Rs60.39

Rs13.05

Rs955.80

Rs0.00

Rs2.50

Rs1,454.56

B. Labour charges

Same as per M10 concrete

Rs69.60

C. Hire charge of machineries :

Same as per M10 concrete

(A + B + C ) =

Rs133.20

Rs1,657.36

Or Say

Rs165.74

Rs1,823.10 /cum

Rs1,823.10 /cum

Overhead charges @10% of (A+B+C)=

27.

Cement concrete M15 grade with crushed granite coarse aggregate of size

20mm and down graded mixed in batching and mixing plant including cost of

all materials, machineries and labour and transportation of mixed concrete

within initial lead of 1km by mechanical means and laying in dams, barrages,

power house and pen stock with all lifts/delifts upto 1.5m height above

average ground level in respective blocks as per direction of Engineer-incharge. (Cost of transportation to be added)

Unit - Per 1 cum

A. Materials

i) Cost of 20mm down graded aggregate

20 mm down graded metal will contain

20mm

10mm

ii) Sand

iii) Cement

0.54 @

0.36 @

0.45 cum

2.88 qtl

-28-

@

@

Rs638.00

Rs671.00

Rs344.52

Rs241.56

Rs29.00

Rs13.05

Rs354.00 Rs1,019.52

iv) Admixtures (to be added if used)

v) Water cost (to be added if supply

mains not provided by the department)

L.S.

L.S.

Total =

Rs0.00

Rs2.50

Rs1,621.15

B. Labour charges for feeding materials, laying

cleaning and curing etc. :

Same as per M10 concrete

Rs69.60

C. Hire charge of machineries :

Same as per M10 concrete

(A + B + C ) =

Rs133.20

Rs1,823.95

Or Say

Rs182.40

Rs2,006.35 /cum

Rs2,006.40 /cum

Overhead charges @10% of (A+B+C)=

28.

Cement concrete M20 grade with crushed granite coarse aggregate of size

20mm and down graded mixed in batching and mixing plant including cost of

all materials, machineries and labour and transportation of mixed concrete

within initial lead of 1km by mechanical means and laying in dams, barrages,

power house and pen stock with all lifts/delifts upto 1.5m height above

average ground level in respective blocks as per direction of Engineer-incharge.

Unit - Per 1 cum

A. Materials

i) Cost of 20mm down graded aggregate

20mm

0.54 cum

10mm

0.36 cum

ii) Sand

0.45 cum

iii) Cement

3.47 qtl

iv) Admixtures (to be added if used)

v) Water cost (to be added if supply

mains not provided by the department)

@

@

@

@

Rs638.00

Rs344.52

Rs671.00

Rs241.56

Rs29.00

Rs13.05

Rs354.00 Rs1,228.38

L.S.

Rs0.00

L.S.

Total =

B. Labour charges :

Same as per M10 concrete

Rs69.60

C. Hire charge of machineries :

Same as per M10 concrete

(A + B + C ) =

Rs133.20

Rs2,032.81

Or Say

Rs203.28

Rs2,236.09 /cum

Rs2,236.10 /cum

Overhead charges @10% of (A+B+C+D)

29.

Rs2.50

Rs1,830.01

Providing porous cement concrete pipes of size 0.69m x 0.69m cross section

with 23cm dia holes with porous concrete 1:3.5 proportion with 20mm

downgraded coarse aggregate within initial lead and lift/ delift of 20m from

average N.S.L. of dam block including supply of all materials, shuttering

charges, labour charges including positioning in dam with curing complete as

per the direction of Engineer-in-charge.

-29-

Unit - 1 r.m.

Volume of porous concrete/m =

(0.69² - (pi/4) x 0.23²) =

0.435 cum.

A. Materials

i) Cost of 20mm down graded aggregate

0.435 cum

20 mm down graded metal will contain

20mm to 10mm (60%)

10mm to 6mm (40%)

Rate/cum = (638x0.60+671.00x0.400=

Rate for 0.435 cum

ii) Cement

iii) Water cost (to be added if supply

mains not provided by the department)

60% @

40% @

Rs638.00

Rs671.00

0.435 cum

@

Rs651.20

Rs651.20

Rs283.27

1.76 qtl

@

Rs354.00

Rs623.04

L.S.

Total =

Rs2.50

Rs908.81

B. Labour charges

i) Washing of aggregate :

Female Worker

0.15 nos.

@

Rs55.00

Rs8.25

ii) Feeding Mixer :

Male/Female Worker

0.15 nos.

@

Rs55.00

Rs8.25

iii) Shuttering :

Fitter/Carpenter

Male Worker

0.04 nos.

0.04 nos.

@

@

Rs85.00

Rs55.00

Rs3.40

Rs2.20

iv) Laying concrete, finishing, curing :

Mason Special

Male/Female Worker

0.05 nos.

0.25 nos.

@

@

Rs85.00

Rs55.00

Rs4.25

Rs13.75

@

@

Rs85.00

Rs55.00

Total =

Rs4.25

Rs41.25

Rs85.60

v) Conveyance of precast block to placement spot and

aligning & fixing :

Mason Special

0.05 nos.

Male/Female Worker

0.75 nos.

C. Shuttering Charges

One steel centring box and one M.S. pipe 23cm dia

can be used for 60 times and salvage value will

be 20% only.

The porous blocks shall be cast in 0.5m high pieces.

For one shutter of 0.5m height

a) M.S. angle 50x50x6mm

thick 7.6m @ 4.5 kg/m =

b) M.S. plate 2.3mm thick

(4x0.65x0.5) = 1.3 sqm

@ 18 kg/sqm

=

34.20 kg

23.40 kg

57.60 kg

-30-

Cost of 57.60 kg

Manufacturing cost with incidentals

for 57.60 kg

@

Rs30.64 Rs1,764.86

@

Cost of 23cm dia M.S. pipe of 0.5m =

Cost of one shutter =

Rs5.00

L.S.

Cost of 2 sets =

Deduct scrap value (20%) =

Rs200.00

Rs2,252.86

(-)

Cost /use for block of 1m height = 3604.58/60 =

D. Hire charge of mixer for

Rs4,505.72

Rs901.14

Rs3,604.58

Rs60.08

0.176 hr

Hire charge of mixer /hr =

Rs126.96

Hire charge of mixer /r.m. = 126.96 x 0.176=

Rs22.34

(A + B + C + D) =

Rs1,076.83

Overhead charges @10% of (A+B+C+D)

Or Say

30.

Rs288.00

Rs107.68

Rs1,184.51 /r.m.

Rs1,184.50 /r.m.

Flush pointing to stone masonry in cement mortar 1:3 including racking out

joints 5mm deep, cleaning, pressing cement mortar finishing and curing

including cost of materials, labour, scaffolding with initial lead and lift upto 10m

etc. complete as per the direction of Engineer-in-charge.

Unit - 1 sqm

A. Materials

i) Cement

ii) Sand

B. Labour charges

Mason Special

Male Worker

Female Worker

0.043 qtl

0.009 cum

@

@

Rs354.00

Rs29.00

Total =

Rs15.22

Rs0.26

Rs15.48

0.11 nos.

0.10 nos.

0.30 nos.

@

@

@

Rs85.00

Rs55.00

Rs55.00

Total =

Rs9.35

Rs5.50

Rs16.50

Rs31.35

C. Scaffolding Charges

3 % of Labour charges (C) =

Rs0.94

(A + B + C ) =

Rs47.77

Or Say

Rs4.78

Rs52.55 /sqm

Rs52.60 /sqm

Overhead charges @10% of (A+B+C)

31.

Rule pointing to stone masonry in cement mortar 1:3 including racking out

joints 5mm deep, cleaning, pressing cement mortar finishing and curing

including cost of materials, labour, scaffolding with initial lead and lift up to

10m etc. complete as per the direction of Engineer-in-charge.

-31-

Unit - 1 sqm

A. Materials

i) Cement

ii) Sand

0.0516 qtl

0.011 cum

@

@

Rs354.00

Rs29.00

Total =

Rs18.27

Rs0.32

Rs18.59

0.172 nos.

0.10 nos.

0.30 nos.

@

@

@

Rs85.00

Rs55.00

Rs55.00

Total =

Rs14.62

Rs5.50

Rs16.50

Rs36.62

B. Labour charges

Mason Special

Male Worker

Female Worker

C. Scaffolding Charges

3 % of Labour charges (C) =

Rs1.10

(A + B + C ) =

Rs56.31

Or Say

Rs5.63

Rs61.94 /sqm

Rs61.90 /sqm

Overhead charges @10% of (A+B+C)

32.

25mm thick (average) cement plaster in contraction joints in masonry dams in

cement mortar 1:3 including surface preparation by racking out joints etc.and

curing including cost of materials, labour, scaffolding with initial lead and lift up

to 10m etc.complete as per the direction of Engineer-in-charge.

Unit - 1 sqm

A. Materials

i) Cement

ii) Sand

B. Labour charges

Mason Special

Male Worker

Female Worker

0.145 qtl

0.026 cum

@

@

Rs354.00

Rs29.00

Total =

Rs51.33

Rs0.75

Rs52.08

0.18 nos.

0.15 nos.

0.11 nos.

@

@

@

Rs85.00

Rs55.00

Rs55.00

Total =

Rs15.30

Rs8.25

Rs6.05

Rs29.60

C. Scaffolding Charges

3 % of Labour charges (C) =

Rs0.89

(A + B + C ) =

Rs82.57

Or Say

Rs8.26

Rs90.83 /sqm

Rs90.80 /sqm

Overhead charges @10% of (A+B+C)

-32-

33.

Providing contraction joints of masonry and concete dams by installation of

two lines of Z-type copper sealing strips of 16 S.W.G (1.63mm thick)

excluding cost of copper strips, G.I. pipes of 20mm dia, fabrication, filling with

asphalt of approved grade complete, excluding cost of copper sheet as per

the direction of Engineer-in-charge. ( Any plastering or shuttering required for

groove or notch to be paid separately.)

Unit - 1 r.m.

A. Materials

i) Copper sheet 1.63mm thick 0.6m wide

2nos.x0.6x1.0x(1.63x8900)/1000 =

(Weight of copper 8900 kg/cum)

Brazing charges of copper strips at ends

17.41 kg

0.24 m

@

Rs50.00

Rs12.00

3.72 kg

2.00 m

@

@

Rs28.58

Rs55.00

L.S.

Total =

Rs106.32

Rs110.00

Rs120.00

Rs348.32

1.00 nos.

3.00 nos.

@

@

Rs85.00

Rs55.00

Total =

Rs85.00

Rs165.00

Rs250.00

(A + B ) =

Rs598.32

Or Say

Rs59.83

Rs658.15 /r.m.

Rs658.20 /r.m.

ii) 10mm dia M.S. rods for fixing copper

strips (2x4nos.x0.75mx0.62)

iii) Cost of 20mm diaG.I.Pipes 2m.

iv) Cost of Asphalt

B. Labour charges

Fitter Special

Male Worker

Overhead charges @10% of (A+B) =

34.

Providing contraction joint in the dam including fixing one line of Z-type copper

sealing strip of 16 SWG (1.63 mm thick) and one line of P.V.C. water stop of

approved design including fixing 20 mm dia G.I. pipes for heating and filling

with asphalt of approved grade but excluding cost of copper strip and P.V.C.

strip but including cost of all other materials complete including jointing sheets

with bredzing/araldite etc. as directed by the Engineer-in- Charge (Any

plastering or shuttering required for groove or notch to be paid separately).

Unit - 1 r.m.

A. Materials

i) Copper sheet 1.63mm thick 0.6mm wide

1 meter - 8.705 K.G

ii) P.V.C. water stop - 1 mtr

iii) Brazing copper sheet

0.60 mtr

@

Rs50.00

Rs30.00

3.72 kg

2.00 mtr

@

@

Rs28.58

Rs55.00

L.S.

Rs106.32

Rs110.00

Rs120.00

Rs366.32

iv) 10mm dia MS rods for fixing strips

v) 20mm dia G.I pipe

vi) Cost of Asphalt

-33-

B. Labour Charges

i) Fitter Special

ii) Male worker

0.80 nos

2.00 nos

@

@

Rs85.00

Rs55.00

(A + B ) =

Rs544.32

Or Say

Rs54.43

Rs598.75

Rs599.00 /1r.m.

Overhead charges @10% of (A+B) =

35.

Rs68.00

Rs110.00

Rs178.00

Providing P.V.C. water stop for drainage gallery as per approved design

including fixing in proper allignment and joining with araldite etc. excluding

cost of P.V.C water stop as directed by Engineer-in-Charge.

Unit 1 R.M.

A. Materials

i) Cost of P.V.C. water stop - 1 mtr.

ii) 10mm dia MS rods for supporting in position

2x2x0.75 = 3m @ 0.62 K.G/m =

1.86 kg

B. Labour Charges

i) Fitter Special

0.25 nos

ii) Male worker

0.50 nos

Rs0.00

@

1.86

28.58

@

@

Rs85.00

Rs55.00

(A + B ) =

Rs21.25

Rs27.50

Rs48.75

Rs101.91

Or Say

Rs10.19

Rs112.10

Rs112.10 /R.M.

Overhead charges @10% of (A+B) =

36.

Rs53.16

Providing rigid shuttering with the box type steel shuttering plates with keys for

intermediate construction joints in rafts of weirs, barrages and dam blocks

including cost of all materials, labour, T. & P. etc. complete as directed by the

Engineer-in-charge including removal of forms.

Unit- 1 cum of concrete / 1 sqm of shuttering

It is assumed that the concrete shall be laid in 0.5m layers in confined

areas of 15m x 10m. Considering two vertical faces of the confined area

require intermediate shuttering and two other faces is already available,

Area of shuttering =(15.00+10.00)x0.5 =

Zig zag faces

= 25 x 0.15 x 0.5 =

Volume of concrete = (15.00x10.00x0.5)=

A. Materials

a) Cost of shuttering boxes :Boxes of 1.00mx0.5mx0.5m having three faces shall be used with

50x50x6mm angles and 2.5mm plates.

M.S. Angles 50x50x6mm

-34-

12.50

1.88

14.38 sqm

75.00 cum

8.0m @ 4.5 kg/m =

M.S. plate 2.5mm thick

1 sqm @ 19.62 kg/sqm

36.00 kg

19.62 kg

55.62 kg

=

Structural Steel 55.62 kg

Fabrication charges for 55.62 kg

Fixing keys 25mm dia rod, 0.3m @ 3.85 kg/m

=

1.16 kg

Support Angle 50x50x6mm

1.0m @ 4.5 kg/m =

4.50 kg

@

@

Rs30.64 Rs1,704.20

Rs2.70

Rs150.17

Rs1,854.37

@

Rs15.00

Rs17.40

@

Rs30.64

Rs137.88

Fixing bolts and nuts 2nos. 16mm dia 5cm bolts

L.S.

Deduct scrap value after uses @ 20% =

Considering 70 uses, cost per use =

1610.12/70 =

For 25 nos. of shutters & fixtures =

23.00x25 =

Rs575.00

Rs75.00

Rs55.00

Total =

Rs75.00

Rs220.00

Rs295.00

(A+B)=

Rs870.00

B. Labour charges for fixing, removal etc.

Fitter

1.00 nos.

Male Worker

4.00 nos.

@

@

Overhead charges @10% of (A+B)

Rs23.00

Rs87.00

Rs957.00

1. Volume of Concrete =

Rate per cum of concrete =

75.00 cum

957.00 / 75 =

2. Area of Shuttering =

Rate per sqm =

37.

Rs3.00

Rs2,012.65

Rs402.53

Rs1,610.12

Or Say

Rs12.76

Rs12.80 /cum

14.38 sqm

957.00 / 14.38 =

Or Say

Rs66.57

Rs66.60 /sqm

Providing formwork for concrete with F1 finish for upstream faces of dam,

spillway, glacis of barrages, unexposed surfaces of foundation, block joints

etc.with steel shutters rigidly fixed and removal of forms and making good to

the surfaces where necessary complete with all labour, materials and T & P