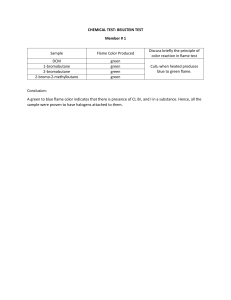

SYSTEM 3000 / 4000 FLAME AMPLIFIER MODULE 3001 TECHNICAL DESCRIPTION EDITION TB 3001- REV 2 BFI – Automation Dipl.-Ing. K.-H. Mindermann GmbH, Eggerscheidter Str. 57, D-40883 Ratingen Phone +49 (0) 2102 96 82 – 0, Fax +49 (0) 2102 9682 – 42 Email: info@bfi-automation.de 1 Flame amplifier module 3001 - Precise display of intensity - Fault diagnosis - Setting of threshold value - Variable closing delay time - Variable OFF delay time - Relay signal output - Pre-alarm Application The flame scanner 3001 is a system plug-in unit of the 3000 line, which, in connection with the flame detectors of the system, is providing fullscale flame monitoring for any burner output, fuel, and combustion process. The flame monitoring system 3000/4000 is tested by TÜV in accordance with EN 230 and EN 298 and approved according to DIN DVGW. It meets the requirements of TRD 411 to 414. The plug-in unit is approved for continuous operation because of continuous fully electronic fail-safe checking of its function. Front view 70,78 (14TE - 0,34 ) BFI 8 1: LED time I Sensitivity 78 456 45 6 x 10 1 x1 Flame Signal 78 901 23 78 90 1 456 Sensitivity 7: LED MA – M-alarm 8: sensitivity I II 456 78 90 1 3 23 x1 5: sensitivity II 6: threshold value (MT) RM x 10 23 5 2 Flame 45 6 128,70 RF M-Alarm MT 3: LED RM – monitoring channel 4: LED time II MA 6 2: LED RF – evaluation channel I I 23 78 90 1 23 901 7 Time Time 4 3001 2 Function The self-checking and fail-safe flame scanner 3001 contains two separate signal processing channels of differing layout, which are being synchronised by a processor. Internal and external faults of any kind trigger automatically immediate actuation of the safety devices. c) Defects in the electronic system of the flame detector. EVALUATION CHANNEL (RF) The evaluation channel contains all the necessary precision components which are providing the sign-off times differing per level. The sign-off times are selected per DIP switches (S2/S3). Further, the evaluation channel supports the setting of the hysteresis for pre-selecting the switching threshold "Flame on" (DIP switch S1). In connection with the monitoring channel the evaluation channel addresses the output relay K 101. Two independent monitoring levels (time level I, time level II) can freely be selected by means of an external control signal. Each level is described by its sensitivity setting and sign-off time. In this way a fuel- and load-related optimisation of flame monitoring is easy to implement. The connection of a second flame detector in parallel or alternating operation is possible. The output signal of the flame detector is transmitted as a pulse message via a filter and pulse shaper stage to the sensitive controllers. Two rotary switches are available per time level for setting the desired signal amplification. This flame signal is distributed on three further function channels: 1. Measuring channel 2. Monitoring channel 3. Evaluation channel After satisfactory start-up of the monitoring system 3000 the LED RM lights up immediately at flame signal, whereas the LED RF switches timedelayed depending on selected sensitivity and hysteresis stage. The important floating relay contact K 101 "Flame on", assigned to the external safety circuit, is fused inside the device, thus excluding any contact welding. In addition, a further non-fused auxiliary circuit is available. The adjustable pre-alarm (MT) signals unfavourable combustion processes depending on flame intensity, before a final switching off happens. Indication is by LED MA. For external processing an output 24 V / 100 mA is available. (M) (RM) (RF) MEASURING CHANNEL (M) The analogue measuring channel is designed as a attenuation filter with signal contractor followed by a voltage-current transformer. The output of the transformer supplies the internal analogue intensity indicator and through output terminals the remote display instruments with 0 - 20 mA resp. 4 - 20 mA. MONITORING CHANNEL (RM) The monitoring channel contains all the periodical self-monitoring checks of the system required for continuous operation. In case of malfunction of the flame monitoring system 3000 the processor-based control logic reacts immediately and the relay assigned to LED RM drops and interrupts burner operation within the safety switch off time set for the monitoring channel (S4/S5). Should the LED RM not be lit during burner start operation or extinguish during operation the following malfunctions may exist: a) Module defect in flame scanner 3001 for inst. failure of clock signal. b) Disturbing pulse effects on not correctly connected or installed flame detector lines (induced voltage). 3 connection diagram 3001 3001 back panel F101 +24V M0.8A G a2 supply 24V DC +-20%/0,5Amax. c2 01 a4 02 c4 03 a6 04 c6 05 a8 06 c8 07 a10 08 c10 09 a12 10 c12 11 a14 13 c14 14 a16 12 c16 15 a18 16 time. II "ON" c18 17 measurement channel c20 18 subsidiary circuit flame "OFF" 24V DC/1A max. a22 19 subsidiary circuit flame "ON" c22 20 subsidiary circuit lead c26 21 a28 22 c30 23 safety circuit lead safety circuit lead flame "OFF"' must be included actively in the start monitoring! safety circuit lead flame "ON" a32 24 ground lead pulse USig connection of flame scanner K1 +24V V110 K1 supply 0V Masse (GND) time. I 0V time. II 24V DC/40mA max. early warning "MA" 24V DC/100mA max. switchover 3 X3 1 2 +15V K2 X3 X4 K101 F102 M1A G K101 connection diagram flame scanner BFI-special cable KW5 3001 back panel a4 a6 a8 2 4 6 a10 8 a12 10 a16 12 power supply 24V DC green 4 4 pulse brown 2 2 signal white 1 1 signal ground pink 3 3 power supply 0V ground yellow 5 5 sensitivity switch-over (option) grey 6 6 power supply 24V DC green 4 4 pulse brown 2 2 signal white 1 1 signal ground pink 3 3 power supply 0V ground yellow 5 5 sensitivity switch-over (option) grey 6 6 flamescanner I outer braided shield BFI-special cable KW5 c4 c6 c8 3 5 7 c10 9 c12 11 c16 12 outer braided shield 4 flamescanner II ATTENTION: The outer braided shield shall be clamped between the plastic insert and the srewed coupler in the compression gland on the scanner side. The inner screening shall be cut on the scanner side and connected to ground at the flame controller. Technical data The flame amplifier is self-monitoring for the fail-safe function control accordance to EN 230, EN 298. Conform to the requirement of DIN VDE0116 and TRD 411 to 414, approved accordance to DIN DVGW. Two safety times Two sensitivity ranges Hysteresis: Switching point flame „ON“ Switching point flame „OFF“ set in 1 - 6 steps (1 –6 seconds), longer times on request set by digital switches, ratio 1:99 adjustable in 64 steps, 5 - 15 mA < 5 mA Flame relay: 2 changeover contacts, floating (1 safety circuit, 1 subsidiary circuit) Flame intensity display: Current output 0-20 or 4-20 mA: 0-100 % (Built-in luminous bar indicator) selection-jumper shunt resistance max. 300 Ω Pre-alarm: Pre-alarm output: set by 10 steps / 2 mA 24 V, 100 mA, short circuit proof Channel selection: Quantization switchover: Locked range switchover or monitoring channel „off“ 24 V, 40 mA plug-in bridges Status indication on LEDs: channel I or channel II 'on' = green evaluation channel (RF) and monitoring channel (RM) 'on' = yellow Pre-alarm signal (MA) 'on' = yellow Supply: Current consumption: Ambient temperature: Protection: Weight: Part-no.: 24V DC, 500 mA approximate 150 mA -20°C to +70°C IP 00 700 g G 601 message 15 V/10 mA The following applies to the safety circuit: VDE 0110, class C 250 V max. switching voltage: 250 V ohmic load max. switching current: 1 A, ohmic load max. switching power: 300 VA All modules of the series 3000 are plug-in types for using in 19“-magazines accordance to DIN 41494 (19“-norm). The dimensions of all modules are: Width Height Depth Edition: Rev 2 70.78 mm = 14 DIV 128.70 mm = 3 DIV 188.00 mm Right of technical modifications reserved 5 © BFI Automation 2012