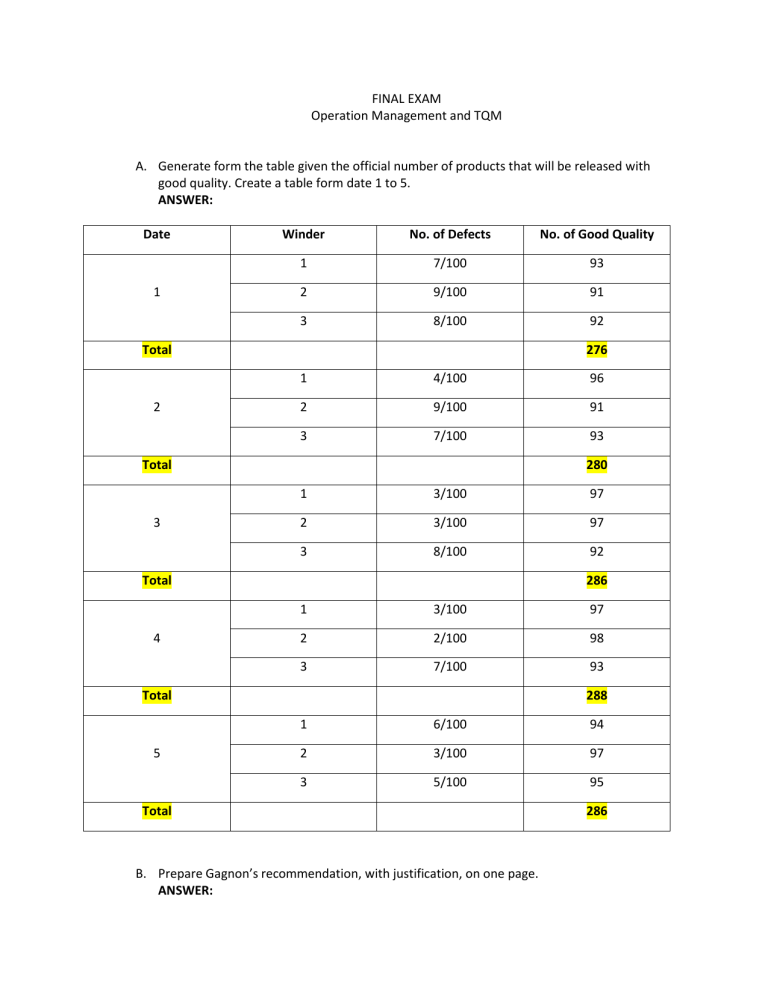

FINAL EXAM Operation Management and TQM A. Generate form the table given the official number of products that will be released with good quality. Create a table form date 1 to 5. ANSWER: Date 1 Winder No. of Defects No. of Good Quality 1 7/100 93 2 9/100 91 3 8/100 92 Total 2 276 1 4/100 96 2 9/100 91 3 7/100 93 Total 3 280 1 3/100 97 2 3/100 97 3 8/100 92 Total 4 286 1 3/100 97 2 2/100 98 3 7/100 93 Total 5 288 1 6/100 94 2 3/100 97 3 5/100 95 Total B. Prepare Gagnon’s recommendation, with justification, on one page. ANSWER: 286 Westover Electrical, Inc. was continuously producing product with defects. And to help, Gagnon’s recommendation greatly help them to look for the cause of the defects products. And upon checking, Gagnon first check the production floor and upon checking, I may say that he doesn’t see anything wrong about the floor. Because he seeks for the help of the production personnel of the company and ask what are possible cause of the defects of the product. I think that they used also different processes and inspections to determine the main cause of the defectives product. After discussion and tour in winding operation, they discovered that the three machines were producing defectives. Ask for the help of the expert to fix the machine. And to give recommendations: Check first the production floor and Quality Control Seek for the help of the personnel of the production Have a tour for the production room to check one by one the machines Also checked the whole process to find where is the defects Analyzed and discussed the possible reasons of the defectives Seek for the possible solution from the experts Also check the past records of the Quality Control Department Check always the machine first before to continue the process of production C. Using the DMAIC principle. Discuss how the process can be improved. Cite relevant examples from your company that can be used as reference from this improvement. ANSWER: DMAIC Principle or the Define, Measure, Analyze, Improve and Control Principle, has a big help in terms of improving the whole process of the production. And to explain each of the principle, first step is to define, this step is one of most important as in this step includes the company’s goal, the company’s budget, the company’s personnel from the executive leaders down up to finance representative. In addition, in this step also includes the studying of the customer wants through maybe by surveys and analytical and factual data. In short, through these step, the company will know how to get the customer’s satisfaction. Next step would be the measure, in this step, you can now measure and create the sampling design that will use and which also based from what the customer wanted. It also measures some parameters about the quality of the product to produce. And to make sure that the product that will going to produce is with higher quality, the analyzation step is important where the looking of data and research for the better quality includes. This also to make sure or at least lessen the number of unexpected defects that may produce, after analyzing, the improvement for the product is the next must to do. And lastly, after achieving the improvement step, the step that will be needed is just to control the whole process. Maintain the whole process to continuously produce a higher quality and no defects in the outcomes products.