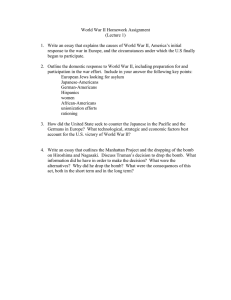

NAVWEPS OP 2216 (VOLUME 1) AIRCRAFT BOMBS, FUZES AND ASSOCIATED COMPONENTS THIS PUBLICATION SUPERSEDES OP 988, 1050, 1087, 1234, 1280, ,343, 1531, 1548, 1585, 1884, 1903, 2307, AND 2559. OCL AV 24-45, AV31-45, AV32-45, AND AV2-46. OHI A12-45, AV22-43, A 3-45 AND AVI-54. OMI V3-50. OML AV3-51. OTI AV7-43, AVI-45, AN D AV6-45. NAVORDINST 8150.6, 8150.7, 8150.8, 8150.10, 8150.12, 8150.13, 8150.14, 8150.18, AN D 8150.20. PUBLISHED BY DIRECTION OF THE CHIEF OF THE BUREAU OF NAVAL W EAPONS 1 AUGUST 1960 CONTENTS Chapter 1— 2— GEN E RA L INFORM ATION Scope ......................................... ..................... Purpose o f A ircraft Bombs ........................ Obsolescent Items ............... ............. ........... Obsolete Items ...............................— .... — Bomb Operation ............................................ Classification o f Bombs ......... — ............... Classification o f Fuzes ------------------ ------Bomb Components ...................... Marking and Identification ------ M Packaging ................................. Handling and Stowage .... ........................Disposal ......... ................................ — ............ Page Chapter 2— 1-3 1-3 1-3 1-3 1-3 1-6 1-8 1-11 1-19 1-21 1-21 1-24 FUZES Impact Nose Fuze AN-M 103A1, A N M139A1, and AN-M 140A1 ................... 2-1 Impact Nose Fuze AN-M 110A1 (obsoles­ cen t), AN-M 126, AN-M 126A1 (obso­ lescent), AN-M 158, and AN-M 159 ___ 2-7 Impact Nose Fuze AN -M k 219 (obsoles­ cent) Mods 3 and 4 ............. 2-12 Impact Nose Fuze Mk 243 Mod 0 and Mk 244 Mod 1 ........................... 2-17 Mechanical Time Fuze AN-M 145A1 and AN-M 146A1 ................ 2-22 Mechanical Time Fuze, M155A1 ............. 2-30 VT Fuze, AN-M 166, AN-M 166E1, A N M166E3, AN-M 168, AN-M 168E1, A N M168E2, (T50E1, T50E4, T51E1, T91 -------obsolescent), and T93 ...................... 2-33 Impact Tail Fuze, AN-M 100A2, A N M101A2, AN-M102A2, M160, M161, M162, M172, AN-M 175, M176, A N M177, AN-M 184, AN-M 185, AN-M 194, and AN-M 195 ................. 2-36 Impact Tail Fuze, AN-M 112, A N M112A1, AN-M 113, AN-M 113A1, A N M114, AN-M 114A1, AN-M 115, A N M116, AN-M 117, M178, M179, M180, M181, M182 and M183 ........................... 2-43 Impact Tail Fuze, A N -M k 228 Mods 0 and 1, (obsolete) ...................................... 2-60 Impact Tail Fuze, AN-M k 247 Mod 0..... ...... Long-Delay Tail Fuze, AN-M 123, A N M123A1, AN-M 124, AN-M 124A1, and AN-M125A1 ...... 2-59 Long-Delay Tail Fuze, AN-M 132, A N M133, and AN-M134 ________________ 2-68 FUZES (Contd) Hydrostatic Tail Fuze, Type 1 AN-M k 230 Mods 4, 5, and 6, (obsolescent) ..... Multi-Position Fuze M157, AN-M173, and AN-M 173A1 ................ Impact Side Fuze, M129 ............ ................. Time Side Fuze, M130 and M130A1 ....... Antidisturbance Side Fuze, M131 and M131A1 __ _____M ......— ..... ................. 3— Page 2-77 2-83 2-89 2-93 2-97 BOMB COMPONENTS OTHER THAN FUZES Adapter-Booster M102A1 ---- ----------------- 3-1 Adapter-Booster M115A1 -----------------— 3-2 Adapter-Booster M117 ....... ........................ 3-3 Adapter-Booster T45E1 __ _____ ___ _____ 3—4 Adapter-Booster T46E4 .... ......................... 3-5 Auxiliary Booster Mk 1 Mod 0 ................. 3-6 Auxiliary Booster Mk 4 Mod 0 ..... ...... — 3-7 Burster M10 ........................... — ................. 3-8 Burster AN-M 12 ................... — ........- ....... 3-9 Burster AN -M 13 ............ — ......................... 3-10 Bursters AN-M 14, AN -M 15, and A N M16 ...... ............................ „ .... .................. 3-11 Burster AN -M 18 .............. 3-12 Burster AN-M 20 ............. 3-13 Igniter A N -M 5 ................ 3-14 Igniter A N -M 9 ................ 3-15 Igniter M l5 ..................... 3-16 Igniter AN-M 16 ............. 3-18 Igniter M23 ...................... 3-20 Practice Bomb Signal Mk 4 Mods 3 and 4 3-21 Practice Bomb Signal Mk 5 Mod 0 (Obso­ lete) .................................. 3-23 Practice Bomb Signal Mk 6 Mod 0 ......... 3-24 Practice Bomb Signal Mk 7 Mod 0 (obso­ lete) ............................... 3-26 Primer-Detonator M14 ............. 3-28 Primer-Detonators M16 and M16A1 ..... 3-30 4— ARM OR-PIERCING AND SEM I-AR­ M OR-PIERCING BOMB ASSEM ­ BLIES 2-65 1000-lb AP Bomb A N -M k 33 Mods 1, 2, and 3 (obsolete) ...................................... 1600-lb A P Bomb A N -M k 1 Mods 1, 2, and 3 (obsolete) ............ ......................... 500-lb SAP Bomb AN-M 58, AN-M58A1, AN-M 58A2 (obsolete) ..... ...................... 4-1 4-6 4-10 III N A V W E P S OP 2216 (V O L U M E 1) Chapter Page 4— ARMOR-PIERCING AND SEM I-AR­ MOR-PIERCING BOMB ASSEM ­ BLIES (Contd) 1000-lb SAP Bomb AN -M 59 (obsolete) and AN-M 59A1 .................................. —- 4-14 2000-lb SAP Bomb M103 (obsolete) ........ 4-18 5— GEN E RA L PURPOSE BOMB ASSEM ­ BLIES 100-lb GP Bomb AN-M 30A1 with Fin Assembly AN-M 103A1 .................. - ......- 5-1 100-lb GP Bomb AN-M 30A1 with Fin Assembly M135 .................. ...................... 5-5 250-lb GP Bomb AN-M 57A1 with Fin Assembly AN-M 106A1 ......... ........... 5-7 250-lb GP Bomb AN-M 57A1 with Fin Assembly M126 ........ ........................ 5-11 500-lb GP Bomb AN-M 64A1 with Fin Assembly AN-M 109A1 ................ 5-12 500-lb GP Bomb AN-M 64A1 with Fin Assembly M128A1 _........ ................. ....... 5-16 1000-lb GP Bomb AN-M 65A1 with Fin Assembly AN-M 113A1 ............................ 5-18 1000-lb GP Bomb AN-M 65A1 with Fin Assembly M129 5-22 2000-lb GP Bomb AN-M 66A2 with Fin Assembly AN-M 116A1 .............. 5-24 2000-lb GP Bomb AN-M 66A2 with Fin Assembly M130 ___ 5-29 250-lb Low Drag Bomb (G P) Mk 81 Mod 1 ................. 5-31 500-lb Low Drag Bomb (G P ) Mk 82 Mod 1 ....................... 5-35 1000-lb Low Drag Bomb (G P) Mk 83 Mod 3 .... ................ 5-39 2000-lb Low Drag Bomb (G P) Mk 84 Mod 1 ........... 5-43 6— A IR C R A F T DEPTH BOMB ASSEM ­ BLIES 350-lb A ircraft Depth Bomb A N -M k 54 Mods 0 and 1 (obsolete) .............. ....... 6-1 7— FRAGM EN TATIO N BOMB ASSEM ­ BLIES 4-Ib Frag Bomb M83 .............................. 7-1 20-lb Frag Bomb AN-M 41A1 _____ 7-4 90-lb Frag Bomb M82 (Obsolescent) ..... 7-7 220-lb Frag Bomb AN-M 88 with Fin Assembly AN-M 103A1 .... 7-13 220-lb F rag Bomb AN -M 88 with Fin Assembly M135 ............................. 7-14 260-lb Frag Bomb AN-M 81 with Fin Assembly AN-M103A1 ........ ... ____ 7-19 260-lb Frag Bomb AN-M 81 with Fin Assembly M135 7-20 8— FRAGM EN TATIO N BOMB CLUS­ TERS AND AD A PTE RS 100-lb Frag Bomb Cluster AN-M 1A2 (obsolete) .............. .................................... IV 8-1 Chapter 8— 9— 10— 11— Page FRAGMENTATION BOMB CLUS­ TERS AND ADAPTERS (Contd) 100-lb Frag Bomb Cluster M28A2 ............ 8-5 500-lb Frag Bomb Cluster M26A2 (obso­ lete) _______________________ 500-lb Frag Bomb Cluster M27A1 (ob­ solete) ........................ 8-14 500-lb Frag Bomb Cluster M29A1 ........... 8-19 DEM OLITION BOMBS 750-lb Demolition Bomb M117 _________ 3000-lb Demolition Bomb M118 .................. 8-9 9-1 9-5 CHEM ICAL (G A S ), SMOKE, AND IN C E N D IA R Y BOMB ASSEM BLIES 116-lb Chemical (Gas) Bomb M70A1 .... 10-1 500-lb Chemical (Gas) Bomb AN -M 78 . 10-4 1000-lb Chemical (Gas) Bomb A N -M 79 .. 10-8 100-lb Smoke Bomb A N -M 47A 4 ______ 10-12 100-lb Incendiary Bomb A N -M 47A 4 10-16 500-lb Incendiary Bomb AN -M 76 with Fin Assembly AN-M 109A1 (Box-type) (obsolescent) ............................... 500-lb Incendiary Bomb A N -M 76 with Fin Assembly M128A1 (Conical) ____ 10-23 500-lb Fire Bomb Mk 77 Mod 1 .......... 10-25 750-lb Fire Bomb Mk 77 Mod 0 . ......... 10-29 750-lb Fire Bomb Mk 77 Mod 0 with Bomb Conversion Kit Mk 19 Mod 0 .... 10-34 750-lb Fire Bomb Mk 78 Mod 2 ........ .... 10-38 1000-lb Fire Bomb Mk 79 Mod 1 ..... ........ 10-42 PRACTICE BOMB A SSEM BLIES 3-lb Miniature Practice Bomb Mk 5 Mod 2 and 3 (obsolescent) ___________ ___ 11-1 3-lb Miniature Practice Bomb A N -M k 23 Mod 1 _________ ____ ______ _____ ______ 11-1 4.5-lb Miniature Practice Bomb Mk 43 Mod 1 (obsolete) ____ ___ ___ _________ 11-1 13-lb Miniature Practice Bomb Mk 19 Mods 0 and 1 (obsolescent) .... ...... . 11-5 5-lb Practice Bomb Mk 106 Mod 0 _____ 11-9 25-lb Practice Bomb Mk 76 Mods 0, 1, and 2 (obsolescent) ............................... 11-12 56-lb Practice Bomb Mk 89 Mod 0 and 1 11-16 100-lb Practice Bomb Mk 15 Mods 2, 3, and 4 _____ ____ _______ _________ 11-21 250-lb Practice Bomb Mk 86 Mod 0 and 1 11-29 500-lb Practice Bomb Mk 65 Mod 0 ........ 11-33 500-lb Practice Bomb Mk 87 Mod 0 ........ 11-38 1000-lb Practice Bomb Mk 66 Mod 0 ____ 11-42 1000-lb Practice Bomb Mk 88 Mod 0 11-47 2000-lb Practice Bomb Mk 67 Mod 0 ........ 11-51 2000-lb Practice Bomb Mk 104 Mod 0 _ 11-56 Practice Depth Bomb Mk 100 Mod 0 11-61 Practice Depth Bomb Mk 102 Mod 0 ... 11-76 12— S A F E T Y PRECAUTIO NS .................. 12-1 IN DEX .......................................................... 1-1 10-19 ILLUSTRATIONS Figure Page Figure Page 1-0. Frontispiece: Bombing Attack Deliv­ 2-20. Impact Tail Fuze AN-M115, Cross ered by Carrier A ircraft ..... .............. xii Section ................................. 2-21. Impact Tail Fuze AN -M k 228 .......... 2-50 1-1. Representative Bombs and Clusters — 1-4 2-22. Impact Tail Fuze A N -M k 228, Cross 1-2. Explosive Train ..............................-....... 1-7 Section ______ 2-51 1-3. Arm ing Vanes ................ ......................... 1-9 2-23. 1-4. Bomb Fuzing ..................... 1-10 Impact Tail Fuze AN-M k 228, Indica­ tion o f Armed Condition .............. 2-53 1-5. Arming Wires ---- ----- ------ ------------ ----- 1-12 1-6. Typical Cluster Adapters ...................... 1-14 2-24. Tail Fuze A N -M k 247 Mod 0 ............. 2-55 2-25. Impact Tail Fuze A N -M k 247, Cross 1-7. Typical Box Fin Assemblies ....... — 1-15 Section .................................................. 2-56 1-8. Typical Conical Fin Assembly ..... ....... 1-16 2-26. Long-Delay Tail Fuzes AN-M 123A1, 1-9. Typical Fin Locknuts ............................. 1-17 AN-M 124A1, and AN-M 125A1 ...... 2-59 1-10. Fin Locking Web ..................—.............1-18 2-27. Long-Delay Tail Fuze AN-M 123A1, 1-11. Typical Suspension Band ....... ............ 1-19 Cutaway View ...... 2-60 1-12. Shipping Containers fo r Bombs -------- 1-22 2-28. Long-Delay Tail Fuze AN-M 123A1, 1 - 13. Shipping Containers fo r Bomb Fins Details o f Operation ........................... 2-63 and Arming Wires .................... 1-23 2-29. Long-Delay Tail Fuzes AN-M 132, 2 - 1. Nose Fuzes AN-M 103A1, ANAN-M 133, and AN-M 134 ............. 2-68 M139A1, and AN-M 140A1 ________ 2-1 2-30. Long-Delay Tail Fuze AN-M 132, 2-2. Impact Nose Fuze A N -M 103A1, Cross Cross Section _________ 2-70 Section ........ ........................... .............. 2-2 2-31. Long-Delay Tail Fuze AN-M 132, As 2-3. Nose Fuzes AN-M 158 and AN-M 169 2-7 Shipped, Detail ............. 2-71 2-4. Impact Nose Fuze AN-M 158, Cross 2-32. Long-Delay Tail Fuze AN-M132, De­ Section .................................................. 2-8 tails o f Operation ..... 2-72 2-5. Nose Fuze A N -M k 219 ........................ 2-12 2-33. Hydrostatic Tail Fuze A N -M k 230 2-6. Impact Nose Fuze A N -M k 219, Cross Mod 5 ...................... 2-77 Section .......... 2-13 2-34. Hydrostatic Tail Fuze A N -M k 230, 2-7. Impact Nose Fuze A N -M k 219, De­ Cross Section ....... 2-78 tails of Operation ................ 2-14 2-35. Hydrostatic Tail Fuze AN -M k 230, 2-8. Nose Fuzes Mk 243 Mod 0 and Mk 244 Comparison o f Boosters ................ 2-79 Mod 1 ...... 2-17 2-36. Multi-Position Fuze M157, Exterior 2-9. Impact Nose Fuze Mk 244, Cross Sec­ View ......................................... tion ______________ ______—...... ........ 2-18 2-37. Multi-Position Fuze AN-M173 ‘.1, E x­ 2-10. Mechanical Time Nose Fuzes A N ....... ................................ 2-83 terior View M145A1 and AN-M 146A1 2-22 2-38. Multi-Position Fuze M157, Cross Sec­ 2-11. Mechanical Time Fuze AN-M 146A1, tion . ................................... Cutaway View, Unarmed ..... 2-23 2-39. Multi-Position Fuze AN-M173A1, 2-12. Mechanical Time Fuze AN-M 146A1, Cross Section ..................................... 2-85 Cutaway View, Armed ...................... 2-24 2-40. Multi-Position Fuze M157, Installed 2-13. Mechanical Time Fuze AN-M146A1, in Igniter M15 ...... . ............... 2-86 Details o f Firing-Pin Operation 2-26 2-41. Multi-Position Fuze -'N-M 173A1, In­ 2-14. Mechanical Time Fuze M155A1, E x­ stalled in Igniter M23 ....._. ............. terior View ...... 2-30 2-87 2-42. Side Fuze M129 .......................... 2-89 2-15. Mechanical Time Fuze M155A1, Cross Section ........ .. ........ „ ................... .. 2-31 2-43. Side Fuze M129, Cross Section and Details of Operation .............. 2-90 2-16. V T Fuzes AN-M 166 and AN-M 168 2-33 2-44. Side Fuze M130A1 2-93 2-17. Tail Fuzes AN-M 100A2, AN-M 101A2, 2-45. Side Fuze M l30 \1, Cross Section 2-94 and AN-M 102A2 .... 2-36 2-18. Impact Tail Fuze AN-M 100A2, Cross 2-46. Side Fuze M131A1 2-97 Section ............ . .... 2-38 2 - 47. Side Fuze M131A1, Cross Section and 2-19. Impact Tail Fuzes AN-M 115, A N Details o f Operation ............. 2-98 3— 1. Adapter-Booster M102A1 ............... 3-1 M116, and AN-M 117 .................. 2-44 V 2-45 2-83 2-84 N A V W E P S OP 2216 (V O L U M E 1) Figure Page Figure 5-1. Adapter-Booster M115A1 ..... ....... ....... 3-2 Adapter-Booster M117 ..............-.......... 3-3 Adapter-Booster T45E1 ........ ............... 3-4 5-2. Adapter-Booster T46E4 ........ ........—. 3-5 Auxiliary Booster Mk 1 Mod 0 ........... 3-6 Auxiliary Booster Mk 4 Mod 0 — 3-7 5-3. Burster M10 ............ ...... ......................... 3-8 Burster AN-M 12 ........................— 3-9 Burster AN-M 13 ....................... 3-10 5-4. Burster AN-M 14, AN-M 15, and A N M16 ......... ........................... - .... ......... 3-11 5-5. 3-12. Burster AN-M 18 ...........................- ..... 3-12 3-13. Burster AN-M 20 .................................... 3-13 5-6. 3-14. Igniter AN -M 5 ............................... ........ 3-14 3-15. Igniter AN -M 9 ................. ....... ............... 3-15 3-16. Igniter M15 ..................................... 3-16 5-7. 3-17. Igniter AN-M16, Exterior V ie w -------- 3-18 3-18. Igniter M23 .............................................. 3-20 3-19. Practice Bomb Signal Mk 4 Mods 3 5-8. and 4 ..... ................................................ 3-21 3-20. Practice Bomb Signal Mk 5 Mod 0 3-23 5-9. 3-21. Practice Bomb Signal Mk 6 Mod 0, Assembled with Fuze ..... ......._.....3-24 3-22. Practice Bomb Signal Mk 7 Mod 0, 5-10. Assembled with Fuze ............. ........ 3-26 3-23. Primer-Detonator M14 .... ..................... 3-28 3 - 24. Primer-Detonator M16A1 ................. 3-30 5—11. 4 - 1.1000-lb AP Bomb AN -M k 33 Mods 1, 2, and 3, Exterior View .......... ......... 4-1 4-2. 1000-lb AP Bomb AN -M k 33 Mods 1, 5-12. 2, and 3, Exploded View ... 4-2 4-3. 1000-lb AP Bomb A N -M k 33 Mods 1, 5-13. 2, and 3, Cutaway View ________... 4-3 4-4. 1600-lb AP Bomb AN-M k 1 Mods 1, 2, and 3, Exterior View _____ _____ 4-6 5-14. 4-5. 1600-lb AP Bomb AN -M k 1 Mods 1, 2, and 3, Exploded View ...... ....... 4-7 4-6. 1600-lb AP Bomb AN-M k 1 Mods 1, 5-15. 2, and 3, Cutaway View ....... ....... 4-8 4-7. 500-lb SAP Bomb AN-M 58A2, Exte­ rior View ......... .................................. 4-10 5-16. 4-8. 500-lb SAP Bomb AN-M 58A2, Ex­ 4 -H ploded View .................. ................... 5-17. 4-9. 500-lb SAP Bomb AN-M 58A2, Cut­ away View ...... 4-12 4-10. 1000-lb SAP Bomb AN-M 59A1, Exte­ 5-18. rior View ............. ....... . .... 4-15 3-2. 3-3. 3-4. 3-5. 3-6. 3-7. 3-8. 3-9. 3-10. 3-11. 4-11. 1000-lb SAP Bomb AN-M 59A1, Ex­ ploded View ..... ................................... 4-12. 1000-lb SAP Bomb AN-M59A1, Cut­ away View ......... 4-13. 2000-lb SAP Bomb M103, Exterior View ........................... . ............. 4-14. 2000-lb SAP Bomb M103, Exploded View .............................. 4-15. 2000-lb SAP Bomb M103, Cutaway View ...... 4-15 4_16 4_i8 4-19 4_20 100-lb GP Bomb AN-M 30A1 with Fin Assembly AN-M 103A1, Exterior View ...... .............................. —.......... .. 100-lb GP Bomb AN-M 30A1 with Fin Assembly AN-M 103A1, Exploded View ............................... — —• 100-lb GP Bomb AN-M30A1 with Fin Assembly AN-M 103A1, Cutaway View ...... .........- ..................... — .....— 100-lb GP Bomb AN-M 30A1 with Fin Assembly M135,Exploded View 250-lb GP Bomb AN-M 57A1 with Fin Assembly AN-M 106A1, Exterior View ......... ............ ............... ......... ..... 250-lb GP Bomb AN-M57A1 with Fin Assembly AN-M 106A1, Exploded View .................................................... 250-lb GP Bomb AN-M 57A1 with Fin Assembly AN-M106A1, Cutaway View ....... ............................. ..... .... 250-lb GP Bomb AN-M57A1 with Fin Assembly M126,Exploded View 500-lb GP Bomb AN-M 64A1 with Fin Assembly AN-M 109A1, Exterior View -----500-lb GP Bomb AN-M 64A1 with Fin Assembly AN-M109A1, Exploded View ........ 500-lb GP Bomb AN-M 64A1 with Fin Assembly AN-M109A1, Cutaway View .... ....... ................................ ... 500-lb GP Bomb AN-M 64A1 with Fin Assembly M128A1,Exploded View 1000-lb GP Bomb AN-M 65A1 with Fin Assembly AN-M 113A1, Exte­ rior View ..................... 1000-lb GP Bomb AN-M 65A1 with Fin Assembly AN-M 113A1, E x­ ploded View .............. 1000-lb GP Bomb AN-M65A1 with Fin Assembly AN-M113A1, Cut­ away View ...................... ... 1000-lb GP Bomb AN-M 65A1 with Fin Assembly M129, Exploded View 2000-lb GP Bomb AN-M 66A2 with Fin Assembly AN-M116A1, Exte­ rior View ........ .................. ....... .. 2000-lb GP Bomb AN-M 66A2 with Fin Assembly AN-M116A1, Ex­ ploded View ....................... ........... ...... 5-19. 2000-lb GP Bomb AN-M 66A2 with Fin Assembly AN-M 116A1, Cut­ away View ................... .... ....... . 5-20. 2000-lb GP Bomb AN-M 66A2 with Fin Assembly M130, Exploded View 5-21. 250-lb Low-Drag Bomb (G P) Mk 81 Mod 1 (Mechanically Fuzed), Ex­ terior View ........................................ Page 5-2 5-2 5-4 5-5 5-8 5-9 5-10 5-11 5-13 5-14 5-15 5-16 5-19 5-20 5-21 5-22 5-25 5-26 5-27 5-29 5-31 IL L U ST R A T IO N S Figure Page 6-22. 250-lb Low-Drag Bomb (G P) Mk 81 Mod 1 (Mechanically Fuzed), Ex­ ploded View ---------------------5-23. 250-lb Low-Drag Bomb (G P) Mk 81 Mod 1 (Mechanically Fuzed), Cut­ away View ........ - ...........- ---------------- 5-33 5-24. 500-lb Low-Drag Bomb (G P) Mk 82 Mod 1 (Mechanically Fuzed), Exte­ rior View ....... - -........ — I 5-36 5-25. 600-lb Low-Drag Bomb (G P) Mk 82 Mod 1 (Mechanically Fuzed), Ex­ ploded View --------------------5-26. 500-lb Low-Drag Bomb (G P) Mk 82 Mod 1 (Mechanically Fuzed), Cut­ away View - ..... —--------------------5-27. 1000-lb Low-Drag Bomb (G P) Mk 83 Mod 3 (Mechanically Fuzed), Ex­ terior View _______ _____ ___ —....... 5-39 5-28. 1000-lb Low-Drag Bomb (G P) Mk 83 Mod 3 (Mechanically Fuzed), E x­ ploded View ....... ................................. 5—40 5- 29. 1000-lb Low-Drag Bomb (G P) Mk 83 Mod 3 (Mechanically Fuzed), Cut­ away View ...... ...........- ........................ 5—41 6 - 30. 2000-lb Low-Drag Bomb (G P) Mk 84 Mod 1 (Mechanically Fuzed), Exte­ rior View ....................................—....... 6-43 5-31. 2000-lb Low-Drag Bomb (G P) Mk 84 Mod 1 (Mechanically Fuzed), Ex­ ploded View ............. .......................... . 5—44 5- 32. 2000-lb Low-Drag Bomb (G P) Mk 84 Mod 1 (Mechanically Fuzed), Cut­ away View ................................... .... 5-45 6 - 1. 350-lb A ircraft Depth Bomb A N -M k 54 Mod 1, Exterior View ..... ...... 6-2 6-2. 350-lb A ircraft Depth Bomb A N -M k 54 Mod 1, Exploded View .... 6-3 6 - 3. 350-lb A ircraft Depth Bomb A N -M k 54 Mod 1, Cutaway V ie w _________ 6-4 7 - 1. 4-lb Frag Bomb M83, Exterior View 7-2 7-2. 4-lb Frag Bomb M83, Cutaway View 7-3 7-3. 20-lb F rag Bomb AN-M 41A1, Exte­ rior View .............................................. 7-4 7-4. 20-lb Frag Bomb AN-M 41A1, E x­ ploded View ___ _____________ _____ 7-5 7-6. 20-lb Frag Bomb AN-M 41A1, Cut­ away View ............................................ 7-5 7-6. 90-lb Frag Bomb M82, Exterior View 7-7 7-7. 90-lb F rag Bomb M82, Exploded View 7-8 7-8. 90-lb F rag Bomb M82, Cross Section 7-8 7-9. 220-lb Frag Bomb AN-M 88 with Fin Assembly AN-M103A1, Exterior View .......................................... .......... 7-10 7-10. 220-lb Frag Bomb AN-M 88 with Fin Assembly AN-M 103A1, Exploded View ----------------- ----------- -------- ------ 7-10 7-11. 220-lb Frag Bomb AN-M 88 with Fin Assembly AN-M103A1, Cutaway View ______ ___ ___ ___ ______ ___ __7-12 Figure Page 7-12. 220-lb Frag Bomb AN-M 88 with Fin Assembly M135, Exploded View ..... 7-14 7-13. 260-lb Frag Bomb AN-M 81 with Fin 5-32 Assembly AN-M 103A1, Exterior View ------- ------------------ ------------------ 7-17 7-14. 260-lb F rag Bomb AN-M81 with Fin Assembly AN-M 103A1, Exploded View ---- -------------------------- ------------- 7-17 7-15. 260-lb F rag Bomb AN-M 81 with Fin Assembly AN-M 103A1, Cutaway View _____ _____ ______ __ ______ __ 7-18 75-36 - 16. 260-lb Frag Bomb AN-M 81 with Fin Assembly M135, Exploded View ...... 7-20 8 - 1. 100-lb Frag Bomb Cluster A N -M 1A 2 8-1 8-2. Cluster Adapter A N -M 1A3 ___ ___ —. 8-2 5-37 8-3. 100-lb Frag Bomb Cluster A N -M 1A2, Perspective View .... .................— ..... 8—4 8—4. 100-lb F rag Bomb Cluster M28A2, Ex­ terior View ______ _____________ __ 8-5 8-5. Cluster Adapter M15A2...... .............. 8-6 8-6. 100-lb Frag Bomb Cluster M28A2, Cutaway View --------- ------ --------------- 8-8 8-7. 500-lb Frag Bomb Ck-ster M26A2 ..... 8-9 8-8. Cluster Adapter AN-M 13A2 ...... 8-10 8-9. 500-lb Frag Bomb Cluster M26A2, Perspective View _____ ____ ______ 8-11 8-10. 500-lb Frag Bomb Cluster M27A1 .... . 8-14 8-11. Cluster Adapter M14A1............. ...... 8-15 8-12. 500-lb Frag Bomb Cluster M27A1, Perspective View __ 8-16 8-13. 500-lb Frag Bomb Cluster M29A1 ..... 8-19 8-14. 4-lb Frag Bomb M83 and W afer As­ sembly ---- ---------- --------------------------- 8-20 8 - 15. 500-lb Frag Bomb Cluster M29A1, Cutaway View ......... 8-21 9 - 1. 750-lb Demolition Bomb M117 (Me­ chanically Fuzed), Exterior View .... 9-1 9-2. 750-lb Demolition Bomb M117 (Me­ chanically Fuzed), Exploded View . 9-2 9-3. 750-lb Demolition Bomb M117 (Me­ chanically F uzed), Cutaway View .. 9-3 9-4. 3000-lb Demolition Bomb M118 (Me­ chanically Fuzed), Exterior View 9-6 9-5. 3000-lb Demolition Bomb M118 (Me­ chanically Fi’ zed), Exploded View .. 9-6 9-6. 3000-lb Demolition Bomb M118 (Me­ chanically Fuzed), Cutaway View _ 9-7 10-1. 115-lb Chemical (Gas) Bomb M70A1, Exterior View _____________ _______ 10-1 10-2. 115-lb Chemical (Gas) Bomb M70A1, Exploded View ___ _____________ __ 10-2 10-3. 115-lb Chemical (Gas) Bomb M70A1, Cutaway View __________ _______ 10-3 10-4. 500-lb Chemical (Gas) Bomb A N M78, Exterior View ........ ........ .......... 10-4 10-5. 500-lb Chemical (Gas) Bomb A N M78, Exploded View __ _____ ______ 10-5 10-6. 500-lb Chemical (Gas) Bomb A N M78, Cross Section ............__....... ...... 10-7 •• VII N A V W E P S OP 2216 (V O L U M E 1) Figure 10-7. Page 1000-lb Chemical (Gas) Bomb A N M79, Exterior View ------- --------------- 10-9 10-8. 1000-lb Chemical (Gas) Bomb A N M79, Exploded View ....... ................. 10-10 10-9. 1000-lb Chemical (Gas) Bomb A N M79, Cross Section ............. ............... 10-11 10-10. 100-lb Smoke or Incendiary Bomb AN-M 47A4, Exterior View ..... ....... 10-12 10-11. 100-lb Smoke or Incendiary Bomb AN-M47A4, Exploded View ............ 10-13 10-12. 100-Ib Smoke or Incendiary Bomb AN-M 47A4,Cutaway View ________ 10-14 10-13. 500-lb Incendiary Bomb AN -M 76 with Fin Assembly AN-M 109A1, Exte­ rior View ........ - ..... - _______ ______ 10-20 10-14. 500-lb Incendiary Bomb AN-M 76 with Fin Assembly AN-M 109A1, Ex­ ploded View __ 10-21 10-15. 500-Ib Incendiary Bomb AN-M 76 with Fin Assembly AN-M 109A1, Cross Section ______ 10-22 10-16. 500-lb Incendiary Bomb AN-M 76 with Fin Assembly M128A1, Exploded View ___ 10-23 10-17. 500-lb Fire Bomb Mk 77 Mod 1, Ex­ terior View .............. ...... .................. 10-25 10-18. 500-lb Fire Bomb Mk 77 Mod 1, Ex­ ploded View ___ ___ ____ __ _______ 10-26 10-19. 500-lb Fire Bomb Mk 77 Mod 1, Cut­ 10-27 away View __________________ ___ _ 10-20. 760-lb Fire Bomb Mk 77 Mod 0, Ex­ terior View .......... ..........................._.. 10-29 10-21. 750-Ib Fire Bomb Mk 77 Mod 0, Ex­ ploded View _________ _ ________ 10-30 10-22. 750-lb Fire Bomb Mk 77 Mod 0, As­ sembly Details ______ ______ _______ 10-31 10-23. 750-lb Fire Bomb Mk 77 Mod 0, Cut­ away View ........................................... 10-32 10-24. 750-lb Fire Bomb Mk 77 Mod 0 with Bomb Conversion Kit Mk 19 Mod 0, Exploded View ........ ........ .................. 10-34 10-25. 750-lb Fire Bomb Mk 78 Mod 2, Ex­ terior View __ ____________ __ _____ 10-38 10-26. 750-lb Fire Bomb Mk 78 Mod 2, Ex­ ploded View ...... ...... ............................ 10-39 10-27. 750-lb Fire Bomb Mk 78 Mod 2, Cut­ away View _____ ____ ___________ 10-40 10-28. 1000-lb Fire Bomb Mk 79 Md. 1, Ex­ terior View _________ _______ ____ 10-42 10-29. 1000-lb Fire Bomb Mk 79 Mod 1, E x­ ploded View ........................................ 10-43 10- 30. 1000-lb Fire Bomb Mk 79 Mod 1, Cut­ away View ........ .................................. 10-44 11- 1. 3-lb Miniature Practice Bomb AN -M k 23 Mod 1, Exterior View . ............ 11-2 11-2. 3-lb Miniature Practice Bomb AN -M k 23 Mod 1, Exploded View ......... . . 11-2 VIII Figure 11-3. 11-4. 11-5. 11-6. 11—7. 11-8. 11-9. 11-10. 11-11. 11-12. 11-13. 11-14. 11-15. 11-16. 11-17. 11-18. 11-19. 11-20. 11-21. 11-22. 11-23. 11-24. 11-25. 11-26. 11-27. 11-28. 11-29. 11-30. 11-31. Page 3-lb Miniature Practice Bomb A N -M k 23 Mod 1, Cutaway View and Detail Showing Signal Mk 5 Mod 0 In­ stalled ....... ............................... ............ 11-3 13-lb Miniature Practice Bomb Mk 19 Mod 1, Exterior View ------------ ----—. 11-5 13-lb Miniature Practice Bomb Mk 19 Mod 1, Exploded View ...................... 11-6 13-lb Miniature Practice Bomb Mk 19 Mod 1, Cutaway View ..............—...... 11-7 5-lb Practice Bomb Mk 106 Mod 0, Exterior View .............. ..................... 11-9 5-lb Practice Bomb Mk 106 Mod 0, E x­ ploded View ...... —----- --------------------- 11-10 5-lb Practice Bomb Mk 106 Mod 0, Cutaway View -----------11-10 25-lb Practice Bomb Mk 76 Mods ........ 11-12 56-lb Practice Bomb Mk 89 Mod 0, E x­ terior View ............. 11-16 56-lb Practice Bomb Mk 89 Mod 0, Ex­ ploded View -------11-17 56-lb Practice Bomb Mk 89 Mod 1, E x­ 11-18 ploded View ----56-lb Practice Bomb Mk 89 Mod 0, Cutaway View --------------11-19 100-lb Practice Bomb Mk 15 Mods ___ 11-21 100-lb Practice Bomb Mk 15 Mod 3, Exploded View ..... 11-22 100-lb Practice Bomb Mk 15 Mod 4, Exploded View _______ __ .....___ _ 11-23 100-lb Practice Bomb Mk 15 Mod 3, Cutaway View ...... ............................... .11-24 100-lb Practice Bomb Mk 15 Mod 4, Cutaway View ............... 11-26 250-lb Practice Bomb Mk 86 Mod 0, Exterior View ................... 11-29 250-lb Practice Bomb Mk 86 Mod 0, Exploded View ______ ___ __________ 11-30 250-lb Practice Bomb Mk 86 Mod 0, Cutaway View ___ ___ ____ ____ __ _ 11-31 500-lb Practice Bomb Mk 65 Mod 0, Exterior View ___ ________ _________ 11-33 500-lb Practice Bomb Mk 65 Mod 0, Exploded View _____ 11-34 500-lb Practice Bomb Mk 65 Mod 0, Cutaway View ...... 11-36 500-lb Practice Bomb Mk 87 Mod 0, Exterior View ...... .............................. . 11-38 500-lb Practice Bomb Mk 87 Mod 0, Exploded View ........... ...................... 11-39 500-lb Practice Bomb Mk 87 Mod 0, Cutaway View ____ __ ___ ____ ___ _ 11-40 1000-lb Practice Bomb Mk 66 Mod 0, Exterior View ____ __ ________ __ _ 11-43 1000-lb Practice Bomb Mk 66 Mod 0, Exploded View .... ...... ....... ..... ........ 11-44 1000-lb Practice Bomb Mk 66 Mod 0, Cutaway View ................ ..................... 11-45 IL L U ST R A T IO N S Figure 11-32. 1000-lb Practice Bomb Mk 88 Mod 0, Exterior View ___________ ________11-33. 1000-lb Practice Bomb Mk 88 Mod 0, Exploded View .................................... 11-34. 1000-lb Practice Bomb Mk 88 Mod 0, Cutaway View ........ ...........—............... 11-35. 200-lb Practice Bomb Mk 67 Mod 0, Exterior View __________ 11-36. 2000-lb Practice Bomb Mk 67 Mod 0, Exploded View ____________ 11 -37. 2000-lb Practice Bomb Mk 67 Mod 0, Cutaway View ............. 11-38. 2000-lb Practice Bomb Mk 104 Mod 0, Exterior View ________ __ .....______ 11-39. 2000-lb Practice Bomb Mk 104 Mod 0, Exploded View ..... 11-40. 2000-lb Practice Bomb Mk 104 Mod 0, Cutaway View ....................................... 11-41. Practice Depth Bomb Mk 100 Mod 0, M ajor Components ................ 11-42. Nose Section —... 11-43. Afterbody .................. 11-44. Parachute Pack Secured to Shroud Ring .......— ......... ................................. Page 11-47 11-48 11-49 11-52 11-53 11-54 11-56 11-57 11-58 11-61 11-62 11-63 11-64 Figure 11-45. Parachute Bomb Marker Mk 17 Mod 0 and Wrench .....................................— 11-46. Marker Mounted on Nose o f Practice Bomb ...... 11-47. Adapter Bracket for Marker ................. 11-48. Practice Bomb with Marker Mounted on Adapter Bracket ........................ 11-49. Lug Adapter Mounted on Forward Suspension Lug .................................. 11-50. Weapon Response Simulator Mk 4 Mod 0 ...............................................— . 11-51. Weapon Response Simulator Mk 4 Mod 0, Schematic W iring Diagram 11-52. Parachute Static Line Replacement .... 11-53. Practice Depth Bomb Mk 102 Mod 0 11-54. Cutaway o f Assembled Practice Bomb 11-55. Manual Switch Mk 52 Mod 0, Installed 11-56. Weapon Connector Mk 22 Mod 0, In­ stalled ..... 11-57. Manual Switch Mk 52 Mod 0 and Arming Wrench ........... 11-58. Weapon Connector Mk 22 Mod 0 and Adapter Plug .................................... 11-59. Schematic W iring Diagram Practice Depth Bomb Mk 102 Mod 0 __ _____ Page 11-65 11-65 11-66 11-66 11-67 11-67 11-68 11-70 11-76 11-77 11-78 11-78 11-79 11-79 11-82 IX SAFETY PRECAUTION WARNING For the protection of personnel handling aircraft bombs, fuzes, and associated components, it is imperative that the reader be familiar with the Safety Precautions contained in chapter 12. N A V W E P S OP 2216 (V O L U M E 1) aV Figure 1-0.— Frontispiece: Bombing Attack Delivered by Carrier Aircraft. x ii Chapter 1 GENERAL INFORMATION Scope Ordnance Pamphlet 2216 (Volume 1) de­ scribes and illustrates aircraft bombs, fuzes, and associated components, used by the operating forces of the Navy. The text includes information on identification, dif­ ferences in models, handling, safety proce­ dures, and assembling of components. This publication is intended to provide trained and authorized personnel with gen­ eral and specific information including de­ scription, identification, assembly, and use of aircraft bombs, fuzes, and associated components. As new items are developed and accepted for use by the Naval Service, changes to this publication will be issued. Similarly, as items are removed from service use, notices will be promulgated to remove the applicable pages of the publication. Suggestions for additions or changes are in­ vited from the users of this pamphlet; address suggestions to NAVY DEPART­ MENT, Bureau of Naval Weapons, Wash­ ington 25, D.C. To facilitate a wider dissemination of information, classified material is included in volume 2. Specific information concerning installa­ tion or the releasing of bombs from air­ craft is not included. Purpose of Aircraft Bombs Aircraft bombs, figure 1-1, are used to destroy installations, armament, and per­ sonnel, and to provide direct support of our land and sea forces engaged in offensive or defensive operations. Obsolescent Items The following material is obsolescent; however, descriptive data are being retained until disposition of all material is complete. 1. 90-lb Frag Bomb M82. 2. 500-lb Incendiary Bomb AN-M76. 3. 3-lb Miniature Practice Bomb Mk 5. 4. 13-lb Miniature Practice Bomb Mk 19. 5. 25-lb Practice Bomb Mk 76 Mod 0. 6. Impact Nose Fuze AN-M110A1. 7. Impact Nose Fuze AN-M126A1. 8. Impact Nose Fuze AN-M k 219. 9. Hydrostatic Tail Fuze AN-M k 230. 10. Mechanical Time Fuze T50E1. 11. Mechanical Time Fuze T50E4. 12. Mechanical Time Fuze T91. Obsolete Items The following material has been declared obsolete; however, descriptive data are be­ ing retained until disposition of all the ma­ terial is complete. 1. All armor-piercing (AP) bombs. 2. 500-lb Semi-Armor Piercing (SAP) Bomb AN-M58, AN-M58A1, A N M58A2. 3. 1000-lb Semi-Armor Piercing (SAP) Bomb AN-M59. 4. 2000-lb Semi-Armor-Piercing (SAP) Bomb M103. 5. 350-lb Aircraft Depth Bomb A N Mk 54 Mod 0. 6. 100-lb Frag Bomb Cluster A N M1A2. 7. 500-lb Frag Bomb Cluster M26A2, M27A1. 8. 4.5-lb Minature Practice Bomb Mk 43 Mod 1. 9. Tail Fuze AN-Mk 228. 10. Practice Bomb Signal Mk 5 Mod 0. 11. Practice Bomb Signal Mk 7 Mod 0. Bomb Operation General. Bombs are carried either in the bomb bay of aircraft or externally under the wings or fuselage. Hooks on aircraft racks and shackles engage suspension lugs attached to the bomb body. For mechani­ cally fuzed bombs, the loop of an arming wire is attached to a separate hook at the center of the rack or shackle. The free ends of the arming wire are passed through 1-3 N A V W E P S OP 2216 (V O L U M E 1) ARMOR-PIERCING BOMB SEM I-A R M O R -P IE R C IN G BOMB GENERAL PURPOSE BOMB Figure 1—1.— Representative Bombs and Clusters. 1-4 G E N E R A L IN F O R M A T IO N FIRE BOMB (.1/3 RELATIVE S IZ E ) CHEMICAL BOMB FRAGMENTATION BOMB CLUSTER (Q U IC K -O P E N IN G FRAME TYPE) F RAGMEN IATION (B U ITE R FLY ) BOMB FRAGMENTATION BOMB CLUSTER (A IM A B LE TYPE) MINIATURE PRACTICE BOMB FRAGMENTATION BOMB Figure 1-1.— Representative Bombs and Clusters, (continued) 1-5 N A V W E P S OP 2216 (V O L U M E 1) safety devices in the fuze and maintain the fuze in an unarmed condition. Safety (Fahnestock) clips are placed over the pro­ truding ends of the arming wire to prevent it from slipping out of the fuze safety de­ vices prior to bomb release. If a bomb must be released over friendly territory, the arming wire is released with the bomb and stays in place as the bomb falls. This prevents the fuze from arming so that the bomb does not explode upon impact. When the bomb is released for effect, the arming wire is retained with the aircraft, and the fuze is free to become armed. Electrically fuzed bombs do not require arming wires. Refer to volume 2 of this publication for information. Explosive Train (figure 1-2). After re­ lease of the bomb, the airstream causes the arming vane of the fuze to rotate, thus arm­ ing the fuze. Some fuzes arm by spring action, others by clockwork or electrical means, but most fuzes now in use are armed by action of the fuze arming vane. The arming vane may drive a gear train which, after a definite interval, removes safety blocks or alines the detonator with the next element in the explosive train. The detonator is fired by mechanical or electrical action, and its explosion is am­ plified and relayed to the main charge by a booster. This pattern of action is called the explosive train. Bomb Blast. More serious damage can be done by the blast effect of high-explosive bombs than by their fragmentation. When a high explosive bomb is detonated, the charge is instantaneously converted into high temperature gases which exert a tre­ mendous pressure and burst the bomb body. Upon release from confinement, the gaseous products of detonation expand suddenly and move outward in all directions at a high velocity, generating shock and pressure waves, and shattering or displacing sur­ rounding material. Classification of Bombs Bombs are classified according to use as follows; they are generally referred to by the abbreviations given in parentheses. 1-6 Armor-Piercing (A P ). Semi-Armor-Piercing (SAP). General Purpose (G P ). Aircraft Depth (A D B ). Fragmentation (Frag). Demolition. Chemical (Gas). Smoke. Fire (and Incendiary). Practice (PB). Armor-Piercing Bombs. AP bombs have heavy cases and thick noses. Approximately 13 percent of the weight of the bomb con­ sists of explosive. This type of bomb is used against heavy armor and reinforced concrete. AP bombs contain a delay ac­ tion tail fuze to permit penetration of the target before the bomb explodes; they do not have a nose fuze. Semi-Armor-Piercing Bombs. SAP bombs have wall thickness smaller than the AP bombs and are normally tail fuzed; however, a solid metal nose plug can be replaced with a nose fuze when necessary. Thirty percent of the complete weight of the bomb is explosive. Semi-armor-piercing bombs are sometimes used as substitutes for gen­ eral purpose bombs. General Purpose Bombs. GP bombs are used in the majority of bombing operations. Their cases are relatively light and approxi­ mately 50 percent of their complete weight is explosive. GP bombs may use both nose and tail fuzes. A conical fin may be used with the AN series GP bombs instead of the box-type fin to improve aerodynamic per­ formance when carried externally and to provide greater ballistic accuracy. Aircraft Depth Bombs. While the ADB is used primarily against underwater tar­ gets, it has a secondary use as a demolition bomb. Because of its light case, approxi­ mately 70 percent of its complete weight is explosive. A flat nose prevents ricochet when the bomb is dropped into the water. The depth bomb has a hydrostatic tail fuze that functions at a predetermined depth rather than on impact. A nose fuze may be armed and the hydrostatic tail fuze dropped safe when the ADB is used as a demolition bomb. G E N E R A L IN F O R M A T IO N 1-7 N A V W E P S OP 2216 (V O L U M E 1) Fragmentation Bombs. The body of a frag bomb usually consists of a thin steel tube with square wire spirally wound on the outside. The wire provides the prin­ cipal source of fragments when the bomb is detonated. The explosive filler comprises about 14 percent of the total weight of the bomb. Fragmentation bombs are used against personnel and unarmored targets. Most frag bombs have provisions for either a nose or a tail fuze, although some of the smaller bombs can accommodate only a nose fuze. The lockring thread of frag bombs often is used for the attachment of a para­ chute unit. Demolition Bombs. This type of bomb is designed to carry maximum explosive charge; the explosive comprises 48 percent or more of its total weight. To insure func­ tioning upon impact, both a nose and a tail fuze are used. Chemical (Gas) Bombs. Gas bombs re­ semble general purpose bombs in shape and size. The body of the gas bomb serves as the filling container and support for the components. These bombs have a full-length burster charge which splits the bomb case and disperses the filling over the area to be contaminated. Gas bombs are fuzed to explode instantaneously upon contact, or to provide an aerial burst. Smoke Bombs. Smoke bombs are gen­ erally used for screening purposes to con­ ceal shore areas and the movement of troops and ships. Their bodies are constructed of thin metal, somewhat similar to that used for 100-pound practice bombs. The bomb is filled with a smoke agent. Functioning of a fuze and a burster shatters the bomb on impact, dispersing the smoke agent over a wide area. Atmospheric oxygen ignites the filling, causing it to burn and to produce smoke. Fire Bombs. Fire bombs are usually thinskinned containers of gasoline gel designed for use against dug-in troops, supply instal­ lations, wooden structures, and land convoys. The bombs rupture upon impact or air burst in the air to spread burning gasoline gel on surrounding objects. Fuzes, bursters, 1-8 and igniters are used to ignite the combusti­ ble filling. Practice and Miniature Practice Bombs. These bombs are used for target practice. There is a wide range of types and weights in order to simulate all varieties of service bombs. Some practice bombs have a fuze and a spotting charge; others are completely inert. Practice bombs are usually filled with sand or water. Some are fabricated to the desired weight. Classification of Fuzes A fuze is a device which is utilized to initiate the detonation or dispersion of the filling o f a bomb under desired conditions. Interchangeable arming vanes, figure 1-3, may be used on some fuzes. These vanes differ in degree of pitch, shape, and length of blade. This is necessary to control the arming distance of the fuzes when used with different types of bombs. Many fuzes, figure 1—4, incorporate the following special safety features. D etonator S a fe . Fuzes that are detona­ tor safe have the elements of their firing train firmly fixed out of alinement in the fuze body while the fuze is unarmed. This increases safety during shipping, stowage, and handling. The arming action of the fuze alines the firing train. S hear S a f e . A shear safe fuze will not become armed if its arming mechanism is damaged or completely severed from the fuze body. Shear safe fuzes afford addi­ tional security for bombs used in carrier operations and for externally mounted bombs. D e l a y A r m in g . This feature, mechani­ cally or electrically, slows the arming of the fuze and keeps it in the safe condition until the bomb has fallen a sufficient distance away from the plane to minimize the effects of a premature explosion. Delay arming helps to make dive bombing and carrier operations safer in that a bomb accidentally released on landing or takeoff will not ordinarily have sufficient air travel to arm the fuze. Fuzes are classified according to use as follows. G E N E R A L IN F O R M A T IO N Impact Nose. Mechanical Time. VT. Impact Tail. Long-Delay Tail. Hydrostatic Tail. Multi-Position. Side. Electric (Refer to volume 2 of this publication for information). Impact Nose Fuze. Fuzes of this type are vane operated and delay armed. Their ac­ tion can be instantaneous or delayed by the selective setting of a control pin. STANDARD VANE - 6 0 ' PITCH SHORT VANE - 6 0 ’ PITCH LONG AIR TRAVEL V A N E - 9 0 ' PITCH ON INNER PART OF EACH BLADE FLAT V A N E - 3 0 ’ PITCH Figure 1-3.— Arming Vanes. 1-9 N A V W E P S OP 2216 (V O L U M E 1) SCREW FUZE IN T O BOMB. THREAD ARMING WIRE T H R O U G H FUZE EYELET H O LES. R EM O VE PIN. SCREW FU ZE IN T O FUZE SEAT. SECURE A R M ING -VANE ASSEMBLY TO FU ZE. H O LES.ATTACH SAFETY CLIP. R EM O VE COTTER P IN . SECURE ARMING-VANE ASSEMBLY TO FU ZE. A TTA C H SAFETY C LIP TO ARMING W IR E. Figure 1-4.— Bomb Fuzing. 1-10 G E N E R A L IN F O R M A T IO N Mechanical Time Fuze. These fuzes are armed by mechanical and time mechanisms. The time of detonation after release can be preset for a predetermined time. If the time setting is greater than the time of flight, impact will cause the fuze to function. VT Fuze. VT (proximity) fuzes are es­ sentially radio transmitting and receiving units that function automatically on ap­ proaching or passing any material object, causing an air burst at an effective height or distance. Impact Tail Fuze. Fuzes of this type are vane armed and inertia fired. The arming is mechanically delayed by reduction gear­ ing. Fuzes of this type are used in bombs launched by carrier-based aircraft and dive bombers, armor piercing bombs, and prac­ tice bombs Long-Delay Tail Fuze. These fuzes re­ quire less than 100 feet of air travel to initiate the delayed action. Any attempt to remove these fuzes after installation will result in functioning of the antiwithdrawal mechanism, followed by instantaneous det­ onation. Hydrostatic Tail Fuze. The hydrostatic fuzes are vane operated and require 400 to 500 feet of air travel to arm. Water pres­ sure operates the hydrostatic mechanism that detonates thq fuze. The depth at which detonation occurs can be controlled. Multi-Position Fuze. The inertia firing, impact, multi-position fuzes are fully armed by anemometer type vanes after completing the air travel. Once the fuzes are armed, impact forces from any direction will cause instantaneous detonation. These fuzes are principally assembled in conjunction with igniters or bursters in fire bombs. Side Fuze. These fuzes are used only with fragmentation bombs. The fuzes are armed by the “ butterfly wings” of the bomb and are preset to detonate in the air or on impact, either delayed (subject to handling, shock, or vibration) or instantaneous. Bomb Components Adapter-Booster. An adapter-booster is a bushing threaded on the outside for assem­ bly to the bomb body and on the inside for assembly of the fuze. Adapter-boosters, normally assembled to high-explosive and chemical bombs as issued, are drilled for the insertion of lock pins to prevent their removal when antiwithdrawal type fuzes are to be assembled to the bomb. Since general purpose bombs are usually adapted for large diameter nose fuzes, a nose adapter-booster is issued separately to adapt these bombs for use with small diameter fuzes. Lowdrag GP bombs, developed primarily for electrical fuzing, require nose and tail adap­ ter-boosters when mechanical fuzes are in­ stalled. Arming Wires. Arming wires, figure 1-5, usually consist of either one or two strands of wire attached to a swivel loop. They are used to lock the fuze arming mechanism in the unarmed position. Safety (Fahnestock) clips are attached to the ends of the wires after installation of fuzes in the bomb. This prevents accidental withdrawal of the wires while the aircraft is in flight. When a bomb is to be released ARMED from the rack, the wire is pulled from the fuze head, allowing the fuze vanes to rotate and to arm the fuze. When the bomb is to be released SAFE, the arming wire is not separated from the fuze head. When installed, arming wires are subject to considerable wear caused by vibration; where reused, they must be inspected before each flight. The standard arming-wire assemblies will fit any bomb up to and including a weight of 2000 pounds. For larger bombs an exten­ sion cable is supplied. After the bomb is installed on the shackle, the wire is cut ap­ proximately 21/2 inches beyond the fuze. For proper release, wire must be free from twists, kinks, and burrs. Arming-wire brack­ ets, which are furnished with armor-pierc­ ing bomb fin assemblies, must be requested separately for use with depth bombs. A metal tubular protector is used with the arming-wire bracket to prevent chafing of the wire by the fuze vane. Arming wires are usually packed in metal containers holding 50 or 100 assemblies. Safety clips are packed with the wires. 1-11 N A V W E P S OP 2216 (V O L U M E 1) Fragmentation bomb clusters, however, are supplied with their own arming-wire assem­ blies installed. Auxiliary Booster. The auxiliary booster, which consists of a column of tetryl pellets in a suitable container, relays and amplifies detonation waves to insure the explosion of the main charge. The auxiliary booster may be cast within the explosive charge adjacent to the fuze seat liner, or the adapter-booster, or both. It also may be issued separately for installation in a fuze seat liner. c (( A R M IN G W IR E S F IG U R E TYPE M A T E R IA L D IA M E T E R (IN.) MK 1 MOD LEG ___ LENG TH (IN.) TO TAL LENG TH D R A W IN G (IN.) NUM BER 0 A S IN G L E BRONZE 0 .0 6 4 57 0 57 0 422872 MK 3 MOD 0 A S IN G L E STEEL 0 .0 3 3 57 0 57 0 375994 MK 2 MOD 0 B DOUBLE BRONZE 0 064 57 0 570 114 0 422872 A N -M 6 A 2 C S IN G L E BRA SS 0 064 570 _ 5 7 .0 8 2 -3 -2 3 4 A r:-f.;iA 2 D DOUBLE BRA SS 0 .0 6 4 2 7 .0 33 0 60 0 8 2 -3 -2 3 4 •— A N -M 7 A I D DOUBLE BRA SS 0 064 36 5 450 81 5 8 2 -3 -2 3 4 A N -M 8 A I D D O U B LE BRASS 0 .0 6 4 5 7 .0 6 0 .0 117 0 8 2 -3 -2 3 4 M 13 D D O U BLE BRASS 0 064 3 6 .0 7 0 .0 106 0 8 2 -3 -2 3 4 M16 D D O U BLE BRA SS 0 .0 6 4 56 0 90 0 146.0 8 2 -3 -2 3 4 * MOT STO CKED BY NAVY Figure 1 -5 .— Arming Wires. 1-12 G E N E R A L IN F O R M A T IO N Base Plug. The base plug closes the fill­ ing hole in the end of the bomb body. An extension of the plug to the rear is threaded to provide space for attachment of the fin assembly by means of the fin locknut. In later (A l) modifications of GP bombs, the base plug has studs extending into the ex­ plosive charge to prevent removal of the plug. The plug is threaded to receive an adapter-booster, and has a circular groove which receives the adapter-booster lock pin. Bomb Body. The bomb body is a metal container that holds an explosive, chemical, or inert filler. Its case may consist of a sin­ gle piece of metal, or several pieces welded or otherwise joined together. It usually is formed in the shape of a streamlined cylin­ der, closed at each end. Nose Fuze Seat. Seats for noze fuzes are usually machined into the bomb case and, to provide for maximum flexibility, their di­ mensions (thread size and depth of seat) are standardized as much as practicable. Large bombs have the GP-type fuze seat which has a 2-inch thread diameter and is 5 inches deep. Smaller bombs have the frag­ mentation-type fuze seat which is 1.5 inches in thread diameter by 1.3 inches deep. Aimable clusters have a flare-type fuze seat which is 1.5 inches in thread diameter by 0.84 inch deep. Adapter boosters also are used to provide fuze seats, as described fully in chapter 3. Tail Fuze Seat. Tail fuze seats for GP, SAP, chemical, and fragmentation bombs are provided by adapter-boosters, as fully described in chapter 3. Burster. A burster is an explosive charge used to open an incendiary or smoke bomb and to spread the bomb filling. It consists of a long plastic or paper and chipboard tube, closed at both ends, and is filled with TNT, black powder and magnesium, tetryl pellets, or other explosive. It fits into either the burster well or the igniter cavity. The bursters for bombs included in this publica­ tion are described in chapter 3. Closing Plug. Metal closing plugs are used to protect the fuze seat cavity and threads from damage during shipping and stowage. They are removed only for in­ spection or for fuzing the bomb. If a bomb is returned to stowage after being prepared for use, the fuzes are removed and the closing plugs replaced. Low-drag GP bombs are equipped with steel nose and tail plugs. When these bombs are to be used with mechanical fuzes, the plugs are re­ moved and discarded prior to the insertion of adapter-boosters. When the bombs re­ quire electrical fuzes, the nose and tail plugs are reinstalled after the electrical fuzes have been inserted. Cluster Adapter. A cluster adapter, fig­ ure 1-6, is a mechanical device by means of which several bombs are suspended in the carrying station for one bomb. Two types are covered by this publication: the quick­ opening (frame) type to which several bombs are attached by metal straps, and the aimable adapters which enclose the bombs in a cylindrical container. Explosive Charge. When the bomb body is filled with an explosive charge, the type of explosive depends upon the prospective use of the bomb. In some bombs, thin pads of inert wax in the nose and tail cavities pro­ tect the explosive from moisture and also prevent the entrance of the explosive into thread crevices. These bombs can be identi­ fied by the marking “ with pad.” The explosive charge in GP and fragmen­ tation bombs is usually cast and is uniform throughout unless the explosive is amatol or composition B, in which case the nose and tail portions are pure TNT “ booster sur­ rounds” to provide protection from mois­ ture. The high explosives used in bombs are as follows. A m a to l . Amatol, a mixture of ammo­ nium nitrate and TNT, is less sensitive than TNT. When used in a 50/50 ratio, it has approximately the same rate of detonation and brisance (shattering ability) as TNT. Amatol is now obsolete, but it was used as a main charge in bombs prior to and during the early part of World War II. C omposition B. Composition B (comp B) is a very powerful explosive, particularly 1-13 N A V W E P S OP 2216 (V O L U M E 1) from the fragmentation standpoint. It con­ sists of large percentages of RDX and TNT with a small amount of wax. The principal ingredient, RDX, is a powerful but sensitive explosive and is therefore always used in mixtures with other materials. Comp B is presently being used as the main filler in fragmentation bombs. E dn atol . Ednatol is a composition of 55 percent haleite and 45 percent TNT. It is more sensitive and has greater brisance than TNT. As an explosive for producing blast effect, it is superior to amatol and nearly equal to comp B. Ednatol is now obsolete, but it was normally used in fragmentation bombs. E xplosive D ( A m m o n iu m P icrate ). E x­ plosive D is the least sensitive to shock and friction of currently used military explosives. For this reason it is used in armor-piercing bombs which must withstand severe shock and stresses before detonating. HBX. HBX is a chemically stable, noncorrosive explosive containing RDX, TNT, QUICK-OPENING FRAH/IE TYPE ADAPTER SPOILER RING. AND DRAG PLATE Figure 1-6.— Typical Cluster Adapters. 1-14 G EN ER A L IN F O R M A T IO N aluminum powder, and wax, that is in the same general class as TNT with respect to safety of handling. Although HBX is no longer used in its original form, it has some important variations. HBX-1 and HBX-3, which provide greater stability and power than HBX, are used as explosive fillers in underwater ordnance. H-6 is a variation of HBX developed for bombs. PlCRATOL. Picratol is a composition con­ taining 52 percent of explosive D and 48 percent of TNT. Picratol is now obsolete, but it was normally used as an explosive charge in semi-armor-piercing bombs. TNT (T rinitroto luen e ). TNT is a rela­ tively insensitive high explosive of great stability which has been used as the main charge in GP bombs. In recent years it has been superseded by more powerful explo­ sives, such as tritonal. T rito nal . Tritonal, the previous stand­ ard explosive filler in GP bombs, is an 80/20 ratio by weight of TNT and aluminum powder. Its sensitivity properties are of the same order of magnitude as T N T ; however, its blast effect is greater. H-6. H-6, the present standard explosive filler in GP bombs, is a variation of HBX developed for use in bombs to give maximum a,'r blast effect. Fin Assembly. The fin assembly provides for stability of the bomb in flight. Smaller bombs (usually 100-pound and under) have the fin assembled to the bomb body prior to shipment. Some 100-pound and all larger bombs are shipped with the fin unassembled, in which case the fin assembly is shipped separately in a metal crate. There are two types of fin assemblies: the box-type assem­ bly and the conical assembly. B ox -T ype F in A sse m b l y . The box-type fin assembly, figure 1 -7 , generally used with larger bombs, consists of a fin sleeve that fits over the tail of the bomb and is held in place by a thin locknut. Sheet metal fin blades are attached to the fin sleeve and to each other by supports to form a square box­ like assembly. Some fin assemblies (earlier than M118) were made of a light gage metal but in­ creased bomb ceilings required the use of heavier metals to insure more reliable bal­ listics. Only those box-type fin assemblies designated by either A or M -A l, lower than Ml 18, are made of a light gage metal. All model designations higher than M118 are made of the heavier gage metal. C onical F in A sse m b l y , figure 1-8. Com­ ical fins are designed for use on cylindricalcase GP and frag bombs to provide for bet- Figure 1-7.— Typical Box Fin Assemblies. 1-15 N A V W E P S OP 2216 (V O L U M E 1) ter aerodynamic performance of these bombs when carried externally on high­ speed aircraft. In addition, greater ballistic accuracy is obtained. The fin assemblies consist of four quarter sections of sheet steel welded together, with four integral fin blades. The fin assembly is secured to the bomb by means of a coupling tube, a metal locking web, and a special fin locknut. Each coupling tube has three equally spaced set­ screws for locking the tube to the base plug of the bomb. The fin assembly is placed over the coupling tube and is secured by the locking web and fin locknut. Since these fin assemblies are longer than the box-type, they require longer tail fuzes and longer arming-wire assemblies. F in L o c k n u t s . The fin locknut, figure 1-9, is a bushing which is threaded onto a base plug or a coupling tube to secure the fin assembly to the bomb. Three types of locknuts are currently provided for varying conditions, as follows. O R D I N A R Y Or REGULAR-TYPE LOCKNUT. This type of locknut is assem­ bled to the base plug of a bomb as shipped and is used on bombs assembled in the fields with box-type fin assemblies. During as­ sembly, the locknut is removed, the fin as­ sembly is placed over the tail of the bomb, and the locknut is then screwed onto the base plug and tightened with a wrench. The ordinary locknut provides no other means for attachment in the base plug; therefore, it is not normally used when bombs are to be carried externally on air­ craft expected to exceed 350 knots, or in bomb bays subject to excessive air current. NEW-TYPE LOCKNUT. The new-type locknuts differ from the regular locknuts in that they do incorporate a means of locking themselves to the base plug by setscrews. These fin locknuts are intended for gen­ eral use and should be installed when bombs with box-type fin assemblies are carried ex­ ternally on aircraft expected to exceed 350 knots, or are carried in bomb bays subject to air currents that can cause rotation of Figure 1-8.— Typical Conical Fin Assembly. 1-16 G E N E R A L IN F O R M A T IO N fins with the regular locknut installed. When the new type locknuts are not avail­ able, the regular type may be used. The new types are recommended for the type bombs as follows: F in L ocknut B ombs U sed W ith Mk l Mod 0 _____ SAP AN -M 58A1, AN M58A2, and AN-M 59A1. Mk 2 Mod 0 or M l. GP AN M30A1 and AN M57A1. FRAG AN-M81 and AN-M 88. Mk 3 Mod 0 or M2 GP AN-M 64A1 and AN-M 65A1. Mk 4 Mod 0 or M3. GP AN-M 66A2. The new-type fin locknut is installed in essentially the same manner as the regulartype locknut. However, after screwing the fin locknut onto the collar of the base plug as far as possible, the setscrews are tight­ ened with an Allen wrench so that approxi­ mately equal pressure is exerted by each of a pair of opposite screws. CONICAL FIN LOCKNUT and LOCK­ ING WEB. The conical fin locknut and locking web, figure 1-10, secure the conical fin assembly to the coupling tube. During assembly, the regular fin locknut found on the bomb for use with box-type fin assem­ blies and the fin locknut packaged with the early models of conical fins are removed and discarded. After the conical fin assembly is placed over the coupling tube, the locking web is placed over the end of the coupling tube so that the corner slots engage the four fins. The fin locknut is screwed onto the coupling tube and tightened securely in such a manner that two slots in the fin locknut are directly over two tabs of the fin locking web. The two tabs are bent back to engage the slots of the fin locknut securely. The three setscrews of the fin locknut then are tightened. Fuze Seat Liner. The fuze seat liner is a metal cup secured inside the nose of the bomb to keep a cavity clear for assembling the nose fuze and auxiliary booster. Igniter. An igniter is a charge for setting fire to the fillings of incendiary and fire bombs. Igniters vary considerably in their Figure 1-9.— Typical Fin Locknuts. 1-17 N A V W E P S OP 2216 (V O L U M E 1) Figure 7-JO ,— Fin Locking Web. shape and method of operation; they are fully illustrated and described in chapter 3. Practice Bomb Signal. The practice bomb signal is a cylindrical container filled with black powder or a fluorescein dye. The pur­ pose of the signal is to indicate the point of impact of a practice bomb when dropped either on land or water targets. Blackpowder signals, upon impact, produce a flash and a puff of smoke. Fluorescein-dye sig­ nals are actuated by water and produce a slick for spotting purposes. Primer-detonator. Primer-detonators are interchangeable units that provide a varia­ tion of delay action in tail fuzes. Some units are “ nondelay.” Each unit contains a pri­ mer, a delay charge (if required), a relay, and a detonator. When the firing pin of a fuze is driven by its spring into the primer, the flame from the primer ignites the delay element. After the proper time interval has elapsed, the relay ignites and explodes the detonator. Upon severe impact the plunger is arrested by the shoulder of the primerdetonator so that the blow on the primer has only the force of the firing-pin spring, thus avoiding malfunction due to a pierced pri­ mer. 1-18 Since a primer-detonator may be assigned one of a number of different delay periods, the units are stamped and painted to indicate the length of delay. Primer-detonators of different model num­ bers vary in the pitch of their threads and are not interchangeable. Care must be taken to install only the proper model primer-detonator in a fuze in order to avoid damage to the threads of both the fuze and the primer-detonator. Primer-detonators which have loose prim­ ers or show signs of corrosion or other visible defects must be disposed of in accord­ ance with current directives. Shipping Band. Shipping bands are at­ tached to the bomb to protect the suspension lugs and to facilitate handling problems. They may be compressed paper with a recess for the lug or may be of metal in the form of a U-shaped channel. They are not removed until the bomb is prepared for use. Suspension Band. Metal suspension bands, figure 1-11, provide 14-inch suspension for bombs already equipped with suspension lugs spaced 30 inches apart, as found on the 2000pound Army-Navy GP bombs. G EN ER A L IN F O R M A T IO N Figure 1-11.— Typical Suspension Band. M arking and Identification Bombs and bomb components are com­ pletely identified by standard nomenclature and ammunition lot numbers stamped on all packings as well as on the item itself. Mark Numbers. In order to distinguish between different designs of the same type, a Mk/Mark number (Navy) or M/Model (Army) is assigned at the time a design is adopted as a standard item. N a v y . Items of Navy designs are desig­ nated by the word Mark or its abbreviation Mk followed by an Arabic numeral (i.e. Mk 107). Modifications of the original design are indicated by the term Mod and an Ara­ bic numeral following the Mark designation (i.e. Mk 107 Mod 1). An original design item includes the term Mod 0 to distinguish it from later modifications (i.e. Mk 107 Mod 0 ). A rmy. On items of Army design the Model designation consists of the letter M followed by an Arabic numeral (i.e. M6). Modification of the original design is indi­ cated by the letter A and the appropriate Arabic numeral added to the model designa­ tion (i.e. M 6A1). The designation T l, T2, etc., indicates a developmental item. While in the develop­ ment stage, and when a major change is incorporated, the item will take a designa­ tion such as T1E1 or T1E2. Such a designa­ tion indicates a change affecting military characteristics or installation. A r m y -N a v y . Certain items have been standardized for use by both the Army and the Navy. The model'designation of such an item is prefixed by the letters AN (i.e. A N Mk 107 Mod 0). When an AN is de-standardized by either the Army or the Navy, the AN is deleted from the model designation; how­ ever, to preclude loss of identity, the AN designation is carried parenthetically in standard nomenclature; for example, M120A1 (AN-M120A1). When an item is classified as AN standard, the previous model is carried parenthetically; for example, A N M146 (M146). Color Coding. Bombs are painted in various color schemes as a ready means of identification. Color bands, depending upon their color, size, and location, indicate the type of bomb and the type of explosive used. Identification marking and its color provide further identification of the bomb. Two color coding systems are indicated in the following chart. The newer system, apply­ ing to new-issue bombs, establishes a uni­ form color coding system (MIL-STD 709 NOrd) for various types of ammunition used by the Navy. The older system, apply­ ing to old-issue bombs, will be phased out when those bombs are depleted. Ammunition Code. The code established by the Navy for the identification of am­ munition is used: (1) to standardize nomen­ clature to insure positive identification of assembled ammunition and components; and (2) to permit the use of mechanical tabulating equipment to prepare consoli­ dated records of station on-hand balances. Each item of ammunition is assigned a spe­ cific code; code numbers for bombs, com­ ponents, and accessories are contained in OP 1219A. Fire bombs, components, and accessories are contained in OP 1219C. Federal Supply Classification (FSC). The Federal Supply Classificaton and its indexes have been developed and adopted by the 1-19 N A V W E P S OP 2216 (V O L U M E 1) Bomb Color Coding B an d C olor B omb T ype M a r k in g C olor B ody C olor O ld I ssue N e w I ssue O ld I ssu e N e w I ssue AP, SAP________ Olive drab Y e llo w ............... (No new Issue). _ Black__________ GP Olive d r a b __ Yellow__ ___ . (No new Issue). . Black___ _____ (No new Issue.) GP(LD) Olive drab Yellow . . Yellow. ___ Yellow . __ Yellow. Depth __ _ Olive drab Yellow. ____ Yellow __ Black. _____ Yellow. Frag _ _ Olive drab 1____ Y e l l o w .__ ____ Yellow B lack.. Yellow__ Demolition____ Olive drab. . (No band) Y ellow .. Black___ Yellow. Chemical: Gas Smoke _ Incendiary^-. Fire . Gray___ ___ _ Gray____ ____ G ray.. __ ____ Olive drab * . Green.. Yellow_______ Purple Purple ___ __ Red or Green 1 2'3. Blue__ __ P u r p le ............... (No band) Green ___ Yellow Purple Black 4 *____ Red or Green.1 Blue. Purple. Yellow. Black 8 (Old Issue). Orange (New Is­ sue). (No band)8. (No band)7 ___ White 8_______ White. - - Practice __ __ __ __ . _. __ __ (No new Issue.) . . 1Small frag bombs (except M83) have yellow nose and tail. 2 Red for harassing; green for casualty. 3 One band for nonpersistent; two bands for persistent; three bands for G-series. * FB Mk 77 Mod 0 and 1 has unpainted body and red marking. ‘ MPB Mk 5, A N -M k 23, and Mk 43 are unpainted; PB Mk 19 tail section only is black. • PB Mk 106, Mk 76 Mod 1, 2, and 4, and Mk 89 have white bands. 7 PB Mk 106 has white bands. 3 PB Mk 104 has white identification marking and yellow informational marking. Office of the Secretary of Defense for use in classifying items of supply identified in the Federal Catalog System. The FSC is a commodity classification de­ signed to serve the functions of supply and is sufficiently comprehensive in scope to per­ mit the classification of all items of personal property. In order to accomplish this, groups and classes have been established for the universe of commodities, with em­ phasis on the items known to be in the sup­ ply systems of the Federal Government. The structure of the FSC, as presently es­ tablished, consists of 75 groups, which are 1-20 subdivided into approximately 540 classes. Each class covers a relatively homogeneous area of commodities, in respect to” their physical or performance characteristics, or in the respect that the items included therein are such as are usually requisitioned or is­ sued together. The FSC utilizes a four-digit coding struc­ ture. The first two digits of the code num­ ber identify the group, and the last two digits of the code number identify the classes within each group. Code numbers are so assigned as to make it possible to expand the number of groups and classes G E N E R A L IN F O R M A T IO N when that becomes necessary. In most in­ stances gaps have been left within each group, between the numbers assigned to ad­ jacent classes, to permit the insertion of new classes in logical sequence, when neces­ sary, because of technological advances or to accomplish other desirable additions and changes. The primary application of the FSC class code number is in the Federal stock number (F S N ). The FSC for an item of supply con­ sists of the applicable four-digit FSC class code number plus the seven-digit Federal item identification number. Ammunition Data Card. The ammunition data card is a 5- by 8-inch card prepared for each lot of ammunition and forwarded with each shipment of ammunition. In addition to the ammunition lot number, it gives the lot numbers of the components and other pertinent information concerning the am­ munition. When required, instructions for assembly are printed on the reverse side of the card. Packaging The following table provides packaging data for bombs and their components, figures 1-12 and 1-13. Handling and Stowage Because of the area of destructiveness of explosives in the event of accidental ignition Packaging B omb B ody F in A ssembly Armor Piercing (A P ). No protection; fuze cavities plugged. Semi-Armor Piercing (SAP). Metal Containers with lugs, arming wires, and mount­ ing screws. Metal Containers... Metal shipping rings; fuze cavities plugged. Metal or Composi­ Metal Containers___ tion shipping rings; fuze cavities plugged. Metal shipping rings; Metal Containers___ fuze cavities plugged. B omb T ype General Purpose (GP). Fragmentation (Frag). Fragmentation Bomb Clusters. Aircraft Depth Bomb (ADB). Miniature Practice Bombs (MPB). Practice Bombs (PB). Fire Bomb 1_________ Smoke and Incendi­ ary Bombs (100-lb size). Incendiary Bombs (500-lb size). Metal containers____ Fiberboard contain­ ers. Metal containers____ A ssembled B ombs GP 100-lb bomb is shipped as a unit in a metal con­ tainer. In clusters or wafers (See Frag Clus­ ters). Shipping bands. Metal containers Metal containers____ Metal or wood con­ tainers. Wood or metal con­ tainers. Metal containers____ Wood containers. Metal shipping rings; fuze cavities plugged. Metal containers 1 The center section of Fire Bomb Mk 79 Mod 1 is used as a shipping container for the bombs four sections: fins, filling-hole covers, lock pins, and a fiber pounding block. 1-21 N A V W E P S OP 2216 (V O L U M E 1) A. AP BOMB D. GP BOMB C. GP OR SAP BOMB F. FRAG BOMB CLUSTER G. MINIATURE PRACTICE BOMBS H. PRACTICE BOMBS J. AIRCRAFT DEPTH BOMB Figure 7— T2.-»— Shipping Containers for Bombs. 1-22 G E N E R A L IN F O R M A T IO N B. AP : >MB FIN ASSEMBLY C. SAP AND PRACTICE BOMB ASSEMBLY A. GP BOMS FIN ASSEMBLY D. FRAGMENTATION BOMB FIN ASSEMBLY E. AIRCRAFT DEPTH BOMB FIN ASSEMBLY F. ARMING W IRES Figure 1-13.— Shipping Containers for Bomb Fins and Arming Wires. 1-23 G EN ER A L IN F O R M A T IO N As a safety precaution, it must be as­ sumed that fuzes may function at some in­ determinate time after the dumping of bombs, regardless of the method of disposal. Lower the bombs over the side to the water surface. Keep them off the hull to the fullest extent practicable. Release bombs into the water with the least amount of fall that circumstances permit. 1-25 Chapter 2 FUZES IM P A C T NOSE FUZE A N -M 1 0 3 A 1 , A N -M 1 3 9 A 1 , A N D A N -M 1 4 0 A 1 AN-M139A1 0.01 SEC. DELAY AN-M140A1 0 .0 2 5 SEC. DELAY Figure 2 -1 .— Nose Fuzes A N M 1 0 3 A 1 , A N -M 1 3 9 A 1 , a n d A N M U 0 A 1 . Model __ ___ _ ------------- . . Firing Action ................ Firing Delay (sec)_____ __ __ _. Assembly Drawing No ... Arming: T ype ----------- ---------------------------Instantaneous Setting (rev.) -_ Delay Setting (rev.) ______ Air Travel to Arm (ft) ------------__ Overall Length (in.) _ _ ____ — Protrusion from Bomb ( i n . ) __ __ Vane Span ( i n . ) . . . . - ... . -Weight (lb) . ______ Number of Vanes. _ ___ __ Booster Charge: Type--------------- -------------Weight (oz) A N -M 103A 1_____. . . . Impact __ 0 .1 _____________ . . . . 7 3 -8-14__________ . . . . A N -M 139A 1_____ . . Impact . 0 .0 1 _____________ . . . . 73-8-14_________ ___ Delayed ___ Delayed ___ . .. 302 _____________. . . . 302 _____________ 180 _______ . . . 180_____________ .. . . . 510 to 54 2 5 ... 510 to 5425 _. ___ 7.23 - ___ 7 .2 3 __ ... _ ... _ 2 . 13_ _ 2 _______________ .... _ 6 ___ ____ 6 ________ .... - 3 .7 ______ _____ . . . . 3 .7 _______ 2 .......... . 2 ______ _____ ... ------ . _ T etryl __________ ___ Tetryl __________ ___ _ 1.9_ .... 1 .9 _____________ General Description The impact nose fuzes of this type, figure 2-2, are vane operated and delay armed. Their action can be either instantaneous or delayed by the selective presetting of a control pin. The air travel (510 feet to 5425 feet) re­ AN-M140A1 Impact. 0.025. 73-8-14. Delayed 302. 180. 510 to 5425. 7.23. 2. G. 3.7. 2. Tetryl. 1.9. quired to arm these fuzes makes them safe for use in dive bombing and carrier opera­ tions. Air travel is governed by the size of the bomb and the type of arming vane used. Nose Fuzes AN-M103A1, AN-M139A1, and AN-M140A1 are structurally similar, differing only in their firing delay elements. 2-1 N A V W E P S OP 2216 (V O L U M E 1) VANE HUB SPRING VANE HUB ARMING-VANE ASSEMBLY ELET PIN VANE STRAP EYELET STRAP REDUCTION GEAR MECHANISM STRIKER FLANGE VANE CUP- SHEAR PIN SETTING PIN ARMING SCREW ARMING DISC STRIKER ASSEM BLY- ARMING STEM DELAY FIRING PIN A R M IN G -STEM HOLLAR PRIMEI A R M IN G -S TE M SPRING DELAY ELEMENT UZE BODY INSTANTANEOUS FIRING PIN RL LAY- DETONATOR- DELAY BOOSTER DETONATOR SLIDER LEAD I -IN S T A N T A N E O U S BOOSTER LEAD-IN CUF Figure 2-2.— Impact Nose Fuze A N -M 103A1, Cross Section. 2 -2 FUZES Arm ing Vanes One of four types of interchangeable arm­ ing vanes may be used on these fuzes, figure 1-3, differing in the degree of pitch of the vane and the length o f the blade: (1) a standard vane, Ml (60-degree pitch) ; (2) a short vane (60-degree pitch) ; (3) a flat vane (30-degree p itch ); or (4) a long air travel vane, M2 (90-degree pitch on inner half of each blade). The bomb in which the fuze is installed and the required arming distance will determine the vane to be used. For general-purpose bombs, the standard vane M l (60-degree pitch) is used for a short arming distance, and the M2 (90degree pitch on inner half of blade) is used for a longer arming distance. At present, only the M l vane is provided with these fuzes. Separate action is necessary to requisition the M2 vane. For flat-nosed depth bombs, where air travel to arm is necessarily shorter because of low altitude release, the fuze is equipped with a flat arming vane (30-degree pitch). These fuzes also are used with certain fragmentation bombs in clusters. Cluster arrangement necessitates the use of short vanes having a 60-degree pitch; a long air travel to arm results. Delay Elements These fuzes differ in their firing delay ele­ ments. Some have a 0.1-second delay ele­ ment, others have a 0.01-second delay element, and still others a 0.025-second de­ lay element. Black wedge markings on the fuze head identify the delay time of the fuze. Explosive Components These fuzes contain two explosive trains, one for delay action and one for instanta­ neous action. The delay action explosive train consists of a primer, a delay element, a relay, a deto­ nator, a booster lead-in, and a booster. The primer and delay element assembly, con­ taining the delay element and relay, are assembled in the fuze body and are sealed as a protection against moisture. The instantaneous explosive train consists of a detonator, a booster lead-in, and a booster. The same detonator is used in both explo­ sive trains. It is alined with one of the ex­ plosive trains during the arming operations; its final position depends upon the preset position of the setting pin. Safety Features During shipping and stowage, a safety wire is threaded through the holes in the vane hub, vane strap, and eyelet strap. The ends of this wire are secured with a car seal. A safety cotter pin is secured through another set of holes in the eyelet strap and vane diametrically opposite the first set. The wire and cotter pin prevent operation of the arming mechanism. Instruction tags are attached to the seal wire, and on a wire attached to a pull ring through the eye of the cotter pin. As installed in a bomb, with the arming wire in place, these fuzes are in the unarmed condition; both the delay and instantaneous explosive trains are broken by the detonator being out of alinement. The arming discs prevent premature fir­ ing of the explosive train by holding the striker outward from the fuze body. These discs are not ejected until the fuze arms. Fuzes of this type are both detonator safe and shear safe; these terms have been fully explained in chapter 1. These fuzes in ex­ ternally carried stores are restricted in accordance with NAVORDINST 8024.25, latest issue. Presetting Selection of either delay or instantaneous action is made by presetting the setting pin. The pin has two slots, one for each of the two possible actions. The deep slot is for delay action, the shallow slot for instanta­ neous action. The fuzes are shipped and stowed with the setting pin in the deep slot or delay posi­ tion. To set for instantaneous action, lift the pin, rotate it one quarter turn, and drop it into the shallow slot. The portion of the fuze body adjacent to the setting pin is 2-3 N A V W E P S OP 2216 (V O L U M E 1) stamped DEEP SLOT DELAY— SHALLOW SLOT INST. Functioning General. When the bomb is dropped ARMED, the arming wire is retained in the bomb rack. This frees the arming-vane as­ sembly, which rotates in the air stream to operate the delay arming mechanism. The air travel to arm these fuzes is ap­ proximately 510 to 5425 feet. Continued rotation of the arming-vane assembly, after arming is completed, unscrews the arming mechanism from the fuze. Arming distance varies with the vane type and bomb used. Upon impact the fuze will detonate in­ stantaneously, or after its rated delay, ex­ ploding the bomb. Arming. The arming-vane assembly is mounted on the vane hub by means of the vane hub spring and positioned on the vane strap by pins. The arming-vane assembly is connected to the arming screw through a reduction gear train. A reduction ratio of 65 revolutions of the arming-vane assembly to 1 revolution of the arming screw is ob­ tained with this gearing arrangement. The arming screw engages a striker as­ sembly which contains two firing pins, one for the delay and one for the instantaneous explosive trains. The striker is prevented from moving by the shear pin and the set­ ting pin. A ring of 13 arming discs, housed in the vane cup, are positioned between the flange of the striker body and the fuze body. These prevent the striker body from being driven into the fuze body before arming has oc­ curred. The fuzes do not become armed until the 13 arming discs are ejected and the detona­ tor is brought into alinement with one of the explosive trains. The detonator is contained in the detonator slider, a block of metal that rides in a recess in the fuze. Compressed springs that act on the slider tend to move the detonator into alinement with one of the explosive trains. An arming stem, acted upon by a com­ pressed spring, bears against the inner sur­ 2-4 face of the reduction gear assembly. The inner end of the arming stem keeps the detonator slider, which contains the deto­ nator, out of the functioning position until the fuze arms. As previously described, the air stream rotates the arming-vane assembly and, through the reduction gear mechanism, un­ screws the arming screw from the striker assembly, carrying the vane cup and the re­ duction gear outward. When the vane cup has progressed sufficiently, the arming discs are ejected by means of a flat spring assem­ bled within the circle of discs. As the arm­ ing screw advances, carrying the reduction gear and vane cup outward, the arming stem follows, driven by its spring. If the fuze setting pin has been preset in the deep slot (for delayed action), it is in the way of the advancing arming stem collar. The progress of the arming stem is stopped when the collar of the stem contacts the setting pin. At this point the arming stem has cleared the first step of the detona­ tor slider. The two compressed springs force the slider over until its shoulder con­ tacts the partially withdrawn arming stem. This alines the detonator with the delay ele­ ment. The arming screw continues to free itself from the striker until the vane cup assembly (vane cup and reduction gears) drops off. If the fuze has been set in the shallow slot (for instantaneous action), the setting pin stem will not stop the progress of the arming stem during the arming sequence described. During arming, the arming stem rides outward, clearing both steps of the detonator slider and allowing the detonator to aline with the instantaneous firing pin. Action. When the arming discs have been ejected, the striker can be driven into the fuze body. Impact drives the striker in­ ward, shearing the shear pin and the stem of the setting pin. The delay firing pin sets off the delay primer and the instantaneous fir­ ing pin is driven either into a cavity in the detonator slider or into the detonator. A striker retaining pin passes through the FUZES fuze body and into a slot in the striker; it prevents the striker from moving outward but does not prevent the striker’s motion inward. Detonation. If the fuze has been set for delay action, the detonator is alined with the delay explosive components. Impact fires the delay primer. The flash from the primer sets off the black powder delay element which burns through and sets off, respec­ tively, the relay, the detonator, the booster lead-in, and the booster. When the fuze is set for instantaneous action, the detonator is in line with the in­ stantaneous explosive components. Impact drives the instantaneous firing pin into the alined detonator, setting it off. The detona­ tor relays the explosion to the booster lead-in, which explodes the booster. Released Safe If it is necessary to release fuzed bombs over friendly territory, the aircraft arming controls are set in the SAFE position before the bombs are jettisoned. In this position, the arming wire is released from the bomb racks with the bomb, preventing the armingvane assembly from rotating and arming the fuze. The unarmed fuze will not function upon impact. Accidental Arm ing Recognition. When the arming mecha­ nism is missing, or has unscrewed from the striker far enough to allow the arming discs between the striker flange and the fuze body to be ejected, the fuze is armed. If the clearance between the vane cup and the fuze body is greater than Vs inch, but the arming discs are not ejected, the fuze is partially armed. Handling. The arming-vane assembly of both armed and partially armed fuzes may be turned backwards (counterclockwise look­ ing at the nose of the fuze) with safety. This will not unarm a fuze when the deto­ nator slider has already moved over, but will unarm a partially armed fuze. Fuzes in which the clearance between the vane cup and the fuze body is greater than i/8 inch, but in which the arming discs are still in place, are safe for handling although they are no longer detonator safe. Fuzes which have had the arming discs ejected may be made safe for handling by placing metal (or wood) blocks between the striker flange and the fuze body. They must be held in place by some suitable means, such as adhesive tape. The blocks will pre­ vent the striker from being driven into the fuze accidentally. No attempt should be made to disassemble this fuze. Fuzes which are armed or par­ tially armed should be disposed of by au­ thorized and qualified personnel. Fuzing 1. Unseal the fuze container and remove the fuze. 2. Inspect the overall appearance of the fuze; see that the arming-vane assembly and threads are in the proper condition. 3. Adjust the setting pin for the desired action (instantaneous or delay). The pin has two slots. The deep slot is for delay action, the shallow slot for instantaneous action. To change the delay setting, which is under spring action, pull out the setting pin from the fuze body, twist it a quarter turn, and then release it. The vane cup of the AN-M139A1 has a black painted seg­ ment covering one-eighth of the cup; the AN-M140A1 has a segment covering onefourth of the cup; the AN-M103A1 has no painted segment. 4. Obtain the proper vane assembly and inspect it for damage. 5. Remove the nose shipping plug and in­ spect the fuze seat and threads for corrosion and stripping. If necessary, clean the fuze seat and threads. 6. Cut and remove the seal wire. CAUTION: Do not remove the cotter pin that locks the vane strap and eyelet strap until the bomb is installed in the bomb rack. 7. Screw the fuze, less the arming-vane assembly, into the nose of the bomb, hand tight. Use no tools. 2-5 N A V W E P S OP 2216 (V O L U M E 1) 8. Thread the arming wire through the forward bomb suspension lug, then through the upper pair of eyelets in the vane strap and eyelet strap. If upper pair of eyelets is occupied by a cotter pin, place a spare cotter pin in the opposite eyelets and replace the original pin with the arming wire. 9. Adjust the arming wire to protrude 2 to 3 inches from the vane strap. 10. Slip Fahnestock safety clips (nor­ mally two) over the end of the arming wire until they just touch the face of the vane strap. Be sure that the arming wire is free from kinks and burrs. See instructions for the particular bomb assembly to determine how many, if any, safety clips are to be used. 11. Slip the arming-vane assembly over the vane hub, so that the heads of the two vane pins enter the mating holes in the flange of the vane hub, and so that the vanehub spring snaps into the groove on the vane hub. 12. Remove the cotter pin. Defuzing CAUTION: Before attempting to remove a fuze from a bomb, be sure it is in the unarmed condition or safe to handle.1 1. 2. 3. 4. 2 -6 Replace Remove Remove Remove the the the the cotter pin and tag. safety clips. arming-vane assembly. arming wire and repack. 5. Replace the seal wire and seal ends to­ gether. 6. Unscrew the fuze from the bomb, and replace it in the fuze container. Packaging and M arking Fuze Container. One fuze, including the standard arming vane M l, not marked as such, is packed in a cylindrical metal con­ tainer having a maximum diameter of 3.46 inches and a maximum length of 7.51 inches. The weight of the fuze and container to­ gether is approximately 4.5 pounds. The container is sealed, and opened, by a metal tear strip soldered to it. A ring on the end of the tear strip facilitates opening. The container is painted black and is marked as follows: FUZE, BOMB, NOSE AN-103A1 Loader’s Initials Loaded (Month and Year) Drawing No. Revision Date of Drawing Packing Box. Twenty-five fuzes in con­ tainers are normally packed in a wood pack­ ing box. However one fuze and container may be removed, if necessary, to make room for a package of M2 arming vanes and in­ structions. The weight of the box and its contents is approximately 132.5 pounds. Its dimensions are 22(4 by 17Va by 9% 0 inches. The lid of the box is secured by wood screws, and the end of the box is marked as follows: (No.) FUZES, BOMB, NOSE AN-M103A1 LOT NO. FUZES IM P A C T NO SE FUZE A N -M 1 1 0 A 1 , A N -M 1 2 6 , A N -M 1 2 6 A 1 , A N -M 1 5 8 , A N D A N -M 1 5 9 Model . . . Status. ___ ____ Firing A ction ... ----Firing Delay . . . . Assembly Drawing N o. Arming: T ype------------------Revolutions to Arm. Air travel to Arm (ft). Overall Length (in.) — Protrusion from Bomb (in.). Vane Span (in.). ----Weight (lb) ____ Number of Vanes Booster Charge: T ype------------------- A N -M 126____ A N -M 110A 1-. Obsolescent___ Impact________ Impact ____ Instantaneous. _ Instantaneous. _ 73-8-77_______ 73-8-166. . A N -M 126A 1.. Obsolescent. Impact . . . Instantaneous.. 73-8-167______ A N -M 158____ AN-M159. Im pact.. __ Instantaneous 73-8-390.. . . . Impact. Instantaneous. E14-15-256. Delayed . 260___________ Delayed . . 260___________ Delayed. 375 to 512____ Delayed. 414 to 512. 725___________ 1200__________ 1200. Delayed__ 570___________ 725___________ 3 .7 ___________ 2 .3 9 __________ 3 .1 2 __________ 2 .2 8 __________ 3 .2 4 ________ 2 .4 ___________ 3 .7 6 __________ 2 .4 ___________ 3.24. 2.4. 2 .9 ___________ 1 .0 2 __________ 3 .9 ___________ .68 (alum.) 1.16 (steel). 2_____________ 3 .0 ___________ 1 .10__________ 3_____________ 1 .0 2 __________ 3. 0.65. 2_____________ 2_____________ 2. Tetryl P ellet... Small Tetryl Column. 2_____________ Tetryl Pellet. Figure 2-3.— Nose Fuzes A N -M 1 5 8 and AN-M 159. General Description The impact nose fuzes of this type, figure 2-4, are vane operated and delay armed. They act to detonate the bomb instanta­ neously upon impact. The lengthy air travel necessary to arm these fuzes (1200 feet) makes them suitable for use with land-based and carrier aircraft. The AN-M158 and AN-M159 fuzes differ from each other only in the size of their main explosive element. Fuze AN-M158 has a booster containing 0.6 ounce of tetryl. This has been replaced on the AN-M159 by a smaller metal holder containing a column of tetryl. This difference in booster volume of the two fuzes has resulted in a variance in fuze length. In all other respects the two fuzes are identical. Other fuzes similar to these are the fol­ lowing. Nose Fuze AN-M110A1. Although very similar in external appearance, the A N M110A1 (now obsolescent) differs in nu­ merous features from the AN-M158. The AN-M110A1 does not have the springactuated detonator shutter; it has a gear re­ duction of 1:34 (instead of 1 :4 0 ); its arming sleeve moves down (instead of up) ; it arms in 260 revolutions and 725 feet (in­ stead of 440 revolutions and 1200 feet) ; it has a lighter striker and firing pin, and its striker has a retaining pin rather than a retaining ring. Detonator M13 in the AN-M110A1 extends into the booster charge; Detonator M20 in the AN-M158 is contained in the detonator shutter. 2-7 N A V W E P S OP 2216 (V O L U M E 1) ARMING-VANE ASSEMBLY STRIKER VANE NUT VANE TAB A R M IN G FIRING PIN SPRING HU! tTTi FUZE BODY' ARMING-WIRE GUIDE ARMING SLEEVE UTER GEAR PINION INNER GEAR FIRING PI DETONATOR SHUTTER SHUTTER SPRING- DETONATOR OOSTER LEAD-IN BOOSTER CU Figure 2-4.— Impact Nose Fuze A N-M 158, Cross Section. Nose Fuzes AN-M126 and AN-M126A1. The AN-M126A1 is identical both in con­ struction- and in operation to the A N M110A1, except that instead of a booster, the AN-M126A1 has a steel cylinder the same size as the booster. This cylinder con­ tains an enlarged firing train consisting of a primer, an upper detonator, and a lower detonator, which is seated against the tetryl burster in chemical bombs. The AN-M126 (now obsolescent) has more teeth on the gears than the AN-M126A1 and requires 570 vane revolutions to arm as opposed to 2 -8 260 vane revolutions in the AN-M126A1. It also has three safety blocks, each 120degree segments; the arming sleeve fits in a groove in the blocks in the unarmed posi­ tion, preventing them from falling out. Explosive Component’s The main charge of the fuze is either a 0.6 ounce tetryl booster or a small column of tetryl in a metal holder. Two other ele­ ments complete the explosive components of both fuzes: a booster lead-in and a detonator. The detonator is fired by the penetration of FUZES the firing pin. Until arming, the detonator is out of alinement with the other explosive components. Safety Features During shipping and stowage, the fuze is made safe by a safety wire passing through the vane tab and arming-wire guide. The ends of the wire are secured with a car seal. These fuzes in externally carried stores are restricted in accordance with NAVORDINST 8024.25, latest issue. Functioning General. When the bomb is dropped armed, the arming wire is retained in the bomb rack and frees the arming-vane assem­ bly. The vanes rotate in the air stream to operate the delay-arming mechanism, and arm the fuze. The fuze becomes completely armed after the arming-vane assembly has completed between 375 and 512 revolutions; this requires approximately 1200 feet of air travel. After the fuze is completely armed, the arming-vane assembly is in a free­ wheeling state in which its continued rota­ tion produces n6 mechanical effect upon the fuze. Impact drives the striker into the fuze and sets off the explosive components to detonate the bomb. Arming. The delay arming mechanism is composed of the arming-vane assembly, an inner and outer gear, and a pinion. The armjng-vane assembly is threaded onto the arming hub, outside the fuze body. Secured in place at the other end of the arming hub, within the fuze body, is the outer gear, which has 39 teeth. Threads are cut on the inside surface of the arming hub to accom­ modate the threaded arming sleeve. The inner gear, which has 40 teeth, is attached to the arming sleeve at its inner end. The pinion meshes with the outer and inner gears. As the arming-vane assembly rotates, it revolves the arming hub and arming sleeve. The outer and inner gears contact the pinion, which has an equal number of teeth on its outer and inner portions. Since the number of teeth on the outer and inner gears is not equal, the outer gear turns the pinion, and the pinion meshing with the inner gear causes the inner gear to lag one tooth each revolution. Motion is then induced between the arming hub and arming sleeve, causing the sleeve to thread itself into the arming hub. As the arming sleeve rises in the arming hub, it forces the firing-pin spring to push the striker outward. The firing pin is con­ nected to the striker and is withdrawn with it. The detonator is contained in the deto­ nator shutter, which pivots on one corner under spring action. When the fuze is in the unarmed state, the firing pin extends into a cavity of the detonator shutter. This holds the shutter against the action of the shutter spring and keeps the detonator out of alinement with the explosive components. The firing pin is withdrawn from the shut­ ter cavity as the fuze arms. When the firing pin has moved outward between Vi and 1/3 inch, it clears the shutter. The shutter spring pivots the detonator into alinement with the explosive train, and a spring detent locks the shutter in place. When the fuze is fully armed, the striker has moved outward Vi to V3 inch and is supported in this position by the firing-pin spring. The inner gear has risen to the point where it free-wheels in the groove of the pinion. The arming hub and arming sleeve now revolve together. Action. Upon impact, the striker is driven inward against the firing-pin spring. The striker forces the firing pin into the alined detonator. Detonation. The detonator explodes when struck by the firing pin. The explosion is transmitted to the booster lead-in and then to a booster, or to a column of tetryl, de­ pending upon which particular fuze is used. Released Safe If it is necessary to release fuzed bombs over friendly territory, the aircraft arming controls are set in the SAFE position before the bombs are jettisoned. In this position, 2-9 N A V W E P S OP 2216 (V O L U M E 1) the arming wire is released from the bomb rack with the bomb, preventing the armingvane assembly from rotating and arming the fuze. The unarmed fuze will not func­ tion upon impact. Accidental Arming Recognition. If the striker has risen more than 14. inch above the vane nut, the fuze must be considered armed. Handling. Fuzes that have become armed can be made safe for handling by placing metal or wooden blocks between the striker and the vane nut. This will prevent the striker from driving the firing pin into the detonator. Secure the blocks with adhesive tape and unscrew the fuze from the bomb. CAUTION: Under no condition will any attempt be made to unarm a fuze of this type which is sus­ pected of being armed. Reverse rotation of the arming-vane as­ sembly will force the firing pin into the detonator and fire the fuze. An armed fuze must be disposed of by authorized and qualified personnel. Fuzing 1. Unseal the fuze container and remove the fuze. 2. Inspect the fuze threads to see that they are clean and serviceable and that the vanes are not bent. The striker must be firm against the vane nut. 3. Remove the nose shipping plug from the bomb. Inspect the fuze seat to see that it is clean and that the threads are in good condition. Clean the threads if necessary. 4. Screw the fuze into the nose of the bomb, hand tight. Use no tools. 5. If the bomb is clustered, install the vane lock in accordance with the instructions for the cluster adapter given in chapter 8. Be sure that the vane lock prevents rotation of the fuze’s arming-vane assembly. Cut and remove the sealed wire and tag from the fuze. 6. If the bomb is for individual suspen­ sion, pass the arming wire through the for­ 2 -1 0 ward bomb suspension lug, then through the inner holes in the arming-wire guide and vane tab. Adjust the arming wire so that the swivel loop is midway between the two bomb suspension lugs. 7. Adjust the arming wire to extend 2 to 3 inches beyond the vane tab. Cut off excess wire. 8. Slip two safety clips (Fahnestock clips) over the end of the arming wire, until they just touch the face of the vane tab. Be sure that the wire is not kinked or burred. Defuzing CAUTION: Before attempting to remove a fuze from a bomb, be sure that it is unarmed or safe to handle. If the striker has risen more than 14 inch above the vane nut, the fuze must be considered armed. See in­ structions for handling in the pre­ ceding section before proceeding further. If the bomb was prepared for individual suspension and not dropped: 1. Replace the safety wire through the vane tab and arming wire guide, and twist the ends together. 2. Remove the safety clips (Fahnestock clips) and withdraw the arming wire. Re­ pack the clips and wire. 3. Unscrew the fuze from the bomb, and repack in metal can; reseal the can with adhesive tape. If the bomb is part of a cluster that was not dropped: 1. Replace safety wire in each fuze of the cluster. Secure the wire by twisting two ends together. 2. Remove the bomb from the cluster. 3. Unscrew the fuze from the bomb and repack in metal container. Reseal the con­ tainer with adhesive tape. Packaging and M arking Fuze Container. Each fuze is individually packed in a black cylindrical metal container. Soldered to the container and cover is a metal strip which seals the container during FUZES shipping and stowage. A key is attached to the cover of the can to be used in removing the metal strip. The following is a typical container marking. FUZE, BOMB, NOSE AN-M158 LOADED (date) DRG. 73-8-390 REV. (date) Packing Box. Thirty fuzes, in containers, are packed in a single wooden box fastened together by wood screws and secured with steel bands. It weighs 58.5 pounds gross and its dimensions are 20%e by 12 by 103% 2 inches. The following is a typical packing box identification: 30 NOSE FUZES BOMB, NOSE, AN-M158 (or as applicable) 2 -1 1 N A V W E P S OP 2216 (V O LU M E 1) IM P A C T NOSE FUZE A N - M k 219 Mods 3 and 4 M a r k _____ ________________ Mods _____ _______ ____ ___ Firing Action __ Firing Delay __ General Arrangement Drawing No. AN-Mk 219 _____3 and 4 Impact Instantaneous 202656 Arming Type Revolutions to Arm Air Travel to Arm (ft) Overall Length (in.) Protrusion from Bomb (in.) Vane Span (in.) Weight (lb) Number o f Vanes Detonator Designation Booster Charge Type Weight (oz) . Figure 2-5.— Nose Fuze A N -M k 219. General Description This detonator-safe, vane-operated nose fuze, figure 2-6, is fired instantaneously upon impact. Approximately 1000 feet of air travel is necessary for the delay-arming mechanism to arm the fuze. These fuzes in externally carried stores are restricted in accordance with NAVORDINST 8024.25, latest issue. Mod 3 and Mod 4 are the same mechanically; the mod numbers merely des­ ignate different manufacturers. Explosive Components The explosive components consist of a detonator, an auxiliary booster lead-in, a booster lead-in, and a booster. The booster is about 0.9 ounce tetryl, either pelletloaded or loaded in place. It is held into the fuze body by the booster cover, which is crimped into the groove provided. The fuze is set off when the firing pin is driven into the detonator upon impact. Delayed 175 1000 5.5 2.9 4.8 4.0 4 Mk 12 Mod 0 Tetryl 0.9 vane carrier lug and the flange of the striker, which locks the delay arming mechanism. This safety cotter pin is provided with a pull ring and an instruction tag. The fuze is further protected by the metal packing can in which it is sealed. When unarmed, the explosive train is broken. The explosive components cannot become alined until the arming mechanism operates during arming and completes the necessary number of revolutions. As installed in a bomb, the fuze is in an unarmed condition. The arming wire takes the place of the safety cotter pin and pre­ vents rotation of the arming mechanism. Should the detonator explode when the fuze is in the unarmed condition, the gases would expand in the space above, and no further action would take place. The delay arming mechanism furnishes maximum safety for dive bombing as well as protection against detonation when the bomb is accidentally released from an air­ plane flying at low altitudes. Functioning Safety Features The fuze is made safe during shipping and stowage, by a safety cotter pin through the 2 -1 2 General. When the bomb is released free to arm, the vane carrier is unlocked from the striker flange by the withdrawal of the FUZES Figure 2-6. Impact Nose Fuze A N -M k 219, Cross Section. arming wire. The vane carrier then rotates by action of the air stream on the armingvane assembly, driving the reduction gears which arm the fuze. Completion of 175 revolutions of the arming-vane assembly arms the fuze fully; this requires about 1000 feet of air travel along the trajectory of the bomb. Impact drives the firing pin into the detonator and the fuze acts instanta­ neously to explode the bomb. Arming. The revolving arming-vane as­ sembly is connected to the arming shaft through the reduction gear train, which con­ sists of an inner gear, an outer gear, and a pinion. The outer gear has 23 teeth and is connected directly to the arming shaft. The inner gear has 22 teeth and is secured to the inner gear carrier. The inner gear carrier is prevented from rotating by the inne gear carrier lug, which is set into a recess on the inner sleeve. The outer gear and the inner gear mesh with the pinion, which has an equal number of teeth on its inner and outer portions. As the pinion is driven around the inner and outer gears by the arming-vane assembly, it forces the outer gear one tooth ahead each revolution, resulting in a ratio of one turn of the outer gear to 23 turns of the arming-vane assem­ bly. 2-13 N A V W E P S OP 2216 (V O L U M E 1) A i UNARMED f ROTOR l ARMED STRIKER, GEAR CARRIER, AND VANE ASSEMBLY HAVE MOVED OUTWARD EXPLOSIVE TRAIN UNAUNED ALINED Figure 2-7 .— Impact Nose Fuze A N -M k 219, Details of Operation. The arming shaft, to which the outer gear is secured, is threaded into the shaft nut at the innermost end. As the outer gear and the shaft revolve, the shaft moves out­ ward from the shaft nut. It is stopped by the shoulder of the shaft screw jamming with the shaft nut. The inner gear carrier and striker are carried outward with the arming shaft by the shaft collar. When the shaft screw jams, the inner gear carrier lug has been disengaged from the slot in the inner sleeve, freeing the inner gear carrier. The outer gear is prevented from rotating by the jammed shaft screw. Therefore, the pinion will act to turn the inner gear and the inner gear carrier. The guide pins prevent the striker from revolv­ ing with the inner gear carrier. The inner gear carrier houses the firingpin extension. Below the inner gear carrier, within the inner sleeve, is the firing-pin holder. This holder contains the firing pin, which is secured in position by a shear pin. The firing-pin holder is a partial cylinder fitting around the arming shaft. About one-third of the firing-pin holder cylinder is broken away; the inner gear carrier lug is located in the upper portion of the brokenaway area. 2-14 The rotor pivots about the arming shaft, at the inner end above the shaft nut. This unit contains the fuze detonator. The re­ spective positions of the inner gear carrier, inner sleeve, firing-pin holder, and rotor can be seen in figure 2-7. As the inner gear carrier revolves, the inner gear carrier lug contacts the edge of the firing-pin holder and carries the holder with it. The firing pin holder then pushes the rotor as the inner gear carrier continues to rotate. When the inner gear carrier has revolved appoximately 345 degrees, the alinement of the firing-pin extension, the firing pin, the detonator, and the auxiliary booster lead-in is complete. At this point a detent locks the inner gear carrier to the striker, preventing further rotation. Action. Impact drives the fuze head, vane carrier, striker, and inner gear carrier into the fuze body, thereby shearing the pin in the shaft. The firing-pin extension on the inner gear carrier strikes the firing pin and shears the firing-pin shear pin. Detonation. The firing pin penetrates and initiates the detonator which, in turn, fires the auxiliary booster lead-in. the booster lead-in, and the booster. Fuze deto­ nation is instantaneous upon impact. FUZES Released Safe If it is necessary to release fuzed bombs over friendly territory, the aircraft arming controls are set in the SAFE position before the bombs are jettisoned. In this position, the arming wire is released from the bomb rack with the bomb, preventing the armingvane assembly from rotating and arming the fuze. The unarmed fuze will not func­ tion upon impact. Accidental Arm ing Recognition. This fuze will be regarded as armed if the striker flange has advanced 3/ig inch from the outer sleeve. From out­ ward appearances, it is practically impossi­ ble to obtain a definite indication as to whether or not the fuze is partially or fully armed. When fully armed, the flange of the striker is separated from the outer sleeve by inch and the inner gear carrier has ro­ tated 345 degrees, bringing the firing-pin extension, the firing pin, and the detonator into alinement. Handling. Armed and partially armed fuzes should be removed from bombs by authorized and qualified personnel only. To remove an armed fuze from a bomb, care­ fully remove the lock screw in the outer sleeve. Gently withdraw the detonator and striker assembly by grasping the striker flange and pulling it outward along the axis of the fuze until completely withdrawn. Then unscrew the fuze body from the bomb. Fuzing 1. Unseal the fuze container and remove the fuze. Inspect the overall appearance to insure that it is clean and serviceable; look particularly for bent vanes and damaged threads. 2. Remove the nose shipping plug from the bomb. Inspect the fuze seat and threads; clean if necessary. A fuze adapter and an auxiliary booster are required; in­ spect to see that they are in place. 3. Screw the fuze into the fuze adapter at the nose of the bomb until it is seated handtight. If the threads are not free run­ ning, a small spanner wrench may be used to seat the fuze. 4. Remove the safety cotter pin from the fuze and rotate the vane carrier slightly in each direction to insure free rotation. Do not rotate the vane carrier more than one turn in either direction. 5. Thread the end of arming wire through the forward bomb lug, then through the uppermost hole in the striker flange and the hole in the nearest vane carrier lug. Ad­ just the arming wire to protrude about 4 inches from the fuze. 6. Slip two safety (Fahnestock) clips over the end of the arming wire until they just touch the face of the vane carrier lug. Make certain that the arming wire is not kinked or burred. The arming wire may be assembled to the bomb and fuze either after the bomb is placed in bomb rack or immedi­ ately before. The safety pin must not be removed until just before the arming wire is threaded through the holes in the striker flange and the vane carrier lug. Defuzing CAUTION: Before attempting to remove a fuze from a bomb, be sure it is unarmed or safe to handle. This fuze will be regarded as armed if the striker flange has advanced % 6 inch from the outer sleeve. From outward appearances it is practically impossible to obtain a definite indication as to whether the fuze is partially or fully armed. See the preceding subparagraph, Accidental Arming, for further in­ formation on recognition and han­ dling of armed or partially armed fuzes. 1. Hold the arming vane assembly to pre­ vent rotation and remove the safety clips from the arming wire. 2. Withdraw the arming wire and insert the original safety pin and tag. 3. Repack the safety clips and wire. 4. Unscrew the fuze from the bomb and repack in the metal can; reseal can with adhesive tape. 2-15 N A V W E P S OP 2216 (V O L U M E 1) Packaging and M arking Fuze Container. One fuze with two safety (Fahnestock) clips is hermetically sealed in a metal container; six loaded containers are packed in a metal packing box. The dimen­ sions of the box are 15!/2 by 10 7/10 by 6%0 inches, and its weight about 36 pounds loaded. The individual metal containers are marked as follows: 1 FUZE, BOMB, NOSE AN-Mk 219 (Date Loaded) Lot No. Place Loaded Inspector’s Initials Contract No. Weight: Empty, loaded The metal packing box is marked as fol­ lows: 2-16 6 FUZES, BOMB, NOSE AN-Mk 219 Lot No. Weight: (Date Loaded) Inspector’s Initials Packing Box. Shipments from the manu­ facturer contain a convenient number of metal packing boxes in an outside wooden shipping box. Each box is marked “ Deto­ nating Fuzes— Handle Carefully.” The top is marked “ This side up.” It is also marked as follows. (Number) Aircraft Bomb Fuzes, Mk 219, Mod— Lot Number Name of Manufacturer Requisition, Contract, or Order Number Inspector’s Initials Shipping Address FUZES IM P A C T NOSE FUZE M k 243 M od 0 and M k 244 M od 1 Mark___ _______ ___ _ M o d _________ _____ ______ Firing Action_____________ Firing Delay (sec.)________ General Arrangement_____ Arming T ype-------------------------Revolutions to Arm. . Air Travel to Arm (ft) Overall Length (in.)_______ Protrusion from Bomb (in.) Body Diameter ( i n , ) . . ___ Vane Span (in.)___________ Weight (lb )_______________ Number of Vanes_________ Detonator Designation____ Booster Charge T yp e------------------------Weight (oz)__________ 243___ 244. 0____ 1. Impact 0 .0 2 5 .. 344638. Impact, 4. 344764. Delayed_____ 130___ 450_______... 8 .9 ____ 3 .9 ____ 2 .5 __________ Delayed. 130. 450. 8.9. 3.9. 2.5. 6 ____________________ . . 6. 4 .4 __________ 4.4. 2 __________ 2. Mk 22 Mod 0 344470 Mk 22 Mod 0 344470. T etryl_______________ 1 .9 __________________ Tetryl. 1.9. General Description Figure 2 -8 .— Nose Fuzes Mk 243 M od 0 and Mk 244 Mod I. These vane type, delay armed impact nose fuzes, figure 2-9, are either water-discrimi­ nating or not water-discriminating, depend­ ing upon the design of the striker plate and the shear threads supporting the striker. Approximately 450 feet of air travel is necessary to arm these fuzes for action. Nose Fuze Mk 243 Mod 0 differs from Nose Fuze Mk 244 Mod 1 in external mark­ ings and in the delay element. Nose Fuze Mk 243 Mod 0 is water discriminating. It functions after a delay of 0.025 second, while Nose Fuze Mk 244 Mod 1 is not water dis­ criminating and has a delay of 4 seconds. When Nose Fuze Mk 243 Mod 0 is installed in a 500-pound GP bomb, a drop from 20,000 feet into water will not result in fuze action. Impact with at least 14 inch steel plate or hard ground is necessary for detonation. When used with certain inertia firing tail fuzes that have a 0.24-second M14 primerdetonator, a dual purpose effect is achieved. Nose Fuze Mk 243 Mod 0 will detonate the bomb with a 0.025-second delay in case of a direct hit on the target. In case of a near miss, the tail fuze will detonate the bomb at an optimum depth of about 25 feet to pro­ duce a mining effect. 2-17 N A V W E P S OP 2216 (V O L U M E 1) RING SPRING VANE CAP------ FUZE BODY ARMING STEI ARMING-STEM SPRING FIRING PI BOOSTS DETONATOR BOOST!.R Figure 2 -9 .— Impact Nose Fuze Mk 244, Cross Section. 2-18 ' OP FUZES Nose Fuze Mk 244 Mod 1 is not water discriminating. It has an added striker plate which increases the striker surface seven times. Also, the number of shear threads supporting the striker is only half the number of those on Nose Fuze Mk 243 Mod 0. Nose Fuze Mk 244 Mod 1 will func­ tion when dropped on soft ground from an altitude of 1000 feet, or on water from an altitude of 3000 feet. The fuze body is labeled 4 SEC. DELAY. Explosive Components The explosive components consist of a de­ lay element, a detonator, a booster lead-in, and a booster charge. The booster consists of 1.9 ounces of tetryl. Safety Features Each fuze is individually packed in a sealed metal container. The fuzes are kept in an unarmed condition by a safety cotter pin, with an attached tag, which passes through holes in the flange of the vane cup and in the flange of the vane cup support. This locks the reduction mechanism to pre­ vent the fuze from arming. The arming wire keeps the fuze unarmed until it is withdrawn when the bomb is re­ leased. This wire passes through the for­ ward suspension lug o f the bomb, through a pair of holes in the flange of the vane cup, and through the flange of the vane cup sup­ port, preventing rotation of the arming-vane assembly. These fuzes are detonator safe since the detonator is out of alinement until the fuze is armed; they are also shear safe. These fuzes in externally carried stores are re­ stricted in accordance with NAVORDINST 8024.25, latest issue. Functioning General. When the bomb is dropped ARMED, the arming wire is retained in the bomb rack and withdrawn from the vane cup and vane cup support. This unlocks the re­ duction gear mechanism to arm the fuze. After 130 revolutions of the arming-vane assembly, taking approximately 450 feet of air travel along the trajectory of the bomb, the fuzes become armed and the arming mechanism is released into the air stream. These fuzes will detonate upon impact with a sufficiently dense substance. Arming. The vane cup and arming-vane assembly are connected directly by the eye­ let pins. The revolving arming vanes turn the vane cup to operate the delay arming mechanism. The delay arming mechanism is composed of an inner and outer gear, a pinion, an arming screw, and an arming stem. The movable outer gear, which is attached to the arming screw has 23 teeth. The inner gear, which has 22 teeth, is prevented from mov­ ing by the inner gear stop. As the arming vanes turn the vane cup, the pinion is forced to walk around the outer and inner gears. The difference in the num­ ber of teeth between the outer and inner gears causes the pinion to advance the outer gear one tooth each complete revolution. This moves the arming screw outward on its threads. The reduction ratio obtained is one revolution of the arming screw to 23 revolutions of the arming-vane assembly. The reduction gears, vane cup, and arm­ ing-vane assembly are carried outward by means of the arming-screw collar. The arming stem rides outward with the arming screw, under the action of the arming-stem spring. When the arming screw has ad­ vanced approximately one-fourth inch, the arming stem clears the detonator slider. The detonator slider is a cube of metal containing the detonator. It is confined in a recess of the fuze body, and is under spring action from one side. The arming stem holds the slider against the slider springs to prevent the detonator from becoming alined with the explosive train. Raising of the arming stem during arming allows the slider springs to move the slider sideways. At a point where the detonator is alined properly with the delay element and the booster leadin, the slider is locked in position by a spring loaded detent and a lock pin. Continued rotation of the arming vanes unscrews the arming screw from the striker, freeing the reduction gears, the vane cup, 2-19 N A V W E P S OP 2216 (V O L U M E 1) and the arming-vane assembly to the air stream. The fuze now is armed. Action. Impact with a sufficiently dense substance drives the striker inward. The striker shears the brass shear threads and shear pin, and then strikes the firing pin. Detonation. The firing pin fires the delay element, setting off the explosive train. The delay element relays the explosion to the detonator which, in turn, sets off the booster lead-in and the booster. Released Safe If it is necessary to release fuzed bombs over friendly territory, the aircraft arming controls are set in the SAFE position before the bombs are jettisoned. In this position, the arming wire is released from the bomb rack with the bomb, preventing the arming vane from rotating and arming the fuze. The unarmed fuze will not function on im­ pact. Accidental Arming Recognition. If the arming assembly (arming vanes, vane cup, and reduction gears) is missing, the fuze is armed. If the arming assembly is not missing, visual evidence of arming can be gained by measuring the distance between the flange of the vane cup and the flange of the vane cup support. When this distance measures % inch or more, the fuze is fully armed. Any distance less than Vi inch is an indica­ tion that the fuze is partially armed. Handling. If a fuze has become armed and must be removed from a bomb, lock the vane cup (if still attached) to the vane cup support by means of a cotter pin. This will prevent partially armed fuzes from becom­ ing fully armed. The vane cup offers some protection in handling partially and fully armed fuzes since it acts as a shield against sharp blows being transmitted directly to the striker. As long as the fuze is protected against severe blows, it is reasonably safe to handle. Salvaging. If the fuze is in the partially armed condition, with less than 14 inch dis­ tance between flanges, it may be made safe 2 -2 0 by turning the vanes in a counterclockwise direction. This will force the screw to push the arming stem downward and, by means of its collar, compress the arming spring. The counterclockwise rotation must be continued until the mechanism jam s; then the direction must be reversed one turn. A fuze returned to an unarmed condition will require ap­ proximately the same air travel to arm as was originally necessary. After returning the fuze of its unarmed condition, remove it from the bomb and repack. Fully armed fuzes must be disposed of by authorized and qualified personnel. No attempt is to be made to return the fuze to its unarmed condition. Fuzing 1. Remove the shipping plug from the bomb. Inspect the fuze seat threads to see that they are clean. 2. Remove the fuze from its sealed container and examine for any physical de­ fects. Look for damaged threads and dented parts. 3. Unwrap the arming-vane assembly from its heavy waterproofed paper wrap­ ping. The arming-vane assembly is in the fuze container together with the fuze. 4. Place the arming-vane assembly on the vane cup hub. Press down firmly on the arming-vane cap until the ring spring en­ gages the groove in the vane cup hub. This operation will secure the arming-vane as­ sembly to the fuze. 5. Remove the safety cotter pin and turn the arming-vane assembly one complete revolution in each direction in order to make sure that it will rotate freely. Replace the safety cotter pin. 6. Screw the fuze into the fuze seat handtight. Do not use a wrench or other tools since this might make it difficult to remove the fuze if defuzing becomes necessary. 7. Insert the arming wire through the forward suspension lug of the bomb and through the nearest pair of holes in the flange of the vane cup support and the flange of the vane cup. If the safety cotter pin FUZES occupies the nearest set of holes, remove the cotter pin and place it through another set. 8. Cut the arming wire so that approxi­ mately 3 inches extends beyond the fuze. Place the two safety (Fahnestock) clips over the end of the arming wire, pushing them up against the vane cup. Remove the safety cotter pin. Defuzing CAUTION: Before attempting to remove a fuze from a bomb, be sure it is unarmed, or safe to handle. If the arming assembly (arming vanes, vane cup, and reduction gears) is missing, the fuze is armed. If the arming assembly is not miss­ ing, measure the distance between the flange of the vane cup and the flange of the vane cup support. If this distance is 14 inch or more, the fuze is fully armed. If less than */4 inch, the fuze is partially armed. See preceding subparagraph Acci­ dental Arming, for instructions on handling this type of fuze. 1. Replace and secure the safety cotter through a set of holes in the flange of the vane cup and the flange of the vane cup sup­ port. 2. Remove two safety (Fahnestock) clips and also the arming wire from the fuze. 3. Unscrew the fuze from the fuze seat of the bomb. 4. Free the arming vane assembly from the vane cup hub of the fuze. It may be necessary to place the end of a screwdriver between the vane cup hub and the vane assembly and gently pry the vane assembly free. 5. Return the fuze to its container. Re­ wrap the arming vane assembly in heavy, waterproof wrapping and place it into the fuze container along with the fuze. Packaging and M arking Fuze Container. Each fuze comes in a hermetically sealed metal container. The arming-vane assembly for each fuze is packed in the same container and is wrapped in heavy waterproofed paper. The con­ tainer has a tear strip to facilitate opening, and is marked as follows. BOMB FUZE Mk 244 MOD 1 Packing Box. Fifteen containers are packed in a wooden box. The dimensions of the box are 2 6 J/2 by 151/2 by 1 1 inches, and it weighs 98 pounds. It is marked as follows. 15 NOSE FUZES BOMB, NOSE, Mk 244 Mod 1 4 SEC. DELAY PACKED (MONTH AND YEAR) LOT NO. 2 -2 1 N A V W E P S OP 2216 (V O L U M E 1) M E C H A N IC A L T IM E NOSE FUZE A N -M 1 4 5 A 1 AN-M145A1________ Mechanical time_____ Aerial burst, 5-92 sec­ onds, or instantane­ ous. P-84247____________ AN-M146A1. Mechanical time. Aerial burst, 5-92 sec­ onds, or instantane­ ous. P-83745. Vane and time_____ _ 260-350_____________ 4 .5 ____________ 1000-1300_____ _____ 6 .3 _______ _____ ____ 4 .9 _________________ 1 .9 3 ..____ _________ 3___________________ Vane and time. 260-350. 4.5. 1000-1300. 5.7. 4.9. 1 .93. 3. 1 . 6. 5-92. 2. M19A2. Model- ____ Firing Action Firing Delay. Assembly Drawing N o____ Arming T ype-------------------------Revolutions to Arm. _ Time to Arm (sec)____ Air travel to Arm (ft) Overall Length (in.)_______ Protrusion from Bomb (in.) Body Diameter (in.)______ Vane Span (in.)___________ Weight (lb)_______________ Time Setting Range (sec).. Number of Vanes_________ Detonator Designation____ Booster Charge T ype------- -------- ---------Weight (grains)______ l . J Figure 2-10.— Mechanical Time Nose Fuzes A N -M 1 4 5 A 1 and A N-M 146A1. General Description Nose fuzes of this type, figures 2-11 and 2 -2 2 and A N -M 1 4 6 A 1 1.6 __________ 5-92________________ 2 __________ M19A2___ __________ Tetryl.................... ..... 125_________________ Black Powder. 110 . 2-12, are armed by mechanical and time mechanisms. The time of detonation after release can be preset for 5 to 92 seconds. Should the time setting be greater than the time of the flight of the bomb, impact will cause the fuze to function instantaneously, provided it is armed. An air travel of 1000 to 1300 feet is necessary to arm these fuzes. Mechanical Time Nose Fuzes AN-M145A1 and AN-M146A1 are identical except for their boosters. The AN-M146A1 has a black-powder booster which is used for igni­ tion purposes. The AN-M145A1 contains tetryl and is used for detonating purposes. These fuzes are detonator safe. These fuzes in externally carried stores are restricted in accordance with NAVORDINST 8024.25. latest issue. Fuzes AN-M145 and AN-M146 modified an earlier Fuze M111A2 by the addition of a detonator slider held out of line until the fuze became partially armed by a crank­ shaped arming stem. The later fuzes are also equipped with a spinner device to force safety blocks to rotate with the arming vane to insure positive ejection of the safety block after the arming sleeve has withdrawn. Fuze AN-M145E2 is the AN-M145 with a FUZES VA N E-NU T PIN STRIKER ARMING VANE SAFETY BLOCK STRIKER STOP SAFETY-BLOCK ARMING SLEEVE VANE NUT ARMING HUB STATIONARY GEAR HEAD --------VANE TAB THUMBSCREW MOVABLE GEAR PINION BODY F IR IN G -P IN SPRING TIMING DISC ------------------FIRING PIN ARMING CAM ARMING-WIRE GUIDE ARMING LEVER -PIN SPRING CLOCKWORK MECHANISM ARMING PIN DETONATOR DETENT DETONATOR SLIDER DETENT SPRING DETONATOR SLI SPRING BOOSTER CHARGE SLIDER COVER CUP Figure 2-11.— Mechanical Time Fuze A N -M 1 4 6 A 1 , Cutaway View, Unarmed. 2-23 N A V W E P S OP 2216 (V O L U M E 1) VANE NUT PIN STRIKER SAFETY BLOCK COLLAR ARMING VANE ARMING HUB VANE NUT ARMING SLEEVE FIRING PIN SPRING' VANE TAB STATIONARY GEAR HEADPINION MOVABLE GEAR THUMBSCREWFIRING PIN BODY TIM ING DISC RMING-WIRE GUIDE ARMING CAM ARMING LEVER CLOCKWORK MECHANISM DETONATOR DETENT DETENT SPRING DETONATOR SLIDER DETONATOR SLIDER SPRING' BOOSTER CHARGE SLIDER COVER BOOSTER CUP Figure 2-12.- Mechanical Time Fuze A N M l4 6 A 1 , Cutaway View, Armed. 2-24 FUZES clockwork mechanism that has been re­ worked for low-temperature operation. An added protective finish changed the A N M145E2 to the AN-M145E3, which became standardized as the AN-M145A1. Fuze M146E1 is Fuze M146 with the booster charge increased from 70 to 110 grains of black powder. Fuze AN-M146E2 is Fuze AN-M146E1 with a clockwork mechanism reworked for low temperature operation. Fuze AN-M146E3, which was standardized to become Fuze AN-M146A1, is Fuze AN-M146E2 with an added protec­ tive finish. Explosive Components The explosive components of this type of fuze consists of a detonator, a booster leadin, and a booster. The booster is held out of alinement until arming occurs. Safety Features The fuze has a combination of four fea­ tures to keep it in the unarmed state and to prevent detonation during shipping and stowage. A sealed safety wire, with attached in­ struction tag, is threaded through the vane tab, the arming-wire guide, the striker stop, and the eye of the cotter pin which se­ cures the arming pin. This wire locks the mechanical arming system. A safety block is located between the striker and the vane nut, preventing the firing pin from being driven inward pre­ maturely. A cotter pin through the arming pin and the arming-pin bracket holds the arming pin in against the action of its spring. An arming pin locked in this position will not allow the time arming mechanism or time train to operate. Additional safety is provided by having the detonator out of alinement with the ex­ plosive train until the fuze arms. When installed in a bomb the arming wire prevents the arming pin from being ejected and the arming-vane assembly from rotat­ ing, thus keeping the fuze in the unarmed condition. Presetting The fuze can be preset to detonate from 5 to 92 seconds after release. Markings corresponding to these times are engraved on the fuze head. The graduations are di­ vided into one-half second increments and numbered every 3 seconds. To set the time of detonation, loosen the thumbscrew and turn the fuze head so that the engraved line representing the desired time alines with the index mark on the fuze body. Tighten the thumbscrew to lock the setting. Functioning General. When the bomb is released ARMED, the arming wire withdraws from the fuze and remains in the bomb rack. As the arming wire is withdrawn, the arm­ ing pin is ejected by the arming-pin spring and the arming-vane assembly rotates in the air stream. When the arming pin is ejected, the time mechanism is set in motion, initiat­ ing the time train and turning the time arm­ ing cam. After 4.5 seconds the time arming cam places the detonator in alinement with the explosive train. The arming-vane as­ sembly operates the delay-arming mecha­ nism (mechanical arming) to remove the safety block between the striker and the vane nut. Approximately 1000 to 1300 feet of air travel is necessary for the armingvane assembly to remove the safety block. After this distance the fuze will function on impact, if not previously fired by the timing mechanism of the time set. Arming. There are two distinct opera­ tions for arming these fuzes. The mechani­ cal arming mechanism functions to remove the safety block, and the time arming mechanism functions to bring the detonator into alinement with the rest of the explosive components. The mechanical delay arming mechanism is composed of the arming-vane assembly, an outer and inner gear, and a pinion. The arming-vane assembly is threaded onto the arming hub, outside the fuze body. The outer gear, containing 39 teeth, is secured in place at the other end of the arming hub, within the fuze body. Threads are cut on the inside surface of the 2-25 N A V W E P S OP 2216 (V O L U M E 1) STI !K( .: SPRING TIMING-DISC LEVER H A LF-R O U N D PIN LEVER TIMING DISC FIRING PIN . DETONATOR POSITION BEFORE FIRING POSITION AT TIME OF FIRING Figure 2-13.— Mechanical Time Fuze A N -M 1 4 6 A 1 , Details of Firing-Pin Operation. arming hub to accommodate the threaded arming sleeve. The inner gear, containing 40 teeth, is attached to the arming sleeve at its innermost end. The pinion meshes with the outer and inner gears. As the arming-vane assembly rotates, it turns the arming hub and arming sleeve. The outer gear meshes with the pinion and forces it to rotate. Since the number of teeth on the outer and inner gears are not equal, the outer gear turning the pinion and the pinion meshing with the inner gear causes the inner gear to lag one tooth each revolution of the outer gear. Motion is thereby induced between the arming hub and the arming sleeve, causing the arming sleeve 2-26 to unscrew itself from the arming hub. When the arming sleeve is withdrawn from the safety block, centrifugal force throws the safety block clear of the fuze. As soon as the safety block is removed, the mechani­ cal arming of the fuze is complete. The safety block has a collar which bears on pins in the vane nut. This insures that the safety block will spin with the armingvane assembly, and sufficient centrifugal force will be developed to throw the block clear when the arming sleeve is withdrawn. The second phase of arming is the process of bringing the detonator into alinement with the rest of the explosive components. The detonator is contained in the detonator FUZES slider, which is under pressure from the compressed slider spring. The slider spring is prevented from forcing the slider inward by the arming lever, which contacts a shoul­ der of the detonator slider. At the same time that the arming wire is withdrawn from the arming-vane assembly, it is also withdrawn from the arming pin. The arming pin is ejected by the armingpin spring and the timing mechanism is set in motion. The timing mechanism turns a shaft on which the time arming cam is mounted. As the cam rotates, it strikes the arming lever, which pivots and releases the the detonator slider. The slider is driven by the slider spring deeper into the fuze body, alining the detonator with the firing pin. The elapsed time for alinement is 4.5 seconds after release. Action. All mechanical time fuzes are essentially of one type. The principle of operation is that of the common alarm clock. A trigger arm assembly (firing lever and timing-disc lever), which re­ strains a spring-loaded firing-pin assembly, figure 2-13, rides on the edge of a circular timing disc. The disc has one notch cut into its edge which, in the unarmed condition, is occupied by the arming pin. The arming pin holds the timing disc in place against the action of the timing mechanism. When the arming pin is ejected upon withdrawal of the arming wire, the clockwork turns the timing disc at a uniform rate until the tim­ ing-disc lever drops into the notch and releases the firing lever. The firing lever pivots and releases a half-round pin, which had previously restrained the spring-loaded firing pin by contacting the firing pin collar. The collar had rested on one-half of the halfround pin, keeping the pin under a rotary force. Releasing the firing lever frees the half-round pin, which is forced to pivot by the spring-loaded firing pin. The firing pin is driven into the alined detonator. Rotating the fuze head during the time setting operation moves the timing-disc lever around the timing disc. Locating the lever at different positions varies the distance the notch must travel to have the lever drop in, and thereby varies the time of detonation. The outside of the fuze head is engraved with time settings corresponding to locating positions for the timing-disc lever. Detonation. The firing pin explodes the detonator, which relays the explosion to the booster lead-in. The booster lead-in fires the booster, exploding the main charge of the bomb. Released Safe If it is necessary to release fuzed bombs over friendly territory, the aircraft arming controls are set in the SAFE position before the bombs are jettisoned. In this position, the arming wire is released from the bomb rack with the bomb, preventing the armingvane assembly from rotating and the arm­ ing pin from being ejected. The unarmed fuze will not function in the air or on impact. Accidental Arm ing Recognition. This fuze is considered armed when any of the following conditions exist: absence of the safety block; complete or partial ejection of the arming pin; and failure of the trigger arm assembly to sup­ port the striker as evidenced by the striker bearing down tightly against the safety block. Handling. If any of these conditions exist, the safety block should be fastened in place with tape. If the original safety block is missing, a spare or improvised block should be used. The fuze then may be han­ dled with comparative safety until it can be disposed of by authorized personnel. Such fuzes cannot be returned to a serviceable condition and no attempt should be made to do so. Fuzing 1. Remove the fuze from its packing and inspect it to insure that the safety block is in place, the arming pin is in its proper position, the fuze threads are clean, and that there is no indication of serious cor­ rosion or other evidence of unserviceability. Special attention should be given to exami­ 2-27 N A V W E P S OP 2216 (V O L U M E 1) nation for evidence of corrosion. A small amount of external corrosion may indicate sufficient internal corrosion to freeze the time mechanism or detonator slider and cause a dud or, conversely, it may indicate primer corrosion or weakening of light parts which would render the fuze unsafe to han­ dle. Holding the safety block in place, re­ move the striker stop and examine for clearance between striker and safety block. If a clearance does not exist, it is an in­ dication that the half-round pin is not sup­ porting the firing pin and the fuze may fire as soon as the safety block is ejected. In this event, the safety block should be taped in place and the fuze destroyed as soon as possible. Shake the fuze gently to see if the safety block falls out. If it does, re­ place it, secure it with tape, and dispose of the fuze as soon as possible. Replace the striker stop if these tests have indicated that the fuze is serviceable. 2. Loosen the thumbscrew and turn the head until the desired time is indicated by the index mark on the body. Tighten the thumbscrew to lock the setting. It should be noted that there is a time lag of 0.2 second between the release of the bomb and the starting of the time mechanism. This is due to the fact that the bomb falls for 0.2 second after release before the arming wire is withdrawn and the arming pin ejected. Consideration should be given to the time lag in selecting the time setting. Thus, if it is desired that the fuze function 21.5 seconds after release, the fuze should be set for 21.3 seconds. 3. Remove the nose plug from the bomb and inspect the fuze seat to be sure that it is clean and that the threads are not dam­ aged. The fuze may be installed in the bomb before the bomb is placed in the rack, but it is preferred that all fuzing be done after the item is installed in the rack. 4. If the threaded hole in the bomb is too large, install the appropriate adapter booster. 5. Screw the fuze into the cavity, handtight. 2-28 6. Attach the arming-wire loop to the shackle. Straighten the free end of the wire and pass it through, in turn, the front sus­ pension lug, the smaller hole in the spoiler ring (if present), the outer holes in the arming-pin bracket and arming pin, and the outer holes in the arming-wire guide and arming vane. Take up slack in the wire by pulling it forward through the arming pin and arming vane. The use of a Fahnestock clip on the arming wires of mechanical time fuzes is mandatory where munitions, so fuzed, are by tactical necessity carried on external bomb racks or carried on internal racks of aircraft whose rated cruising speed is in excess of 300 knots. Use is optional when the munitions are carried internally in slower rated aircraft. Cut off the arming wire 2 or 3 inches in front of the arming vane or safety Fahnestock clip. Be sure that no kinks or burrs are in the arming wire. 7. Check the time setting on the fuze. 8. Remove the striker stop, the safety cotter pin, and the seal wire. Check again for clearance between the striker and the safety block as described in step 1. If the safety block should fall out, replace it, se­ cure it with tape, remove the fuze from the bomb, and set it aside for destruction. Defuxing CAUTION: Before removing a fuze from a bomb, be sure it is un­ armed or safe to handle. Check for clearance between the striker and safety block as described in Fuzing, step 1. If the striker should snap down or tightly against the safety block, or if the safety block should fall out, replace the block, secure it with tape, remove fuze from bomb or cluster, and set it aside for disposal by authorized personnel. 1. Replace the cotter pin in the fuze arm­ ing pin. 2. Replace the striker stop between the striker and safety block. FUZES 3. Pass the seal wire through the holes in the arming vane and the arming-wire guide, and fasten the ends of the wire to­ gether. 4. Remove the arming wire and unscrew the fuze. 5. Replace the closing plug in the bomb. 6. Return the fuze to its original con­ tainer and seal with adhesive tape. Packaging and M arking Fuze Container. Each fuze is hermetically sealed in a metal container. Soldered to the container and cover is a metal strip, sealing the container during shipping and stowage. A key is provided to facilitate the removal of this strip. The following is a typical container marking. FUZE, BOMB, NOSE, M. T. AN-M145A1 PACKED (date) (drawing no.) REV. DATE OF FUZE DRAWING Packing Box. Fifteen fuzes in containers are packed in a wooden packing box fastened with wood screws and secured with steel bands. The following is a typical packing box marking. 15 NOSE FUZES BOMB, NOSE, AN-M145A1, M. T. PACKED (date) LOT NO. 2-29 N A V W E P S OP 2216 (V O L U M E 1) M E C H A N IC A L T IM E FUZE M155A1 Model ........ Firing Action Firing Delay _ ............. ..... ....... M155A1. Mechanical time. __ ___ ______ Aerial burst, 5-92 seconds or instan­ taneous. Assembly Drawing No. _________P-83912. Arming Type .................................................Vane and time. Revolutions to Arm _______ ___6 to 9 Air travel to Arm (ft) ____ 50 Overall Length (in.) ___ ..... . ... 4.5 Protrusion from Bomb (in.) 3.7 Body Diameter (in.) 1.63 Vane Span (in.) ....._______ _____ 3 Weight (lb) ___ __ ____ ________ __ 1.4 Time Setting Range (sec) .........5-92 Number of Vanes ____________ 2 Percussion Primer Designation ___ M26 Booster Charge Type ____________ ______ ______ ..Black powder Weight (grains) ___ ___ 120 Figure 2-14.— Mechanical Time Fuze M155A1, Exterior View. General Description Mechanical Time Fuze M155A1 is similar in operation to Mechanical Time Fuze A N M145A1 previously described in this chapter. It is a “ detonator-in line” fuze; however it is not detonator safe. This fuze is not to be used from aircraft carriers and is not to be installed in a bomb or cluster before it is loaded in a plane. It may possibly function when dropped unarmed. These fuzes in externally carried stores are restricted in accordance with NAVORDINST 8024.25, latest issue. Fuze M155A1 differs from the earlier M ill series of fuzes in that it does not have reduction gearing but has direct mechanical arming instead. Fuze M ill had a minimum time setting of 15 seconds; it required 570 vane revolutions to arm; it had a 4-inch vane 2-30 span and a three-segment safety block. M111A1 was similar but required a minimum time setting of about 8 seconds. M111A2 has a 3-inch vane span and a C-shaped safety block. It has a minimum time setting of 5 seconds. The M155 is similar to the M111A2 but has no reduction gearing and has a safety block ejection spinner. M155A1 has been reworked to provide for low-temperature operation. Fuzing 1. Remove the fuze from its packing and inspect it to insure that the safety block is in place, the arming pin is in its proper position, the fuze threads are clean, and that there is no indication of serious corro­ sion or other evidence of unserviceability. Special attention should be given to exami­ nation for evidence of corrosion. A small amount of external corrosion may indicate sufficient internal corrosion to freeze the time mechanism and cause a dud or, con­ versely, it may indicate primer corrosion or weakening of light parts which would render the fuze unsafe to handle. Holding the safety block in place, remove the striker stop and examine for clearance between the FUZES ■------- STRIKER SAFETY BLOCK ARMING ARMING HUB STRIKER STOP GEAR VANE TAB HEAD FIRING-PIN SPf THUMBSCREW (OUT OF POSITION] HALF-ROUND PIN (OUT OF POSITION] TIMING DISC FIRING PIN BOOSTER Figure 2-15.— Mechanical Time Fuze M155A1, Cross Section. striker and the safety block. If a clearance does not exist, it is an indication that the half-round pin is not supporting the firing pin and that the fuze may fire as soon as the safety block is ejected. In this event, the safety block must be taped in place and the fuze destroyed as soon as possible. Other­ wise, if the safety block should fall out, the fuze would fire immediately. If the clear­ ance between the striker and the safety block does exist, however, shake the fuze gently to see if the safety block falls out. If it does, replace it, secure it with tape, and dispose of the fuze as soon as possible. Re­ place the striker stop if these tests have indicated that the fuze is serviceable. 2-31 N A V W E P S OP 2216 (V O L U M E 1) 2. Loosen the thumbscrew and turn the head until the desired time is indicated by the index mark on the body. Tighten the thumbscrew to lock the setting. Note that there is a time lag of 0.2 second between the release of the bomb and the starting of the time mechanism. This is due to the fact that the bomb falls for 0.2 second after release before the arming wire is withdrawn and the arming pin ejected. Consideration should be given to the time lag in selecting the time setting. Thus, if it is desired that the fuze function 21.5 seconds after release, set it for 21.3 seconds. 3. Remove the nose plug from the bomb and inspect the fuze seat to be sure that it is clean and that the threads are not dam­ aged. The fuze may be installed in the bomb before the bomb is placed in the rack, but it is preferred that all fuzing be done after the bomb is installed. 4. If the threaded hole in the bomb is too large, install the appropriate adapter booster. 5. Screw the fuze into the cavity handtight. 6. Attach the arming-wire loop to the shackle. Straighten the free end of the wire and pass it through, in turn, the front sus­ pension lug, the smaller hole in the spoiler ring (if present), the outer holes in the arming-pin bracket and arming pin, and the outer holes in the arming-wire guide and arming vane. Take up slack in the wire by pulling it forward through the arming pin and arming vane. The use of a Fahnestock clip on the arming wires of mechanical time fuzes is mandatory where munitions, so fuzed, are by tactical necessity carried on external bomb racks or on internal racks of aircraft whose rated cruising speed is in excess of 300 knots. Use is optional when the munitions are carried internally in slower 2-32 rated aircraft. Cut off the arming wire 2 or 3 inches in front of the arming vane or safety Fahnestock clip. Be sure that no kinks or burrs are in the arming wire. 7. Check the time setting on the fuze. 8. Remove the striker stop, the safety cotter pin, and the seal wire. Check again for clearance between the striker and the safety block as described in step 1. If the safety block should fall out, replace it, secure it with tape, remove the fuze from the bomb, and set it aside for destruction. Defuzing CAUTION: Before removing a fuze from a bomb, be sure it is un­ armed or safe to handle. Check for clearance between the striker and the safety block as described in Fuzing, step 1. If the striker should snap down or tightly against the safety block, or if the safety block should fall out, replace the block, secure it with tape, remove the fuze from the bomb or cluster, and set it aside for disposal by authorized personnel. 1. Replace the cotter pin in the fuze arm­ ing pin. 2. Replace the striker stop between the striker and the safety block. 3. Pass the seal wire through the holes in the arming vane and the arming-wire guide, and fasten the ends of the wire together. 4. Remove the arming wire and unscrew the fuze. 5. Replace the closing plug in the bomb. 6. Return the fuze to its original con­ tainer and seal with adhesive tape. N A V W E P S OP 2216 (V O L U M E 1) M inim um S a f e A ir F uze T ype T ravel A pplication (F e e t ) A N -M 166___________________ B ar-........... 3600_______ AN-M166E1________________ AN-M166E3* AN-M168 Bar.............. 2000_______ Ring____ 2000 AN-M 168E1___ _____ _______ Ring AN-M168E2* T50E1. ____________ _ . . . T50E4________ ______ _____ . Ring.......... . 3600 . . R in g -.......... 3 6 0 0 ... T51E1_______________________ T91_________: ________ _____ T93_________________________ Bar___ . R i n g . . ___ Ring___ __ . 2000. . 3600_______ 2000 . . 2000. ___ 100-lb GP AN-M 30A1. 250-lb GP AN-M 57A1. 500-lb GP AN-M 64A1. 1000-lb GP AN M65A1. 2000-lb GP AN-M 66A2. 220-lb Frag AN-M 88. 260-lb Frag AN-M 81. Same as AN-M 166. 100-lb GP AN-M 30A1. 250-lb GP AN-M 57A1. 500-lb GP AN-M 64A1. 2000-lb GP AN-M 66A2. 220-lb Frag AN-M 88. 260-lb Frag AN-M 81. 100-lb GP AN-M 30A1. 250-lb GP AN-M 57A1. 500-lb GP AN-M 64A1. 1000-lb GP AN-M 65A1. 260-lb Frag AN-M 81. Same as AN-M168. 500-lb GP AN-M 64A1. 1000-lb GP AN-M65A1. Same as AN-M 168. Same as AN-M168E1. * Information classified, see Fuze Catalog AD-305 024. is quite sensitive to targets directly in front of it and correspondingly less sensitive to passing targets. Fuze Components The fuze body consists of two cylinders which house all the internal components. The larger cylinder is 3.4 inches in diameter, the smaller approximately 1.7 inches in diameter. Two wrench lugs are mounted on the large cylinder. The smaller cylinder contains a booster, a detonator, a firing con­ denser, and fuze threads. The arming vane is a steel or plastic pro­ peller which drives the internal mechanism. Ring-type fuze propellers are 10-finned; bartype are 3-finned. The arming ring is ap­ 2-34 proximately 3.8 inches in diameter; arming bars are 10.0 inches across. The booster comprises an assembly of booster cup and retainer sleeve. The cup contains the booster charge; the retainer threads into the small cylinder of the body. The safety pin extends 2 inches into the fuze, locking the detonator rotor in a safe position. The pin is removed prior to as­ sembly of the fuze to the bomb. Some fuzes include a thumbscrew for manual setting of reduced fuze sensitivity. For normal sensitivity, the thumbscrew is removed. It remains in place for reduced sensitivity. Internal components include a transmit­ FUZES ter-receiver, a power supply, a firing con­ denser, and an electric detonator circuit. Ring-Type V T Fuzes VT Fuze AN-M168 is the preferred ringtype fuze. Minimum safe air travel (MINSAT) is 2000 feet; burst is 30 to 60 feet above ground. It has a steel body, plas­ tic top, and either a steel or a plastic arming vane. VT Fuze AN-M168E1 is similar to the AN-M168 and is used as an alternate. VT Fuze T93 is a ring-type fuze with a sensitivity-setting thumbscrew. It was de­ signed by the Air Force to be used both for ground and for airborne targets; however, it is not intended that this feature be used by Naval forces. When the sensitivity-setting thumbscrew is removed, the fuze be­ comes the AN-M168E1 fuze. The T93 fuze is used only in case of AN-M168 shortage. Bar-Type V T Fuzes VT Fuze AN-M166E1 is the preferred bar-type fuze. MINSAT is 2000 feet; burst is 50 to 125 feet above ground at normal sensitivity, 25 to 65 feet at reduced sen­ sitivity. It has a steel body, plastic top, aluminum bars, and a plastic arming vane. Use The bar-type fuze can be used effectively in any bomb with a fuze well that will ac­ commodate nose fuzes similar to the A N M103 series. The ring-type fits the same size fuze well; however, it is used only in the bomb sizes for which it is specified. When not used in the proper size bombs, very low bursts of 3 to 10 feet will generally be obtained with ring-type fuzes. 2-35 N A V W E P S OP 2216 (V O L U M E 1) IM P A C T T A IL FUZE A N -M 1 0 0 A 2 , A N - M l 01A2, A N -M 1 0 2 A 2 , M160, M161, M l 62, M l 72, A N - M l 75, M176, A N -M 1 7 7 , A N -M 1 8 4 , A N -M 1 8 5 , A N —M l 94 A N D A N -M 1 9 5 Figure 2-17.— Tail Fuzes A N -M 100A2, A N -M 101A2, and A N -M 102A2. 2-36 FUZES M odel___ _ . . _____ __ _ Firing A ction.. ____ . .. Firing Delay__ _______________ A N -M 100A 2____ I m p a c t___ __ Delay or Nondelay. 7 3 -8 -3 __________ 73-8-183________ A N -M 101A 2____ Impact. _ . _____ Delay or Nondelay. 7 3 -8 -7 __________ 73-8-181________ A N -M 102A 2____ Impact____ __ Delay or Nondelay. 73-8-8. 73-8-72_________ M160. Impact. Delay or Nondelay. Assembly Drawing N o________ ______ 73-8-359. Arming: T ype-------------------------------Vane, delayed___ Vane, delayed___ Vane, delayed___ Vane, delayed. Revolutions to Arm______ 150 to 170_______ 150 to 170_______ 150 to 170. Air Travel to Arm (ft.)-M4 V a n e .......... ............ 445-650_________ 445-650_________ 445-650. M5 Vane______ . . . 1225-1420_______ 1225-1420_______ 1225-1420. Overall Length (in .)-.............9 .2 6 ____________ 12.26___________ 16.26___________ 9.26. Protrusion from Bomb (in.)___ 6 .2 6 ____________ 9 .2 6 ____________ 13.26___________ 6.31. Body Diameter (in.). ______ . 1 .5 _____________ 1 .5 _____________ 1 .5 _____________ 1.44. Vane Span (in.)____ _______ . 5 .0 _____________ 5 .0 _____________ 5 .0 _____________ 4.85. 2 .7 ______________ 2 .9 ______________ 3 .2 _____________ Weight ( l b ) .. ___ __ ____ 2.7. No. of Blades on Vane __ 4 ________________ 4 ________________ 4 ________________ 4. Types of V a n e . .......................... M4 or M5 . M4 or M5_ M4 or M5 _____ M4 or M5. Model M l 61_________ M l 62_________ A N -M 175____ M l 76. M172_________ Firing Action______ - Impact___ Im pact.. Impact. Impact . Impact . . . . . . Delay or Non­ Delay or Non­ Delay or Non­ Delay or Non­ Firing D e l a y ___ ____ Delay or Non­ delay. delay. delay. delay. delay. Assembly Drawing N o. 73-8-359______ 73-8-359______ 73-8-470______ 73-8-471______ 73-8-471. Arming: Vane, delayed. . Vane, delayed. T ype------------------- Vane, delayed Vane, delayed.. Vane, delayed Revolutions to 150 to 170____ 150 to 170. Arm. Air Travel to Arm (ft.): M4 Vane____ 500. M5 Vane Overall Length (in.)___ 12.26_________ 16.26_________ 25.29_________ 25.29_________ 37.05. Protrusion from Bomb 9 .3 1 __________ 34.05. 13.31_________ 22 .2 9 _________ 22.29_________ (in.). 1 .4 4 __________ Body Diameter (in.) — 1 .5 ___________ 1.5. 1 .44__________ 1 .5 ___________ Vane Span (in.)__ __ . 4 .8 5 __________ 4 .8 5 __________ 5 .0 ___________ 5.0. 5 .0 ___________ Weight (lb)_______ 3 .6 5 __________ 3 .6 5 __________ 4.4. 2 .9 ___________ 3 .2 ___________ No. of Blades on Vane. 4 _____________ 4 _____________ 4. 4 ______ . . . 4 _____________ M5 or M4. Types of Vane____ M4 or M 5_____ M4 or M 5 ___ M4 or M5__ . M5 or M 4___ AN-M 195. Model . . . ______ A N -M 177____ A N -M 185____ A N -M 184____ A N -M 194____ Firing Action................ Impact Impact __ __ Impact. Im pact.. Impact . . . Firing Delay____ __ Delay or NonDelay or NonDelay or NonDelay or NonDelay or Nondelay. delay. delay. delay. delay. Assembly Drawing N o, 73-8-471______ 73-8-470______ 73-8-470______ 73-8-470______ 73-8-470. Arming: T ype------------------- Vane, delayed.- Vane, delayed.. Vane, delayed.. Vane, delayed. Vane, delayed. Revolutions to 150 to 170. Arm. Air Travel to Arm (ft): M4 Vane____ 550. 550___________ 450, 460_______ 5 0 0 .. ........... M5 Vane Overall Length (in.)___ 45.12_________ 37.05_________ 45.12_________ 31.035________ 28.972. Protrusion from Bomb 42.12______ 34.05_________ 42.12_________ 28.035________ 25.972. (in.). Body Diameter (in .)--- 1 .5 ___________ 1 .5 ___________ 1 .5 ___________ 1 .5 ...........— 1.5. Vane Span ( i n . ) - , ___ 5 _____________ 5 .0 ___________ 5 .0 ___________ 5.0. 5 .0 _________ Weight (lb )__________ 5 .0 ___________ 4 .4 ___________ 3.9. 5 .0 ___________ 4 .1 ___________ No. of Blades on Vane. 4 ______________ 4 _____________ 4 ....................... 4 _____________ 4. Types of V a n e ... . M4 or M5. M5 or M 4 ___ Mk4 or 5_____ Mk4 or M k 5 ... M4 or M 5_. . . 2-37 N A V W E P S OP 2216 (V O L U M E 1) VANE HUB VANE NUT ARMING-VANE ASSEMBLY EYELET PIN BEARING -CU P EYELET GUIDE PI FIRING PLUNGER FUZE B O D Y-. PRIMER ANTICREEP SPRING PRIMER-DETONATOR ASSEMBLY RELAY DETONATOR Figure 2-18.— Impact Tail Fuze A N-M 100A2, Cross Section. 2-38 FUZES General Description The impact tail fuzes of this type, figure 2-18, are armed and inertia fired. The arming is mechanically delayed by reduc­ tion gearing. When issued, the fuzes are equipped with an 0.025-second delay M14 primer detonator, which can be interchanged with other M14 primer detonators to give a selection of time delays. The lengthy air travel necessary to arm these fuzes (445 to 650 feet with M4 vane and 1225 to 1420 feet with M5 vane) makes them safe for use with carrier-based aircraft and for dive bombing. These fuzes in externally carried stores are restricted in accordance with NAVORDINST 8024.25, latest issue. The overall length o f the fuzes varies be­ cause of differences in the length of the arming-stem tube. These differences in length are necessary to properly locate the arming-vane assembly in the air stream so that the same time fuze can be used with various size bombs. Tail fuzes AN-M100A2, AN-M101A2, and AN-M102A2 are for use with box-fin assemblies. Tail Fuzes M172, AN-M184, and AN-M185 are used with conical-fin as­ semblies. Tail fuzes AN-M185, AN-M194, and AN-M195 are used in low drag bombs. Fuzes AN-M100A1, AN-M101A1, and AN-M102A1 are earlier models of the A N M100A2 series. These differ from the A N M100A2 series in that each of these fuzes has 24 single threads on the arming stem and eight broad vanes with less pitch than the A2 series; they require about 720 vane revolutions to arm. Each fuze incorporates the interchangeable Primer Detonator M14. Fuzes M160, M161, and M162 are similar to the AN-M100A2 series except for the arming stem which has finer threads (28 single threads to the inch against 20 double threads in the AN-M100 series) and a longer engagement with the firing plunger (0.75 inch against 0.50 inch). The M160 therefore requires a longer arming time. The M160 series fuzes are distinguished from the AN-M100 group by a yellow band 3 inches wide painted around the armingstem case. Fuzes AN-M101A2C and AN-M102A2C were the first of the slower-arming tail fuzes. They have the same number of threads per inch as the M160 series, but have the shorter engagement of the AN-M100 series fuzes. The yellow band is painted on, as in the M160 series fuzes. Fuzes AN-M175, M176, and AN-M177 are long-length fuzes developed for use with specific conical bomb fin assemblies. They are externally identical to the AN-M100A2 series tail fuze. The arming stem of the AN-M175 series, however, has finer threads than that of the AN-M100A2 series, in­ creasing the air travel to arm. Arm ing Vanes Two types of interchangeable armingvane assemblies are used on these fuzes. The difference between the two vanes is the degree of pitch of the vane with respect to the plane of rotation. This difference is necessary in order to vary the arming dis­ tance of the fuzes when required by operat­ ing conditions. For shorter arming distances, the stand­ ard vane M4, which has a 45-degree pitch, is used. When longer air travel to arm is desired, an M5 vane, having a pitch of 75 degrees, is used. At present only the M4 vane is provided with these fuzes. Separate action is neces­ sary to requisition the M5 vane. Safety Features During shipment and stowage the fuze is made safe by a cotter pin, with attached tag, that extends through the fuze body and firing plunger. This prevents movement of the firing plunger, which fires the detonator. A safety pin, through a set of holes in the bearing-cup eyelet and arming-stem cup, locks the gear mechanism. A sealed safety wire, with attached instruction tag, is threaded through a hole in the lower end of the safety pin to prevent its removal. The fuze cannot be installed without first re­ moving the cotter pin through the fuze body. When a fuze is properly installed in a bomb, with the arming wire in place, the 2-39 N A V W E P S OP 2216 (V O L U M E 1) arming-vane assembly is prevented from ro­ tating and arming the fuze. The fuze is in the safe condition until the bomb has been released and has traveled the distance re­ quired for arming. The firing plunger is in line with the explosive train at all times. The plunger is held in place, however, by the arming stem until the arming stem is unscrewed by rotation of the arming-vane assembly. The arming stem also is threaded to the fuze body cap. This pre­ vents accidental blows on the arming-vane assembly from being transmitted to the fir­ ing plunger. Functioning General. When the bomb is dropped ARMED, the arming wire is retained in the bomb rack and withdrawn from the fuze. This frees the arming-vane assembly which rotates in the air stream to arm the fuze. After the arming vanes have made from 150 to 170 revolutions, the fuze is fully armed. After approximately 200 more revolutions of the arming-vane assembly, the arming stem unscrews from the fuze body cap and the entire arming assembly (arming vanes, reduction gears, and arming stem) is released into the air stream. Air travel necessary to arm these fuzes is ap­ proximately 445 to 650 feet with an M4 vane, varying with the bomb used. Upon impact’, inertia drives the firing plunger into the primer to fire the fuze and detonate the bomb. Arming. The arming-vane assembly is assembled to the bearing cup by the vane nut. Eyelet pins lock the bearing cup and arming-vane assembly together. The eyelet pins fit into notches in the vane hub to in­ sure positive rotation of the bearing cup with the arming-vane assembly. Delay arming is obtained by reduction gearing between the arming-vane assembly and the arming stem. The ratio is 30 revolutions of the arming-vane assembly to one revolution of the arming stem. Reduc­ tion is derived from a pinion gear, a movable gear, and a stationary gear. The movable gear has 30 teeth; the sta­ 2-40 tionary gear has 29 teeth. The idler gear (pinion) is driven around the stationary gear and movable gear by the bearing cup and arming-vane assembly. Since the mov­ able gear contains one more tooth than the stationary gear, the movable gear is forced one tooth ahead with each complete revolution of the pinion around the stationary gear. When the pinion has circled the stationary gear 30 times, the movable gear has completed one revolution. The movable gear is connected to the arming stem by means of the movable gear carrier. The stationary gear is secured to the sta­ tionary-gear carrier. Rotation of the mov­ able gear carrier is prevented by the carrier stop. As the arming-vane assembly rotates, mo­ tion is transmitted through the reduction gears to the arming stem. As the arming stem revolves, it unscrews from the firing plunger and fuze body cap. The armingvane assembly is strong enough to withstand air speeds up to 600 knots. Action. When arming is complete, the arming stem has unscrewed itself from the firing plunger. The firing mechanism con­ sists of a firing plunger and an anticreep spring. A guide pin through the fuze-body cap and into the firing plunger prevents rotation of the plunger as the arming stem unscrews, but does not prevent the plunger from sliding in and out. The anticreep spring supports the plunger against the fuze-body cap. This spring is only strong enough to support the weight of the firing plunger. Upon impact, the plunger compresses the anticreep spring and is driven forward into the primer by inertia. Detonation. The primer, when struck by the firing pin, explodes and sets off the delay element. After burning through, the delay element sets off the relay which fires the detonator and the bomb. Released Safe If it is necessary to release fuzed bombs over friendly territory, the aircraft arming controls are set in the SAFE position before the bombs are jettisoned. In this position, FUZES the arming wire is released from the bomb rack with the bomb, preventing the armingvane assembly from rotating and arming the fuze. The unarmed fuze will not func­ tion upon impact. Accidental Arming Recognition. If the arming-vane assem­ bly and the reduction gear mechanism are missing, the fuze is armed. If they are not missing, however, the fuze is not necessarily in the unarmed or SAFE condition. The degree of arming can be determined by meas­ uring the distance between the eyelet on the bearing cup and the flange on the armingstem cup. If the distance is less than !/2 inch, the fuze is only partially armed. If the distance is from 14 to % inch, arming is questionable, and the fuze must be considered armed. If the distance is greater than % inch, the fuze is definitely armed. Handling. If the fuze is not installed in a bomb, it may be made safe for handling by inserting a pin through the hole in the fuze body and the firing plunger, or by unscrew­ ing the primer detonator in the base of the fuze. If the fuze is installed in a bomb, it is impossible to insert a pin through the fuze body and the firing plunger. CAUTION: No attempt should be made to unarm the fuze by turning the arming vane backwards. If the threads on the arming stem fail to engage the threads on the firing plunger, the firing plunger will be pushed into the primer with proba­ ble initiation of the explosive com­ ponents. To remove the fuze from a bomb, the vanes must be secured in their existing po­ sition and the fuze carefully unscrewed. Immediately upon removal, a pin should be inserted through the fuze body and firing plunger. Then the primer detonator may be unscrewed. Such removal shall be ac­ complished by authorized and qualified per­ sonnel only. Salvaging. Fuzes which have become armed or partially armed may be salvaged by authorized and qualified personnel. In­ sert the safety cotter pin through the fuze body and firing plunger, turning the armingvane assembly as far counterclockwise as it will go, and then turn it clockwise about twenty revolutions. Fuzes so salvaged will require approximately the same air travel to arm as when issued. To repack the fuze, remove the arming-vane assembly, replace the safety pin which locks the reduction gear mechanism, and pack in the fuze container. Fuzing 1. Remove the fuze from its sealed con­ tainer and inspect the general overall ap­ pearance, checking proper condition of the arming-vane assembly and threads. Vanes (M4) are not assembled to the fuze as is­ sued, but come in the same shipping box as the sealed fuze container. 2. Inspect the adapter booster and threads in the bomb. Clean if necessary. 3. Check the fuze for installation of the desired primer detonator. 4. If a different time delay is required, unscrew the existing primer detonator. 5. Select a primer detonator with the proper delay; inspect for corrosion and loose primer. If the primer detonator has a loose primer, it must be disposed of by authorized personnel. 6. Screw the desired primer detonator into the fuze, hand tight. Use no tools. 7. Remove the cotter pin from the fuze body. 8. Screw the fuze, less the arming-vane assembly, into the adapter booster in the tail of the bomb until it seats hand tight. Use no tools. No auxiliary booster is re­ quired. 9. Draw one lead of the arming-wire as­ sembly through the rear suspension lug of the bomb, and the nearer of two pair of holes in the bearing-cup eyelet and armingstem cup. If the nearer pair of holes is occupied by the safety pin, place the spare pin through the holes diametrically opposite before removing the original pin. The other lead of the arming-wire assembly is for a 2.41 N A V W E P S OP 2216 (V O L U M E 1) nose fuze. If no nose fuze is used, cut off the second lead. 10. Cut the sealed wire and remove the safety pin locking-gear mechanism. 11. Thread the end of the arming wire through the eyelet in the arming-vane as­ sembly. Slip the arming-vane assembly over the end of the fuze so that the slots in the hub fit over the heads of the two eyelet pins of the bearing cup. 12. Screw the vane nut on the threaded end of the bearing cup, hand tight. 13. Adjust the arming wire to protrude 2 to 3 inches beyond the arming-vane assem­ bly. Cut off excess arming wire; be sure the arming wire is free of kinks and burrs. 14. Slip two safety (Fahnestock) clips over the end of the arming wire until one clip just touches the face of the armingvane assembly. Defusing CAUTION: Before removing a fuze from a bomb, be sure that it is unarmed, or safe to handle. The fuze is armed if the arming-vane assembly and reduction-gear mech­ anism are missing. If these are not missing, the fuze is not neces­ sarily in the unarmed or SAFE condition. Measure the distance between the eyelet on the bearing cup and the flange on the armingstem cup. If the distance is less than V2 inch, the fuze is partially armed; if Va to ■% inch, arming is questionable; if more than % inch, the fuze is definitely armed. In any case, it is important to see the sub-paragraph on Handling in the preceding section before proceed­ ing further. 1. Unscrew the vane nut from the bear­ ing cup. 2. Remove the safety clips and withdraw 2-42 the arming-vane assembly from the fuze and arming wire. 3. Place the original safety pin in the un­ occupied hole in the bearing-cup eyelet and stem cup. Secure the safety pin by thread­ ing a retaining wire through the hole in the lower end of the safety pin and twist the ends of the wire together. 4. Withdraw the arming wire from the fuze and repack. 5. Unscrew the fuze from the bomb and insert the cotter pin in the fuze body. Open the legs of the cotter pin to prevent it from slipping out. Repack the fuze in its con­ tainer and seal with adhesive tape. Packaging and M arking Fuze Container. One fuze, less arming vane, is packed in a black cylindrical metal container. Soldered to the container and cover is a metal tear strip which seals the container during shipping and stowage. A ring, attached to one end of the tear strip, facilitates opening. The following is a typical container mark­ ing. FUZE, BOMB, TAIL, AN-M100A2 LESS ARMING VANE .025 SEC. DELAY LOADER’S INITIALS, LOT NO. PACKED (Month and Year) (Drawing No.) REV. DATE OF FUZE DRAWING Packing Boxes. Twenty-five fuzes, with a corresponding number of arming-vane as­ semblies, (Vane M4, not marked as such) are packed in a single wood box. The box is fastened with screws and secured with two steel bands. Each fuze is packed in an individual container. The following is a typical packing box marking. 25 TAIL FUZES BOMB, TAIL, AN-M101A2 0.025 SEC. DELAY Packed (Month and Year) LOT NO. FUZES IM P A C T T A IL FUZE A N -M 1 1 2 , A N -M 1 1 2 A 1 , A N -M 1 1 3 , A N -M 1 1 3 A 1 , A N -M 1 1 4 , A N -M 1 1 4 A 1 , A N -M 1 1 5 , A N -M 1 1 6 , A N - M 1 1 7 # M178, M179, M l 80, M181, M l 82, A N D M 183 M odel__________________ Firing A ction .. . . . . _ Firing Delay___________ Assembly Dwg N o __ __ Arming: T ype---------------------Revolutions to Arm. Air Travel to Arm (ft): M4 Vane______ M5 Vane______ Overall Length ( i n . ) . __ Protrusion from Bomb (in.). Body Diameter (in.)____ Vane Span (in.). _______ Weight (lbs.)___________ Number of Vanes_______ Shipping Container: Number per Container. Type Container (outer). Weight Filled (lb.). Model__ _____ __________ Firing Action________ . . Firing Delay____________ Assembly Dwg N o ______ Arming: Type---------------------Revolutions to Arm. Air Travel to Arm (ft.): M4 Vane M5 Vane Overall Length (in.)____ Protrusion from Bomb (ft.). Body Diameter (in.). Vane Span (in.). Weight (lbs.)___________ Number of Vanes_______ Shipping Container: Number per Con­ tainer. Type Container (outer). Weight Filled (lb.). ANM112A1. Inertial____ 8-15 sec. or 4-5 sec. 7 3 -8 -1 1 2 ... ANM113A1. Inertial____ 8-15 sec. or 4-5 sec. 7 3 -8 -1 1 4 ... ANM114A1. Inertial____ 8-15 sec. or 4-5 sec. 7 3 -8 -1 1 6 ... Delayed___ Delayed___ Delayed___ A N -M 115-. A N -M 1 1 6 .. AN-M 117. Inertial____ Inertial____ Inertial. According to primer detonator used. 7 3 -8 -1 5 8 ... 7 3 -8 -1 6 0 ... 73-8-162. Delayed___ 150-170___ Delayed___ 150-170___ Delayed. 150-170. 445-650___ 445-650. 12.54______ 9 .5 4 _______ 16.54. 13.54. 9 .6 ________ 6 . 6 . . . ......... 1 2.6_______ 9 .7 ________ 1 6 .6 _______ 1 3.7_______ 445-650___ 1225-1420. 9 .5 4 _______ 6 .5 4 ............ 1 .43_______ 4 . 8 3 . . ......... 2 .3 ________ 4 __________ 1 .5 ________ 4 .9 ________ 2 .5 ________ 4 __________ 1 .4 3 _______ 4 .8 3 _______ 2.8________ 4__________ 1 .5 ________ 5__________ 2 . 7 . ............ 4................... 1 .5 ________ 5__________ 2 .9 ________ 4 __________ 1.5. 5. 3.2. 4. 2 5 ............... 25_________ 25. 116.3........... 128.9. 145.3. Wood crate. M178______ Inertial____ 8-15 sec or 4-5 sec. 73-8-4 73A .. M179______ Inertial____ 8-15 sec or 4-5 sec. 73-8-473B-. M180______ Inertial____ 8-15 sec or 4-5 sec. 73-8-473C-. M181______ Inertial__ _ 4-5 sec or 8-15 sec. 73-8-473C .- M182______ Inertial____ 4-5 sec or 8-15 sec. 73-8-475B-. M183. Inertial. 4-5 sec or 8-15 sec. 73-8-475C. Delayed___ Delayed___ Delayed___ Delayed___ Delayed___ Delayed. 24.85______ 21.85........... 36.65______ 33.65______ 44.71______ 41.71______ 2 4 .6 _______ 21.6_______ 36.97______ 33.97______ 45.03. 42.03. 3 . 4 . ............. 4 ................... 4 .1 ________ 4 __________ 4 .6 ________ 4__________ 3 .6 5 _______ 4__________ 4 .4 ________ 4__________ 5.0. 4. 2-43 N A V W E P S OP 2216 (V O L U M E 1) 16754 9“ 54 AN-M115 AN-M116 AN-M117 Figure 2-19.— Impact Tail Fuzes A N - M 1 15, AN -M 116, and AN-M 117. General Description Impact Tail Fuzes AN-M115, AN-M1I6, and AN-M117. The impact tail fuze of this type, figure 2-20, are vane operated and inertia fired. Their arming is mechanically delayed by reduction gearing. The explo­ sive components of the fuzes are contained in one interchangeable primer detonator. By substituting primer detonators with different delay elements, the delay time between im­ pact and detonation can be varied. The fuzes of this series differ in overall length so that the same type fuzes can be 2-44 used in various size bombs. The differences in length are necessary to locate the armingvane assemblies properly in the air stream. The M4 and M5 arming-vane assemblies are used with the AN-M115 series. The standard vane M4 (45-degree pitch) is used for shorter arming distances; the M5 vane (75-degree pitch) is used for longer arming distances. At present, only the M4 vane is issued with these fuzes. Separate action is necessary to requisition the M5 vane. Other fuzes similar to the AN-M115 series are the following. FUZES VANE NUT BALL MOVABLE GEAR CARRIER ARMING STEM IONARY GEAR CARRIER ARMING-STEM TUBE CARRIER STOP BODY CAP PLUNGER -PIN SPRING FUZE BODY PIN LOCKING BALL ANTICREEP SPRING PRIMER SPRING RETAINER DELAY ELEMENT DELAY HOLDER PRIMER-DETONATOR A- Ei.lt > HOLDER Figure 2-20.— Impact Tail Fuze A N-M 115, Cross Section. 2-45 N A V W E P S OP 2216 (V O L U M E 1) Impact Tail Fuzes AN-M112, AN-M113, and AN-M114 (and their A1 modifications). These fuzes differ from the AN-M115 series in that they do not have reduction gears in the vane assembly and therefore require a longer arming period. The fuzes in this series differ from each other only in length; they are for use with box fins. As the vanes rotate, the arming stem is unthreaded from the plunger. The arming stem is secured to the vane nut by a cotter pin; 18 to 21 revolutions of the vane will free the plunger. The air travel to arm is 100 feet. Fuzes of this series will function on an impact angle of 3 degrees and give positive action because of the cocked firing pin. These fuzes are not to be used from aircraft carriers. The original AN-M112, AN-M113, and AN-M114 fuzes used Primer Detonator M16. This primer detonator was modified to the M16A1, which has a higher shoulder. The AN-M112 series was modified to the A N M112A1 series in order to accommodate the M16A1 primer detonator. Impact Tail Fuzes M178, M179, and M180. This series has the same operating charac­ teristics as the AN-M112A1 series (no re­ duction gear, fast arming) but has the longer arming stem necessary for use with a conical-fin assembly. Impact Tail Fuzes M181, M182, and M183. This series has the same operating charac­ teristics as the AN-M115 series (reduction gear in arming-vane assembly), and also the longer arming stem necessary for use with conical fin assemblies. Safety Features During shipping and stowage, the fuze is in the unarmed condition. A safety pin, inserted through the hole in the arming-stem cup and bearing-cup eyelet, prevents the re­ duction gears from revolving and arming the fuze. A wire, with an instruction tag attached, is threaded through the hole in the lower end of the pin and sealed with a car seal. A second instruction tag is secured to the arming-stem tube. 2-46 When installed in a bomb with the arming wire in place, the arming-vane assembly is prevented from rotating and arming the fuze. The fuze is in the safe condition until the bomb has been released and has traveled the distance required for arming. The firing pin and plunger are in line with explosive components at all times. However, the firing plunger is held in place by the arming stem until the arming stem is unscrewed by rota­ tion of the arming-vane assembly. The arm­ ing stem also is threaded through the fuze body cap. This prevents the transmission of accidental blows on the arming-vane assem­ bly to the firing plunger. These fuzes in externally carried stores are restricted in accordance with NAVORDINST 8024.25, latest issue. Functioning General. When the bomb is dropped ARMED, the arming wire is withdrawn from the fuze and retained in the bomb rack. This frees the arming-vane assembly, allowing it to rotate in the air stream and to arm the fuze. After 150 to 170 revolutions, the fuze is fully armed. After approximately 200 more revolutions of the arming-vane assembly, the arming stem unscrews from the fuze body cap and the entire arming assembly (arm­ ing-vane assembly, reduction gears, and arm­ ing mechanism) is released into the air stream. As bomb sizes increase, a greater air travel is required for arming, ranging from 450 to 650 feet. Upon impact, inertia drives the firing pin into the primer to fire the fuze and detonate the bomb. Arming. Eyelet pins, fitting into notches in the arming-vane hub, insure positive ro­ tation of the bearing cup with the armingvane assembly. Delay arming is obtained by a reduction gear train which is located between the arming-vane assembly and the arming stem, and which consists of a pinion gear, a mov­ able gear, and a stationary gear. The ratio is 30 revolutions of the arming-vane assem­ FUZES bly to one revolution of the arming stem. The movable gear has 30 teeth, while the stationary gear has 29. The idler gear (pinion) is driven around the stationary and movable gears by the bearing cup and the arming-vane assembly. Since the movable gear contains one more tooth than the sta­ tionary gear, the pinion pushes the movable gear one tooth forward for each complete revolution. When the pinion has made 30 revolutions, the movable gear has completed one revolution. The movable gear is con­ nected to the arming stem through the mov­ able gear carrier. The stationary gear is secured to the stationary gear carrier, which is prevented from rotating by the carrier stop. As the arming-vane assembly rotates, mo­ tion is transmitted through the reduction gears to the arming stem. The arming stem revolves and unscrews itself from the firing plunger and fuze body cap. The firing mechanism consists of a firing plunger, locking balls, an anticreep spring, a spring retainer, and a hollow firing pin, housing a cocked firing-pin spring. The firing pin and spring are assembled inside the plunger; the compressed firingpin spring is behind the firing pin. They are held in this position by two locking balls in the plunger, which are wedged in posi­ tion by the inner surface of the fuze body and the beveled edge of the firing pin. The plunger is prevented from revolving with the arming stem by a pin passing through the fuze-body cap and into the vertical groove in the plunger. This pin does not prevent the plunger from sliding in and out. Action. When arming is complete, the the arming stem has unscrewed itself from the firing plunger and the plunger is held back by the anticreep spring. This spring is strong enough only to offset the weight of the plunger and the firing-pin spring. Upon impact, the plunger is driven forward by inertia, compressing the anticreep spring. After moving forward a short distance, the locking balls pass a shoulder on the inner surface of the fuze body and are forced out by the spring-loaded firing pin, thereby un­ locking the firing pin. The compressed firing-pin spring then drives the firing pin into the primer. Detonation. The primer fires when struck by the firing pin, setting off the delay ele­ ment. After burning through, the delay element sets off the relay, which fires the detonator, the booster, and the bomb. Released Safe If it is necessary to release fuzed bombs over friendly territory, the aircraft arming controls are set in the “ SAFE” position before the bombs are jettisoned. In this position, the arming wire is released from the bomb rack with the bomb, preventing the arming-vane assembly from rotating and arming the fuze. The unarmed fuze will not function upon impact. Accidental Arm ing Recognition. If the arming-vane assem­ bly and reduction-gear mechanism are miss­ ing, the fuze is armed. If they are not miss­ ing, however, the fuze is not necessarily in the unarmed or SAFE condition. The de­ gree of arming can be determined by meas­ uring the distance between the bearing-cup eyelet on the gear mechanism and the arming-stem-cup flange. If the distance is less than V2 inch, the fuze is only partially armed. If the distance is 1/2 to % inch, the arming is questionable and the fuze must be considered armed. If the distance is greater than % inch, the fuze is definitely armed. Handling. Armed or partially armed fuzes should be removed only by authorized and qualified personnel. CAUTION: Prevent the armingvane assembly from rotating by in­ serting a cotter pin or wire through the holes in the arming-stem cup and the bearing-cup eyelet. This will not make the fuze any safer if it is fully armed, but will pre­ vent partially armed fuzes from be­ coming completely armed. Unscrew the fuze from the bomb; do not jar or drop either the fuze or the bomb. 2-47 N A V W E P S OP 2216 (V O L U M E 1) The bomb must be maintained in a hori­ zontal position, or with the nose end up. Immediately after removal, keep the fuze in a vertical position (vane end down) and unscrew the primer detonator from the fuze body. Salvaging. Do not attempt to unarm fully or questionably armed fuzes by turning the arming vane; such fuzes should be turned over to authorized and qualified personnel. Fuzing 1. Remove the fuze from its sealed con­ tainer and inspect the general overall ap­ pearance. Check for proper condition of vanes and threads. The arming-vane as­ sembly is not assembled to the fuze as issued but comes in the same shipping box as the sealed fuze container. 2. Change the primer detonator if a dif­ ferent delay is desired. To change, unscrew the primer detonator by hand and screw in the primer detonator with the desired delay. Primer detonators having loose primers, evi­ dence of corrosion, or other visible defects should be disposed of by authorized per­ sonnel. 3. Screw the fuze, less the arming-vane assembly, into the adapter-booster in the tail of the bomb until it seats handtight. Use no tools. No auxiliary boosters are necessary. 4. Thread one lead of arming-wire assem­ bly through the rear suspension lug of the bomb and the nearest of two pairs of holes through the arming-stem cup and bearingcup eyelet. If the nearer pair of holes is occupied by the safety pin, place a spare pin through the pair of holes diametrically op­ posite the first pair before removing the original safety pin. The other end of the arming-wire assembly is for a nose fuze and should be cut off when a nose fuze is not installed. 5. Cut the sealed retaining wire and re­ move the safety pin. 6. Position the arming-vane assembly so that the slots in the vane hub will fit over the heads of the eyelet pins and the arming wire will pass through the hole in the 2-48 alined vane. Attach two safety clips to the end of the arming wire. 7. Screw the vane nut on the threaded end of the bearing cup, handtight. 8. Slip two safety clips snugly against the vane. Cut off excess arming wire, al­ lowing the end to extend 2 to 3 inches past the vane and clips. The end of the wire must be free of kinks and burrs. Defuzing CAUTION: Before attempting to remove the fuze from the bomb, be sure it is in the unarmed con­ dition, or safe to handle. If the arming-vane assembly and reduc­ tion-gear mechanism are missing, the fuze is armed. If the armingvane assembly and gear mechanism are not missing, however, the fuze is not necessarily in the unarmed or SAFE condition. Measure the distance between the bearing-cup eyelet on the gear mechanism and the arming-stem-cup flange. If the distance is less than 1/2 inch, the fuze is partially armed; if i/2 to % inch, arming is questionable and the fuze must be considered armed; if greater than % inch, the fuze is definitely armed. In any case, it is important to see the information on Handling in the preceding sec­ tion before proceeding further. 1. Loosen the vane nut by unscrewing it. 2. Remove the safety clips. Withdraw the arming-vane assembly from the fuze and arming wire. 3. Place a safety pin through the unoc­ cupied hole of the bearing-cup eyelet and arming-stem cup. Secure the safety pin by threading a retaining wire through the hole in its lower end. Twist the ends of wire together. 4. Withdraw the arming wire from the fuze and repack. 5. Unscrew the fuze from the bomb and repack it in its container. FUZES Packaging and M arking Fuze Container. One fuze, less armingvane assembly, is packed in a black cylin­ drical metal container. A metal tear strip, soldered to the container and cover, seals it during shipping and stowage. A ring attached to the end of the tear strip facili­ tates opening. The following is a typical container mark­ ing. FUZE, BOMB, TAIL, AN-M115 LESS ARMING VANE 8 TO 15 SEC. DELAY Loader’s Initials Lot No. Packed (Month & Year) Drawing No. Rev. Date of Fuze Drawing Packing Boxes. Twenty-five fuzes in con­ tainers and 25 arming-vane assemblies are packed in a wooden packing box. The pack­ ing box cover is fastened with flathead screws and the box is bound with two steel straps. A sample marking on the side of the box follows. 25 FUZES BOMB, TAIL, AN-M115 8 TO 15 SEC. DELAY Packed (Month and Year) Lot No. 2-49 N A V W E P S OP 2216 (V O L U M E 1) IM P A C T T A IL FUZE A N - M k 228 Mark _________________ ____ _____ A N -M k Firing Action ____________ ____ Impact Firing Delay (sec) 0.08 General Arrangement 236220 Arming Type Delayed Air Travel to Arm (ft) 1100 Overall Length (in.) __________ __ ___ 16.4 Protrusion from Bomb (in.) 12.4 Vane Span (in.) — 6.3 Weight (lb) ____ 10.5 Number of V a n e s ------ ----------------------- 16 Booster Charge Type . . ...................... ....... Weight (grams) 228 Tetryl 38.2 changeable with parts of the same fuze made by another manufacturer. Use extreme care in handling these fuzes; some lots are dangerously sensitive. Refer to OP 1515 (Ammunition: Unserviceable, Limited-Use, and Suspended) before using AN-Mk 228 fuzes. These fuzes in externally carried stores are restricted in accordance with NAVORDINST 8024.25, latest issue. Explosive Components Figure 2—21.— Impact Tail Fuze A N -M k 228. Generol Description The detonator safe, delay armed tail fuze of this type, figure 2-22, is vane operated and arms after 1100 feet c f air travel. It functions upon impact through two indepen­ dent trains of 0.08-second delay. The fuze is now obsolete; it generally was used in con­ junction with armor-piercing bombs where the delay allowed penetration of the target before detonation. The fuze is bottle-shaped with a 16-blade arming-vane assembly attached to its outer end. A cylindrical extension, housing the booster, projects from the base of the fuze body. The designations Mod 0 and Mod 1 merely indicate different manufacturers. Because of the differences in manufacturing practices, however, the parts of a fuze made by one manufacturer are not necessarily inter- 2-50 This type of fuze contains two explosive trains for greater reliability. Each consists of a primer, a delay element, a relay, a det­ onator, an auxiliary booster lead-in, a booster lead-in, and a booster of approxi­ mately 38.2 grams (1.346 ounces) of tetryl. The booster is located at the base of the fuze body. Safety Features Each fuze is individually packed in a her­ metically sealed container. The arming mechanism is prevented from operating by a safety cotter pin, with a pull ring and instruction tag attached, which passes through the body of the fuze (bushing) and vane shaft. The fuze is detonator safe. The arming wire keeps the fuze unarmed until it is withdrawn when the bomb is released. This arming wire passes through the rear suspension lug of the bomb and arming bracket on the fuze, preventing ro­ tation of the arming-vane assembly. FUZES COTTER PIN ARMING-WIRE TUBE ARMING VANE ASSEMBLY BUSHING ARMING BRACKE1 VANE SHAFT COVER COVER OUTER GEAR VANE SHAFT EXTENSION INNER GEAR STRIKER PINION INNER GEAR CARRIER DETENT AND SHEAR PIN GUIDE PIN OUTER SLEEVE CARRIER INNER GEAR CARRIER LUG PRIMER FIRING-PIN EXTENSION DELAY ELEMENT FIRING f IN RELAY ARMING SHAFT DETONATOR INNER SLEEVE ROTOR AUXILIARY BOOSTER LEAD-IN BOOSTER LEAD IN SHAFT NUT BOOSTER 9HAFT SCREW BOOSTER CAP Figure 2-22.— Impact Tail Fuze A N -M k 228, Cross Section. N A V W E P S OP 2216 (V O L U M E 1) A small glass window, figure 2-23, in the side of the fuze permits visual examination of the unarmed or armed condition of the fuze mechanism. If unarmed, the upper surface of the striker and the lower edge of the gear cover are about flush with the top edge of the outer sleeve. If armed, the striker has moved away from the outer sleeve approximately 11/32 inch. Functioning General. When the bomb is dropped armed, the arming wire is withdrawn from the arming-vane assembly and the armingwire bracket, allowing the arming-vane as­ sembly to rotate. This rotation is trans­ ferred to the arming shaft, through a reduc­ tion-gear train, to arm the fuze. After 150 to 160 revolutions of the arming-vane assem­ bly, all elements of the explosive train are locked in alinement, and the fuze is armed. When the explosive components lock in the armed position, the arming-vane assembly will usually cease to rotate. If the armingvane assembly is forced to continue rotating, however, pins in the reduction-gear train will shear and the arming-vane assembly will be free to rotate with the no additional effect. Upon impact, inertia drives the striker toward the booster, forcing the firing pins into their respective detonators and firing the fuze. Arming. The revolving motion of the arming-vane assembly is transmitted through the vane-shaft and vane-shaft ex­ tension to the reduction-gear train. The reduction-gear train consists of an outer (movable) gear, an inner (stationary) gear, and a pinion. The outer gear has 23 teeth and is connected directly to the arming shaft. The inner gear has 22 teeth and is secured to the inner gear carrier. The inner gear carrier is prevented from revolving by the inner gear carrier lug, which is set into a recess on the inner sleeve. The outer and inner gears mesh with the pinion, which has an equal number of teeth on its outer and inner portions. As the pinion is driven around the outer and inner gears by the 2-52 arming-vane assembly, it forces the outei gear one tooth ahead each revolution. This results in a ratio of one turn of the outei gear to 23 turns of the arming-vane assem­ bly. The arming shaft, to which the outer gear is secured, is threaded into the shaft nut at its lower end. As the outer gear and arm­ ing shaft revolve, the arming shaft rises in the shaft nut until it is stopped by the shoulder on the shaft screw jamming with the shaft nut. The inner gear carrier and the striker are carried outward with the arming shaft by the collar and shear pin. When the arming shaft jams, the lug on the inner gear carrier is disengaged from the slot in the inner sleeve, freeing the inner gear carrier. The outer gear is prevented from rotating by the jammed shaft screw; therefore, the pinion will act to turn the lower gear carrier and lower gear. The guide pins prevent the striker from revolv­ ing with the inner gear carrier. The inner gear carrier houses the firing pin extensions. Below the inner gear car­ rier, within the inner sleeve, is the delay carrier— a circular cylinder which rotates around the shaft and which contains the firing pin, the primer, and the delay ele­ ment. A protruding lug is positioned on the upper end of the delay carrier, in the path of the inner gear carrier lug. Contact is made between these two lugs as the inner gear carrier revolves after freeing itself from the inner sleeve. Below the delay carrier is the rotor, which consists of a hub and two wing-shaped deto­ nator containers that project from the hub. The hub allows the detonator containers to rotate about the arming shaft. A lug on the delay carrier is positioned in the space be­ tween the detonator containers. As the inner gear carrier lug contacts the outer lug of the delay carrier, the delay carrier turns, contacting the rotor and ro­ tating it. When the inner gear carrier has traveled 170 degrees, the firing-pin exten­ sions and all components of the two explo­ sive trains are in alinement. At this point, detents lock the inner gear carrier to the FUZES striker, and also the delay carrier to the inner sleeve. The fuze is now fully armed. The arming-vane assembly has made between 150 and 160 revolutions, and the bomb has traveled the necessary 1100 feet along its trajectory. Action. Inertia, upon impact, forces the striker and inner gear carrier toward the booster, shearing the shear pin which runs through the supporting collar and arming shaft. The firing-pin extensions, protrud­ ing from the inner gear carrier, strike the firing pins, driving them into their primers. One firing-pin extension is slightly longer than the other; therefore the explosive com­ ponents are not initiated simultaneously. Greater reliability of fire results from this arrangement since all the force of the inner gear carrier and striker is directed onto one firing pin at a time. Detonation. The firing pins ignite the primers, and the flash from the primers sets off the delay elements. The delay elements set off the relays which, in turn, fire the detonators, the auxiliary booster lead-ins, the booster lead-ins, and the booster. Released Safe If it is necessary to release fuzed bombs over friendly territory, the aircraft arming controls are set in the SAFE position before the bombs are jettisoned. In this position, the arming wire is released from the bomb rack with the bomb. This prevents the arming-vane assembly from rotating and arming the fuze. The unarmed fuze will not function upon impact. Accidental Arming Recognition. The degree of arming can be seen through a small glass window on the side of the fuze. Examining the relative positions of the striker, the cover, and the outer sleeve affords an indication of the degree of arming. If the upper surface of the striker and the lower edge of the cover are about flush with the top edge of the sleeve, the fuze can be considered unarmed. If the position of the striker is not more than -y, (i inch away ARMED UNARMED Figure 2-23.— Impact Tail Fuze A N -M k 228, Indication of Armed Condition. from the outer sleeve, the fuze can be con­ sidered only partially armed. If the striker has moved away from the outer sleeve about n/ !2 inch, the fuze is to be considered fully armed. Handling. In the armed condition, all explosive components are alined with the firing pins and firing-pin extensions. A sharp blow to the arming-vane assembly may be severe enough to detonate the fuze. If a fuze is partially armed, the vanes should be taped to prevent further arming and turned over to authorized and qualified personnel. If a fuze is so distorted that it cannot be removed from the bomb, it must be considered armed. Tape the vanes to prevent further arming and turn both the bomb and the fuze over to authorized and qualified personnel. When removing an armed or partially armed fuze from a bomb, use the utmost caution. Do not jar either the bomb or the fuze. Fuzing 1. Remove the shipping plug from the bomb; inspect the fuze seat and threads. Clean if necessary. Make sure Auxiliary Booster Mk 1 Mod 0 is in place in the bomb. 2. Unseal the hermetically sealed con­ tainer and remove the fuze. Inspect its gen­ eral appearance. Check for bent armingvane assembly, damaged threads, or corro­ sion. Use only serviceable fuzes. 3. If there is no arming-wire bracket on the fin assembly of the bomb, it will be nec­ essary to attach one to the neck of the fuze. To do this, remove the cotter pin holding the arming-vane assembly to the vane shaft and remove the arming-vane assembly. 2-53 N A V W E P S OP 2216 (V O L U M E 1) CAUTION: Do not remove the safety cotter pin that locks the arming mechanism. Attach the arming bracket loosely to the neck of fuze. Replace the arming-vane as­ sembly and the cotter pin. Spread the ends of the cotter pin 180 degrees. 4. Screw the fuze into the bomb, handtight. A small spanner wrench may be used if necessary. 5. Rotate the arming bracket so that it will be in a vertical position when the bomb is placed in the rack; tighten the bracket. 6. Thread the arming wire through the rear suspension lug of the bomb and then through the arming bracket on the fuze. Be sure the arming-wire tube (the brass tube furnished with the bracket) covers the arm­ ing wire where it passes between the blades of the arming-vane assembly. 7. Adjust the wire to protrude 2 to 3 inches past the arming bracket on the fuze. Place two safety clips on the arming wire and push them up until they are just touch­ ing the arming bracket. Make sure the arming wire is free from kinks and burrs. Remove the safety cotter pin, passing it through the body of the fuze (bushing) and the vane shaft. Defuzing CAUTION: Before attempting to remove a fuze from a bomb, be sure that it is unarmed, or safe to han­ dle. The degree of arming can be determined through a small glass window in the side of the fuze by examining the relative positions of the striker, cover, and outer sleeve. If the upper surface of the striker and the lower edge of the cover are about flush with the top edge of the sleeve, the fuze can be con­ sidered unarmed. If the position of the striker is not more than 3/i 6 inch away from the outer sleeve, the fuze can be considered 2-54 only partially armed. If the striker has moved away from the outer sleeve about 11/z2 inch, the fuze is to be considered fully armed. See the preceding section on han­ dling for further information be­ fore proceeding further. 1. Replace and secure the safety cotter pin through the holes on the vane shaft and bushing directly behind the armingvane assembly. 2. Remove the two safety clips and also the arming wire from the fuze. 3. Unscrew the fuze from the fuze seat in the bomb. 4. Remove the arming bracket from the fuze, if one was fastened to the fuze during the fuzing operation. 5. Return the fuze to its packing; reseal the fuze container with adhesive tape. Packaging and M arking Fuze Container. One loaded fuze, com­ plete with arming-vane assembly, and two safety (Fahnestock) clips are packed in a hermetically sealed metal container. The fuze is stamped with the mark and mod number, lot number, year, manufacturer’s initials, and inspector’s initials. A typical fuze container is marked as follows. FUZE, BOMB, TAIL AN-M k 228 (Date Packed) Contract No. Manufacturer & Place loaded Weight: Loaded; Inspector’s Initials empty Lot No. Packing Box. Four fuzes in their metal containers are issued in one metal packing box weighing 60 pounds, the dimensions of which are 17.1 inches by 11.6 inches by 11.6 inches. The box is marked as follows. 4 TAIL FUZES BOMB, TAIL, AN-M k 228 Requisition No. Manufacturer Contract No. Inspector’s Initials Weight of Crate & Contents FUZES IM P A C T T A IL FUZE A N - M k 247 M od 0 M a r k ................................................. 247 Mod ___ __ ____ ___________ _ __ _ 0 Firing Action Inertia! Firing Delay ( s e c ) _____________ None General A rra n gem en t__________ 398792 Arming Type ...................... ..... .... .......... Direct Revolutions to Arm __________ 13 Air Travel to Arm (ft) 60 to 240 (depending upon launching conditions) Overall Length (in.) ....... ........ 4.6 Protrusion from Bomb (in.) 3.85 Vane Span (in.) _ ___________ _ 4.0 Weight (oz) ... 10 Number of V a n e s ______________ . 2 This type of impact tail fuze, figure 2-25, is vane operated and inertia fired, and re­ quires from 65 to 240 feet of air travel to arm, depending upon launching conditions. It acts instantaneously upon impact to det­ onate the signal of a practice bomb. These fuzes in externally carried stores are re­ stricted in accordance with NAVORDINST 8024.25, latest issue. fuzing operation. A safety cotter pin, with pull ring and instruction tag, attached ex­ tends through the fuze body. This cotter pin locks the arming mechanism and firing mech­ anism so that the fuze will not accidently detonate the signal during fuzing. The cot­ ter pin should not be removed until the fuze is completely installed and the arming wire attached. The fuze is shipped assembled to the practice bomb signal, less the blank cartridge. When this fuze is properly installed in a signal which, in turn, is in place in a bomb, the arming wire of the bomb prevents the arming-vane assembly of the fuze from ro­ tating and arming the fuze. The unarmed fuze cannot function. Explosive Components Functioning There are no internal explosive compo­ nents in this type of fuze since it serves only as a trigger for firing the signal in a prac­ tice bomb. The explosive elements are ex­ ternal; they consist of a black-powder-filled signal and a blank .38 caliber cartridge, both of which are shipped in the same container with the fuze. Upon impact, the fuze firing pin strikes the black cartridge and the exploding cartridge fires the signal. General. When the bomb is dropped ARMED, the arming wire is withdrawn from the fuze and retained in the bomb rack. This frees the arming-vane assembly which ro­ tates in the air stream. The arming-vane assembly arms the fuze after approximately 13 revolutions, which require from 65 to 240 feet of air travel depending upon launching conditions. When the arming-vane assembly completes ap­ proximately 25 revolutions, it is freed into the air stream. Upon impact, the fuze firing pin is driven into the blank cartridge, igniting the signal. Figure 2-24 .— Tail Fuze A N -M k 247 Mod 0. General Description Safety Features Since the fuze is inert, it is safe to handle. The blank cartridge is not installed until the 2-55 N A V W E P S OP 2216 (V O L U M E 1) VANE HUB ARMING-VANE ASSEMBLY COTTER PIN ARMING /VIRE GUIDE ARMING SCREW FIRING PL'JNGER COTTER P IN 1 ANTICRI EP Figure 2-25 .— Impact Tail Fuze A N -M k 247, Cross Section. 2-56 FUZES Arming. The arming-vane assembly is connected to the arming screw, which is threaded into the firing plunger. As the arming-vane assembly rotates, it causes the arming screw to unscrew itself from the firing plunger. This raises the armingvane assembly outward from the fuze. The firing plunger rides vertically in the fuze body. It is prevented from rotating by a pin passing through the fuze body and into a vertical groove in the firing plunger. The anticreep spring supports the weight of the plunger, the arming screw, and the arming-vane assembly. The spring is strong enough only to offset this weight; any added force will cause the spring to compress and the firing plunger to ride toward the blank cartridge in the signal. Until the arming-vane assembly has made the necessary 13 revolutions, the fuze cannot fire the signal. This is because the armingvane assembly has not raised sufficiently from the fuze to allow the firing plunger and pin to reach the blank cartridge. When 13 revolutions are completed, the plunger can move inward far enough to allow the firing pin to strike the blank cartridge. Continued rotation of the arming-vane assembly causes the arming screw to free itself from the firing plunger. Both the arming-vane as­ sembly and the arming screw are released into the airstream. Action. When the bomb strikes a target, the inertia of the firing plunger compresses the anticreep spring and drives the plunger toward the blank cartridge. Detonation. The firing pin strikes the blank .38 caliber cartridge which ignites the signal. Released Safe When the bomb is released SAFE, the air­ craft arming controls are set in the SAFE position. The arming wire is then released with the bomb when the bomb is jettisoned. With the arming wire in place, the armingvane assembly cannot rotate and arm the fuze. The unarmed fuze will not function on impact. Accidental Arming Recognition. If the arming-vane assem­ bly and the arming screw are missing, or if the arming-vane assembly is raised from the fuze V2 inch or more, the fuze is armed. Handling. An armed fuze which is in place in a signal can be made safe for han­ dling by inserting the original cotter pin or a duplicate through the fuze body. This will lock the firing plunger in place. The fuze and signal then can be removed from the bomb and separated. The fuze is safe to handle once it is re­ moved from the signal since it contains no explosive. Salvaging. Armed or partially armed fuzes may be returned to their original con­ dition by rotating the arming-vane assem­ bly counterclockwise until the holes in the fuze body, the firing plunger, and the arm­ ing screw aline. Lock the fuze in this posi­ tion by passing the cotter pin through the holes and securing it. Fuzing 1. Remove the thumb nuts, lockwashers, and C-plate from the two studs next to the opening in the tail of the bomb. 2. Unpack from the corrugated carton Practice Bomb Signal Mk 7 Mod 0 with Tail Fuze Mk 247 Mod 0 attached, the arming-vane assembly of the fuze, and the cotter pin and blank .38 caliber cartridge which are sealed in an envelope in the car­ ton. 3. Check the signal and fuze for any physical defects; look for dented parts. 4. Place the arming-vane assembly on the arming screw of the fuze and adjust it so that the holes in the vane hub aline with those in the arming screw. Insert the cotter pin provided through the holes and secure it by spreading its ends. 5. Loosen the locknuts on the fuze and unscrew it from the signal; insert the blank .38 caliber cartridge provided into the car­ tridge chamber of the signal. Rescrew the fuze into the signal; tighten the locknuts downward until they join. 2-57 N A V W E P S OP 2216 (V O L U M E 1) 6. Insert the fuzed signal into the open­ ing in the tail of the bomb; adjust the sig­ nal so that the hole in the arming-wire guide of the fuze is in line with the rear sus­ pension lug of the bomb. Seat the signal firmly. 7. Place the C-plate around the fuze and over the signal; secure the C-plate with thumb nuts and lockwashers; tighten the thumb nuts finger tight. 8. Thread the arming wire through the rear suspension lug of the bomb, the armingwire guide, and the arming-vane assembly of the fuze. 9. Place the two safety clips on the end of the arming wire. Move the clips up the wire until they touch the arming-vane as­ sembly. Be sure the wire is free of kinks and burrs. 10. Pull the safety cotter pin from the fuze body. Defuzing CAUTION: Before removing a fuzed signal from a bomb, be sure it is unarmed, or safe to handle. If the arming-vane assembly and the arming screw are missing, or if the arming-vane assembly is raised from the fuze i/u inch or more, the fuze is armed. See the para­ graph, Accidental Arming, in the preceding section for information on handling before proceeding fur­ ther. 2. Remove the safety clips from the arm­ ing wire. Withdraw the arming wire from the arming-vane assembly and the armingwire guide. 3. Loosen the thumb nuts and remove the C-plate from around the fuze and the sig­ nal. Withdraw the fuzed signal from the bomb. Replace the C-plate, thumb nuts, and lockwashers. 4. Loosen the locknuts at the base of the fuze; unscrew the fuze from the signal. 5. Remove the blank cartridge from the cartridge chamber of the signal. Rescrew the fuze into the signal; tighten the locknuts of the fuze. 6. Remove the cotter pin from the armingvane assembly and arming screw of the fuze. Remove the arming-vane assembly from the fuze. 7. Return the signal, with attached fuze, arming-vane assembly, blank cartridge, and cotter pin to the cardboard container. Re­ seal the container with adhesive tape. Packaging Fuze Container. Each fuze comes assem­ bled to Practice Bomb Signal Mk 7 Mod 0, less the blank cartridge. The arming-vane assembly of the fuze is detached and placed next to it in the carton. The cotter pin and blank .38 caliber cartridge are placed in an envelope and are also packed in the fuze carton which is made out of corrugated card­ board. Packing Box. Twelve cartons, each con­ 1. Insert the safety cotter pin through taining a fuze, a signal, and accessories, are the fuze body and secure it in place. packed in a 20-mm ammunition box. 2-58 FUZES L O N G -D E L A Y T A IL FUZE A N -M 1 2 3 , A N -M 1 2 3 A 1 , A N -M 1 2 4 , A N -M 1 2 4 A 1 , A N D M125A1 Figure 2-26.— Long-Delay Tail Fuzes A N -M 123A 1, A N -M 124 A 1 and A N-M 125A1. M od el............ Firing Action__________ Firing Delay (hr)____ Assembly Drawing No__ Arming: Type--------------------Air Travel to Arm (ft). Overall Length (in.)____ Protrusion from Bomb (in.). Body Diameter (in.) Vane Span (in.) _ _ Weight (lb)__ _________ Number of Vanes. ____ Detonator Designation. AN-M123A1____ . . . . . Chemical long-delay or instantaneous on attempted withdrawal. 1-44________ _________ 73 8 109 ____ 73-8-170_____ _ . ___ AN-M124A1____ . . . Chemical long-delay or instantaneous on attempted withdrawal. 1-44____________________ 73-8-169________________ 73-8-170.. . . . . . ____ AN-M125A1. Chemical long-delay or stantaneous on attempted withdrawal. 1-44. 73-8-169. 73-8-170. Direct______ ____ Less than 100____ ____ __ Direct _________ ______ Less than 100.. . . ___ Direct. Less than 100. 9.24 . 6.24 ____ 12.24 .................. 9.24____________________ 16.24. 13.24. 1.3. ___________________ 5,0 3 .1 _______ _________ . . . . 8____ M19A2_________________ 1.3. 5.0. 3.4. 8. M19A2. _________ 1.3 . ... . _____ . 5.0 2 .9 ______ ____ . . . . 8_______________________ M19A2___ . . . ____ . . . 2-59 N A V W E P S OP 2216 (V O L U M E 1) SAFETY CAP ARMING STEM- FUZE BODY AMPOULE RETAINER STEM COLLAR SOLVENT AMPOULE- ■ RETAINER LOCKING NUT LOCKNUT- RETAINER SEALING CUP FIRING-PIN SCREW DELAY WAD CELLULOID DELAY COLLAR FIRING-PIN BALLS FIRING-PIN SPRINGCLIP- SLEEVE SPRING SLEEVE FIRING PIN­ SLEEVE BALLS SEALING DISC -LOCKING BALL WASHER FUZE BODY EXTENSION TOR HOLDER------------------- - Figure 2-27. — Long-Delay Tail Fuze A N -M 1 2 3 A 1 , Cutaway View. 2-60 DETONATOR FUZES General Description Explosive Components The vane operated, long-delay tail fuzes of this type, figure 2-27, are designed for limited use only. These fuzes in externally carried stores are restricted in accordance with NAVORDINST 8024.25, latest issue. These fuzes incorporate an antiwith­ drawal device. The fuzes act to detonate the bomb after a delay of from 1 to 144 hours; specifically: 1, 2, 6, 12, 24, 26, 72, and 144 hours. Less than 100 feet of air travel is necessary to initiate this delay action. Any attempt to unscrew these fuzes will result in the functioning of the antiwith­ drawal mechanism, followed by instan­ taneous detonation. The detonator is the only explosive ele­ ment used in these fuzes. It is contained in the detonator holder and is always in line with the spring-loaded firing pin. The det­ onator holder screws into the base of the body extension. The detonator and detona­ tor holder are not assembled in the fuze as issued, and must be installed prior to the bomb fuzing operation. WARNING Once installed, no attempt shall be made to remove these fuzes from bombs. Long-Delay Tail Fuzes AN-M123A1, A N M124A1, and AN-M125A1 differ in overall length so that the same type fuzes can be used in various size bombs. The differences in length are necessary to locate the arming vanes properly in the air stream. Each fuze of the series has a nominal delay-firing time of 1, 2, 6, 12, 24, 36, 72, or 144 hours; this nominal time is indicated on the fuze. This type of fuze is particularly responsive to heat and cold; high temperatures acceler­ ate its action while low temperatures retard it. Temperature effect must be taken into consideration when selecting a fuze of any particular delay. See the following table, Delay Times of Long-Delay Tail Fuzes for the effects of temperature on delay times. These fuzes differ from the earlier A N M123, AN-M124, and AN-M125 fuzes in that the AN-M123 series has reduction gear­ ing and 4-bladed arming vanes. It also requires 80 to 100 feet to initiate delay ac­ tion and 900 to 1800 feet to seal the fuzes against leakage of solvent or entrance of moisture. The AN-M123A1 series has no reduction gearing, has 8 vanes, and requires less than 100 feet both to initiate the delay action and to seal the fuze. Restrictions Return of bombs to airfields or carriers is restricted. Bombs with this type of fuze may be returned to airfields or carriers pro­ vided that the following conditions prevail. 1. Bomb rack malfunction prevents re­ lease. 2. Efforts to release by maneuvering of aircraft are unsuccessful. 3. Bombs and fin assemblies are undam­ aged and fuze arming wires are in place as observed by check of aircraft before landing. Fuzed bombs are immediately disposed of by qualified and authorized personnel upon landing of aircraft. NO ATTEMPT SHALL BE MADE TO REMOVE FUZES FROM BOMBS. Special M arking of Bombs When this type o f fuze is used with the possibility of return to airfields or carriers, special marking of bombs or fuzes is au­ thorized if, in the judgment of the cogni­ zant officer, safety considerations outweigh any possibility of enemy forces being able to identify long-delay fuzed bombs more readily. Hung Bombs When hung bombs are carried away in landing or separate from the aircraft during takeoff because of malfunction of gear, the resulting shock of impact may break the glass ampoule solvent containers in fuzes of this type. Under such conditions of acci­ dental release, the fuze firing delay period allows time for the disposal of bombs. See the following table, Delay Times of Long2 -6 1 N A V W E P S OP 2216 (V O L U M E 1) Delay Tail Fuzes AN-M123 series, for the effect of temperature on delay times. nator holder, a shipping plug is seated in the fuze body extension. This makes the fuze safe for handling. Bomb Disposal Time The fuze body extension is prevented from unscrewing by a wire safety clip which locks the fuze body extension to the fuze body. This clip is not removed until the fuze is prepared for installation in a bomb. A safety pin, held in place by a sealed safety wire, locks the clip disc and prevents the arming stem from rotating and arming the fuze. Four instruction tags are attached to the fuze. As indicated by the following table, Delay Times of Long-Delay Tail Fuzes AN-M123 series, the minimum time available for clear­ ing fuzed bombs under accident conditions will depend upon fuze delay and tempera­ ture. For example, action to complete a bomb removal and disposition must be taken within 15 minutes for fuzes having a time delay of 1 hour when the fuze temperature is estimated to be 115° F. The packing box, containing the fuzes, has indicator vials disclosing the various tem­ perature ranges to which the fuzes have been subjected during shipping and stowage. This system of indicator vials will prevent the use of fuzes which have experienced temperatures rendering them dangerous to handle. Effect of Temperature on Delay Action These fuzes are responsive to changes in temperature. Temperatures above 50° F cause them to function earlier than specified; temperatures below 50° F cause them to function later than specified. The following table gives the average actual delay in hours and minutes at various temperatures, and must be consulted when selecting a fuze for a particular delay. When the fuze is installed in a bomb, the arming wire prevents the arming stem from rotating and initiating the delay action. This is the only safety feature afforded these fuzes once they are installed. At­ tempted withdrawal or tampering with these fuzes will cause the fuze to detonate the bomb. Severe shock may cause the glass ampoule to be broken prematurely and begin the delay action before desired. Safety Features Each fuze is packed in an individual metal container during shipping and stowage. Until the fuzing operation the detonator holder, containing the detonator, is not as­ sembled in the fuze. In place of the deto­ Delay Times of Long-Delay Tail Fuzes A N - M 1 2 3 Series T e m p e r a t u r e (d e g r e e s A v e r a g e d e l a y (h r h a v in g 1 hr 2-62 a c t u a l F) 2 hr 6 hr : m in ) a t n o m in a l 12 h r 0:15 0:20 0:20 0:50 1:00 1:30 1:15 2:30 0:30 0:45 2:12 1:00 1:30 3:15 2:00 3:00 11:00 3:50 9:00 30:00 v a r io u s d e l a y s 24 h r t e m p e r a t u r e s o f f o r f u z e s : 36 hr 72 hr 144 h r 8:00 15:00 38:00 70:00 24:00 37:00 96:00 135:00 FUZES Safety Precautions The following precautions must be ob­ served in handling these fuzes. The detonator holder must not be assem­ bled to fuzes, and fuzes must not be assem­ bled to bombs in anticipation of future needs. Particular care must be taken to protect these fuzes from heat and shock. Examine the indicator vials when the fuze jacking box is opened. If all fuzes in the box are not used, leave the vials in the box with the remaining fuzes and reinspect them when the box is reopened. When engaging threads of mating parts in assembling this fuze to a bomb, do not turn one part back and forth until the threads engage. Use a “ screwing-in” motion only. The antiwithdrawal device will cause the fuze and bomb to detonate if the fuze is ro­ tated counterclockwise while in the adapterbooster, even before the threads are engaged. Functioning General. When the bomb is dropped ARMED, the arming wire is withdrawn from the arming-vane assembly, stem disc, and clip. The freed arming-vane assembly rotates in the air stream. After completion of less than 100 feet of air travel, the fuze is armed and sealed against the entrance of moisture and the escape of solvent. Impact produces no effect upon the armed fuze. The fuze does not act to explode the bomb until the delay time has expired, fig­ ure 2-28, or until someone attempts to de­ fuze the bomb. Arming. The arming-vane assembly is connected directly to the arming stem by means of the safety catch. At its lower end, the arming stem is threaded into the re­ tainer locking nut and ampoule retainer. As the arming-vane assembly turns the arming stem, the stem is screwed into the ampoule retainer and ampoule-retainer nut. After a short air travel, the stem, moving into the fuze body, crushes the solvent am­ poule and frees the solvent. With additional air travel, the arming stem progresses far enough to force the stem collar against the retainer locking nut. This action seals the outer end of the fuze body to prevent the escape of solvent or the entrance of moisture. 2-63 N A V W E P S OP 2216 (V O L U M E 1) Action. The solvent from the crushed ampoule filters through the delay wad to contact the celluloid delay collar. It is this celluloid delay collar that is the key to the locking arrangement of the spring-loaded fir­ ing pin. The firing-pin balls are wedged between the head of the firing-pin screw and the sleeve. These balls lock the firing pin in place against the action of the compressed firing-pin spring. The celluloid delay collar prevents the firing-pin balls from being forced outward. Antiwithdrawal. If any attempt is made to remove the fuze from the bomb before the delay time has expired, the antiwithdrawal device will detonate the fuze. The following characteristics and mecha­ nisms of the fuze are related to the anti­ withdrawal feature. The body assembly consists of two parts, the fuze body and the fuze body extension. The fuze body contains the firing pin and sleeve assembly, the delay wad, and also the solvent-filled ampoule. The body ex­ tension contains the detonator holder, which is screwed into the base. An off-centered circumferential groove is machined into the outer surface of the body extension. This groove contains the locking ball, used in con­ junction with the antiwithdrawal mecha­ nism. The sleeve within the fuze body is held in place against the- action of the compressed sleeve spring by the sleeve balls. These balls are wedged between the sleeve shoulder and the body-extension shoulder and are held in place by the lips of the fuze body. Since the ball groove of the fuze body extension is machined off-center, the lock­ ing ball is forced outward when the fuze is turned' counterclockwise. This action wedges the ball between the adapter-booster wall and the fuze body extension, thus lock­ ing the fuze body extension in place. Any further counterclockwise rotation unscrews the fuze body extension from the fuze body. When the fuze body has been separated from the fuze body extension inch, the sleeve balls are released and move outward. The sleeve and firing-pin assembly are driven 2-64 forward as a unit by the sleeve spring, caus­ ing the firing pin to puncture the sealing disc and strike the detonator. As further insurance against withdrawal, the adapter-booster of current design is drilled for the insertion of a metal locking pin supplied with the fuze. When this pin is in place, the adapter-booster is locked to the base plug of the bomb, thus preventing removal of the fuze by the unscrewing of the adapter-booster. Detonation. When the firing pin punc­ tures the sealing disc and the detonator, the detonator explodes, setting off the booster and the bomb. Accidental Arming Recognition. From outward appearances there is no way of determining definitely whether these fuzes are armed or are in a safe condition. The best policy is to regard them as being armed at all times. Any fuze that has been dropped from a height of 10 feet or more, or has had its arming-vane assembly free to rotate, must be disposed of as quickly as possible by authorized and qualified personnel. Handling. If the red-stoppered indicator vial in the fuze packing box shows that the fuzes have been subjected to temperatures over 170° F, the fuzes must be destroyed by authorized personnel. Return of bombs to airfields or carriers is restricted. CAUTION: Bombs fuzed with AN-M123A1, AN-M124A1, or AN-M125A1 fuzes cannot be re­ leased SAFE. Impact will cause the solvent ampoule to shatter and to initiate the delay train, even with the arming wire in place. In the event of incomplete missions, these fuzed bombs are to be jet­ tisoned over enemy territory or deep water. Once installed, no at­ tempt shall be made to remove the fuzes from the bombs. Fuzing Inspection Prior To Use. There are two indicator vials packed in each box of fuzes. FUZES Each of these vials contains a powder which melts at a critical temperature. When a box of fuzes is opened, inspect the vials and proceed as follows. 1. If the powder in the green-stoppered vial has solidified, it indicates that the fuzes have been subjected to temperatures higher than 150° F. This temperature causes the powder to melt; it solidifies into a homo­ geneous mass upon cooling. CAUTION: Use none of the fuzes in this box for low-altitude bomb­ ing. 2. If the powder in the red-stoppered vial is solidified, it indicates that the fuzes have been exposed to temperatures above 170° F. This temperature causes the powder in this vial to melt; solidification occurs upon cool­ ing. CAUTION: Make no attempt to install detonators in fuzes of this box. Fuzes must be disposed of by authorized personnel. 3. If there is any doubt whether the powder in either vial is solidified, open the vial and inspect its contents. Personnel handling these fuzes should be able to differ­ entiate between powdered and solidified con­ dition of the two vials. This is best learned by removing some powder from each vial, melting it, and allowing it to solidify. Installing the Fuze. 1. Remove the fuze and its components from the container and inspect the general condition. Back off the locknut and then replace it to make sure the threads are clean and undamaged. 2. Hold the fuze body extension during the rest of the operation to prevent separation of the fuze body extension from the fuze body. 3. Remove the tape and shipping plug from the end of the fuze body extension. 4. Insert the sealing disc (aluminum or copper) into the end of the fuze. Be sure this disc rests on the shoulder of the fuze body extension. If the firing pin inter­ feres with the seating of the disc, do not use the fuze. 5. Insert the washer over the disc. 6. Screw the detonator holder into the body extension and tighten with the wrench supplied in the box of fuzes. Since the pur­ pose of the disc and washer is to seal the fuze against escape of solvent and entrance of moisture. Care must be taken to seat the detonator holder firmly. 7. Remove the safety clip. After the safety clip is removed, particular care must be taken to prevent the fuze body extension from unscrewing from the fuze body. WARNING The fuze will detonate if the exten­ sion is unscrewed by any amount. 8. If the bomb is not fitted with an adap­ ter-booster listed on the lockpin instruction tag, the adapter-booster that is assembled to the bomb must be staked to the base plug staked to the bomb body. Use nonsparking tools for the staking operation. 9. Gage the adapter-booster threads with the proper gage, or insert the fuze (any standard tail fuze, except one of the type with an antiwithdrawal device, without a primer-detonator may be used). 10. If the bomb is fitted with the listed adapter-booster, insert the lockpin (supplied with the fuze) into the hole in the adapterbooster. 11. Be sure the locknut is screwed all the way into the fuze. Then carefully insert and screw the fuze as far as possible into the adapter-booster. Tighten the locknut with the wrench supplied in the box of fuzes. WARNING Once the fuze is inserted in the adapter-booster, the fuze must not be turned backward (counterclock­ wise) by any amount, however slight. Engage the threads by a screwing-in motion only. Do not attempt to unscrew the fuze; screw­ ing-out motion will cause the lock­ ing ball to become wedged against 2-65 N A V W E P S OP 2216 (V O L U M E 1) the wall of the adapter-booster and any further turning will detonate both the fuze and the bomb. 12. Remove the safety catch from the clip disc; position the arming-vane assembly so that the hole in the vane cap is alined with the hole in the clip disc. 13. Replace the safety catch and secure the hook end. 14. After threading the arming wire through the rear bomb suspension lug, pass it through the clip, the stem disc, the clip disc, and the arming-vane assembly, re­ spectively. Adjust the arming wire to pro­ trude 2 to 3 inches beyond the arming-vane assembly. Place two safety clips on the arm­ ing wire and slide them up until the inner one touches the arming-vane assembly. Be sure the arming wire is free of kinks and burrs. 15. Remove the safety pin. If it is in­ tended to keep the fuze SAFE until the plane is airborne, replace the safety pin with the cotter-pin pull-ring assembly provided with the fuze. Remove the cotter pin while the plane is in flight. 16. Bombs fuzed with AN-M123A1, A N M124A1, and AN-M125A1 type antiwith­ drawal fuzes must be used on the mission for which they are fuzed. In the event of incomplete missions, unused bombs must be dropped over enemy territory or into deep water. Once installed, no attempt shall be made to remove these fuzes from bombs. Return of bombs to airfields or carriers is restricted. CAUTION: If anything interferes with the completion of the fuzing operation, no attempt shall be made to defuze the bomb. The bomb, with the fuze in place, shall be dis­ posed of by authorized personnel. See instructions for handling in the preceding section before proceeding further. Defusing NO ATTEMPT SHOULD BE MADE TO DEFUZE A BOMB ASSEMBLED WITH 2-66 AN-M123A1, AN-M124A1, or AN-M125A1 FUZES. THE COUNTERCLOCKWISE MOTION NECESSARY TO REMOVE THE FUZE WILL CAUSE THE ANTIWITH­ DRAWAL MECHANISM TO FUNCTION AND THE FUZE AND BOMB WILL DET­ ONATE. Packaging and M arking Fuze Marking. Marking on the body of the fuze is located just below the threads and includes nomenclature, nominal delay, lot number, and date loaded. In addition, four tags attached to the fuze read as fol­ lows. 1. For the cotter pin pull ring assembly: “ For use if safety pins are to be removed after the plane is airborne.” 2. Around the stem tube: “ DANGER never remove this tag. This fuze contains a booby trap. NEVER ATTEMPT TO RE­ MOVE THIS FUZE FROM THE BOMB.” 3. For the adapter-booster lock pin: “ This pin is used for the adapter-booster on the following bombs: GP 100-lb., AN-M30A1 and GP 250-lb., AN-M57A1.” (This infor­ mation will alter as applicable.) 4. The fourth tag contains some of the instructions given in the fuzing operations. Fuze Container. One fuze, less its arming vane, is sealed in a cylindrical black metal container. The detonator holder, washer, and sealing disc are packed in the same con­ tainer and are fitted into a drilled-out por­ tion of a wood block. A key is soldered to the bottom o f the can to facilitate opening the sealed container. The following is a typical fuze container marking. FUZE, BOMB, TAIL, AN-M123A1 LESS ARMING VANES (date packed) Drawing No. REV. (date) Packing Box. Twenty-five containers, with 25 vane assemblies on a spindle, are packed in a wood box. Each packing box contains two indicator vials, two wrenches, and a thread gage. These fuzes may also be packed 24 to a box, in which event all FUZES accessories will be included, or the box may contain 25 fuzes, but no wrenches or thread gage. The following is a typical packing box marking. 25 TAIL FUZES BOMB, TAIL, AN-M123A1 PACKED (month and year) LOT NO. 2-67 N A V W E P S OP 2216 (V O L U M E 1) L O N G -D E L A Y T A IL FUZE A N -M 1 3 2 , A N -M 1 3 3 , A N D A N -M 1 3 4 M133 M132 M134 Figure 2-29. — Long-Delay Tail Fuzes AN-M132, A N -M 1 33, and A N -M 1 34. General Description The vane operated, long-delay tail fuzes of this type, figure 2-30, are delay armed and incorporate an antiwithdrawal feature. Approximately 100 feet of air travel is nec­ essary for arming. These fuzes in externally carried stores are restricted in accordance with NAVORDINST 8024.25, latest issue. All fuzes in this group have the same de­ lay rating; they act to detonate the bomb 2-68 16 minutes after arming at a temperature of 80° F. The delay time will vary with changes in temperature; high temperature will accelerate it and lower temperature will retard it. WARNING Once installed, no attempt shall be made to remove these fuzes from bombs. Any attempt to remove them will cause the antiwithdrawal FUZES Model_______________ Firing Action________ Firing Delay (min)___ Assembly Drawing No. Arming: Type-----------------Air Travel to Arm (ft)----------------Overall Length (in .)... Protrusion from Bomb (in.)---------------------Vane Span (in .)... . . Weight (lb) _____ . Number of Vanes____ Detonator Designation- AN-M132________ Chemical long-delay or instantaneous on attempted withdrawal. 16 at 80° F _______ 73-8-199_________ AN-M133________ Chemical long-delay or instantaneous on attempted withdrawal. 16 at 80° F _______ 73-8-199_________ AN-M134. Chemical long-delay or instantaneous on attempted withdrawal. 16 at 80° F. 73-8-199. Direct.................. . D ir e c t________ Direct. 100_______________ 9.57______________ 100_______________ 12.57_____________ • 100. 16.57. 6.57______________ 5 .0 _______________ 2 .1 _______________ 4_________________ M19A2___________ 9.57______________ 5 .0_______________ 2 .3 _______________ 4_________________ M19A2___________ 13.57. 5.0. 2.6. 4. M19A2. device to detonate the fuze instan­ taneously. Long-Delay Tail Fuzes AN-M132, A N M133, and AN-M134 differ in overall length so that the same type of fuze can be used in various size bombs. The differences in length are necessary to locate the arming vanes properly in the air stream. The M4 and M5 arming-vane assemblies are used with these fuzes. For shorter arm­ ing distances, the standard vane M4 (45degree pitch) is used; for longer arming distances, the M5 vane (75-degree pitch) is used. At present, only the M4 vane is issued with these fuzes. Separate action is necessary to requisition the M5 vane. Explosive Components The detonator is the only explosive ele­ ment used in these fuzes. It is contained in the detonator holder and is always in line with the spring-loaded firing pin. The deto­ nator and detonator holder are not assem­ bled in the fuze as issued, and must be in­ stalled prior to the bomb fuzing operation. . 2. Efforts to release by maneuvering of aircraft are unsuccessful. 3. Bombs and fin assemblies are undam­ aged and fuze arming wires are in place as observed by check of aircraft before landing. Fuzed bombs are immediately disposed of by authorized and qualified personnel upon landing of aircraft. NO ATTEMPT SHALL BE MADE TO REMOVE FUZES FROM BOMBS. Special M arking of Bombs When this type of fuze is used with the possibility of return to airfields or carriers, special marking o f bombs or fuzes is au­ thorized if, in the judgment of the cognizant officer, safety considerations outweigh any possibility of enemy forces being able to identify long-delay fuzed bombs more readily. Hung Bombs When hung bombs are carried away in landing or separate from the aircraft dur­ ing takeoff because of malfunction of gear, the resulting shock of impact may rupture the metal bellows solvent containers in these Restrictions fuzes. Under such conditions of accidental Bombs having this type of fuze may be release, the fuze firing delay period allows returned to airfields or carriers provided time for the disposal of bombs. See the that the following conditions prevail. following table, Delay Times of Long-Delay 1. Bomb rack malfunction prevents re­ Tail Fuzes, Type II, for the effect of tem­ lease. perature on delay times. 2-69 N A V W E P S OP 2216 (V O L U M E 1) VANE HUB- VANE NUT BEARING CUPMOVABLE GEAR CARRIER- ARMING-VANE ASSEMBLY PINION­ EYELET PIN STATIONARY GEAR CARRIER' BEARING-CUP EYELET ARMING-STEM CUP MOVABLE GEAR ARMING oTEM TUBE STATIONARY GEAR CARRIER STOP ARMING STB FUZE HEAD ARMING-STEM COLLAR BELLOWS PLUNGER LOCK NUT BELLOWS HOLDER BELLOWS SEALING CUP FUZE BODY FELT WASHER DELAY HOLDER CLLLULOID CYLINDER CLOSING SCREW ARMING HOUSING CLOSING-SCREW WASHER FIRING-PIN SPRING EIRING-PIN BALL LOCKING BALL FIRING PIN- SEALING WASHER DETONATOR- — DETONATOR HOLDER Figure 2-30. — Long-Delay Tail Fuze AN-M 132, Cross Section. 2-70 FUZES Bomb Disposal Time As indicated by the following table, Delay Times of Long-Delay Tail Fuzes AN-M132, AN-M133, and AN-M134, the minimum time available for clearing fuzed bombs under accident conditions will depend upon fuze temperature. For example, action to complete bomb removal and disposition must be taken within 6 minutes for this type of fuze when the fuze temperature is estimated to 120° F. Effect of Temperature on Delay Action These fuzes are responsive to changes in temperature. They are rated as having a 16-minute delay at 80° F. Higher tempera­ tures cause the fuze to function earlier than specified; lower temperatures retard its functioning. The following table gives the average actual delay in minutes at various temperatures and should be consulted before using the fuze. Delay Times of Long-Delay Tail Fuzes AN-M132, AN-M133, and AN-M134 fuze head. This safety clip prevents rota­ tion between the fuze head and the fuze body. A safety screw located in the fuze body locks the firing mechanism in position. The safety clip and safety screw prevent premature activation of the antiwithdrawal mechanism. A safety pin locks the bearing cup to the arming-stem cup until fuzing, pre­ venting operation of the delay arming mech­ anism. The packing box in which the fuzes are shipped contains indicator vials that show the various temperature ranges to which the fuzes have been subjected during ship­ ping and stowage. This prevents the use of those fuzes which have experienced tem­ peratures rendering them dangerous to handle. When the fuze is installed in a bomb, the arming wire prevents the arming stem from rotating and arming the fuze. This is the only safety feature afforded these fuzes once they are installed. Attempted with­ drawal or tampering will cause the fuze to detonate the bomb. P revailing T emperature A verage D elay D egrees (F ) (M in u t e s ) 120 6 100 10 80 16 60 26 40 40 20 59 10 _________ 80 Safety Features Each fuze is packed in an individual metal container. The detonator holder containing the detonator is not assembled in the fuze as issued, and the detonator-holder cavity in the fuze base is plugged with absorbent cotton. This leaves the fuze inert at all times during shipping and stowage. The cotton will show leakage of solvent prior to fuzing by being stained red, indicating fuzes that are unserviceable. During shipping and stowage, these fuzes are equipped with a safety clip having two studs. One stud engages a hole in the fuze body and the other engages a hole in the Figure 2-31. — Long-Delay Tail Fuze A N -M 1 32, As Shipped, Defail. 2-71 N A V W E P S OP 2216 (V O LU M E 1) Safety Precautions The following precautions must be ob­ served in handling these fuzes. The detonator holder must not be assem­ bled to fuzes, and fuzes must not be assem­ bled to bombs in anticipation of future needs. Particular care must be taken to protect these fuzes from heat and shock. Examine the indicator vials when the fuze packing box is opened. If all fuzes in the box are not used, leave the vials in the box with the remaining fuzes and reinspect them when the box is reopened. When engaging threads of mating parts in assembling this fuze to a bomb, do not turn one part back and forth until the threads engage. Use a screwing-in motion only. The antiwithdrawal device will cause the fuze and bomb to detonate if the fuze is rotated counterclockwise while in the adapter-booster, even before the threads are engaged. The warning tag attached to this fuze should not be removed when the fuze is assembled to the bomb. Functioning General. When the bomb is dropped ARMED, the arming wire is retained in the bomb rack and withdrawn from the fuze. This frees the arming-vane assembly which rotates in the air stream. The revolving motion of the arming-vane assembly is trans­ mitted through the reduction gears to initi­ ate the time train, arming the fuze. Ap­ proximately 100 feet of air travel along the trajectory of the bomb is necessary to com­ plete this operation. Impact will not cause the fuze to detonate. Detonation will take place when the delay time has run out or when an attempt is made to remove the fuze from the bomb. Such an attempt will cause the anti withdrawal device to detonate the fuze instantaneously. Arming. The arming-vane assembly is assembled to the bearing cup by the vane nut. Eyelet pins, which fit into notches in HEAD BODY LOCKING BALL A Figure 2-32.— Long-Delay Tail Fuze A N -M 1 32, Defails of Operation. 2-72 FUZES the vane hub, insure positive rotation of the bearing cup with the arming-vane assembly. Delay arming is obtained by a reduction gear train between the arming-vane assem­ bly and the arming stem. The ratio is one revolution of the arming stem to 30 revolu­ tions of the arming-vane assembly. The reduction-gear train is composed of a pin­ ion, a movable gear, and a stationary gear. The movable gear has 30 teeth while the stationary gear has 29. The idler gear (pin­ ion) is driven around the stationary and movable gears by the bearing cup and the arming-vane assembly. Since the movable gear contains one more tooth than the sta­ tionary gear, the pinion pushes the movable gear one tooth forward each complete revo­ lution. When the pinion has completed 30 revolutions, the movable gear has completed one. The movable gear is connected to the arming stem through the movable-gear car­ rier. The stationary gear is secured to the stationary-gear carrier, which is prevented from rotating by the carrier stop. The lower end of the arming stem is threaded into the bellows plunger. The arm­ ing-stem collar is pinned to the arming stem to prevent any axial movement of the arming stem. As the arming stem revolves, it is unscrewed from the bellows plunger. This forces the bellows plunger inward, com­ pressing the bellows and puncturing the sealing cup. The solvent contained in the compressed bellows is forced out through the bellows holder. The fuze is now armed. Delayed Action. The delay element con­ sists of a celluloid cylinder seated within three felt washers. The freed solvent filters through openings in the delay holder and is then absorbed by the felt washers. The celluloid cylinder serves as a lock for the firing mechanism. The firing mechanism consists of a firing pin, an arming housing, a compressed fir­ ing-pin spring, and firing-pin balls. The firing-pin balls seat in the groove of the firing pin, rest on the inner shoulder of the fuze body, and prevent the compressed firingpin spring from driving the firing pin into the detonator. The lower lip of the arming housing retains the firing-pin balls in this position, preventing them from riding up on the fuze body shoulder and releasing the firing pin. The celluloid cylinder of the delay element is positioned between the delay holder and the arming housing. This prevents the compresssed firing-pin spring from raising the arming housing and freeing the firing-pin balls. The solvent absorbed by the felt washers begins dissolving the celluloid cylinder as soon as contact is made. After a time lapse which depends upon the existing tempera­ ture, the cylinder is dissolved sufficiently so that the firing-pin spring can force the arm­ ing housing outward to release the firing-pin balls. This frees the firing pin which is then driven into the detonator by the firingpin spring. Antiwithdrawal. The body assembly con­ sists of two parts, the fuze body and the fuze head. The fuze head contains the bellows assembly and the stem collar. The fuze body contains the spring-loaded firing pin, the arming housing, the delay element, and the holder. An off-centered circumferential groove is machined on the outer surface of the fuze body. This groove contains the locking ball used in conjunction with the antiwithdrawal mechanism. The ball groove on the fuze body, being machined off-center, forces the locking ball outward when the fuze is turned counter­ clockwise in an attempt to defuze a bomb. This action wedges the ball between the adapter-booster wall and the fuze body, thus locking the fuze body in place. Any further counterclockwise rotation unscrews the fuze head from the fuze body. As the head is unscrewed, the firing-pin spring pushes the arming housing outward. When the housing has cleared the firing-pin balls, the firing pin is freed to detonate the fuze. As further assurance against withdrawal, current adapter-boosters are drilled for the insertion of a metal locking pin supplied with the fuze. When this pin is in place, the adapter-booster is locked to the base plug of the bomb, thus preventing removal of the 2-73 N A V W E P S OP 2216 (V O L U M E 1) fuze by the unscrewing of the adapter-boos­ ter. Detonation. When the firing pin punc­ tures the sealing disc and the detonator, the detonator explodes, setting off the booster and the bomb. Released Safe Bombs fuzed with this type of antiwith­ drawal fuze cannot be presumed to be re­ leased SAFE. In the event of incomplete missions, therefore, these fuzed bombs must be released over enemy territory or dropped in deep water. Once installed, no attempt shall be made to remove these fuzes from bombs. Accidental Arming Recognition. From outward appearances there is no way of definitely determining whether these fuzes are armed or in a safe condition after they have been installed in a bomb. The best policy is to regard them as being armed at all times. If a fuze has had its arming-vane assembly free to rotate, or if there is any doubt about it being in an armed condition, both fuze and bomb must be dis­ posed of as quickly as possible by authorized personnel. Handling. No attempt must be made to remove a fuze after it has been partially or completely installed in a bomb. If the redstoppered indicator vial in the fuze packing box shows that the fuze has been subjected to temperatures exceeding 170° F, the fuze must be destroyed by qualified and author­ ized personnel. In the event of incomplete missions, fuzed bombs must be released over enemy territory or deep water. Return of bombs to airfields or carriers is restricted. jected to temperatures higher than 150° F. This temperature caused the powder to melt; it solidified into a homogeneous mass upon cooling. CAUTION: Use none of the fuzes in this box for low-altitude bomb­ ing. 2. If the powder in the red-stoppered vial is solidified, the fuzes have been exposed to temperatures above 170° F. This tempera­ ture caused the powder in this vial to melt; solidification occurred upon cooling. CAUTION: Make no attempt to install detonators in the fuzes of this box. Fuzes must be disposed of by authorized personnel. 3. If there is any doubt whether the pow­ der in either vial is solidified, open the vial and inspect the contents. Personnel han­ dling these fuzes should be able to differen­ tiate between powdered and solidified con­ dition of vials. This is best learned by removing some powder from each vial, melt­ ing it, and allowing it to solidify. Installing the Fuze. 1. Remove the fuze, detonator holder, sealing washer, closing screw, and closingscrew washer from the fuze container. In­ spect the threads of the fuze for cleanliness and the safety clip for proper positioning. This must be done one-half hour before fuz­ ing. Remove the absorbent cotton from the detonator-holder cavity. Be sure no solvent has leaked onto the cotton. If the cotton in­ dicates leaking by being stained red, the fuze must be disposed of by authorized per­ sonnel. 2. Replace the cotton in the detonatorFuzing holder cavity. Inspection Prior To Use. There are two 3. Remove the safety thumb screw. Shake indicator vials packed in each box of fuzes. the fuze several times but do not strike it. Each of these vials contains a powder which 4. Stand the fuze on the detonator-holder melts at a critical temperature. When a box end and let it remain in this position for of fuzes is opened, inspect the vials and pro­ one-half hour. ceed as follows. 1. If the powder in the green-stoppered 5. After one-half hour, remove the cotton vial has solidified, the fuze has been sub­ and inspect it for evidence of leakage. If 2-74 FUZES the cotton has been stained red, the fuze must be disposed of by authorized personnel. 6. Replace the thumb screw in the fuze body. If it cannot be replaced, the fuze must be disposed of by authorized personnel. 7. Check the bomb for presence of the proper adapter-booster. Remove the adapter-booster lockpin from the fuze. In­ sert the pin in the hole inside the wall of the fuze cavity in the adapter-booster. The end of the pin must be flush with or below the inside surface of the adapter-booster before the fuze can be assembled to the bomb. 8. If the bomb to be fuzed is not fitted with the adapter-booster listed on the lockpin instruction tag, it is necessary, before assembling the fuze to the bomb, to stake the adapter-booster to the base plug of the bomb, and to stake the base plug to the bomb body. Use nonsparking tools for the staking operation. 9. Screw the thread gage (supplied in the fuze packing box) into the bomb fuze cavity until it seats. This assures that the fuze will seat without difficulty. Remove the thread gage. Do not use the bomb if its threads are damaged. 10. Remove the safety screw from the fuze body and insert the closing screw washer and closing screw in its place. Tighten the closing screw. 11. Insert the sealing washer into the detonator-holder cavity. 12. Screw the detonator holder over the washer. In doing this, hold the fuze body (not the fuze head) to prevent rotation of parts. Tighten the detonator holder se­ curely with the pin wrench supplied in the fuze packing box. 13. The locking ball should move freely in a small arc of the ball groove provided for it. 14. Remove the safety clip from the fuze body. Do not allow the fuze body to rotate around the fuze head at any time after re­ moval of the safety clip. 15. Hold the fuze by the arming-stem tube and turn the locknut so that it passes over all the threads in order to make sure that the threads are in good condition. Posi­ tion the locknut as far toward the vane end as possible. Do not use fuzes with damaged threads. 16. Screw the fuze into the bomb by hand as far as possible. Tighten the locknut with the L-wrench supplied with the fuzes. Tap the wrench lightly with a small hammer to insure that the nut is tight. WARNING Once the fuze is inserted in the adapter-booster, the fuze must not be turned backward (counterclock­ wise) by any amount, however slight. Engage the threads by a screwing-in motion only. Do not attempt to unscrew the fuze; a screwing-out motion will cause the locking ball to become wedged against the adapter-booster. Fur­ ther unscrewing action will cause the fuze to detonate. 17. Thread the longer end of the armingwire assembly through the rear suspension lug of the bomb and the nearer pair of eye­ lets in the bearing cup and arming-stem cup. If the nearer pair of eyelets is occupied by the safety pin and sealing wire, place a spare pin diametrically opposite before re­ moving the original safety pin. 18. Cut the sealing wire and remove the safety pin. 19. Thread the arming wire through the appropriate eyelet in the arming-vane as­ sembly. At the same time, slip the armingvane assembly over the end of the fuze so that the slots in the vane hub fit over the heads of the two eyelet pins. 20. Screw the vane nut on the threaded end of the bearing cup. Tighten the nut by hand. 21. Adjust the arming wire to protrude 2 to 3 inches beyond the arming-vane assem­ bly. Cut off excess wire. 22. Slip two safety clips over the end of the wire. Push them up the wire until the inner one touches the arming-vane assem­ bly. Be sure there are no kinks or burrs in the wire. 2-75 N A V W E P S OP 2216 (V O L U M E 1) 23. Remove the safety pin. If it is in­ tended to keep the fuze SAFE until the plane is airborne, replace the safety pin with the cotter-pin pull-ring assembly pro­ vided with the fuze. Remove the cotter pin when the aircraft is in flight. 24. Bombs fuzed with AN-M132, A N M133, and AN-M134 type anti withdrawal fuzes must be used on the mission for which they are fuzed. In the event of incomplete missions, unused bombs must be dropped over enemy territory or into deep water. Once installed, no attempt should be made to remove these fuzes from bombs. Return of bombs to airfields or carriers is restricted. CAUTION: If anything interferes with completion of the fuzing opera­ tion, NO ATTEMPT SHALL BE MADE TO DEFUZE THE BOMB. The bomb, with the fuze in place, shall be disposed of by authorized personnel. See instructions for the disposal of fuzed bombs. Defuzing NO ATTEMPT SHOULD BE MADE TO DEFUZE A BOMB ASSEMBLED WITH AN-M132, AN-M133, AND AN-M134 FUZES. The counterclockwise motion necessary to remove the fuze will cause functioning of the antiwithdrawal mecha­ nism and detonation of both the fuze and the bomb. Packaging and M arking Fuze Marking. Markings on the fuze body are located just below the threads and in­ clude nomenclature, lot number, and date loaded. In addition, four tags attached to the fuze read as follows: 1. For cotter pin pull ring assembly: “ For 2-76 use if safety pins are to be pulled after plane is airborne.” 2. Around arming stem tube: “ DANGER never remove this tag. This fuze contains a booby trap. NEVER ATTEMPT TO RE­ MOVE THIS FUZE FROM THE BOMB.” 3. For the adapter-booster lock pin: “ This pin is for use in the adapter-booster of the following bombs: GP 100-lb AN-M130A1 and GP 250-lb AN-M57A1.” (This data may alter as applicable.) 4. For seal wire and safety pin: “ Remove this wire after arming wire has been in­ serted, before arming vane is attached. DO NOT UNSCREW FUZE DURING OR AFTER ASSEMBLY TO BOMB.” Fuze Container. One fuze, less its armingvane assembly, is sealed in a black cylindrical metal container. The detonator holder, seal­ ing washer, closing screw, and closing-screw washer are packed in a drilled-out portion of a wooden block, in the same container as the fuze. A key is soldered to the bottom of the can to facilitate opening the sealed con­ tainer. The following is a typical fuze con­ tainer marking. FUZE, BOMB, TAIL AN-M132 LESS ARMING VANE (Date packed) Drawing No. REV. (Date) Packing Box. Twenty-five fuze containers, with 25 arming-vane assemblies on a rack, are packed in a wood box. Each packing box also contains two indicator vials, two wrenches, and a thread gage. These fuzes may also be packed 12 in a box in the same manner and with the same equipment. The following is a typical packing box marking. 25 TAIL FUZES BOMB, TAIL, AN-M132 Packed (Month and Year) LOT NO. FUZES H Y D R O S T A T IC T A IL FUZE A N - M K 230 M O D S 4, 5, A N D 6 M a r k ..__ ______ AN-Mk 230 ____ AN-Mk 230 M od__ . . _________ 4 _____________ 5. ______________ Firing Action. ____ Water pressure . . . . Water pressure _ _ Firing Delay (ft) (De­ termined by Depth Setting). ________ 25, 50, 75,100,125. _ 25, 50,75,100, 125 . General Arrangement.. 344703 . . . . ___ 344740____________ Arming TvDe... Vann __ Vane . Revolutions to Arm__ 110_______________ n o ______ Air Travel to Arm (ft)----------------- 300-400___________ 300-400__________ Overall Length (in .)... 15.4........ ............ 15.4 ___ Protrusion from Bomb (in.)------------------12.7______________ ..1 2 .7 ____________ Body Diameter (in.)__ 3.38______________ 3.38. Vane Span (in.) 5.25________ _ . 5.25. Weight (lb)__ . 15________________ 15________________ Number of Vanes. .. 16________________ 16. Detonator Designation- Mk 20 Mod 0_____ Mk 20 Mod 0_____ Booster Charge Type------------------ Tetryl___________ Tetryl__________ _ Weight (gm) _ _ _ 22________ 13 _____________ ____ AN-Mk 230. 6. Water pressure. 25, 50,75,100,1: 344703. Vane. 110. 300-400. 15.4. 12.7. 15. Mk 20 Mod 0. Tetryl. 22. General Description Figure 2-33.— Hydrostatic Tail Fuze A N -M k 230 M od 5. Hydrostatic Tail Fuze AN-Mk 230, figure 2-34, is vane operated and requires from 400 to 500 feet of air travel to arm. It is bottle-shaped in appearance and has a 16blade arming-vane assembly attached to its head. This type of fuze is sometimes used in conjunction with a nose fuze. Water pressure operates the hydrostatic mechanism that detonates the fuze. The depth at which detonation will occur can be controlled by presetting the depth-setting knob. This knob is located on the side of the fuze and its face is marked with the five possible depth settings: 25, 50, 75, 100, and 125 feet. When issued, the fuze is locked at the 25-foot setting by means of the depth­ setting rod and lock. Hydrostatic Tail Fuzes AN-Mk 230 Mod 5 and Mod 6 differ from Mod 4 by having the accuracy of their 25-foot depth setting em­ phasized. Mod 4 has the accuracy of the 50-foot setting emphasized. The booster of Mod 5 differs from that of Mod 4 and Mod 6 in that the firing pins of Mod 5 are welded to the booster cap and its booster charge is 2-77 N A V W E P S OP 2216 (V O L U M E 1) COTTER PIN' VANE HUB ARMINt - VANE ASSEMBLY BUSHING' ARMING MECHANISM HOUSING VANE SHAFT SHAFT NUT GEAR COVER MOVABLE GEAR PLANETARY GEAR COVER PINION STATIONARY GEAR COUNTER BALANCE ARMING SHAFT STATIONARY GEAR CARRIER ARMING-N JT PIN ARMING NUT STRAP DETENT RETAINING CUP DETENT DEPTH-SPRING STEM NUT DETENT RETAINING PIN DETENT CARRIER DEPTH SPRING DEPTH-SPRING STEM DEPTH-SETTING SLEEVE COUNTERWEIGHT RACK DEPTH-SETTING MECHANISM HOUSING FUZE BODY --DEPTH-SETT IN' 3 ROD •DEPTH-SETTING KNOB -DEPTH-SETTINC ; CAM DEPTH-SETTING LOCK ^ — -BEI .LOWS •HYDROSTATIC P ISTON FIRING PLUNGER LOCKING BALL LEAD OUT CHARGE LEAD-IN CHARGE PLUNGER HOUSING DETONATOR FIRING POINT RELAY BOOSTER Figure 2-34.— Hydrostatic Tail Fuze A N -M k 230, Cross Section. 2-78 FUZES smaller. These fuzes in externally carried stores are restricted in accordance with NAVORDINST 8024.25, latest issue. Explosive Component's The explosive components of this fuze consist of the detonator, the lead-out charges, the lead-in charges, a relay, and a booster charge. The detonator and lead-out charges are in the firing plunger. The booster charge, the relay, and the lead-in charges consist of approximately 25.5 grams (0.9 ounce) of tetryl. Safety Features Each fuze is individually packed in a sealed metal container. The fuze body, plunger housing, and firing plunger are locked by a safety rod to prevent operation of the hydrostatic mechanism and conse­ quent premature functioning of the fuze. The safety rod is protected against acci­ dental withdrawal by a cotter pin through a hole at the protruding end. A safety cotter pin, provided with a pull ring and instruction tag, locks the bushing and arming-vane assembly together to pre­ vent the arming vane from rotating and arming the fuze. In all, four cotter pins are used externally on this fuze: one to prevent withdrawal of the setting rod, one to prevent withdrawal of the safety rod, one to lock the vane as­ sembly in place, and a fourth to connect the arming-vane hub to the vane shaft. An arming bracket is used with fuzes of this type when they are assembled in bombs that are to be carried on external racks of high-speed aircraft. The bracket insures that the arming wire will not shear, allow­ ing the fuze to arm. When placed in a bomb, the fuze is in an unarmed condition as long as the arming wire is in place. It will not begin to func­ tion until the bomb is dropped armed and the arming wire is withdrawn from the arming-vane assembly and bushing. The fuze is detonator safe as well as shear safe. These terms have been fully explained in chapter 1. Functioning General. When the bomb is dropped ARMED, the arming wire is withdrawn and the arming-vane assembly is free to rotate in the air stream. After the bomb com­ pletes from 300 to 400 feet of air travel along its trajectory, the fuze is fully armed. The fuze begins functioning when water enters its body. Water pressure, increasing with depth, expands a bellows, causing alinement of the explosive elements and detona­ tion of the fuze. Arming. Delayed arming of the fuze is obtained by a reduction-gear mechanism be­ tween the vane shaft and the arming shaft. ■FIRING PLUNGERLEAD-OUT CHARGF — DETONATOR^ LEAD-IN CHARGERELAY BOOSTER MOOS 4 AND 6 MOD 5 Figure 2-35.— Hydrostatic Tail Fuze A N -M k 230, Comparison of Boosters. 2-79 N A V W E P S OP 2216 (V O L U M E 1) The rotating arming vanes turn the vane shaft, the gear cover, and the planetarygear cover. An idler gear (pinion) is mounted on the planetary-gear cover. The number of teeth on the upper and lower por­ tions of the pinion is the same. The plane­ tary-gear cover turns about the arming shaft and is supported vertically by the sta­ tionary gear and the stationary-gear carrier. The movable gear is secured to the arming shaft at its forward end, above the plane­ tary-gear cover. The shaft nut locks the movable gear in place. The movable gear has 23 teeth while the stationary gear has 22. As the vanes revolve to turn the plane­ tary-gear cover, the pinion is driven around the stationary and movable gears, with their teeth meshing. The difference between the number of teeth on the stationary and mov­ able gears causes the pinion to force the movable gear one tooth ahead with each revolution of the planetary gear cover. This gives a reduction ratio of one revolution of the arming shaft to 23 revolutions of the arming-vane assembly. Rotation of the arming shaft causes the arming-nut assembly to rise upward on the arming shaft, withdrawing the arming-nut pins from the detent carrier. When the pins are fully clear of the detent carrier, further rotation of the arming shaft causes the pins to turn the detent-retaining cup until openings on the cup sides are opposite the detents. The detents jump out, freeing the depth-spring-stem nut. The detents are prevented from jumping completely out of their holes by detent retaining pins which are fitted into the detent carrier. A metal strap passes over the detentretaining cup, preventing its removal from the detent carrier. If, therefore, the armingmechanism housing is broken free without rotation of the arming-vane assembly, the fuze will not become armed (shear safe). Depth-Setting Mechanism. The basic concept of the depth-setting arrangement of this fuze is a bellows expanding against the compressive resistance of a spring. The hydrostatic piston and depth-spring stem ride vertically through the depth-setting 2-80 sleeve and the depth spring. The bellows is secured to the piston and the depth-springstem nut is secured to the depth-spring stem. The depth-setting sleeve can be positioned in any one of five possible locations along the depth-spring stem by turning the depth­ setting knob. Moving the depth-setting sleeve vertically up and down the depth­ spring stem regulates the space between the depth-spring-stem nut and the base of the depth spring. The distance which the piston and the depth-spring-stem nut must move to detonate the fuze is constant for any depth. Selectivity is gained by causing a portion of the movement to be made against the compressive resistance of the depth spring. The closer the depth spring is brought to the stem nut, the greater the distance the hydrostatic piston has to move against the spring to detonate the fuze. Since hydrostatic pressure is the motivat­ ing force that operates the bellow-actuated piston, greater depths are necessary to pro­ duce sufficient pressure to overcome the com­ pressive strength of the spring. Action. The hydrostatic piston, the coun­ terweight rack, the depth-spring stem, and the depth-spring-stem nut move as a single unit. One end of the hydrostatic bellows is secured to the hydrostatic piston; the other end is secured to the depth-setting-mecha­ nism housing, which is stationary. When the fuze goes below the water sur­ face, water enters the fuze body through two port holes. The water then passes through four holes in the depth-settingmechanism housing and enters the bellows. The bellows expands as water pressure is built up when the fuze submerges. The expanding bellows draws the hydro­ static piston downwards, compressing the firing spring and depth spring. As the piston moves downwards, it rides over the firing plunger and plunger housing. The detonator and lead-out charges are contained in the firing plunger, which is locked to the plunger housing by six locking balls. After the hydrostatic piston has moved downward about % inch (this dis­ tance is the same for all settings), the balls FUZES locking the firing plunger are forced out into the circular recess in the hydrostatic piston. The compressed firing spring then drives the freed plunger into the firing point. At this point the explosive train is completed by the alinement of the lead-out and lead-in charges and the fuze is detonated. Detonation. The explosion, caused by the detonator being driven into the firing point, is passed to the lead-out charges, then to the lead-in charges, the relay, and finally the booster, which sets off the bomb. Inertia] Counterbalancing. Two inertia counterweights are attached to the hydro­ static piston through the counterweight rack to prevent inertial forces from firing the fuze. On impact, they provide a positive force (since they weigh slightly more than the piston assembly) which holds the hydro­ static piston up in the nonfiring position. Released Safe If it is necessary to release fuzed bombs over friendly territory, the aircraft arming controls are set in the SAFE position before the bombs are jettisoned. In this position, the arming wire is released from the bomb rack with the bomb, preventing the armingvane assembly from rotating and arming the fuze. The unarmed fuze will not function upon impact. Accidental Arm ing Recognition. There is no way of deter­ mining from the visual appearance of the fuze whether or not is is armed. By turning the arming vane backwards, a partially armed fuze can be disarmed. H a n d l in g . Even if the fuze is fully armed, it will not fire from handling or shock because the functioning mechanism is counterbalanced. It will fire, however, if sufficient air or water pressure enters the fuze through the ports. Armed fuzes may be removed from a bomb with relative safety. However, the safety rod that locks the firing plunger to the plunger housing should be inserted immedi­ ately. Salvaging. The only authorized salvaging operation is the removal of the delay-arm­ ing-mechanism subassembly. Only qualified and authorized personnel should attempt to do this work. Fuzing 1. Unscrew the shipping plug and fuze adapter from the adapter-booster in the tail of the bomb. Inspect the adapter-booster and threads; if any dirt or other foreign material has collected, clean the threads with a pointed stick. 2. Remove the fuze from its packings and inspect it for damaged threads and dented surfaces. CAUTION: Do not partially pre­ arm Hydrostatic Tail Fuze A N Mk 230 to insure arming at low altitudes. The extent of arming cannot be determined by visual ex­ amination. If the fuze is already in a state of partial arming, ad­ ditional rotation of the vanes may complete arming and render the fuze dangerous since fluid pressure (air or water) applied through parts in the body may build up suf­ ficiently to detonate the fuze. 3. Set the desired depth as follows. a. Remove the cotter pin from the depth-setting rod. Withdraw the rod from the depth-setting knob. b. Turn the depth-setting knob to the desired depth. The figure on the setting dial closest to the lock indicates the depth for which the fuze is set. c. Replace the depth-setting rod through the depth-setting knob and through the slot in the depth-setting lock. Replace the cotter pin in the depth-setting rod. It is easiest to set the depth desired before the fuze is placed in the bomb. The setting can be changed, however, after the fuze has been installed. 4. Remove the cotter pin from the safety rod and withdraw the rod from the fuze. 5. Make sure the fuze gasket is in place. Screw the fuze into the tail of the bomb. In order to obtain a watertight seal, tighten 2-81 N A V W E P S OP 2216 (V O L U M E 1) the fuze with a large spanner wrench. Do not use grease or sealing compound. Grease or waterproofing preparations might seep into the fuze and cause a dud. 6 . Thread one end of the arming wire through the rear suspension lug of the bomb and then through the nearest pair of four pairs of holes in the bushing and armingvane assembly of the fuze. If the safety cotter pin occupies the nearest pair of holes, insert a spare cotter pin in another set of holes; then remove the original cotter pin to free the holes desired. If no nose fuze is used with the bomb, cut off the other end of the arming-wire assembly. 7. Adjust the arming wire to protrude from 2 to 3 inches beyond the arming-vane assembly. Secure two safety clips on the wire against the face of the arming-vane assembly. Be sure that the arming wire is free from kinks and burrs. 8 . If an arming bracket is to be used, at­ tach it so that it will be in a vertical posi­ tion when the bomb is placed in the rack. Thread the long end of the arming wire through the bracket and arming-wire tube. Adjust the arming wire so that it extends 2 to 3 inches beyond the bracket. Be sure the arming wire is free of burrs and kinks. Slip two safety clips over the end of the arming wire until the first one just touches the bracket. 9. Remove the safety cotter pin from the arming-vane assembly and bushing. Defuzing CAUTION : Before attempting to remove a fuze from a bomb, be sure it is unarmed or safe to handle. THERE IS NO WAY OF TELL­ ING FROM VISUAL INSPEC­ TION OF THE FUZE WHETHER OR NOT IT IS ARMED. See pre­ ceding instructions on handling these fuzes before defuzing. 1. Replace the safety cotter pin through one pair of holes in the vane assembly and flange of the bushing to lock the arming mechanism. 2. Remove the two safety clips; remove the arming wire from the fuze. 2-82 3. Unscrew the fuze from the bomb. Re­ place the safety rod in the base of the fuze and secure it with the cotter pin. (If the safety rod cannot be reinserted into the fuze, the fuze must be considered dangerous and disposed of by authorized personnel. This rod locks the firing plunger in the plunger housing; if it is not in place, the firing plunger will be free to detonate the fuze if sufficient water or air pressure enter the fuze through the ports.) 4. Adjust the depth-setting knob to the 25-foot setting. Make sure both depth­ setting rod and safety rod are secured with safety cotter pins. 5. Return the fuze to its container and reseal with adhesive tape. Packaging and M arking Fuze Container. Each fuze is packed in a sealed cylindrical metal container which is opened by a scored tear strip. The con­ tainer has a maximum diameter of 5 11/^(J inches and a maximum length of I 6 V20 inches. The weight of the fuze and the con­ tainer together is 17 pounds. The container is marked as follows. ONE HYDROSTATIC BOMB FUZE AN-Mk 230 U.S.N. LOT NO. YEAR OF MANUFACTURE NAME OF MANUFACTURER INSPECTOR Fuze Container Crate. Four fuzes in their containers are packed in a metal fuze con­ tainer crate, the approximate dimensions of which are 1 1 % by 1 1 % by I 6 I/2 inches. The crate and fuzes weigh approximately 75 pounds. The top of the crate is marked as follows. FOUR HYDROSTATIC BOMB FUZES AN-Mk 230 LOT NO. NAME OF MANUFACTURER CONTRACT NO. YEAR OF MANU­ FACTURE INSPECTOR’S INITIALS NET WEIGHT LBS. GROSS WEIGHT LBS. FUZES M U L T I-P O S IT IO N FUZE M l 57, A N -M 1 7 3 , A N D A N -M 1 7 3 A 1 Figure 2-36. — Multi-Position Fuze M l 57, Exterior View. Model________________________________ Firing Action_________________________ Firing Delay__________________________ Assembly Drawing No_________________ Arming: Type------------------------------------------Revolutions to Arm: For Impact along Fuze Axis___ For All-Ways Action__________ Time to Arm (sec) Air Travel to Arm (ft): For Impact Along Fuze Axis__ For All-Ways Action_____ ____ Overall Length (in.)___________________ Protrusion from Bomb (in.)____________ Vane Span (in.)_______________________ Weight (lb)__________________________ Number of Vanes_____________________ Primer Designation___________________ Detonator Designation________________ Booster Charge: Type-------------------------------------------Weight (grams)___________________ Figure 2-37. — Multi-Position Fuze A N -M 1 7 3 A 1 , Exterior View. M l 57....................... Impact . AN-M173A1. Instantaneous___ ... C14—15—191__ Impact. Instantaneous. C14-15-638. Vane____ Vane. __ 18_____ _________ . . . 34_______________ . . . 150__________ ______ 220_________ ______ 3 .4 _________ ______ 0 .6 _________ ______ 2 .0 _________ ______ 0 .4 _________ ______ 4____________ ______ M2 6________ ______ li . 34. 150. 220. 4.19. 0.6. 2.0. 0.45. 4. M26. M31. Black powder. . _ Tetryl. 12. 0.75_____________ 2-83 N A V W E P S OP 2216 (V O L U M E 1) \ ANEMOMETER VANE HUB ARMING SCREW ARMING HEAD LOCKING BALL FIRING PLUNGER FUZE BODY HOLDER ANTICREEP SPRING G PIN RIMER BOOSTER Figure 2-38.- Multi-Position Fuze M l 57, Cross Section. 2-84 FUZES J PIN ANEMOMETER VANE ANEMOMETER HUB ARMING STEM ARMING SCREW FUZE HEAD LOCKING BALL FIRING PLUNGER FUZE BODY FIRING PIN PRIMER HOLDER ANTICREEP SPRING BOOSTER DETONATOR Figure 2-39. Multi-Position Fuze AN-M 173A1, Cross Section. 2-85 N A V W E P S OP 2216 (V O L U M E 1) General Description The inertia firing, impact, multi-position fuze M157 and AN-M173A1, figures 2-38 and 2-39, is fully armed by anemometer type vanes after completing 220 feet of air travel. Once the fuze is armed, impact forces from any direction will cause instantaneous deto­ nation. These fuzes are assembled in con­ junction with igniters or bursters in fire bombs. These fuzes in externally carried stores are restricted in accordance with NAVORDINST 8024.25, latest issue. Explosive Components The AN-M173A1 employs three explosive elements: a primer, a detonator, and a booster. The M157 fuze has a primer and a booster. Safety Features Each fuze is individually packed in a her­ metically sealed metal container. The fuze is kept in an unarmed condition by a safety cotter pin, with a pull ring and instruction tag attached, which passes through two offcentered holes in the anemometer hub. The cotter pin prevents the anemometer vanes from rotating and arming the fuze. When installed in an igniter, the arming wire replaces the safety cotter pin and pre­ vents the anemometer vanes from rotating and arming the fuze. The arming wire main­ tains this position until it is withdrawn, after the bomb is dropped ARMED. Functioning General. When the bomb is dropped ARMED, the arming wire is retained in the bomb rack and withdrawn with the fuze. This frees the anemometer vanes, which rotate in the air stream to arm the fuze. When fuzes of this type are used with cer­ tain fire bombs, a nose cone covers the fuze until the bomb is released armed. A sepa­ rate arming wire releases the nose cone, exposing the fuze to the air stream. After 18 revolutions (approximately 120 feet of air travel) the fuze will detonate when the force of impact is directed along its axis. After 34 revolutions of the anemom­ eter vanes (approximately 220 feet of air travel), the fuze is fully armed so that im­ pact forces from any direction will cause detonation ( “ all-ways action” ). With an additional 15 revolutions, the anemometer vanes are released into the air stream. Figure 2-40.— Multi-Position Fuze M l 57, Installed in Igniter M l 5. 2-86 FUZES Figure 2-41. Multi-Position Fuze A N -M 1 7 3 A 1 , Installed in Igniter M23. Upon impact, the fuze detonates instan­ taneously. Arming. The anemometer vanes are di­ rectly connected to the arming screw by a pin. The arming screw is threaded into the fuze head. At the inner end of the arming screw is the inner arming stem which locks the firing plunger in place. Next to the fuze head, within the fuze body, are the firing plunger and the primer holder. The primer holder is a hollow cylin­ drical capsule with a round inward end and an open outward end. The primer is posi­ tioned in a seat provided at the inward end of the primer holder; it is always in line with the firing pin. Two locking balls prevent the firing plunger from being driven into the primer holder and detonating the fuze. The lock­ ing balls extend from the firing plunger and bear against an internal shoulder of the primer holder. These locking balls are held outward in their extended position by the arming stem. The arming stem extends into the upper cavity of the firing plunger and seats between the two locking balls. The recess for the locking balls is bevelled to prevent them from falling out. As the anemometer vanes rotate and the arming screw separates from the fuze head, the arming stem is withdrawn from the firing plunger. When it is withdrawn suf­ ficiently so that it no longer holds the lock­ ing balls outward, the fuze is armed. When the anemometer vanes have completed ap­ proximately 60 revolutions, they are freed from the fuze head and released to the air stream. Premature firing of the fuze is prevented by the anticreep spring, which holds the fir­ ing plunger away from the primer after arming is completed. This spring is strong enough only to offset the weight of the fir­ ing plunger; additional weight or force will overcome its strength. Action. The shock produced by impact along the fuze axis drives the firing plunger inward, forcing the locking balls into the firing plunger and compressing the anti­ creep spring. Shock, produced by impact, along the sides of the fuze, causes the firing plunger and the primer holder to be forced together by the tapered end of the fuze head and the tapered inside surface of the fuze body. This forces the locking balls into the firing plunger and causes the firing plunger to compress the anticreep spring. The flash from the primer is sufficiently strong so that the flame will ignite the deto­ nator, or booster, regardless of the position in the fuze body at which the primer fires. Detonation. In Multi-Position Fuze A N M173A1, the firing pin explodes the primer, which sets off the detonator. The detonator relays the explosion to the booster which, in turn, bursts the igniter. In Multi-Position Fuze M157, the firing pin explodes the primer, which sets off the booster. The booster relays the explosion to a C8R1 Burster which bursts the igniter. Released Safe When assembled with an igniter, this fuze cannot be released SAFE. Even if the igniter is released SAFE and the fuze does not function, impact may break the igniter open and scatter its white phosphorus or sodium filler. This will ignite the gasoline 2-87 N A V W E P S OP 2216 (V O L U M E 1) gel just as though the explosion had scat­ tered the filler. Accidental Arming Recognition. If the anemometer hub has separated from the fuze head by Vg inch or more, or if the anemometer vanes are com­ pletely removed from the fuze, the fuze is armed. Handling. When the fuze is armed, the firing plunger is held away from the primer by the anticreep spring. This spring is strong enough only to offset the weight of the firing plunger. Therefore the fuze, the igniter, and the bomb must be protected against shock once the fuze is armed. A blow at any point on the surface may deto­ nate the fuze since it is responsive to forces from any direction. The removal of armed or partially armed fuzes from igniters must be performed by authorized and qualified personnel. Fuzing 1. Remove the igniter from its sealed metal container and examine it for any ob­ vious physical defects. 2. Unseal the metal fuze container and remove the fuze. Inspect the general ap­ pearance of the fuze; check for damaged threads, damaged anemometer vanes, or cor­ rosion. Use only serviceable fuzes. 3. Screw the fuze into the threaded ig­ niter adapter. 4. Install the igniter in the fire bomb. 5. Revolve the fuze until the open set of off-centered holes of the anemometer vane hub aline with the rack, shackle, or other point of attachment. The arming wire should pull straight out of the arming-wire hole in the fuze. Tighten the setscrew. 6. Thread the arming wire through the open set of off-centered holes drilled through 2-88 the anemometer hub. Adjust the arming wire so that at least 3 inches extends be­ yond the fuze. Place two safety clips on the end of the arming wire and move them up until they touch the anemometer vane. Be sure the arming wire is free from kinks and burrs. 7. Pull the safety cotter pin out of the other set of holes drilled through the anemometer hub. De fuzing CAUTION: Before removing a fuze from a bomb, be sure it is unarmed or safe to handle. If the anemometer hub has separated from the fuze head by l/g inch or more, or if the anemometer vanes are completely removed from the fuze, the fuze is armed. See the preceding section on accidental arming before defuzing. 1. Replace the safety cotter pin in the unoccupied set of holes drilled through the anemometer hub. 2. Remove the two safety clips from the arming wire. Pull the arming wire out of the off-centered holes of the anemometer hub. 3. Remove the igniter from the bomb. 4. Loosen the setscrew and remove the fuze. 5. Return the fuze to its metal container and reseal with adhesive tape. Packaging and M arking Fuze Container. Each fuze comes in a hermetically sealed container which has a tear strip to facilitate opening. Packing Box. Fifty metal containers, each containing a fuze, are packed in a wood crate. FUZES IM P A C T SIDE FUZE M 129 Figure 2-42.— Side Fuze M l 29. Model ........... ....... Firing- Action .......... Firing Delay Air Impact ._ Asembly Drawing No. Arming Type Revolutions to Arm Air Travel to Arm (ft) Overall Length (in.) Protrusion from Bomb (in.) Body Diameter (in.) Weight (lb) Detonator Designation Primer Designation Booster Type ....M129 Aerial burstor impact 2.5 seconds after arming Instantaneous 73—8—252 ... Direct 3% to 5 _ 50 3.0 1.2 1.75 0.4 M31 M41A1 Tetryl pellet General Description Impact Side Fuze M129, figure 2-43, is used only with the fragmentation (butter­ fly) bomb. It is armed by the “ butterfly wings” of the bomb and can be preset to detonate in the air or instantaneously upon impact. Fragmentation bombs are assembled into clusters which require mechanical time fuzes for cluster opening. These cluster assem­ blies are described in chapter 8, Fragmenta­ tion Bomb Clusters and Adapters. Approximately 50 feet of air travel is re­ quired to arm the Type I impact side fuze. If set for aerial burst, the fuze is detonated 2Vii seconds after arming. For ground burst, the delay train action is initiated after the fuze has completed 50 feet of air travel. Two and one-half seconds later, the delay train is halted and is not reactivated until impact occurs, resulting in detonation. The words AIR and GROUND are em­ bossed on the outside of the fuze cap and in­ dicate the position of the setting plug. The embossing is a distinguishing feature of this type of fuze and differentiates it from simi­ lar fuzes. The setting is made at the time of manu­ facture, and only fuzes set for ground burst are supplied to the Navy. No one except authorized personnel should attempt to change this setting, to remove the fuze from the bomb, or to work on the fuze in any manner. Because the time fuzes used with these fuzes utilize arming wires, these fuzes in externally carried stores are restricted in accordance with NAVORDINST 8024.25, latest issue. Explosive Components The main charge of the fuze is a tetryl pellet booster which is housed in a metal cup protruding from the fuze base. A detonator is positioned in the center of the booster at its innermost end. The primer is housed in the main body of the fuze where it is alined with the firing pin at all times. When the fuze is in the unarmed condition, however, the arming stem tip is interposed between these components. Safety Features Some additional safety features not pro­ vided in the AIR burst setting are present 2-89 N A V W E P S OP 2216 (V O L U M E 1) SEGMENT FIRING-PIN FIRING PIN A C Figure 2-43.— Side Fuze M l 29, Cross Section and Details of Operation. 2-90 FUZES with the GROUND burst setting of the fuze. Should the arming stem become unscrewed prematurely, allowing the fuze to arm, the fuze will not function unless a shock suffi­ cient to simulate the impact force of the bomb is applied to the fuze. In the AIR burst setting the fuze would detonate 2U2 seconds after arming, under similar circum­ stances. Presetting The setting plug, located on the fuze cap, is used to select the AIR or GROUND burst setting. Turning the pointer to either of the settings operates a spring-actuated seting pin. In the AIR position, the cam sur­ face on the underside of the setting plug forces the setting pin inward to contact the safety-pellet assembly. In the GROUND position, the setting pin is held in the fuze cap, away from the safety-pellet assembly, by the setting pin spring. Functioning General. When the fragmentation bomb is released from the cluster, the butterfly wings snap open and ride to the top of the cable attached to the arming stem. The rotation of the wings in this position causes the cable to turn, unscrewing the arming stem far enough to initiate the arming mechanism of the fuze. This action requires 3 1/2 to 5 revolutions of the wings and ap­ proximately 50 feet of air travel. If the fuze has been set for AIR burst, it will detonate 2|/2 seconds after the arming action is completed. If the fuze has been set for GROUND burst, it will not detonate until impact oc­ curs. Arming. As the butterfly wings rotate in the air stream, the arming stem is un­ screwed from its centrally threaded hole in the fuze cap. When the arming stem has completed between 3V2 and 5 turns, it has withdrawn from the movement assembly housing sufficiently to free the clockwork mechanism. The fuze is technically armed at this time. The clockwork mechanism constitutes a delay firing mechanism. The clockwork assembly is contained in the movement assembly housing and includes the segment gear (regulated by the gear train or movement assembly), the segmentgear stop, the segment-gear camshaft, and the safety-pellet assembly (pellet, shell, and spring). The spring-loaded firing pin bears on one edge of the segment-gear camshaft, which is connected to the segment gear. The seg­ ment gear bears against the arming screw and prevents the spring-loaded firing pin from turning the camshaft. The withdrawal of the arming screw from the movement assembly housing allows the firing pin to rotate the camshaft. The cam­ shaft moves the segment gear in a clockwise direction. A gear train, which is contacted by the external teeth of the segment gear, controls the speed at which the firing pin will rotate the camshaft. The segment gear contacts the segment-gear stop 2'/2 seconds after it is freed. Ground Burst Action. If the setting plug, located in the fuze body cap assembly, is turned to indicate GROUND, the setting pin is retracted into the cap. In this case, the segment gear stop is restrained by the tip of the safety pellet, which projects through the safety-pellet shell. When the segment gear contacts the segment-gear stop after with­ drawal of the arming stem, it is stopped and held in place. In this position, the firing pin is still restrained from forward action by the camshaft. Upon impact, the com­ plete safety-pellet assembly is depressed by inertia. Almost simultaneously with this action, the gear stop and segment gear pass over the safety pellet assembly, permitting the camshaft to rotate further until the halfround notch cut in the camshaft has alined with the firing pin. This frees the firing pin, which is driven into the primer. Air Burst Action. If the setting plug is positioned to indicate AIR, the setting pin is forced downward and depresses the safety-pellet assembly. When the segment gear is freed and contacts the gear stop, the segment gear moves the segment-gear stop over the depressed safety-pellet assembly. 2-91 N A V W E P S OP 2216 (V O L U M E 1) This allows the camshaft to rotate until its half-round notch alines with the firing pin. The firing pin then is freed and driven into the primer by the compressed firing-pin spring. Detonation. The primer is ignited by the firing pin and the flash from the explosion passes through the explosive canal to the detonator. This sets off the detonator which, in turn, fires the booster and bomb. Released Safe If it is necessary to release the cluster SAFE over friendly territory, the aircraft arming controls are set in the SAFE posi­ tion. In this position, the arming wire through the time fuze is released with the cluster when the cluster is jettisoned. This prevents the time fuze from functioning and opening the cluster. Bombs in the unopened cluster will not function upon impact since the individual fuzes are unarmed. Accidental Arming Recognition. From outward appearances it is impossible to tell the condition of the arming mechanism. Consider the fuzes armed if the arming stem has risen more than Vs inch from the fuze cap. Handling. If the fuze has been set for 2-92 GROUND burst and is armed, it is reason­ ably safe to handle but must be protected against shock. A severe shock may cause the safety-pellet assembly to depress enough to allow the segment gear to ride over it and free the firing pin. A fuze set for AIR burst detonates ap­ proximately 2i/2 seconds after the arming stem frees the segment gear. If the arm­ ing stem has risen more than Yg inch and the fuze has not detonated, the fuze is only partially armed. It must be handled cau­ tiously, however, since the margin of safety is uncertain. The segment gear may be held back by the lower edge of the arming stem. A severe shock may free the segment gear and fire the fuze. No attempt should be made to remove an armed, unarmed, or questionably armed fuze from a bomb. The fuzes are set and in­ stalled in the bomb by the manufacturer. In the event of an armed or questionably armed fuze, notify authorized personnel for destruction. Packing and M arking This fuze is installed in the bomb M83 by the manufacturer. No fuzes are shipped without bombs. The Navy is supplied with fuzes set for GROUND burst. FUZES T IM E SIDE FUZE M 130 and M130A1 60 minutes after arming, depending upon the setting made at the time of manufacture. Fragmentation bombs are assembled into clusters which require mechanical time fuzes for cluster opening. These cluster assem­ blies are described in chapter 8, Fragmenta­ tion Bomb Clusters and Adapters. Bomb Clusters and Adapters Model Firing Action Firing Delay (min) ______ M130 AND M130A1 Mechanical time 10, 20, 30, 40, 50, or 60 Assembly Drawing No. 73-8-225 73-8-226 Arming Type ------------------ Direct Revolutions to Arm 3V2 to 5 Air travel to Arm (ft) ... 50 Overall Length (in.) 3.14 Protrusion from Bomb (in.) 1.2 Body Diameter (in.) 1.75 Weight (lb) 0.4 Detonator Designation M31 Primer Designation M41A1 Booster Type Tetryl pellets General Description The mechanical time side fuze is used only with the fragmentation (butterfly) bomb. It is armed by the “ butterfly wings” of the bomb. Its time train is initiated after 50 feet of air travel have been completed. Detonation will occur 10, 20, 30, 40, 50, or Side Fuzes M130 and M130A1 are identi­ cal in operation and appearance with the exception that the M130A1 has a window in the side which permits visual inspection to determine whether or not the fuze is armed. This window is not visible once the fuze is installed in the bomb. The fuze is very similar in appearance to the M129 (which is distinguishable by the words AIR and GROUND embossed on its cap) ; the M130, M130A1, and M131A1 are identical in appearance when assembled in a bomb. These fuzes are installed in bombs by the manufacturer. In addition, the fuzed bombs are issued in wafer assemblies or in com­ plete cluster assemblies. No attempt should be made to remove them except by author­ ized personnel. From outward appearances, it is impossi­ ble to tell the condition of the arming mech­ anism of the M130 or M130A1 in a fuzed bomb. Consider the fuze armed if the arm­ ing stem has risen from the fuze cap more than Vn inch. WARNING DO NOT ATTEMPT TO REMOVE AN ARMED, UNARMED, OR QUESTIONABLY ARMED FUZE FROM A BOMB. FUZE M131A1, WHICH IS VERY SIMILAR IN APPEARANCE TO THE M130 AND M130A1 FUZES, HAS AN ANTIDISTURBANCE FEATURE WHICH WILL DETONATE AN ARMED BOMB WHEN SLIGHTLY VIBRATED. 2-93 N A V W E P S OP 2216 (V O L U M E 1) ARMING STEM- FUZE BODY CAP SPRING WHEEL BODY Figure 2 - 4 5 Side Fuze M130A1, Cross Section. Because the time fuzes used with these fuzes utilize arming wires, these fuzes in externally carried stores are restricted in accordance with NAVORDINST 8024.25, latest issue. Explosive Components The main charge of the fuze is a tetryl booster, housed in a metal cup which pro­ trudes from the fuze base. A primer and a detonator complete the explosive compo­ nents of the fuze. Safety Features The fuze is not armed until the cluster is released to eject the bombs and the bombs 2-94 have covered the necessary 50 feet of air travel to initiate the time train. Functioning General. When the fragmentation bomb is released from its cluster, the butterfly wings snap open and ride to the top of the cable (part of the bomb), attached to the arming stem. The rotation of the wings in this position causes the cable to turn and unscrew the arming stem. When the arming stem is withdrawn ap­ proximately Vi inch, the fuze is armed and the timing mechanism is initiated. This ac­ tion requires SV> to 5 revolutions of the wings and approximately 50 feet of air travel. FUZES The fuze detonates after the time train runs out. This may be 10, 20, 30, 40, 50, or 60 minutes after arming, depending upon the setting made at the time of manufacture. Arming. When the arming stem is in place in the unarmed position, the arming lever is held against the stem by the action of the balance wheel pin, which bears on the projection of the arming lever. The balance wheel is under action of the clock­ work (movement assembly) driven by the main spring. The wedging action of the arming lever and the arming stem prevents the balance wheel from turning as long as the arming stem is in place. This locks the clockwork mechanism against the force of the main spring. As the butterfly wings rotate in the air stream, the arming stem is unscrewed from its centrally threaded hole in the fuze-body cap. When the arming stem is withdrawn, the pin on the balance wheel forces the pro­ jection of the arming lever to rotate and pivot the arming lever. The arming lever moves a limited distance until it is cen­ tered over the hole previously occupied by the arming stem. This action prevents re­ insertion of the arming stem and starts the operation of the time mechanism as the pro­ jection on the arming lever frees the balance wheel. Action. With the maximum time setting of 60 minutes the action is as follows. The timing gear, under the influence of the main spring, rotates in a counterclockwise direc­ tion. Near the end of its first revolution, the stud on the timing gear engages the first slot on the setting plate. The stud pulls the setting plate around with it a limited dis­ tance in a clockwise direction. Near the end of the second revolution of the timing gear the stud engages the second slot in the setting plate, again moving the setting plate a limited distance in a clock­ wise direction. This action of the gear and stud continues four more times. The setting plate is re­ tained a slight amount each revolution of the timing gear. Near the end of the sixth revolution, the stud on the timing gear en­ gages the heel of the setting plate and moves the setting plate clear of the timing gear. With the setting plate in this position, the setting-plate cam presents the cutaway sec­ tion to the release arm. Before it is released, the release arm bears against the setting-plate cam. The force of the spring-loaded striker is applied to the release arm cam, to which the release arm is secured, and keeps the release arm against the setting-plate cam. The springloaded striker engages the cam by a notch cut into the striker. The notch bears against one-half of the release-arm cam in order to produce the rotational force. As the setting-plate cam presents its cutaway section to the release arm, the re­ lease arm pivots clockwise with the releasearm cam. The release-arm cam frees the striker, which rotates in a counterclockwise direction undet the action of the spring and strikes the primer. Each complete revolution of the timing gear takes approximately 9 to 10 minutes and, with the maximum setting of the set­ ting plate, a delay of 54 to 60 minutes will result. By varying the initial position of the setting plate or the timing gear, or both, at the factory, the fuze can be set to func­ tion at any desired time up to 60 minutes. Detonation. The primer is fired by the striker and sets off the detonator. The deto­ nator ignites the booster, which sets off the bomb. Released Safe If it is necessary to release the cluster SAFE over friendly territory, the aircraft arming controls are set in the SAFE posi­ tion. In this position, the arming wire through the time fuze is released with the cluster when the cluster is jettisoned. This prevents the time fuze from functioning and opening the cluster. Bombs in the un­ opened cluster will not function upon impact since the individual fuzes are unarmed. Accidental Arming Recognition. From outward appearances it is frequently impossible to tell the con- 2-95 N A V W E P S OP 2216 (V O L U M E 1) dition of the arming mechanism. The best policy is to consider the fuze armed if the arming stem has risen from the fuze cap more than !/s inch. Some fuzes have been modified and have a window in the side which permits visual examination to deter­ mine if the fuze is in the armed condition. Handling. No attempt should be made to remove an armed, unarmed, or questionably armed fuze from a bomb. The fuzes are set 2-96 and installed in the the bomb by the manu­ facturer. In the event of an armed or questionably armed fuze, notify authorized personnel for destruction. Packing and M arking This fuze is installed in the bomb M83 by the manufacturer. No fuzes are shipped without bombs. FUZES A N T ID IS T U R B A N C E SIDE FUZE Figure 2- 46 . Model Firing Action Side Fuze M 131A1. _______ ____ _ M131A1 Fired by any disturbance after initial impact None 73-8—282 Firing Delay Assembly Drawing No. Arming Type ......... .. Direct by me­ chanical timing and impact Revolutions to Arm 3 Vz to 5 Air Travel to Arm (ft) 50 Overall Length (in.) 3.1 Protrusion from Bomb (in.) ... 1.3 Body Diameter (in.) 1.75 Weight (lb) 0.4 Detonator Designation M31 Primer Designation M41A1 Booster Type Tetryl pellets M131 and M131A1 not occur immediately upon impact, but only after a second shock initiates the sensitive antidisturbance mechanism. Fragmentation bombs are assembled into clusters which require mechanical time fuzes for cluster opening. These cluster assem­ blies are described in chapter 8, Fragmenta­ tion Bomb Clusters and Adapters. Side Fuze M131A1 is very similar in ap­ pearance to the M129 (which is distinguish­ able by the words AIR and GROUND em­ bossed on its cap). The M131A1 fuze is identical to the M130 and M130A1 when assembled in a bomb. These fuzes are installed in bombs by the manufacturer. In addition, the fuzed bombs are issued in wafer assemblies or in complete cluster assemblies. No attempt should be made to remove them except by authorized personnel. From outward appearance it is impossi­ ble to tell the condition of the arming mech­ anism of the M131A1 in a fuzed bomb. Con­ sider the fuze armed if the arming stem has risen from the fuze cap more than •/« inch. WARNING DO NOT ATTEMPT TO REMOVE AN ARMED, UNARMED, OR QUESTIONABLY ARMED FUZE FROM A BOMB. THE ANTIDIS­ TURBANCE MECHANISM IN THE FUZE WILL DETONATE THE BOMB IF THE FUZE IS ARMED. Because the time fuzes used with these fuzes utilize arming wires, these fuzes in externally carried stores are restricted in accordance with NAVORDINST 8024.25, latest issue. General Description The mechanical antidisturbance Side Fuze M131A1 is used only with the fragmenta­ tion (butterfly) bombs. It is armed by the “ butterfly wings” of the bomb. It is a time fuze also and the time train is initiated after 50 feet of air travel. Detonation does Explosive Components The main charge of the fuze is a tetryl booster housed in a metal cup which pro­ trudes from the fuze base. A primer and a detonator complete the explosive compo­ nents of the fuze. 2-97 N A V W E P S OP 2216 (V O L U M E 1) F ig u re 2 - 4 7 . — S id e F u ze M 1 3 1 A 1 , C ro ss S e c tio n a n d D e ta ils o f O p e r a t io n . 2-98 FUZES Safety Features The fuze is not armed until the cluster is released to eject the bombs and the bombs have covered the 50 feet of air travel neces­ sary to initiate the time train. Functioning General. When the fragmentation bomb is released from its cluster, the butterfly wings snap open and ride to the top of the cable attached to the arming stem. The rotation of the wings in this position causes the cable to turn and unscrew the arming stem, initiating the steps in the firing ac­ tion. When the arming stem has risen approxi­ mately Ys inch, the fuze is considered armed. After completion of approximately 50 feet of air travel, the arming stem has raised about inch. This allows the “ first re­ lease” in the firing action, which requires about J/2 second, to take place. The “ second release” occurs upon impact. The force of impact is utilized to prepare the antidisturbance device of the fuze for action. This phase of the firing sequence is completed 2 seconds after impact. After the second release, the fuze is in the extremely sensitive state. Should it be subjected to handling, shock, or vibration, the antidisturbance device will be released ( “ third release” ), and the fuze will detonate. Arming. When the arming stem has raised approximately Ys inch by action of the butterfly wings, it has been withdrawn from its original position between the firing pin and the primer. In this condition, the fuze is considered armed. Action. When the arming stem has risen inch, its inner end has cleared the escapewheel spring and the timing gear, freeing them. The released timing gear is rotated in a clockwise direction under the force of the coil drive spring. The speed of the timing gear is controlled by the escape movement (gear train, escape wheel, and escape-wheel spring). After about Yi second, the stud on the inner surface of the timing gear contacts a projection on the second release weight (impact spring), bringing the entire mech­ anism to a halt and completing the first re­ lease. This condition exists until impact. Upon impact, the second release weight deflects, disengaging the impact spring and the impact-spring stud. The timing gear again rotates under action of the coil-drive spring until a stud on the outer edge of the timing gear contacts the small projection at the end of the antidisturbance block (third release block). Here the timing mechanism is once more brought to a halt and the fuze is prepared for its third release phase. The time delay after the second release al­ lows the antidisturbance block to damp out the oscillation caused by impact. The second release time is about 2 seconds. Detonation. The firing pin sets off the primer which relays the explosion to the detonator. The detonator explodes the booster. Released Safe If it is necessary to release the cluster SAFE over friendly territory, the aircraft arming controls are set in the SAFE posi­ tion. In this position, the arming wire through the time fuze is released with the cluster when the cluster is jettisoned. This prevents the time fuze from functioning and opening the cluster. Bombs in the unopened cluster will not function upon impact since the individual fuzes are unarmed. Accidental Arm ing CAUTION: When fully armed, this fuze is extremely sensitive and very dangerous. Only a slight vibration is needed to initiate the antidisturbance mechanism and ex­ plode the bomb. DO NOT HAN­ DLE armed or questionably armed fuzes of this type; they are to be destroyed by authorized and quali­ fied personnel, together with the bomb. Recognition. From outward appearances, it is impossible to tell the condition of the arming mechanism. The best policy is to 2-99 N A V W E P S OP 2216 (V O L U M E 1) consider the fuze armed if the arming stem has risen from the fuze body cap more than Ys inch. Handling. No attempt should be made to remove an armed, unarmed, or questionably armed fuze from a bomb. In the event of an armed or questionably armed fuze, do not disturb either the fuze or the bomb since the delicate antidisturbance mecha­ 2-100 nism may detonate both. Notify authorized personnel for destruction of both bomb and fuze. Packing and M arking This fuze is installed in the bomb by the manufacturer. No fuzes are shipped with­ out bombs. Chapter 3 BOMB COMPONENTS OTHER THAN FUZES A D A P T ER -B O O ST E R M102A1 I 'G A SKET CLOSING CUP ASSEMBLY 4164 BOOSTER CHARGE OISC F ig u re 3 -1 .- — A d a p t e r -B o o s t e r M l 0 2 A h Model ........ ........................................... M102A1 Assembly Drawing No. 82—3—129 Length (in.) ...... ....................... 4.61 Closing-Cup Assembly Charge Type _________ - ............—- ........................Tetryl Weight (grains) 1.53 Booster Charge Type .................................................... Tetryl W eight (grains) ..... 884 General Description Adapter-Booster M102A1 provides a tail fuze seat for certain GP and SAP bombs. It requires an adapter-booster lock pin to prevent its removal after an antiwithdrawal fuze is inserted in the bomb. The required lock pin is assembled to the wire holding the lock pin instruction card to the fuze. The M102A1 differs from the M102 in its provision for locking pins. This adapter-booster has an inner diam­ eter of 1.5 inches and its cavity is 2.86 inches deep. It is used on the following bombs : 500-lb SAP Bomb AN-M58 1000-lb SAP Bomb AN-M59 250-lb GP Bomb AN-M57 100-lb GP Bomb AN-M30 It receives Army designed fuzes only. Adapter-boosters are described in chapter 1. 3-1 N A V W E P S OP 2216 (V O L U M E 1) A D A PT ER -B O O ST E R M115A1 CLOSING FUZE ADAPTER CLOSING CUP CHARGE BOOSTER CHARGE F ig u re 3 - 2 . — A d a p t e r -B o o s ie r M115A1. Model ........................................................ Assembly Drawing No................ . Length (in.) .. Closing-Cup Assembly Charge Type .... Weight (grains) _____ ___ ____ _______ Booster Charge Type --------------Weight (grains) .......................... .......... . M115A1 82-3—356 4.64 Tetryl 1.53 Tetryl 1853 General Description Adapter-Booster M115A1 provides a tail fuze seat for the following GP, chemical, and incendiary bombs. 500-lb GP Bomb AN-M64 1000-lb GP Bomb AN-M65 2000-lb GP Bomb AN-M66 500-lb Chemical Bomb AN-M78 3-2 1000-lb Chemical Bomb AN-M79 500-lb Incendiary Bomb AN-M76 The adapter-booster requires a lock pin to prevent its removal after an antiwith­ drawal fuze is inserted in the bomb. The required lock pin is assembled to the wire holding the lock pin instruction card to the fuze. The M115A1 differs from the M115 in its provision for the locking pin. This adapter-booster has an inner sleeve that has an inside diameter of 1.5 inches to accommodate Army designed fuzes. If the sleeve is removed, the adapter-booster will accommodate Navy fuzes, which have inner diameters of 2.00 inches. The cavity provided by the adapter-booster is 2.68 inches deep. Adapter-boosters are described in chapter 1. B O M B C O M P O N E N T S O TH ER T H A N FUZES A D A PT ER -B O O ST ER M l 17 6"35 F ig u re 3 - 3 . — A d a p t e r -B o o s t e r M l 17. Model _____ ________ _________ ___ ___ _____ Assembly Drawing No................................. Length (in.) ............... .................................... Booster Charge Type ........ .............................................. Weight (lb) ............................................... M117 82—3—491 6.35 Tetryl 0.29 General Description Adapter-Booster Ml 17 adapts GP bombs with large nose fuze seats to small frag­ mentation-type fuzes. Installation To installthis adapter-booster, proceed as follows. 1. Unpack the adapter-booster and re­ move the shipping plug. Inspect it both internally and externally to be sure that it is clean and the threads are clear. Inspect the bomb fuze seat. 2. Screw the adapter-booster into the bomb until it is firmly seated, but do not use force. 3. Unless the fuze is to be assembled im­ mediately, replace the shipping plug, hand tight. 4. If the use of the adapter-booster be­ comes unnecessary, remove the unit and return it to its original packings and condi­ tion. 3-3 N A V W E P S OP 2216 (V O L U M E 1) A D A PT ER -BO O ST E R T45E1 CLOSING PLUG C.OSING CUP BOOSTER CHARGE FELT DISC F ig u re 3 - 4 . — A d a p t e r -B o o s t e r T 4 5 E 1. General Description Adapter-Booster T45E1 permits the use of 2-inch thread size mechanical or VT nose fuzes in low-drag GP bombs. This is an 3-4 interim measure pending availability of elec­ trical fuzes specially designed for these bombs. BO M B C O M P O N E N T S O TH ER T H A N FUZES A D A PT ER -B O O ST E R T46E4 CLOSING PLUG FUZE ADAPTER CHARGE ZE WELL FlgSEMBLV F ig u re 3 - 5 p - A d a p f e r - B o o s t e r T 46E 4. General Description Adapter-Booster T46E4 permits the use of 1.5-inch thread size mechanical tail fuzes in all low-drag GP bombs. This is an in­ terim measure pending availability of elec­ trical fuzes specially designed for these bombs. 3-5 N A V W E P S OP 2216 (V O L U M E 1) A U X IL IA R Y BOOSTER M k 1 M od 0 F ig u re 3 - 6 . — A u x ilia r y B oo ste r M k 1 M o d Mark ....... .............................................................. Mod ........ ........................................................... General Arrangement ___ ___________ .. Diameter (in.) _____ _____________ ________ Height (in.) .......... ............. ................L.... Explosive Charge Type ___ Weight (grams) 1 0 327960 1.85 2.98 TNT 180 General Description Auxiliary Booster Mk 1 Mod 0 is a stand­ 3-6 0. ard booster shipped in the nose or tail fuze seat liner, or both, of Navy designed bombs weighing over 100 pounds, with the excep­ tion of the low-drag series of GP bombs. Some bombs may require the use of two auxiliary boosters to complete the explosive train between the fuze and the main charge of the bomb. B O M B C O M P O N E N T S O TH ER T H A N FUZES A U X IL IA R Y BOOSTER M k 4 Mod 0 F ig u re 3 - 7 . — A u x ilia r y B oo ste r M k 4 M o d 0. Mark ........... ........................................................ Mod ........... ......................................................... Genera] Arrangement ..................... Diameter (in.) ............................................. Height (in.) ............................... ......... Explosive Charge Type ______ Weight (grams) ... ......................... 4 0 389101 1.6 3.0 TNT 63 General Description Auxiliary Booster Mk 4 Mod 0 is an ex­ plosive contained in a chipboard tube which is closed at both ends by metal caps cemented to the tube. White bond paper is glued to the outside of the tube and is covered by a transparent lacquer or shellac. The auxiliary booster is used in the nose fuze seat liners of AN-GP bombs when Nose Fuze Mk 219 is used. Navy bombs, with the exception of low-drag GP bombs, require the use of one auxiliary booster, which is usually shipped assembled in the bomb. 3-7 N A V W E P S OP 2216 (V O L U M E 1) BURSTER M 1 0 F ig u re 3 - 8 . — Burster M IO . Model .................. Assembly Drawing No. Diameter (in.) ....... ........... Length (in.) Type of Tube ____ __ ____ Explosive Charge Type Weight (lb) ... Shipping Container Number per container .... . Type Container Weight Filled (lb) Cubage (ft) ________ MIO 82-3—385 1.13 36.00 Paper or Plastic Tetryl pellets 1.48 50 Wood box 150 2.7 General Description Burster MIO is an explosive-filled tube 3-8 that has a threaded plastic or steel round plug at one end. The other end is closed by a threaded plug assembly consisting of a gilding-metal cup and a steel cup holder with a hexagonal or round shoulder for position­ ing the burster. The cup, which is thin enough to be ruptured by the fuze detonator, is fitted into a hole in the cup holder and contains a small charge of tetryl. This burster is used in the 115-lb Chemical Bomb M70. B O M B C O M P O N E N T S O TH ER T H A N FUZES BURSTER A N —M l 2 37.-88 ------------------------------------------------------------------------------ -j ■' CUP \ ' BODY 1* ‘ 1 " 1T PLUG / •• . / CUP HOLDER CHARGE F ig u re 3 - 9 . — Burster A N Model ........................................ Assembly Drawing No............ Diameter (in.) ___ ____ Length (in.) ..................... Type of Tube Explosive Charge Type ______ ____ AN-M 12 C14—5—315 1.3 37.88 Plastic or Aluminum Black Powder and Magnesium 1.1 W eight (lb) ________ Shipping Container Number per Container 50 Type Container _____ Wood box Weight Filled (lb) ........ 113 Cubage (ft) 2.6 20 Wood box 54 1.4 M l 2. General Description Burster AN-M12 is an explosive-filled tube that has a threaded plastic or steel round plug at one end. The other end is closed by a threaded plug assembly consist­ ing of an aluminum cup and a steel cup holder with a hexagonal shoulder for posi­ tioning the burster. The cup, which is thin enough to be readily ruptured by the fuze detonator, is fitted into a hole in the cup holder. This burster is used in AN-M47A4type incendiary bombs. 3-9 N A V W E P S OP 2216 (V O L U M E 1) BURSTER A N - M 1 3 ------------------- 3 6 *0 ------------------- F ig u re 3 - 1 0 . — Burster A N - M 1 3 . Model ..................... ....................... Assembly Drawing No. _____ Diameter (in.) .. Length (in.) Type of Tube Explosive Charge Type AN-M 13 C14—5—500 0.45 36.00 Plastic TNT and tetryl pellets Weight (gram s) ..........__............. 60—70 Shipping Container Number per Container 100 Type Container Wood box 3-10 Weight Filled (lb) ..... 85 Cubage (ft) ........................ 0.9 General Description Burster AN-M13 is an explosive-filled tube closed at each end with a soft brass cap. It is filled with about 65 grams of TNT and has a 0.41-gram tetryl pellet at each end. This burster is used with Igniter A N M9 in incendiary bombs AN-M47A4 type. B O M B C O M P O N E N T S O TH ER T H A N FUZES BURSTERS A N -M 1 4 . A N -M 1 5 . and A N - M 1 6 _L 1’33 AN M14 ~r AN-M15 1T69 ------------ -------------------------------------- r 4 1 - 9 7 -------- ---------------------------------------------------- _L - ~ - METAL END BURSTER CHARGE P69 AN-M16 ........................ .............................................- METAL END CHIPBOARD TUBE F ig u re 3 - 1 1 . — Burster A N - M 1 4 , A N - M 1 5 , a n d A N - M 1 6 . .. Model. Assembly Drawing No. Diameter (in.)____ _. . Length (in.). Type of Tube Explosive Charge: Type. Weight (lb ). . .. . Shipping Container: Number per Container. Type Container Weight Filled (lb) Cubage (ft). AN-M 14 82-3-422. .. 1 .3 3 __________ 35.83 Paper and chipboard AN-M 15 82-3-422. 1.69 35.83 ......................... Paper and chipboard TN T (25%) Cast tetryl (75%). 1 .23 TN T (25%) Cast tetryl (75%). 2.54 50 12 Metal-lined wood box. 70 Metal-lined wood box 70 1.7 1 .6 . AN-M 16. 82-3 422. 1.69. 41.97. Paper and chipboard. TN T (25%) Cast tetr. (75%). 4.29. . 8. Metal-lined wood box 65. 1 . 5. General Description Bursters AN-M14, AN-M15, and AN-M16 consist of paper and chip­ board tubes closed at both ends with thin steel caps. Bursters AN-M14 are used with Igniters AN-M5 in 500-pound incendiary bombs. Bursters AN-M15 are used in 500-pound chemical bombs. Burster AN-M16 is used in the 1000-pound chemical bomb. 3-11 N A V W E P S OP 2216 (V O L U M E 1) BURSTER A N —M l 8 3 7 “ 94 - i BURSTER CHARGE PLUG ASSEMBLY Figu re 3 - 1 2 . — Burster A N - M l t s . Model ..... -........ ........... Assembly Drawing No.. AN—M18 82—3—516 Diameter (in.) Length (in.) ..................... 1.13 37.94 Type of Tube .................. Plastic Explosive Charge Type ...... - .... Black powder Weight (lb) 0.6 Shipping Container Number per Container 50 Type Container Wood box ....... ...... Weight Filled (lb) 120 Cubage (ft) ............................. 3 3-12 General Description Burster AN-M18 is an explosive-filled plastic tube closed at one end by means of a threaded plastic or steel round plug. The other end is closed by a threaded plug as­ sembly consisting of a gilding-metal cup and a steel cup holder with a hexagonal shoulder for positioning the burster. The cup, which is thin enough to be readily ruptured by the fuze detonators, is fitted into a hole in the cup holder. This burster is used with 100pound smoke bombs for low-altitude bomb­ ing. B O M B C O M P O N E N T S O TH ER T H A N FUZES F ig u re 3 - 1 3 . — Burster A N - M 20. Model .................................... Assembly Drawing No. .. AN-M 20 C14—5—892 Diameter (in.) ............. ......... ............. 1.13 Length (in.) ..... ..................... .... 37.94 Type of Tube ......... .................. Plastic Explosive Charge Type .................................................. Tetryl pellets Weight (lb) ...................................... 0.87 Shipping Container Number per Container ....... 50 Type Container ..... ... ....... Wood box Weight Filled (lb) ___ 155 Cubage (ft) ..... .................................. 3 General Description Burster AN-M20 consists of an explosiveloaded plastic tube closed at one end by a threaded plastic or steel round plug. The other end is closed by a threaded plug as­ sembly consisting of a gilding-metal cup and steel cup holder with a hexagonal shoul­ der for positioning the burster. The cup, which is thin enough to be readily ruptured by the fuze detonator, is fitted into a hole in the cup holder and contains a small charge of tetryl. This burster is used in 100-pound smoke bombs. 3-13 N A V W E P S OP 2216 (V O L U M E 1) IG N IT E R A N - M 5 3 5 3 1 ----------------------------------------------— ---------- „ ------------------ ------------ --------------- [ FILLING PLUG OUTER TUBE F ig u re 3 - 1 4 . - Model ................... .............. Assembly Drawing No. Outside Diameter (in.) .... Inside Diameter (in.) ....... Length (in.) ... Filler Type ................ .............—........ AN-M 5 82-3-432 3 1% 35-Viu White Phosphorous (W P) 9 Weight (lb) Shipping Container Number per Container 5 Type Container ....................... Wood box 3-14 Ign iter A N - M 5 . Weight Filled (lb) Cubage (ft) 28 0.7 General Description Igniter AN-M5, a component of the 500lb Incendiary Bomb AN-M76, consists es­ sentially of two concentric steel tubes welded to annular ends. One end ring has two filling holes which are closed with pipe plugs. These pipe plugs must not be tampered with or removed. BO M B C O M P O N E N T S O TH ER T H A N FUZES IG N IT E R A N - M 9 -----------------------38’ 34------------ 1—1— INNER TUBE BURSTER WELL OUTER TUBE F ig u re 3 - 1 5 . — Ign iter A N - M 9 . Model . Drawing No. . ... Outside Diameter (in.) Inside Diameter (in.) Length (in.) ... .. Filler Type . Weight (lb) Shipping Container Number per Container Type Container W eight Filled (lb) Cubage (ft) .............. ... _ A N -M 9 0 4 - 5 —218 .... .......... . 1V4 % 38' *(12 WP or Na 1.6 20 .............. Wood box 80 2.4 General Description Igniter AN-M9 consists essentially of two concentric steel tubes joined at both ends to form an annular space which is filled with white phosphorus (WP) for land bombing or sodium (Na) for water bombing. The sodium-filled igniter was formerly called Igniter E2. The inner tube, which is about 1V4 inches shorter than the outer tube, con­ tains a small coil spring for snubbing an in­ serted burster. 3-15 N A V W E P S OP 2216 (V O L U M E 1) IG N IT E R M 15 ARMING VANES ARMING WIRE SETSCREW • 7 C8R1 BURSTER WP OR NA " GRENADE F igu re 3 - 1 6 . — Ig n ite r M l 5. Model Assembly Drawing' No. Filler Type Weight (lb) Shipping Container Igniters Number per Container Type Container 3-16 M15 C 4-6-75 WP or Na 0.95 (W P) 0.52 (Na) 16 (individually packaged in vacuum-type metal cans) Wood box Weight Filled (lb) WP Filled Sodium Filled Cubage (ft) Bursters and Fuzes Number per Container Type Container Weight Filled (lb) Cubage (ft) 75 69 2 50 cans Wood box 46 1.3 General Description Igniter M15 is an incendiary explosive which is used to ignite the filling of fire B O M B C O M P O N E N T S O TH ER T H A N FUZES bombs. It is an M15 hand grenade with the Bouchon fuze replaced by an impact all­ ways anemometer-type fuze. A threaded igniter adapter is installed in the grenade for mounting the fuze. The fuze seats above a Burster C8R1 (a blasting cap and 2.5 grams of tetryl) in the grenade-burster well. The igniter is filled with white phosphorus (W P) for land bombing or sodium (Na) for water bombing. Functioning When a bomb assembled with this igniter is dropped, the arming wire is pulled and the fuze arms after about 100 feet of air travel. On impact, the fuze ignites the primer which initiates the fuze booster charge. This explodes Burster C8R1 which, in turn, breaks the grenade case, allowing WP or sodium to ignite the incendiary mix­ ture scattered by the bursting tank. Even if the igniter is released SAFE and the fuze does not function, impact may break open the grenade and scatter the filler. This will ignite the chemical filler of the bomb. For this reason the igniter cannot be considered capable of SAFE dropping with absolute assurance of nonfunctioning. CAUTION: All igniters now in stock, with the exception of those procured during or after 1950, have Arming-Wire Assemblies C-10 packed in the same shipping box. Because of reported malfunc­ tions, these wires are to be used only in the event that standard arming wires are not readily avail­ able. If used, precautions must be taken to crimp the ferrule (or slide) with pliers and to bend back the short length of the loop at­ tached to the swivel 180 degrees on itself. 3-17 N A V W E P S OP 2216 (V O L U M E 1) F ig u re 3 - 1 7 . — Ign iter A N - M 1 6 , Exterior V iew . Model ...................................... Assembly Drawing No. Filler Type _____ ___ ____ ____ ___ ___ Weight (lb) ................................... Shipping Container Igniters Number per Container ......... AN-M 16 C4—6—33 WP or Na 0.95 (W P) 0.52 (Na) (individually packaged in vacuum-type metal cans) ________ Wood box Type Container Weight Filled (lb) WP Filled .... .............. Sodium Filled Cubage (ft) Bursters and Fuzes Number per Container 3-18 16 75 69 2 50 cans Type Container ________________ Wood box Weight Filled (lb) 46 Cubage (ft) .. 1.3 General Description Igniter AN-M16 is an incendiary explo­ sive type igniter used in fire bombs. It is an M15 hand grenade with the Bouchon fuze replaced by an impact all-ways ane­ mometer-type fuze. A threaded igniter adapter is installed in the grenade for mounting the fuze. The fuze seats above a Burster C8R1 (a blasting cap and 2.5 grams of tetryl) in the grenade-burster well. A crimped locking flange for mounting in the fuel tank filler neck is attached to the B O M B C O M P O N E N T S O TH ER T H A N FUZES igniter body with setscrews. The igniter is filled with white phosphorus (W P) for land bombing or sodium (Na) for water bomb­ ing. Functioning When a bomb assembled with this igniter is dropped, the arming wire is pulled and the fuze arms after about 100 feet of air travel. On impact, the fuze ignites its primer which initiates the fuze booster charge. This ex­ plodes the Burster C8R1 which, in turn, breaks the grenade case, allowing WP or sodium to ignite the incendiary mixture scat­ tered by the bursting tank. Even if the igniter is released SAFE and the fuze does not function, impact may break open the grenade and scatter its filler. This will ignite the chemical filler of the bomb. For this reason the igniter cannot be con­ sidered capable of SAFE dropping with ab­ solute assurance of non-functioning. CAUTION: All igniters now in stock, with the exception of those procured during or after 1950, have Arming-Wire assemblies C-10 packed in the same shipping box. Because of reported malfunctions, these wires are to be used only in the event that standard arming wires are not readily available. If used, precautions must be taken to crimp the ferrule (or slide) with pliers and to bend back the short length of the loop attached to the swivel 180 degrees on itself. 3-19 N A V W E F S OP 2216 (V O L U M E 1) IG N IT E R M 23 Model .......... ....... M23 Assembly Drawing No. C—14—5-805 Filler Type ..... ................ ..... Weight (lb) ......... ............ Shipping Container Igniters Number perContainer Type Container Weight Filled (lb) Cubage (ft) Fuzes and Arming-Wires Number per Container Type Container Weight Filled (lb) Cubage (ft) ___________ 3-20 WP 1.25 25 (individually packaged in vacuum-type metal cans) Wood box 125 2.1 50 Wood box 60 1.8 General Description Igniter M23 is used with fire bombs. Its steel body has external threads for mount­ ing in the tank flange and internal threads for mounting a fuze. The fuze used with this igniter is an impact anemometer-type. Fuze and arming wire are procured and is­ sued separately. Functioning Upon release of the fire bomb, the arming wire is withdrawn from the fuze. The fuze is armed after about 8 feet of air travel or 17 vane revolutions. Upon impact, the fuze bursts and splits the igniter body. Scat­ tered filling burns upon atmospheric contact and ignites the incendiary fuel from the tank. B O M B C O M P O N E N T S O TH ER T H A N FUZES P R A C T IC E BO M B S IG N A L M k 4 M ods 3 and 4 &to 4 ■- '■ ' — — — ■ F ig u re 3 - 1 9 . — P ra cfice B o m b S ig n a l M k 4 M o d s 3 & 4. Mark______________________ Mod _ ________ ___ General Arrangement______ List of Drawings___ ______ Length (in.)_______________ Diameter (in.)_____________ Weight (lb)-----------------------Case Material. . . Expelling Charge__ . ___ Marker L o a d .............. .......... Shipping Containers: Cardboard Carton____ Wood Box . __ __ General Description Practice Bomb Signals Mk 4 Mods 3 and 4 are essentially 10-gage shotgun shells of 4 ____________________ 3. . . . . . _________ 398800.. Sk 166560.. ________ 6.0 ____________ 4. 4. 1211717. 256093. 6 . 0. 0 .8 5 _________________ 0.16 _____________ Aluminum___________ Smokeless powder___ Stabilized red phos­ phorous. 0.85. 0.16. Aluminum. Smokeless powder. Zinc oxide. 200 signals_____ 200 signals. 25 cartons__ 25 cartons. extra length. They contain an expelling charge of smokeless powder and are primed with a commercial primer. A pyrotechnic 3-21 N A V W E P S OP 2216 (V O L U M E 1) or inert marker load is separated from the expelling charge by a disc and cardboard gun-wad. The end of the shell is closed by felt gun-wads which are secured by a cemented cover. Use The signals are used either in the minia­ ture or the larger practice bombs. Installed in the miniature practice bombs, the signals do not consistently produce a visible signal on impact with water or soft earth when dropped from an altitude of 10,000 feet or higher. The bomb, when dropped from that height, enters the water or earth so quickly that the signal frequently does not have time to function. Functioning When the practice bomb in which the sig­ nal is installed strikes water or the earth, impact causes the firing pin in the nose of the bomb to impinge upon the primer of the signal. The primer ignites the expelling charge, forcing the marker load out through an opening in the bomb. The resulting flash and puff of white smoke permit observation as to bombing accuracy. Assembly During loading operations, the signal is placed in position in the bomb. The firingpin assembly then is inserted with the firing pin facing toward the signal. A cotter or plain pin is inserted in the nose of the bomb to prevent the firing-pin assembly and the signal from falling out. See assembly pro­ cedures under the particular bomb to be used. 3-22 Differences Am ong Mods Signal Mk 4 Mod 0 was the first of this type developed. Mods 1 and 2 were pro­ cured for issue to activities limited by en­ vironment to performing practice bombing in the vicinity of flammable areas. These signals contain inert materials which pro­ duce very little flash and a smoke puff markedly inferior to that of the Mod 0 signal. Signal Mk 4 Mod 3 is similar to the Mk 4 Mod 0 but differs in that: (1) the car­ tridge case of the Mk 4 Mod 3 is extruded aluminum instead of paper; (2) a primer mixture with improved storage character­ istics has been used; and (3) a new pyro­ technic load which produces about the same flash, but a superior smoke puff, has been incorporated. The Mk 4 Mod 4 signal is similar to the Mk 4 Mod 3 with the exception of an inert marker load of zinc oxide. In both mods the cover and cartridge case are cemented together; in Mod 3 the assembly also is staked in four equally spaced places. Safety Precautions Rough handling may cause immediate functioning of the signal or may damage it so that it will not function properly. Signals must not be unpacked in advance of requirements. If unpacked and not used, return to original packing. Swollen or deformed signals are not to be used. The primer must be flush with or slightly below the base of the signal. De­ fective signals will be turned over to a bomb disposal officer. Under no circumstances should a signal case be opened or tampered with. B O M B C O M P O N E N T S O T H ER T H A N FUZES P R A C T IC E B O M B S IG N A L M k 5 M od 0 F ig u re 3 - 2 0 . — P ractice B o m b S ig n a l M k 5 M o d Mark ............... .....................5 Mod ..... ........................ ............................ 0 General Arrangement ____________ 344644 Length (in.) ....... .................... ..... 1.74 Diameter (in.) .. .................... 0.93 W eight (oz) . 0.5 Cylinder Material . Plastic Dye Filling (Type) ........ . Fluorescein Dye Color Dry ....................................................... Brick red Dissolved in Water Bright green Shipping Containers Cardboard Carton 200 signals Wood box _____ 5 cartons General Description Practice Bomb Signal Mk 5 Mod 0 is ap­ proximately the size of a 10-gage shotgun shell. A shoulder, which increases the diam­ eter of one end, serves to locate the signal in the bomb. The signal is a plastic cylinder containing 10 grams of fluorescein dye. This dye is a highly-soluble salt of sodium, brick red in color, becoming bright green when dissolved in water. Use The signal, for use in dive-bombing prac­ 0. tice, can be used in any miniature practice bomb in which Signal Mk 4 can be used. It is dropped only on water targets during day­ light. When a wind is blowing, the smoke from the Mk 4 signal often blows away before the pilot can get into position to view the results of his attack. The slick from the Mk 5 signal can be seen from an altitude of 15,000 feet. Functioning The bombs are dropped in a normal man­ ner. Upon impact, water enters the nose of the bomb, breaks the weak ends of the plastic container, and forces the dye out the tail end of the bomb. Assembly The bomb is prepared for use by removing the cotter pin and the firing-pin assembly. The signal then is inserted with the small end toward the tail of the bomb. The signal is fixed in place by replacing the cotter pin; the firing-pin assembly is not used. 3-23 N A V W E P S OP 2216 (V O L U M E 1) FUZE LOCKNUT CONTAINER EXPLOSIVE CHARGE F ig u re 3 - 2 1 . — P ractice B o m b S ig n a l M k 6 M o d 0, A s s e m b le d with Fuze. Mark ____ _________ ___________ - 6 Mod _____ ______ _______ .. 0 General Arrangement 438277 List of Drawings 109524 Length (in.) 8.0 Diameter (in.) ............... ....... .........3.0 Weight of Assembled Signal (lb) 3.7 Container Material Steel Explosive Charge Type Black powder Weight (lb) ........... 2.0 General Description Practice Bomb Signal Mk 6 Mod 0 is es­ 3-24 sentially a can of black powder fitted with the inert Fuze AN-Mk 247 Mod 0 and a blank .38 caliber cartridge which is used as a detonator. The Mk 6 is generally the same as the Mk 7 signal except that the fuze is mounted off-center in the Mk 6 and its black powder filling weighs approximately 1 pound more. The Mk 6 signal is used with prac­ tice bombs for observation as to bombing accuracy. BO M B C O M P O N E N T S O TH ER T H A N FUZES Functioning Upon release from the plane, the arming wire is withdrawn, permitting the fuze arm­ ing vane to rotate and arm the signal. Upon impact of the bomb, the firing pin in the fuze overcomes a creep spring and impinges upon the primer of the blank cartridge, which, in turn, ignites the black-powder charge. The resulting explosion produces a flash of light and a large puff of gray smoke. Assembly When the signal is placed in the bomb, the fuze is unscrewed and the blank cartridge is inserted in the cartridge chamber. The fuze then is re-inserted and secured by lock­ nuts. At the time of loading the bomb into the plane, the arming wire is inserted through a flange on the fuze and through the fuze arming vane. After the bomb and arming wire completely and securely are in­ stalled in the plane, the safety pin is removed from the body of the fuze. Packaging When shipped, the signal is assembled with the fuze and packed in a corrugated cardboard carton. The carton also contains the blank cartridge (sealed in a separate envelope), the signal clamp assembly, the fuze arming vane, and a cotter pin for se­ curing the vane to the fuze. 20-mm Am­ munition Box Mk 3 Mod 1 will accommodate twelve of these cartons. Safety Precautions Signals should not be unpacked in advance of requirements. If unpacked and not used, return them to their original packing. If signal cartons are punctured, split, or badly damaged, or if seals are broken, the contents are considered unserviceable. This does not apply to signals repacked in the field and sealed with adhesive tape for tem­ porary protection. These assemblies must be examined carefully for serviceability by qualified personnel. Avoid dropping or jarring signal at all times to prevent accidental detonation. Stow signals in a dry, ventilated location, out of the direct rays of the sun. Signals and signal cartridges must not be deformed in any manner. If necessary to disassemble the signal, the safety cotter pin must be installed in the body of the fuze before the arming wire is removed. 3-25 N A V W E P S OP 2216 (V O L U M E 1) P R A C T IC E BO M B S IG N A L M k 7 M od 0 F ig u re 3 - 2 2 . — P ractice B o m b S ig n a l M k 7 M o d 0, A s s e m b le d with Fuze. Mark .......... ....... .......................... Mod ___________ ____ _____ _____ General Arrangement List of Drawings ............................ Length (in.) Diameter (in.) _________________ Weight of Assembled Signal (lb) Container Material ______ _____ L Explosive Charge Type ............................... .. Weight (lb) .... ........................... General Description Practice Bomb Signal Mk 7 Mod 0 is es­ sentially a can of black powder fitted with the inert Fuze AN-Mk 247 Mod 0 and a blank .38 caliber cartridge which is used as a detonator. The Mk 7 signal is generally the same as the Mk 6 signal except that the fuze is mounted off-center in the Mk 6 and its black-powder filling weighs about 1 pound more. The Mk 7 signal is used with 3-26 7 0 439736 109535 10.12 2.0 2.5 Steel Black powder 1.0 practice bombs for observation as to bomb­ ing accuracy. Functioning Upon release from the plane, the arming wire is withdrawn, permitting the fuze arming vane to rotate and arm the signal. Upon impact of the bomb, the firing pin in the fuze overcomes a creep spring and im­ pinges upon the primer of the blank car­ tridge which, in turn, ignites the black- B O M B C O M P O N E N T S O TH ER T H A N FUZES powder charge. The resulting explosion produces a flash of light and a large puff of gray smoke. Assembly When the signal is placed in the bomb, the fuze is unscrewed, and the blank car­ tridge is inserted in the cartridge chamber. The fuze then is re-inserted and secured by two locknuts. At the time of loading the bomb into the plane, the arming wire is in­ serted through a flange on the fuze and through the fuze arming vane. After the bomb and arming wire are completely and securely installed in the plane, the safety pin is removed from the body of the fuze. Packaging When shipped, the signal is assembled with the fuze and packed in a corrugated cardboard carton. The carton also contains the blank cartridge (sealed in a separate envelope), the fuze arming-vane, and a cot­ ter pin for securing the vane to the fuze. The 20-mm Ammunition Box Mk 3 Mod 1 will accommodate 12 cartons. Safety Precautions Signals should not be unpacked in ad­ vance of requirements. If unpacked and not used, return them to their original packings. If signal cartons are punctured, split, or badly damaged, or if the seals are broken, the contents are considered unserviceable. The latter does not apply to signals repacked in the field and sealed with adhesive tape for temporary protection. These assemblies must be examined carefully for service­ ability by qualified personnel. Avoid dropping or jarring signals at all times to prevent accidental detonation. Signals must be stowed in a dry, venti­ lated location, out of the direct rays of the sun. Signals and signal cartridges must not be deformed in any manner. If necessary to disassemble the signal, the safety cotter pin must be installed in the body of the fuze before the arming wire is removed. 3-27 N A V W E P S OP 2216 (V O L U M E 1) P R IM E R -D E T O N A T O R M l 4 — BODY CHARGE HOLDER (WHITE) 0.01 SEC DELAY (1/8 BLACK) 0.025 SEC DELAY (1/4 B U C K ) 0.10 SEC DELAY (BLACK) 0.24 SEC DELAY (GREEN) Figure 3-23. — Primer-Detonator M l 4. Model _______________ _____ _____ .._______ - ................................................ Assembly Drawing No. Nondelay .... ............................................... ..........................—................. 0.01 sec delay ......... ............................................... ................................... 0.025 sec delay --------- ----- ------ ---------------------- --------- -----------0.10 sec delay ... ............. ................. ............ ......................................... 0.24 sec delay .............................................................................. ......... Percussion Primer _______________ __ ___ _______ ______ ______ ________ ___ Detonator ........................— ...............- .................-------- ---------------------- ------- ... General Description Primer-Detonator M14 is available with delays of 0.01, 0.025, 0.10, and 0.24 second. A nondelay primer detonator also is avail­ able. The delay length of time (or the word “ nondelay” ) is stamped on the end of each primer-detonator. The time also is indi­ cated by the color of the exposed surface: non-delay-white, 0.01-*/« black, 0.25-14 black, 3-28 M14 73-8-70 73-8-68 73-8-69 73-8-67 73-8-354 M39 M17 0.10-black, and 0.24-green. Primer-detona­ tors are described fully in chapter 1. The M14 has a plain knurled head and is threaded with 12 threads per inch. It is thus distinguished from the M16 and M16A1, each of which has a groove around the head and 20 threads per inch. Do not attempt to assemble the wrong type primerdetonator into a fuze; this will ruin both the fuze and the primer-detonator. B O M B C O M P O N E N T S O TH ER T H A N FUZES Changing a Primer-Detonator To change a primer-detonator already in­ stalled in a fuze in order to provide a dif­ ferent delay, proceed as follows. 1. Remove a primer-detonator with the desired delay from its packing and inspect it for any obvious defects. 2. Unscrew the undesired primer-detona­ tor from the fuze body. If the plunger spring or spring washer fall out, replace them before installing the new primer-deto­ nator. 3. Screw the new primer-detonator into the fuze, hand tight. Do not use tools. If hand force is insufficient, turn in the fuze as unserviceable. 4. Seal the primer-detonator removed from the fuze in the packing of the substi­ tute, and mark it to indicate the delay. Packaging One primer-detonator is packed in a black cylindrical metal container 1.3 inches in diameter and 2.2 inches long. The weight of the primer-detonator and container is about 0.5 pound. The cover is sealed with an adhesive-tape strip, with a tab to facili­ tate opening. Twenty-five primer-detonators in metal cans are packed in an 8- by 8- by 2.25-inch metal container. The cover is sealed with an adhesive-tape sealing strip with a tab to facilitate opening. The weight of box and the contents is about 13% pounds. 3-29 N A V W E P S OP 2216 (V O L U M E 1) P R IM E R -D E T O N A T O R S M l 6 and M 16A1 DETONATOR PRIMER BODY RELAY CHARGE DELAY ELEMENT PRIMER SOLID YELLOW F ig u re 3-24. — P rim e r-D e to n a to r Mode] ........... ................................................... Assembly Drawing No. 4- to 5-sec delay ... ................................. 8- to 15-sec delay ......... ...................... Primer .... ........................................................ Detonator ........................ ........................... General Description Primer-Detonators M16 and M16A1 are available with delays of 4 to 5 seconds or 8 to 15 seconds. The delay time is stamped on the end of each primer-detonator. 3-30 M 16A1. ........... M16A1 ......................... .. ...................... ....... ............................................... — ......................... ______________ _______ _______ 73-8-84 73-8-83 M39A1 M17 Primer-detonators chapter 1. The M16 differs turally only in that shoulder. The end are described fully in from the M16A1 struc­ the M16A1 has a higher of the M16A1 is painted BO M B C O M P O N E N T S O TH ER T H A N FUZES yellow. Both the M16 and M16A1 have a groove around the head as distinguished from the plain knurled head of the M14. They differ also in thread pitch from the M14. The M14 has 12 threads per inch; the M16 and M16A1 have 20 threads per inch. Do not attempt to assemble the wrong type primer-detonator into a fuze; to do so will ruin both fuze and primer-detonator. The 4- to 5-second delay of the M16 and M16A1 is used against ship targets, the 8to 15-second delay against shore targets. Changing a Primer-Detonator To change a primer-detonator already in­ stalled in a fuze in order to provide a dif­ ferent delay, proceed as follows. 1. Remove a primer-detonator with the desired delay from its packing and inspect it for any obvious defects. 2. Unscrew the undesired primer-detona­ tor from the fuze body. If the plunger spring or spring washer fall out, replace them before installing the new primerdetonator. 3. Screw the new primer-detonator into the fuze, handtight. Do not use tools. If hand force is insufficient, turn in the fuze as unserviceable. 4. Seal the primer-detonator removed from the fuze in the packings of the substi­ tute, and mark it to indicate the delay. Packaging One primer-detonator is packed in a black cylindrical metal container 1.3 inches in diameter and 2.2 inches long. The weight of the primer-detonator and container is about 0.5 pound. The cover is sealed with an adhesive-tape strip, with a tab to facili­ tate opening. Twenty-five primer-detonators in metal cans are packed in an 8- by 8- by 2.25-inch metal container. The cover is sealed with an adhesive-tape sealing strip, which has a tab to facilitate opening. The weight of the box and its contents is about 13% pounds. 3-31 Chapter 4 ARMOR-PIERCING AND SEMI-ARMOR-PIERCING BOMB ASSEMBLIES 1000-LB A P BO M B A N - M k 33 Mods 1, 2, and 3 F ig u re 4— 1 .— 1 0 0 0 -lb A P B o m b A N - M k 3 3 M o d s 1, 2, & 3, Exte rio r View . A N -M k _________ ______ ___ ____ Mod _________ _____________ — .... General Arrangement .. .... ...... List o f Drawings _________ _____ Fin Assembly Drawing No. ___ Length of Assembled Bomb (in.) Body Diameter (in.) __________ Fin Span (in.) .............................. Weight of Explosive Charge (lb) Weight o f Fin Assembly (lb) .... Weight o f Assembled Bomb (lb) Arming-W ire Assembly .... Arming Bracket .......... .............. Auxiliary Booster _____________ Tail Fuze ______ ________ ____ General Description The 1000-lb AP Bomb AN-Mk 33 Mods 1, 2, and 3, now obsolete, is a thick metal cased bomb with a solid, pointed nose; it is equipped with a box-type fin assembly. 33 1, 2, 3 329536 Sk 90916 328811 73.0 12.0 16.0 140.0 21.5 1008.0 Mk 1 or AN-M6A2 Mk 1 Mod 0 Mk 1 Mod 0 AN -M k 228 and Mods The only fuze authorized for use with this bomb is the AN-Mk 228 tail impact fuze. The bursting charge is explosive D. Ap­ proximately 13 percent of the complete re­ leased weight of the bomb consists of the explosive charge. 4-1 N A V W E P S OP 2216 (V O L U M E 1) ARMING W IRE TUBE ARMING WIRE ASSEMBLY ARMING BRACKET MK 1 SECURING WIRE SCREWS SUSPENSION LUG FIN LOCK NUT HOISTING LUG BOX FIN ASSEMBLY BOMB BODY F ig u re 4 —2. — 1 0 0 0 -lb A P B o m b A N - M k 3 3 M o d z 1 , 2 , & 3, E x p l o d e d V iew . Two suspension lugs, 14 inches apart, are attached to the bomb body by slotted cap­ screws. A hoisting lug is attached similarly between the two suspension lugs. D and Q Differences among Mods There are no physical differences among Mods 1, 2, and 3. The mod number is used only to identify the manufacturer. List of Attachments A list of the attachments packed in each bomb tail crate (Drawing 328382) follows. 4-2 P u a n t it y N Painting and M arking The entire bomb has a protective coating of olive drab paint. A 1-inch wide yellow band is painted around the nose of the bomb, and a 3-inch wide yellow band encircles the conical after end. A Vi-inch wide broken yellow band may encircle the bomb at its center of gravity; however, this is no longer required. Identifying nomenclature is sten­ ciled on the cylindrical portion of the bomb body in black letters, and similar data is stamped on the conical after end. r a w in g A ie c e ttach m ent um ber 2 3 2 8 8 1 3 -1 1 3 2 8 8 1 3 -2 1 3 2 8 8 1 3 -3 2 3 2 8 8 1 3 -5 11 3 2 8 8 1 3 -6 2 3 2 8 8 1 3 -7 1 3 2 8 8 1 3 -1 0 1 3 2 8 8 1 3 -1 1 1 300207 Suspension Lugs— for U.S. Rack and Shackles. Hoisting Lug— Single to U.S. Racks. Guide Stud— for U.S. Sling Suspension. Trunnions— for Dive Bomb­ ing. Cap Screws— V i " x V \ " . Trunnion Lock Washers. Safety Wire— Vie" x 24", Coil. Single Suspension Lug— Brit­ ish type. Arming Bracket Assembly-— for Tail Fuze. Special Instructions 1. Paint on attachments may, in some cases, interfere with installing the screws. Removal of the paint may be necessary in such instances. A R M O R -P IE R C IN G A N D S E M I-A R M O R -P IE R C IN G BO M B A SSEM B LIES AIL FUZE AUXILIARY BOOSTER BASE PLUG ARMING-WIRE ASSEMBLY BODY EXPLOSIVE CHARGE Figure 4 - 3 .— 1000-lb AP Bomb A N -M k 33 Mods 1, 2, & 3, Cutaway View. 4-3 N A V W E P S OP 2216 (V O L U M E 1) 2. All attachments not used in fitting up bombs are to be disposed of in accordance with current Bureau of Weapons instruc­ tions. 3. Use hoisting lug 328813-2, when it is intended to hoist to a U.S.N. rack, using a single cable; use hoisting band Mark 8 (uni­ versal) when it is intended to hoist a bomb with or without shackle attached, using two hoisting cables or, with shackle attached, using one hoisting cable. a wooden drift against the pins of the lock­ nut. Tap the drift lightly. Tighten the setscrews on the locknut. CAUTION: Do not use a fin as­ sembly if it cannot be properly secured to the bomb. If the fin assembly is loose and turns while on the bomb, it will pull the arming wire from the tail fuze, and the fuze may arm before the bomb is dropped. Assembly CAUTION: Fuzes and bombs are not unpacked in advance of require­ ments and are to be returned to their original packings, if not used. 1. Remove shipping plugs from the holes to be used for securing suspension lugs or hoisting lug. Clean the holes. 2. Remove the fin assembly and attach­ ments from their shipping crate. CAUTION: Use only blies that are in good Reject fin assemblies rusted, dented, bent, or fins. fin assem­ condition. that are have loose 3. Remove the required fuze and arming wire from their packings and inspect; make sure the fuze is unarmed by looking through the inspection window in it. 4. Attach the required suspension fittings. Tighten securely. Screws holding the sus­ pension lugs should be safety-wired in pairs. CAUTION: Inspect suspension and hoisting lugs for damage or defects before securing them to the bomb body. Replace if necessary. 5. Remove the shipping plug from the fuze cavity of the bomb. Be sure the aux­ iliary booster is in place and that the tail fuze seat is clean. 6. Back off the setscrews and unscrew the fin locknut. Locate the fin vanes in a posi­ tion that will clear the aircraft structure and ground, when installed on the plane. Replace the fin locknut and tighten it. Hold 4-4 7. The AN-Mk 228 tail impact fuze is used with the 1000-lb AP AN-Mk 33 bomb. For detailed information on fuzing and defuzing, refer to chapter 2. CAUTION: Never use an arming wire that is twisted, kinked, or burred. These conditions are caused by mishandling. Burrs may result when cutting the arming wire to its required length or at any other point in the operation. File or recut to remedy the condi­ tion. Fit of Suspension Lugs Some difficulty may be encountered in at­ taching suspension lugs to the bomb. In some of the earlier lots, tapped holes in the bomb were mislocated. The holes in the suspension lugs were properly located with the result that they failed to line up with the mislocated holes in the bomb body. This condition has since been corrected at the source of manufacture. In addition, the holes in the suspension lugs have been in­ creased in diameter from inch to 17/u;i inch to facilitate attachment. Where a proper fit cannot be obtained, the holes of the suspension lug, dwg 328813, Piece 1, may be reamed out by increasing the diameter of each hole l/(U inch, i.e., from a normal inch to ' 5 7/:rj inch. To main­ 6 tain the required degree of safety, IN NO CASE SHOULD THE HOLES OF THE SUSPENSION LUGS BE ENLARGED MORE THAN y64 INCH. A '% a inch drill A R M O R -P IE R C IN G A N D S E M I-A R M O R -P IE R C IN G BO M B A SSEM B LIES may be used if a suitable reamer is not available. In some cases only one or two holes need to be reamed out to insure proper fit. Since the head of the screw must seat properly to provide adequate strength, it may be necessary in some cases to increase also the diameter of the counterbore by inch. Suspension lugs that are reamed out should either be kept attached to the bomb body or so marked that they can be rein­ stalled exactly as fitted. 4-5 N A V W E P S OP 2216 (V O L U M E 1) F ig u re 4 —4. — 16 00-1b A P B o m b A N - M k 1 M o d s 1, 2, & 3, Exterior V iew . AN-M k ...... ..................................... Mods ......................... ........ ............... Genera] Arrangement ___________ List of Drawings ............................ Fin Assembly Drawing No. ______ Length of Assembled Bomb (in.) Body Diameter (in.) ........... ........... Fin Span (in.) .................................. Weight of Explosive Charge (lb) Weight of Fin Assembly (lb) Weight of Assembled Bomb (lb) .. Arming-Wire Assembly ................. Arming Bracket Auxiliary Booster Tail Fuze . ......... ............................. General Description The 1600-lb AP Bomb AN-Mk 1 Mods 1, 2, and 3, now obsolete, is a thick metal cased bomb with a solid pointed nose. The thick case is designed to penetrate the 4-6 1 1, 2, 3 329431 Sk 91009 294201 83.50 14.0 20.60 209.0 28.50 1590.0 Mk 1 or AN-M 6A2 Mk 1 Mk 1 Mod 0 A N -M k 228 heaviest horizontal armor of combat ships. The bomb is equipped with a box-type fin assembly. The only fuze authorized for use with the AN-Mk 1 bomb is the AN-Mk 228 tail im- A R M O R -P IE R C IN G A N D S E M I-A R M O R -P IE R C IN G B O M B A SSE M B L IE S ARMING WIRE ASSEMBLY. FAHNESTOCK CLIPS ARMING WIRE T U B E ^ SECURING WIRE SCREWS SUSPENSION LUG ARMING BRACKET MK 1 TAIL FUZE \ SCREWS ---------- SUSPENSION LUG HOISTING LUG FIN LOCK NUT BOX FIN ASSEMBLY BOMB BODY F ig u re 4 - 5 . — 1 6 0 0 -lb A P Bomb A N - M k pact fuze. The bursting charge of explo­ sive D comprises approximately 13 percent of the weight of the complete round. Four sets of threaded holes in the bomb body permit mounting of lugs for either 14or 30-inch suspension. For single suspen­ sion, a lug may be secured to the underside of the bomb body by means of slotted cap­ screws. A hoisting lug is similarly at­ tached between and in line with the two suspension lugs. Painting and M arking The bomb is painted olive drab. A 1-inch wide yellow band encircles the nose end of the bomb and a 5.75-inch wide band en­ circles its conical aft portion. A >4-inch wide broken yellow band may be found at the center of gravity; however, this is no longer required. Identifying nomenclature is stenciled on the cylindrical portion of the bomb body in black letters, and similar data is stamped on the conical after end. Differences among Mods There are no physical differences among Mods 1, 2, and 3. The complete rounds con­ tain the same components and the mod num­ ber is used only to identify the manufac­ turer. 1 M o d s 1, 2, & 3, E x p l o d e d V iew . Assembly CAUTION: Fuzes and bombs are not unpacked in advance of re­ quirements and are to be returned to their original packing if not used. 1. Remove shipping plugs from the threaded holes in the bomb body where it is desired to attach the suspension and hoist­ ing lugs. Clean the threaded holes. 2. Remove the fin assembly and attach­ ments from their shipping crate. CAUTION: Use only blies that are in good Reject fin assemblies rusted, dented, bent, or fins. fin assem­ condition. that are have loose 3. Remove the required fuze and arming wire from their packings and inspect; make sure the fuze is unarmed by looking through the inspection window in it. 4. Attach the fittings for suspension and hoisting, using the slotted capscrews pro­ vided. Use a screwdriver of the proper size and tighten securely. Screws holding the suspension lugs to the bomb body should be safety wired in pairs. 4-7 N A V W E P S OP 2216 (V O L U M E 1) ARMING BRACKET AUXILIARY BOOSTER TAIL FUZE ARMING-WIRE ASSEMBLY BOMB BODY EXPLOSIVE CHARGE Figure 4-6. 4-8 1600-lb AP Bomb A N -M k 1 Mods 1, 2, & 3, Cutaway View. A R M O R -P IE R C IN G A N D S E M I-A R M O R -P IE R C IN G B O M B A SSE M B L IE S CAUTION : Inspect suspension and hoisting lugs for damage or defects before securing them to the bomb body. Replace if necessary. 5. Remove the fuze hole cover from the bomb and clean the threads if necessary. Be sure the auxiliary booster is in place. 6. Back off the two setscrews holding the tail locknut in place; remove the locknut and fit the tail to the body. Replace the tail locknut and tighten by hand. Rotate the vanes until their position clears the airplane structure and the ground when the bomb is installed. Tighten the locknut se­ curely. Hold a wooden drift against the pins of the locknut. Tap the drift lightly. Tighten the setscrews on the locknut. 7. The AN-Mk 228 tail impact fuze is used with the 1600-lb AP AN-M k 1 bomb. For detailed information on fuzing and defuzing, refer to chapter 2. CAUTION: Never use an arming wire that is twisted, kinked, or burred. These conditions are caused by mishandling. Burrs may result when cutting the arming wire to its required length or at any other point in the operation. File or recut to remedy this con­ dition. 4-9 N A V W E P S OP 2216 (V O L U M E 1) F ig u re 4 - 7 . — 5 0 0 -lb S A P B o m b A N - M 5 8 A 2, Exte rio r V ie w . Model ................................................ Assembly Drawing No. ______ Length of Assembled Bomb (in.) Body Diameter (in.) Fin Span (in.) _________ ______ Weight of Explosive Charge (lb) TNT ..... .............. Picratol __________________ Weight of Fin Assembly (lb) Weight of Assembled Bomb (lb) Loaded with TNT ____ _______ Loaded with Picratol ........... Fin Assembly ....... ................... Fin Locknut Arming-Wire Assembly .. Adapter-Booster Nose Fuze Tail Fuze . 4-10 ..... ...... AN-M 58A2 82-0-61 57.80 11.82 16.18 152.0 154.0 17.5 552.0 554.0 AN-M110A1 Mk 1 Mod 0 Mk 1 or A N -M 6A2 M102A1 AN-M103A1, AN-M139A1, AN-M140A1 AN-M101A2, AN-M116, AN-M124A1, AN-M113 A R M O R -P IE R C IN G A N D S E M I-A R M O R -P IE R C IN G B O M B A SSEM B L IES F ig u re 4 —8 . — 5 0 0 - lb S A P B o m b A N - M 5 8 A 2, E x p lo d e d V iew . General Description Painting and M arking The 500-lb SAP Bomb AN-M58A2, now obsolete, has a cylindrical heavy steel casing with a pointed nose. A box-type fin assem­ bly is attached to the aft end of the bomb body by a fin locknut. The base plug locks securely in place and the adapter-booster may be locked to the base plug. Yellow bands on the nose and aft end of the bomb body identify the explosive charge. Identifying nomenclature is sten­ ciled in black on an olive drab painted bomb casing. This bomb accommodates both nose and tail fuzes. Tactical requirements usually nullify the need for a nose fuze, in which case the nose fuze cavity is fitted with a solid steel plug. The 500-lb SAP Bomb AN-M58A2 was developed to provide greater penetrative ability than that af­ forded by a comparable weight GP bomb. Picratol, AM 50-50 (Amatol), and TNT fillers account for the differences in released weights. Bombs filled with Amatol 50-50 include a booster surround of TNT and the Auxiliary Booster M104, which is inserted during the filling process. Bombs filled with Picratol include the auxiliary booster less the TNT surround; TNT filled bombs do not include the auxiliary booster. Suspension lugs for either single or dual point suspension are welded to the bomb body. Differences Am ong Bombs A N -M 5 8 A 2 , A N -M 5 8 A 1 , and A N -M 5 8 The AN-M58A2, AN-M58A1, and A N M58 bombs are similar to each other on out­ ward appearance. However, the AN-M58A2 contains antiwithdrawal pins in the base plug, and an adapter-booster which can be locked in place, while the AN-M58 and A N M58A1 bombs lack these features. The three bombs also differ in their re­ leased weights. The AN-M58 has a lighter body than its two modifications. Its com­ plete round weighs 480 pounds, of which 154.6 pounds, 32.3 percent of the total bomb weight, is explosive filler. The AN-M58A1 weighs 499.5 pounds as released; its explo­ sive filler weighs 145.1 pounds, 29 percent of the total bomb weight. Assembly CAUTION: Fuzes and bombs are 4-11 N A V W E P S OP 2216 (V O L U M E 1) TAI L LOCKING PIN IG SEALER ARMING-WIRE ASSEMBLY SURROUND BOOSTER BODY EXPLOSIVE CHARGE INERT SEALER COMPOUND (WAX PAD) PLUG Figure 4-9.— 500-lb SAP Bomb A N -M 58A 2, Cutaway View. 4-12 A R M O R -P IE R C IN G A N D S E M I-A R M O R -P IE R C IN G B O M B A SSE M B L IE S not unpacked in advance of require­ ments and are to be returned to their original packing if not used. 1. Remove the shipping bands from the bomb by removing the nuts from the se­ curing bolts. Remove the closing plugs. CAUTION: Inspect for damage, cracks, or broken weldments which might weaken the lugs or their at­ tachment to the bomb body. 2. Cut the shipping wire and remove the fin locknut and its protector. Remove the protector from the locknut. 3. Remove the fin assembly and its at­ tachments from the shipping crate. Place the fin assembly over the end of the bomb with one fin in line with the suspension lugs. If hung in external racks, locate the fin to clear the aircraft and the ground when installed. Replace the fin locknut and tighten it with a wrench. When the bomb is to be carried externally at speeds in excess of 350 knots, Fin Locknut Mk 1 Mod 0 must be used in place of the regular fin locknut in order to prevent rotation of the fin assembly. CAUTION: Do not use a fin as­ sembly if it cannot be properly secured to the bomb. If the fin as­ sembly is loose and turns on the bomb, it will pull the arming wire from the tail fuze, causing it to arm prematurely. Use only those fin assemblies that are in good con­ dition. Reject those that are rusted, dented, bent, or have loose fins. 4. Install the bomb on the aircraft and securely lock it in place. If the bomb bay joes not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the rack. 5. Remove the required number of fuzes and arming-wire assemblies from their con­ tainers. CAUTION: If the containers are found to be punctured, split, or if the seal is broken in any way, the fuzes contained therein are con­ sidered unserviceable. This does not apply to fuzes replaced in the field and resealed with adhesive tape for temporary protection. Such fuzes should be carefully ex­ amined for serviceability. 6. For detailed information on fuzing and defuzing, refer to chapter 2 under the par­ ticular fuze to be installed. CAUTION: One of the fuzes used with this bomb is the AN-M124A1 tail fuze which incorporates the use of an antiwithdrawal device. Nondetonation of bombs fuzed with the AN-M124A1 cannot be relied upon when released SAFE because the glass solvent ampoules in the fuze may be broken upon impact of the bomb. Once an A N M124A1 fuze is installed, no at­ tempt should be made either to re­ move the fuze from the bomb or to return the bomb to an airfield or aircraft carrier upon an incom­ plete mission. Do not turn the fuze back and forth to engage threads; use a screwing-in motion only. The antiwithdrawal device will cause the fuze and the bomb to detonate if the fuze is rotated counterclock­ wise while in the adapter-booster, even before the threads are en­ gaged. 4-13 N A V W E P S OP 2216 (V O L U M E 1) 1000-LB SAP BO M B A N -M 5 9 A 1 AN-M59A1 82-0-62 70.38 15.13 20.72 Model .. ..... ................................ .. Assembly Drawing No. . ........... Length o f Assembled Bomb (in.) Body Diameter (in.) ........ ..... ..... Fin Span (in.) ....... ..................... Weight o f Explosive Charge (lb) Amatol .... ..................................... TNT .. ............. ....... .......... ...... Picratol ........... ................... ........ Weight o f Fin Assembly (lb) .... Weight o f Assembled Bomb (lb) Loaded with Amatol .................. Loaded with TNT .... ................. Loaded with Picratol ___ _____ Fin Assembly ....... .......................... Fin Locknut ...................... Arming-Wire Assembly ...... ......... Adapter-Booster ......... .................. Nose Fuze ........................................ 292.25 315.0 320.0 25.5 1032.0 1039.0 1042.0 AN-M114A1 Mk 1 Mod 0 Mk 1 or AN-M 6A2 M102A1 AN-M103A1, AN-M139A1, AN-M140A1 AN-M 102A2, AN-M117, AN-M 125A1, AN-M134 Tail Fuze __ _________ _________ General Description The 1000-lb SAP Bomb AN-M59A1 has a thick metal body designed to give greater penetration than a general purpose bomb of comparable weight. It is a heavy nosed cylindrical shaped bomb. A box-type fin assembly is attached to the aft end by a fin locknut. The base plug of the A N M59A1 bomb locks securely in place and the adapter-booster may be locked to the base plug. This bomb can accommodate both nose and tail fuzes. Tactical requirements usu­ ally nullify the need for a nose fuze, in which case the nose fuze cavity is fitted with a solid steel plug. Approximately 30 percent of the total weight of the 1000-lb SAP AN-M59A1 bomb is explosive charge. Bombs filled with Amatol 50-50 include a booster surround of cast TNT and the Aux­ iliary Booster M104, which is inserted dur­ ing the filling process. Bombs filled with Picratol include the auxiliary booster less the TNT surround; TNT filled bombs do not include the auxiliary booster. Painting and M arking Yellow bands around the nose and aft 4-14 end of the bomb identify the explosive charge. Identifying nomenclature is sten­ ciled in black on an olive drab painted bomb casing. Differences Between Bombs A N -M 5 9 A 1 and A N - M 5 9 The 1000-lb SAP Bomb AN-M59A1 has antiwithdrawal pins in the base plug and an adapter-booster which can be locked to the base plug. The AN-M59 bomb, now obsolete, lacks these features. The explo­ sive charge in the AN-M59 bomb is ap­ proximately 315 pounds, or 31.8 percent of the bomb’s complete weight of 990 pounds. In all other physical respects, the 1000-lb SAP Bomb AN-M59 is identical to the 1000-lb SAP Bomb AN-M59A1. Assembly CAUTION : Fuzes and bombs are not unpacked in advance of require­ ments and are to be returned to their original packing if not used. 1. Remove the shipping bands from the bomb by removing the nuts from the se­ curing bolts. Remove the closing plugs. A R M O R -P IE R C IN G A N D S E M I-A R M O R -P IE R C IN G B O M B A SSEM B LIES 70"38- F i g ore 4 -1 0 .— 1 0 0 0 -lb S A P B o m b A N - M 5 9 A 1 , Exterior V iew . Figure 4 -1 1 .— 1000-lb SAP Bomb A N M59A1, Exploded View. 4-15 N A V W E P S OP 2216 (V O L U M E 1) LOCKING PIN ARMING-WIRE ASSEMBLY SEALER BOOSTER BODY OSIVE CHARGE NERT SEALER COMPOUND (WAX PAD) PLUG Figure 4-12. 4-16 1000-lb SAP Bomb A N M 59A 1, Cutaway View. A R M O R -P IE R C IN G A N D S E M I-A R M O R -P IE R C IN G B O M B A SSEM B LIES CAUTION : Inspect for damage, cracks, or broken weldments which might weaken the lugs or their attachment to the bomb body. 2. Cut the shipping wire and remove the fin locknut and its protector. Remove the protector from the locknut. 3. Remove the fin assembly and its at­ tachments from the shipping crate. Place the fin assembly over the end of the bomb with one fin in line with the suspension lugs. If hung in external racks, turn the fin and locate it so as to clear the aircraft structure and the ground when installed. Replace the fin locknut and tighten with a wrench. When the bomb is to be carried externally at speeds in excess of 350 knots, Fin Locknut Mk 1 Mod 0 should be used in place of the regular locknut. Setscrews should be se­ curely tightened in order to prevent rotation of the fin assembly. CAUTION: Do not use a fin as­ sembly if it cannot be properly secured to the bomb. If the fin assembly is loose and turns on the bomb, it will pull the arming-wire from the tail fuze, causing it to arm prematurely. Use only those fin assemblies that are in good con­ dition. Reject those that are rusted, dented, bent, or have loose fins. 4. Install the bomb on the aircraft and securely lock it in place. If the bomb bay does not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the rack. 5. Remove the required number of fuzes and arming-wire assemblies from their con­ tainers, and examine them carefully for serviceability. 6. For detailed information on fuzing and defuzing, refer to chapter 2 under the par­ ticular fuze to be installed. CAUTION: The AN-M59A1 bomb uses the AN-M125A1 and the A N M134 tail fuzes which incorporate the use of an antiwithdrawal de­ vice. Nondetonation of bombs fuzed with the AN-M125A1 and AN-M134 fuzes cannot be relied upon when released SAFE be­ cause the glass solvent ampoule in the fuze may be broken upon im­ pact of the bomb. Once an A N M125A1 or AN-M134 fuze is in­ stalled, no attempt should be made to remove the fuze or to return the bomb to an airfield or aircraft carrier upon an incomplete mission. Do not turn an AN-M125A1 or an AN-M134 fuze back and forth to engage threads; use a screwing-in motion only. The antiwithdrawal device will cause the fuze and the bomb to detonate if the fuze is ro­ tated counterclockwise while in the adapter-booster, even before the threads are engaged. 4-17 N A V W E P S OP 2216 (V O L U M E 1) 2000-LB SA P B O M B M l 03 Figure 4-13. — 2000-lb SAP Bomb M l 03, Exterior View. Model ..... ..................—.............. - .... Assembly Drawing No. .... ........... Length o f Assembled Bomb (in.) Body Diameter (in.) ...................... Fin Span (in.) ................................ Weight of Explosive Charge (lb) Weight of Fin Assembly (lb) .... Weight o f Assembled Bomb (lb) Fin Assembly ....... .......................... Arming-W ire Assembly ................ Adapter-Booster ......... .................. Tail Fuze __________ _______ ___ General Description The 2000-lb SAP Bomb M103, now ob­ solete, is fabricated from seamless steel tubing and has a solid, semipointed nose. 4-18 M103 82-0-133 88.45 18.75 25.84 556.48 52.75 2039.35 M117A1 Mk 1 or A N -M 6A 2 M115A1 AN-M 102A2, AN-M117, AN-M 125A1, AN-M 134 This bomb takes only a tail fuze, having no provision for a nose fuze. A box-type fin assembly is used, as on other SAP bombs. Approximately 27 percent of the total A R M O R -P IE R C IN G A N D S E M I-A R M O R -P IE R C IN G B O M B A SSEM B LIES ARMING WIRE ASSEMBLY FAHNESTOCK CU PS Figure 4—14.— 2OOO-lb S A P Bomb M l 03, Exploded View. weight of the bomb is explosive filler Picratol. Double suspension lugs having a 30inch spacing are welded to the bomb casing. A single lug is located on the side opposite from the double lugs. Painting and M arking Yellow bands on the nose and aft end of the body identify the high-explosive charge. Identifying nomenclature is sten­ ciled in black on an olive drab painted bomb casing. Assembly CAUTION: Fuzes and bombs are not unpacked in advance of re­ quirements and are to be returned to their original packing if not used. 1. Remove the shipping bands from the bomb by removing the nuts from the se­ curing bolts. Remove the closing plugs. CAUTION: Inspect for damage, cracks, or broken weldments which might weaken the lugs or their at­ tachment to the bomb body. 2. Cut the shipping wire and remove the fin locknut and its protector. Remove the protector from the locknut. 3. Remove the fin assembly and its at­ tachments from the shipping crate. Place th3 fin assembly over the end of the bomb with one fin in line with the suspension lugs. If hung in external racks, turn the fin and locate it so as to clear the aircraft struc­ ture and the ground when installed. Re­ place the fin locknut and tighten it with a wrench. CAUTION: Do not use a fin as­ sembly if it cannot be properly se­ cured to the bomb. If the fin as­ sembly is loose and turns on the bomb, it will pull the arming-wire from the tail fuze, causing it to arm prematurely. Use only those fin assemblies that are in good condi­ tion. Reject those that are rusted, dented, bent, or have loose fins. 4. Install the bomb on the aircraft and securely lock it in place. If the bomb bay does not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the rack. 5. Remove the required number of fuzes 4-19 N A V W E P S OP 2216 (V O L U M E 1) TAIL FUZE LOCKING AIMING-WIRE ASSEMBLY TAIL SEALER AUXILIARY BOOSTER EXPLOSIVE CHARGE BOMB BODY NOSE SEALER (WAX PAD) Figure 4-15.— 2000-lb SAP Bomb M l 03, Cutaway View. 4-20 A R M O R -P IE R C IN G A N D S E M I-A R M O R -P IE R C IN G B O M B A SSEM B L IES and arming-wire assemblies from their con­ tainers, and examine them carefully for serviceability. 6. For detailed information on fuzing and defuzing, refer to chapter 2 under the par­ ticular fuze to be installed. CAUTION: The M103 bomb uses the AN-M125A1 and the A N M134 tail fuzes which incorporate the use of an antiwithdrawal de­ vice. Nondetonation of bombs fuzed with the AN-M125A1 and AN-M134 fuzes cannot be relied upon when released SAFE because the glass solvent ampoule in the fuze may be broken upon impact of the bomb. Once an AN-M125A1 or AN-M134 fuze is installed, no attempt should be made to remove the fuze or to return the bomb to an airfield or aircraft carrier upon an incomplete mission. Do not turn an AN-M125A1 or an A N M134 fuze back and forth to engage threads; use a screwing-in mo­ tion only. The antiwithdrawal de­ vice will cause the fuze and the bomb to detonate if the fuze is ro­ tated counterclockwise while in the adapter-booster, even before the threads are engaged. 4-21 Chapter 5 GENERAL PURPOSE BOMB ASSEMBLIES 100-LB GP B O M B A N -M 3 0 A 1 W ith F in A ssem bly A N -M 1 0 3 A 1 W ith F in A ssem bly M 135 M odel..................... __....................... Assembly Drawing No - ______ Length of Assembled Bomb (in.)__ Body Diameter (in.)______________ Fin Span (in.). . ______ _______ Weight of Explosive Charge (lb): T N T _________ _____ ______ Tritonal ________ _____ _____ Weight of Fin Assembly (lb )______ Weight of Assembled Bomb (lb ): Loaded with T N T _____ ______ Loaded with Tritonal _ . Fin Locknut........................................ Fin Locking Web . _ _ _ Arming-Wire Assembly_______ A N -M 30A 1_____________ 82-0-12. 40.26___________________ 8 .1 8 ____________________ 1 1 .0 . . ________________ AN-M 30A1. 5 7.0____________________ 6 2 .0 . __________________ 5 .6 _____________________ 57.0. 62.0. 17.5. 119.5. __________ ______ 124.5 . . . . . ............. M l or Mk 2 ___ ________ Not U sed.. . ___ Mk 1, A N -M 6A 2_______ Adapter-Booster_ _ . Nose Fuze....... .................................... M102A1________________ AN-M 103A1, A N M139A1, AN-M140A1, Mk 243 Mod 0, Mk 244 Mod 1, AN-M 166 (VT), AN-M 168 (VT). AN-M 100A2, A N M115, AN-M123A1, or AN-M 132. 131.5. 136.5. Sk 329153. Dwg 1350522. Mk 1 or A N -M 6A2, and M13. M102A1. AN-M 103A1, A N M139A1, AN-M140A1, Mk 243 Mod 0, Mk 244 Mod 1, AN-M 166 (VT), AN-M 168 (VT). M -172 or AN-M175. Tail Fuze____________ _____ ______ General Description The 100-lb GP Bomb AN-M30A1 is a relatively thin cased bomb with an ogival nose, parallel side walls, and a tapered aft section. A box-type fin assembly is fastened to the aft end of the bomb with a fin lock­ nut. The bomb uses both nose and tail fuzes. The base plug of the bomb is locked securely to the bomb body by two studs which ex­ tend from the base plug into the solidified explosive charge. This bomb also provides a means of locking the adapter-booster to the base plug; a locking pin is passed through a hole in the adapter-booster into a groove in the base plug. These modifica­ 54.2. 8.18. 11.18. tions were initiated to prevent removal of the base plug and adapter-booster to make the antiwithdrawal devices of long-delay fuzes more effective. Two suspension lugs, 14 inches apart, are welded to one side of the bomb body. A single lug is welded to the opposite side at the center of gravity. Approximately 50 per­ cent of the released weight of the bomb is its explosive charge of TNT or Tritonal. Painting and M arking Yellow color bands on an olive drab body identify the high-explosive charge. Identi­ fying nomenclature is stenciled on the nose, 5-1 N A V W E P S OP 2216 (V O L U M E 1) F ig u re 5 - 1 .— 1 0 0 -lb G P B o m b A N - M 3 0 A 1 with Fin A s s e m b ly A N - M 1 0 3 A 1 , Exterior V ie w . ARMING WIRE ASSEMBLY FAHNESTOCK. CLIPS, TAIL FUZE FAHNESTOCK CLIPS IN LOCK NUT BOX FIN ASSEMBLY BOMB BODY NOSE FUZE Figure 5-2.— 100-lb GP Bomb A N -M 3 0 A 1 with Fin Assembly A N —M103A1, Exploded View. 5-2 G E N E R A L PURPOSE B O M B A SSEM B LIES midsection, and conical aft section in black paint. Difference Between Mods The AN-M30A1 bomb contains antiwith­ drawal pins in the base plug and a device for locking the adapter-booster to the base plug. The earlier model, AN-M30, does not have these features. The AN-M30 bomb is lighter in weight than its modification, the AN-M30A1. The AN-M30 may be loaded with 105.5 pounds of Tritonal, 102.5 pounds of TNT, or 99.0 pounds of Amatol 50-50. Assembly CAUTION: Fuzes and bombs are not to be unpacked in advance of requirements. Return them to their original packing if not used. 1. Remove the shipping bands from the bomb by removing the nut from the se­ curing bolts. Remove the closing plugs. Inspect for damage, cracks, or broken weld­ ments which might weaken the lugs or their attachment to the bomb body. 2. Cut the shipping wire and remove the fin locknut and discard it with its protector. 3. Remove the fin assembly and its at­ tachments from the shipping crate. Place the fin assembly over the end of the bomb with one fin in line with the suspension lugs. If hung on external racks, turn the fin and locate it so that it will clear the aircraft and the ground when installed. Replace the fin locknut and tighten it with a wrench. Fin Locknut M l or Mk 2 Mod 0 should al­ ways be used in place of the regular fin locknut. Fin locknut setscrews should be tightened securely. This is necessary to prevent rotation of the fin assembly. CAUTION: Do not use fin assem­ bly if it cannot be properly se­ cured to the bomb. If the fin assembly is loose and turns on the bomb, it will pull the arming wire from the tail fuze, causing it to arm prematurely. 4. Install the bomb on the aircraft and securely lock it in place. If the bomb bay does not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the bomb rack. 5. Remove the required number of fuzes and arming-wire assemblies from their con­ tainers and examine them carefully for serviceability. 6. For detailed information on fuzing and defuzing, refer to chapter 2 under the par­ ticular fuze to be installed. CAUTION: The AN-M30A1 bomb uses the AN-M123A1 and the A N M132 tail fuzes which incorporate the use of an antiwithdrawal de­ vice. Nondetonation of bombs fuzed with AN-M123A1 and A N M132 fuzes cannot be relied upon when released SAFE because the glass solvent ampoule in the fuze may break upon impact of the bomb. Once an AN-M123A1 or AN-M132 fuze is installed, no at­ tempt should be made to remove the fuze. Return of bombs to air­ fields or carriers is restricted. Bombs fuzed with AN-M123A1 or AN-M132 fuzes may be returned to an airfield or carrier provided that: (1) Bomb rack malfunction pre­ vents release. (2) Efforts to re­ lease by maneuvering of aircraft are unsuccessful. (3) Bomb and fin assemblies are undamaged and fuze arming wires are in place, as observed by check of aircraft before landing. (4) Fuzed bombs are immediately disposed of by au­ thorized personnel upon landing of aircraft. Do not turn an A N M123A1 or AN-M132 fuze back and forth to engage the threads; use a screwing-in motion only. The antiwithdrawal device will cause the fuze and bomb to detonate if the fuze is rotated counterclockwise while in the adapter-booster, even before the threads are engaged. 5-3 N A V W E P S OP 2216 (V O L U M E 1) TAIL FUZE LOCKING ARMING-WIRE ASSEMBLY INERT SEALER COMPOUND BODY FUZE SEAT LINER INERT SEALER COMPOUND (WAX PAD) FUZE Figure 5-3.— 100-lb GP Bomb A N -M 30A 1 with Fin Assembly A N -M 1 0 3 A 1 , Cutaway View. 5-4 G E N E R A L PURPOSE BO M B A SSEM B LIES 100-LB GP B O M B A N -M 3 0 A 1 W IT H ARMING WIRE ASSEMBLY FAHNESTOCK CLIPS FIN A S S E M B L Y M 135 FIN LOCKING WEB FIN LOCK NUT CENTER SUPPORT TUBE Figure 5—4 .— 100-lb GP Bomb A N -M 30A 1 with Fin Assembly M l 35, Exploded View. General Description When equipped with Fin Assembly M135, the 100-lb GP Bomb AN-M30A1 uses the standard AN-M30A1 bomb body. Fin As­ sembly M l35 consists of an elongated fin cone with four integral fins spaced at equal distances on the cone surface. It was de­ veloped to increase aerodynamic perform­ ance and accuracy in bombing. Use of the conical fin lengthens the overall dimension of the bomb. This necessitates the use of a tail fuze with an extra-long arming stem and tube (long stem fuze) so that the arming vane of the fuze can be located effectively in the air stream. ments which might weaken the lugs or their attachment to the bomb body. 2. Cut the shipping wire. Remove the fin locknut and discard it with its protector. 3. Remove the fin assembly and its attachments from the shipping crate. Thread the center support tube onto the base plug of the bomb (locknut seat) and tighten the tube with a wrench. Tighten the setscrews in the support tube. Place the fin cone over the support tube and slide the cone back until it is jammed against the bomb body. Position the fins so that they will clear the aircraft structure and the ground when in­ stalled. Place the fin locking web over the support tube so that it engages the fins of Assembly the fin assembly. Secure the conical fin assembly to the support tube by threading CAUTION: Fuzes and bombs are on the special locknut (discard the locknut not to be unpacked in advance of supplied with the fin assembly). Tighten requirements. Return them to the locknut with the special notched wrench. their original packing if not used.1 Bend two tabs of the locking web into the locknut slots. Secure the nut in position by 1. Remove the shipping bands from the means of setscrews. bomb by removing the nut from the se­ 4. Install the bomb on the aircraft and curing bolts. Remove the closing plugs. securely lock it in place. If the bomb bay Inspect for damage, cracks, or broken weld­ 5-5 N A V W E P S OP 2216 (V O L U M E 1) does not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the bomb rack. 5. Remove the required number of fuzes and arming-wire assemblies from their con­ 5-6 tainers and examine them carefully for serv­ iceability. 6. For detailed information on fuzing and defuzing, refer to chapter 2 under the particular fuze to be installed. G EN ER A L PURPOSE B O M B A SSEM B LIES 250-LB GP B O M B A N -M 5 7 A 1 W it h F in A ssem bly W it h A N -M 1 0 6 A 1 M odel______ _______ ___________ Assembly Drawing No . Length of Assembled Bomb (in.) __ Body Diameter ( i n . ) . _ ..................... Fin Span (in.)..................................... Weight of Explosive Charge (lb): Amatol 50-50 ................... T N T . ......................................... Tritonal......... ...................... . . Weight of Fin Assembly (lb )......... Weight of Assembled Bomb (lb): Loaded with Amatol 50-50___ Loaded with T N T . _________ Loaded with T rito n a l............ Fin Locknut....................................... Fin Locking W eb.............................. Arming-Wire Assembly. _________ Adapter-Booster................................. Nose Fuze................... ....................... Tail Fuze........................................... F in A ssem bly M l 26 A N -M 57A 1........................ 82-0-60____________ ____ 4 7 .8 __________ __________ 1 0 .9 ____________________ 14.90.......... ........................ AN-M57A1. 82-0-162. 62.2. 10.9. 15.0. 98.4 ................................. 1 2 7 .0 _______ ______ . 136 0 ______________ ____ 8 0 _____________________ 98.4. 127.0. 136.0. 25.0. 256.63__________________ 263.35____ _____ _______ 272.35............ .................... M l or Mk 2 Mod 0 _____ Not Used...................... . . Mk 1 or AN M6A2____ 273.63. 280.35. 289.35. Sk 329153. Dwg 1350522. Mk 1 or AN-M 6A2, and M13. M102A1. AN-M 103A1, A N M139A1, AN-M140A1, Mk 243 ModO, Mk244 Mod 1, AN-M 166 (VT), AN-M 168 (VT). M l72, AN-M 175, M181. M102A1______ _____ ____ AN-M103A1, A N M139A1, AN-M140A1, Mk 243 ModO, Mk244 Mod 1, AN-M 166 (VT), AN-M 168 (VT). AN-M 100A2, AN-M 115, AN-M 123A1, A N M132. General Description The 250-lb GP Bomb AN-M57A1 is a relatively thin cased bomb with an ogival nose, parallel side walls, and a tapered aft section. A box-type fin assembly is fastened to the aft end of the bomb with a fin locknut. A nose and tail fuze are used for the majority of bombing operations. The base plug of the AN-M57A1 bomb is locked se­ curely to the bomb body by two studs which extend from the base plug into the solidified explosive filler. A locking pin is passed through a hole in the adapter-booster into a groove in the base plug. These modifica­ tions were initiated to prevent removal of the base plug and adapter-booster to make the antiwithdrawal devices of long delay fuzes more effective. Double suspension lugs are welded to the body 14 inches apart. A single lug is welded to the opposite side of the body at the center of gravity. Approximately 50 percent of the complete weight of the round is its ex­ plosive charge of Amatol 50-50, TNT, or Tritonal. Bombs filled with Amatol 50-50 include nose and tail surrounds of TNT, a body gasket, and Auxiliary Booster M104. These features are not included with other explosives. Painting and M arking Yellow bands on an olive drab body identify the high-explosive charge. Identi­ fying nomenclature is stenciled on the nose, mid-sections, and aft portion of the bomb in black paint. 5-7 N A V W E P S OP 2216 (V O L U M E 1) Figure 5-5. — 250-lb GP Bomb A N -M 57A 1 with Fin Assembly A N -M 1 0 6 A 1 , Exterior View. Differences Between Mods The AN-M57A1 bomb contains antiwith­ drawal pins in the base plug and an adapterbooster which can be locked to the base plug. The earlier model, AN-M57, does not have these features. Assembly CAUTION: Fuzes and bombs are not to be unpacked in advance of requirements. Return them to their original packing if not used. 1. Remove the shipping bands from the 5-8 bomb by removing the nuts from the secur­ ing bolts. Remove the closing plugs. In­ spect for damage, cracks, or broken weldments which might weaken the lugs or their attachment to the bomb body. 2. Cut the shipping wire and remove the fin locknut and discard it with its protector. 3. Remove the fin assembly and its at­ tachments from the shipping crate. Posi­ tion the fins so that they will clear the air­ craft structure and the ground when in­ stalled. Fin Locknut Ml or Mk 2 Mod 0 should always be used in place of the regu­ lar fin locknut. Fin locknut setscrews should G E N E R A L PURPOSE BO M B A SSEM B LIES Figure 5—6.— 250-lb GP Bomb A N - M 5 7 A 1 with Fin Assembly A N M 106A1, Exploded View. be tightened securely, in order to prevent rotation of the fin assembly. CAUTION: Do not use a fin as­ sembly if it cannot be properly secured to the bomb. If the fin as­ sembly is loose and turns on the bomb, it will pull the arming wire from the tail fuze, causing it to arm prematurely. 4. Install the bomb on the aircraft and securely lock it in place. If the bomb bay does not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the bomb rack. 5. Remove the required number of fuzes and arming wire assemblies from their con­ tainers and examine them carefully for serviceability. 6. For detailed information on fuzing and defuzing, refer to chapter 2 under the par­ ticular fuze to be installed. CAUTION: The AN-M57A1 bomb uses the AN-M123A1 and AN­ RI 132 tail fuzes which incorporate the use of an antiwithdrawal de­ vice. Nondetonation of bombs fuzed with AN-M123A1 and A N M132 fuzes cannot be relied upon when released “ SAFE” because the glass solvent ampoule in the fuze may break upon impact of the bomb. Once an AN-M123A1 or AN-M132 fuze is installed, no at­ tempt should be made to remove the fuze or return the bomb to an air­ field or aircraft carrier upon an in­ complete mission. DO NOT TURN AN AN-M123A1 OR AN-M132 FUZE BACK AND FORTH TO ENGAGE THE THREADS; USE A SCREWING-IN MOTION ONLY. THE ANTIWITH­ DRAWAL DEVICE WILL CAUSE THE FUZE AND BOMB TO DET­ ONATE IF THE FUZE IS RO­ TATED COUNTERCLOCKWISE WHILE IN THE ADAPTERBOOSTER, EVEN BEFORE THE THREADS ARE ENGAGED. 5-9 N A V W E P S OP 2216 (V O L U M E 1) TAIL LOCKING INERT SEALER COMPOUND ASSEMBLY AUXILIARY BOOSTERS B BODY CHARGE SURROUND INERT SEALER COMPOUND (WAX PAD) FUZE Figure 5-7.— 250-lb GP Bomb A N -M 5 7 A 1 with Fin Assembly A N -M 1 0 6 A 1 , Cutaway View. 5-10 G E N E R A L PURPOSE BO M B A SSEM B LIES 250-LB GP B O M B A N -M 5 7 A 1 W IT H ARMING WIRE ASSEMBLY FAHNESTOCK CLIPS FIN A S S E M B L Y M 126 FIN LOCKING WEB, FIN LOCK NUT Figure 5-8. — 250-lb GP Bomb AN-M57A1 with Fin Assembly M l 26, Exploded View. General Description When equipped with Fin Assembly M126, the 250-lb GP Bomb AN-M57A1 uses the standard AN-M57A1 bomb body. The fin assembly consists of an elongated fin cone with four integral fins spaced at equal dis­ tances on the cone surface. A support tube runs through the center of the cone and the fin assembly is secured to the bomb body by means of this support tube, a locking web, and a locknut. The conical fin length­ ens the overall dimension of the 250-lb GP Bomb AN-M57A1. This necessitates the use of a long stem tail fuze so that the arm­ ing vane can be located effectively in the airstream. The M126 conical fin assembly improves aerodynamic performance and ac­ curacy in bombing. Assembly CAUTION: Fuzes and bombs are not to be unpacked in advance of requirements. Return them to their original packing if not used. 1. Remove the shipping bands from the bomb by removing the nuts from the secur­ ing bolts. Remove the closing plugs. In­ spect for damage, cracks, or broken weldments which might weaken the lugs or their attachment to the bomb body. 2. Cut the shipping wire. Remove the fin locknut and discard it with its protector. 3. Remove the fin assembly and its at­ tachments from the shipping crate. Thread the center support tube onto the base plug of the bomb (locknut seat) and tighten the tube with a wrench. Tighten the setscrews in the support tube. Place the fin cone over the support tube and slide the cone back until it is jammed against the bomb body. Position the fins so that they will clear the aircraft structure and the ground when in­ stalled. Place the fin locking web over the support tube so that it engages the fins of the fin assembly. Secure the conical fin asembly to the support tube by threading on the special locknut. Tighten the locknut with the special notched wrench. Bend two tabs of the locking web into the locknut slots. Secure the nut in position by means of setscrews. 4. Install the bomb on the aircraft and securely lock it in place. If the bomb bay does not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the bomb rack. 5. Remove the required number of fuzes and arming-wire assemblies from their con­ tainers and examine them carefully for serviceability. 6. For detailed information on fuzing and defuzing, refer to chapter 2 under the par­ ticular fuze to be installed. 5-11 N A V W E P S OP 2216 (V O L U M E 1) 500-LB GP B O M B A N -M 6 4 A 1 W it h F in A ssem bly W it h AN-M109A1 M o d e l.............................................. Assembly Drawing N o____________ Length of Assembled Bomb (in.)__ Body Diameter (in.)---------------------Fin Span (in.)____________________ Weight of Explosive Charge (lb): Amatol 5 0 -50_____________ T N T ______________________ Composition B _____________ Tritonal___________________ Weight of Fin Assembly (lb )____ Weight of Assembled Bomb (lb): Loaded with Amatol 50-50___ Loaded with T N T ____________ Loaded with Composition B .-_ Loaded with Tritonal.............. . Fin Locknut______________ _______ Fin Locking W eb_________________ Arming-Wire Assembly..................... Adapter-Booster Nose Fuze......... Tail Fuze in A ssem bly AN-M64A1 82-0-74___ 59.16.......... 14.18______ 18.94_____ AN-M64A1. 82-0-160. 72.10. 14.18. 19.56. 257.20 265.70 272.40 283.0. 1 8 .6__ 257.20. 265.70. 272.40. 283.0. 41.0. 541.87____________ 548.69_______________ 555.39_______________ 560.99_______________ M2 or Mk 3 Mod 0 .. . Not Used____________ Mk 1 or A N -M 6 A 2 ... 564.27. 571.09. 577.79. 585.78. Sk 329153. Dwg 1350522. Mk 1 or AN-M 6A2, and M13. M115A1. AN-M 103A1, A N M139A1, AN-M 140A1, Mk 243 M od 0, Mk 244 M od 1, AN-M 166 (VT), AN-M 168 (VT). M172, AN-M 175, M181. M115A1_____ ______ ____ AN-M103A1, A N M139A1, AN-M 140A1, Mk 243 Mod 0, Mk 244 Mod 1, AN-M 166 (VT), AN-M 168 (VT). AN-M101A2, A N -M k 230, AN-M 116, ANM124A1, AN-M133. General Description The 500-lb GP Bomb AN-M64A1 has a cylindrical metal casing, an ogival nose, and a tapered aft end. A box-type fin assembly is secured to the aft end of the bomb with a fin locknut. Both a nose and a tail fuze are usually used for the majority of operations with this bomb. Unlike the smaller bombs of the GP series, the AN-M64A1 bomb has an adapter-booster capable of receiving a tail fuze with a two-inch thread (such as the AN-Mk 230 hydrostatic tail fuze) instead of the usual U/2 inch thread. A fuze adapter is used on the inside of the adapter-booster 5-12 F M128A1 to convert the seat to accommodate fuzes with the smaller lV 2 -inch threads. Special studs attached to the base plug are imbedded in the solidified explosive filler, locking the base plug to the bomb body. The adapter-booster and fuze adapter are locked in the base plug by a locking pin that extends from the adapter-booster to a groove in the base plug. Approximately 50 percent of the complete weight of the bomb is an explosive filler of Amatol 50-50, TNT, Composition B, or Tri­ tonal. Bombs filled with Amatol 50-50, such as that illustrated, include nose and tail sur­ rounds of TNT, a body gasket, and an Aux- G E N E R A L PURPOSE BO M B A SSEM B LIES 14 "18 18."94 Figure 5-9.— 500-lb C P Bomb A N -M 64A 1 with Fin Assembly A N-M 109A1, Exterior View. iliary Booster M104. These features are not included with other explosives. Double suspension lugs are welded 14 inches apart and a single suspension lug is welded to the opposite side of the bomb body. The AN-M43 bomb, an earlier model of the 500-lb GP bomb, is similar to the A N M64, but has an Adapter-Booster M102 as­ sembled which will accept only fuzes with a lH -inch diameter thread. Painting and M arking Assembly The bomb is painted olive drab; yellow color bands and black stenciled nomenclature identify the bomb and its high-explosive charge. CAUTION: Fuzes and bombs are not to be unpacked in advance of requirements. Return them to their original packing if not used. 1. Remove the shipping bands from the bomb by removing the nuts from the se­ curing bolts. Remove the closing plugs. In­ spect for damage, cracks, or broken weldments which might weaken the lugs or their attachment to the bomb body. 2. Cut the shipping wire and remove the Differences Among Mods The AN-M64A1 bomb contains antiwith­ drawal pins in the base plug and an adapterbooster and fuze adapter that can be locked in place. The earlier AN-M64 bomb lacks these antiwithdrawal features. 5-13 N A V W E P S OP 2216 (V O L U M E 1) FAHNESTOCK CLIFFS TAIL FUZE ARMING WIRE ASSEMBLY FAHNESTOCK CLIP'S LOCK NUT FIN ASSEMBLY BODY FUZE Figure 5—10.— 500-lb GP Bomb A N —M64A1 with Fin Assembly A N —M 109A1, Exploded View. fin locknut and discard it with its protector. 3. Remove the fin assembly and its at­ tachments from the shipping crate. Posi­ tion the fins so that they will clear the air­ craft structure and the ground when in­ stalled. Replace the fin locknut and tighten it with a wrench. Fin Locknut M2 or Mk 3 Mod 0 should always be used in place of the regular fin locknut. Fin locknut setscrews should be tightened securely in order to pre­ vent rotation of the fin assembly. CAUTION: Do not use a fin as­ sembly if it cannot be properly se­ cured to the bomb. If the fin assembly is loose and turns on the bomb, it will pull the arming wire from the tail fuze, causing it to arm prematurely. 4. Install the bomb on the aircraft and securely lock it in place. If the bomb bay does not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the bomb rack. 5. Remove the required number of fuzes and arming-wire assemblies from their con­ tainers and examine them carefully for serviceability. 5-14 6. For detailed information on fuzing and defuzing, refer to chapter 2 under the par­ ticular fuze to be installed. CAUTION: The 500-lb GP Bomb AN-M64A1 uses the AN-M124A1 and the AN-M133 tail fuzes which incorporate the use of an antiwith­ drawal device. Nondetonation of bombs fuzed with AN-M124A1 and AN-M133 fuzes cannot be relied upon when released SAFE because the glass solvent ampoule in the fuze may break upon impact of the bomb. Once an AN-M124A1 or AN-M133 fuze is installed, no at­ tempt should be made to remove it from the bomb. Do not turn an AN-M124A1 or AN-M133 fuze back and forth to engage the threads; use a screwing-in motion only. The antiwithdrawal device will cause the fuze and bomb to det­ onate if the fuze is rotated counter­ clockwise while in the adapterbooster, even before the threads are engaged. G E N E R A L PURPOSE B O M B A SSEM B LIES TAIL FUZE BASE PLUG LOCKING PIN EXPLOSIVE CHARGE ARMING •WIRE SEALER COMPOUND AUXILIARY BOOSTER BOMB BODY AUXILIARY BOOSTER CHARGE SURROUND INERT SEALER COMPOUND (WAX PAD) NOSE FUZE Figure 5 -J J .— 500-lb GP Bomb A N -M 64A 1 with Fin Assembly A N -M 1 0 9 A 1 , Cutaway View. 5-15 N A V W E P S OP 2216 (V O L U M E 1) 500-LB GP B O M B A N -M 6 4 A 1 W IT H FIN A S S E M B L Y M128A1 FAHNESTOCK CLIPS FIN LOCKING WEB FIN LOCK NUT ARMING WIRE ASSEMBLY. CONICAL FIN CENTER SUPPORT TUBE NOSE FUZE BOMB BODY Figure 5—12.— 500-lb GP Bomb A N —M64A1 with Fin Assembly M128A1, Exploded View. curing bolts. Remove the closing plugs. Inspect for damage, cracks, or broken When equipped with Fin Assembly weldments which might weaken the lugs M128A1, the 500-lb GP Bomb AN-M64A1 or their attachment to the bomb body. uses the standard AN-M64A1 bomb body. 2. Cut the shipping wire. Remove the The elongated cone of the assembled fin fin locknut and discard it with its protector. lengthens and streamlines the bomb, in­ 3. Remove the fin assembly and its at­ creasing its aerodynamic performance and tachments from the shipping crate. Thread accuracy. The M128A1 conical fin assembly the center support tube onto the base plug consists of an elongated cone with four in­ of the bomb (locknut seat) and tighten the tegral fins spaced at equal distances. A tube with a wrench. Tighten the setscrews support tube runs through the center of in the support tube. Place the fin cone over the cone and the fin assembly is secured to the support tube and slide the cone back the bomb body by means of this support until it is jammed against the bomb body. tube, a locking web, and a locknut. When Position the fins so that they will clear the a conical fin assembly is installed on the aircraft structure and the ground when in­ bomb, the new long-stem tail fuzes are re­ stalled. Place the fin locking web over the quired so that the arming vane is located support tube so that it engages the fins effectively in the air stream. of the fin assembly. Secure the conical fin assembly to the support tube by threading Assembly on the special locknut. Tighten the locknut CAUTION: Fuzes and bombs are with the special notched wrench. Bend two not to be unpacked in advance of tabs of the locking web into the locknut requirements. Return them to slots. Secure the nut in position by means their original packing if not used. of setscrews. 4. Install the bomb on the aircraft and 1. Remove the shipping bands from the bomb by removing the nuts from the se­ securely lock it in place. If the bomb bay General Description 5-16 G E N E R A L PURPOSE BO M B A SSE M B L IE S does not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the bomb rack. 5. Remove the required number of fuzes and arming-wire assemblies from their con­ tainers and examine them carefully for serviceability. 6. For detailed information on fuzing and defuzing, refer to chapter 2 under the par­ ticular fuze to be installed. 5-17 N A V W E P S OP 2216 (V O L U M E 1) 1000-LB GP B O M B A N -M 6 5 A 1 M odel________ .. . . _______ Assembly Drawing No __ _ _ Fin Assembly Drawing N o .. Length of Assembled Bomb (in.)__ Body Diameter (in.)_____ ______ Fin Span (in.). _______ ________ Weight of Explosive Charge (lb): T N T _________________________ Tritonal______________________ Weight of Fin Assembly (lb )______ Weight of Assembled Bomb (lb): Loaded with T N T ________ Loaded with Tritonal____ Fin L o c k n u t._________ Fin Locking W eb............. .. ............. Arming-Wire Assembly_______ . W ith F in A ssem bly W ith F in A ssem bly A N -M 1 1 3 A 1 M 129 A N -M 65A 1_____ _______ 341696. . . . ... 82-3-363 6 9 .5 ____________________ 1 8 .8 _______ _____ . . . . 2 5 .4 ___________ . . . . . . AN-M 65A1. 341696. 82-3-751. 91.1. 18.8. 26.2. 555.0_______ _______ ____ 595.0_________________ 3 2 .1 ________________ . . 555.0. 595.0. 73.0. 1064.0_______ . . . 1104.0_____ . . .. M2 or Mk 3 Mod 0 . . . . Not Used. _ . ________ Mk 1, AN -M 6A2, or Mk 2. A d a p ter-B o o ste r............................. M115A1 . . . Nose Fuze .. ______ . AN-M 103A1, A N M139A1, AN-M 140A1, Mk 243 Mod 0, Mk 244 Mod 1, AN-M 166 (V T), AN-M 168 (VT). Tail Fuze__ __ AN-M 102A2, A N -M k 230, Mods 4, 5, 6; A N -M 117, M125A1, AN-M 134. General Description The 1000-lb GP Bomb AN-M65A1 has a cylindrical metal casing, an ogival nose, and a tapered aft end. A box-type fin assem­ bly is secured to the aft end of the bomb with a fin locknut. Both a nose and a tail fuze are generally used for the majority of operations with this bomb. The AN-M65A1 uses an adapterbooster that will accommodate tail fuzes with 2-inch diameter threads. A fuze adapter is used on the inside of the adapterbooster to convert the seat to accommodate fuzes with the smaller 1^-inch threads. Special studs attached to the base plug and imbedded in the solidified explosive filler prevent removal of the base plug. The adapter-booster and fuze adapter are locked 5-18 1165.2. 1205.21. Sk 329153. Dwg 1350522. Mk 1 or A N -M 6A 2, and M13. M115A1. AN-M 103A1, A N M139A1, AN-M 140A1, Mk 243 Mod 0, M k244 Mod 1, AN -M 166 (VT), AN -M 168 (VT). M176 (T744), M182 (T782), M184(T739). to the base plug with a locking pin that ex­ tends from the adapter-booster to a groove in the base plug. Approximately 50 percent of the complete weight of the bomb is explosive filler. Dou­ ble suspension lugs are welded 14 inches apart and a single suspension lug is welded to the opposite side of the bomb case. Painting and M arking The bomb is painted olive drab; yellow color bands and black stenciled nomenclature identify the bomb and its high-explosive charge. Differences Between M ods The AN-M65A1 bomb contains antiwith­ drawal pins in the base plug and an adapter- G E N E R A L PURPOSE BO M B A SSE M B L IE S Figure 5—13.— 1000-lb GP Bomb A N -M 65A 1 with Fin Assembly A N -M 113A1, Exterior View. booster and fuze adapter that can be locked in place. The earlier AN-M65 bomb lacks these antiwithdrawal features. Released weight of the AN-M65 is greater than that of the AN-M65A1, the AN-M65 having an explosive charge of 53 percent as compared to the 50 percent ratio of the A N M65A1 bomb. " O ld " Series Bombs The AN-M44 bomb, an earlier model of the 1000-lb GP bomb, is similar to the A N M65 but has an Adapter-Booster M102 as­ sembled which will accept only fuzes with a lV 2 -inch diameter thread. Assembly CAUTION: Fuzes and bombs are not to be unpacked in advance of requirements. Return them to their original packing if not used. 1. Remove the shipping bands from the bomb by removing the nuts from the se­ curing bolts. Remove the closing plugs. Inspect for damage, cracks, or broken weld­ ments which might weaken the lugs or their attachment to the bomb body. 2. Cut the shipping wire and remove the fin locknut and discard it with its protector. 3. Remove the fin assembly and its at- 5-19 N A V W E P S OP 2216 (V O L U M E 1) ARMING WIRE FAHNESTOCK CLIPS V, TAIL FUZE FAHNESTOCK CLIPS LOCK NUT FIN ASSEMBLY BOMB BODY NOSE FUZE Figure 5 -1 4 .— 1000-lb GP Bomb A N M 6 5 A I with Fin Assembly A N -M 113 A 1 , Exploded View. tachments from the shipping crate. Posi­ tion the fins so that they will clear the air­ craft structure and the ground when in­ stalled. Replace the fin locknut and tighten it with a wrench. Fin Locknut M2 or Fin Locknut Mk 3 Mod 0 should always be used in place of the regular fin locknut. Fin locknut setscrews should be tightened se­ curely in order to prevent rotation of the fin assembly. CAUTION: Do not use a fin as­ sembly if it cannot be properly se­ cured to the bomb. If the fin assembly is loose and turns on the bomb, it will pull the arming wire from the tail fuze, causing it to arm prematurely. 4. Install the bomb on the aircraft and securely lock it in place. If the bomb bay does not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the bomb rack. 5. Remove the required number of fuzes and arming-wire assemblies from their con­ tainers and examine them carefully for serviceability. 6. For detailed information on fuzing and 5-20 defuzing, refer to chapter 2 under the par­ ticular fuze to be installed. CAUTION: The 1000-lb GP Bomb AN-M65A1 uses the AN-M125A1 and the AN-M134 tail fuzes which incorporate the use of an antiwith­ drawal device. Nondetonation of bombs fuzed with AN-M125A1 and AN-M134 fuzes cannot be relied upon when released “ SAFE” because the glass solvent ampoule in the fuze may break upon impact of the bomb. Once an A N M125A1 or AN-M134 fuze is in­ stalled, no attempt should be made to remove it from the bomb. DO NOT TURN AN AN-M125A1 OR AN-M134 FUZE BACK AND FORTH TO ENGAGE THE THREADS; USE A SCREWINGIN MOTION ONLY. THE ANTI­ WITHDRAWAL DEVICE WILL CAUSE THE FUZE AND BOMB TO DETONATE IF THE FUZE IS ROTATED COUNTERCLOCK­ WISE WHILE IN THE ADAP­ TER BOOSTER, EVEN BEFORE THE THREADS ARE ENGAGED. G E N E R A L PURPOSE B O M B A SSEM B LIES TAIL FUZE LOCKING PIN BASE PLUG ARMING-WIRE ASSEMBLY SURROUND AUXILIARY BOOSTERS BOMB BODY 'EXPLOSIVE CHARGE SURROUND NOSE FUZE Figure 5 -1 5 .— 1000-lb GP Bomb A N -M 65A 1 with Fin Assembly A N - M 1 13A1, Cutaway View. 5-21 N A V W E P S OP 2216 (V O L U M E 1) 1000-LB GP B O M B A N -M 6 5 A 1 W IT H FIN A SSEM BLY FIN LOCKING WEB M 129 FIN LOCK NUT NOSE FUZE Figure 5—16.— 1000-lb GP Bomb A N —M65A1 with Fin Assembly M l 29, Exploded View. General Description When equipped with Fin Assembly M129, the 1000-lb GP Bomb AN-M65A1 uses the standard AN-M65A1 bomb body. The elongated cone of the fin assembly lengthens and streamlines the bomb. The M129 coni­ cal fin assembly consists of a fin cone with four integral fins spaced at equal distances. A support tube runs through the center of the cone and the fin assembly is secured to the bomb body by means of this support tube, a locking web, and a locknut. The conical fin assembly was developed to in­ crease the aerodynamic performance and accuracy of the bomb. When a conical fin assembly is installed on the AN-M65A1 bomb, the new long-stem tail fuzes are re­ quired so that the arming vane can be lo­ cated effectively in the air stream. Assembly CAUTION : Fuzes and bombs are not to be unpacked in advance of requirements. Return them to their original packing if not used. 1. Remove the shipping bands from the 5-22 bomb by removing the nuts from the secur­ ing bolts. Remove the closing plugs. Inspect for damage, cracks, or broken weld­ ments which might weaken the lugs or their attachment to the bomb body. 2. Cut the shipping wire. Remove the fin locknut and discard it with its protector. 3. Remove the fin assembly and its at­ tachments from the shipping crate. Thread the center support tube onto the base plug of the bomb (locknut seat) and tighten the tube with a wrench. Tighten the setscrew in the support tube. Place the fin cone over the support tube and slide the cone back until it is jammed against the bomb body. Position the fins so that they will clear the aircraft structure and the ground when installed. Place the fin locking web over the support tube so that it engages the fin of the fin assembly. Secure the conical fin assem­ bly to the support tube by threading on the special locknut. Tighten the locknut with the special notched wrench. Bend two tabs of the locking web into locknut slots. Sesure the nut in position by means of set­ screws. G E N E R A L PURPOSE BO M B A SSEM B LIES 4. Install the bomb on the aircraft and securely lock it in place. If the bomb bay does not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the bomb rack. 5. Remove the required number of fuzes and arming-wire assemblies from their con­ tainers and examine them carefully for serviceability. 6. For detailed information on fuzing and defuzing, refer to chapter 2 under the par­ ticular fuze to be installed. 5-23 N A V W E P S OP 2216 (V O L U M E 1) 2000-LB GP B O M B A N - M 6 6 A 2 Model _ _ ____________________ Assembly Drawing N o. --------------Length of Assembled Bomb (in.)__ Body Diameter (in.)_ __________ Fin Span (lb)_____________ _____ Weight of Explosive Charge (lb ): T N T _________________________ Tritonal______ ___________ . Weight of Fin Assembly (lb)______ Weight of Assembled Bomb (lb): Loaded with T N T _____ _ Loaded with T r ito n a l____ . _ Fin Locknut_________ ______ _ _ _ Fin Locking W eb- _______________ Arming Wire Assembly_______ _ - W ith F in A s se m bly W ith F in A sse m bly A N -M 1 1 6 A 1 M 130 A N -M 66A 2_____________ 82-0-76_________________ 92.63___________________ 23.29 - - - - 3 1 .6 --- _ - AN-M 66A2. 82-0-193. 116.80. 23.29. 32.32. 1097.7__________________ 1181.0______________ -5 4.4____________________ 1097.7. 1181.0. 135.0. 2113.2. _____ _________ 2196.5_____ ________ M3 or Mk 4 Mod 0_____ Not Used_____________ _ Mk 1, AN-M 6A2, or AN-M 8A1 with Mk 1 Extension. Adapter-Booster__ _______________ M115A1________________ Nose Fuze............. ......- ____ __ . AN-M 103A1, A N M139A1, AN-M 140A1, Mk 243 M od 0, M k 244 Mod 1, AN-M 166 (V T), A N -M 168 (VT). Tail Fuze______________________ - AN-M 102A2, A N -M k 230 Mods 4, 5, 6; A N -M 117, A N M125A1, AN-M 134. General Description The 2000-lb GP Bomb AN-M66A2 has a cylindrical metal case, an ogival nose, and a tapered aft end. A box-type fin assembly is secured to the aft end of the bomb with a fin locknut. The bomb accommodates a nose and a tail fuze, both of which are used for the majority of bombing operations. The bomb has an adapter-booster capable of receiving tail fuzes with a 2-inch thread diameter. A fuze adapter may be inserted into the adapterbooster to accommodate smaller fuzes with i y 2-inch diameter threads. Special studs attached to the base plug and imbedded in the solidified explosive filler prevent removal of the base plug. The adapter-booster (and fuze adapter, when 5-24 2194.5. 2277.5. Sk 329153. Dwg 1350522. Mk 1 or A N -M 6A 2, and M16. M115A1. AN-M 103A1, A N M139A1, AN-M 140A1, Mk 243 M od 0, Mk 244 Mod 1, AN -M 166 (VT), A N -M 168 (VT). A N -M 177, M l 83, A N M185. used) are locked to the base plug with a locking pin that extends from the adapterbooster to a groove in the base plug. Approximately 50 percent of the complete weight of the bomb consists of explosive filler. Two suspension lugs are welded to the bomb case with 30 inches between cen­ ters. A single suspension lug is welded to the case on the opposite side at the center of gravity. Painting and M arking The bomb is painted olive drab; yellow color bands and black stenciled nomencla­ ture identify the bomb and its high-explosive charge. Differences Am ong M ods The AN-M66A2 and AN-M66A1 bombs G E N E R A L PURPOSE B O M B A SSE M B L IE S 92!63 Figure 5-17. — 2000-lb GP Bomb A N M 6 6 A 2 with Fin Assembly A N -M 1 1 6 A 1 , Exterior View. contain antiwithdrawal pins in the base plug and an adapter-booster and fuze adapter that can be locked in place. The earlier AN-M66 bomb lacks these features. The AN-M66A2 differs further from the AN-M66A1 and AN-M66 bombs by having a thicker and rounder nose. In the A N M66A2 bomb, the ratio of explosive charge to total weight is approximately 50 percent as compared to an average weight ratio of 53 percent in the other two bombs. Assembly " O ld " Series Bombs 1. Remove the shipping bands from the bomb by removing the nuts from the secur­ ing bolts. Remove the closing plugs. The AN-M34 bomb, an earlier model of the 2000-lb GP Bomb, is similar to the AN M66 but has an Adapter-Booster M102 which will accept only those fuzes with a lV2-inch diameter thread. CAUTION: Fuzes and bombs are not to be unpacked in advance of requirements. Return them to their original packing if not used. 5-25 N A V W E P S OP 2216 (V O L U M E 1) FAHNESTOCK CLIPS ARMING WIRE ASSEMBLY FAHNESTOCK CLIPS FIN LOCK NUT FIN ASSEMBLY BOMB BODY NOSE FUZE Figure 5-18. — 2000-lb G P Bomb A N -M 6 6 A 2 with Fin Assembly A N -M 1 1 6 A 1 , Exploded View. Inspect for damage, cracks, or broken weld­ ments which might weaken the lugs or their attachment to the bomb body. 2. Cut the shipping wire and remove the fin locknut and discard it with its protector. 3. Remove the fin assembly and its at­ tachments from the shipping crate. Posi­ tion the fins so that they will clear the air­ craft structure and the ground when in­ stalled. Replace the fin locknut and tighten it with a wrench. Fin Locknut M3 or Mk 4 Mod 0 should always be used in place of the regular fin locknut. Fin locknut set­ screws should be tightened securely in order to prevent rotation of the fin assembly. CAUTION: Do not use a fin as­ sembly if it cannot be secured properly to the bomb. If the fin as­ sembly is loose and turns on the bomb, it will pull the arming wire from the tail fuze, causing it to arm prematurely. 4. Install the bomb on the aircraft and securely lock it in place. If the bomb bay does not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the bomb rack. 5. Remove the required number of fuzes 5-26 and arming-wire assemblies from their con­ tainers and examine them carefully for serviceability. 6. For detailed information on fuzing and defuzing, refer to chapter 2 under the par­ ticular fuze to be installed. CAUTION: The 2000-lb GP Bomb AN-M66A2 uses the AN-M125A1 and the AN—M134 tail fuzes which incorporate the use of an antiwith­ drawal device. Nondetonation of bombs fuzed with AN-M125A1 and AN-M134 fuzes cannot be relied upon when released SAFE because the glass solvent ampoule in the fuze may break upon impact of the bomb. Once an AN-M125A1 or AN-M134 fuze is installed, no attempt should be made to remove it from the bomb. Do not turn an AN-M125A1 or AN-M134 fuze back and forth to engage the threads; use a screwing-in motion only. The antiwithdrawal device will cause the fuze and bomb to detonate if the fuze is rotated coun­ terclockwise while in the adapterbooster, even before the threads are engaged. G E N E R A L PURPOSE B O M B A SSE M B L IE S BASE PLUG LOCKING PIN ARMING-WIRE T AI L FUZE INERT SEALER COMPOUND EXPLOSIVE BOMB BODY INERT SEALER COMPOUND (WAX PAD) NOSE FUZE Figure 5-19. — 2000-lb GP Bomb A N -M 6 6 A 2 with Fin Assembly A N -M 116 A 1 , Cutaway View. 5-27 N A V W E P S OP 2216 (V O L U M E 1) Suspension Band M k 34 M od 0 Mk 34 Mod 0 Suspension Band, dwg 561640, was designed to provide 14-inch suspension for 2000-lb GP Bomb AN-M66 and Mods, which are equipped with suspen­ sion lugs 30 inches apart. This band is used primarily on aircraft carrying the 2000-lb GP bomb externally. Either two Suspension Bands Mk 34 Mod 0 (one sus­ pension lug on each band) or Suspension Band Mk 10 Mod 1 (a double band) may be used to suspend the 2000-lb GP bomb in bomb bays or on 14-inch racks or shackles. The Mk 10 band is not to be used on bombs on the centerline station of AD type aircraft. The Mk 34 band is lighter in weight (ap­ proximately 13 pounds) and presents less frontal area than previous suspension bands. 5-28 It is suitable for use on AD aircraft equipped with the Douglas bomb ejector. Two bands should be oriented 14 inches apart on the bomb with respect to the 30inch suspension lugs so that these lugs will not interfere with the installation of the bomb on the plane. The forward band should be positioned so that the center of its suspension lug is 26.5 inches from the nose of the unfuzed bomb. After positioning, each of the 5 bolts on the band should be tightened, hand tight, then gradually tightened successively with a wrench to 28 foot-pounds torque. The after band is positioned so that the two suspen­ sion lugs on the bands are 14 inches apart, center-to-center. Tighten the after band in the same manner as the forward band. G E N E R A L PURPOSE B O M B A SSEM B L IES 2000-LB GP B O M B A N - M 6 6 A 2 W IT H ARMING WIRE ASSEMBLY FIN ASSEM BLY FIN LOCKING WEB M l 30 FIN LOCK NUT NOSE FUZE Figure 5-20. — 2000-lb GP Bomb A N -M 6 6 A 2 with Fin Assembly M l 30, Exploded View. General Description When equipped with Fin Assembly M130, the 2000-lb GP Bomb AN-M66A2 uses the standard AN-M66A2 bomb body. The elon­ gated fin assembly lengthens and streamlines the bomb, improving its aerodynamic per­ formance and accuracy. When the bomb is installed with a conical fin assembly, the new long-stem tail fuzes are required so that the arming vane can be located effec­ tively in the air stream. Assembly CAUTION: Fuzes and bombs are not to be unpacked in advance of requirements. Return them to their original packing if not used.1 1. Remove the shipping bands from the bomb by removing the nuts from the secur­ ing bolts. Remove the closing plugs. Inspect for damage, cracks, or broken weld­ ments which might weaken the lugs or their attachment to the bomb body. 2. Cut the shipping wire. Remove the fin locknut and discard it with its protector. 3. Remove the fin assembly and its at­ tachments from the shipping crate. Thread the center support tube onto the base plug of the bomb (locknut seat) and tighten the tube with a wrench. Tighten the setscrews in the support tube. Place the fin cone over the support tube and slide the cone back until it is jammed against the bomb body. Position the fins so that they will clear the aircraft structure and the ground when installed. Place the fin locking web over the support tube so that it engages the fins of the fin assembly. Secure the conical fin assembly to the support tube by thread­ ing on the special locknut. Tighten the locknut with the special notched wrench. Bend two tabs of the locking web into the locknut slots. Secure the nut in position by means of setscrews. 4. Install the bomb on the aircraft and securely lock it in place. If the bomb bay does not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the bomb rack. 5. Remove the required number of fuzes and arming-wire assemblies from their con­ tainers and examine them carefully for serv­ iceability. 5-29 N A V W E P S OP 2216 (V O L U M E 1) 6. For detailed information on fuzing and defuzing, refer to chapter 2 under the par­ ticular fuze to be installed. 7. Install the arming wire so that two to 5-30 three inches protrude beyond the fuze vanes, and attach the safety clips. wire. Cut off excess G E N E R A L PURPOSE BO M B A SSEM B 1 IES 250-LB L O W -D R A G B O M B (GP) M k 81 M od 1 Figure 5-21. — 250-lb Low-Drag Bomb (GP) Mk 81 M od 1 (Mechanically Fuzed), Exterior View. Mark _____________ ________ _______ Mod ...... ....... ............ ........................... General Arrangement _____ _______ List of Drawings _________ ___ ____ Length of Assembled Bomb (in.) Body Diameter (in.) ___ ________ ___ Fin Span (in.) _________ ___ _______ Weight of Explosive Charge (lb) .... Weight of Assembled Bomb (lb) ___ Arming-Wire Assembly Cable Assembly (for electric fuzing) Adapter-Booster Nose ......................... ....................... Tail ...................... ............................. Nose Fuze ............. ........ ...... .......... Tail Fuze 81 1 1366064 165790 74.1 9.0 12.62 100.0 260.0 Mk 1 or A N -M 6A2 (for nose fuze) and M13 (for tail fuze) M71 (T26) T45E1 T46E4 AN-M103A1, AN-M139A1, AN-M140A1, Mk 243 Mod 0, Mk 244 Mod 1, AN-M168 (V T ), AN-M166 (V T ), M193 (VT-T768 electric), M910 ( VT-T750 with T49 drive), M990 (T905) (electric), M904 (T709) T750 (V T ) with T49 drive, M913 (V T ) (T768 electric), XB-113 (electric), M905 (T771 with T49 drive), M906 (T778 with T49 drive), M990 (T905 electric), M194 (T791) 5-31 N A V W E P S OP 2216 (V O L U M E 1) Figure 5-22.— 250-lb Low-Drag Bomb (GP) Mk 81 M od 1 (Mechanically Fuzed), Exploded View. General Description The 250-lb LD Bomb Mk 81 Mod 1 has a slender body with a long pointed nose. A conical type fin is attached to the aft end of the bomb body by eight setscrews. The bomb uses VT, mechanical, or electri­ cal fuzes. Mechanical and VT fuzes re­ quire the installation of adapter-boosters to provide fuze seats of smaller diameters. Two conduits for the electric fuze cable har­ ness connect the nose and tail fuze cavities with the charging receptacle cavity between the lugs of the outer surface of the bomb case. When electric fuzes are not used, a plug is threaded into the charging receptacle cavity. When fuzes are not installed, the bomb body has a nose fuze plug, a base fuze plug, and a support cup in the nose fuze cavity. When the bomb is mechanically fuzed, these three parts are removed and the adapterboosters and fuzes are inserted. The nose fuze plug and base fuze plug are replaced after electric fuzes have been installed. Adapter-boosters and arming wires are not used with the electric fuzes. If the bomb is tail fuzed only, the support cup must be reinserted in the nose cavity to prevent collapse of the fuze cavity on heavy impact. 5-32 The bomb body has a base plug containing locking pins which are imbedded in the so­ lidified explosive filler. Two suspension lugs spaced 14 inches apart and a hoisting lug at the center of gravity are threaded into lug inserts on the bomb body (at time of use). Painting and M arking The high-explosive filler of the bomb, Tritonal 80-20, or H-6, is identified by yellow stenciled nomenclature on the bomb body and a yellow band around the body. The base color of the bomb is olive drab. Differences Between M ods Bombs and fin assemblies of the A. O. Smith Corporation Lot Number 1 have lo­ cating pins in the bomb body and holes in the fin assemblies for receiving these locat­ ing pins. The reverse is true for bomb bodies and fin assemblies manufactured by the A. O. Smith Corporation subsequent to this lot. Bodies and fin assemblies of the later lots are not interchangeable with bomb bodies and fin assemblies of Lot Number 1. To ensure that Lot Number 1 bomb bodies and fin assemblies are not issued with bomb bodies and fin assemblies of later lots, the G E N E R A L PURPOSE BO M B A SSEM B LIES **A r Figure 5-23.— 250-/b Low-Drag Bomb (GP) Mk 81 Mod 1 (Mechanically Fuzed), Cutaway View. 5-33 N A V W E P S OP 2216 (V O L U M E 1) designation of Lot Number 1 has been changed to Mk 81 Mod 0. Assembly CAUTION: Fuzes and bombs are not to be unpacked in advance of requirements. Return them to their original packing if not used. Mechanical Fuzing of the Mk 81 Mod 1 LD Bomb. 1. Remove the shipping cap on rear of the bomb body. 2. Inspect bomb for damage, cracks, or broken weldments which might weaken threaded lug inserts or their attachment to the bomb body. 3. Remove the nose plug, base plug, and support cup from the nose fuze cavity. Re­ move the hoisting lug from the tail fuze cavity. Install the required adapter-booster for mechanical fuzing. 4. Remove the fin assembly and suspen­ sion lugs from the fin shipping crate. Place the fin assembly over the end of the bomb body with one fin in line with the suspension lugs; if hung on external racks, turn the fin and locate it so as to clear the aircraft and the ground when installed. Butt the fin against the aft end of the bomb and se­ cure it with setscrews located on the edge of the cone. Assemble the two suspension lugs 5-34 and the hoisting lug in their respective threaded holes. 5. Open the access door by unlocking the attaching fasteners. 6. Remove the fuzes and arming-wire as­ sembly from their containers and examine carefully for serviceability. 7. Insert the required tail fuze through the opening in the rear of the fin assembly. Grasp the fuze through the access door open­ ing and screw the fuze into the fuze well until hand tight. Apply torque to the fuze at the body adjacent to the adapter-booster. Do not apply torque at the vane end of the fuze. 8. The Mk 81 Mod 1 LD bomb uses the AN-M103A1 series of nose fuzes. If nose fuzing is not to be used, replace the nose plug and support cup and secure the nose plug with the setscrew. 9. For detailed information on fuzing and defuzing with the AN-M103A1 nose fuze, refer to chapter 2. 10. Install the bomb securely on the air­ craft and sway brace. If the bomb bay does not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the rack. 11. Install the arming wire. Electrical Fuzing of the Mk 81 Mod 1 LD Bomb. Follow the assembly procedure pro­ vided in volume 2 of this publication. G E N E R A L PURPOSE B O M B A SSE M B L IE S 500-LB L O W -D R A G B O M B (GP) M k 82 M od 1 ------------- --------------------------------- 86 V '- ------------------------------------------------------ Figure 5-24. — 500-lb Low-Drag Bomb (GP) Mk 82 M od 1 (Mechanically Fuzed), Exterior View. Mark ________________ _____ H . ______ Mod - ...... |......................____________ General Arrangement _______________ List o f Drawings ______________ _____ Pin Assembly Drawing No. _________ Length o f Assembled Bomb (in.) ....... Body Diameter (in.) ______^ i.........Fin Span (in.) ______ _______________ Weight o f Explosive Charge (lb) ....... W eight of Assembled Bomb (lb) Arming-W ire Assembly ___ 82 1 1380543 165796 1380512 86.90 10.75 15.1 192.0 531.0 Mk 1 or A N -M 6A2 (fo r nose fuze) M13 (fo r tail fuze) Cable Assembly (for electric fuzing).. M72 (T32) Adapter-Booster N o s e ^ B ..— B _____________________ T45E1 Tail ___________ ___________________ T46E4 Nose Fuze JP..... ...................................... AN-M103A1, AN-M 139A1, AN-M140A1, Mk 243 Mod 0, Mk 244, AN-M166 (V T ), AN-M 168 (V T ), M913 (V T) (T768) (electric), M990 (T905) (electric), M904 (T709), M910 (V T ) (T750) (with T49 drive) Tail Fuze ............. M ________ _____ M195 (T792), M990 (T905) (electric), M910 (V T ) (T750) (with T49 drive), M913 (V T ) (T768) (electric), XB-113 (electric), M905 (T771) (with T49 drive), M906 (T788) (with T49 drive) General Description The 500-lb LD Bomb Mk 82 Mod 1 has a slender body with a long pointed nose. A conical type fin is attached to the aft end of the bomb body by six setscrews. The bomb uses VT, mechanical, or elec- 5-35 N A V W E P S OP 2216 (V O L U M E 1) trical fuzes. Mechanical and VT fuzes re­ quire the installation of adapter-boosters to provide fuze seats of smaller diameters. Two conduits for the electric fuze cable harness connect the nose and tail fuze cavi­ ties with the charging receptacle cavity be­ tween the lugs of the outer surface of the bomb case. When electric fuzes are not used, a plug is threaded into the charging receptacle cavity. When fuzes are not installed, the bomb body has a nose fuze plug, a base fuze plug, and a support cup in the nose fuze cavity. When the bomb is mechanically fuzed, these three parts are removed and the adapterboosters and fuzes are inserted. The nose fuze plug and base fuze plug are replaced after electric fuzes have been installed. Adapter-boosters and arming wires are not used with the electric fuzes. If the bomb is tail fuzed only, the support cup must be reinserted in the nose cavity to prevent col­ lapse of the fuze cavity on heavy impact. The bomb body has a base plug contain­ ing locking pins which are imbedded in the solidified explosive filler. Two suspension lugs spaced 14 inches apart and a hoisting lug at the center of gravity are threaded into lug inserts on the bomb body. Painting and M arking The high-explosive filler of the bomb, Tritonal 80-20, or H-6, is identified by yellow stenciled nomenclature on the bomb body and a yellow band around the body. The base color of the bomb is olive drab. Differences Between M ods Bomb Mk 82 Mod 1 differs from Bomb Mk 82 Mod 0 only in the method used to construct the bomb body. Assembly CAUTION: Fuzes and bombs are not to be unpacked in advance of requirements. Return them to their original packing if not used. Mechanical Fuzing of the Mk 82 Mod 1 LD Bomb. 1. Remove the shipping cap on the rear of the bomb body. 2. Inspect bomb for damage, cracks, or broken weldments which might weaken threaded lug inserts or their attachment to the bomb body. 3. Remove the nose plug, base plug, and support cup from the nose fuze cavity. Re­ move the hoisting lug from the tail fuze ARMING WIRE ASSEMBLY FAHNESTOCK CLIF>S Figure 5-25.— 500-lb Low-Drag Bomb (GP) Mk 82 Mod 1 (Mechanically Fuzed), Exploded View. 5-36 G E N E R A L PURPOSE B O M B A SSEM B LIES BASE PLUG TAIL FUZE ARMING WIRE ASSEMBLY EXPLOSIVE CHARGE REAR CHARGING TUBE FORWARD CHARGING TUBE BODY LINER FUZE Figure 5 -2 6.— 500-lb Low-Drag Bomb (GP) Mk 82 M od 1 (Mechanically Fuzed), Cutaway View, 5-37 N A V W E P S OP 2216 (V O L U M E 1) cavity. Install the required adapter-booster for mechanical fuzing. 4. Remove the fin assembly and suspen­ sion lugs from the fin shipping crate. Place the fin assembly over the end of the bomb body with one fin in line with the suspension lugs; if hung in external racks, turn the fin and locate it so as to clear the aircraft and the ground when installed. Butt the fin against the aft end of the bomb and secure it with setscrews located on the edge of the cone. Assemble the two suspension lugs and the hoisting lug in their respective threaded holes. 5. Open the access door by unlocking the attaching fasteners. 6. Remove the fuzes and arming-wire as­ sembly from their containers and examine carefully for serviceability. 7. Insert the required tail fuze through the opening in the rear of the fin assembly. Grasp the fuze through the access door opening and screw the fuze into the fuze well until hand tight. Apply torque to the fuze at the body adjacent to the adapterbooster. Do not apply torque at the vane end of the fuze. 8. The Mk 82 Mod 1 LD bomb uses the AN-M103A1 series of nose fuzes. If nose 5-38 fuzing is not to be used, replace the nose plug and support cup and secure the nose plug with the setscrew. 9. For detailed information on fuzing and defuzing with the AN-M103A1 nose fuze, refer to chapter 2. 10. Install the bomb securely on the air­ craft and sway brace. If the bomb bay does not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the rack. 11. Install the arming wire. CAUTION: On certain aircraft, the arming wire leading to the tail fuze has been observed to whip dur­ ing high-speed flight. To reduce this whipping action, at least one arming wire guide should be in­ stalled at approximately the mid­ point on the tail cone of the fin as­ sembly. A standard eyebolt, Navy Stock Catalog No. R5306-6382217-GIAN, is a suitable arming wire guide. Electrical Fuzing of the Mk 82 Mod 1 LD Bomb. Follow the assembly procedure pro­ vided in volume 2 of this publication. G E N E R A L PURPOSE B O M B A SSEM B LIES 1000-LB L O W -D R A G B O M B (GP) M k 83 M od 3 ----------------------------------------------- 118"42 ------------------------------------ V" A PI — — 14'.'0 Figure 5—27.— 1000-lb Low-Drag Bomb (GP) Mk 83 Mod 3 (Mechanically Fuzed), Exterior View. Mark .... ............................................... Mod ..._J................................................... General Arrangement ..... .................... List of Drawings .... ............................ Fin Assembly Drawing No. ........ ..... Length of Assembled Bomb (in.) Body Diameter (in.) ............................ Fin Span (in.) ....................................... Weight of Explosive Charge (lb) Weight o f Assembled Bomb (lb) Arming-W ire Assembly ...................... 83 3 1380261 166791 1380606 118.42 14.0 19.62 446.0 985.0 Mk 1 or AN-M 6A2 (fo r nose fuze) M16 (for tail fuze) M73 (T27) Cable Assembly (for electric fuzing) Adapter-Booster T45E1 Nose ....... .................:....................... Tail .......... .............................. ............. ................................ T46E4 Nose Fuze .............................................. AN-M103A1, AN-M139A1, AN-M140A1, Mk 243 Mod 0, Mk 244 Mod 1, AN-M166 (V T ), AN-M168 (V T ), M910 (V T) (T750) (with T49 drive), M913 (V T ) (T768) (electric), M990 (T905) (electric) Tail Fuze M913 (V T ) (T768) (electric) M905 (T771) (with T49 drive), M906 (T788) (with T49 drive), M177 (T745) M183 (T783), M185 (T740), M990 (T905) (electric), XB-113 (electric) 5-39 N A V W E P S OP 2216 (V O L U M E 1) LONG STEM TAIL FUZE Figure 5-28.— 1000-lb Low-Drag Bomb (GP) Mk 83 Mod 3 (Mechanically Fuzed), Exploded View. General Description The 1000-lb LD Bomb Mk 83 Mod 3 has a slender body with a long pointed nose. A conical type fin is attached to the aft end of the bomb body by six setscrews. The bomb uses VT, mechanical, or elec­ trical fuzes. Mechanical and VT fuzes re­ quire the installation of adapter-boosters to provide fuze seats of smaller diameters. Two conduits for an electric fuze cable har­ ness connect the nose and tail fuze cavities with the charging receptacle cavity between the lugs on the outer surface of the bomb case. When the electric fuzes are not used, a plug is threaded into the charging re­ ceptacle cavity. When fuzes are not installed, the bomb body has a nose fuze plug, a base fuze plug, and a support cup in the nose fuze cavity. When the bomb is mechanically fuzed, these three parts are removed and the adapterboosters and fuzes are inserted. The nose fuze plug and base fuze plug are replaced after electric fuzes have been installed. Adapter-boosters are not used with the elec­ tric fuzes. If the bomb is tail fuzed only, the support cup must be used to prevent col­ lapse of the fuze cavity on heavy impact. The bomb body has a base plug containing 5-40 locking pins which are imbedded in the so­ lidified explosive filler. Two suspension lugs spaced 14 inches apart and a hoisting lug at the center of gravity are threaded into lug inserts on the bomb body. Painting and M arking The high-explosive filler of the bomb, Tritonal 80-20, or H-6, is identified by yellow bands around the nose and conical sections of the bomb body. The base color is olive drab; identifying nomenclature is stenciled in yellow and die-stamped on one side of the bomb body. Differences Between Mods Bomb Mk 83 consists of the Mod 2 and the Mod 3. Differences lie in the methods used in the construction of the bomb bodies. Assembly CAUTION: Fuzes and bombs are not to be unpacked in advance of requirements. Return them to their original packing if not used. Mechanical Fuzing of the Mk 83 Mod 3 LD Bomb. 1. Remove the shipping cap on the rear of G E N E R A L PURPOSE BO M B A SSEM B LIES FUZE LINER ASSEMBLY ■ BASE PLUG ASSEMBLY REAR CHARGING TUBE EXPLOSIVE CHARGE ARMING-W IRE ASSEMBLY FORWARD CHARGING TUBE BOMB BODY -FUZE LINER ASSEMBLY NOSE FUZE Figure 5-29.— 1000-lb Low-Drag Bomb (GP) Mk 83 Mod 3 (Mechanically Fuzed), Cutaway View. 5-41 N A V W E P S OP 2216 (V O L U M E 1) the bomb body by removing the hex head bolts. 2. Inspect bomb for damage, cracks, or broken weldments which might weaken threaded lug inserts or their attachment to the bomb body. 3. Remove the nose plug, base plug, and support cup from the nose fuze cavity. Re­ move the hoisting lug from the tail fuze cavity. Install the required adapter-boosters for mechanical fuzing. 4. Remove the fin assembly and suspen­ sion lugs from the fin shipping crate. Place the fin assembly over the end of the bomb body with one fin in line with the suspension lugs; if hung on external racks, turn the fin and locate it so as to clear the aircraft and the ground when installed. Butt the fin against the aft end of the bomb and secure it with setscrews located on the edge of the cone. Assemble the two suspension lugs and the hoisting lug in their respec­ tive threaded holes. 5. Open the access door by unlocking the attaching fastener. 6. Remove the fuzes and arming-wire as­ sembly from their containers and examine carefully for serviceability. 7. Insert the required tail fuze through the opening in the rear of the fin assembly. Grasp the fuze through the access door open­ 5-42 ing and screw the fuze into the fuze well until hand tight. Apply torque to the fuze at the body adjacent to the adapter-booster. Do not apply torque at the vane end of the fuze. 8. For detailed information on fuzing and defuzing, refer to chapter 2 under the par­ ticular fuze to be installed. 9. Install the bomb securely on the air­ craft and sway brace. If the bomb bay does not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the rack. 10. Install arming wire. CAUTION: On certain aircraft, the arming wire leading to Tail Fuze M185(T740) or M177(T745) has been observed to whip during high-speed flight. To reduce this whipping action, at least one arm­ ing wire guide should be installed at approximately the mid point on the tail cone of the fin assembly. A standard eyebolt, Navy Stock Catalog No. R5306-638-2217GIAN, is a suitable arming wire guide. Electrical Fuzing of the Mk 83 Mod 3 LD Bomb. Follow the assembly procedure pro­ vided in volume 2 of this publication. G E N E R A L PURPOSE B O M B A SSEM B LIES Figure 5-30. — 2000-lb Low-Drag Bomb (GP) Mk 84 M od J (Mechanically Fuzed), Exterior View. Mark ...................... ......- ...................... Mod ......... ..............- ........-.....-................... General Arrangement .................._ List o f Drawings ................... ................ Fin Assembly Drawing No.............. . Length of Assembled Bomb (in.) Body Diameter (in.) ------ -----------------Fin Span (in .).......... ..........................— Weight of Explosive Charge (lb) ....... Weight of Assembled Bomb (lb) ..... Arming-W ire Assembly ....... ................ Cable Assembly (for electric fu zin g ).. Adapter-Booster Nose ...... ........................................ Tail ............. ....................................... Nose Fuze .............................................. Tail Fuze 84 1 1380522 165795 1380529 151.50 18.0 25.31 945.0 1970.0 Mk 1 or AN-M 6A2 (for nose or tail fuze) M74 (T28) T45E1 T46E4 AN-M103A1, AN-M139A1, AN-M140A1, AN-M166 (V T ), AN-M 168 (V T ), T750 (V T ), M904 (T709), M913 (V T ) (T768) (electric), M990 (T905) (electric) M913 (V T) (T768) (electric), M190 (T759), M990 (T905) (electric), XB-113 (electric) General Description The 2000-lb LD Bomb Mk 84 Mod 1 has a slender body with a longr pointed nose. A conical type fin is attached to the aft end of the bomb body by eight setscrews. The bomb uses VT, mechanical, or elec­ trical fuzes. Mechanical and VT fuzes re­ quire the installation of adapter-boosters to provide fuze seats of smaller diameters. Two conduits for an electric fuze cable har- 5-43 N A V W E P S OP 2216 (V O L U M E 1) FAHNESTOCK CLIPS. Figure 5-31. — 2000-lb Low-Drag Bomb (GP) Mk 84 Mod 1 (Mechanically Fuzed), Exploded View. ness connect the nose and tail fuze cavities with the charging receptacle cavity between the lugs on the outer surface of the bomb case. When the electric fuzes are not used, a plug is threaded into the charging recep­ tacle cavity. When fuzes are not installed, the bomb body has a nose fuze plug, a base fuze plug, and a support cup in the nose fuze cavity. When the bomb is mechanically fuzed, these three parts are removed and the adapterboosters and fuzes are inserted. The nose fuze plug and base fuze plug are replaced after electric fuzes have been installed. Adapter-boosters are not used with the elec­ tric fuzes. If the bomb is tail fuzed only, the support cup must be used in the nose fuze cavity to prevent collapse upon heavy impact. The bomb body has a base plug contain­ ing locking pins which are imbedded in the solidified explosive filler. Two suspension lugs spaced 30 inches apart and a hoisting lug located at the center of gravity are threaded into lug inserts on the bomb body. Painting and M arking The high-explosive filler of this bomb, Tritonal 80-20, or H-6, is identified by yellow bands around the nose and conical sections 5-44 of the bomb body. The base color is olive drab; identifying nomenclature is stenciled in yellow and die-stamped on one side of the bomb body. Differences Between M ods Bomb Mk 84 Mod 1 differs from the earlier Mod 0 bomb in that the tail fins of the Mod 1 are canted 2 degrees for added stability. Assembly CAUTION : Fuzes and bombs are not to be unpacked in advance of requirements. Return them to their original packing if not used. Mechanical Fuzing of the Mk 84 Mod 1 LD Bomb. 1. Remove the shipping cap on the rear of the bomb body by removing the hex head bolts. 2. Inspect bomb for damage, cracks, or broken weldments which might weaken threaded lug inserts or their attachment to the bomb body. 3. Remove the nose plug, base plug, and support cup from the nose fuze cavity. Re­ move the hoisting lug from the tail fuze cavity. Install the required adapter-boosters for mechanical fuzing. G E N E R A L PURPOSE B O M B A SSEM B LIES TAIL FUZE BASE REAR CHARGING TUBE ARMING-WIRE ASSEMBLY CHARGE FORWARD CHARGING TUBE BOMB BODY LINER NOSE FUZE Figure 5-32.— 2000-lb Low-Drag Bomb (GP) Mk 84 Mod I (Mechanically Fuzed), Cutaway View. 5-45 N A V W E P S OP 2216 (V O L U M E 1) 4. Remove the fin assembly and suspen­ sion lugs from the fin shipping crate. Place the fin assembly over the end of the bomb body so that the pin in the fin assembly alines with a hole in the body. Butt the fin against the aft end of the bomb and secure it with setscrews located on the edge of the cone. Assemble the two suspension lugs and the hoisting lug in their respective threaded holes. 5. Open the access door by unlocking the attaching fastener. 6. Remove the fuzes and arming-wire as­ sembly from their containers and examine them carefully for serviceability. 7. Insert the required tail fuze through the opening in the fin assembly. Grasp the fuze through the access door opening and screw the fuze into the fuze well until hand 5-46 tight. Apply torque to the fuze at the body adjacent to the adapter-booster. Do not apply torque at the vane end of the fuze. 8. For detailed information on fuzing and defuzing, refer to chapter 2 under the par­ ticular fuze to be installed. 9. Install the bomb securely on the air­ craft and sway brace. If the bomb bay does not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the rack. 10. Install the arming wire so that two to three inches protrude beyond the fuze vanes and attach the safety clips. Cut off excess wire. Arming wire should be free from kinks, twists, and burrs. Electrical Fuzing of the Mk 84 Mod 1 LD Bomb. Follow the assembly procedure pro­ vided in volume 2 of this publication. Chapter 6 AIRCRAFT DEPTH BOMB ASSEMBLIES 350-LB A IR C R A F T DEPTH BO M B A N - M k 54 Mod 1 AN-M ark ................... ..................... Mod .................................................... General Arrangement ..... .............. List of Drawings ............................ Fin Assembly Drawing No........ .. Length o f Assembled Bomb (in.) Body Diameter (in.) ...................... Fin Span (in.) _______ ____ ______ Weight of Explosive Charge (lb) TNT ........................................... .... HBX or HBX-1 ....... .................. Weight of Fin Assembly (lb) ___ Weight of Assembled Bomb (lb) Loaded with T N T _____ _______ Loaded with HBX or HBX-1 Arming-Wire Assembly _____ ___ Arming Bracket ...... ....................... Auxiliary Booster ............ .............. Nose Fuze ....... ..... ....................... Tail Fuze 54 1 438064 Sk 165766 394196 54.6 13.5 13.88 225.5 248.0 19.5 323.8 346.3 Mk 1 or AN-M 6A2 Mk 1 Mod 0 Mk 1 Mod 0 (2) AN-M103A1, AN-M139A1, AN-M 140A1, AN-M k 219* Mods 2, 3, 4 A N -M k 230 Mods 4, 5, 6 *A fuze adapter and an additional Auxiliary Booster Mk 1 Mod 0 are required for the A N -M k 219 fuze. General Description The 350-lb ADB AN-Mk 54 Mod 1 is a flat nosed, thin walled bomb. The fin as­ sembly consists of a fin cone and four fin blades surrounded by a shroud; it is at­ tached to the aft end of the bomb body by. capscrews. This bomb is used against underwater targets. The flat nose prevents ricochet upon water impact. The depth of detonation is determined by the setting of the hydrostatic tail fuze. Depth bombs are usually tail fuzed only, but provision is made for nose fuzing in the event that a blast effect is desired. With both fuzes installed, the aircraft depth bomb may be selectively armed by releasing one of the arming wires with the bomb. Depth settings are made prior to flight. The lethal radius of underwater effective­ ness of the bomb is approximately 17 feet; however, damage may be expected up to 45 feet from the center of the blast. Two suspension lugs are welded to the body 14 inches apart and a single suspen­ sion lug is located diametrically opposite. Tapped holes are provided for attaching hoisting lugs which may be needed for the handling of the bomb when not in use. These holes are closed with special plugs. Approximately 70 percent of the weight of the bomb is high-explosive filler. Painting and M arking Yellow bands painted on the nose and aft end of the bomb body identify the highexplosive filler of TNT, HBX, or HBX-1. Identifying nomenclature is stenciled in black (old issue) or in yellow (new issue) on the olive drab bomb body. 6-1 N A V W E P S OP 2216 (V O L U M E 1) 54:6 Figure 6-1. — 350-lb Aircraft Depth Bomb A N -M k 54 Mod 1, Exterior View. Differences Between Mods The earlier mod, now obsolete, Mk 54 Mod 0, had no attached suspension lugs. The suspension lugs were attached in the field with capscrews; all of the suspension lug fitting holes of the Mod 0 were plugged. Assembly CAUTION: Fuzes and bombs are not to be unpacked in advance of requirements. If unpacked and not used, return them to their origi­ nal packings.1 1. Open the shipping crate by removing the cotter pins from the three lid latches. Unthread the hex-head screws from the bands which secure the bomb in the case. 6-2 Lift the bomb body out of the case. CAUTION: The bomb body is easily damaged because of its light construction. Inspect it for dam­ age. 2. Remove the closing plugs which seal the fuze cavities. 3. Remove the fin assembly and its at­ tachments from the shipping crate. Place the fin assembly over the conical end of the bomb so that one fin is in line with the sus­ pension lugs. Secure with hex-head cap screws. CAUTION: Do not use a fin as­ sembly if it cannot be properly secured to the bomb. A IR C R A F T DEPTH B O M B A SSEM B LIES 4. Hoist and secure the bomb to the air­ craft. If the bomb bay does not provide sufficient room for fuzing, this operation must be performed before hoisting. 5. Remove the required number of fuzes and arming wire assemblies from their con­ tainers and examine them carefully for serv­ iceability. 6. For detailed information on fuzing and defuzing, refer to chapter 2 under the par­ ticular fuze to be installed. ARMING WIRE ASSEMBLY FAHNESTOCK CLIPS. HOISTING LUG FAHNESTOCK CLIF>S C 'O SIN G PLUG TAIL FUZE BODY NOSE FUZE Figure 6-2. — 350-lb Aircraft Depth Bomb A N -M k 54 M od 1, Exploded View. N A V W E P S OP 2216 (V O L U M E 1) Figure 6-3. — 350-lb Aircraft Depth Bomb A N -M k 54 Mod 1, Cutaway View. Chapter 7 FRAGMENTATION BOMB ASSEMBLIES 4-LB FRAG B O M B M 83 Model ___ ____________ ______ - .......... Assembly Drawing No. ____________ Length o f Assembled Bomb (in.) ..... Body Diameter (in.) ......... ............... Butterfly-wing Span (in.) _________ Butterfly-wing Length (in.) ________ W eight o f Explosive Charge (lb) Weight o f Assembled Bomb (lb) Loaded with Composition B _____ Loaded with Ednatol ____________ Loaded with TNT _______________ Fuze (integral) ____ _______________ Bomb Cluster 100-lb size _____________ __________ 500-lb size .......................................... Cluster Adapter 100-lb size ___ ___ ___ _________ ___ 500-lb size ______________________ General Description The 4-lb Frag Bomb M83 is a small barrel­ shaped bomb. Its fuze, assembled at the time of manufacture, is mounted on the bomb case midway between the cylinder ends. Two semicylindrical surfaces (butter­ fly wings) and two discs (propeller blades) are spring-hinged together independent of the bomb. In the unarmed position, these four pieces, or vanes, are folded about the bomb, forming a cylindrical outer bomb cas­ ing. A cable extension projects from the fuze through the folded outer bomb casing. The 4-lb fragmentation bomb uses the M129, M130, and M131 fuzes. Impact, me­ chanical time delay, and antidisturbance fir­ ing actions are obtained by selection of the respective fuze. The fuzes are installed and their actions are set at the time of manu­ facture. Approximately 12 percent of the complete weight of the bomb is explosive filler com­ position B, Ednatol, or TNT. The M83 bombs are issued assembled in clusters of the M28 series or in the form of ..... ... ..... ._ M83 82-0-106 11.13 3.12 9.5 .... 3.0 .... 0.5 ... .... ..... .... 3.82 3.81 3.80 M129, M l 30, M131 ..... M28A2 __ M29A1 ..._ M15A2 ..... M16A1 bomb wafers to be assembled in M29 clusters in the field. Painting and M arking The bomb is painted olive drab; yellow bands and black (old issue) or yellow (new issue) stenciled nomenclature identify the bomb and its high-explosive content. Assembly of M 2 9 Clusters 1. Ten 4-lb Frag Bombs M83 are shipped from the manufacturer in wafer assemblies which are bound with two metal straps. The wafer assemblies are individually packed in metal lined wafer boxes and are secured to plywood inserts. Fuzes are in­ stalled and set at the factory. CAUTION: No attempt should be made to remove the fuzes, change the setting, or work on them in any way. 2. Always handle wafers by the cable as­ semblies (pigtails) or by the flat side, not by the strapping. 7-1 N A V W E P S OP 2216 (V O L U M E 1) 11. i. ll \ Figure 7—1.— 4-lb Frag Bomb M83, Exterior View. 7-2 F R A G M E N T A T IO N B O M B A SSE M B L IE S 3. Refer to chapter 8, Fragmentation Bomb Clusters and Adapters, for detailed procedures on handling, installation, and general precautions for fragmentation bomb wafers. Failure to follow these instructions may permit the bomb to spring out of the cluster and the case assemblies (butterfly wings) to open. Figure 7-2.— 4-lb Frag Bomb M83, Cutaway View. 7-3 N A V W E P S OP 2216 (V O L U M E 1) 20-LB FRAG B O M B A N -M 4 1 A 1 Figure 7-3. — 20-lb Frag Bomb A N -M 4 1 A 1 , Exterior View. Model ...... .... ........................ ............. Assembly Drawing No. ......... . Length of Assembled Bomb (in.) Body Diameter (in.) .......... ..... Fin Span (in.) .... ........................ Weight of Explosive Charge (lb) AM50-50 ____ ______________ TNT .......... ......... ......................... Weight o f Fin Assembly (lb) Weight of Assembled Bomb (lb) Loaded with AM 50-50 Loaded with TNT __________ Nose Fuze ____________ ________ Bomb Cluster 100-lb size ... ................................ 500-lb size ..... .............................. Cluster Adapter 100-lb size ......... .......................... 500-Ib size .... ........ ............. ........ J General Description The 20-lb Frag Bomb AN-M41A1 is con­ structed of spirally wound wire and cast steel nose and tail pieces. A seamless steel 7-4 AN-M 41A1 82-0-39 22.4 3.64 5.13 2.57 2.7 1.6 19.7 19.8 AN-M 110A1, AN-M158 AN-M 1A2 M26A2 AN-M 1A3 M13A2 inner tube is threaded to the nose and tail piece to form the base for the spiral wound wire. The fin assembly is made of four rec­ tangular sheet steel vanes welded to a 1-inch F R A G M E N T A T IO N B O M B A SSEM B LIES Figure 7-4. — 20-lb Frag Bomb A N -M 4 1 A 1 , Exploded View. Figure 7-5. — 20-lb Frag Bomb A N -M 4 1 A 1 , Cutaway View. diameter pipe. The threaded end of the pipe is secured to the base filling plug. The nose section of the bomb is threaded to receive an impact fuze. At the center of gravity, a U-shaped eyebolt of steel is welded to the bomb case for horizontal suspension; an eyebolt is welded to the tail for vertical suspension. Approximately 13 percent of the complete weight of the bomb is explosive filler AM 50-50 or TNT. The AN-M41A1 bomb is used in the 100and 500-lb fragmentation bomb clusters of the AN-M1 and the M26 series. Painting and M arking Old issue bombs have a yellow colored head and base to identify the high-explosive filler; identifying nomenclature is stenciled in black on the bomb body. Body windings are painted olive drab. New issue bombs have an olive drab body, yellow bands, and yellow identification mark­ ings. " O ld " Series Bombs The AN-M41 bomb, which is the earlier model, differs from the AN-M41A1 in length. A change in construction added a 7-5 N A V W E P S OP 2216 (V O L U M E 1) V^-inch shoulder to the nose of the bomb to facilitate clustering with unfuzed bombs; this change in design alone constitutes the A1 modification. The AN-M41 bomb, when issued in cluster form, always is fuzed. If unpacked and not used, return them to their original packings. 2. Remove the bomb closing plug. Inspect the threads and clean, if necessary. Assembly 3. Remove the fuze from its container and examine it carefully for serviceability. 1. This bomb is usually furnished in clus­ ters which are completely assembled except 4. For detailed information on fuzing and for the fuzes. defuzing, refer to chapter 2 under the par­ CAUTION: Fuzes are not un­ packed in advance of requirements. 7-6 ticular fuze to be installed, and to chapter 8 for the assembly of bomb clusters. F R A G M E N T A T IO N B O M B A SSEM B LIES 90-LB FRAG BOMB M82 2 8 :o Figure 7-6. — 90-lb Frog Bomb M82, Exterior View. Model ................................................Assembly Drawing No. ........... ...... Fin Assembly .... .......................... Length o f Assembled Bomb (in.) Body Diameter (in.) .............. Fin Span (in.) .................. ............... Weight of Explosive Charge (lb) Composition B ......................... TNT ................................................ Weight o f Fin Assembly (lb) ..... Weight o f Assembled Bomb (lb) Loaded with Composition B ..... Loaded with TNT ...... ................. Arming-W ire Assembly ............... Nose Fuze .................................... Bomb Cluster Cluster Adapter M82 82-0-105 M101 28.0 6.06 8.11 12.3 11.4 2.46 86.6 87.4 Mk 1 or AN-M 6A2 AN-M103A1, AN-M139A1, AN-M140A1, AN-M166 (V T ), AN-M168 (V T )* M27A1 M14A1 ‘ Short Vane Assembly (dwg 73-8-281) used when clustering bombs. 7-7 N A V W E P S OP 2216 (V O L U M E 1) General Description The 90-lb Frag Bomb M82, now obsoles­ cent, is constructed of spirally wound wire. A seamless steel inner tube forms the base for the outer wound steel wire. A rounded nose piece houses the nose fuze, and a boxtype fin assembly is attached to the tapered aft end by a fin locknut. The bomb is designed for use in clusters and for single suspension. It has only one suspension lug welded to its casing. When adapted for single suspension, instantaneous or VT fuzes are used. The fitting of a me­ chanical time fuze is permitted with the addition of an adapter-booster. Approximately 13 percent of the complete weight of the bomb consists of composition B or TNT. Painting and M arking Old-issue bombs have yellow bands on the nose end and aft end of the bomb body to identify the high-explosive charge. Identi­ fying nomenclature is stenciled in black on ARMING WIRE ASSEMBLY FAHNESTOCK CLIPS IOX FIN ASSEMBLY BOMB BODY NOSE FUZE Figure 7-7.— 90-lb Frag Bomb M82, Exploded View. NOSE FUZE FUZE SEAT LINER EXPLOSIVE CHARGE nr SURROUND SURROUNI Figure 7-8.— 90-lb Frag Bomb M82, Cross Section. 7-8 CLOSING PLUG F R A G M E N T A T IO N B O M B A SSE M B L IE S the olive drab painted bomb casing. New-issue bombs have olive drab bodies, yellow bands, and yellow identification markings. Assembly CAUTION: Fuzes and bombs are not unpacked in advance of require­ ments. If unpacked and not used, return them to their original pack­ ings. 1. Remove the shipping bands from the bomb by removing the nut from the securing bolts. Remove the closing plug from the nose end. Inspect for damage, cracks, or broken weldments which might weaken the lug or its attachment to the bomb body. 2. Cut the shipping wire and remove the fin locknut and its protector. Remove the protector from the locknut. 3. Remove the fin assembly and its at­ tachments from the shipping crate. Posi­ tion the fin on the bomb so that it will clear the aircraft and the ground when installed. Replace the fin locknut and tighten it with a wrench. CAUTION: Do not use a fin as­ sembly if it cannot be properly se­ cured to the bomb. 4. Install the bomb in accordance with the type of rack in use, and lock it securely in place. If the bomb bay does not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the rack. 5. Remove the required fuze and armingwire assembly from their containers and examine them carefully for serviceability. All fuzes must have their safety devices (cotter, shear, and arming pins) in place. If any safety device is missing, handle the fuze with extreme care. Return it to its container and mark the container for dis­ posal by authorized personnel. 6. For detailed information on fuzing and defuzing, refer to chapter 2 under the par­ ticular fuze to be installed, and to chapter 8 for the assembly of bomb clusters. 7-9 N A V W E P S OP 2216 (V O L U M E 1) Figure 7-9. — 220-lb Frag Bomb A N -M 8 8 with Fin Assembly A N -M 1 0 3 A 1 , Exterior View. ARMING WIRE ASSEMBLY. FAHNESTOCK CLIPS. TAIL FUZE. FAHNESTOCK CLIP’S FIN LOCK NUT BOX FIN ASSEMBLY BOMB BODY NOSE FUZE Figure 7-10.— 220-lb Frag Bomb A N -M 8 8 with Fin Assembly A N -M 1 0 3 A 1 , Exploded View. 7-10 F R A G M E N T A T IO N BO M B A SSEM B L IES 220-LB FRAG BO M B A N - M 8 8 W ith F in A s se m bly I W ith F in A sse m bly M135 A N -M 1 0 3 A 1 M odel_______ __________________ Assembly Drawing No _____ Fin Assembly Drawing N o________ Length of Assembled Bomb (in.)_._ Body Diameter (in.)____________ . Fin Span (in.) ___________ Weight of Explosive Charge (lb): Composition B ___________ EdnatoL _________________ _ T N T ____________________ Weight of Fin Assembly (lb)____ _ Weight of Assembled Bomb (lb): Loaded with Composition B __ Loaded with Ednatol_______ . Loaded with TN T . . _____ Fin Locknut__________ ______ Fin Locking W eb_____________ _ Arming-Wire Assembly- ___ A N -M 8 8 -.......................... 82-0-132. 8 2 -3 -4 3 7 ... . .. ... 4 3 .7 . .. ________________ 8 .1 2 . __________________ 1 1 .0 . . .... AN-M 88. 4 1 .4 ____________________ 4 1 .2 ____________________ 4 1 .2 . .. __________ _____ 4 .1 ....................................... 41.4. 41.2. 41.2. 17.5. 2 1 6 .2 ............................... 217.7_____________ _____ 217.7___________________ M l or Mk 2 M od 0_____ Not Used______ ___ Mk 1 or A N -M 6 A 2 _____ Nose F u z e .______ ____ _______ AN-M 103A1, A N M139A1, AN-M 140A1, A N -M k 219 1 Mods 3, 4; AN-M 166 (VT), AN -M 168 (VT). AN-M 100A2 (with Primer-Detonator M14 (nondelay)). 229.6. 231.1. 231.1. Sk 329153. Dwg 1350522. M k 1 or AN -M 6A2, and M13. AN-M103A1, A N M139A1, AN-M140A1, A N -M k 219 1 Mods 3, 4; AN-M 166 (VT), AN -M 168 (VT). M172, AN-M 175. Tail Fuze........................................... 82-3-778. 58.0. 8 . 12. 11.19. 1 Requires Adapter Ring (dwg 294376-2 and Auxiliary Booster Mk 4. 7-11 N A V W E P S OP 2216 (V O L U M E 1) TAIL FUZE ARMING-WIRE ASSEMBLY SURROUND AUXILIARY BOOSTER. STEEL TUBE BOMB BODY EXPLOSIVE CHARGE •SURROUND FUZE SEAT LINER Figure 7-11.— 220-lb Frag Bomb A N -M 8 8 with Fin Assembly A N -M 1 0 3 A 1 , Cutaway View. 7-12 F R A G M E N T A T IO N B O M B A SSEM B L IES 220-LB FRAG B O M B A N - M 8 8 W IT H FIN A S S E M B L Y A N -M 1 0 3 A 1 General Description The 220-lb Frag Bomb AN-M88 has a body constructed of spirally wound 1% 0-inch square steel wire. A seamless steel tube forms the base for the outer wrapping. The steel wire winding is forged at the nose and tail to form solid nose and tail sections. A box-type fin is secured to the aft end by a fin locknut. The nose and tail sections are threaded to accommodate nose and tail fuzes. Two suspension lugs are welded 14 inches apart on one side of the bomb body; a single lug is attached to the opposite side at the approximate center of gravity. The explosive charge comprises approxi­ mately 19 percent of the complete weight of the bomb. Painting and M arking Older issues of Frag Bomb AN-M88 have yellow bands on the nose and aft end of the bomb body to identify its high-explosive filler of composition B, Ednatol, or TNT. When filled with composition B, nose and tail surrounds of TNT are employed. Identify­ ing nomenclature is stenciled in black on the olive drab colored bomb casing. Newer issues of the bomb have olive drab bodies, yellow bands, and yellow markings. " O ld " Series Bombs The 260-lb Frag Bomb AN-M81 is an earlier modification of the AN-M 88; it is heavier because of its thicker windings. Both bombs have the same outside diameter; however, the larger explosive cavity of the AN-M88 contains about 5 pounds more ex­ plosive filler. The physical characteristics of the two bombs are otherwise similar. The 260-lb bomb is more effective for fragmentation effect than an equivalent bomb station load of 500-lb GP bombs, 100lb GP bombs, and 20-lb frag bombs, except for the casualty effect on unprotected per­ sonnel by the 20-lb frag bomb when released from altitudes up to 10,000 feet. The 200lb fragmentation bomb compares similarly in effectiveness with the 260-lb fragmenta­ tion bomb, with an overall increase of frag­ mentation effect under all conditions. Assembly CAUTION: Fuzes and bombs are not to be unpacked in advance of requirements. When unpacked and not used, fuzes are to be re­ turned to their original packing. 1. Remove the shipping bands from the bomb by removing the nuts from the secur­ ing bolts. Inspect for damage, cracks, or broken weldments which might weaken the lugs or their attachment to the bomb body. 2. Cut the shipping wire and remove the fin locknut and discard it with its protector. Remove the protector from the locknut. 3. Remove the fin assembly and its at­ tachment from the shipping crate. Position the fin on the bomb so that it will clear the aircraft structure and the ground when in­ stalled. Replace the fin locknut and tighten it with a wrench. Always use Fin Locknut M l or Mk 2 Mod 0 in place of the regular fin locknut. Clean all threaded surfaces on the after end of the bomb before installing the fin assembly. CAUTION: Reject any fin assem­ bly which is cracked, deformed, or which cannot be properly secured to the bomb. 4. Remove the nose and tail shipping plugs and inspect the fuze cavities to be sure they are free from rust and corrosion. 5. Install the bomb on the aircraft and lock it securely in place. If the bomb bay does not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the rack. 6. Remove the required fuze and armingwire assembly from their containers and inspect carefully for serviceability. 7. For detailed information on fuzing and defuzing, refer to chapter 2 under the par­ ticular fuze to be installed. 7-13 N A V W E P S OP 2216 (V O L U M E 1) 220-LB FRAG BO M B A N - M 8 8 W IT H FIN A S S E M B L Y M l 35 curing bolts. Remove the closing plugs. Inspect for damage, cracks, or broken weld­ When equipped with the conical fin as­ ments which might weaken the lugs or their sembly M135, the 220-lb Frag Bomb A N attachment to the bomb body. M88 uses the standard AN-M88 bomb body. 2. Cut the shipping wire. Remove and This elongated conical fin assembly lengthens discard the fin locknut and its protector. and streamlines the bomb, improving its 3. Remove the fin assembly and its at­ aerodynamic performance and accuracy. tachments from the shipping crate. Thread The M135 fin assembly consists of an the center support tube onto the base plug elongated cone with four integral blades of the bomb (locknut seat). Tighten the spaced at equal distances. A support tube tube with a wrench and tighten the set­ runs through the center of the cone; the fin screws in the support tube. Place the fin assembly is secured to the bomb body by cone over the support tube. Slide the cone means of this support tube, a locking web, back until it is jammed against the bomb and a locknut. Installation of the M135 body. Position the fin assembly so that it conical fin assembly requires the use of one will clear the aircraft structure and the of the new long-stem tail fuzes to locate ground when installed. Place the fin lock­ the arming vane effectively in the air stream. ing web over the support tube so that it engages the blades of the fin assembly. Se­ Assembly cure the conical fin assembly to the support CAUTION: Fuzes and bombs are tube by threading on the special locknut, not to be unpacked in advance of and tighten the locknut with special notched requirements. If unpacked and not wrench. Bend two tabs of the locking web used, return them to their original into the locknut slots. Secure the nut in packings.1 position by means of setscrews. 1. Remove the shipping bands from the 4. Install the bomb on the aircraft and bomb by removing the nuts from the se­ lock it securely in place. If the bomb bay General Description ARMING WIRE ASSEMBLY FAHNESTOCK CLIPS FIN LOCKING WEB LONG STEM TAIL FUZE. FAHNESTOCK CLIPS I FIN LOCK NUT CONICAL FIN CENTER SUPPORT TUBE BOMB BODY 'G NOSE FUZE Figure 7—12.— 220-lb Frag Bomb A N —M88 with Fin Assembly M 135, Exploded View. 7-14 F R A G M E N T A T IO N B O M B A SSE M B L IE S does not provide enough space for fuzing, this operation will be performed before the bomb is hoisted into place on the rack. 5. Remove the required number of fuzes and arming-wire assemblies from their con­ tainers and inspect them carefully for serv­ iceability. 6. For detailed information on fuzing and defuzing, refer to chapter 2 under the par­ ticular fuze to be installed. 7-15 N A V W E P S OP 2216 (V O L U M E 1) 260-LB FRAG B O M B A N -M 8 1 1 M odel __________________________ Assembly Drawing No _. . __ Fin Assembly Drawing N o _______ Length of Assembled Bomb (in.)__ Bomb Diameter (in.)____ . _ Fin Span (in.)............. . __ . Weight of Fin Assembly (lb )______ Weight of Explosive Charge (lb): Composition B ___ T N T _______ . ___ ... Weight of Assembled Bomb (lb): Loaded with Composition B __ Loaded with T N T _____ __ Fin Locknut.... .................................. Fin Locking W e b .. __ Arming-Wire Assembly___________ Nose Fuze____ _______ _________ Tail F u ze ............ _ __ 1Requires 7-16 ____ W ith F in A sse m bly W ith F in A sse m bly A N -M 1 0 3 A 1 M 135 A N -M 81________________ 82-0-102. 82-3-437_______ . 4 3.7________ _____ _ . . . 8 .1 3 . _________ 11 0 . . . 4 .1 _________________ . . . A N -M 8 1 . 3 6.2_______ ________ 3 4 .5 ................. ... 36.0. 34.5. 263.0___________________ 261.5___________________ M l or Mk 2 M od 0_____ Not Used . . ............. Mk 2 . ___ AN-M 103A1, A N M145,1 AN-M 166 (V T), AN -M 168 (VT). AN-M 100A2 (with Primer-Detonator M14 (nondelay)). 276.5. 275.0. Sk 329153. Dwg 1350522. Mk 2. AN-M 103A1, A N M145,1 AN-M 166 (V T), AN -M 168 (VT). M172 or AN-M 175 (with Primer-DetonatorM14 (nondelay)). Adapter Booster M117 82-3-778. 58.0. 6.13. 11.19. 17.5. F R A G M E N T A T IO N BO M B A SSEM B LIES Figure 7—13.— 260-lb Frag Bomb A N -M 81 with Fin Assembly A N -M 1 0 3 A 1 , Exterior View. Figure 7-14.— 260-lb Frag Bomb A N -M 81 with Fin Assembly A N -M 1 0 3 A 1 , Exploded View. 7-17 N A V W E P S OP 2216 (V O L U M E 1) 260-LB FRAG BO M B A N -M 8 1 W IT H FIN A S S E M B L Y A N -M 1 0 3 A 1 TAIL FUZE FIN ASSEMBLY ARM ING WIRE ASSEMBLY SURROUND BOMB BODY STEEL TUBE EXPLOSIVE CHARGE 'AUXILIARY BOOSTER SURROUND FUZE SEAT LINER NOSE FUZE Figure 7-15.— 260-lb Frag Bomb AN -M 81 with Fin Assembly A N -M 1 0 3 A 1 , Cutaway View. 7-18 F R A G M E N T A T IO N BO M B A SSEM B LIES General Description The 260-lb Frag Bomb AN-M81 has a body constructed of spirally wound 1-inch square steel wire. A seamless steel tube forms the basis for the outer wrapping. The steel wire winding is forged at the nose and tail to form solid nose and tail sections. A box-type fin is secured to the aft end by a fin locknut. The nose and tail sections are threaded to accommodate nose and tail fuzes. Two suspension lugs are welded 14 inches apart on one side of the bomb body; a single lug is attached to the opposite side at the approximate center of gravity. The explosive charge comprises approxi­ mately 13 percent of the complete weight of the bomb. Painting and M arking Older issues of the bomb have yellow bands on the nose and aft end of the body to identify its high-explosive filler of com­ position B or TNT. When filled with com­ position B, nose and tail surrounds of TNT are employed. Identifying nomenclature is stenciled in black on the olive drab colored bomb casing. Newer issues of the bomb have olive drab bodies, yellow bands, and yellow markings. New Series Bombs The 220-lb Frag Bomb AN-M88 is a later modification of the AN-M81; it is lighter because of its thinner windings. Both bombs have the same outside diameter; however, the smaller explosive cavity of the AN-M81 contains about 5 pounds less ex­ plosive filler. The physical characteristics of the two bombs are otherwise similar. The 260-lb Frag Bomb AN-M81 is more effective for fragmentation effect than an equivalent bomb station load of 500-lb GP bombs, and 20-lb frag bombs, except for the casualty effect on unprotected personnel by the 20-lb frag bomb when released from alti­ tudes up to 10,000 feet. The 220-lb frag­ mentation bomb compares similarly in effec­ tiveness with the 260-lb fragmentation bomb, with an overall increase of fragmenta­ tion effect under all conditions. Assembly CAUTION: Fuzes and bombs are not to be unpacked in advance of requirements. When unpacked and not used, fuzes are to be returned to their original packing. 1. Remove the shipping bands from the bomb by removing the nuts from the secur­ ing bolts. Inspect for damage, cracks, or broken weldments which might weaken the lugs or their attachment to the bomb body. 2. Cut the shipping wire and remove the fin locknut and discard it with its protector. Remove the protector from the locknut. 3. Remove the fin assembly and its at­ tachment from the shipping crate. Position the fin on the bomb so that it will clear the aircraft structure and the ground when in­ stalled. Replace the fin locknut and tighten it with a wrench. Always use Fin Locknut M l in place of the regular fin locknut. Clean all threaded surfaces on the after end of the bomb before installing the fin assembly. CAUTION: Reject any fin assem­ bly which is cracked, deformed, or which cannot be properly secured to the bomb. 4. Remove the nose and tail shipping plugs and inspect the fuze cavities to be sure they are free from rust and corrosion. 5. Install the bomb on the aircraft and lock it securely in place. If the bomb bay does not provide enough space for fuzing, this operation will be performed before the the bomb is hoisted into place on the rack. 6. Remove the required fuze and armingwire assembly from their containers and in­ spect carefully for serviceability. 7. For detailed information on fuzing and defuzing, refer to chapter 2 under the par­ ticular fuze to be installed. 7-19 N A V W E P S OP 2216 (V O L U M E 1) 260-LB FRAG B O M B A N -M 8 1 W IT H ARMING WIRE ASSEMBLY FAHNESTOCK C U PS FIN A S S E M B L Y M l 35 FIN LOCKING W EB . LONG STEM TAIL FUZE FIN LOCK NUT CONICAL FIN CENTER SUPPORT TUBE BOMB BODY NOSE FUZE Figure 7—16.— 260-lb Frag Bomb A N -M 8 1 with Fin Assembly M l 35, Exploded View. curing bolts. Remove the closing plugs. Inspect for damage, cracks, or broken weld­ When equipped with the conical fin assem­ ments which might weaken the lugs or their bly M135, the 260-lb Frag Bomb AN-M81 attachment to the bomb body. uses the standard AN-M81 bomb body. This 2. Cut the shipping wire. Remove and elongated conical fin assembly lengthens and discard the fin locknut and its protector. streamlines the bomb, improving its aero­ 3. Remove the fin assembly and its at­ dynamic performance and accuracy. tachments from the shipping crate. Thread The M135 fin assembly consists of an elon­ the center support tube onto the base plug gated cone with four integral blades spaced of the bomb (locknut seat). Tighten the at equal distances. A support tube runs tube with a wrench and tighten the set­ through the center of the cone; the fin as­ screws in the support tube. Place the fin sembly is secured to the bomb body by cone over the support tube. Slide the cone means of this support tube, a locking web, back until it is jammed against the bomb and a locknut. Installation of the M135 body. Position the fin assembly so that it conical fin assembly requires the use of one will clear the aircraft structure and the of the new long-stem tail fuzes to locate ground when installed. Place the fin lock­ the arming vane effectively in the air stream. ing web over the support tube so that it en­ gages the blades of the fin assembly. Se­ Assembly cure the conical fin assembly to the support CAUTION : Fuzes and bombs are tube by threading on the special locknut, and not to be unpacked in advance of tighten the locknut with the special notched requirements. If unpacked and not wrench. Bend two tabs of the locking web used, return them to their original into the locknut slots. Secure the nut in packings.1 position by means of setscrews. 4. Install the bomb on the aircraft and 1. Remove the shipping bands from the lock it securely in place. If the bomb bomb by removing the nuts from the se­ General Description 7-20 F R A G M E N T A T IO N B O M B A SSEM B LIES bay does not provide enough space for fuz­ ing, this operation will be performed before the bomb is hoisted into place on the rack. 5. Remove the required number of fuzes and arming-wire assemblies from their con­ tainers and inspect them carefully for serv­ iceability. 6. For detailed information on fuzing and defuzing, refer to chapter 2 under the par­ ticular fuze to be installed. 7-21 Chapter 8 FRAGMENTATION BOMB CLUSTERS AND ADAPTERS 100-LB FRAG B O M B CLU STER A N - M 1 A 2 Figure 8 -1 .— 100-lb Frag Bomb Cluster A N -M 1A 2. Model ........... .......................................................................... Assembly Drawing N o.................. ...................... ...................... Length o f Cluster ( i n . ) ........... ..............................................— Width o f Cluster (in.) .................. - .................. Height of Cluster (in.) AN-M 1A2 82-0-69 46.6 8.9 10.3 Cluster Adapter Model .......................................................... ................................ AN-M 1A3 Length (in.) ...................... ........ ............................................ 38.25 Frag Bombs Model ................... .......... ....................... ..................... Number Required ..... ................................ ............ ............ Weight o f Each Bomb (lb) ...... .................... ......... W eight of Cluster (lb) .......... ................................................ AN-M41A1 6 20.0 128.0 Nose Fuzes Model ......... .................................................... - .......................... AN-M110A1 or AN-M158 Number Required ........... ............................ 6 8-1 N A V W E P S OP 2216 (V O L U M E 1) Figure 8-2.— Cluster Adapter A N -M 1A 3. General Description The 100-lb Frag Bomb Cluster AN-M1A2, now obsolete, consists of six 20-lb A N M41A1 frag bombs assembled in an A N M1A3 cluster adapter. The AN-M1A3 is a “ quick-opening frame,” mechanical type of adapter which holds the bombs in two banks of three bombs each and releases them upon withdrawal of the arming wires. The bomb cluster is issued with individual bombs assembled but unfuzed; fuzing is per­ formed before the cluster is installed in the aircraft. The AN-M1A3 cluster adapter has four sheet metal bomb supports spaced at inter­ vals on two tubes. Three flat steel suspen­ sion lugs and two side plates are attached to the upper tube. Two spring strips are fitted to the bottom tube. Fuze vane lock springs fit into a ferrule in front of the spring strips. Three lock springs pass through the front support and three through the third support. The fuze vane lock springs prevent the rotation of the fuze 8-2 arming vanes while the bombs are in the cluster. Two metal straps hold the bombs in place against the adapter; their free ends are locked in place by a toggle strap clamp se­ cured by the arming wire. When the cluster is released armed, the arming wire is pulled out, the strap clamp opens, and the bombs are freed from the adapter. The spring strip aids in forcing the bombs away from the adapter. Flat steel lugs located on the upper tube provide for one or two point (14-inch) suspension. Painting and M arking Identifying nomenclature is stenciled in black on the face of the forward support. The high-explosive contents are identified by the yellow head and base of each of the 20-lb frag bombs. Differences Between Frag Bomb Clusters A N —M 1 A 2 and A N -M 1 A 1 The difference between frag bomb cluster F R A G M E N T A T IO N B O M B CLU STERS A N D A D A PT ER S AN-M1A2 and frag bomb cluster A N M1A1 lies in the cluster adapters. The A N M1A2 cluster is the only one of this series that is issued unfuzed. The AN-M1A1 cluster uses the M1A2 or M1A1 cluster adapter which has narrow U-type suspen­ sion lugs; with these lugs, the complete weight of the cluster is only 125 pounds. Assembly CAUTION: Boxed frag bomb clusters should be handled care­ fully. When set down, place them in a horizontal position. Do not slide, tumble, or strike the pack­ ings. 1. Unpack the cluster and its components. CAUTION: Upon opening the box, inspect the clusters to be sure that the fuze safety devices are in place. If a fuze is armed, the cluster will be destroyed by authorized and qualified personnel. Binding straps which hold the bombs in place should be tight and unbroken. Broken straps may be replaced and the cluster used. 2. Thread one branch of the arming wire through the forward suspension lug and through the holes in the front release mech­ anism. 3. Thread the other branch of the arm­ ing wire through the rear lug and release mechanism. 4. Place two safety clips at each end of the arming wire; cut off excess wire. CAUTION : Arming wire must be free from kinks, twists, and burrs. 5. Pull up the suspension lugs and fasten them with the cotter pins supplied. 6. Assemble the nose fuzes to the bombs according to the procedure outlined in chap­ ter 2. 7. Install the cluster and remove the cot­ ter pins from the release mechanism. 8. If the cluster is not dropped, replace all pins and tapes before repacking the cluster for storage. 8-3 N A V W E P S OP 2216 (V O L U M E 1) SUPPORT- STRAP CLAMP- STRAP SUSPENSION LUGS RELEASING MECHANISM ARMING WIRE ASSEMBLY COTTER PIN SIDE PLATE Figure 8-3.— 100-lb Frag Bomb Cluster A N -M 1 A 2, Perspective View. 8-4 F R A G M E N T A T IO N B O M B CLU STERS A N D A D A P T ER S 100-LB FRAG B O M B CLU STER M 2 8 A 2 Figure 8-4. — 100-lb Frag Bomb Cluster M28A2, Exterior View. Model ____________________________ ______ ____ ....._______________________ M28A2 Assembly Drawing N o .___________________ ___________.___ ___ __________ 82-0-107 Length o f Cluster (in.) ...... ................................................................................ 47.48 Diameter (in.) | ~ _________________________ _____ ___ _____ ___ ________ 8.0 Cluster Adapter Model _______ ________________________________ _______ _______ ________ M15A2 Length (in.) _____ ___ - ................................................................................. 43.67 Fin Span (in.) ..................................... ............................................... ................... 11.0 Frag Bombs Model _____ ________________ ____________ ___ _____ ______ ______ ___ _____ M83 Number Required ........... ............................................... ................................... 24 Weight of Each Bomb (lb) ____________________________ ____________ _ 3.81 Weight o f Cluster (lb) ..___ __________________ ___ ___ __ ____ ______ ______ 115.7 Fuze (Cluster-Opening) ___ _________________ .....___ ____________________ AN-M146A1 Bushing, Case Locking ..... .................................................................................... 438075 L General Description The 100-lb Frag Bomb Cluster M28A2 consists of 24 four-lb M83 frag bombs as­ sembled in an M15A2 cluster adapter. The M15A2, an aimable type adapter, is bomb­ like in appearance and has a standard type fin. It holds the frag bombs in eight banks of three each. Loading and dispersal of bombs is accom­ plished through a hinged lid on the adapter which is held in place by a nose locking cup. A spoiler ring is held in place against the 8-5 N A V W E P S OP 2216 (V O L U M E 1) nose of the adapter by the nose fuze, and a drag plate is secured to the fin assembly. Two suspension lugs, spaced 14 inches apart, protrude through slots in the lid section. If single hook suspension is desired, the two lugs are removed from the case and a single lug is attached by four screws to the upper surface of the adapter at the center of gravity. When the cluster is released armed, the arming wire is withdrawn from the time fuze, allowing the fuze to arm. When the designated time has elapsed the fuze func­ tions, blowing the nose locking bushing rear­ ward into the adapter case and permitting the cluster to open. The 24 frag bombs are dispersed by spring action when their wings open and project them into the air. Painting and M arking Identifying nomenclature is stenciled in black on the olive drab painted adapter casing. The high-explosive content is in­ dicated by yellow bands on the nose and aft section of the cluster adapter. Differences Am ong Frag Bomb Clusters M28, M 28A1, and M 28A2 The frag bomb clusters in the M28 series are similar to each other in appearance, dif­ fering only in their adapters. The M28 cluster uses cluster adapter M15; the M28A1 uses the M15A1 (with spoiler ring and drag plate) ; and the M28A2 uses cluster adapter M15A2 (which contains a Figure 8-5.— Cluster Adapter M15A2. 8-6 F R A G M E N T A T IO N B O M B CLU STERS A N D A D A PT ER S new case locking bushing in addition to the spoiler ring and drag plate). Assembly CAUTION: Do not disassemble the cluster or any of its compo­ nents. 1. Unpack the cluster and its components. As issued, the cluster contains 24 M83 frag bombs. 2. Support the cluster in a horizontal po­ sition so that the tail fin is several inches above the ground. 3. Fit the drag plate over the tail fin so that one ear rests against the outside of each fin blade. 4. If holes are not drilled in the tail fin to accommodate the drag plate, drill holes with a No. 30 drill (0.128 inch in diameter). Use the holes in the drag plate ears as guides. 5. Screw the drag plate to the fin with the self-tapping screws that are issued with the drag plate. Tighten the screws securely. 6. Unthread the bolts and remove the Lshaped protectors from the suspension lugs. For single suspension, remove the double suspension lugs from the cases and attach the single lugs to the bomb cases with the screws provided. 7. Cut the wire on the nose cup retainer; remove the wire and the retainer. CAUTION: The locking cup screws must be tight before the nose cup retainer is removed. 8. Place the spoiler ring over the fuze cavity of the cluster adapter so that the flange of the spoiler ring hole fits inside the cavity. 9. While holding the spoiler ring in the above position, screw the fuze into the fuze cavity. Tighten the fuze by hand, adjust­ ing the spoiler ring at the same tim e; in its final position, the spoiler ring must be lo­ cated so that the small hole in the ring is in line with the arming pin of the fuze. When the arming wire is installed, it must pass through the hole in the spoiler ring. 10. If the cluster is not used, restore the components to their original condition and return to their original packings. CAUTION: Protect clusters from moisture. unpacked 11. Aircraft armed with these clusters are not to be catapulted unless they have been equipped with the case locking bushing, dwg 438075. Clusters will be jettisoned before landing; they cannot be guaranteed to drop SAFE. 8-7 N A V W E P S OP 2216 (V O L U M E 1) DRAG PLATE TAIL FIN HINGE ARMING WIRE ADAPTER COVER ADAPTER FRAG BOMBS LOCKING CUP RING Figure 8—6.— 100-lb Frag Bomb Cluster M28A2, Cutaway View. F R A G M E N T A T IO N B O M B CLU STERS A N D A D A PT ER S 500-LB FRAG B O M B C LU STER M 2 6 A 2 Figure 8-7. — 500-lb Frag Bomb Cluster M26A2. Model ......... ..............................- ..... Assembly Drawing No................. Length o f Cluster (in.) Width of Cluster (in.) ................. Height o f Cluster (in.) Cluster Adapter Model ____ Length (in.) ............... ......... Frag Bombs Model _______ ________ _____ _ Number Required ______ ____ Weight o f Each Bomb (lb) Weight o f Cluster (lb) ............. Nose Fuzes Required For Each Bomb AN-M41A1 For Cluster Adapter M13A2 M26A2 82-0-111 52.56 14.7 14.1 M13A2 48.9 AN-M41A1 20 20.0 416.0 AN-M110A1 M155A1 or AN-M158 8-9 N A V W E P S OP 2216 (V O L U M E 1) Figure 8-8.— Cluster Adapter A N -M 13A 2. General Description The 500-lb Frag Bomb Cluster M26A2, now obsolete, consists of twenty 20-lb A N M41A1 frag bombs assembled in an M13A2 cluster adapter. The M13A2 is a “ quick­ opening frame” type of adapter which holds the bombs in two banks of ten bombs each. The M13A2 adapter may be set for im­ mediate or delayed action release of the bombs. A fuze is not required for immedi­ ate release since withdrawal of the arming wire opens the adapter. For delayed ac­ tion, a mechanical time fuze is inserted in the adapter. The fuze is set to function after a specified time delay following re­ lease of the cluster from the aircraft. Fuze 8-10 detonation drives a plug rearward, cutting the shear wires and opening the adapter. The M13A2 cluster adapter is a steel framework consisting of a tubular center bar, suspension lugs, separator plates, and two metal bands. Each separator plate fits in front of a bank of bombs and contains arming vane stops. Two suspension lugs spaced 14 inches apart provide for two point suspension. A lug located at the center of gravity provides for single point suspension. Painting and M arking Identifying nomenclature is stenciled in black letters on the face of the first sup­ port plate. The overall frame is olive F R A G M E N T A T IO N B O M B C LU STERS A N D A D A PT ER S Figure 8-9.— 500-lb Frag Bomb Cluster M26A2, Perspective View. 8-11 F R A G M E N T A T IO N B O M B CLU STERS A N D A D A PT ER S Figure 8-9.— 500-lb Frag Bomb Cluster M26A2, Perspective View. 8-11 N A V W E P S OP 2216 (V O L U M E 1) drab. The high-explosive contents of the 20-lb AN-M41A1 frag bombs are identified by a yellow head and base. Differences Between Frag Bomb Clusters M 2 6 A 2 and M 26A1 The M26A2 frag bomb cluster differs from the M26A1 frag bomb cluster in the adapters and bombs used, as well as in the fuzing components. The M26A1 cluster is issued with 20 fuzed AN-M41 frag bombs assem­ bled in an M13A1 cluster adapter. The M26A2 cluster is issued with 20 unfuzed AN-41A1 frag bombs assembled in an M13A2 cluster adapter. Assembly 1. Unpack the cluster and remove all pack­ ing accessories. CAUTION: Inspect the cluster for serviceability. Be sure that the cotter pins and shear wires are secure in the band clamps. Bands which hold the bombs in place should be tight and unbroken. 2. Cut and remove the wire holding the removable fuze vane locks on the long sepa­ rator assembly rods of the cluster. Retain the two cotter pins which are threaded on the wire. 3. Unpack and inspect the fuzes. For de­ tailed information on fuzing, refer to chap­ ter 2 under the particular fuze to be installed. 4. Cut, but do not remove, the fuze seal wires; hold the wires in place by twisting them. 5. Assemble the fuzes to the lower layer of the rear bank of bombs. Adjust the arming-wire guide on each fuze body so that it does not interfere with the assembly of the fuze vane lock. 6. Assemble fuzes to the middle layer of bombs; adjust the arming-wire guide of each fuze body so that it does not interfere with the assembly of the upper and lower fuze vane locks. 7. Replace the lower fuze vane lock on 8-12 the rod; insert the cotter pin and spread it at least 90 degrees. 8. Assemble the fuzes to the upper layer of bombs and replace the upper fuze vane lock; insert the cotter pin and spread it at least 90 degrees. 9. Assemble the fuzes and fuze vane locks to the front bank of bombs exactly as de­ scribed in the procedure for the rear bomb banks. 10. After the vane locks are secured, re­ move the fuze sealing wires. Preparing Bomb Cluster M 2 6 A 2 for Immediate Opening 1. Cut off the fine branch of the arming wire, which has three branches. 2. Pass one heavy branch of the arming wire through the forward suspension lug and through the outer holes in the forward band clamp. Pass the other heavy branch of the arming wire through the rear lug and rear band clamp. 3. At each band clamp, cut the shear wire between the clamp and the sleeve, and pull the wire out from the under side of the tube. 4. Remove the band clamps. 5. Install the cluster on the aircraft. Preparing Bomb Cluster M 2 6 A 2 for Delayed Opening 1. Inspect the fuze well in the center tube for serviceability; clean it if necessary. In­ spect the center tube for presence of the steel plug and its holding wire. 2. Install the bomb cluster securely to the bomb rack. 3. Inspect mechanical time fuze M155A1 for serviceability. Set the fuze for the time desired. Refer to chapter 2 for detailed in­ formation on setting this fuze. 4. Screw the fuze into the center tube until it is hand tight. 5. Pass the fine branch of the arming wire through the front suspension lug and through the holes in the mechanical time fuze arming pin bracket and vane. Cut off excess wire so that it extends 2 to 3 inches beyond the fuze. If the bomb is to be carried on external racks, or carried in­ F R A G M E N T A T IO N B O M B C LU STERS A N D A D A PT ER S ternally at speeds in excess of 300 knots, place one safety clip on the end of the wire. 6. Pass the heavy branches of the arm­ ing wire through the suspension lugs and band clamps. Do not cut the shear wire of each band clamp. Arming wires must be free from kinks, twists, and burrs. 7. Remove the cotter pins from the band clamps. Remove the sealing wire, cotter pin, and striker stop from the mechanical time fuze. Disassembly If the cluster is not used, replace the seal­ ing wire, cotter pin, and striker stop in the time fuze. Replace the cotter pins in the cluster band clamps. Remove the arming wire from the time fuze and remove the time fuze for separate storage. Remove the cluster from the bomb rack. For temporary storage (alerted ammunition) the cluster may be stored without unfuzing the indi­ vidual bombs. For other than temporary storage the individual bombs will be unfuzed as follows. 1. Replace and secure the seal wires in the fuzes in the top layer of bombs. 2. Remove the upper fuze vane lock. 3. Replace and secure the seal wires in the fuzes in the middle layer of bombs. 4. Remove the fuzes from the top layer of bombs; refer to chapter 2 for the removal of fuzes from the bombs. 5. Replace and secure the seal wires on the fuzes in the bottom layer of bombs. 6. Remove the lower fuze vane lock. 7. Remove the fuzes from the center and bottom layers of bombs. 8. Repack the fuzes in containers and seal with adhesive tape. 9. Replace the fuze well plugs and return the cluster to its original packing. NOTE: If the cluster was pre­ pared for immediate opening, new shear wires must be installed before the cluster can be used for delayed opening. 8-13 N A V W E P S OP 2216 (V O L U M E 1) 500-LB FRAG B O M B C LU STER M 27A1 Figure 8-10. — 500-lb Frag Bomb Cluster M27A1. Model ........................................... Assembly Drawing No___ ___ Length o f Cluster (in.) ....... . Width of Cluster (in.) .............. Cluster Adapter M o d e l..................................... Length (in.) ......................... Frag Bombs Model ..................................... Number Required ____ _____ Weight o f Each Bomb (lb) __ Weight o f Cluster (lb) .......... Nose Fuzes Required For Each Bomb M82 ______ For Cluster Adapter M14A1 General Description The 500-lb Frag Bomb Cluster M27A1, now obsolete, consists of six 90-lb M82 frag bombs assembled in an M14A1 cluster 8-14 M27A1 82-0-124 59.0 15.5 M14A1 55.33 M82 6 86.6 585.0 AN-M103A1 M155A1 adapter. The M14A1 is a “ quick-opening frame” type of adapter which holds the bombs in two banks of three bombs each. The M14A1 adapter may be set for im­ F R A G M E N T A T IO N B O M B CLU STERS A N D A D A PT ER S mediate or delayed action release of the bombs. A fuze is not required for immedi­ ate release since withdrawal of the arming wire opens the adapter. For delayed action, one or two mechanical time fuzes are in­ serted in the adapter. The fuzes are set to function after a specified time delay fol­ lowing release of the cluster from the air­ craft. Fuze detonation drives a plug rear­ ward, cutting the shear wires and opening the adapter. The M14A1 adapter consists of two steel tubes, to which four steel support plates are welded. These plates form the support for the six M82 frag bombs. The lower tube is the backbone of the cluster, and the upper tube carries the suspension lugs, buckles, and the fuze adapters. The M27A1 frag bomb cluster is assem­ bled in the field, and its components may be supplied unassembled or partially assembled. Two lugs, spaced 14 inches apart, provide for two point suspension. A lug located at the center of gravity provides for single sus­ pension. Painting and M arking The adapter frame is olive drab and no­ menclature is stenciled in black. The highexplosive contents are identified by yellow painted heads and bases on each bomb. Differences Between Frag Bomb Clusters M 2 7 and M27A1 The difference between the M27 and the M27A1 clusters lies in the cluster adapter. The M27 cluster uses the M14 adapter and the M27A1 cluster uses the M14A1 adapter. The M14A1 adapter is similar to the M14 adapter except that the M14 has wider fuze Figure 8-11.— Cluster Adapter M14A1. 8-15 N A V W E P S OP 2216 (V O L U M E 1) ARMING V A N E , EXTENSION ASSEMBLY- ARM ING WIRE FUZE CLAMP COTTER PLATES RELEASE FUZE Figure 8-12.— 500-lb Frag Bomb Cluster M27A1, Perspective View. 8-16 F R A G M E N T A T IO N BO M B CLUSTERS A N D A D A PT ERS vane lock plates, reinforced sway brace plates, a leaf spring for the bottom bomb, and a l'/s-inch wide release strap. Assembly 1. Remove the bomb cluster from the shipping bands. 2. Remove the nose plugs and nose pro­ tector caps. 3. Release the locknuts and remove the connectors. 4. Remove the fin locknuts from all the bombs in the cluster. 5. Inspect the fuze cavities and threads. 6. Assemble the fin assemblies to the bombs. Fins must not interfere with or damage each other when the cluster is as­ sembled in the aircraft. 7. Unpack six bomb fuzes and inspect them for serviceability. Discard the vane assembly supplied with the fuze. 8. Set each fuze for instantaneous action by pulling out the setting pin and turning it so that the locating pin seats in the shal­ low slot. 9. Screw a fuze, handtight, into the nose of each bomb. Safety cotter pins must be accessible from the outside of the cluster. 10. Cut and remove the fuze seal wire. Assemble the short (4.6-inch) vane supplied with the fin assembly. 11. Remove the safety cotter pin and turn the vane each way to insure that the adapter vane stop will prevent the fuze vane from rotating. Preparing Bomb Cluster M27A1 for Immediate Opening Prepare the bombs as in steps 1 through 11 above; then proceed as follows. 1. Thread a heavy branch of arming wire through each suspension lug and through the holes in each corresponding release mecha­ nism. Place a safety clip on each branch of wire. 2. Cut off both fine branches of arming wire at the swivel loop. 3. Cut the shear wire in each release mechanism close to the clamp. 4. Install the cluster securely in the air­ craft and sway brace. 5. Remove the safety cotter pins from both release mechanisms and from the six bomb fuzes. 6. If the bomb cluster is not used, replace all cotter pins and shear wires, or tie a con­ spicuous tag to the release mechanism to indicate that the shear wire has been cut and that the cluster is prepared for im­ mediate opening only. Preparing Bomb Cluster M 27A1 for Delayed Opening Prepare the bombs as outlined in steps 1 through 11 of the assembly instructions above; then proceed as follows. 1. Remove the plug from the nose fuze adapter in the upper steel tube. Remove the envelope containing the setscrew. In­ spect to see if the cavity is clear. 2. Unpack the mechanical time nose fuze and inspect it for serviceability. Remove and replace the striker stop to be sure that the safety block will not fall out. If the trigger mechanism is intact, there will be a noticeable gap between the striker and the safety block. 3. Set the time desired on the mechanical time fuze, referring to chapter 2 for in­ structions. 4. Screw the fuze into the fuze adapter, handtight. Insert the setscrew and locknut. Back off the fuze until the arming pin points up. Tighten the setscrew and locknut. 5. Thread a heavy branch of arming wire through each suspension lug to the front and rear release buckles. Thread each wire through the empty hole in the release mech­ anism and attach a safety clip to the end of each wire. 6. Thread a fine branch of arming wire through each suspension lug to the two me­ chanical time fuzes. If only one fuze is used, cut off the rear branch of fine wire at the swivel loop. Pass the wire through the fuze arming pin, the arming wire guide, and the vane tab of each fuze so that the wire pro­ trudes about 2.5 inches beyond the vane tab. If the cluster is to be carried externally, or if it is to be carried internally at speeds in 8-17 N A V W E P S OP 2216 (V O L U M E 1) excess of 300 knots, place a safety clip on each arming wire past the fuze vane tabs. 8. Install the cluster securely on the air­ craft and sway brace. 9. Remove the safety cotter pins from 7. Cut and remove the fuze sealing wire, the cluster release mechanisms and from the the safety cotter pin, and the striker stop. six bomb fuzes. 8-18 F R A G M E N T A T IO N BO M B CLU STERS A N D A D A PT ER S 500-LB FRAG B O M B C LU STER M29A1 Figure 8-13. — 500-lb Frag Bomb Cluster M29A1. Model .......... ............................ Assembly Drawing No. Length o f Cluster (in.) Width of Cluster (in.) Cluster Adapter Frag Bombs Model ___________ Number Required ....... . Weight o f Each Bomb (lb) Weight of Cluster (lb) ...... Nose Fuzes Required For Each Bomb M83 For Cluster Adapter M16A1 General Description The 500-lb Frag Bomb Cluster M29A1 consists of ninety 4-lb Frag Bombs M83 as­ sembled in a cluster Adapter M16A1. The M29A1 82-0-108 59.4 13.9 M16A1 M83 90 4 415.1 M129, M130, or M131 M155 M29A1 is a “ quick-opening frame” type of adapter which holds the bombs in nine banks of ten bombs each. When the cluster is released armed, the 8-19 N A V W E P S OP 2216 (V O L U M E 1) Figure 8-14. — 4-lb Frag Bomb M83 and Wafer Assembly. arming wire is withdrawn from the time fuze. When the fuze detonates it drives the nose cup rearward, opening the adapter. The frag bombs are dispersed when spring action opens their wings to release the bombs. The cluster is assembled in the field. Two lugs, spaced 14 inches apart, provide for two point suspension. A lug located at the center of gravity provides for single sus­ pension. Painting and M arking The bomb cluster case is olive drab and nomenclature is stenciled in black. The high-explosive contents are identified by two one-inch yellow painted stripes. Differences Between Frag Bomb Clusters M 29 and M29A1 The difference between the M29 and M29A1 clusters lies in the cluster adapter. The M29 cluster uses the M16 adapter and the M29A1 cluster uses the M16A1 adapter. The M29A1 adapter is similar to the M29 adapter except that the M16A1 has a newtype locking cup and a case-locking bushing. 8-20 Assembly 1. Remove Cluster Adapter M16A1 from the crate and place the adapter on horizontal supports so that the tail fin is off the ground. 2. Unscrew and remove the suspension lug guards. 3. Cut the shipping wire on the cup con­ tainer located in the adapter nose. 4. Turn the screws of the locking cup in a counterclockwise direction forcing the locking cup inward. Open the adapter cover by prying with a screwdriver along the seam, a little way from the nose. For Adapter M16, drive back the locking cup by inserting a wooden stick, or similar object, into the nose fuze well and tapping inward to dislodge the cup. 5. Thread a cord through the hole in the pull piece of the locking cup, passing the free end through the nose fuze well open­ ing. Close the lid and pull the locking cup into place. 6. Open the individually packed wafer boxes by tearing open the metal liner and removing the strapping which secures the wafers to the plywood inserts. Remove the twine that is packed with the wafers and save for later use. F R A G M E N T A T IO N B O M B CLU STERS A N D A D A PT ER S HINGE ARM ING WIRE COVER ADAPTER WAFER ASSEMBLY LOCKING CUP Figure 8—15.— 500-lb Frag Bomb Cluster M29A1, Cutaway View. 8-21 N A V W E P S OP 2216 (V O L U M E 1) 7. Lift the wafers by the cable assemblies and place four wafers in the two center bays of the bottom half of the adapter. CAUTION: Do not handle wafers by the strappings. 8. If the cluster is to be suspended from a single suspension lug, remove the metal brace, single suspension lug, and screws from the inside of the case in which the adapter cluster is packed. 9. Remove the two regular suspension lugs and fasten the metal brace in place be­ tween the partitions using screws taken from the two lugs. 10. Fasten the single suspension lug in place on the metal brace with the machine screws in the two sets of holes nearest the tail end of the adapter. There are three sets of holes on the brace; the forward set is not used. 11. Fasten the suspension lug over the center portion of the cluster adapter with the small portion of the lug forward. The two regular suspension lugs remain in place. 12. Place two wafers in the front bay and three wafers in the rear bay. 13. Tie all wafers down separately with the twine provided. Pass the twine over the bombs and around the outside of the bottom half of the adapter; tie securely. 14. Cut and remove the metal strappings from the bombs, leaving the twine to hold the bombs together. Settle the bombs into place by careful shifting of the wafers. No rigid part of a bomb must interfere with closing of the cluster lid. 15. Close the adapter by lowering the cover slowly; at the same time, adjust the cable assemblies of the bombs so that they do not rest across the partitions and do not obstruct the cover. When closing the cover, see that the rear corners of the cover are seated under the rear flange of the bottom half of the adapter, and that the reinforce­ ment strips on the edge of the cover are inside the bottom half. CAUTION: When the adapter is closed, the cover may cut some of 8-22 the twine with which the wafers are tied. Do not reopen the cover because the untied bombs will spring out. 16. When using Cluster Adapter M16, pull the locking cup into position with the cord attached to it. Use the hook and prying tool provided to wedge the cup securely in the forward position. When using Adapter M16A1, pull the locking cup into position and turn the locking screws in a clockwise di­ rection which will draw and hold the locking cup against the nose of the cluster. 17. Insert measuring gage, provided in kit, into fuze well of the adapter until it is against the bottom surface of the locking cup. The maximum distance permissible between the nose of the cluster and the bot­ tom surface of the locking cup is 1.375 inches. For Cluster Adapter M29, the mini­ mum distance is 0.8437 inch. CAUTION: If adapters do not gage properly and cannot be ad­ justed, they should not be used. 18. With the cover securely in place and held by the locking cup, cut and remove the twine with which the wafers are tied. If the twine does not pull out easily, cut the pieces on both sides of the adapter at the seam, and leave the upper portion in the adapter. 19. Remove Mechanical Time Fuze M155 from the packing and inspect the fuze for damage. For information on fuzing refer to chapter 2. 20. Install bomb securely on the aircraft. 21. Pass one branch of the arming wire through the forward suspension lug, arm­ ing bracket, and vane of the fuze. Remove the fuze cotter pin and sealing wire. The arming wire should extend 2 to 3 inches beyond the fuze vane. If the bomb is to be carried externally, or internally at speeds in excess of 300 knots, place one Fahnestock clip on the end of the wire. 22. If Bomb Cluster M29A1 is not used, remove arming wire and fuze as outlined in chapter 2. F R A G M E N T A T IO N B O M B C LU STERS A N D A D A P T ER S CAUTION: Store loaded clusters off the ground and under cover. Store for as short a period as pos­ sible, because this material is sus­ ceptible to damage by atmospheric moisture. Once loaded, the adapter shall not be reopened. Locking cups must be in the fully locked po­ sition before the time fuze is inserted. 8-23 Chapter 9 DEMOLITION BOMBS 750-LB D E M O L IT IO N B O M B M l 17 Figure 9 -1 . — 750-lb Demolition Bomb M l 17 (M echanically Fuzed), Exterior View. Model .... .............................................._ Assembly Drawing No. Electrically Fuzed __________ ___ Mechanically Fuzed __ __ _______ Length o f Assembled Bomb (in.) ..... Body Diameter (in.) ......... ............... Fin Span (in.) ______ ______________ W eight of Explosive Charge (lb) Tritonal .... ...................................... Weight o f Fin Assembly M131 (lb) W eight o f Assembled Bomb (lb) Loaded with Tritonal ____________ Nose F u z e .......... _................... .............. Tail Fuze ........................................................ Adapter-Boosters (for mechanical fuzing) M117 F8796759 F8796758 84.0 16.1 22.4 386 44 799 AN-M103A1 VT Fuze T750 VT Fuze AN-166 M990 (T905) (electric) M190 (T759) M990 (T906) (electric) T45E1 (nose) T46E4 (tail) Arming W ire Assembly 9-1 N A V W E P S OP 2216 (V O L U M E 1) Figure 9—2.— 750-lb Demolition Bomb M l 17 (Mechanically Fuzed), Exploded View. General Description The 750-lb Demolition Bomb M117, fig­ ure 9-1, has a short ogival nose, a cylindri­ cal body, and a tapered aft end. A conicaltype fin assembly is bolted to the rear of the bomb to improve its aerodynamic perform­ ance and accuracy in flight. The bomb is designed primarily for elec­ tric fuzing. Two conduits for the electric fuze cable harness connect the nose and tail fuze cavities with a charging receptacle located between the suspension lugs on the surface of the bomb case. When electrical fuzes are not used, a plug is threaded into the charging receptacle cavity. The steel nose fuze-hole plug and base fuze-hole plug are replaced in their respective cavities after electric fuzes have been installed. Pending the availability of electric fuzes, mechanical fuzes are used in the nose cavity, tail cavity, or both. Adapter-boosters must be installed in the fuze cavities to permit use of the mechanical fuzes. The bomb uses a mechanical tail fuze which projects into the airstream on the side of the bomb fin cone, rather than straight out the aft end. To accomplish this, the fuze has a flexible arming stem. To install 9-2 the fuze, an access cover is removed from the side of the fin cone and the fuze body is inserted through the opening and threaded into the fuze cavity. The arming head is se­ cured to the side of the fin cone and the arming stem then is joined to the fuze body. Two suspension lugs spaced 14 inches apart, are threaded into lug inserts on the bomb case. All seams and crevices are sealed with an inert sealing compound to prevent leakage. Approximately 50 percent of the total bomb weight is explosive charge. Painting and M arking The bomb is painted olive drab. On bombs of recent issue, the identification data is stenciled in yellow letters in at least two places adjacent to a yellow band. On bombs of older issue, the identifying nomenclature was stenciled in black on the olive drab body. For permanent identification, nomenclature is stamped into the bomb body. Use The 750-lb Demoltion Bomb M117 is de­ signed for a higher blast effect than a gen­ eral purpose bomb of comparable weight. D E M O L IT IO N BO M BS CONICAL FIN ASSEMBLY. FAHNESTOCK CLIPS LONG STEM TAIL FUZE SET SCREW SUSPENSION LUGS ARMING WIRE ASSEMBLY PLUGS BOMB BODY -NOSE FUZE -FAHNESTOCK CLIPS Figure 9-3.— 750-lb Demolition Bomb M l 17 (Mechanically Fuzed), Cutaway View. 9-3 N A V W E P S OP 2216 (V O L U M E 1) Assembly CAUTION: Fuzes and bombs are not to be unpacked in advance of requirements. Return them to their original packing if not used. Mechanical Fuzing. 1. Remove the bomb body and compo­ nents from their packing cases. Remove the shipping ring from the rear of the bomb body by unscrewing the studs. CAUTION: Inspect for damage (cracks, broken weldments, etc.) which might cause leaks in the bomb body or weaken lugs or their attachment to the bomb body. 2. Place the conical fin assembly over the end of the bomb with one of the fins in line with the suspension lugs. If suspended in external racks, turn the fin and locate it to clear the aircraft structure and the ground when installed. Secure the fin to the aft end of the bomb with setscrews lo­ cated on the edge of the cone. Assemble the two suspension lugs in their respective, threaded holes. 3. Remove the hand-hole cover on the fin cone by taking out the securing screws. 4. Remove the base fuze-hole plug threaded into the rear fuze cavity. 5. If a nose fuze is required, remove the nose fuze-hole plug. 6. Install the adapter-boosters in the nose and tail fuze cavities as required for mechanical fuzing. 7. Install the bomb on the aircraft and securely lock the bomb in place. If the bomb bay does not provide enough space for fuz­ ing, fuzing shall be done prior to hoisting the bomb into place on the rack. 8. Remove the required number of fuzes and arming wire assemblies from their con­ tainers. CAUTION: If containers are punctured, split, or if the seal is 9-4 broken in any way, the fuzes con­ tained therein shall be considered unserviceable. This does not apply to fuzes repacked in the field and resealed with adhesive tape for temporary protection. These fuzes should be examined carefully for serviceability. 9. For detailed information on fuzing and defuzing, refer to chapter 2. 10. Thread the tail fuze body into the tail fuze cavity handtight. 11. Insert the flexible arming stem with fuze head through the fuze opening in the fin cone skin. Thread the retaining collar on the flexible arming stem over the fuze neck of the fuze body, and tighten the col­ lar by hand. Secure the fuze head to the fin cone skin with the studs supplied with the fuze. 12. Install the nose fuze into the nose fuze cavity handtight. 13. Insert the arming wires through the suspension lugs to each fuze. The arming wires should protrude two inches beyond the fuze vanes. Cut off the excess wire. If the bomb is tail-fuzed only, cut off one branch of the arming wire assembly. The arming wire should be free from kinks, twists, and burrs. Electric Fuzing. 1. Perform the preceding steps 1 through 5 under Mechanical Fuzing. 2. Install the electric fuzes in the nose and tail fuze cavities. 3. Replace the nose fuze-hole plug, base fuze-hole plug, and fin access hand-hole cover. 4. Remove the charging receptacle plug from the bomb body. 5. Install the bomb on the aircraft and lock the bomb securely in place. If the bomb bay does not provide enough space for fuzing, fuzing shall be done prior to hoist­ ing the bomb into place on the rack. D E M O L IT IO N BO M BS 3000-LB D E M O L IT IO N BO M B M l 18 Figure 9-4. — 3000-lb Demolition Bomb M l 18 (Mechanically Fuzed), Exterior View. Model ............. ................................... Assembly Drawing No. Electrically Fuzed ....... .................. Mechanically F u z e d ^ ^ ..________ Length o f Assembled Bomb (in.) . Body Diameter (in.) _____ ____ ___ Fin Span (in.) ... ............................... Weight o f Explosive Charge (lb) T rito n a l............. .................. ........... . Weight o f Fin Assembly M132 (lb) W eight of Assembled Bomb (lb) Loaded with Tritonal . ___ Nose Fuze ..... ................................... . Tail Fuze ___________ _________ __________ Adapter-Boosters (for mechanical fuzing) ___ M118 ....... 82-0-197 ....... 82-0-208 ____ 130 24.13 ...... 14.1 ____1888 ___ 162 ... 3020 AN-M103A1 VT Fuze T750 VT Fuze AN-M166 ...... M192 (T761) ...... T45E1 (nose) T46E4 (tail) Arming Wire Assembly General Description The 3000-lb Demolition Bomb M118, fig­ ure 9-4, has a short ogival nose, a cylindrical body, and a tapered aft end. A conical-type fin assembly is bolted to the rear of the bomb to improve its aerodynamic performance and accuracy in flight. Two conduits for an electric fuze cable harness connect the nose and tail fuze cavi­ ties with a charging receptacle located be­ tween the suspension lugs on the surface ol the bomb case. Since electric fuzes are not used, a plug is threaded into the charging receptacle cavity. Mechanical fuzes are used in the nose cavity, tail cavity, or both. Adapter-boosters are installed in the fuze cavities to permit use of the mechanical fuzes. 9-5 N A V W E P S OP 2216 (V O L U M E 1) Figure 9-5. — 3000-lb Demolition Bomb M l 18 (Mechanically Fuzed), Exploded View. The bomb uses a mechanical tail fuze which projects into the airstream on the side of the bomb fin cone, rather than straight out the aft end. To accomplish this, the fuze has a flexible arming stem. To install the fuze, an access cover is removed from the side of the fin cone, and the fuze body is inserted through the opening and threaded into the fuze cavity. The arming head is secured to the side of the fin cone, and then the arming stem is joined to the fuze body. Two suspension lugs, spaced 30 inches apart, are bolted to the bomb body. A single hoisting lug may be attached to the bomb at the center of gravity and may be used for an alternate 14-inch suspension mount. All seams and crevices are sealed with an inert sealing compound to prevent leakage. Ap­ proximately 65 percent of the total bomb weight is explosive charge. Painting and M arking The bomb is painted olive drab. On bombs of recent issue, the identification data is stenciled in yellow letters in at least two places adjacent to a yellow band. On bombs of older issue, the identifying nomenclature was stenciled in black on the olive drab body. For permanent identification, nomen­ clature is stamped into the bomb body. 9-6 Use The 3000-lb Demolition Bomb M118 is de­ signed for a higher blast effect than a gen­ eral purpose bomb of comparable weight. Assembly CAUTION: Fuzes and bombs are not to be unpacked in advance of requirements. Return them to their original packing if not used. 1. Remove the bomb body and components from their packing cases. Remove the ship­ ping ring from the rear of the bomb body by unscrewing the studs. CAUTION: Inspect for damage (cracks, broken weldments, etc.) which might cause leaks in the bomb body or weaken lugs or their attachment to the bomb body. 2. Remove the hand-hole covers on the fin cone by unthreading the fasteners. 3. Place the conical fin assembly over the end of the bomb with one fin in line with the suspension lugs. If suspended in external racks, turn the fin and locate it to clear the aircraft structure and the ground when in­ stalled. Align holes on the facing plate of the fin assembly with the bolt holes on the base plate of the bomb. Place lockwashers D E M O L IT IO N BO M BS Figure 9-6.— 3000-lb Demolition Bomb M l 18 (Mechanically Fuzed), Cutaway View. 9-7 N A V W E P S OP 2216 (V O L U M E 1) on the bolts, and screw the bolts into the bomb body from inside the fin cone. Tighten the bolts securely. Assemble the two sus­ pension lugs to the bomb body by assembling with four cap screws. 4. Remove the base fuze-hole p l u g threaded into the rear fuze cavity. 5. If the nose fuze is required, remove the nose fuze-hole plug. 6. Install the adapter-boosters in the nose and tail fuze cavities as required for me­ chanical fuzing. 7. Install the bomb on the aircraft and securely lock the bomb in place. If the bomb bay does not provide enough space for fuz­ ing, fuzing shall be done prior to hoisting the bomb into place on the rack. 8. Remove the required number of fuzes and arming wire assemblies from their con­ tainers. CAUTION: If containers are punc­ tured, split, or if the seal is broken in any way, the fuzes contained therein shall be considered unserv­ iceable. This does not apply to 9-8 fuzes repacked in the field and re­ sealed with adhesive tape for tem­ porary protection. These fuzes should be examined carefully for serviceability. 9. For detailed information on fuzing and defuzing, refer to chapter 2. 10. Thread the tail fuze body into the tail fuze cavity handtight. 11. Insert the flexible arming stem with fuze head through the fuze opening in the fin cone skin. Thread the retaining collar on the flexible arming stem over the fuze neck of the fuze body, and tighten the collar by hand. Secure the fuze head to the fin cone skin with the studs supplied with the fuze. 12. Install the nose fuze into the nose fuze cavity handtight. 13. Insert the arming wires through the suspension lugs to each fuze. The arming wires should protrude two inches beyond the fuze vanes. Cut off the excess wire. If the bomb is tail-fuzed only, cut off one branch of the arming wire assembly. The arming wire should be free from kinks, twists, and burrs. Chapter 10 CHEMICAL (GAS), SMOKE# AND INCENDIARY BOMB ASSEMBLIES 115-LB C H E M IC A L (GAS) B O M B M 70A1 Figure 10-1.— 115-lb Chemical (Gas) Bomb M70A1, Exferior View. Model ..................................... ............ Assembly Drawing No........ ..... ...... Fin Assembly (M odel) ____ _____ Length o f Assembled Bomb (in.) Body Diameter (in.) ............... ...... Fin Span (in.) _________ _________ Weight o f Empty Bomb (lb) Filling _______ ___ _________ ______ Filling Weight (lb) ............. .......... Weight o f Fin Assembly (lb) ___ Weight o f Assembled Bomb (lb) Arming-W ire Assembly ........ ...... Burster .............. ............................ Nose Fuze .......................................... ... M70A1 ... 82-0-83 D14-5-1187 AN-M103A1 ._ 51.5 ... 8.0 ... 11.0 ... 55.0 ... Distilled Mustard (H D ). ._ 60.6 ... 5.6 ... 128.1 ... Mk 1 or AN-M 6A2 ... M10 ... AN-M158 10-1 N A V W E P S OP 2216 (V O L U M E 1) Figure 10—2 .— 115-lb Chemical (Gas) Bomb M70A1, Exploded View. General Description The 115-lb Chemical Bomb M70A1 is made from a seamless steel tubing; it has an ogival nose and a conical rear section. A burster-well tube runs the entire length of the body and fits into a positioning cup at the rear. The forward end of the burster well is threaded to receive a nose fuze. Two suspension lugs, 14 inches apart, are welded to the bomb body. A single lug is attached to the underside at the approximate center of gravity. A standard box-type fin as­ sembly is secured to the bomb by a fin lock­ nut. Functioning Detonation of the fuze on impact sets off 10-2 the burster, exploding the bomb and dis­ persing its agent. Painting and M arking The bomb body is painted gray. Green bands painted around the periphery of the bomb identify the filling. Weight, type, filling, model, and lot number are stenciled in green on the bomb body. Packaging The bomb is protected during shipping and stowage either by lug protectors or by shipping bands. Shipping weight is ap­ proximately 135 pounds. The explosive components, the arming wire, and the fin assembly are packed separately. C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSEM B LIES ARMING-WIRE ASSEMBLY BOMB BODY BURSTER WELL BURSTER FILLER CAVITY NOSE FUZE Figure 10-3.— 115-lb Chemical (Gas) Bomb M70A1, Cutaway View. 10-3 N A V W E P S OP 2216 (V O L U M E 1) 500-LB C H E M IC A L (GAS) B O M B A N - M 7 8 Figure 10—4.— 500-lb Chemical (Gas) Bomb A N -M 78, Exterior View. Model .......... ...................................... Assembly Drawing No. ........ ........ Fin Assembly (model) ____ ______ Length of Assembled Bomb (in.) Body Diameter (in.) __________ Fin Span (in.) .............. ................Weight o f Empty Bomb (lb) ____ F illin g ..... ....................... .............. .... Filling Weight CG (lb) ............................... CK (lb) ....................... ........ Weight of Fin Assembly (lb) Weight of Assembled Bomb Filled with CG (lb) __ ___ Filled with CK (lb) ............ 10-4 AN-M 78 82-0-115 AN-M109A1 59.25 14.18 18.94 260.0 Phosgene (CG) or Cyanogen Chloride (CK) 205.0 176.0 18.6 495.0 466.0 C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y BO M B A SSE M B L IE S Mk 1, AN-M 6A2, or M13 i M115 or M115A1 AN-M15 M163, M164, M165, AN-M103A1, AN-139A1, AN-M140A1, AN-M 166 (V T) ... AN-M101A2 Arming-W ire A sse m b ly ...................... Adapter-Booster (Holder Assembly) Burster .................................................... Nose Fuze ......... .................................... Tail Fuze Special Information Conical Fin Assembly M128A1 can also be used; secure it with fin locknut, BuOrd Sketch 329153, and fin locking web, drawing 1350522. If used, the adapter-booster holder should be staked prior to assembly and, in this case, Tail Fuze M172 is required. Adapter-Booster Ml 17 may be used in con­ junction with AN-M145A1 and AN-M146A1 type mechanical time fuzes for aerial burst when the bomb is filled with persistent gas. General Description The 500-lb Chemical Bomb AN-M78 re­ sembles the 500-lb GP Bomb AN-M64A1 in construction. The body is of one-piece cast steel construction with a burster well run­ ning the entire length of the bomb. The ARM ING WIRE ASSEMBLY burster-well assembly is threaded at its for­ ward end to receive a nose fuze and at its rear to receive Adapter-Booster M115A1. The rear section of the bomb tapers down to approximately an 8-inch diameter where a base plate is welded, closing the body. The base plug consists of a special forging welded to the case, containing Needle Valve Ml. Two suspension lugs, 14 inches apart, are welded to the bomb body. A single lug is attached to the underside at the approximate center of gravity. A standard box-type fin assembly or a conical fin assembly can be used with the bomb. Nondelay impact fuzes are preferred when the bomb is filled with a nonpersistent gas. Functioning Detonation of the fuze sets off the burster, FAHNESTOCK CLIPS,. LONG STEM TAIL FUZE FAHNESTOCK CLIPS FIN LOCKING NUT FIN ASSEMBLY BODY Figure 10-5.— 500-lb Chemical (Gas) Bomb A N -M 78, Exploded View. 10-5 N A V W E P S OP 2216 (V O L U M E 1) exploding the bomb and dispersing its agent. The nose fuze normally detonates the burster but, in the event of malfunction, the tail fuze sets off the burster through the adapterbooster charge. Painting and M arking The bomb body is painted gray. Three green bands— one near the nose, one near the middle, and one near the tail— identify 10-6 the filling. Weight, type, filling, model, and lot number are stenciled in green on the bomb body. Packaging Shipping bands protect the bomb during shipping and storage. Shipping weight is ap­ proximately 472 pounds when CG-filled. The explosive components, arming wire, and fin assembly are packed separately. C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSE M B L IE S FIN ASSEMBLY ADAPTER-BOOSTER TAIL FUZE ARMING-WIRE ASSEMBLY BOMB BODY BURSTER WELL FILLER CAVITY BURSTER -FU ZE SEAT LINER -NOSE FUZE “ SAFETY CLIPS Figure 10-6.— 500-lb Chemical (Gas) Bomb A N -M 7 8 , Cross Section. 10-7 N A V W E P S OP 2216 (V O L U M E 1) 1000-LB C H E M IC A L (GAS) B O M B A N -7 9 Model _______________ __________ Assembly Drawing N o ._________ Fin Assembly (Model) ................ Length o f Assembled Bomb (in.) Body Diameter (in.) ... ................ Fin Span (in.) .............................. Weight of Empty Bomb (lb) .... Filling ............................................. Filling Weight CG (lb) .......................................... CK (lb) .............. 1 . ____ __________ AC (lb) ____________________ _____ W eight o f Fin Assembly (lb) ........... Weight of Assembled Bomb Filled with CG (lb) ........ ................. Filled with CK (lb) ...................... Filled with AC (lb) _____ _________ Arming Wire Assembly ____________ Adapter-Booster (Holder Assembly) Burster .......... ........................ ................ Nose Fuze _________________________ Tail Fuze Special Information Conical Fin Assembly M129 also can be used; secure it with fin locknut (sk 329153) and fin locking web (dwg 1350522). Tail Fuze AN-M184 is required for use with M129 fins. Adapter-Booster Ml 17 may be used in conjunction with AN-M145A1 and A N M146A1 type mechanical time fuzes for aerial burst when the bomb is filled with persistent gas. General Description The 100-lb Chemical Bomb AN-M79 re­ sembles the 1000-lb GP Bomb AN-M65A1, utilizing the same fin assemblies, arming wires, and fuzes. The body is of one-piece cast-steel construction and has a burster well running the entire length of the bomb body. The burster well is expanded both in the nose and in the base plate before welding in order to eliminate possibilities of decomposi­ tion of the chemical agent due to the pres­ 10-8 ... ... ... ... ... ... ... AN-M 79 82-0-98 AN-M113A1 69.5 18.8 25.4 485.0 Phosgene (C G ), Cyanogen Chloride (C K ), or Hydrocyanic Acid (A C) ... ... ... ... 415.0 351.0 195.0 21.5 ... ... ... ... ... ... ... 937.0 873.0 717.0 Mk 1, AN-M 6A2, or M13 M115A1 AN-M 16 M163, M164, M165, AN-M 103A1, AN-M 139A1, AN-M 140A1, AN-M 168 (V T ) ... M162, AN-M 102A2 ence of crevices. The base plate differs from that of the standard GP bomb in that it is a special forging welded to the case, having a filling hole, a hole for a venting and sam­ pling Needle Valve M l, and a threaded cen­ ter hole for an adapter-booster. The filling hole is closed by a soft iron gasket, a hard steel gasket plug, and a threaded closing plug. Horizontal suspension is accomplished by two lugs, 14 inches apart or a single lug 180 degrees removed from these two at the center of gravity; all are welded to the bomb body. Nondelay impact fuzes are preferred when the bomb is filled with a nonpersistent gas. Functioning Detonation of the fuze sets off the burster, which breaks the bomb case into a few large pieces and releases the gas. The initial cloud formed by the burst of the bomb, when filled with CG, covers an area of 100 yards in diameter within approximately 8 to 10 C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSE M B L IE S seconds. The nose fuze normally detonates the burster but, in the event of malfunction, the tail fuze sets it off through the adapterbooster charge. Painting and M arking The bomb body is painted gray. Green bands painted around the nose, the middle, and the tail identify the filling. Weight, type, filling, model, and lot number are sten­ ciled in green on the bomb body. Packaging Shipping bands protect the bomb during shipping and storage. Shipping weight is approximately 930 pounds when CG-filled, 866 pounds when CK-filled, and 710 pounds when AC-filled. The explosive components, arming wire, and fin assembly are packed separately. Figure 10-7.— 1000-lb Chemical (Gas) Bomb A N -M 7 9 , Exterior View. 10-9 N A V W E P S OP 2216 (V O L U M E 1) Figure 10-8. — 1000-lb Chemical (Gas) Bomb A N -M 7 9 , Exploded View. 10-10 C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSEM B L IES Figure 10-9.— 1000-lb Chemical (Gas) Bomb A N -M 7 9 , Cross Section. 10-11 N A V W E P S OP 2216 (V O L U M E 1) 100-LB SMOKE BOMB A N -M 47A 4 and 100-LB INCENDIARY BOMB A N -M 47A4 51"7 Figure 10—10 . — 100-lb Smoke or Incendiary Bomb A N -M 4 7 A 4 , Exterior View. S moke AN-M 47A4 ._ Model _ 82-0-80 _____ Assembly Drawing No Length of Assembled Bomb (in.)__ 5 1 .7_ _______ 8.1_____________________ Body Diameter (in.) Fin Span (in.)_____________ ______ 11.0____________________ Weight of Empty Bomb (lb ). ___ 2 6 .0 _________ _________ Weight of Filler: PT1, IM , or NP (lb)_________ WP (lb)________ _____________ 100.0. PWP (lb)_____ ________ _. 74.0. Weight of Assembled Bomb (lb)___ 105.1 or 130.6_______ . . . Mk 3_________________ Arming-Wire Assembly____ _______ Igniter__________ - ............. ..... None________ Burster________________ Nose Fuze ________ A N -M 18 or A N -M -2 0 . AN-M 159 General Description The 100-lb smoke and the 100-lb incen­ diary bombs are similar in outward ap­ 10-12 I n c e n d ia r y AN-M 47A4. C14-5-651. 51.7. 8.1. 11.0. 26.0. 42.0. 70.0. M2. A N -M 9 (used with Burster A N -M 13). AN -M 12 or AN-M 13. AN-M 159. pearance and in many details, the chief differences consisting of their chemical fill­ ings, their functioning, and their use. C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSEM B LIES ARMING WIRE ASSEMBLY BOMB BODY FAHNESTOCK CLIP BANDS BURSTER SCREW BURSTER WELL ASSEMBLY NOSE FUZE LOCK WASHER Figure 1 0 -1 1 . — 100-lb Smoke or Incendiary Bomb A N -M 4 7 A 4 , Exploded View. The 100-lb Smoke Bomb AN-M47A4 has a cylindrical body, a rounded nose, and a tapered aft section to which a box-type fin assembly is welded. The bomb is con­ structed of thin sheet steel and is threaded at the nose to receive an axial burster well which extends to the aft end of the bomb body. Two suspension bands of sheet steel, each equipped with a heavy-gage suspension lug, circumscribe the bomb body. For single suspension, one band is removed; the other band is loosened, slid to the approximate center of gravity, and then retightened. The AN-M47A4 smoke bomb is filled with PWP (plasticized white phosphorous) or WP. PWP is more effective than WP be­ cause of its longer burning, reduced pillar­ ing, and antipersonnel effect. Either the AN-M20 or the AN-M18 burster is used with this bomb. The burster is secured in place by an impact type nose fuze which is threaded into the foward end of the burster well. The AN-M18 burster is used when the bomb is to be dropped from low altitudes. Use Smoke bombs are used to conceal all types of troop and ship movements and installa­ tions in both the combat zone and rear areas. Functioning Upon impact of the bomb, functioning of the fuze detonates the burster. The burster shatters the bomb and disperses the agent over a circular area of 30 to 50 yards in radius. Atmospheric oxygen ignites and causes the agent to burn and produce smoke; an effective white smoke screen may be produced with a duration up to 5 minutes. Painting and Marking The base color of the bomb is blue-gray. A yellow band one inch in width, denoting the smoke filling, is painted around the midsection of the bomb. Identifying nomen­ clature is stenciled in yellow letters forward of the rear metal suspension band. Packaging Each bomb is shipped in a wooden box; the shipping box is marked with the same 10-13 N A V W E P S OP 2216 (V O L U M E 1) BOMB BODY ARMING WIRE ASSEMBLY BURSTER FILLER CAVITY BURSTER WELL 'NOSE FUZE Figure 10-12.— 100-lb Smoke or Incendiary Bomb A N -M 47A 4, Cutaway View. 10-14 C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSEM B LIES information that appears on the bomb body. The markings are applied to the shipping box to identify the material and to comply with Interstate Commerce Commission Regu­ lations. If smoke bomb shipping containers are repainted, they should be marked with a facsimile of the original markings. The burster, fuze, and arming wire are assembled to the bomb in the field to form a complete round. Differences Among Mods The AN-M47A3 has lighter-gage suspen­ sion lugs; otherwise, it is identical to the AN-M47A4 bomb. The only difference between the A N M47A2 the AN-M47A3 is in the length of the tail fins. The tail fins of the AN-M47A3 are 3 inches longer for increased flight stability. Assembly CAUTION: Bombs, fuzes, and bursters are not to be removed from stowage or packings in ad­ vance of requirements. If un­ packed and not used, return them to their original condition. 1. Inspect the suspension lugs and fin assembly for alinement, straightness, and security of attachment to the bomb body. For single suspension, remove one suspen­ sion band; loosen the other, slide it up to the approximate center of gravity, and re­ tighten it. 2. Remove the shipping plug and cork stopper from the nose of the bomb. Inspect the burster well. Threads must be clean and all surfaces must be free from foreign matter. 3. Install the bomb on the aircraft and lock it securely in place. 4. Remove the required number of fuzes, bursters, and arming wires from their con­ tainers; examine them carefully for service­ ability. Refer to chapters 2 and 3 for de­ tailed information on the particular fuze and burster to be used. 5. Seat the burster in the burster well, hand tight; do not use force. 6. Thread the fuze into the fuze adapter hand tight, until it seals firmly. Use no tools. 7. Thread the arming wire through the front suspension lug, then through the arm­ ing-wire guide and the tab on the fuze. Adjust the wire to protrude 4 inches beyond the fuze vane. Cut off excess wire. Arm­ ing wire must be free from kinks, burrs, and corrosion. 8. Slip two safety clips over the arming wire and push them up to the tab on the fuze vane. 9. Remove the sealing wire from the fuze and the adhesive tape from the fuze collar, if present. Safety Precautions Handling. As WP munitions ignite spon­ taneously upon contact with the air, they should not be handled roughly. If a fire does occur, personnel should wear gloves and keep both gloves and shoes wet. WP smoke is toxic on prolonged and repeated inhalation, but is not likely to be harmful in the con­ centrations found in smoke screens in the open air. Gas masks afford complete pro­ tection from concentrated WP smoke, but they tend to become clogged and therefore should not be worn except where serious ex­ posure in enclosed spaces is involved. Stowage. Any bomb leakage or malfunc­ tioning in stowage would result in the gen­ eration of quantities of acrid smoke and fires which are difficult to extinguish perma­ nently while aboard ship. Bomb stowage afloat shall be in accordance with OP 4, Ammunition Afloat. Ashore, the bombs should be stowed in fireproof magazines away from all other types of munitions. No WP munitions should be stowed where tem­ peratures exceed 100° F. Decontamination. White phosphorus fires are easily extinguished permanently with a 5 percent copper-sulphate solution. If this solution is not available, water or wet sand may be used to extinguish the fire tempo­ rarily. Fires thus extinguished, however, will re-ignite when the phosphorus has dried out; therefore, they must be kept wet until 10-15 N A V W E P S OP 2216 (V O L U M E 1) all the white phosphorus has been removed. WP in contact with the skin will cause severe and lingering burns. Places of con­ tact should be washed immediately and kept wet until the phosphorus has been removed. Washing the affected area with a soda solu­ tion, followed by a 5 percent copper sulphate solution, is very effective. Greasy ointments should never be used since they merely spread the contamination. 100-LB INCENDIARY BOMB AN -M 47A 4 General Description The 100-lb Incendiary Bomb AN-M47A4 uses the same body as the 100-lb Smoke Bomb AN-M47A4. Whereas the smoke bomb is used as an obscurant, the incendiary bomb is designed for use against combustible land targets where large and numerous fires will cause serious damage, and for use over water to ignite oil slicks. The types of land targets against which the incendiary bomb is effective include warehouses, factories, docks, storage dumps, barracks, and resi­ dential and industrial structures. When ships in a harbor or oil storage tanks near a harbor are damaged, oil slicks are formed which are frequently of sufficient thickness to be ignited by incendiary bombs and to burn intensely. Three types of incendiary fillings are used in the incendiary bomb: PT1, IM, and NP. PT1 is a complex mixture based on “ goop,” which is comprised of magnesium dust, mag­ nesium oxide, and carbon, with a sufficient amount of petroleum distillate and asphalt to form a paste. IM (Oil, Incendiary, Iso­ butyl Methacrylate, Type I) is a mixture of 88.75 percent gasoline, 5 percent isobutyl methacrylate, 3 percent stearic acid, 2 per­ cent calcium oxide, and 1.25 percent water. NP (Oil, Incendiary, Napalm Type I) is a mixture of 88.5 percent gasoline and 11.5 percent Napalm thickener. The AN-M47A4 incendiary bomb uses Igniter AN-M 9 (white phosphorus or so­ dium filled) with Burster AN-M13 (TNT and tetryl filled). Burster AN-M12 (black powder and magnesium) may be used in lieu of the AN-M 9 igniter and an AN-M13 burster when the bomb is to be dropped on land targets. When the AN-M 9 igniter and 10-16 AN-M13 burster combination is used, a small coil spring is placed in the bottom of the inner tube of the igniter before the burster is installed to insure firm contact between the burster and the fuze. No spring is used when the AN-M12 burster is in­ stalled. Bursters and igniters are secured in the burster well by an impact type nose fuze which is threaded into the nose of the burster well. With the burster well installed, the empty bomb weighs approximately 26 pounds. When filled and assembled with the fuze, burster, and igniter, the bomb weighs ap­ proximately 70 pounds. Functioning When the incendiary bomb, equipped with a sodium igniter, impacts on the target, it bursts and scatters burning gobs of incen­ diary gel containing particles of sodium. These gobs of gel will float and the sodium will ignite spontaneously upon contact with water, thereby insuring the ignition o f flam­ mable oil slicks. If the incendiary bomb penetrates the surface of a wooden dock or pier and bursts below the dock, the incen­ diary gel will continue to burn in spite of the water present. If a white phosphorusfilled igniter is used, the scattering and igni­ tion of the gel takes place, but ignition of the gel on water is not assured. Burning gobs of incendiary gel will produce a tem­ perature of 50 to 675° C at a height of 3 inches above the flame over a maximum period of approximately 8 minutes. Painting and Marking The base color of the bomb is blue-gray. A purple band one inch in width, denoting C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSE M B L IE S the incendiary filling, is painted around the midsection of the bomb. Identifying nomen­ clature, filling, lot number, date of loading, and identification mark of the loading fa­ cility are stenciled in purple letters on the bomb body. Packaging Each bomb is shipped in a wooden box; the shipping box is marked with the same information that appears on the bomb body. The markings are applied to the shipping box to identify the material and to comply with Interstate Commerce Commission Regulations. If smoke bomb shipping con­ tainers are repainted, they should be marked with a facsimile of the original markings. Bursters, igniters, fuzes, and arming wires are assembled to the bomb in the field to form a complete round. Assembly CAUTION: Bombs, fuzes, ig­ niters, and bursters are not to be removed from stowage or packing in advance of requirements. If removed and not used, return them to their original condition.1 1. Inspect the suspension lugs and fin as­ sembly for alinement, straightness, and se­ curity of attachment to the bomb body. For single suspension, remove one suspension band; loosen the other, slide it up to the approximate center of gravity, and re­ tighten. 2. Remove the shipping plug and cork stopper from the nose of the bomb. Inspect the burster well. Threads must be clean and all surfaces must be free from foreign matter. 3. Install the bomb on the aircraft and lock it securely in place. 4. Remove the required number of fuzes, bursters, igniters, and arming wires from their containers; examine them carefully for serviceability. Refer to chapters 2 and 3 for detailed information on each item to be used. 5. Insert Igniter AN-M 9 all the way into the burster well in the bomb until the flange on the igniter seats against the shoulder in the fuze adapter. Do not use force. 6. Screw the retainer ring into the fuze adapter to insure a tight fit of the igniter. 7. Place the small spring at the bottom of the inside of the igniter tube. 8. Insert the explosive burster AN-M13 into the igniter tube. 9. Thread the fuze into the fuze adapter, hand tight, until it seats; use no tools. 10. Thread the arming wire through the front suspension lug, then through the arm­ ing-wire guide and tab on the fuze. Ad­ just the wire so that it protrudes 4 inches beyond the fuze vane. Cut off excess wire. The arming wire must be free from kinks and burrs. 11. Slip two safety clips over the arming wire and push them up to the tab on the fuze vane. 12. Remove sealing wire from the fuze and adhesive tape from the fuze collar, if present. Safety Precautions Handling. Incendiary bombs and compo­ nents have satisfactorily withstood tests simulating the normal handling expected to be received during loading, shipment, un­ loading, and stowage. However, they can easily be damaged by unnecessarily rough treatment and should be handled with care at all times. Sodium-loaded igniters should be handled very carefully to prevent leakage of the sodium, which ignites spontaneously and with great violence when it comes into contact with moisture. WP-loaded igniters should be handled very carefully to prevent leakage of the white phosphorus, which ig­ nites spontaneously when it comes into con­ tact with the atmosphere. Stowage. Incendiary bombs, unfuzed and without burster or igniter, should be stowed in a magazine containing incendiary bombs only. Sodium igniters should be stowed only with other sodium-filled items. White phos­ phorus igniters should be stowed only with other white phosphorus loaded items. This is necessary because of the different fire­ 10-17 N A V W E P S OP 2216 (V O L U M E 1) fighting techniques employed in combating sodium and white phosphorus fires. Fire. If fire occurs in a magazine con­ taining incendiary bombs, it should be fought with the same equipment and in the same manner as a gasoline fire. Fire in a maga­ zine containing WP loaded igniters should be fought with water or wet sand. Care must be taken that white phosphorus fires extinguished with water do not re-ignite when the firefighting water has drained away or evaporated from the exposed white phosphorus. If air is excluded from WP, it will not burn. WP may be extinguished permanently with a 5 percent solution of copper sulphate in water, provided the white phosphorus layer is not too thick, in which case repeated application of the copper sul­ phate solution may be necessary. 10-18 Water must never be used on burning sodium or on burning buildings or equipment in which sodium is stored or used. Dry soda-ash, dry graphite, or dry sand will quickly smother sodium fires. Chemical so­ lution type,, vaporizing liquid type, or car­ bon-dioxide extinguishers are not effective, and their use will add to the hazard instead of reducing it. The chemical solution type of extinguisher (soda acid) contains water, while the vaporizing liquid type (carbontetrachloride) and carbon dioxide both react violently with sodium. The fumes of burn­ ing sodium are essentially caustic and there­ fore irritating. An approved type of respirator should always be available, and personnel should always put on the respira­ tor before attempting to fight a sodium fire. C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y BO M B A SSEM B LIES 500-LB INCENDIARY BOMB A N -M 7 6 W ITH FIN ASSEMBLY AN-M109A1 (BOX-TYPE) W ith F in A ssem bly AN-M109A1 (B o x - t y p e ) M odel________ ______ __________ Assembly Drawing N o_________ Length of Assembled Bomb (in.) Body Diameter (in.)___________ Fin Span (in.)_________________ Weight of Filler (lb)___________ Weight of Fin Assembly (lb)___ Weight of Assembled Bomb (lb). Fin Locknut___________________ Fin Locking Web_______ ______ Arming-Wire Assembly________ Igniter____ _____ ______________ Burster_______________ ______ Nose Fuze.............. ...................... Tail Fuze______________________ General Description The 500-lb Incendiary Bomb AN-M76, now obsolescent, resembles the 500-lb A N M64A1 GP bomb and uses the same fin as­ sembly. It has a cylindrical metal casing, an ogival nose, and a tapered aft end to which a box-type fin assembly is secured by a fin locknut. The rear section of the bomb tapers down to about 8 inches; a base plate is welded on at this point. The base plate has two filling holes and a threaded center hole to receive an adapter-booster holder assembly consist­ ing of the M115A1 adapter-booster, an adapter-booster holder, and a fuze closing plug. An impact-type tail fuze having a non-delay primer-detonator (M14) is threaded into the adapter-booster. A burster-well, attached to the base plate, ex­ tends throughout the axial length of the bomb body. The burster well is secured to the nose of the bomb and is threaded at its forward end to receive a nose fuze. Suspension lugs, 14 inches apart, are welded to the bomb body; a single lug is at­ AN-M 76. 82-0-100. 59.2. 14.18. 18.94. 174.0. 18.6. 468.8. M2 or Mk 3 Mod 0. Not Used. Mk 1 or AN-M 6A2. A N -M 5. AN-M 14. AN-M 103A1, AN-M 139A1, or AN-M140A1. AN-M101A2. tached 180 degrees from the other lugs at the center of gravity of the bomb. The bomb is filled with approximately 174 pounds of Incendiary Mixture PT1, consist­ ing essentially of gasoline, magnesium, and carbon, with a sufficient amount of petro­ leum distillate and asphalt to form a paste. The AN-M5 (white phosphorus) igniter and AN-M14 (tetrytol) burster are used with this bomb. Functioning Impact of the bomb causes both the nose and tail fuzes to function, the nose fuze act­ ing faster. The nose fuze normally deto­ nates the burster; if the nose fuze should fail, however, the tail fuze sets off the burster through the adapter-booster charge. The burster shatters the igniter and the bomb body, causing the white phosphorus in the igniter to burn on contact with the air and to ignite the incendiary filling. The bomb has a dispersal area of 300 by 600 feet. 10-19 N A V W E P S OP 2216 (V O L U M E 1) Figure 10-13. — 500-lb Incendiary Bomb A N - M 7 6 with Fin Assembly A N - M 1 0 9 A 1 , Exterior View. Painting and Marking The base color of the bomb is gray. Pur­ ple identification bands are painted around the nose, middle, and tail sections. Weight, type, filling, model number, and lot number are stenciled in purple on the bomb body. Packaging During shipment and stowage, the bomb is protected by shipping bands. The explo­ sive components, fin assembly, and arming wires are assembled to the bomb in the field to form a complete round. Assembly CAUTION: 10-20 Bombs, fuzes, bursters, and igniters are not to be removed from stowage or pack­ ing in advance of requirements. If removed and not used, return them to their original condition. 1. Remove the shipping bands from the bomb by removing the nuts from the secur­ ing bolts. Inspect for damage, cracks, and broken weldments which might weaken the lugs or their attachment to the bomb body. 2. Remove the nose plug and shipping plate which is attached to the base plate by four screws. Inspect and clean all threads, cavities, and mating parts. Make sure that the fuze seat liner is properly installed in the nose of the bomb. C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSE M B L IE S FAHNESTOCK CUF>S LONG STEM TAIL FUZE ARMING WIRE ASSEMBLY FAHNESTOCK CLIPS FIN LOCKING NUT BOX FIN ASSEMBLY BOMB BODY Figure 10-14. — 500-lb Incendiary Bomb A N - M 7 6 with Fin Assembly A N - M 1 0 9 A 1 , Exploded View. 3. Remove the required number of fuzes, bursters, igniters, arming wires, and adapter-booster holder assemblies from their containers. Examine them carefully for serviceability. Refer to chapters 2 and 3 for detailed information on the explosive com­ ponents to be installed. 4. Insert the igniter, with its two pipe plugs facing aft, in the burster well from the rear of the bomb. Insert the burster in the igniter cavity. 5. Install the adapter-booster holder as­ sembly in the base plate and remove the fin locknut. 6. Remove the fin assembly from the shipping crate. Place the fin assembly over the rear of the bomb with fins positioned 45 degrees from the suspension lugs. Thread the fin locknut on the external threads of the adapter-booster holder and tighten it with a wrench. Fin Locknut M2 or Mk 3 Mod 0 is always used in place of the regular fin locknut. Fin locknut screws should be tightened securely to prevent rotation of the fin assembly. CAUTION: Do not use a fin as­ sembly if it cannot be properly secured to the bomb. If the fin assembly is loose and turns on the bomb, it will pull the arming wire from the tail fuze, causing it to arm prematurely. 7. Install the bomb on the aircraft and lock it securely in place. 8. Remove the plug from the adapterbooster and install the tail fuze. After making sure that the nose fuze seat liner is properly seated, install the nose fuze. Do not use tools in the fuzing process; fuzes are to be seated hand tight. 9. Install the arming wire so that 4 inches of wire protrude beyond the nose and tail fuze vanes. Clip off excess wire. Place two safety clips on both ends of the wire and slide them up close to the fuze vanes. Arm­ ing wires must be free from kinks, twists, and burrs. Safety Precautions The pipe plugs in the igniter and filling plugs in the bomb body should not be re­ moved under any circumstances. Bombs and components must be handled as little as possible. Do not drop them or subject them to bumps, shocks, or blows. Protect them from rain, spray, and the di­ rect rays of the sun. Stored bombs should be inspected frequently so that leakers may be detected and properly processed. 10-21 N A V W E P S OP 2216 (V O L U M E 1) ADAPTER-BOOSTER HOLDER ASSEMBLY ARMING-WIRE TAIL FU2E BOMB BODY FILLER CAVITY IGNITER FUZE Figure 10—15.— 500-lb Incendiary Bomb A N M 7 6 wifh Fin Assembly A N - M 1 0 9 A 1 , Cross Section. 10-22 C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSE M B L IE S 500-LB INCENDIARY BOMB A N -M 7 6 W ITH FIN ASSEMBLY M128A1 (CONICAL) LONG STEM TAIL FUZEv FIN LOCKING NUT, FAHNESTOCK CLIPS ARMING WIRE ASSEMBLY > SET SCREW FIN LOCKING WEE CONICAL FIN 'CENTER SUPPORT TUBE BOMB BODY NOSE FUZE BURSTER Figure 10-16.— Incendiary Bomb A N - M 7 6 with Fin Assembly M 128A 1, Exploded View. ing bolts. Inspect for damage, cracks, and broken weldments which might weaken the Equipped with Fin Assembly M128A1, the lugs or their attachment to the bomb body. 500-lb Incendiary Bomb AN-M76, now ob­ 2. Remove the nose plug and shipping solescent, uses the standard AN-M76 bomb plate which is attached to the base plate by body. The elongated cone of the assembled four screws. Inspect and clean all threads, fin lengthens and streamlines the bomb, in­ cavities, and mating parts. Make sure that creasing its aerodynamic performance and the fuze seat liner is properly installed in accuracy. The M128A1 conical fin assembly the nose of the bomb. consists of an elongated cone with four inte­ 3. Remove the required number of burst­ gral fins spaced at equal distances on the ers, igniters, and adapter-booster holder as­ cone. A support tube runs through the cen­ semblies from their containers. Examine ter of the cone; the fin assembly is secured them carefully for serviceability. to the bomb body by means of the support tube, a locking web, and a fin locknut. When 4. Insert the igniter, with its two pipe a conical fin assembly is installed on the plugs facing aft, in the burster well from the bomb, the new long-stem tail fuzes are re­ rear of the bomb. Insert the burster in the quired so that the arming vane is located igniter cavity. effectively in the air stream. 5. Remove the plug from the adapterbooster holder assembly. Install the as­ Assembly sembly in the base plate and remove the fin CAUTION: Fuzes and bombs are locknut. Discard the locknut. not to be unpacked in advance of 6. Remove the fin assembly and its at­ requirements. Return them to tachments from the shipping crate. Thread their original condition if not used. the center support tube onto the external 1. Remove the shipping bands from the threads of the adapter-booster holder. bomb by removing the nuts from the secur­ Tighten the tube with a wrench. Tighten General Description 10-23 N A V W E P S OP 2216 (V O L U M E 1) the setscrews in the support tube. Place the fin cone over the support tube and slide the cone back until it is jammed against the bomb body. Position the fins so as to clear the aircraft structure and ground when installed. 7. Place the fin locking web over the sup­ port tube so that it engages the fins of the fin assembly. Secure the conical fin as­ sembly to the support tube by threading on the special locknut. Tighten the locknut with special notched wrench. Bend two tabs of the locking web into the locknut slots and secure the nut in position by means of setscrews. 10-24 8. Install the bomb on the aircraft and lock it securely in place. 9. Remove the required number of fuzes and arming-wire assemblies from their con­ tainers and examine them carefully for serv­ iceability. For detailed information on fuzing and defuzing, refer to chapter 2 under the particular fuzes to be installed. 10. Install the arming wire so that 4 inches protrude beyond the nose and tail fuze vanes. Clip off excess wire. Place two safety clips on both ends of the wire and slide them up close to the fuze vanes. Arm­ ing wires must be free from kinks, twists, and burrs. C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSE M B L IE S 500-LB FIRE B O M B M k 77 M od 1 Figure 10—17.— 500-lb Fire Bomb Mk 77 M od 1, Exterior View. Mark .... .................... ......................... Mod _.... ...... ..................... -.............. General Arrangement List of Drawings ......... .................. Length of Assembled Bomb (in.) Body Diameter (in.) ..................... Filler Capacity (gal) ................... W eight o f Empty Bomb (lb) ..... W eight o f Filler (lb) __________ W eight o f Assembled Bomb (lb) Igniter ............... .................L..... .... Fuzes .................................................. General Description The 500-lb Fire Bomb Mk 77 Mod 1 is a 75-gallon capacity bomb obtained by modify­ ing the 750-lb Fire Bomb Mk 77 Mod 0. The modification consists of cutting off approxi­ mately 2 inches from the nose and tail body sections and approximately 12 inches from each end of the center section of the Mod 0, 77 1 1380243 165789 108.59 18.73 75.0 63.0 450.0 520.0 M15, M16, or M23 M157 (used with Igniters M15 and M16), or AN-M173 (used with Igniter M23) and welding the remaining pieces together to form the smaller Mod 1. Igniters and fuzes are used in the nose and tail of the Mk 77 Mod 1 fire bomb. Three igniters may be used; the M15, the AN-M16, and the M23. The bomb is designed for primary use of the M23 igniter with the AN-M173 fuze in both the nose and the tail. 10-25 N A V W E P S OP 2216 (V O L U M E 1) ARMING WIRE A S S E M B L E V - FAHNESTOCK CLIPS TA ILC O N E. FAHNESTOCK CLIP’S V SCREW IGNITER WELDED BODY SECTION IGNITER F ig u re SCREW 10-18.— 500-lb Fire Bomb M k 77 Mod 1, Exploded V iew . Adapters are furnished with the bomb so that the M15 igniter with the M157 fuze can be used in the nose or tail of the bomb. The M16 igniter with the M157 fuze is normally used only in the tail of the bomb, since the nose cone will not accommodate this larger igniter. If the nose cone is left olf the bomb, however, the M16 igniter can be used in the nose. The arming wires and cone-release wires are carried to the nose and tail of the bomb through internal tubes. When the conerelease wires are withdrawn, the springs in the cone-ring adapters eject both nose and tail cones from the bomb, exposing the fuzes to the air stream. Two suspension lugs are mounted on the body 14 inches apart. Two gasket sealed filler holes are located on the upper bomb surface. The bomb is filled with 75 gallons of gasoline gel; a minimum air space of 3 percent of the capacity of the bomb is re­ quired. Once a bomb is filled it cannot be disassembled; it must either be used or jettisoned. Painting and M arking The base color of the bomb is the natural aluminum color of the body. Purple identi­ 10-26 fication bands are painted around it. Identi­ fying nomenclature is stenciled on this modified bomb body in red letters. Assembly NOTE : The assembly instructions following do not cover the uncrat­ ing or the physical modification de­ tails for converting the Mk 77 Mod 0 bomb to the Mk 77 Mod 1. For unpacking, refer to the section on the Mk 77 Mod 0 fire bomb. 1. Check the bomb for damage, broken weldments, or cracks that may weaken the suspension or cause leaks in the casing. 2. Check the nose and tail sections for the presence of cones, cone-ring adapters, ship­ ping pins, igniter adapters, and filling-hole covers. 3. Remove the tail-cone screws from the tail-cone adapter. 4. Pull the shipping pin from the clevis pin in the tail-cone adapter and remove the clevis pin and clevis-pin spring to release the tail-cone adapter. 5. Remove the igniter adapter from the tail end-plate casting. 6. Remove the nose cone. C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSEM B LIES 7. Follow the procedure given in step 4 above to release the nose-cone adapter. 8. Remove the igniter adapter from the nose end-plate casting. 9. Screw the igniter adapter in the nose end-plate casting until it bottoms. 10. Replace the nose-cone adapter, the clevis-pin spring, and the clevis pin. Replace the shipping pin in order to secure the as­ sembly. Check the nose-cone adapter re­ lease mechanism by pulling out the shipping pin. 11. Reassemble the nose-cone adapter and assemble the nose cone. CAUTION: Do not damage the nose cone by tightening the screws excessively. If the bomb is not to be used immediately, the nose cone need not be assembled to the nosecone adapter until the bomb is fuzed. 12. Screw the igniter adapter into the tail end-plate casting until it bottoms. 13. Replace the tail-cone adapter, follow­ ing the procedure given in steps 10 and 11. 14. The 500-lb Fire Bomb Mk 77 Mod 1 is normally loaded on the aircraft while empty and then filled with gasoline gel. However, this procedure is not always prac­ tical. Detailed instructions for mixing the gasoline gel and filling the bomb are given in OP 2183. TAIL CONE FILLER CAP ARMING -WIRE , ASSEMBLIES ARMING-WIRE TUBE IGNITER BOMB BODY 'T IE ROD NOSE CONE SAFETY CLIP Figure 70-19.— 500-lb Fire Bomb Mk 77 Mod 1, Cutaway View. 10-27 N A V W E P S OP 2216 (V O L U M E 1) 15. Fill the bombs either through one or through both filling holes; both covers must be removed even if the bomb is filled through one hole. Secure the covers after filling. 16. Install the bomb securely on the air­ craft and sway brace. After the bomb is installed and filled, fuze and arm it as follows. 17. Remove the screws securing the nose cone to the adapter, and remove the nose cone. 18. Thread the two nose arming wires through the suspension fittings and internal arming-wire guide tube to the nose end-plate casting. 19. Insert one wire through the hole in the end of the clevis pin. 20. Attach the arming wire to the bomb rack. 21. Remove the clevis-pin shipping pin. 22. Repeat steps 17 through 21 to install the rear arming wires. 23. Install the nose and tail igniters. a. Clamp Igniter M15 into the igniter 10-28 adapter in the nose, and Igniter M15 or M16 into the igniter adapter in the tail. b. If Igniters M23 are used, unscrew the adapters and screw the igniters into the forward and rear walls. 24. Insert the arming wires into the nose and tail fuzes. 25. Attach the safety clips to the ends of the arming wire of each fuze. Cut off excess arming wire. CAUTION: Remove all kinks, twists, or burrs from arming wires to prevent possible malfunctioning. 26. Remove the safety pins from the ig­ niter fuzes. 27. Install the nose and tail cones and secure them with screws. Do not tighten the screws excessively. 28. Only an unfilled bomb may be disas­ sembled. CAUTION: Once filled, a bomb must be used or jettisoned. C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSE M B L IE S 750-LB FIRE B O M B M k 77 M od 0 Figure 10-20.— 750-lb Fire Bomb Mk 77 M od 0, Exterior View. Mark ........ |____ ______ _______ __ ___ ____ ___ Mod ____ _____________ ____ ________________ General Arrangement List o f Drawings .......... ........ ........... Length of Assembled Bomb (in.) Body Diameter (in.) Filler Capacity (gal) ........ ........................... W eight o f Empty Bomb (lb) W eight of Filler (lb) ......... Weight o f Igniters (lb) ... .................... ..... Weight of Assembled Bomb (lb) Weight o f Bomb and Crate as shipped (lb) Nose Igniter _______________ ______________ Tail Igniter .................. ..... ........ ....... ....... Fuzes ____ ___________ _________________ _ General Description The 750-lb Fire Bomb Mk 77 Mod 0 is a nonstabilized cigar-shaped bomb constructed of aluminum. It consists of three main sec­ tions and two end cones. A center tie rod holds the nose, center, and aft sections to­ gether and aluminum ring adapters secure the nose and tail cones to the main sections. ... 77 .. 0 434200 .. 165788 .. 138.0 18.63 .. 110.0 82.0 668.0 10.0 760.0 138.0 M15 or M23 M15, M16, or M23 M157 (used with Igniters M15 and M16) AN-M173 (used with Igniter M23) The bomb is filled with 110 gallons of gaso­ line gel and uses two igniter and fuze com­ binations to ignite the gel upon impact. Three igniters may be used with the Mk 77 Mod 0 fire bomb: the M15, the M16, or the M23. The bomb is designed for primary use of Igniter M23. Adapters are furnished with the bomb so that Igniter M15 may be 10-29 N A V W E P S OP 2216 (V O L U M E 1) ARMING WIRE ASSEMBLIES, TAIL SECTION .FAHNESTOCK CLIPS CENTER SECTION TAIL CONE FILLER CAP J Ck NOSE SECTION FAHNESTOCK CLIPS IGNITER , SCREW / NUT LOCK WASHER WASHER Figure 10-21.— 750-lb Fire Bomb Mk 77 Mod 0, Exploded View. used for either nose or tail fuzing. Igniter M16 normally is used only for tail fuzing. When the bomb is assembled, one igniter is attached to each end. Tubes carry the arming wires and cone release wires from the outside of the bomb to the inside. When the release wires are withdrawn, springs in the ring adapters eject both adapters and cones. Double suspension lugs are mounted on the body 14 inches apart. Two gasket sealed filler holes are located on the upper side of the bomb body. A gasoline and napalm mix­ ture (gel) fills the bomb body; gaskets be­ tween the three main sections prevent leak­ age of the gasoline gel. A minimum air space of 3 percent of the capacity of the bomb is required. Once a bomb is filled it cannot be disassembled; it must be used or jettisoned. Painting and M arking The base color of the bomb is olive drab, and purple identification bands are painted around it. Identifying nomenclature is stenciled on the bomb assembly in red letters. Assembly CAUTION: 10-30 Igniters, fuzes, and bombs are not to be unpacked in advance of requirements. If un­ packed and not used, return them to their original packings. 1. Remove the bomb body and its com­ ponents from their packing crate as follows. a. Remove the eight screws securing the end panel of the shipping crate of the bomb. b. Remove the end panel of the crate. c. Cut the four metal straps which secure the bomb sections to the crate. d. Slide the bomb sections out of the open end of the crate. e. Remove and open the package con­ taining the tie rods, washers, and nuts. f. Remove the tail cone from the ship­ ping crate end plate. g. Check the sealing gaskets. Gaskets must be in place and sealing surfaces must be free of foreign matter, dents, and nicks. h. Check to see that the nose and tail sections include cones, cone adapters, ship­ ping pins, igniter adapters, and filling hole covers. i. Check the suspension lugs for damage. 2. Remove the tail-cone screws from the tail-cone adapters. 3. Pull the shipping pin from the clevis C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSE M B L IE S pin in the tail-cone adapter and remove the clevis pin and clevis-pin spring to release the tail-cone adapter. 4. Remove the igniter adapter from the tail end-plate casting. 5. Remove the nose cone. 6. Follow the procedure given in step 3 above to release the nose-cone adapter. 7. Remove the igniter adapter from the nose-plate casting. 8. Wipe the gasket surfaces on all sections with carbon tetrachloride or gasoline. 9. Assemble the tie rod sections. Screw the ends of the forward and rear tie rods, which have a 1-inch length of thread, into the center nut until the tie rods come to­ gether. 10. Pass the end of the tie rod with the shortest end of threads through the hole in the nose end-plate casting. Slide the large NOSE-CONE ADAPTER NOSE-CONE SCREW SCREW FASTENERC LEV IS IGNITER M15 ADAPTER-CLAM P SCREW IGNITER M23 IGNITER ADAPTER wnsE CONF Figure JO-22.— 750-lb Fire Bomb Mk 77 Mod 0, Assembly Details. 10-31 N A V W E P S OP 2216 (V O L U M E 1) FILLER CAP .ARMING-WIRE ASSEMBLIES TAIL SECTION CENTER SECTION TIE ROD IGNITER -NOSE SECTION NOSE CONE ^ -SA F E T Y CLIP Figure 10-23.— 750-lb Fire Bomb Mk 77 M od 0, Cutaway View. inside diameter washer over the end of the tie rod and fit it into the recess; place the gasket, small inside diameter flat washer, lockwasher, and self-locking nut on the tie rod, in the order given. Secure by tighten­ ing the self-locking nut on the tie rod. 11. Pass the tie rod assembly through the center section. 12. Move the tail section into position; remove the rear filler cap, reach through the filling hole, and guide the tie rod through the hole in the tail end-plate casting. 13. Slide the large inside diameter washer over the end of the tie rod and fit it into the recess; place the gasket, small inside di­ 10-32 ameter washer, lockwasher, and long nut on the tie rod, in the order given, making certain that the counterbored end of the nut is placed over the tie rod first. 14. Aline the arming-wire tubes on all sections. 15. Secure the tie rod with the long nut and tighten it with a torque wrench to 325 inch-pounds. CAUTION : Before tightening the long nut, make sure that the gaskets on the tie rod are properly seated. 16. Screw the igniter adapter in the nose end-plate casting until it bottoms. C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSE M B L IE S 17. Replace the nose-cone adapter, clevispin spring, and clevis pin. Replace the shipping pin to secure the assembly. Check the nose-cone adapter release mechanism by pulling out the shipping pin. 18. Reassemble the nose-cone adapter and assemble the nose cone. Do not damage the nose cone by tightening the screws exces­ sively. If the bomb is not to be used imme­ diately, the nose cone need not be assembled to the nose-cone adapter until the bomb is fuzed. 19. Screw the igniter adapter into the tail end-plate casting until it bottoms. 20. Replace the tail-cone adapter, follow­ ing the procedure given in steps 17 and 18. 21. The 750-lb Mk 77 fire bomb is nor­ mally loaded on the aircraft while empty and then filled with gasoline gel. However, this procedure is not always practical. De­ tailed instructions for mixing the gasoline gel and filling the bomb are given in OP 2183. 22. Fill the bomb either through one or through both filling holes; both covers must be removed even if it is filled through one hole. Secure the covers after filling. 23. Install the bomb securely on the air­ craft and sway brace. After the bomb is installed and filled, fuze and arm it as fol­ lows. 24. Remove the screws securing the nose cone to the adapter and remove the nose cone. 25. Thread the two nose arming wires through the suspension fitting and armingwire guide tubes to the nose endplate casting. 26. Insert one wire through the hole in the end of the clevis pin. 27. Attach the arming wire to the bomb rack. 28. Remove the clevis-pin shipping pin. 29. Repeat steps 24 to 28 to install the rear arming wires. 30. Install the nose and tail igniters. 31. Insert the arming wires into the nose and tail fuzes. 32. Attach safety clips to the ends of the arming wire of each fuze. Cut off excess arming wire. Remove all kinks, twists, or burrs from the arming wires to prevent possible malfunctioning. 33. Remove the safety pins from the igni­ ter fuzes. 34. Install the nose and tail cones and secure them with screws. Do not tighten the screws excessively. 35. Only an unfilled bomb may be dis­ assembled. Once filled, a bomb must be used or jettisoned. Handling and Stowage Special care must be taken when handling the bomb sections to prevent denting or nicking the sealing gasket seats. 10-33 N A V W E P S OP 2216 (V O L U M E 1) 750-LB FIRE BO M B M k 77 M od 0 W IT H B O M B C O N V E R S IO N K IT M k 19 M od 0 DOUBLE ARMING WIRE ASSEMBLY / FAHNESTOCK CLIF SINGLE ARMING WIRE ASSEMBLY. CONVERSION KIT FIN / SCREW / FILLER CAP FILLER CAP \TAIL NOSE SECTION CONE FAHNESTOCK CLIP NUT LOCK WASHER SET SCREW IGNITER ADAPTER WASHERS SECTION VT FUZE ROD SECTION ROD VT FUZE ADAPTER WASHERS CLAMP BOLT NUT Figure 10—24.— 750-lb Fire Bomb Mk 77 Mod 0 with Bomb Conversion Kit Mk 19 Mod 0, Exploded View. Mark ______________ __________ __________ ______________ M o d ........... ..................................... ................... .1 _____________ _ Installation Drawing No. __ ____ ____________ List o f Drawings ............. ..................................... Length of Assembled Bomb (in.) With Tail Cone Installed _______ ____............................... ...... Without Tail Cone ................... .............................................. ..... Body Diameter (in.) _____ ____________ __ _______ Fin Span (in.) ............................... ................................................... Filler Capacity (gal) . ..... _____________________________ Weight o f Empty Bomb (lb) ________________ _ ____ _____ Weight o f Filler (lb) ... ....... ..... ......... .......... Weight o f Conversion Kit Components (lb) ......... ........ Weight o f Assembled Bomb (lb) _____ _______ __ Weight o f Conversion Kit As Shipped (lb) ............................ Nose Fuze ___________ ____ __ ____ ____________ ________ _ Tail Igniter ........................... ................................ Igniter Fuze ... _________ ____ _____ ___ General Description Bomb Conversion Kit Mk 19 Mod 0 con­ sists of component parts for a shrouded fin assembly, an adapter for the AN-M166E1 VT fuze, and two setscrews to lock in place the igniter clamp which holds the VT fuze 10-34 77 0 1380246 165787 138.0 131.0 18.63 31.75 110.0 82.0 668.0 17.3 777 24.0 AN-M166E1 (V T) M15, M16, or M23 M157 (used with Igniters M15 and M16) AN-M173A1 (used with Igniter M23) adapter. The conversion kit was developed to convert 750-lb Fire Bomb Mk 77 Mod 0 into a weapon that could be used in normal dive-bombing tactics. The Mk 77 Mod 0 bomb, modified with the Mk 19 Mod 0 conversion kit, is stabilized C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSE M B L IE S c. Cut the four metal straps that se­ cure the bomb sections to the crate. d. Slide the bomb sections out of the open end of the crate. e. Remove and open the package con­ taining the tie rods, washers, and nuts. f. Remove the tail cone from the ship­ ping-crate end plate. g. Check the sealing gasket. Gaskets must be in place and sealing surfaces free of foreign matter, dents, and nicks. The nose cone and nose-cone adapter ring h. Check to see that the nose and tail are discarded when the VT fuze is installed. sections include cones, cone adapters, ship­ The use of a tail cone and tail-cone adapter ping pins, igniter adapters, and filling-hole ring is optional with the converted Mk 77 covers. Mod 0 bomb. i. Check the suspension lugs for dam­ age. Assembly 2. Remove the tail-cone screws from the CAUTION: Igniters, fuzes, and tail-cone adapter. bombs are not to be unpacked in 3. Pull the shipping pin from the clevis advance of requirements. If un­ pin in the tail-cone adapter, and remove the packed and not used, return them clevis pin and clevis-pin spring to release the to their original packings. tail-cone adapter. 4. Remove the igniter adapter from the 1. Remove the bomb components from tail end-plate casting. their packing crate as follows. 5. Remove and discard the nose cone. a. Remove the eight screws securing the end panel of the shipping crate of the bomb. 6. Release the nose-cone adapter as in step 3 and discard it. b. Remove the end panel of the crate. during flight by a shrouded fin assembly. The AN-M166E1 VT fuze, housed in the nose of the bomb, functions before impact to rupture the nose casting of the bomb and free the tie rod that holds the three main body sections together. The bomb sections separate upon impact of the bomb; conse­ quently, the gasoline gel is distributed over a greater area and a smaller crater is created than when all the sections remain attached on impact. Components of Bomb Conversion Kit Mk 19 Mod 0 Fin B la d e __ . ___ _ ___ _ _ _ . . Fin Base ______ ___ _________ __ Fin S u p p o r t___ . ______ __ __ ___ Headless Setscrew _ _ _ _ _ _ ___ Instruction Card----------------------- -------- Safety Wire _ __ __ __ Shroud. ..................... VT Fuze Adapter___ . . . Washer Head S c r e w . ..... D ra w in g N um ber Q u a n tity I te m ____ . . . __ ___ .. ....................... .... 4 4 4 2 1 4 1 8 4 1 8 4 8 S tock N um ber 1212123. 1212124. 1212125. AN 565-416-8. 1380254. AN 123961 (spare part). AN 364-1032. 1212126. 1212127. AN 960-10. AN 960-516. AN 525-10-11. 10-35 N A V W E P S OP 2216 (V O L U M E 1) 7. Remove the igniter adapter from the nose-plate casting. 8. Remove the four bolts, washers, O-ring seals, and nuts from the tail section skin of the bomb. Inspect the O-ring seals; if damaged, replace with those furnished with the conversion kit. 9. Remove the eight bolts, washers, and the safety wire from the fin mounting holes in the tail end-plate casting. 10. Mount the four fins from the con­ version kit to the tail section, using the screws, washers, and nuts removed in steps 8 and 9. Care must be taken to see that the O-ring seals seat properly at the bolts passing through the tail section skin. The O-ring seals should be next to the bomb skin with the large flat washer on top so that the washer contains the O-ring seals. 11. Secure the four sections of the tailfin shroud to the fins with the eight screws, washers, and locking nuts contained in the conversion kit. 12. Safety wire the eight fin-securing bolts in the tail end-plate casting. 13. Wipe the gasket surfaces on the three body sections with carbon tetrachloride or gasoline. 14. Assemble the tie rod sections. Screw the ends of the forward and rear tie rods (which have a 1-inch length of thread) into the center nut until the tie rods come to­ gether. 15. Pass the end of the tie rod with the shortest end of thread through the hole in the nose end-plate casting. Slide the large inside diameter washer over the end of the tie rod and fit it into the recess; place the gasket, small inside diameter flat washer, lockwasher, and self-locking nut on the tie rod, in the order given. Secure by tightening the self-locking nut on the tie rod. 16. Pass the tie rod through the center section. 17. Move the tail section into position. Remove the rear filler cap, reach through the filling hole, and guide the tie rod through the hole in the tail end-plate casting. 18. Slide the large inside diameter flat washer, lockwasher, and long nut on the tie 10-36 rod (in the order given), making certain that the counterbored end of the nut is fac­ ing inward. 19. Aline the arming-wire tubes on all sections and tighten the long nut with a torque wrench to 325 inch-pounds. Before tightening the long nut, make sure that the gaskets on the tie rod are properly seated. 20. In the igniter-adapter seat of the nose end-plate casting, drill and tap two holes V4-20NC on opposite sides of the casting flange. Screw the igniter adapter into the nose end-plate casting and lock it in place with the two headless setscrews supplied with the conversion kit. 21. Install the VT fuze adapter in the igniter adapter and tighten it in place with the clamping bolt on the igniter adapter. 22. Screw the igniter adapter into the tail end-plate casting until it bottoms. 23. Replace the tail-cone adapter, clevispin spring, and clevis pin. Replace the shipping pin to secure the assembly. Check the tail-cone-adapter release mechanism by pulling out the shipping pin. 24. Reassemble the tail-cone adapter and assemble the tail cone. Do not damage the tail cone by tightening the screws exces­ sively. If the bomb is not to be used immediately, the tail cone need not be as­ sembled to the tail-cone adapter until the bomb is fuzed. 25. The 750-lb Fire Bomb Mk 77 Mod 0 is normally loaded on the aircraft while empty and then filled with gasoline gel. However, this procedure is not always prac­ tical. Detailed instructions for mixing the gasoline gel and for filling the bomb are given in OP 2183. 26. Fill bombs either through one or through both filling holes; both covers must be removed even if the bomb is filled through one hole. Secure the covers after filling. 27. Install the bomb securely on the air­ craft and sway brace. After the bomb is installed and filled, fuze and arm it as follows. 28. Remove the screws securing the tail cone to the adapter and remove the tail cone. 29. Thread the two tail arming wires C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y BO M B A SSE M B L IE S through the rear suspension lug and the arming-wire guide tubes to the tail endplate casting. 30. Insert one wire through the hole in the end of the clevis pin. 31. Attach the arming wire to the bomb rack. 32. Remove the clevis-pin shipping pin. 33. Install the igniter and fuze into the tail igniter adapter. Refer to chapter 2 for detailed fuzing instructions. 34. Insert the arming wire into the fuze and attach Fahnestock clips to the end of the wire. Replace the tail cone and secure it in place as in step 24. 35. Remove the AN-M166E1 VT fuze from its packings. CAUTION: If the fuze container is damaged or if the seal is broken in any way, the fuze is to be con­ sidered unserviceable. 36. For installation of the AN-M166E1 VT fuze, see the instruction card, dwg 1380254, which is attached to the VT fuze adapter in Bomb Conversion Kit Mk 19 Mod 0. See also OP 1444, 2nd Revision. 37. Thread a single arming wire through the front suspension lug and arming-wire guide tubes to the nose end-plate casting. 38. Pass the arming wire through the VT fuze arming-wire guides and attach one safety clip to the end of the wire. 39. Cut off exess wire at the nose and tail fuze installations. CAUTION: Arming wires must be free from kinks, twists, and burrs to prevent possible mal­ functioning. 10-37 N A V W E P S OP 2216 (V O L U M E 1) 750-LB FIRE BOMB Mk 78 Mod 2 Figure 10-25. — 750-lb Fire Bomb M k 78 M o d 2, Exterior View. Mark .................. ............... ............ I Mod ______ _____ _________________ __ General Arrangement ______ ___ ___ List of Drawings ........ Length of Assembled Bomb ( i n . ) __ Body Diameter (in.) ......................... Filler Capacity (gal) ....... ................ Weight of Empty Bomb (lb) ______ Weight of Filler (lb) ........ ................. Weight o f Assembled Bomb (lb) Arming-Wire Assembly ..... .............. Igniter ....... .... ......... .......................... . Fuze ............... ........................................ General Description The 750-lb Fire Bomb Mk 78 Mod 2 con­ sists of two thin sheet-steel half-shells 10-38 78 2 1380217 165785 89.12 26.4 110.0 90.0 660.0 760.0 Mk 1, AN-M 6A2, or Mk 2 M23 (or Mk 15 or Mk 16 with Fuze Mk 157) AN-M173 welded together. It is non-stabilized and has a 110-gallon capacity. The bomb has two wells located fore and C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSE M B L IE S aft on the upper surface. These wells house two M23 igniters which are secured in place with igniter caps. A filler opening for the gasoline gel is located on the upper surface of the bomb between the fore igniter well and the suspension lugs. Two reinforced lugs provide for a 14-inch suspension. A gasoline gel fills the bomb to 97 percent of its capacity. Once a fire bomb is filled, it cannot be disassembled; it must be used or jettisoned. Painting and Marking This bomb is identified by a purple stripe painted on the nose and tail end of its body. Identifying nomenclature is stenciled in black letters on the upper shell. The base color of the bomb is olive drab. Differences Among Fire Bombs Mk 78 Mods 0, 1, and 2 There are three modifications of 750-lb Fire Bomb Mk 78 Mods 0, 1, and 2. Dif­ ferences exist in the construction and loca­ tion of the wells, brackets, and adapters for use of igniters. The Mod 0 bomb uses an M16 igniter with an M157 fuze installed in the filler hole of the bomb. A second igniter, an M15 with an M l57 fuze, is clamped externally to the aft end of the bomb in a bracket. The Mod 1 bomb is identical to the Mod 0 except for the addition of two external igniter adapters. These adapters, located fore and aft on the upper bomb surface, accommodate M23 igniters with AN-M173 fuzes. The Mod 2 bomb is identical to the Mod 1 except that it has internal igniter wells in place of the external igniter adapters. The wells of the Mod 2 are located higher on the bomb body than the igniter adapters Figure 10-26.— 750-lb Fire Bomb Mk 78 M od 2 Exploded View. 10-39 N A V W E P S OP 2216 (V O L U M E 1) ARMING-WIRE /ASSEMBLY IGNITER BRACKET FILLER CAVITY FILLER CAP IGNITER BOMB BODY Figure 10-27. — 750-lb Fire Bomb M k 78 M o d 2, Cutaway View. of the Mod 1. The M23 igniters set in the wells are secured by igniter caps. Assembly CAUTION: Igniters, fuzes, and bombs are not to be unpacked in advance of requirements. If un­ packed and not used, return them to their original packings. 1. Remove the bomb body and its compo­ nents from the packing crate. Inspect for damage, cracks, or broken weldments which might cause leaks in the bomb body, or damage that might weaken the lugs or their attachment to the bomb body. 10-40 2. Fill the bomb to its required capacity through the filler hole. Secure the cover after filling. Detailed instructions for mix­ ing the gasoline gel and filling the bomb are given in OP 2183. 3. Install the bomb securely on the air­ craft and sway brace. This bomb is nor­ mally loaded on the aircraft while empty and then filled with gasoline gel, although this procedure is not always practical. After the bomb is suspended from the bomb rack and filled, fuze and arm it as fol­ lows : NOTE: For the Mod 2 bomb, dis­ regard steps 4 through 7. C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSE M B L IE S 4. Loosen the bolt on the rear igniter clamp. 5. Install Igniter M15 and tighten the clamp bolt until the igniter is secure. 6. Install Igniter M16 in the filler hole. 7. Remove the igniter well caps and in­ stall the M23 igniters. Replace the well caps, securing the igniters. On Mod 1, in­ stall M23 igniters in the external adapters. 8. Thread the arming wire through the suspension fittings and arming-wire guide brackets. 9. Attach the arming wire to the bomb rack. 10. Insert the arming wires through the nose and tail fuzes. 11. Attach safety clips to the ends of the arming wire of each igniter; the arming wire should protrude approximately 2 inches beyond the fuze vanes (cut off excess wire) and should be free from kinks, twists, or burrs. 12. Remove the safety pins from the ig­ niter fuzes. 13. Only an unfilled bomb may be dis­ assembled. Once filled, the bomb must be used or destroyed; all bombs not used shall be jettisoned prior to landing afloat or ashore. 10-41 N A V W E P S OP 2216 (V O L U M E 1) 1000-LB FIRE BOMB Mk 79 Mod 1 1 6 7 "9 6 - Figure 10-28. — 1000-lb Fire Bomb M k 79 M o d 1, Exterior View. Mark .................................................................... Mod ............................................................... . General Arrangement . ............... ......... List of Drawings _________ _______ _______ Length o f Assembled Bomb (in.) ...... Body Diameter (in.) ________________ _____ Fin Span (in.) ........... .................................... Filler Capacity (gal) .................................... .. Weight o f Filler (lb) ........ ............................. Weight of Assembled Bomb (Empty) (lb) Weight of Bomb as Shipped (lb) ___ __ _ Arming Wire Assembly Igniter ............... ....... ...................................... Fuzes ........ ...................................................... General Description The 1000-lb Fire Bomb Mk 79 Mod 1 is a thin-skinned bomb of low-drag design. The bomb is made up of four basic sections, plus certain accessory parts. These four sections are designated: forward (or nose) section, called Section I; center (or main) 10-42 79 1 1884353 517551 167.9 19.6 27.7 112 700 212 275 M23 AN-M173 (Mech.) (used with Igniter M23) XB66C (Elec.) used with Proximity Fuze Sensing Element M20 (T-18E2) section, called Section I I ; first aft section, called Section III; and second aft (or tail) section, called Section IV. The center (or main) section of the bomb is used as a shipping container into which the other sections (nose, aft, and tail) are nested together and stowed. In this pack­ C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSEM B L IES aged condition, the bomb has an enlarged protective cover at each end of the center section. On one end is a built-up metal dish having four lever handles on its face; this is the forward (or nose) end of the bomb. On the other end is a built-up, drum­ like construction having no exterior lever handles; this is the aft (or tail) end of the bomb. This aft, drum-like cover contains the bomb accessories, and must be removed before the lever handles on a separate tail cover can be reached. The bomb, which has a capacity of ap­ proximately 112 gallons, is filled with gaso­ line mixed with Napalm. This bomb can be fuzed with either stand­ ard mechanical fuzing utilizing the Fuze AN-M173 with the Igniter M23 (two places) for impact functioning or an electric fuzing system consisting of the Electric Fuze XB66C with the Proximity Fuze Sensing Element M20 (T18E2) for either airburst or impact functioning. The following items are furnished with each bomb: one Bomb Cable Assembly Mk 8 Mod 0; two screw-in Suspension Lugs Mk 6 Mod 0, providing for 14-inch suspension; special tools required for assembly consist­ ing of a combination wrench, pounding block, and fuze inserting dowel; and lock pins to hold sections extended for assembly. Other than the special tools furnished with each bomb, the only tools required for un­ packing and assembly of the bomb are a hammer and a screw driver. Painting and M arking The base color of the bomb is olive drab. No stripes encircle the bomb. Identifying nomenclature is stenciled on the bomb as­ sembly in yellow. Differences Between Fire Bombs M k 79 M ods 0 and 1 The Mod 0 bomb was designed to accept standard fuzing only and was never released to procurement. Unpacking CAUTION: The sealed bomb package should not be opened until required for use because these bombs, as shipped are protected internally against corrosion by volatile corrosion inhibitor (VCI) powder. Figure 10-29.— 1000-lb Fire Bomb Mk 79 Mod 1, Exploded View. 10-43 N A V W E P S OP 2216 (V O L U M E 1) T A IL W IN D F A H N E S T O C K C L IP S F U Z E -IG N F IN B L A D E F IL L E R C A P A R M IN G W IR E B O M B BODY F ILLER FUZE L O C K P IN F AH N ESTO CK C L IP S N O S E W IN D C A P Figure 10—30.— 1000-lb Fire Bomb MJc 79 M od 1, Cutaway View. C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSE M B L IE S 1. Lay the bomb on its side and place it on a bomb truck, hand truck, dolly, or other support so that the shipping ends are free of the ground. Block the bomb in place to prevent its rolling. The bomb may however be unpacked on any hard, reasonably smooth surface, such as a deck or flight apron. If this is done, care must be taken to see that the bomb is not allowed to fall when the projecting shipping ends are removed. 2. Inspect the packaged bomb for visible damage to Section II (center section). Some damage to the shipping ends is to be expected. 3. Using a screw driver, pry up the four lever handles on the nose shipping end until they release. After these handles are re­ leased, grasp each one in turn and rotate the attached shafts one-half turn (it may be necessary to push the handle in toward the face of the cover while turning). Turning the handle will release an internal hook at­ tached to the handle shaft; when properly unhooked, there will be no restraint from turning the handle. 4. When (and only when) the four in­ ternal hooks are released, remove the nose cover and the gasket at the edge of this cover. It may be necessary to use a hammer. 5. Attached to the inside of the nose ship­ ping cover are a cone-shaped nose cap and a tail cap. Remove the tail cap from its holding bracket by inserting a screw driver tip into one of the holes in the side of the bracket and depressing the spring pin on the cap. The nose cap should be removed by prying or pulling the holding brackets away from the nose cap. Remove the Bomb Cable Assembly Mk 8 Mod 0 which is packaged inside the tail cap. The nose shipping cover may now be discarded. 6. Reach into the bomb, grasp the forward end of Section I (nose section) and move it up and down or side to side until it is free; pull it forward about one foot. Do not slam or jerk the section; pull firmly and evenly. Wiggle the section from side to side if fric­ tion occurs. CAUTION: Do not remove the tail cover (see step 10) before step 6 is accomplished. 7. At the tail end, note that the accessory cover (aft portion of the tail cover) is held in place by a hooplike clamp ring similar to that found on a commercial open-top steel or fiber shipping drum. This ring is located about four inches forward of the aft end of the cover, and is fastened at one point by a toggle arrangement. Remove the cotter pin, and pry open the toggle. This will allow removal of the clamp ring. 8. Remove the accessory cover by pulling or driving it aft with a hammer. Use care in removing this cover so that the fins do not fall to the ground and become damaged. Discard the O-ring gasket. 9. The following parts are stowed in the accessory cover: a. Four fins b. One fuze inserting dowel c. Two oval-shaped filling hole covers d. One cloth bag containing: (1) Twenty-four lock pins (2) One grooved fiber block (pound­ ing block) (3) One cable retainer assembly con­ sisting of one cable retainer, two bolts, and two lockwashers (4) Two bolts and lockwashers. Re­ move these parts by unclamping them, and inspect them for damage. Place the parts on the deck or in the accessory cover for future use. 10. After removing the accessory cover and accessories, remove the inside tail cover by means of the four lever handles, similar to those previously found on the nose cover. Pry up the handles and turn them to release the internal hooks. (Refer to steps 3 and 4.) Discard the tail shipping cover. 11. Reach into the tail, grasp the tab to unwind the tape that secures the athwartship fuze well package; remove the package and unpack it. Reach into the open tail, grasp the aluminum tail cone section, and pull it out. Do not slam or jerk the section; pull firmly and evenly. Continue to pull the tail section until both parts extend to approx­ imately full length. The end of the tail will 10-45 N A V W E P S OP 2216 (V O L U M E 1) be about five feet beyond the center section when fully extended. Do not slam or jerk the sections; pull them firmly and evenly. Wiggle the sections from side to side if fric­ tion occurs. Assembly 1. Place the bomb on a bench, hand truck, dolly, or on the ground and block it so that it cannot roll. 2. Turn the bomb so that the white painted alinement stripe is clearly visible. This stripe, near the suspension lugs, ex­ tends over all the joints on top of the bomb. 3. Pull out the three fore-and-aft sections to full length, so that the white stripe is in line (by eye) at all joints. Do not slam or jerk the sections; pull firmly and evenly. Wiggle the sections from side to side if fric­ tion occurs. The joint ends of the white alinement stripe should line up within ap­ proximately the thickness of a five cent piece when the bomb sections are properly alined. With the bomb in alinement the two fuze wells, the two filling holes, and the suspension lugs should all be in line; the fin stubs should be at 45 degree to the suspen­ sion lugs. 4. There are outside lock-pin slots ap­ proximately one inch long by one-quarter inch wide near the end of each bomb section. If necessary, insert a screwdriver in the slots and pry or drift the sections into exact alinement. NOTE: When the sections are properly in line and are out to proper length, a mating slot in each under section will appear under­ neath the slot on the outside. 5. Install the lock pins. These pins are in the cloth bag previously removed from the accessory cover. (See step 9 under Un­ packing.) There are twenty-four lockpins; twenty are required to assemble the bomb and four are included as spares. These pins drive like nails and can be driven with any hammer. The pins are self-locking and should be driven flush with the bomb skin. 10-46 CAUTION: If the pins appear to drive too hard, check for misalinement of the bomb sections. Do not force the pins without first being sure of alinement. Damage may be caused to the bomb skin by im­ proper driving of the pins. For easier assembly, drive the lock pins in the following sequence: a. Drive one pin in each joint, pref­ erably on top near the alinement stripe. b. Turn the bomb over and drive a second pin in each joint directly opposite the first pin. c. Drive the remaining pins in any se­ quence. 6. Place the fins over the fin stubs on the tail of Section IV, with the sloping edge forward. Using the fiber pounding block, hammer the fins solidly down and aft until they bottom, making sure that the lower edge of each fin enters the fore-andaft guide clips properly. CAUTION: Do not hammer di­ rectly on the fins. They are soft aluminum and are easily damaged. Instead, place the groove in the fiber pounding block over the edge of each fin and hammer on the block. When each fin is properly in place, bend the longer of the two forward guide clips over the leading edge of the fin, to lock the fin and thus prevent its removal or displacement. 7. Line up the tail cap with the open hole at the tail, and push solidly with the hands until the cap bottoms and the spring pins engage properly. The cap will seem rather loose when properly installed. When neces­ sary, an installed tail cap can be removed by grasping the cap between the hands, and turning and pulling aft at the same time. 8. The nose cap fits into the open hole at the nose of the bomb and is needed only when the standard fuzing system Fuze M173 with Igniter M23 is used. The nose cap may be discarded when the electric fuzing system is to be installed. The wrench furnished C H E M IC A L (GAS), SM O K E, A N D IN C E N D IA R Y B O M B A SSE M B L IE S with each bomb may be used to tighten the nose cap in place. ! 9. To make the athwartship fuze well hole accessible, remove the shipping plug from the top center of the bomb by means of the spanner pins on the furnished wrench; turn the bomb over and remove the bottom shipping plate using the same wrench. Dis­ card both the shipping plug and the plate. CAUTION: Do not discard the nuts and lockwashers holding the bottom plate. Save them for future use. Inspect the athwartship fuze well, making sure that the O-rings in the top and bottom nest firmly in the grooves. Slip the top of the fuze well through the large hole in the bottom of the bomb; align the pilot slot in the bottom flange of the fuze well with the pilot pin on the bomb. Install the two lockwashers and nuts finger tight. Turn the bomb on its side and install the cable retainer assembly in the slot in the top of the bomb. Engage the bolts in the top of the fuze well assembly; then install the other two bolts and lockwashers through the back bone and screw them into the top of the fuze well. Tighten all four bolts evenly and securely. Return to the bottom of the bomb to tighten the two nuts holding the lower flange of the fuze well to the bomb. NOTE: The athwartship fuze well is always installed regardless of whether the electric fuzing system or the alternate standard fuzing system Fuze M173 with Igniter M23 is to be used. 10. Open a filling hole by lifting the cam handle of the cover. Pry up the cam handle with a screwdriver; the spring will keep it open. To insert a cover in the bomb grasp the cover by the cam handle and insert the small end of the bottom plate crosswise in the filling hole. When the bottom plate has entered, turn the cover at right angles so that the small end is aft and the shape of the cover lines up with shape of the hole. The cover should be very free and loose until the cam handle is pushed down. Push the cam handle down flush. This locks and seals the cover. The cam handle should go down smoothly and easily. If it does not, the cover may be fouled on the internal rubber extension sleeve. Shaking the cover in the hole should free it. NOTE: It is suggested that the filling hole covers not be inserted in the bomb until after the bomb is filled with Napalm. If the bomb is stored empty for a period of more than several hours, it is ad­ visable to leave the cam handles open and the covers loose. Electric Fuzing 1. Insert the three-pronged plug of Bomb Cable Assembly Mk 8 Mod 0 into the opening in the nose of the bomb, and feed it through the tube and out of the Section I skin. Pull it through until the single-pronged plug en­ gages the mouth of the tube. CAUTION: Do not engage this plug in the tube by pulling on the cable. Instead, place the hollow end of the fuze inserting dowel over the single prong and force the plug base firmly into the tube. Then re­ move the dowel. Feed the three-pronged plug through the fixed channel on Section I I ; remove the slack. Insert the front channel (the loose piece) through the channel clip on Section I and over the cable engaging the inside of the fixed channel. With a hammer, bend down the ear on the channel clip to approxi­ mately 45 degrees. 2. Remove shipping pin from bottom of fuze and screw white phosphorus filled igni­ ter can to fuze. Insert nose of fuze-igniter can assembly into athwartship fuze well approximately thirteen inches. Place fuze inserting dowel inside of cap assembly with the tongue of the dowel at the spring end. Push fuze-igniter can assembly to top of fuze well and rotate with the dowel until the plug receptacle boss engages the slot in 10-47 N A V W E P S OP 2216 (V O L U M E 1) installed in the flush mounting wells pro­ the upper end of the fuze well. Rotate cap vided. Two igniter-fuze combinations are assembly until slots engage bayonet pins; used. One of each is installed on Sections I rotate with fingers as far as possible. Re­ and IV (the nose and tail) as follows: move dowel and tighten cap assembly with square projection on wrench furnished. In­ 1. Remove the igniter well covers. These sert tetryl loaded burster tube through cut covers are shipped in place in the wells and out in cap into cavity of the igniter can. are held in place by three springs, two of Screw burster tube securely in cavity using which have tabs extending above the cover dowel as a screw driver. Insert three­ to facilitate removal. To remove a cover, pronged plug of the cable into the XB66C squeeze a pair of tabs together between the Electric Fuze, making sure the cable retainer thumb and forefinger until the springs re­ engages the shoulder on the plug to prevent lease. The cover can then be lifted out. withdrawal. 2. Place the igniter-fuze combinations into 3. After the Bomb Cable Assembly Mk 8 the wells, lining up the arming wire holes in Mod 0 has been properly installed, unpack the arming vanes so that they are in line Proximity Fuze Sensing Element M20 (T with the suspension lugs of the bomb. Re­ 18E2) and remove the rear cover. Install place the well cover over each fuze and push the element in the opening in the nose of the down against the spring until the lock pins bomb. Tighten the element in place with the snap into place. It should not be necessary furnished wrench. to remove the safety pins until the well covers have been installed. Install the arm­ Standard Fuzing ing wires, passing them through the guides The igniter-fuze combinations are to be on top of the bomb. 10-48 Chapter 11 PRACTICE BOMB ASSEMBLIES 3-LB M IN IA T U R E P R A C T IC E B O M B M k 5 M ods 2 and 3 3-LB M IN IA T U R E P R A C T IC E B O M B A N - M k 23 Mod 1 4.5-LB M IN IA T U R E PR A C T IC E BO M B M k 43 M od 1 M a r k __ __ _____________ - . M od ________ ________________________ General Arrangement__________ - - List of Drawings---------- -------------- . Length of Assembled Bomb (in.) ___ Diameter (in.).......... ............. - -------- Fin Span (I n .)................... ......... Weight: Without Signal (lb )___. _ ... With M k 4-Type Signal (lb). ___ With Mk 5-Type Signal (lb)_ Firing-Pin Assembly_____________ — Signal . . . ________ _____ ____________ Mk 5__________ _____ . 2 and 3 ............... . 452859____________ .. Sk 165595.. ................. 8 .25____________ _ . 2 .1 8 ___________ _____ . 2 .5 __________________. A N -M k 23________ 1__________________ 452860____________ Sk 165597_________ 8 .2 5 ______________ 2 .1 8 ______________ 2 .5 _______________ 2 .5 6 ________________ . 2 .6 8 ________________ 2 .6 2 ________________ . Mk 1 Mod 0 ________ . Mk 4 Mods or Mk 5 M od 0. 2 .8 7 ______________ . . 3 .0 0 ______________ . . 2 .9 4 ______________ Mk 1 Mod 0_______ . . Mk 4 Mods or Mk 5 Mod 0. . .. .. __ .. .. .. Mk 43. 1. 452858. Sk 165596. 8.25. 2.18 2.5. 4.31. 4 43. 4.37. Mk 1 Mod 0 Mk 4 Mods or Mk 5 Mod 0. General Description Painting and M arking The 3-lb MPB Mk 5 Mods 2 and 3, the 3-lb MPB AN-Mk 23 Mod 1, and the 4.5-lb MPB Mk 43 Mod 1 are similar in physical appearance and differ basically in the metal used to cast the body. Bomb Mk 5, now obsolescent, is manufac­ tured from zinc alloy and weighs the least of the three bombs. Bomb AN-Mk 23 is made of cast iron. Bomb Mk 43, now obsolete, was manufactured from cast lead and was the heaviest of the three bombs. The cast body has a bore throughout its transverse axis which houses a signal and firing-pin assembly. Four fins are cast integrally with the bomb body. A rectangular sheet-metal shroud at­ tached to the fins is used to stabilize the bomb in flight. Two crimps, 180 degrees apart, anchor the shroud to the fin blades. The firing-pin assembly consists of two shallow metal cups, separated by a spacer which houses the firing pin. A cotter pin through the nose of the bomb body and two recesses in the lip of the forward cup lock the firing-pin assembly and signal in place. Identification data is cast integrally on the body of the bomb during manufacture, and the bomb has no color marking other than that of the cast metal. Use The 3-lb MP Bomb Mk 5 is used for bomb­ ing practices on armored-deck target boats. The Bomb AN-Mk 23 is authorized for all bombing practices except those involving armored-deck target boats. The 4.5-lb MP Bomb Mk 43 was used for low-altitude, hori­ zontal or dive bombing and on armoreddeck target boats. The Bombs Mk 5, A N Mk 23, and Mk 43 are used with the Mk 4type signal, which expels a large puff of smoke rearward through the bore of the bomb when detonated by action of the firing pin. They also are used with the Mk 5 type signal, which contains a fluorescein dye and is actuated by a water inertia load on the firing pin. When the Mk 5 type signal is installed, the firing-pin assembly is not used. Special containers are utilized by aircraft to carry and release these bombs. 11-1 N A V W E P S OP 2216 (V O L U M E 1) Figure 11-1.— 3-lb Miniature Practice Bomb A N -M k 23 Mod 1, Exterior View. Figure 11-2.— 3-lb Miniature Practice Bomb A N Mk 23 M od 1, Exploded View. 11-2 P R A C T IC E B O M B A SSE M B L IE S 2. Remove the cotter pin and the firingpin assembly from the nose of the bomb. CAUTION: Signals and bombs The firing-pin assembly should fit loosely are not to be unpacked in advance in the bomb and not bind when being re­ of requirements. If unpacked and moved. not used, return them to their 3. Check the bore through the center of original packings. the bomb; it must be clean, smooth, and not 1. Remove the bomb and the signal from damaged in any way. their packings. 4. Inspect the firing-pin assembly for Assembly W ith the M k 4 Type Signal SHROUD EXPLOSIVE SIGNAL FIRING-PIN ASSEMBLY BOMB BODY FLUORESCEIN DYE SIGNAL Figure 11-3.— 3-lb Miniature Practice Bomb A N -M k 23 Mod 1, Cutaway View and Detail Showing Signal Mk 5 Mod 0 Installed. 11-3 N A V W E P S OP 2216 (V O L U M E 1) damage. Be sure the firing-pin cup is not deformed and that the firing-pin point is below the lip of its cup. 5. Place the bomb in a vertical position, nose end up. 6. Check that the signal is not swollen or deformed in any way. The primer must be flush or slightly below the base of the car­ tridge. Do not use a signal cartridge that is deformed in any way. 7. Insert the signal into the bomb, primer end up, and let it fall gently into place; do not force it. The base flange of the signal cartridge must rest on the bomb bore shoulder. 8. Insert the firing-pin assembly carefully with the firing-pin end toward the signal. The assembly must drop into place under its own weight. CAUTION : Do not apply pressure to force the firing-pin assembly into the bomb. The assembly may col­ lapse and fire the signal. 9. Rotate the firing-pin assembly so that the two notches in the lip line up with the two pin holes in the bomb nose. Do not apply pressure to the firing pin during this operation. 10. Insert the cotter pin through the nose holes and the recesses in the firing-pin as­ sembly. 11. Spread the ends of the cotter pin with a screwdriver sufficiently to retain the pin 11-4 in the bomb. Do not bend the ends of the cotter pin at a right angle to the axis of the cotter pin or strike the ends to bend them into position. CAUTION: Be extremely careful when handling practice bombs loaded with signals. Jarring or dropping the bomb may detonate the signal. Do not, under any cir­ cumstances, point either end of the signal toward other personnel. Loaders must not place their bodies in line with the nose or tail ends of the bombs. Disassembly To disassemble the complete bomb, the previous steps should be carried out in re­ verse order and the components restored to their original condition. Assembly W ith the M k 5 Type Signal 1. Prepare the bomb in accordance with steps 1 through 6 of the assembly instruc­ tions for the Mk 4 type signal. 2. Insert the signal with the small end toward the tail of the bomb. 3. Secure the signal in the bomb by re­ placing the cotter pin. 4. Spread the ends of the cotter pin suffi­ ciently to lock it in place. 5. Retain the discarded firing-pin assem­ blies as spares or return them to the nearest supply point. P R A C T IC E BO M B A SSE M B L IE S 13-LB M IN IA T U R E P R A C T IC E B O M B M k 19 M ods 0 and 1 F ig u re 1 1 - 4 . — 13-lb M in ia tu re P ra ctice B o m b M k 1 9 M o d 1, Exterior V iew . Mark__________________________ M od ___________________________ General Arrangement__________ List of Drawings_______________ Length of Assembled Bomb (in.) Diameter (in.)_________________ Fin Span (in.)__________________ Weight: Wighout Signal (lb)_______ With Signal Mk 4 (lb)_____ With Signal Mk 5 (lb)_____ Signal___________ ______________ Firing Pin Assembly General Description The 13-lb MPB Mk 19 Mods 0 and 1, now obsolescent, is made of cast metal and has a bore through its transverse axis which houses a signal and firing-pin assembly. 19_______________ ___ . . . ___ 284480__________ ___ Sk 90553 ... .... 1 3.1____ 2.6_____________ ___ 3 .7 _____________ 19. 1. 300617. Sk 90842. 13.1. 2.6. 3.7. 13_______________ ___ 1 3.2____________ ___ 1 3.1____________ ___ Mk 4 Mods or Mk 5 Mod 0. Mk 1 Mod 0_________ 13. 13.2. 13.1. Mk 4 Mods or Mk 5 Mod 0. Mk 1 Mod 0. 0________ The body is cast lead-antimony. Four steel sheet-metal fins are cast integral with the bomb body. The firing-pin assembly consists of two shallow metal cups, separated by a spacer 11-5 N A V W E P S OP 2216 (V O L U M E 1) F ig u re 1 1 - 5 .— 1 3 -lb M in ia tu re P ra ctice B o m b M k 19 M o d 1, E x p lo d e d V ie w . which houses the firing pin. A straight steel pin through the nose of the bomb body and two recesses of the forward cup lock the firing-pin assembly and signal in place. The ends of the pin are peened over at assembly and, for shipment, tape is placed over the ends of the pin. The difference between mods 0 and 1 is the bore construction. The center bore of mod 0 is lined with a steel sleeve; mod 1 has no such lining. Painting and M arking The bomb body is painted black; identi­ fication data is stenciled on the body in white letters. Use The bomb is used for high altitude hori­ zontal bombing practice and mod 1 also may be used on armored-deck target boats. The bomb is used with Signal Mk 4 which expels a large puff of smoke rearward through the bore of the bomb when detonated by action of the firing pin. It is used also with Signal Mk 5, which contains a fluorescein dye and is actuated by a water inertia load on the firing pin. When the Signal Mk 5 is installed, the firing pin assembly is not used. 11-6 Assembly W ith Signal M k 4 CAUTION: Signals and bombs are not to be unpacked in advance of their requirements. If unpacked and not used, return them to their original packings. 1. Remove the bomb and signal from their respective packings. 2. Inspect the bomb for damaged seams, cracked weldments, and deformed areas. 3. Remove the tape covering the ends of the retaining pin. Remove the ,etaining pin and the firing pin assembly. 4. Inspect the firing-pin assembly for dam­ age. The firing-pin cups must not be de­ formed, and the point of the firing pin must be below the lip of its cup. 5. Inspect the bore through the center of the bomb. The bore must be clean, smooth, free of obstructions, and undamaged. 6. Inspect the signal to see that it is not swollen or deformed in any manner. The primer must be flush with or slightly below the base of the cartridge. Deformed sig­ nals must not be used. 7. With the firing pin assembly removed, stand the bomb vertically with its nose up. Insert the signal, primer end up, into the P R A C T IC E B O M B A SSE M B L IE S w F ig u re 1 1 - 6 .— 1 3 -lb M in ia tu re Practice B o m b M k 19 M o d 1, C u t a w a y V iew . N A V W E P S OP 2216 (V O L U M E 1) bomb and let it slide gently into place; do not force it. The base flange of the signal cartridge must rest on the shoulder of the bomb bore. 8. Carefully insert the firing-pin assembly into the bomb nose, with the point of the firing pin facing the signal. The firing-pin assembly must drop into place under its own weight. CAUTION: Do not apply pressure to force the firing-pin assembly into the bomb as the assembly may collapse and fire the signal. 9. Rotate the firing-pin assembly so that the two recesses in the lip of the forward cup are aligned with the two pin holes in the bomb nose. CAUTION: Do not exert any downward pressure on the firingpin assembly during this operation. 10. Insert the retaining pin through the holes in the bomb nose and through the two recesses in the cup of the firing-pin assem­ bly. 11-8 11. Peen lead over the ends of the retain­ ing pin or use two patches of adhesive tape to retain pin. Peen only sufficiently to re­ tain pin, to permit withdrawal of the pin. Disassembly To disassemble the complete bomb, the above steps should be carried out in reverse order and the components restored to their original condition. Assembly With Signal Mk 5 1. Prepare the bomb in accordance with steps 1 through 6 of the assembly instruc­ tions for the Signal Mk 4. 2. Insert the signal with the small end toward the tail of the bomb. 3. Secure the signal in the bomb by re­ placing the retaining pin. 4. Peen the ends of the retaining pin only sufficiently to retain the pin, or apply two patches of adhesive tape over the ends of the pin. 5. Retain the discarded firing-pin assem­ blies as spares or return them to the nearest supply point. PR A C T IC E B O M B A SSEM B LIES 5-LB P R A C T IC E B O M B M k 106 Mod 0 F ig u re 11—7. — 5 -lb Practice B o m b M k 1 0 6 M o d 0, Exte rio r V iew . Mark __________-__ ______ _______________ _____ _______ ______ Mod _______ _____ __________ ___ -______________ ______ _______ General Arrangement .. . __ _______________ -...... — ___ _____ List of Drawings ____ ________ ______ __ ________________ ______ Length of Assembled Bomb (in.) ___________ _____ .___ —...... Diameter (in.) .................... .. .............- ______ .______ _________ ____ . Fin Span (in.) ___________ _____ __ _________ ___________ ______ Weight of Assembled Bomb (lb) ............. ........ .... ......... ...... . Signal ______ ______________ __ ________________ ________ ________ Fuze (Impact) ________ _______ _____________ ___ _____________ _____ General Description The 5-lb Practice Bomb Mk 106 Mod 0 is a thin-cased, cylindrical bomb. It is com­ posed of a bomb body assembly, a Mk 4 Mod 3 Practice Bomb Signal, and a modified M173 Impact Fuze assembly. The bomb body is composed of an inner cylinder, an outer cylinder, and a fin assem­ bly. The inner cylinder is composed of two seamless steel tubes; one is the smaller in diameter and is partially inserted into the larger and welded in position. The inner 106 0 1985666 414455 18.75 3.875 3.875 4.56 Mk 4 Mod 3 M173 (modified) cylinder has internal threads on the forwarc end for receiving the M173 fuze assembly. It also forms the base for the outer cylinder and fin assembly. The outer cylinder is fabricated of sheet steel. It is suspended on the forward end of the inner cylinder by two sheet steel supports which are welded to both the inner and outer cylinders. A box-type fin assembly, consisting of four metal vanes welded together, is welded to the aft end of the inner cylinder. The bomb has two % inch indexing holes 11-9 N A V W E P S OP 2216 (V O L U M E 1) F ig u re 1 1 - 8 . — 5 -lb P ractice B o m b M k 10 6 M o d 0, E x p lo d e d V ie w . drilled into the body 2 inches forward of the center of gravity. These holes accommodate the Aero 8A Dispenser. Painting and M arking Identifying nomenclature is stenciled in white marking ink on the side of the body. Early issues of the bomb are coated ex­ ternally with black enamel. Present issues are coated with orange enamel and are en­ circled with one-fourth inch enamel or lac­ quer white stripes terminated by arrowheads which point to the two indexing holes. Use The 5-lb Practice Bomb Mk 106 Mod 0 is designated for low altitude drops. The modified M173 Impact Fuze assembly, con­ sisting of an adapter and the M173 Fuze less booster, is installed in the nose of the bomb. The fuze is fully armed by anemom­ eter-type vanes, after completing 220 feet of air travel. When the fuze is armed, impact forces from any direction will cause instantaneous detonation of the fuze which in turn fires the signal. The Practice Bomb Signal Mk 4 Mod 3 is seated in the inner cylinder of one bomb 11-10 F ig u re 1 1 - 9 . — 5 -lb Practice B o m b M k 10 6 M o d 0, C u t a w a y V iew . P R A C T IC E B O M B A SSEM B LIES body. Smoke produced from the detonated signal is discharged rearward through the inner cylinder. Assembly CAUTION: Signals, fuzes, and bombs are not to be unpacked in advance of requirements. If un­ packed and not used, return them to their original packings. 1. Remove the bomb assembly from con­ tainer. 2. Remove the signal from its packing and check that the signal is not swollen or deformed in any way. The primer must be flush or slightly below the base of the car­ tridge. Do not use a signal cartridge that is deformed in any way. 3. Place the bomb in a vertical position, nose end up. 4. Insert the signal into bomb, primer end up, and let it fall gently into place; do not force it. The base flange of the signal cartridge must rest on the bomb bore shoulder. 5. Remove the fuze and the adapter from their packings, and inspect the fuze to en­ sure that the fuze safety devices are in place. CAUTION: If a fuze is armed or otherwise unsafe to handle, the fuze shall be disposed of by authorized personnel. 6. Carefully screw fuze assembly into nose of bomb until seated. Install positioning clip. 7. Insert arming wire into off-center holes on the fuze anemometer vane hub and in­ stall Fahnestock clip. 8. Remove safety cotter pin from fuze. Disassembly To disassemble the complete bomb, the above steps should be carried out in reverse order and the components restored to their original condition. 11-11 N A V W E P S OP 2216 (V O L U M E 1) 25-LB P R A C T IC E B O M B M k 76 M ods 0,1, and 2 MOD 0 INDEXING HOLE MOD 2 F ig u re 1 1 - 1 0 . — 2 5 -lb P ra ctice B o m b M k 7 6 M o d s. Mod _ General Arrangement _ List of Drawings _ Length of Complete Bomb (with fuze) (in.)--------- . . . . Weight of Complete Bomb (lb). ____ . Signal . . ____ Fuze _ ______ Firing Pin 76 . . . ... 0_________________ 561638. . . . . Sk 165603___ 76 1_____ 1381205-. 165802 22.5______________ 27.155 2 3 .8 .. ______ Mk 4 Mods 0, 1,2, 3 Not Used. __ ___ Mk 1 Mod 0 ___ 25.10_______ . . . . Mk 4 Mod 3_____ . AN-M146E3____ Not Used . General Description The 25-lb PB Mk 76 Mod 0, now obsoles­ cent, has a tear-drop shaped, cast-metal body which is centrally bored. The tail-tube as­ sembly fits into the end of the bore. The conical afterbody covers the tail-tube assem­ bly and is threaded to the body. The two sections are staked together to prevent un­ 11-12 . . .. ___ . 76. 2. 1381208 165803. 22.5. 23.70. Mk 4 Mod 3. Not Used. Mk 1 Mod 0. screwing. The fin assembly is welded to the tail tube. Firing-Pin Assembly Mk 1 Mod 0 and the signal are assembled into the bore of the body and secured in place by a safety cotter pin. In the Mod 0 a single lug is positioned just forward of the center of gravity of the bomb. Some bombs of early manufacture P R A C T IC E B O M B A SSEM B L IES have a suspension lug with a small opening which precludes use of the bomb on Shackle Mk 8 All Mods or Aero 14 and 15 series racks. Later manufacture provided lugs with a larger opening that permits use on this type shackle or rack. Activities may re­ place the older type lugs with lugs having the larger opening (ASRS 307140-A). The threads in the bomb body should be cleaned after the smaller lug is removed. Glycerinelitharge cement should be applied to the threads to hold the newer type lug in posi­ tion. The Mod 1 is designed for air-burst fir­ ing only. The Time Fuze AN-M146E3 is used to fire the Signal Mk 4 Mod 3 which is seated in the bore of the body section. A setscrew (AN-565-D-1032 H5) is threaded into the nose of the bomb to retain the fuze and signal. Smoke produced from the det­ onated signal is discharged rearward through the tube of the fin assembly. CAUTION: Tests have shown that the fuze will fragment the bomb body producing a maximum frag­ ment weight of 254 grams and a maximum fragment velocity of 98 feet per second. Proper precau­ tions should be taken to insure that any personnel who may be scoring drops of this bomb are beyond the maximum range of the burst. In the Mod 1 a single suspension lug is threaded into the bomb body just forward of the center of gravity and cemented in place. Two %-inch indexing holes are drilled into the body to assist in the proper positioning of the bomb in the Aero 8A Practice Bomb Container. The Mod 2 is similar in appearance and functioning to the Mod 0 except that two % inch indexing holes are drilled into the body at the center of gravity to assist in the proper positioning of the bomb in the Aero 8A Practice Bomb Container. Painting and M arking Early issues of the bombs are painted with black enamel and identification data is stenciled in white letters on the body. The Mods 1 and 2 have a f4-inch white stripe painted around the body over the index holes. The purpose of the stripe is to assist ordnance men in properly positioning the bomb in the Aero 8A PB container. Functioning The firing-pin assembly fires the signal in the Mod 0 and the Mod 2. The time fuze fires the signal in the Mod 1. Smoke from the signal is discharged rearward through the central tube. Assembly CAUTION: Signals, fuzes, and bombs are not to be unpacked in advance of requirements. If un­ packed and not used, return them to their original packings. CAUTION: Signals must not be swollen or deformed in any manner. The primer must be flush or slightly below the base of the cartridge. Signal cartridges that are deformed in any way shall not be used. To assemble the Mod 0 or Mod 2, proceed as follows: 1. Remove the bomb and the signal from their packings. 2. Remove the cotter pin and firing-pin assembly from the nose of the bomb. CAUTION: The firing-pin assem­ bly should fit loosely in the bomb and not bind when dropped into position. Inspect firing-pin assem­ bly for damage. Be sure firing-pin cup is not deformed and that the firing-pin point is below the lip of the cup. Check the bore through the center of the bomb; it must be clean, smooth, and not damaged in any way. 3. With the firing-pin assembly removed, place the bomb in a vertical position, nose end up. 4. Insert the signal into the bomb, primer end up, and let it slide gently into place; do not force it. The base flange of the signal 11-13 N A V W E P S OP 2216 (V O L U M E 1) cartridge must rest on the bomb bore shoulder. 5. Insert the firing-pin assembly care­ fully with the firing-pin end toward the signal. CAUTION: The assembly must drop into place under its own weight. Do not apply pressure to force the firing-pin assembly into the bomb because the assembly may deform and fire the signal. 6. Rotate the firing-pin assembly so that the two U-shaped notches in the lip line up with the two pin holes in the bomb nose. Do not apply pressure to the firing pin during this operation. 7. Insert the cotter pin through the nose holes and the recesses in the firing-pin as­ sembly. 8. Spread the ends of the cotter pin just enough to retain it in place. CAUTION: Do not bend the ends of the cotter pin at a right angle to the axis of the cotter pin, or strike the ends to bend the cotter pin into position. To assemble the Mod 1 proceed as follows. 1. Remove the bomb assembly from its crate. 2. Verify that the setscrew is backed off sufficiently to permit entrance of fuze. 3. Place bomb in vertical position, nose end up. 4. Remove the signal from packing and insert the signal into the bomb, primer end up, and let it gently slide into place. Do not use force. The base flange of the sig­ nal must rest on the bomb bore shoulder (about 1.0 inch from the nose of the bomb). 5. Remove fuze from packing and inspect it to insure that the safety block and arming pin are in proper position, fuze threads are clean, and there is no evidence of corrosion or damage. 6. Hold the safety block in place and re­ move the striker stop. Examine for clear­ ance between striker and safety block. n -i4 Shake fuze to determine if safety block will fall out. 7. Replace striker stop. CAUTION: If the striker snaps down tightly against the safety block when the striker stop is with­ drawn, or if the safety block falls out when the fuze is shaken, the fuze shall be disposed of by au­ thorized personnel. 8. Loosen time-setting thumbscrew, and turn head until desired time is indicated by index mark on fuze body. Tighten thumb­ screw to lock time setting. 9. Carefully screw the fuze into the nose of the bomb until seated, then back it off a portion of one turn until the arming pin is in line with the suspension lug. 10. Tighten the setscrew to lock fuze in place. CAUTION: Be extremely careful when handling practice bombs loaded with signals. Jarring or dropping the bomb may detonate the signal. Do not, under any cir­ cumstances, point either end of the signal toward other personnel. Loaders must not place their bodies in line with the nose or tail ends of the bombs. 11. For bombs individually suspended from bomb racks by their suspension lugs, pass an arming wire AN-M6A2 or Mk 1 Mod 0 through the suspension lug, outer holes in the arming pin bracket, arming pin, outer eyelets of wire guide, and vane tab. 12. Install a Fahnestock clip on the arm­ ing wire flush against the vane tab. Cut off the excess arming wire two or three inches in front of the vane tab. 13. Remove striker stop, safety pin, and the seal wire. Check again for clearance between striker and the safety block as de­ scribed in step 6. If the safety block should fall out, replace it, secure it with tape, re­ move the fuze from the bomb, and set it aside for destruction. 14. When used in Aero 8A Containers the P R A C T IC E B O M B A SSEM B L IES arming wire is secured to the forward sec­ tion of the container and passed through the fuze from fore to aft in reverse of step 11. Fahnestock clip is placed flush against the after edge of the arming pin bracket. the suspension lug to the tail arming sole­ noid to obtain a fair lead of the wire. Disassembly To disassemble a complete bomb, the above steps should be carried out in reverse order 15. When suspended from Mk 55 Bomb and the components restored to their origi­ nal condition. Racks, the arming wire should be led through 11-15 N A V W E P S OP 2216 (V O L U M E 1) 56-LB P R A C T IC E B O M B M k 89 M ods 0 and 1 F ig u re i 1— 1 7.— 5 6 -lb P ra ctice B o m b M k 8 9 M o d 0 , E x te rio r V ie w . Mark.. __________________________ M od____________________________ __ General Arrangement________________ List of Drawings______ _____ Length of Bomb (in.) Assembled with Firing Pin -------Assembled with Fuze.. ._ ___ Body Diameter, maximum (in.)_______ Fin Span (in.)_______ ______________ Distance between Suspension Lugs, center-to-center (in.)__________________ Weight of Bomb (lb) Assembled with Firing P in .. Assembled with Fuze AN-M146E3. Assembled with Fuze XB-125A___ Practice Bomb Signal. . Firing Pin_____________________ ___ Fuze*.......... . .................................... 89_____ 0_____ 1525310___ 413702 31.3. .... .... ____ ... ___ 89. 1. 1367164. 290694. 31 .3. 39 4 0 __ 6.6. 14.0 56.6 _ _______ . . . ___ ... _ _ Mk 4 Mod 3 __ . . . Mk 1 Mod 0 _____. .... 9 4.0. 6.6. 14.0. 56.6. 57 3. 57 0. Mk 4 Mod 3. Mk 1 Mod 0. XB-125A. * This fuze was designed specially for use with the Mk 89 Mod 1 bomb. However, as an interim measure the AN-M146E3 fuze may be used until the XB-125A fuze becomes available. General Description The 56-lb PB Mk 89 Mod 0 is a low-drag (sub-caliber) practice bomb, similar in 11-16 shape to the low-drag series of general pur­ pose bombs. The cast iron body is slender, with a long pointed nose. The conical type P R A C T IC E B O M B A SSE M B L IE S SUSPENSION LUG F ig u re 1 1 - 1 2 . — 5 6 -lb P ractice B o m b M k 8 9 M o d 0, E x p lo d e d V iew . fin assembly is of welded sheet metal or cast almag construction. The tail fins are canted 2 degrees to impart spin to the bomb for the purpose of obtaining repeated consistent trajectories. Practice Bomb Signal Mk 4 Mod 3 is in­ stalled in the forward end of the bomb. The smoke produced by the detonated signal is discharged out the rear of the tail fin. Practice Bomb Mk 89 Mod 0 is designed for impact firing. Firing Pin Mk 1 Mod 0 detonates the signal on land or water impact. Practice Bomb Mk 89 Mod 1 is designed for impact or air-burst firing. The signal is detonated by a firing pin or a fuze. A removable nose-bushing provides this dual capability. For impact firing, the bomb is assembled with the bushing installed, se­ cured by a setscrew. Firing Pin Mk 1 Mod 0 fits within the bushing and is held there by a cotter pin. For air-burst firing, the bomb is assembled without the bushing, cotter pin, firing pin. Instead, Fuze X B 125A is threaded into the nose of the bomb. The setscrew retains the fuze and signal. Both mods of Practice Bomb Mk 89 have three threaded holes equally spaced over a 14-inch span on the bomb body. These holes receive suspension lugs or shipping plugs. In some applications, suspension lugs (Mk 10 Mod 0) are installed in the two outer holes; in other applications, a suspension lug is installed in the center hole only. Ship­ ping plugs are installed in all three holes when the bomb is to be used in a dispenser. In the Mod 0, two %-inch holes are drilled into the body near the center of gravity; these holes assist in proper positioning of the bomb in the Aero 8A Practice Bomb Con­ tainer. In the Mod 1, an additional set of two %-inch holes are drilled 1.385 inches closer to the nose end. Two white arrows point to each of these four holes. The for­ ward set of the holes are used to facilitate positioning of bomb in the forward compart­ ment of the container when the bomb is as­ sembled with a fuze. Painting and M arking Identifying nomenclature is stenciled in white marking ink on the side of the body. The exterior surface of the early issues of the bomb are coated with black enamel. In the Mod 0, a Vi-inch white stripe is painted around the body over the indexing holes. In the Mod 1, two white arrows are painted at each of the indexing holes. Functioning The firing pin assembly or the fuze fires the signal. Smoke from the signal is dis­ charged rearward through the central tube. 11-17 N A V W E P S OP 2216 (V O L U M E 1) Assembly CAUTION: Signals and bombs shall not be unpacked in advance of requirements. If unpacked and not used, return them to their origi­ nal packings. CAUTION: Firing pin assemblies must fit loosely and not bind when dropped into position. Inspect fir­ ing pin assembly for damage. Be sure firing-pin cup is not deformed and that the firing-pin point is be­ low the lip of its cup. Check bore through center of bomb; bore must be clear. 2. Remove the cotter pin and firing pin assembly from the nose of bomb. 3. With the firing pin assembly removed, elevate the nose of bomb. Insert Practice Bomb Signal Mk 4 Mod 3, primer end up, and slide it gently into place. Do not use force. The base flange of the signal car­ tridge must rest on the bore shoulder (about li/t inches in from the nose of the bomb). CAUTION: Signals must not be swollen or deformed in any man­ ner. The primer must be flush or slightly below the base of the car­ tridge. Signal cartridges that are deformed in any way shall not be used. To assemble the Mod 0 or 1 for impact firing, proceed as follows. 4. Carefully insert firing pin assembly 1. Remove the bomb assembly and the with firing pin end toward the signal. signal assembly from their packings. Each bomb is shipped from the manufacturer CAUTION : Firing pin assembly with the firing pin assembly installed and must slide into place under its own with a retaining cotter pin through the nose weight. Do not apply pressure to end. force the firing pin assembly into Figure 11—13.- 56-lb Practice Bomb Mk 89 Mod 1, Exploded View. 11-18 P R A C T IC E B O M B A SSEM B LIES Figure 11-14.- 56-lb Practice Bomb Mk 89 M od 0, Cutaway View. 11-19 N A V W E P S OP 2216 (V O L U M E 1) the bomb because the assembly may deform and fire the signal. 5. Rotate the firing pin assembly so that the two U-shaped notches in the lip of the forward cup line up with the pin holes in the bomb nose. Do not apply pressure to the firing pin during this operation. 6. Insert the cotter pin through the pin holes in the nose, passing through the notches in the firing pin assembly. Spread the ends of the cotter pin just enough to retain it in place. CAUTION: Do not bend the ends of the cotter pin at right angles to the cotter pin axis, or strike the ends to bend them in position. To assemble the Mod 1 for air-burst fir­ ing, proceed as follows. 1. Remove the bomb assembly from its crate. 2. Remove the cotter pin and firing pin assembly from the bomb nose. 3. Back off the setscrew and remove the nose bushing. 4. Place the bomb in a vertical position, nose end up. 5. Remove the signal from its packing and insert the signal into the bomb, primer end-up, and let it gently slide into place. Do not use force. The base flange of the signal must rest on the bomb bore shoulder (about 1.25 inch from the nose of the bom b). 11-20 6. Remove the fuze from its packing and inspect it to insure that the fuze safety de­ vices are in place. CAUTION: If the fuze is armed or otherwise unsafe to handle, it shall be disposed of by authorized personnel. 7. Carefully screw the fuze into the nose of the bomb until seated, then back it off a portion of one turn until the arming pin is in line with the suspension lug. 8. Tighten the setscrew to lock the fuze in place. 9. Install the arming wire and Fahnestock clip. CAUTION: Be extremely careful when handling practice bombs loaded with signals. Jarring or dropping the bomb may detonate the signal. Do not, under any cir­ cumstances, point either end of the signal toward other personnel. Loaders must not place their bodies in line with the nose or tail ends of the bombs. Disassembly To disassemble a complete bomb, the steps just listed should be carried out in re­ verse order and the components restored to their original condition. P R A C T IC E B O M B A SSE M B L IE S F ig u re 1 1 - 1 5 .— 1 0 0 -lb P ra ctice B o m b M k 15 M o d s . 15 ________ ______ Mark 1 5 _____ Mod _ ___ . 2 . .. _____ .. . . . 3 __________ . ______ General Arrangement _ 2 0 4 2 7 6 .. _ 439738. List of Drawings Sk 1 0 9 5 3 6 ____ Sk 5 8 1 5 2 _________ Length of Assembled Bomb (in.). 4 1 .2 ___ 4 1 .2 .. ____ Diamter (in.)_ 8 . 0 ____ ___________ 8 .0 . ... ... Fin Span (in.)_______ 1 1 .2 4 .. 11 .2 4 . Weight of Assembled Bomb (lb): Loaded with Wet 100. ____________ Sand _ _ 1 0 0 .. ____ ____ Loaded with Water__ __ ____ 5 6 _____________________ 6 7 _______________ 15. 4. 516342. 261462. 4 1 .5 . 8 .0 . 1 1 .2 4 . 9 7 .0 . 60. 11-21 N A V W E P S OP 2216 (V O L U M E 1) Wet Sand Filler (lb)__ Water Filler (lb).. . . . Water Filler (gal)____ Signal. ____ 76 .... 39_______ 4.6 None__ . . _ 77.4. . ________ 40 4 .7 _______ Mk 7 Mod 0 Fuze__ . ... Firing-Pin Assembly__ Arming-Wire Assembly None___________ None. . . . . . . . . Mk 1 or AN-M6A2 Mk 247 Mod 0 None__________ __ Mk 1 or AN-M6A2 76.0. 39. 4.6. Mk 4 Mods 0, 1, 3,4. None. Mk 1 Mod 0. No Arming Wire. 100-LB P R A C T IC E B O M B M k 15 M od 2 General Description The 100-lb PB Mk 15 Mod 2 is identical to the Mod 3 except that it is not adapted for the use of a fuze and signal. It is filled with water or a mixture of sand and water for spotting purposes. For training purposes, a small washer may be soldered to the nose of the bomb to simulate a fuze. The end of an arming wire which is normally inserted in the fuze of service-type bombs is then secured to the washer. For ARMED releases, the washer is torn free of the bomb by the arming w ire; for SAFE releases, the arming wire remains secured to the washer. When used against armored-deck target boats, it is filled with water and released from an altitude of less than 7000 feet. 100-LB P R A C T IC E BO M B M k 15 M od 3 ARMING WIRE ASSEMBLY FAHNESTOCK CLIPS W ING NUTS & SUSPENSION BANOS . --------- -LOCKWASHERS BODY ^ H E X NUTS CAP SCREWS Figu re 11-16.— 1 0 0 -lb P ra ctice B o m b Mk 15 M o d 3, E x p lo d e d V iew . General Description The 100-lb PB Mk 15 Mod 3 has a lightcased, cylindrical body with a threaded fill­ ing hole in its rounded nose. A box-type 11-22 fin assembly, consisting of four metal vanes attached to a cone, is welded to the after end of the body. A flat nose attachment that prevents ricochet of the bomb at en- P R A C T IC E B O M B A SSE M B L IE S FILLER CAP F ig u re 11— 17.— 1 0 0 -lb P ra ctice B o m b M k 15 M o d 4, E x p lo d e d V iew . trance angles as low as 90 degress is used during antisubmarine practice. The attach­ ment is secured in place by a cap which threads onto the filling hole. The bomb has two metal suspension band assemblies, each consisting of a circular clamp, a suspension lug, and two cap screws for tightening the band to the bomb. The band may be adjusted for double suspension of the bomb by orienting to suit the rack or shackle to which the bomb is to be attached. For single suspension, one band is installed at the approximate center of gravity of the bomb. The bomb is filled either with water or with a mixture of water and sand. Anti­ freeze must be added under freezing condi­ tions to prevent bursting of the bomb case caused by freezing of the filler. Painting and M arking The bomb is painted black; identification data is stenciled on the body in white letters. Use It is used with Practice Bomb Signal Mk 7 Mod 0 and inert Fuze Mk 247 Mod 0, which are secured to the after end of the bomb. Functioning Upon impact of the bomb, the firing pin in the fuze detonates a blank .38 caliber cartridge in the signal which, in turn, ex­ plodes the signal. The explosion of the sig­ nal produces a flash and a large puff of smoke, permitting observation of bombing accuracy. Assembly CAUTION: Signals, fuzes, and bombs are not to be unpacked in advance of requirements. If un­ packed and not used, return them to their original packings. 1. Remove the bomb assembly from its crate. 2. Inspect for damaged seams, cracked weldments, and deformed areas which might cause leaks, weaken the suspension bands, or prevent serviceable use. 3. Stand the bomb vertically with its nose up and remove the filler cap and gasket. Replace the gasket if damaged. 4. Fill the bomb with the required amount of water or wet sand. When necessary, add antifreeze to the filler. In order to fill the bomb with a maximum quantity of wet sand 11-23 N A V W E P S OP 2216 (V O L U M E 1) mixture, approximately one quarter of the bomb should be filled with dry sand. Satu­ rate the sand with water, followed by more sand and more water in successive steps until the bomb is filled. If possible, check the weight of the bomb on a scale to ascer­ tain when the correct weight has been ob­ tained. 5. Reinstall the gasket and filler cap, threading on hand tight. 6. Adjust for 14-inch suspension by loosening and moving the suspension bands. For single suspension, take off one band and move the other to the approximate center of gravity of the bomb. Aline the bands so that the tail fins will clear the aircraft CLIP LOCKING PLATE GUIDE ARMING WIRE ASSEMBLY SIGNAL -SAND FILLER BODY SUSPENSION BAND Figure 11-18.— 100-lb Practice Bomb Mk 15 M od 3, Cutaway View. 11-24 PR A C T IC E B O M B A SSEM B LIES structure and ground when the bomb is installed. Secure the bands in place by tightening the band securing screws. 7. Remove the wing nuts, lockwashers, and locking plate from the two studs in the after end of the bomb. 8. Open the box containing Signal Mk 7, Fuze Mk 247, the fuze arming-vane assem­ bly, the cotter pin, and the blank .38 caliber cartridge which is sealed in an envelope in each carton. If the containers are punc­ tured, split, or badly damaged, or if the seals are broken, the fuze and signal as­ sembly is to be considered unserviceable. This does not apply to fuze and signal as­ semblies repacked in the field and sealed with adhesive tape for temporary protection. Such assemblies must be examined carefully for serviceability. 9. Place the arming-vane assembly on the arming screw of the fuze and adjust it so that the holes in the vane hub aline with those in the arming screw. Insert the cotter pin through the holes and secure it by spread­ ing its two ends. 10. Loosen the locknuts on the fuze and unscrew the fuze from the signal. Insert the blank .38 caliber cartridge into the chamber of the signal, primer end facing aft. Thread the fuze into the signal and secure it by tightening the locknuts. 11. Insert the fuzed signal into the open­ ing in the after end of the bomb, seating it firmly in the guide sleeve attached to the bomb body. Adjust the fuze for correct position to permit a straight pull of the arm­ ing wire. 12. Place the locking plate of the bomb around the fuze and over the signal, secur­ ing it handtight with the wing nuts and lockwashers. 13. Thread the arming wire through the rear suspension lug of the bomb, then through the arming-wire guide and vane assembly of the fuze. The arming wire must be free of kinks and burrs, and should ex­ tend 2 to 3 inches beyond the flange of the fuze. 14. For external suspension of the bomb, place one safety (Fahnestock) clip on the free end of the arming wire, adjacent to the arming vane of the fuze. If the bomb is to be installed in a bomb bay, do not install a safety clip on the arming wire. 15. Install the bomb in accordance with the type of rack or shackle in use, and lock it securely in place. CAUTION: Do not remove the safety cotter pin from the body of fuze before the bomb is secured in the aircraft and the arming wire is completely installed. Disassembly To disassemble the complete bomb, the steps should be carried out in reverse order and the components restored to their ori­ ginal condition. 11-25 N A V W E P S OP 2216 (V O L U M E 1) 100-LB P R A C T IC E B O M B M k 15 M od 4 FLASH TUBE BODY -SAND FILLER SIGNAL CAP FIRING PIN ASSEMBLY F ig u re 1 1 - 1 9 .— 1 0 0 -lb P ractice B o m b M k 15 M o d 4, C u t a w a y V iew . General Description The 100-lb PB Mk 15 Mod 4 is a lightcased, cylindrical bomb with a round nose and an integral box-type fin and cone. A 11-26 flash tube, extending throughout its trans­ verse axis, houses a pyrotechnic signal and firing-pin assembly. Two suspension lugs are welded to the bomb body 14 inches P R A C T IC E B O M B A SSEM B LIES apart. A filling hole is located off-center on the bomb nose and is sealed by a filler cap similar to those used on automobile gas tanks. The firing-pin assembly consists of two shallow metal cups, separated by a spacer which houses the firing pin. A cotter pin through the nose end of the flash tube and two recesses in the lip of the forward cup locks the firing-pin assembly and signal in place. The bomb is filled either with water or with a mixture of water and sand. Anti­ freeze must be added under freezing condi­ tions to prevent bursting of the bomb case caused by freezing of the filler. Painting and M arking The Mk 15 Mod 4 bomb is painted black; identification data is stenciled on the cylin­ drical section of the bomb in white letters. Use It is used with Signal Mk 4. Functioning The signal is firing pin upon explosion of the a large puff of tion of bombing detonated by action of the impact of the bomb. The signal produces a flash and smoke, permitting observa­ accuracy. Assembly CAUTION: Signals and bombs are not to be unpacked in advance of requirements. If unpacked and not used return them to their ori­ ginal packings.1 4 3 2 1. Remove the bomb and the signal from their respective packings. 2. Inspect the bomb for damaged seams, cracked weldments, and deformed areas which might cause leaks in the bomb body or weaken the suspension lugs, or their at­ tachment to the bomb case. 3. Stand the bomb vertically with its nose up. Remove the filler cap and gasket and replace the gasket if damaged. 4. Fill the bomb with the required amount of water or wet sand exactly as for the Mod 3. 5. Replace the filler cap and gasket; be sure the gasket is properly installed. Twist the filler cap on with a spanner wrench until it is locked securely in place. 6. Remove the cotter pin and firing-pin assembly from the nose end of the flash tube. 7. Inspect the firing-pin assembly for damage. The firing-pin cups must not be deformed, and the point of the firing pin must be below the lip of its cup. 8. Inspect the bore of the flash tube through the center of the bomb. The bore must be clean, smooth, free of obstructions, and undamaged. 9. Inspect the signal to see that it is not swollen or deformed in any manner. The primer must be flush with or slightly below the base of the cartridge. Deformed signals must not be used. 10. Insert the signal, primer end up, into the bomb and let it slide gently into place; do not force it. The base flange of the signal cartridge must rest on the shoulder of the flash tube, approximately l l/g inches from the nose of the tube. 11. Carefully insert the firing-pin assem­ bly into the flash tube, with the point of the firing pin facing toward the signal. The firing-pin assembly must drop into place under its own weight. CAUTION: Do not apply pressure to force the firing-pin assembly into the bomb as the assembly may col­ lapse and fire the signal. 12. Rotate the firing-pin assembly so that the two recesses in the lip of the forward cup are alined with the two pin holes in the nose of the flash tube. CAUTION: Do not exert any downward pressure on the firingpin assembly during this operation. 13. Insert the cotter pin through the holes in the nose of the flash tube and the two recesses in the cup of the firing-pin assembly. 14. Spread the ends of the cotter pin suffi­ 11-27 N A V W E P S OP 2216 (V O L U M E 1) ciently to lock the pin in the bomb. Do not bend the ends at right angles to the axis of the cotter pin or strike the ends to bend them into position. CAUTION: Be extremely careful when handling practice bombs loaded with signals. Jarring or dropping the bomb may detonate the signal. Do not, under any cir­ cumstances, point either end of the 11-28 signal toward other personnel. Loaders must not place their bodies in line with the nose or tail ends of the bombs. Disassembly To disassemble the complete bomb, these steps should be carried out in reverse order and the components restored to their ori­ ginal condition. P R A C T IC E B O M B A SSE M B L IE S 250-LB P R A C T IC E B O M B M k 86 M od 0 and 1 F ig u re 1 1 - 2 0 . — 2 5 0 - lb P ra ctice B o m b M k 8 6 M o d 0, Exterior V iew . Mark---------------------- --------------------------Mod_________________________________ General Arrangement____ ____________ List of Drawings ^ _________ _____ Length of Assembled Bomb (in.) __ Body Diameter, maximum (in.)________ Fin Span (in.)________________________ Distance between Suspension Lugs center-to-center (in.)___________________ Weight of Assembled Bomb (lb): Empty Assembled Bomb.. ______ Loaded with Wet Sand___ ______ Loaded with Water___ _ ____ Practice Bomb Signal __ Firing Pin________________ ______ General Description The 250-lb PB Mk 86 Mod 0 is a low-drag bomb of the same size and shape as the Mk 81 low-drag general purpose bombs. It has a streamlined nose and a conically tapered aft end. One filler hole is located on the side, aft of the cylindrical section. Four fin blades perpendicular to each other are lo­ cated forward of the rear end of the bomb. The 250-lb PB Mk 86 Mod 0 is of thincase construction with internal reinforce­ 86. 0______ _____ 158331716579776.0_____ ___ 9 .0 _____________ 12.6. . . ... 86. 1. 2116448. 418759. 76.0. 9.0. 12.6. 14.0. 14.0. . 65.4_____________ . . . 217--. 141 Mk 4 Mod 3_____ Mk 1 Mod 0_____ _ 65.4. 216.5. 141. Mk 4 Mod 3. Mk 1 Mod 0. ment for the sway brace and ejection areas. To provide rigidity, bulkheads and channel reinforcements are used on the inside of the bomb shell. Practice Bomb Signal Mk 4 Mod 3 is used with 250-lb PB Mk 86 Mod 0. A blast tube extends from the nose to the aft end of the bomb and allows for exit of the signal smoke when fired. The firing pin assembly and signal are held in place inside the blast tube by a retaining cotter pin. 11-29 N A V W E P S OP 2216 (V O L U M E 1) SUSPENSION LUG HOISTING LUG SUSPENSION LUG FILLER CAP-' FILLER CAP C LAM P' LOCK W ASH ER' FIRING PIN ASSEMBLY BOMB BODY SC REW ' F ig u re 1 1 - 2 1 . — 2 5 0 -lb P ractice B o m b M k 8 6 M o d 0, E x p l o d e d View . Double suspension lugs are spaced 14 inches apart on the body of the PB Mk 86 Mod 0. The lugs are of the screw-in type used with the low-drag general purpose bomb family. A screw-in type of hoisting lug is provided at the center of gravity of the bomb. This bomb is filled with water or wet sand. Antifreeze is added to the filler dur­ ing freezing conditions. The Practice Bomb Mk 86 Mod 1 is similar to the Mk 86 Mod 0. The major differences between the two mods are that the Mod 1 uses an integrally welded suspension lug and a slightly different internal design. The as­ sembly and disassembly procedures for both mods are identical. There is only a small quantity of the PB Mk 86 Mod 1 in supply. Painting and M arking On bombs of recent issue, the identifica­ tion data is stenciled in white letters on the orange body. On bombs of older issue, the identification data is stenciled in white letters on the black body. Functioning When the bomb strikes its target, the firing pin is forced into the signal primer. The smoke produced from the detonated sig­ nal is discharged out of the end of the bomb through the blast tube. 11-30 Assembly CAUTION: Signals and bomb shall not be unpacked in advance of requirements. If unpacked and not used, return them to their origi­ nal packings. 1. Remove bomb assembly from crate. CAUTION : Inspect for damage, such as cracked weldments, which might cause leaks in the bomb cas­ ing or damage to suspension lugs. 2. Remove safety wire from suspension lugs and hoisting lug. 3. Remove the filler cap from the filler hole by backing off the screws holding the two clamps in place until the clamps can be turned aside. Do not completely remove these screws in order to prevent possible loss of the screws or lockwashers. Inspect the gasket. Damaged gaskets should be re­ placed. 4. Fill with required amount of water or wet sand at loading base; during freezing conditions add antifreeze. Filling the bomb with wet sand can be facilitated by hoisting the tail so the filler will flow toward the nose. 5. Replace filler cap making sure the gasket and gasket seat are free of loose grains of sand. Turn the filler cap clamps P R A C T IC E B O M B A SSE M B L IE S / FIRING-PIN ASSEMBLY Figure 11-22.— 250-lb Practice Bomb Mk 86 M od 0, Cutaway View. 11-31 N A V W E P S OP 2216 (V O L U M E 1) into locking position and tighten the screws securely. 8. Carefully insert firing pin assembly with firing pin end toward the signal. CAUTION: Check to make sure the lockwashers are in place under the heads of the screws. CAUTION: Firing pin assembly must slide into place without fric­ tion. Do not apply pressure to force the firing pin assembly into the bomb because the assembly may collapse and fire the signal. 6. Remove cotter pin and firing pin as­ sembly from the nose of the bomb. CAUTION : Firing pin assembly must fit loosely and not bind when sliding into position. Inspect fir­ ing pin assembly for damage. Be sure firing pin cup is not deformed and that the firing pin point is below the lip of its cup. Check the blast tube. It must be clean and not damaged or blocked in any way. 7. With firing pin assembly removed from the bomb, insert Signal Mk 4 Mod 3, primer end pointing forward, and slide signal gently into place. Do not force into place. The base flange of the signal cartridge must rest on the blast tube shoulder (about lVb inches in from the front of the blast tube). CAUTION: Signals must not be swollen or deformed in any man­ ner. The primer must be flush or slightly below the base of the car­ tridge. Signal cartridges that are deformed in any way shall not be used. 11-32 9. Rotate the firing pin assembly so that the two notches in the lip of the forward cup line up with the cotter pin holes in the nose end of the bomb. Do not apply pressure to the firing pin during this operation. 10. Insert the cotter pin through the pin holes in the bomb body, passing through the notches in the firing pin assembly. Spread the ends of the cotter pin just enough to retain it in place. CAUTION: Do not bend the ends of the cotter pin at right angles to the cotter pin axis, or strike the ends to bend them into position. 11. Install bomb in accordance with type of rack in use and securely lock and sway brace in place. Disassembly To remove the signal and firing pin, carry out the steps for their assembly in reverse order and restore these components to their original condition. P R A C T IC E BO M B A SSEM B LIES 500-LB P R A C T IC E B O M B M k 65 M od 0 F ig u re 1 1 - 2 3 . — 5 0 0 -lb P ractice B o m b M k 6 5 M o d 0, Exterior View . Mark ........... .......... Mod - __ ___ ________ ___ ______ General Arrangement _________ List o f Drawings ..... .................... Fin Assembly Drawing No. ........ Length o f Assembled Bomb (in.) Diameter (in.) Fin Span (in.) .......................... Weight o f Assembled Bomb (lb) Loaded with Wet S a n d ............. Loaded with Water . Wet Sand Filler (lb) Water Filler (lb) Water Filler (gal) ............ . Signal ....... ........................................ Fuze ..... ........................................ Arming-Wire Assembly . 65 0 439700 Sk 109523 438267 56.61 14.0 18.94 443.2 248.8 395.0 200.6 20.0 Mk 6 Mod 0 Mk 247 Mod 0 Mk 1 or AN-M 6A2 11-33 N A V W E P S OP 2216 (V O L U M E 1) A R M IN G W IR E A S S E M B L Y F A H N E S T O C K C L IP S ^ H E X -H D B O L T S FUZE S IG N A L LO C K W A S H E R , S ig n a l b r a c k e t IOX F IN A S S E M B L Y B O M B BODY GASKET F IL L E R C A P F ig u re 1 1 - 2 4 . - K 5 0 0 - l b Practice B o m b M k 6 5 M o d 0, E x p lo d e d V iew . General Description The 500-lb PB Mk 65 Mod 0 has a lightcased, cylindrical body and is constructed of welded sheet steel sections. It has an ogival nose and a tapered aft end to which a box-type fin assembly is bolted. A threaded filling hole is located in the nose of the bomb and is sealed by a nose plug and gasket. The nose plug is wired to a small bracket welded to the nose. Two suspension lugs 14 inches apart are welded to the bomb body and seven threaded recesses are located on the periphery of the bomb at the approximate center of gravity. One or two hoisting lugs, screwed into these recesses, permit hoisting of the bomb by either one or two cables. The bomb is filled either with water or with a mixture of water and sand. Anti­ freeze must be added under freezing condi­ tions to prevent bursting of the bomb case caused by freezing of the filler. Painting and M arking The bomb is painted black; identification data is stenciled on the cylindrical section of the bomb in white letters. Use This bomb is authorized for all types of 11-34 service usage, including catapult and jetassisted takeoffs and arrested landings. It is used with the Mk 6 type signal and inert Fuze Mk 247 Mod 0. The signal is seated in a recess in the tail-end of the bomb body and is secured to the fin assembly by a clamp provided with the signal. This bomb should not be carried externally on jet aircraft. Functioning Upon impact of the bomb, the fuze firing pin initiates a blank .38-caliber cartridge which, in turn, explodes the signal to pro­ duce a flash and a large puff of gray smoke. " O ld " Series Practice Bombs No fuzes were used in the “ old” series practice bombs, and they contained no spot­ ting charge, being filled either with water or with wet sand. Assembly CAUTION: Signals and fuzes are not to be unpacked in advance of requirements. If unpacked and not used, return them to their original packings. 1. Remove the bomb body from storage P R A C T IC E B O M B A SSEM B LIES “ Old” Series Practice Bombs— Data i | ' T otal W eigh t B omb 500-lb Mk 5. ___ 500-lb Mk 11______ 500-lb Mk 21______ L ength 67t3 61 "8 61 "8 D ia m e te r C olor W ater- W e t -S and F illed F illed 16T0 Black. . 360.0 lb s ... 15T0 | Black______ 268.0 lb s ... 15 TO Black______ 273.0 lb s ... I and the fin assembly with its attachment from the shipping crate. Inspect each for damaged seams, cracked weldments, or de­ formed areas which might cause leaks, weaken the suspension lugs, or prevent serv­ iceable use. 2. Remove the shipping wire and nose plug. 3. Inspect the gasket and replace it if damaged. 4. Fill the bomb with the required amount of wet sand or water. When necessary, add a sufficient quantity of antifreeze to the filler. 5. In order to fill the bomb with a maxi­ mum quantity of wet sand mixture, fill approximately one quarter of it with dry sand. Saturate the sand with water, fol­ lowed by more sand and more water in suc­ cessive steps until the bomb is filled. If possible, check the bomb on a suitable scale to ascertain when the correct weight has been obtained. 6. Replace the gasket and nose plug, threading in hand tight. 7. Open the box containing the signal, the fuze, the fuze arming-vane assembly, the cot­ ter pin, and the blank .38 caliber cartridge which is sealed in an envelope in each carton. If the containers are punctured, split, or badly damaged, or if the seals are broken, the fuze and signal assembly is considered unserviceable. This does not apply to assem­ blies repacked in the field and sealed with adhesive tape for temporary protection; 500.0 lbs. 448.0 lbs. 489.0 lbs. these assemblies must be examined care­ fully for serviceability. 8. Place the arming-vane assembly on the arming screw of the fuze and adjust it so that the holes in the vane hub aline with the hole in the arming screw. Insert the cotter pin through the holes and secure it by spreading its ends. 9. Loosen the locknuts on the fuze and un­ screw the fuze from the signal. 10. Inspect the fin assembly for any cracks or deformation and discard it if cracked or badly deformed. All mating surfaces must be thoroughly cleaned prior to assembly. Fin assemblies with bent vanes may be re­ paired and used if the vanes can be straight­ ened easily. If straightened, inspect again for cracking. 11. Fasten the signal clamp to the fin sleeve by means of the clamp taps. To do this, it is necessary to squeeze the clamp ends together so that the slots in the tabs can be slipped under the rivets on the fin sleeve. Se­ cure the clamp to the fin assembly with the nut, bolt, and lockwasher provided. 12. Slip the fin assembly over tail end of the bomb. Aline the holes in the fin-assem­ bly base with the holes in the bomb base so that the tail fin will clear the aircraft struc­ ture and ground when the bomb is installed. 13. Use a wrench to secure the fin assem­ bly to the bomb body with bolts and lockwashers. 14. Slide the cylindrical section of the signal through the signal clamp with the 11-35 N A V W E P S OP 2216 (V O L U M E 1) S IG N A L BRACKET W E T -S A N D F IL L E R A R M IN G -W IR E ASSEM BLY S IG N A L " W E T -S A N D F IL L E R F ILLE R CAP Figure 11-25.— 500-lb Practice Bomb Mk 65 M od 0, Cutaway View. 11-36 P R A C T IC E B O M B A SSEM B L IES cartridge chamber of the signal facing aft. Rotate the signal until the cartridge chamber is alined with the suspension lugs, pressing the signal firmly in place so that its forward end seats snugly into the indentation in the bomb body. Insert a bolt through the holes in the clamp and tighten it until the signal is held securely in place. 15. Insert the blank .38-caliber cartridge into the chamber of the signal. Thread the fuze into the signal, seating it firmly. Ad­ just the fuze to permit a straight pull of the arming wire (when installed), and lock the fuze in position by tightening the fuze lock­ nuts. 16. Thread the arming wire through the rear suspension lug of the bomb, then through the arming-wire guide and vane as­ sembly of the fuze. The arming wire must be free of kinks and burrs, and should extend 2 to 3 inches beyond the flange of the fuze. 17. For external suspension of the bomb, place one safety (Fahnestock) clip on the free end of the arming wire adjacent to the arming vane of the fuze. If the bomb is to be installed in a bomb bay, do not install a safety clip on the arming wire. 18. Install the bomb in accordance with the type of rack or shackle in use, using hoisting lugs supplied for various hoisting conditions. CAUTION: Do not remove the safety cotter pin from the body of the fuze prior to securing the bomb in the aircraft and completely in­ stalling the arming wire. Disassembly To disassemble the complete round, the preceding steps should be carried out in reverse order and the components restored to their original condition. 11-37 N A V W E P S OP 2216 (V O L U M E 1) 500-LB P R A C T IC E B O M B M k 87 M od 0 F igu re 1 1 - 2 6 . — 5 0 0 -lb P ractice B o m b M k 8 7 M o d 0, Ex te rio r V iew . Mark ................... ......... ....... _................................ ......... ................................... Mod .......... ........... ................................................................................... General Arrangement ........... ................................................. ........... List of Drawings ______ ____ _____ ____ ______________ ____ Length of Assembled Bomb (in.) ______ ___ __ _____ Body Diameter, maximum (in.) .... ............................................. .................... Fin Span (in.) _______________ _______ __________ _ Distance between Suspension Lugs, center-to-center (in.) ..... ........... Weight of Assembled Bomb (lb) Empty Assembled Bomb ___ ___ ___ ______________ ___________ Loaded with W et Sand ............ .................................................................. Loaded with Water ...... ....... ......................................................................... Practice Bomb Signal _________________ ___ ___ ____ _____ _____ ____ Firing Pin ..... ................................... ......................................... ... 11-38 87 0 1695657 165798 90.89 10.75 15.06 14 98 333 221 Mk 4 Mod 3 Mk 1 Mod 0 P R A C T IC E B O M B A SSE M B L IE S General Description The 500-lb PB Mk 87 Mod 0 is a low-drag practice bomb, similar in size and shape to the Mk 82 general purpose bomb. It has a long pointed nose and a concially tapered aft end. One filler hole is located on the side, aft of the rear suspension lug. The four tail fins are canted IV2 degrees to impart spin to the bomb to insure good flight stability. The 500-lb PB Mk 87 Mod 0 is of thincase construction with internal reinforce­ ment for the sway brace and ejection areas. To provide rigidity, bulkheads and channel reinforcements are used on the inside of the bomb casing. Firing Pin Mk 1 Mod 0 and Practice Bomb Signal Mk 4 Mod 3 are installed in the for­ ward end of the bomb, and are secured by a cotter pin. The bomb is filled with 235 pounds of wet sand or 123 pounds of water. Two suspension lugs (Mk 6 Mod 0) are spaced 14 inches apart on the body. A hoist­ ing lug is located midway between the sus­ pension lugs. Painting and M arking Bombs of recent issue are painted orange, with identification markings in white. Bombs of older issue have white markings but the overall color is black. Functioning The firing pin assembly fires the signal. The detonated signal produces smoke which is discharged out the rear of the central tube. 11-39 N A V W E P S OP 2216 (V O L U M E 1) BOMB BODY HOIST LUG S U S P E N S IO N LU G FILLER CAP FILLER CAP CLAMP FIRING PIN SIGNAL Figure 11-28.— 500-lb Practice Bomb Mk 87 M od 0, Cutaway View. 11-40 PR A C T IC E BO M B A SSEM B LIES Assembly CAUTION: Signals and bomb shall not be unpacked in advance of requirements. If unpacked and not used, return them to their origi­ nal packings. 1. Remove the bomb assembly from the packing. CAUTION: Inspect for damage, such as cracked weldments, which might cause leaks in the bomb cas­ ing or damage to suspension lugs. 2. Remove filler cap by backing off the screws holding the two clamps in place until the clamps can be turned aside. Inspect the cap gasket and clamps for proper fit. Replace damaged gaskets. 3. Fill with the required amount of wet sand or water at the loading base. During freezing conditions add antifreeze. Filling the bomb with wet sand can be facilitated by hoisting the tail so the filler may flow toward the nose. 4. Replace filler cap after clearing chan­ nel and gasket seal of loose grains of sand. Turn the filler cap clamps into the locking position and tighten the screws securely. 5. Remove cotter pin and firing pin as­ sembly from the nose of the bomb. CAUTION: Firing pin assembly must fit loosely and not bind when sliding into position. Inspect firing pin assembly for damage. Be sure firing pin cup is not deformed and that the firing pin point is below the lip of its cup. Inspect the blast tube. It must be clean and not damaged or blocked in any way. 6. With firing pin assembly removed, in­ sert signal, primer end forward, and slide the signal gently into place. Do not force into place. The base flange of the signal cartridge must rest on the blast tube shoul­ der (about lVs inches in from the nose of the blast tube). CAUTION: Signal must not be swollen or deformed in any man­ ner, The primer must be flush or slightly below the base of the car­ tridge. Signal cartridges that are deformed in any way shall not be used. 7. Carefully insert firing pin assembly with firing pin end toward the signal. CAUTION: Firing pin assembly must slide into place under its own weight. Do not apply pressure to force the firing pin assembly into the bomb because the assembly may deform and fire the signal. 8. Rotate the firing pin assembly so that the two U-shaped notches in the lip of the forward cup line up with the pin holes in the nose of the blast tube. Do not apply pressure to the firing pin during this opera­ tion. 9. Insert the cotter pin through the pin holes in the bore, passing through the notches in the firing pin assembly. Spread the ends of the cotter pin just enough to re­ tain it in place. CAUTION: Do not bend the ends of the cotter pin at right angles to the cotter pin axis, or strike the ends to bend them into position. 10. Install bomb in accordance with type of bomb rack in use and securely lock in place. Disassembly To remove the signal and firing pin, carry out the steps for their assembly in reverse order and restore these components to their original condition. 11-41 N A V W E P S OP 2216 (V O L U M E 1) 1000-LB PR A C T IC E BO M B M k 66 M od 0 Mark .................... -.........------- -------Mod ............................... - ........ ....... General Arrangement .......... ....... List of Drawings _____ __ ______ Fin Assembly Drawing No. ... .... Length o f Assembled Bomb (in.) Diameter (in.) .... .............. ........... Fin Span (in.) _________ ___ ____ Weight o f Assembled Bomb (lb) Loaded with Wet Sand ......... . Loaded with Water ................... Wet Sand Filler (lb) ............. Water Filler (lb) ................ ......... Water Filler (gal) ............. .......... Signal .................... ...............- ..... Fuze _______ ____ ___ ____________ Arming-Wire Assembly .............. 66 0 439701 Sk 109521 438257 66.96 18.63 25.4 883.5 480.5 788.3 385.3 45.0 Mk 6 Mod 0 Mk 247 Mod 0 Mk 1 or AN-M 6A2 General Description Use The 1000-lb PB Mk 66 Mod 0 has a lightcased, cylindrical body and is constructed from welded sheet steel sections. It has an ogival nose and a tapered aft end, to which a box-type fin assembly is bolted. A threaded filling hole is located in the nose of the bomb and is sealed by a nose plug and gasket. The nose plug is wired to a small bracket welded to the nose. A second filler hole, located on the side of the bomb, is capped with a circular plate and gasket and is secured to the bomb with hex-head bolts. The bomb is authorized for all types of service usage, including catapult and jetassisted takeoffs and arrested landings. It is used with the Mk 6-type signal and inert Fuze Mk 247 Mod 0. The signal is seated in a recess in the tail end of the bomb body and is secured to the fin assembly by a clamp provided with the signal. Two suspension lugs 14 inches apart are welded to the bomb body and seven threaded recesses are located on the periphery of the bomb at the approximate center of gravity. One or two hoisting lugs, screwed into these recesses, permit hoisting of the bomb by either one or two cables. The bomb is filled either with water or with a mixture of water and sand. Anti­ freeze must be added under freezing con­ ditions to prevent bursting of the bomb case caused by freezing of the filler. Painting and M arking The bomb is painted black; identification data is stenciled on the cylindrical section of the bomb and the box section of the fin assembly in white letters. 11-42 Functioning Upon impact of the bomb, the fuze firing pin initiates a blank .38-caliber cartridge which, in turn, explodes the signal to produce a flash and a large puff of gray smoke. "O ld " Series Practice Bombs No fuzes were used in the “ old” series practice bombs and they contained no spot­ ting charge, being filled either with water or with wet sand. Filling holes were lo­ cated on the top of the bomb near the nose. Assembly CAUTION: Signals and fuzes are not to be unpacked in advance of requirements. If unpacked and not used, return them to their origi­ nal packings. 1. Remove the bomb body from stowage and the fin assembly with its attachments P R A C T IC E B O M B A SSEM B LIES “ Old” Series Practice Bombs— Data T o tal W e ig h t B omb L ength D ia m e te r C olor W a t e r -F illed 1000-lb Mk 7____ . . 1000-lb Mk 22_____ ___ 80 "0 79 "0 19 ro 1970 Black _ _ 580.0 lbsBlack__ 573.0 lbs___________ W et -S an d F illed 1000.0 lbs. 1013.0 lbs. Figure 11-29.— 1000-lb Practice Bomb Mk 66 Mod 0, Exterior View. 11-43 N A V W E P S OP 2216 (V O L U M E 1) ARMING WIRE ASSEMBLY - FAHNESTOCK CLIF>S LOCK WASHER SIGNAL BRACKET HOISTING LUG HEX-HD BOLTS LOCK WASHER BOX FIN ASSEMBLY BOMB BODY GASKET FILLER CAP F ig u re 1 1 - 3 0 .— 1 0 0 0 -lb Practice B o m b M k 6 6 M o d 0, E x p lo d e d V ie w . from the shipping crate. Inspect each for damaged seams, cracked weldments, or de­ formed areas which might cause leaks, weaken the suspension lugs, or prevent serviceable use. 2. Fill the bomb through the nose or side. If filling through the nose, stand the bomb on its tail end and remove the shipping wire, nose plug, and gasket. If filling through the side, place the bomb on its side with the filler hole on top. Remove the filler cap and gasket. 3. Inspect the gasket and replace if dam­ aged. 4. Fill the bomb with the required amount of wet sand or water. When necessary, add a sufficient quantity of antifreeze to the filler. 5. In order to fill the bomb with a maxi­ mum quantity of wet sand mixture, fill ap­ proximately one quarter of the bomb with dry sand. Saturate the sand with water, followed by more sand and more water in successive steps until the bomb is filled. If possible, check the bomb on a suitable scale to ascertain when the correct weight has been obtained. 6. Replace and secure the nose plug or 11-44 filler cap, making certain that the gasket is installed properly. 7. Open the box containing the signal, the fuze, the fuze arming-vane assembly, the cotter pin, and the blank .38-caliber car­ tridge which is sealed in an envelope in each carton. If the containers are punc­ tured, split, or badly damaged, or if the seals are broken, the fuze and signal assem­ bly is considered unserviceable. This does not apply to assemblies repacked in the field and sealed with adhesive tape for tem­ porary protection. These assemblies must be examined carefully for serviceability. 8. Place the arming-vane assembly on the arming screw of the fuze and adjust it so that the holes in the vane hub aline with the hole in the arming screw. Insert the cotter pin through the holes and secure it by spreading its ends. 9. Loosen the locknuts on the fuze and unscrew it from the signal. 10. Inspect the fin assembly for any cracks or deformation, and discard it if cracked or badly deformed. All mating sur­ faces must be thoroughly cleaned prior to assembly. Fin assemblies with bent vanes may be repaired and used if the vanes can be straightened easily. If straightened, in­ spect again for cracking. P R A C T IC E B O M B A SSEM B LIES 11. Fasten the signal clamp to the fin sleeve by means of the clamp tabs. To do this, it is necessary to squeeze the clamp ends together so that the slots in the tabs can be slipped under the rivets on the fin sleeve. Secure the clamp to the fin assem­ bly with the nut, bolt, and lockwasher pro­ vided. 12. Lay the bomb on its side and slip the fin assembly over its tail end. Aline the holes in the fin-assembly base with the holes in the bomb base so that the tail fin will clear the aircraft structure and ground when the bomb is installed. 13. Use a wrench to secure the fin assem­ bly to the bomb body with bolts and lockwashers. FUZE ARMING-W IRE ASSEMBLY SIGNAL W E T -S A N D FILLER Figure 11-31.— 1000-lb Practice Bomb Mk 66 Mod 0, Cutaway View. 11-45 N A V W E P S OP 2216 (V O L U M E 1) 14. Slide the cylindrical section of the signal through the signal clamp with the cartridge chamber of the signal facing aft. Rotate the signal until the cartridge cham­ ber is alined with the suspension lugs, press­ ing the signal firmly in place so that its for­ ward end seats snugly into the indentation in the bomb body. Insert a bolt through the holes in the clamp and tighten it until the signal is held securely in place. 15. Insert the blank .38-caliber cartridge into the chamber of the signal. Thread the fuze into the signal, seating it firmly. Ad­ just the fuze to permit a straight pull of the arming wire (when installed), and lock it in position by tightening the fuze lock­ nuts. 16. Thread the arming wire through the rear suspension lug of the bomb, then through the arming-wire guide and vane assembly of the fuze. The arming wire must be free of kinks and burrs and should extend 2 to 3 inches beyond the flange of the fuze. 17. For external suspension of the bomb, place one safety (Fahnestock) clip on the free end of the arming wire adjacent to the arming vane of the fuze. If the bomb 11-46 is to be installed in a bomb bay, do not in­ stall a safety clip on the arming wire. 18. Install the bomb in accordance with the type of rack or shackle in use, using hoisting lugs supplied for various hoisting conditions. CAUTION: Do not remove the safety cotter pin from the body of the fuze prior to securing the bomb in the aircraft and completely installing the arming wire. Disassembly To disassemble the complete round, the preceding steps should be carried out in reverse order and the components restored to their original condition. Conversion to Fire Bomb As an emergency measure in the past, the 1000-lb PB Mk 66 Mod 0 was converted to a fire bomb by loading with a gasoline gel and installing igniter-fuze combinations on the fin assembly. Development of the new series of fire bombs by the Navy now precludes the neces­ sity for conversion of the practice bombs. P R A C T IC E BO M B A SSE M B L IE S 1000-LB P R A C T IC E B O M B M k 88 Mod 0 F ig u re 1 1 - 3 2 .— 1 0 0 0 -lb P ractice B o m b M k 88 Mod 0, Exterior V iew . Mark ................................................ Mod ___ __ - ..................................... General Arrangement ............ List o f Drawings ..... ..................... Length of Assembled Bomb (in.) Diameter (in.) .............................. Fin Span (in.) ................................ Weight o f Assembled Bomb (lb) Loaded with Wet Sand .......... Loaded with Water ................. Wet Sand Filler (lb) ....... Water Filler (lb) ......................._... Water Filler (gal) ....... Signal .............................................. General Description The 1000-lb PB Mk 88 Mod 0 has a long, slender body and is constructed of thin sheet metal, with internal reinforcement for the sway brace and ejection areas. Internal bulkheads and channel reinforcements pro­ vide for rigidity of the casing. The bomb has a sharp nose and a tapered aft end to which four fin blades are attached. The 88 0 1290158 165799 119.8 14.0 19.6 783.13 458.13 640.0 315.0 37.7 Mk 4 Mods 0, 1, 2, 3, 4 blades are set perpendicular to the axis of the bomb, approximately 5.5 inches forward of the tail end, and are canted 2 degrees for added stability. Two filling holes are lo­ cated topside in the bomb body and are sealed with filler caps. A single hoisting lug is screwed into the body over the approximate center of gravity. Two suspension lugs, 14 inches apart and equidistant from the hoist- 11-47 N A V W E P S OP 2216 (V O L U M E 1) SUSPENSION LUG F ig u re 1 1 - 3 3 . — 1 0 0 0 -lb P ractice Bomb M k 8 8 M o d ing lug, are threaded into recesses in the bomb body. A blast tube, extending the length of the bomb, houses a pyrotechnic charge and firing-pin assembly. The bomb is filled either with water or with a mixture of water and sand. Anti­ freeze must be added under freezing condi­ tions to prevent bursting of the bomb case caused by freezing of the filler. Painting and M arking The entire bomb is painted black (old issue) or orange (new issue) ; identifica­ tion data is stenciled on the side in white letters. Use The 1000-lb PB Mk 88 Mod 0 is similar in size and shape to the 1000-Ib GP (low-drag) bombs of the Mk 83 series and is authorized for all types of service use. It is used with Firing-Pin Assembly Mk 1 Mod 0 and Sig­ nal Mk 4 Mod 3, both of which are seated in the forward end of the flash tube and locked in place by a cotter pin. Functioning Upon impact of the bomb, the firing pin initiates a blank .38-caliber cartridge which, in turn, explodes the signal to produce a flash and a large puff of smoke. Smoke 11-48 0, E x p l o d e d V iew . produced by the Mk 4 Mod 3 signal is visible from altitudes as high as 30,000 feet. Assembly CAUTION: Signals and bombs are not to be unpacked in advance of requirements. If unpacked and not used, return them to their orig­ inal container. 1. Remove the bomb assembly from its crate and inspect it for damaged seams, cracked weldments, or deformed areas which might cause leaks, weaken the suspension lugs, or otherwise prevent serviceable use. 2. Remove the two filler caps, using a suitable spanner wrench. 3. Inspect the filler-cap gaskets and re­ place if damaged. 4. Fill the bomb with the required amount of wet sand or water. When necessary, add a sufficient quantity of antifreeze to the filler. To facilitate filling, put in as much wet sand as possible when the bomb is on its side. Then close the forward filling hole, hoist the tail of the bomb, and finish filling through the rear hole. 5. In order to fill the bomb with a maxi­ mum quantity of wet-sand mixture, fill ap­ proximately one quarter of it with dry sand. Saturate the sand with water, followed by PR A C T IC E B O M B A SSE M B L IE S F ig u re 1 1 - 3 4 .— 1 0 0 0 -lb P ractice B o m b M k 8 8 M o d 0, C u t a w a y V ie w . more sand and more water in successive steps until the bomb is filled. If possible, check the bomb on a suitable scale to ascer­ tain when the correct weight has been ob­ tained. 6. Twist on the filler caps with a spanner wrench until they are securely locked in place. 7. Remove the cotter pin and firing-pin assembly from the nose of the bomb. 8. Inspect the firing-pin assembly for damage. The firing-pin cups must not be de­ formed and the point of the firing pin must be below the lip of its cup. 9. Inspect the bore of the blast tube. It 11-49 N A V W E P S OP 2216 (V O L U M E 1) must be clean and smooth, free of obstruc­ tions, and not damaged in any manner. 10. Remove the signal from its packing and inspect it for damage. The signal must not be swollen or deformed in any manner, and the primer must be flush with or slightly below the base of the cartridge. Deformed signals must not be used. 11. Insert the signal into the blast tube, primer end forward. Let the signal slide gently into place; do not force it. The base flange of the signal cartridge must rest on the shoulder of the blast tube about lVs inches from the nose of the tube. 12. Carefully insert the firing-pin assem­ bly into the blast tube, with the point of the firing pin facing toward the signal. The firing-pin assembly must slide into place under its own weight. CAUTION: Do not apply pressure to force the firing-pin assembly into the bomb as the assembly may collapse and fire the signal. 13. Rotate the firing-pin assembly so that the two recesses in the lip of the forward cup are alined with the two pin holes in the nose of the blast tube. CAUTION: 11-50 Do not exert any pressure on the firing-pin assembly during this operation. 14. Insert the cotter pin through the holes in the nose of the blast tube and the two recesses in the cup of the firing-pin assembly. 15. Spread the ends of the cotter pin suffi­ ciently to lock the pin in the bomb. Do not bend the ends at right angles to the axis of the cotter pin, or strike the ends to bend them into position. 16. Install the bomb in accordance with the type of rack in use and lock it securely in place. CAUTION: Be extremely careful when handling practice bombs loaded with signals. Jarring or dropping the bomb may detonate the signal. Do not, under any cir­ cumstances, point either end of the signal toward personnel. Loaders must not place their bodies in line with the nose or aft end of the blast tube. Disassembly To disassemble the complete bomb, the foregoing steps should be carried out in re­ verse order and the components restored to their original condition. P R A C T IC E B O M B A SSE M B L IE S 2000-LB P R A C T IC E B O M B M k 67 M od 0 F ig u r e 1 1 - 3 5 . — 2 0 0 0 - lb P ractice B o m b M k 6 7 M o d 0 , Ex te rio r V iew . Mark . ....... Mod ..... ...... .................................... General Arrangement ____ List o f Drawings ..... ............ ........ Fin Assembly Drawing No. Length of Assembled Bomb (in.) Diameter (in.) ................... .............. W eight o f Assembled Bomb (lb) Loaded with W et Sand . Loaded with Water . W et Sand Filler (lb) W ater Filler (lb) ............. ................ Water Filler (gal) .............. .......... Signal _________ __________________ Fuze ..... .............................................. Arming-W ire Assembly _________ 67 0 439703 Sk 109522 438265 90.3 23.0 1617.25 960.75 1473.05 816.55 97.0 Mk 6 Mod 0 Mk 247 Mod 0 Mk 1 or AN-M 6A2 11-51 N A V W E P S OP 2216 (V O L U M E 1) General Description The 2000-lb PB Mk 67 Mod 0 has a lightcased, cylindrical shaped body and is con­ structed of welded sheet steel sections. For added strength and rigidity, reinforcement strips are welded to the inside of the bomb casing. The bomb has an ogival nose and a tapered after end to which a box-type fin assembly is bolted. A threaded filling hole in the nose of the bomb is sealed by a nose plug and gasket. A second filling hole, lo­ cated on the side of the bomb, is capped with a circular plate and gasket and secured by bolts. Two suspension lugs, 30 inches apart, are welded to the body of the bomb 90 degrees from the center of the side filling hole. Two additional lugs, 14 inches apart, are welded to the opposite side of the body. Seven threaded recesses, located on the pe­ riphery of the bomb about the center of gravity, permit various hoisting conditions. One or two hoisting lugs, screwed into these recesses, enable hoisting of the bomb by either one or two cables. The bomb is filled with water or a mixture of water and sand. Antifreeze must be added under freezing conditions to prevent bursting of the case caused by freezing of the filler. Painting and M arking The complete bomb is painted black. Iden­ tification data is stenciled on the cylindrical section of the bomb and box section of the fin assembly in white letters. Use The bomb is authorized for all types of service use. It is used with Signal Mk 6 Mod 0 and inert Fuze Mk 247 Mod 0. The signal is seated in a recess in the tail end of the bomb body and is secured to the fin assembly by a clamp provided with the signal. This bomb should not be carried externally on jet aircraft. Functioning Upon impact of the bomb, the firing pin 11-52 in the fuze detonates a blank .38-caliber car­ tridge in the signal which, in turn, explodes the signal. The explosion of the signal produces a flash and a large puff of gray smoke. Assembly CAUTION: Signals and fuzes are not to be unpacked in advance of requirements. If unpacked and not used, return them to their original packings. 1. Remove the bomb body from stowage and the fin assembly, with its attachments, from the shipping crate. 2. Inspect the bomb body and fin assem­ bly for damaged seams, cracked weldments, or deformed areas that might cause leaks, weaken the suspension lugs, or prevent serv­ iceable use. 3. The bomb may be filled either when in a vertical position or on its side. If it is to be filled when vertical, stand it with either its nose or its tail end up and remove the plug and gasket. Replace the gasket if dam­ aged. 4. If the bomb is to be filled through the filler hole on the side, position it with the side filler hole on top. Remove the bolts, side filler plate, and gasket. Replace the gasket if damaged. 5. Fill the bomb with the required amount of wet sand or water. When necessary, add a sufficient quantity of antifreeze to the filler. In order to fill the bomb with a maximum quantity of wet sand mixture, fill approxi­ mately one quarter of it with dry sand. Saturate the sand with water, followed by more sand and more water in successive steps until the bomb is filled. If possible, check the bomb on a suitable scale to as­ certain when the correct weight has been obtained. 6. Replace and secure the plug or cover, making certain that the gasket is properly installed. P R A C T IC E B O M B A SSEM B L IES FAHNESTOCK CLIPS LOCK WASHERS ARMING WIRE ASSEMBLY. HEX HD BOLTS FUZE k SIGNAL SIGNAL BRACKET GASKET FIN ASSEMBLY BOMB BODY FILLER CAP F ig u re 1 1 - 3 6 . — 2 0 0 0 - lb P ractice B o m b M k 6 7 M o d 0, E x p lo d e d V iew . 7. Open the box containing the signal fuze, the fuze arming-vane assembly, the cotter pin, and the blank .38-caliber car­ tridge which is sealed in an envelope in each carton. If the containers are punctured, split, or badly damaged, or if the seals are broken, the fuze and signal assembly is con­ sidered unserviceable. This does not apply to assemblies repacked in the field and sealed with adhesive tape for temporary protec­ tion ; these assemblies must be examined carefully for serviceability. 8. Place the arming-vane assembly on the arming screw of the fuze and adjust it so that the holes in the vane hub aline with the hole in the arming screw. Insert the cotter pin through the holes and secure it by spreading its ends. 9. Loosen the locknuts on the fuze and unscrew the fuze from the signal. 10. Inspect the fin assembly for any cracks or deformation, and discard if cracked or badly deformed. All mating surfaces must be thoroughly cleaned pUor to assembly. Fin assemblies with bent v.nes may be re­ paired and used if the vanes can be straight­ ened easily. If straightened, inspect again for cracking. 11. Fasten the signal clamp to the fin sleeve by means of the clamp tabs. To do this, squeeze the clamp ends together so that the slots in the tabs can be slipped under the rivets on the fin sleeve. Secure the clamp to the fin assembly with the nut, bolt, and lockwasher provided. 12. Lay the bomb on its side and slip the fin assembly over its tail end. Aline the holes in the fin-assembly base with the holes in the bomb base so that the tail fin will clear the aircraft structure and ground when the bomb is installed. 13. Use a wrench to secure the fin assem­ bly to the bomb body with bolts and lockwashers. 14. Slide the cylindrical section of the signal through the signal clamp, with the cartridge chamber of the signal facing aft. Rotate the signal until the cartridge cham­ ber is alined with the suspension lugs, press­ ing the signal firmly in place so that its for­ ward end seats snugly into the indentation in the bomb body. Insert a bolt through the holes in the clamp and tighten it until the signal is held securely in place. 15. Insert the blank .38-caliber cartridge into the chamber of the signal. Thread the fuze into the signal, seating it firmly. Ad­ just the fuze to permit a straight pull of 11-53 N A V W E P S OP 2216 (V O L U M E 1) a r m i n g - w ir e SIGNAL -HOLE COVER BOMB BODY WET-SAND FILLER NOSE PLUG F ig u re 1 1 - 3 7 . — 2 0 0 0 -lb P ractice B o m b M k 6 7 M o d 0, C u t a w a y V iew . 11-54 P R A C T IC E B O M B A SSE M B L IE S the arming wire (when installed), and lock the fuze in position by tightening the fuze locknuts. 16. Thread the arming wire through the rear suspension lug of the bomb, then through the arming-wire guide and vane assembly of the fuze. The arming wire must be free of kinks and burrs, and should ex­ tend 2 to 3 inches beyond the flange of the fuze. 17. For external suspension of the bomb, place one safety (Fahnestock) clip on the free end of the arming wire adjacent to the arming vane of the fuze. If the bomb is to be installed in a bomb bay, do not install a safety clip on the arming wire. 18. Install the bomb in accordance with the type of rack or shackle in use, using hoisting lugs supplied for various hoisting conditions. CAUTION: Do not remove the safety cotter pin from the body of the fuze prior to securing the bomb in the aircraft and completely installing the arming wire. Disassembly To disassemble the complete round, the preceding steps should be carried out in reverse order and the components restored to their original condition. Conversion to Fire Bomb As an emergency measure in the past, the 2000-lb PB Mk 67 Mod 0 was converted to a fire bomb by loading with a gasoline gel and installing igniter-fuze combinations on the fin assembly. Development of the new series of fire bombs by the Navy now precludes the neces­ sity for conversion of the practice bombs. 11-55 N A V W E P S OP 2216 (V O L U M E 1) 2000-LB P R A C T IC E B O M B M k 104 M od 0 F igu re 11—3 8 . — 2 0 0 0 - lb P ra ctice Bomb M k 1 0 4 M o d 0, Exte rio r V iew . Mark __________________ ___________ _____ Mod ................. —.............................................. General Arrangement ............................. List of Drawings ______ ___ ______ ______ Length o f Assembled Bomb (in.) ... Diameter (in.) ......... ......................... Fin Span (in.) _____ ____________ _______ Weight of Assembled Bomb (lb) ............. Concrete and Steel Shot Filler (lb) .... ...... Signal ..... .......................... ....................... ...... Cable Assembly ....................................... . General Description The 2000-lb PB Mk 104 Mod 0 has a long, slender welded body and is composed of two sheet steel fore and aft conical sections and a heavy steel plate central cylindrical sec­ tion. The body is internally reinforced in the sway brace and ejection areas. Internal bulkheads and a solidified filler provide for rigidity of the casing. The bomb has a conical nose cap and a tapered aft end to which four fins (two folding) are attached. 11-56 ......... ........................................ ______ _____________________ .......... ................................. __ __ ____ _____ __ ______ __ ............... ....................... .......... ......................... ................ .......... ....................................... 104 0 1997659 499774 170.6 20.0 32.0 ....................... 2020 __________________ ______ _____ __________ __________ __________________ _____ _ 1234 Mk 4 Mod 3 CF-3104 Arrows on the bomb body and tail cone line up the tail cone to index position “ O” . The tail cone can be rotated from position “ O” and secured with two index screws at posi­ tion every 15 degrees from position “ O” and at positions 6 degrees 30 minutes from each 15-degree position. The index screws must be installed 180 degrees apart and staked in place. Of the four fins on the tail cone, two 180 degrees opposed are permanently fixed and the other two 180 degrees opposed are P R A C T IC E B O M B A SSE M B L IE S PULSE BREAKAWAY FITTING ASSEMBLY \ DOUBLE SUSPENSION LUGS F igu re 11—3 9 . — 2 0 0 0 -lb P ra ctice Bom b M k folded and latched until the bomb is re­ leased. There is a fin latch release of the folding fins by an explosive actuator at sepa­ ration of the bomb. The fixed fins have no angle of incidence whereas the folding fins have a lVa-degree cant, which provides a roll moment for spin stabilization in a clock­ wise direction as viewed from the aft end of the bomb. Two suspension lugs, 30 inches apart, are threaded into recesses in the bomb body. A blast tube, extending at a slight angle down and aft from the nose cap of the bomb to the lower rear of the aft cone weldment, houses a pyrotechnic charge and firing-pin assembly. The bomb is filled with a concrete and steel shot mixture which is cast in place by the manufacturer of the bomb. When the Mk 104 Mod 0 Practice Bomb is to be carried externally on aircraft fitted with the standard stub pullout connector sys­ tem, Cable Assembly CF-3104 is required to provide an electrical connection between the standard stub pylon and the bomb pulse plug. Cable Assembly CF-3104 is not re­ quired if the aircraft to be used has not been POSITION " 0 " 1 0 4 M o d 0 , E x p lo d e d V iew . converted to the standard stub connector system. Painting and M arking Bombs of recent issue are painted orange, with identifying nomenclature in white, and notations for field-handling personnel in black. Bombs of older issue are painted black, with identifying nomenclature in white, and notations for field-handling personnel in yellow. Use The 2000-lb PB Mk 104 Mod 0 is similar in size and shape to the Mk 28 Special Weapon and is the primary full scale prac­ tice bomb for the Mk 28 series. It is used with Firing-Pin Assembly Mk 1 Mod 0 and Signal Mk 4 Mod 3, both of which are seated in the forward end of the flash tube and locked in place by a cotter pin. The cotter pin also secures the castellated nut holding the nose cap in position. Fittings on the top centerline of the for­ ward cone weldment are dimensionally simi­ lar to the corresponding parent weapon fit- 11-57 N A V W E P S OP 2216 (V O L U M E 1) ACTUATOR ASSEMBLY FIN RELEASE SHAFT POSITION "0" ALIGNMENT ARROW-, RETAIN NK FIXED FIN PULSE BREAKAWAY FITTING ASSEMBLY DOUBLE SUSPENSION LUGS NON FUNCTIONAL. FITTINGS BOMB BODY FILLER NOSE CAP FLASH TUBE -SIGNAL -FIRING PIN ASSEMBLY SPECIAL CASTLE NUT F ig u re T l - 4 0 . — 2OOO-lb P ractice B o m b M k 1 0 4 M o d 0, C u t a w a y V iew . 11-58 P R A C T IC E B O M B A SSEM B LIES tings. They are non-functional and are of value only as drill features. Functioning One pair of fins (180° opposed) are shipped in folded position and are secured at the tips of one fixed and one folded fin. The tips are connected by a sheet metal link, a fixed pin on the folding fin and a retractible pin on the fixed pin. The retractible pin is attached to an explosive powered linear actuator. The following actuation cycle is initiated when the bomb separates from the pylon. 1. Bomb is released and falls. 2. Tension in pylon cable breaks a tension wire in pulse breakaway fitting. As the fitting continues to separate, a ground wire and a 28-volt wire, within the fitting, re­ main as the only connection between the pylon system and the bomb. A 28-volt pulse is initiated and maintained for approxi­ mately two inches of additional separation, after which the two wires break. 3. The 28-volt pulse energizes a trans­ former that transmits a higher voltage output to the M52A4 primer. The primer fires and forces a diaphragm outward to retract the pin securing one end of the re­ taining link at the fin tip. The folding fins are now free to rotate to the open position where they are locked by spring-loaded pins. Upon impact of the bomb, the firing pin initiates the spotting signal to produce a flash and a large puff of smoke. Smoke pro­ duced by the Mk 4 Mod 3 signal is visible from altitudes as high as 30,000 feet. Assembly CAUTION: Signals and bombs are not to be unpacked in advance of requirements. If they are un­ packed and not used, return them to their original containers. 2. Remove the cotter pin, firing-pin as­ sembly, special castle nut, and nose cap from the nose of the bomb. 3. Inspect the nose cap and the firing-pin assembly for damage. The firing-pin cups must not be deformed and the point of the firing pin must not project beyond the lips of the inner cup. 4. Inspect the bore of the flash tube. It must be clean and smooth, free of obstruc­ tions, and not damaged in any manner. 5. Remove the bomb fittings and the wrench, for the bolts and cap screws of the tail fin assembly, that are packed inside the nose cap. Then replace the nose cap on the bomb and install the non-functional fittings. 6. Two M52A4 primers are packaged in a plastic vial taped to the firing pin. Remove the screws securing the fairing at the ex­ treme aft end of the bomb for access to the actuator and the firing pin. Unscrew firing pin assembly. Remove sealing washer and discard. Unpack and insert primer into chamber cavity. Finger-tighten firing pin assembly. Install one or both set screws and tighten. Replace fairing. 7. Remove the signal from its packing and inspect it for damage. The signal must not be swollen or deformed in any manner, and the primer must be flush with or slightly below the base of the cartridge. De­ formed signals must not be used. 8. Insert the signal into the flash tube, primer end last. Slide it into place gently; do not force it. The base flange of the sig­ nal cartridge must rest on the shoulder of the blast tube about 1.08 inches from the nose of the tube. 9. Carefully insert the firing-pin assembly into the flash tube, with the point of the firing pin facing toward the signal. CAUTION: Do not apply pressure to force the firing-pin assembly 1. Remove the bomb assembly from its into the bomb because the assembly crate by means of a hoist on the suspension lugs. Inspect the bomb for damaged seams, might collapse and fire the signal. cracked weldments, or deformed areas which 10. Rotate the firing-pin assembly so that might weaken the suspension lugs or other­ the two recesses in the lip of the forward wise prevent serviceable use. 11-59 N A V W E P S OP 2216 (V O L U M E 1) cup are alined with the two cotter pin holes in the nose of the flash tube. CAUTION: Do not exert any pressure on the firing-pin assem­ bly during this operation. 11. Replace the special castle nut on the flash tube, tighten the nut until it is flush with the nose of the flash tube, and insert the cotter pin through the nut, flash tube, and recesses in the cup of the firing-pin assembly. 12. Spread the ends of the cotter pin sufficiently to lock the pin in the bomb. Do not bend the ends at right angles to the axis of the cotter pin, or strike the ends to bend them into position. 13. Install the bomb in accordance with the type of rack in use and lock it securely in place. CAUTION: Be extremely careful when handling practice bombs loaded with signals. Jarring or dropping the bomb may detonate the signal. Do not, under any cir­ cumstances, point either end of the signal toward personnel. Loaders must not place their bodies in line 11-60 with the nose or aft end of the flash tube. Disassembly To disassemble the complete bomb, the foregoing steps should be carried out in re­ verse order and the components restored to their original condition. It should rarely be necessary to remove the complete tail fin assembly. If necessary, proceed as follows: 1. Remove the 11 flat head sheet metal screws that secure the fairing, and remove the fairing. 2. Remove the round head machine screw, self-locking nut, and plain washer securing the cable clamp at the transformer. Remove the clamp. 3. Remove the four self-tapping screws that secure the pulse plug in the aft cone weldment of the bomb. Remove the pulse plug and detach the wire at the pulse plug. 4. Remove the two field-break index screws and rotate the tail fin assembly to position “ O.” 5. Through the access hole toward the rear of the aft cone weldment, remove the socket head cap screw, and slide the com­ plete tail fin assembly aft. P R A C T IC E B O M B A SSEM B L IES Figure 11-41.— Practice Depth Bomb Mk 100 Mod 0, Major Components. Mark __________ ____________ __________ __________ __ ________-............100 Mod - ............... ........ ....... .................. ........... ........ .............. .................. 0 General Arrangement .............................. ..... ....... ...... 1438551 Length (in.) _______ _______ __ ________________________ 122.0 Length (marker to parachute pack) (in.) _________ __ __________ 125.2 Diameter (in.) _______ _____ __ _____ ____ ______ __ _______________ 31.34 Weight (lb) _____________________ ________________ _______ 2500 Spacing of suspension lugs (in.) 30.0 Parachute Pack ________________________________________________ Mk 25 Mod 0 Practice Bomb Marker ____ ________ __ ____ ____ ___ ___ ______ __ Mk 17 Mod 0 Weapon Response Simulator . ........... .................. ......... . ..... Mk 4 Mod 0 General Description Practice Depth Bomb Mk 100 Mod 0, figure 11-41, is a practice bomb for Depth Bomb Mk 90 Mod 0. The nose section of the practice bomb has an afterbody and a para­ chute pack attached to it. The practice bomb has four functions: 1. Trains flight personnel in the use of Control Boxes Aero 2A, Aero 2B, and Aero 3B, 2. Provides a means for target practice. 3. Provides the pilot with information about how the aircraft will respond when it is carrying the service bomb. 4. Trains ground personnel in methods of loading the service bomb on the aircraft. The monitoring system, the IFI operation, and the manual safety switch of the service bomb are simulated in the practice bomb by means of a weapon response simulator. The simulated signals are required for training personnel in the operation of Control Boxes Aero 2A, Aero 2B, and Aero 3B. A marker can be inserted in place of the eyebolt at the nose of the practice bomb for use in target practice. The marker produces a deep red color on the water surface at the point where the bomb enters the water. The service bomb is described in NAVY SWOP B90-1, Assembly, Test, and Storage Procedures. For information on postload­ ing, pretakeoff, and inflight procedures, re­ fer to the applicable Pilot’s Handbook for the aircraft involved. The procedures in­ cluded in the pilot’s handbook also apply to the practice bomb. The practice depth bomb consists of the following major components: Nose Section. Afterbody. 11-61 N A V W E P S OP 2216 (V O L U M E 1) Parachute Pack Mk 25 Mod 0. Practice Bomb Marker Mk 17 Mod 0. Weapon Response Simulator Mk 4 Mod 0. Nose Section The nose section, figure 11-42, is a steel shell with an ogive-shaped forward end. A lVa-inch threaded opening for an eyebolt or marker, is located at the apex of the ogive. The shell is 63.27 inches long and 31.34 inches in diameter. Two suspension lugs mounted on 30-inch centers are welded to the top of the middle section of the shell. A solid steel cylinder about 18 inches long and 9!4 inches in diameter, is located internally Figure 11-42.- 11-62 to provide the proper weight, center of gravity, and moment of inertia for the prac­ tice bomb. The cylinder is mounted in an opening through the center of a steel disk. The disk is welded in place in a circum­ ferential groove on the inside wall of the shell. The after end of the shell is faced with a steel disk containing twelve threaded studs around the periphery. These studs provide the securing points for the afterbody. Afterbody The afterbody, figure 11-43, is a tapered aluminum shell that streamlines the nose N o s e Secf/'on. P R A C T IC E B O M B A SSE M B L IE S section. The shrouded fins stabilize the un­ derwater trajectory. The forward section of the afterbody has a steel facing with twelve bolt holes which receives the studs of the nose section. An oval-shaped cutout at the top of the after­ body has a flange with six tapped holes used to secure the weapon response simulator. The shroud ring at the after end has twelve lugs bolted to it for attach­ ment of the parachute suspension lines. Two socket-head bolts secure each lug to the shroud ring. Three right-angled clamps, located at the bottom and both sides of the shroud ring, and a key at the top, secure the parachute pack housing. Parachute Pack Parachute Pack Mk 25 Mod 0, figure 1144, consists of a main and an extraction parachute packed in an aluminum pack housing with a cover secured by a ball-lock pack opener. The parachute pack is secured to the shroud ring with the right-angled clamps. The key at the top fits into a cutout at the top of the flange of the pack housing. It secures the top of the pack and prevents the pack from rotating. A threaded inspection plug is located in the center of the reverse side of the pack housing. When removed, the condition of Figure 11-43.— Afterbody. 11-63 N A V W E P S OP 2216 (V O L U M E 1) the E-ring on the base of the plunger of the pack opener may be observed. The main canopy, when inflated, is an el­ liptical nylon parachute 15 feet across its largest diameter. A red 30-inch elliptical nylon extraction parachute is attached to the vent lines of the main canopy. The suspension lines of the main parachute (which emerge from the sides of the pack housing) are attached by clevis pins to the lugs on the shroud ring of the afterbody. The static line is folded in a replaceable pocket secured to the pack cover. One end of the static line is fitted with an adjustable slide fastener and a snap hook for attach­ ment to the aircraft. The other end of the static line is engaged with pack opener by means of a loop and is joined to a static line extension from the main canopy. When the bomb is released, the parachute static line pays out of the pocket as the bomb falls clear of the aircraft. When the static line comes taut, it pulls up on the pack opener, releasing it and allowing the pack C IE V IS PIN AND E RING STATIC LIN E EX T EN SIO N STATIC LIN E PO C KET SH R O U D R IN G KEY / S N A P H OO K PACK H O U SIN G TO A IR C R A F T figure 11-44.— Parachute Pack Secured to Shroud Ring. 11-64 cover to be ejected into the air stream by a spring inside the parachute pack. The pack cover pulls out the extraction parachute, which in turn pulls out the main canopy. In addition, the static line is connected to the main canopy by a break cord which assists the extraction parachute in pulling the main canopy out before it breaks free. As the main canopy deploys, its suspension lines pay out of the pockets in the deployment bag in which they are folded and the canopy in­ flates. Marker Practice Bomb Marker Mk 17 Mod 0, figure 11-45, is used in target practice to produce a deep red color at the point where the weapon enters the water. The marker, about four inches long and four inches in diameter, consists of a plastic housing screwed to an aluminum base. A single lockwire is used between the housing and base to prevent the housing from loosening. The housing is filled with a dark green dye which is sealed against moisture by an Oring between the housing and the base. The housing breaks open when a bomb strikes the water releasing the dye. A chemical reaction between the dye and water causes the dye to turn red. The marker is secured to the nose of the practice bomb by means of a threaded boss on the underside of the base, figure 11^6. It replaces the eyebolt and is tightened to the nose section by use of a special wrench. The wrench fits into three of the six notches cut around the periphery of the base. In some aircraft the practice bomb, with the marker mounted on the nose, will not fit into the bomb bay. In such cases, the marker is mounted on an adapter bracket, figure 11^7, which permits the marker to be located below the ogive surface and some­ what behind the point of the ogive as shown in figure 11-48. Lug Adapter A lug adapter, figure 11-49, is furnished for use when the bomb is carried on an air­ craft that does not have sufficient ground P R A C T IC E B O M B A SSE M B L IE S NOTCH FOR W RENCH WRENCH, H-3082 Figure 11-45.— Parachute Bomb Marker Mk 17 Mod 0 and Wrench. Weapon Response Simulator Figure 11-46.— Marker Mounted on Nose of Practice Bomb. clearance for the weapon. The lug adapter is mounted on the forward suspension lug to raise the tail of the bomb to provide ade­ quate ground clearance. Weapon Response Simulator Mk 4 Mod 0 figure 11-50, simulates the monitoring cir­ cuits, the IFI unit, and the manual safety switch of the service bomb. It can be used with Monitor Test Set Mk 274 Mod 0 or 1 (T-3009 or T-3009A respectively) or Con­ trol Box Aero 2A, Aero 2B or Aero 3B. Physical Description. The simulator con­ sists of a flanged aluminum housing that en­ closes three connectors and the circuit components. The flange has six bolt holes for securing the simulator to the afterbody. Eight threaded holes are located in the flange for attaching the dust cover. Each connector is equipped with a springloaded ball-lock sleeve which mates with a similar sleeve on the aircraft pull-out con­ nectors. The sleeve protects the connectors from oil and dirt while the practice bomb is carried on the aircraft. The ball-lock mech­ anism permits the aircraft connectors to disconnect from the connectors in the weapon response simulator when the prac­ tice bomb is released. A red pin associated with the ball-lock 11-65 N A V W E P S OP 2216 (V O L U M E 1) IN T ER N A L TOOTH L O C KW A SH ER O PEN IN G FOR A TT A C H M EN T OF DYE M A R K E R Figure 11-47.— Adapter Bracket for Marker. mechanism of each connector indicates full engagement with the aircraft connector by protruding above the face of the weapon response simulator when the aircraft con­ nector is inserted fully. The connectors have 35, 14, and 8 pins respectively. However, only 21 of the pins are used in the 35-pin connector, and two each in the 14-pin and 8-pin connectors. A two-position screwdriver-operated switch, located on the face of the simulator, is used to simulate the manual safety switch. A screwdriver is used to turn it to A (armed) or S (safe) position. Operation. The electrical circuit of the simulator, figure 11-51, consists of compo­ nents which simulate the IFI operation, the manual safety switch, and the monitoring circuit. The relay and switch designations used in the following discussion are for ref­ erence only; the designations do not appear on the components. These statements as­ sume that the simulator is connected to the test set; and the lights referred to here are located on this test set. The IFI operation is simulated by use of rotary relays K l, K2, and K3 and a thermal time-delay relay K4. K l and K2 are step­ ping relays. The relay coil of K l operates a single pole switch S I ; K2 operates a twopole switch S2A and S2B. These switches 11-66 are stepped one position when the coil is energized, and remain in this position when the coil is de-energized. When relay K3 is energized, the contacts change position to an open circuit returning to the closed cir­ cuit when the relay is de-energized. K4 is a thermal time-delay relay in which a switch is closed approximately 5 seconds after power is applied to a heater circuit. The function of K l is to step SI one po­ sition so that the OUT or IN IFI light (whichever one is on initially) goes out. It also serves to close the electrical circuit to K4 through one of the switches in K2. K2 switches the IFI light (whichever one is off initially) to ON approximately 5 seconds after K l is energized. The 5-second delay is provided by K4. K3 keeps K l and K2 in synchronization and thereby maintains the proper sequence of operation between the IFI operate switch and the IFI IN and OUT lights. The operations of the weapon response simulator is described in the following steps, starting with the IFI in the OUT position. 1. When the IFI switch on either the test set or on Control Box Aero 2A, Aero 2B or Areo 3B is actuated, 28-volt power is ap­ plied to K l through terminal d on the 35contact connector. 2. With K l energized, SI steps from posi­ tion 1 to position 2. This extinguishes the Figure 11-48.— Practice Bomb with Marker Mounted on Adapter Bracket. P R A C T IC E B O M B A SSEM B LIES 35-PIN CONNECTOR BALL-LOCK SLEEVE 14-PIN CONNECTOR INDICATOR PIN 8-PIN CONNECTOR figure II-4 V .— Lug Adapter Mounted on Forward Suspension Lug. IFI OUT light and channels the 28-volt power from L through S2A1 of K2, to the heater of K4. 3. After approximately 5 seconds, S4 closes, energizing K2 and K3 simultaneously. 4. With K2 energized, S2A and S2B step from position 1 to position 2 and the IFI IN light goes on. Between 5 and 10 seconds later, the heater in K4 cools off, S4 opens and the K3 contacts return to the closed position. 5. With K3 energized, the relay contacts open, interrupting the coil circuit of K1 and the heater circuit of K4. If the IFI switch on the test set or the control box is actuated while S4 is closed, K1 cannot be energized until S4 opens again. The manual safety switch simulator is a SIM U LA TE D M AN U A L SAFETY SWITCH Figure 11-50.— W eapon Response Simulator Mk 4 Mod 0. two position switch. The common lead, fig­ ure 11-51, completes a 28-volt circuit to either the MSS ARMED or SAFE light on the test set or on the control box. The monitor circuit consists of jumpered and grounded terminals which simulate the continuity path through the connectors to components in the service weapon. Unpackaging and Inspection The practice weapon is packaged as five separate pieces. The packaging configura­ tion, dimensions, and gross weights are listed in the following table. Packaging Data I tem P a c k in g C o n fig u r a t io n Nose Section (and Lug Adapter). Nailed wood crate_____ Afterbody__________ __ Wirebound wood crate Parachute Pack. Cylindrical metal container. Fairing Wirebound wood crate Accessory Box. . . Rectangular metal container D im en sions W eigh t Inches Pounds 78.5 x 41 X 41.25_________ 57 x 35 x 35___ _ 36.2 diam. x 13.5 99 x 37 x 46 18.3 x 9.3 x 6 .2 _______ . 2400 546 200 440 40 11-67 N A V W E P S OP 2216 (V O L U M E 1) Figure 11—51.— W eapon Response Simulator Mk 4 Mod 0, Schematic Wiring Diagram. Nose Section. The nose section is clamped to the base of the crate in a horizontal posi­ tion. A metal band around the body of the nose is anchored to the base of the crate by six half-inch hex-heads bolts and nuts. The top, sides, and ends of the unsheathed crate are assembled to the crate base to form the complete crate. The lug adapter is secured to a bracket attached to the base of the crate beneath the ogive of the nose section. The bolt that secures the lug adapter also is used to mount it on the forward suspension lug when the lug adapter is required. U npackaging . Unpackage the nose sec­ tion as follows: 1. Remove the corner strappings at the top of the crate using a claw hammer or crowbar. 2. Knock away the sides and ends of the 11-68 crate from the top panel, and remove the top panel. 3. Remove all nails that project into the crate leaving the sides and ends in position. 4. Remove the nuts on the six bolts, which anchor the metal frame, using a 13X6-inch open-end wrench. 5. Lift and remove the metal frame from the crate. 6. Using a hoist capable of lifting 2500 pounds minimum and an H-3070 sling or equal, lift the nose section by the suspension lugs, and remove it from the crate. 7. Place the nose section on an H-3045 dolly or equal, with the ogive resting against the pillow block, figure 11-42. 8. Remove the tape from the twelve bolts at the aft end of the nose section and inspect for damaged or dirty threads. Clean with trichloroethylene (stock number 55-T 5751), or similar solvent if necessary. The P R A C T IC E B O M B A SSEM B LIES the cover of the container by means of a washers, nuts, and cotter pins should be left metal band consisting of two semicircular on the studs until ready for assembly. 9. The base of the crate may be used as a segments. The ends of each segment termi­ nate in two bolt eyes which are locked by skid for local handling by fork-lift truck. %o-inch bolts. The shroud lines are held When the base is used as a skid for handling together by cotton seine-twine. the nose section, the metal frame must be A four-spot humidity indicator, located in secured to the base by the six anchor bolts the cover of the parachute pack container, and nuts. The sides and end panels should provides a means for checking humidity be disassembled from the base. I n s p e c t i o n . The nose section should be within the container. The spots register inspected for damage or deformation; reject relative humidity from 20 percent to 50 per­ if it is deformed or if deep gouges, dents, or cent in 10 percent increments. The humidity scratches are found. Superficial abrasions inside the container is indicated by the spot or scratches are not cause for rejection. that most closely approximates the lavender Afterbody. The afterbody, positioned shade of the background. If all spots are blue, the humidity is too low; if the 50 spot vertically, is packaged in a wirebound, slatted-wood crate which is expendable. The is lavender, the humidity is above the safe forward end of the afterbody rests on a felt level. In either case, the parachute should be pad at the base of the crate and is anchored unpackaged and left for 36 to 48 hours in an with carriage bolts. The after end is se­ area with a relative humidity between 25 cured at the top of the crate with hold-down percent and 40 percent and repackaged if strips. All end fasteners terminate at the continued storage is planned. same corner. The crate is unpackaged by U n p a c k a g i n g . Unpackage the parachute opening these fasteners and knocking the pack as follows: slats away from the top and bottom of the 1. Check the humidity indicator on the crate. cover of the container. If the humidity indi­ U n p a c k a g i n g . Unpackage the afterbody cator shows excessive humidity, the con­ as follows: tainer should be examined for failure after 1. Open the fastened ends of each wire it is opened. This would be indicated by the loop. presence of excessive dust, foreign matter, 2. Remove the nails at the top of the slats. grease, or fungus growth in the container or 3. Knock the slats away from the top and packing material. A defective container bottom framework. As each side is freed should not be reused unless the cause of from the top and bottom panels, it can be failure can be corrected. unfolded from the crate. 2. Remove the twelve hex nuts that secure 4. Remove the top of the crate and then the cover to the base using a 5/Q-inch speed the two hold-down strips and pads from the wrench. top of the shroud ring. Loosen the carriage 3. Lift the cover off the container and turn bolts with a 5/s-inch open-end wrench. it over. 5. Place the afterbody on a skid or dolly 4. Remove the twine from the eyes of the so that it lies horizontally. Three men can parachute suspension lines. lift it conveniently. 5. Using a %-inch speed wrench, loosen the two nuts which secure the retaining band I n s p e c t i o n . Inspect the afterbody for and remove the parachute pack. damage or deformation; reject if it is de­ formed or if deep gouges, dents, or deep 6 . If the container is in satisfactory con­ scratches are found. Superficial abrasions dition, replace the cover and secure it with or scratches are not cause for rejection. the bolts. Parachute Pack. The parachute pack is 7. Retain the empty container for future shipped and stored in a reusable steel con­ use or return it to the issue point. tainer. The pack is secured to the inside of I n s p e c t i o n . Inspect the parachute pack 11-69 N A V W E P S OP 2216 (V O L U M E 1) assembly after unpackaging and before each mission as follows: 1. Inspect the parachute pack for damage or deformation; reject if deformed or punc­ tured. 2. Inspect the exposed portions of the parachute suspension lines for abrasion; re­ ject the assembly if the lines are damaged. 3. Inspect the static line for wear, abra­ sion, or improper assembly. Carefully check the tie cords that hold the static line in the pocket, figure 11-52, to be sure they are not loose. Replace the static line if unsatis­ factory. A spare static line is located in the accessory box; instructions follow for re­ placing the static line. CAUTION: Failure of the static line tie cords or improper assembly of the pack opener will cause the parachute pack to open before it is released from the aircraft. 4. Inspect the pack opener to make certain that the setscrew on the plunger and the E-ring on the pin are in place and tight. 5. Unscrew the inspection plug on the bottom of the pack housing. Shine a spot­ light through the cylinder to examine the E- Figu re 1 1 - 5 2 . — P a ra c h u te Sta tic Line R ep la cem ent. 11-70 ring at the end of the plunger of the pack opener. Be sure the E-ring is inserted fully and is not deformed. If it is deformed, re­ ject the parachute pack. Replace the in­ spection plug. Accessory Box. The accessory box is a metal container in which the following seven items are packaged: 1. Wrench (H-3082). 2. Parachute static line. 3. Practice Bomb Marker Mk 17 Mod 0. 4. Unit spares bag. 5. Accessory bag. 6. Bracket. 7. Weaon Response Simulator Mk 4 Mod 0. These items are wrapped in fiberboard sealed with paper tape, or enclosed in water­ proof bags. U n p a c k a g i n g . Unpackage the accessory box as follows: 1. Open the box by removing the lockwire from the latch and opening the hinged cover. 2. The wrench is in a fiberboard wrap at the top of the box. Open it by cutting the tape at the seam and unraveling the fiberboard. 3. To open the static line bag, manipulate the static line away from one edge of the bag and cut the edge with scissors. 4. Open the marker container by remov­ ing the tape and pulling apart the two halves of the container. 5. The unit spares bag is opened as fol­ lows : a. Cut one edge of the waterproof bag, with scissors. b. Remove the fiberboard box container, and pull apart the two halves of the con­ tainer. c. Remove the waterproof bag, cut one edge of the bag with scissors and remove the contents. 6 . Open the accessory bag in accordance with step 5. 7. Unpackage the bracket in accordance with step 2 . 8 . Open the container of the weapon re­ sponse simulator by removing the tape from the fiberboard box and opening the lid. Re­ move the waterproof bag containing the P R A C T IC E BO M B A SSEM B LIES simulator. Cut along the edge of the bag with scissors and remove the simulator. I nspectio n . The following items should be inspected before using: 1. Check the parachute static line for abrasion or tears. Check the action of the snap hook to be certain it closes fully. 2. Check the marker for a cracked hous­ ing, loose lockwire, or damaged threads. If the housing is cracked, reject the marker. 3. Inspect the weapon response simulator as follows: a. Remove the 8-32 NC-2 x %-inch socket-head screws with a Vs-inch socket wrench. b. Examine the gasket for cracks or checks. c. Inspect the ball-lock sleeve, connector and the red indicator pins for any deforma­ tion cracks, or breaks. d. Inspect the base to be certain the lockwire is in place. If not, replace it after the simulator has been tested and found sat­ isfactory. Test instructions follow. e. Replace the dust cover, and secure it with the eight retaining screws. Assembly and Test The assembly procedure consists essen­ tially of securing the afterbody to the nose section and installing the parachute pack and weapon response simulator. The marker, when used, is not installed until the practice bomb has been placed un­ der the aircraft prior to loading. This pro­ cedure avoids cracking the plastic housing of the marker and losing the dye. In some instances the bomb bay may be too short to accomodate the marker when it is mounted at the nose of the weapon. In such cases an adapter bracket is used to bring the forward edge of the marker back in line with the apex of the ogive. A horizontal assembly system is used for putting together the major components of the practice bomb. Components are assem­ bled in the following sequence. The after­ body is bolted to the nose section. The para­ chute pack is installed by removing the key and the two clamps at the top and sides of the shroud ring respectively. The para­ chute pack is lowered so that the flange rests in the clamp at the bottom of the shroud ring with the cutout oriented at the top. The key is hooked into the cutout and secured to the shroud ring, and the two side clamps reinstalled. The weapon response simulator is tested with Monitor Test Set Mk 274 Mod 0 or Mod 1 (T-3009 or T-3009A respectively) before it is installed, in accordance with test in­ structions following. If parts such as nuts, washers, or clevis pins are missing, extras will be found in the unit spares bag and accessory bag located in the accessory box. These bags contain the items listed in the following table. In addition to the items listed in the table, there also is a bag containing a parachute static line. Assembly of Afterbody to Nose Section. The afterbody and nose section should be oriented so that the forward end of the afterbody faces the after end of the nose section. Four men will be required for handling the afterbody to avoid damaging the bolt threads on the nose section. If a hoist is available, an alternate method is to place a manila rope of 1 4 -inch or 5/g-inch diameter and about 10 feet long around the notches in the fins of the afterbody. The hoist hook then can be hooked on to the rope and the afterbody raised. Since the after­ body will be unbalanced when raised, one person will be required to guide it. The procedure is as follows: 1 . Remove the cotter pins, nuts, and washers from the studs on the nose section. 2. With the afterbody on the skid or dolly, bring it within about two feet of the nose section. 3. Lift the afterbody and carefully guide is so that the bolt holes pass over the studs on the nose section without damaging the threads. 4. Insert a flat washer and 1/ 2-20 NF-2 castellated hex nut over each stud. Hand tighten all the nuts before releasing the afterbody. 5. Release the afterbody and use a torque 11-71 N A V W E P S OP 2216 (V O L U M E 1) Contents of Accessory Bag and Unit Spares Bag A ccessory B ag A fterbo dy 12 Castellated hex nuts. U n it S pa re s B ag P ar ac h u te P ack M arket 12 Clevis _ .. 2 Internal tooth lock­ washers. 12 Flat wash­ 12 E-rings__ ers. 12 Cotter pins - 1 Special bolt. A fter bo d y 4 Castellated hex nuts. 4 Flat wash­ ers. 4 Cotter pins. wrench with a %-inch socket to tighten the nuts to a torque of 570 ± 20 inchpounds. 6. Insert a 1-inch cotter pin through the hole in each stud and spread the end of the pin. If necessary, back off the nut slightly until the pin can be inserted. Assembly of Parachute Pack to Afterbody. The parachute pack should be inspected as previously described before it is installed. The parachute pack may be assembled to the shroud ring by two men as follows: 1. Using a %6-inch socket wrench, remove the retaining screws and lockwashers from the key at the top of the afterbody shroud ring and the two clamps at either side. Do not remove the bottom clamp. 2 . Locate the cutout in the flange of the parachute pack. With the cutout oriented at the top, lift the pack by the handles and place it in the shroud ring so that the flange drops into the bottom clamp. 3. Place the key in the cutout, figure 1144, and replace the lockwashers and retain­ ing screws. The screws are Vi-20 NC x Viinch socket-head screws and the lockwashers are internal tooth. 4. Replace the two side clamps. Be sure the lockwashers are in place. Replacement of Parachute Static Line. If the practice weapon has been flown three missions without being dropped, it should 11-72 P a r ac h u te P ack W eapon R esponse M ar ker S im u lato r 4 Clevis pins.. 2 Slotted fil­ lister head screws. 4 E-rings____ 2 Spring washers. 2 Internal tooth lock washers. be inspected in accordance with previous instructions and the static line should be replaced as follows: CAUTION: Do not disturb the position of the plunger when en­ gaging or disengaging the static line. Inward or outward plunger movement of only % inch will ac­ tuate the pack opener, ejecting the cover with force sufficient to cause injury. 1. Remove the static line pocket by un­ screwing the retaining screws, figure 11-52. 2. Remove the E-ring from the pin. Loosen the plunger setscrew and remove the pin. Open the hinge lever and remove the static line bight. 3. Open the eye in the end of the static line, figure 11-44, and pass the static line assembly through this eye to disengage the assembly from the static line extension. 4. Put the eye of the new static line through the eye of the static line extension, pass the static line assembly through its eye, and pull the resulting knot tight. 5. Place the bight of the static line under the hinge lever of the pack opener, replace the pin, tighten the setscrew, and install a new E-ring. 6 . Secure the static line pocket in place P R A C T IC E B O M B A SSE M B L IE S with the five 10-32NF x Vfc-inch slotted fillister-head screws previously removed. Installation of Weapon Response Simula­ tor. Install the weapon response simulator as follows: 1. Using a Vs-inch socket wrench, remove the eight socket-head screws from the dust cover. These screws are 8-32NC-2 x % inch long. 2. Remove the bag hanging from the sim­ ulator. The bag contains the mounting screws for the simulator. Place the simu­ lator in the afterbody opening with the 35pin connector facing forward. 3. Insert the six 14-20 UNF-2 x %-inch slotted fillister-head screws using 1 4 -inch spring lockwashers in the six holes around the flange of the simulator. Tighten the screws uniformly. 4. Replace the dust cover and secure it with the socket-head screws. Installation of Marker. The marker, if externally carried, is installed in the nose section after the weapon is loaded, or if internally carried, it is installed just prior to raising the practice bomb into the bomb bay. I n s t a l l a t io n for E xternal Carriage . Install the marker as follows: 1. Unscrew the eyebolt from the nose sec­ tion. 2. Make sure the 114-inch internal tooth lockwasher is on the threaded boss of the marker. 3. Insert the boss in the eyebolt hole and tighten with the special wrench (H-3082) shown in figure 11-45. The marker should be tightened so that the flange comes up flush with the apex of the ogive. CAUTION: Do not tighten the marker by turning the plastic housing. The dye will disperse over a wide area if lost from the case and will penetrate cracks and crevices; it turns red on contact with moisture. I n st a l la tio n for Internal Install the marker as follows: C arriage . 1. Check the length of the bomb bay to see if the weapon with the marker attached at the nose, figure 11-46, will fit. The length of the weapon from parachute pack to marker is 125.125 inches. The bomb bay should be about 135 inches long to allow room for any pitch of the weapon when it is loaded or dropped during a mission. 2. If the bomb bay is too short, use the adapter bracket, figure 11-47. Orient the bracket as shown in figure 1 1 ^ 8 and in­ stall it in the nose using the special bolt and internal tooth lockwasher. A two-inch wrench is necessary. Insert the bolt through the bolt hole. The threaded hole should be below and behind the apex of the ogive. 3. Secure the marker with the lockwasher to the threaded hole in the bracket using the special wrench. CAUTION: Do not tighten the marker by turning the plastic hous­ ing. The dye will disperse over a wide area if lost from the case and will penetrate cracks and crevices, turning red on contact with mois­ ture. 4. Check the lockwire on the marker to be sure it has not been damaged by the wrench. If necessary, replace the lockwire. Installation of Lug Adapter. A lug adapter may be installed on the forward suspension lug, figure 11-49, to provide ad­ ditional ground clearance for the tail of the practice bomb when it is carried ex­ ternally on some aircraft. When directed by the officer-in-charge, install the lug adapter as follows: 1 . Fit the lug adapter snugly over the forward suspension lug. 2. Secure the lug adapter to the suspen­ sion lug with a 1-14NF x 4V8-inch sockethead bolt. Insert the bolt, from front to rear, into the bolt hole in the lug adapter. 3. Place a Vs-inch thick flat washer on the bolt. 4. Screw a 1-14 castellated hex nut tightly onto the bolt. 5. Insert a l/g x lV^-inch cotter pin n -73 N A V W E P S OP 2216 (V O L U M E 1) through the castellated nut and spread the cotter pin. Test Instructions The weapon response simulator is the only component tested in the practice bomb. It is tested with Monitor Test Set Mk 274 Mod 0 or Mod 1 (T-3009 or T-3009A respec­ tively) . The test set indicates by pilot lights that the relays and manual safety switch simulator are operating properly and that the jumpered terminals do not have any loose connections and are connected cor­ rectly. The procedure for performing the test is described in the following paragraphs. Preparation of Test Set. 1. Locate the test set in an area near a 115-volt, 60- to 460-cycle supply. 2. Set the test set on top of the practice weapon and secure it by fastening the straps to the bomb suspension lugs. 3. Open the test set cover and remove the cables from the case. 4. Connect the GROUND CHECK termi­ nal on the test set panel to a good earth ground. If the test set is a Mod 1, connect the power cable to the test set receptacle labeled 95-130V, 55-460 cycles per second. 5. See that the ON-OFF switch is OFF and plug the test set power cable into a 115-volt, 60- to 460-cycle supply. Self-Test of Test Set. Check the test set as follows: 1. Turn the ON-OFF switch ON. The POWER, GROUND CHECK, and BAT­ TERY HEATER lights should come on and the meter should indicate a reading. 2. Rotate the LIGHT TEST switch to ON momentarily. All lights on the panel should come on. Turn the switch OFF. 3. If Monitor Test Set Mk 274 Mod 0 is used, proceed as follows: a. Plug the 35-pin connector of the test cable into the TEST CONNECTOR recepta­ cle on the test set panel. Air the remaining lights except the IFI IN light should come on; the BATTERY HEATER and GROUND CHECK lights should go out. b. Operate the IFI OPERATE switch 11-74 momentarily. The IFI IN light should come on while the switch is operated. c. Rotate the BATTERY TEST switch to the X-UNIT position. The meter should indicate in the orange band. d. Turn the POWER switch OFF and disconnect the test cable. 4. If Monitor Test Set Mk 274 Mod 1 is used, proceed as follows: a. Rotate the BATTERY TEST switch to MC-134. b. If the meter does not read full scale rotate the METER ADJUST control until the meter reads at the high limit of the scale. c. Plug one end of the test cable into the TEST CONNECTOR receptacle on the test set panel. d. Plug the other end of the test cable into the CT-3111 receptacle on the test set panel, and tighten it. e. When the two ends of the cable are connected, all lights should be on except the IFI IN, BATTERY HEATER, and GROUND CHECK lights. f. Operate the IFI OPERATE switch momentarily. The IFI IN light should come on while the switch is operated. g. With the BATTERY TEST switch at MC-134, the meter should read in the orange band. h. Turn the ON-OFF switch OFF and disconnect the test cable. Test Procedure. The weapon response simulator provides simulated indications of all monitor circuits in the service bomb. It does not simulate the battery load test how­ ever. If any of the following tests fail, reject the simulator. Perform the test as follows: 1. Remove the dust cover from the weapon response simulator. 2. Remove the test cable from the TEST CONNECTOR receptacle and plug it into the 35-pin connector of the weapon response simulator. Install the 14-pin and 8-pin test plugs in proper receptacles. Turn the ONOFF switch ON. All the lights in the top panel should come on. The condition of the bottom row lights should be as follows: PR A C T IC E BO M B A SSEM B LIES L ig h t C ondition IFI IN .... .................................................. IFI OUT ............................... ...................... MSS SAFE .................................................. MSS ARMED .... _________ ____ _ IMPACT SWITCH . ..... ......... PULL-UP CONN 1 ____ _____ ____ PULL-UP CONN 2 ............... ............... . PULL SWITCH ............ ................. ....... . Off On On Off On On On On 3. Operate the IFI switch. The light that initially is on should go out when the switch is operated. Five seconds later the other light should come on. 4. If the MSS ARMED light is on, turn the screwdriver-operated switch so that the SAFE light on the test set goes on and the ARMED light goes off. 5. Pull the 14-pin test plug out of the connector with a quick hard pull. The PULL-UP CONN 1 light should go out. 6 . Repeat step 5 with the 8 -pin test plug. The PULL-UP CONN 2 light should go out. 7. Operate the IFI OPERATE switch mo­ mentarily if three minutes have elapsed since the last operation. The IN light should go out immediately and the OUT light should come on in approximately five seconds. Wait three minutes then depress the IFI switch again momentarily and see that the OUT light goes off and the IN light comes on. The IFI should be left in OUT position. 8 . Turn the manual safety switch simu­ lator (screwdriver-operated switch) to A and check to see that the SAFE light goes off and the ARMED light comes on. Set the switch back to S. 9. Turn the POWER switch OFF and disconnect the test gear. 10. Install the simulator in the afterbody as directed in the assembly instructions and replace the dust cover if the practice bomb will not be used immediately. 11-75 N A V W E P S OP 2216 (V O L U M E 1) P R A C T IC E DEPTH B O M B M k 102 M od 0 Figure 11-53.— Practice Depth Bomb Mk 102 M od 0. Mark .......... ............................ Mod .. ------------ -------- ------List of Drawings ______ ____ Hull Assembly (dw g) A f t e r b o d y ................................. Connector Manual Switch Diameter (in.) ....... Length (in.) _____________ __ Weight (lb) ...... ..................... Suspension Lug Spacing (in.) General Description Practice Depth Bomb Mk 102 Mod 0, figure 11-53, is a nonexpendable practice bomb for Depth Bomb Mk 101 Mod 0. The practice bomb simulates the external outline and the weight of the service bomb. It pro­ vides a means of electrical connection with internal switches and wiring to simulate the service bomb electrically when used with Aero 6 A Control Box; Monitor Test Set T 3024, and Safety Switch Test Set T-3026. It also includes a switch that can be adjusted to simulate various fault conditions. The functions of the practice bomb are: 1. Trains personnel in the use of the Aero 6 A Control B ox; Monitor Test Set T-3024; Safety Switch Test Set T-3026. 2. Aids in training air crews in the opera­ tion and capabilities of Magnetic Airborne 11-76 102 0 LD 479317 1501413 Mk 5 Mod 0 (LD 299769) Mk 22 Mod 0 (LD 479307) Mk 52 Mod 0 (LD 479311) 18 92.375 1200 14 Detection (MAD) equipment when used with the Mk 102. 3. Trains pilots and ground personnel in procedures for handling the service bomb and loading it onto the aircraft. 4. Provides pilots with information on how the aircraft will respond when carrying the service bomb. 5. Depth Dummy Bomb Mk 108 Mod 0, described later, provides a means of checking aircraft fit and separation characteristics. The weapon response simulator assembly simulates the weapon connector, the MC725 Arming-Safing Motor Switch (often called the inflight safety switch), the manual safety switch, and monitor circuits of the service bomb. In addition, a selectortype fault switch makes it possible for an instructor to simulate defects in the circuits P R A C T IC E B O M B A SSE M B L IE S and switches of the service-bomb by rotating the fault switch to a desired position in set­ ting up a training problem. The service bomb is described in NAVY SWOP B101-1. Postloading, pre-takeoff, and inflight procedures are the same for the practice bomb as for the service bomb. Practice Depth Bomb Mk 102 Mod 0 has three major components: a hull assembly, an afterbody, and a weapon response simulator assembly. The simulator assembly consists of a weapon connector and a manual switch for the practice bomb. Hull. The hull assembly, figure 11-54, is a blunt-nosed steel cylinder, 45% inches long 18 inches in diameter. A steel bulk­ head is welded into the after-end of the hull as a closure and provides a mount for the weapon connector. The practice bomb sus­ pended in a bomb rack by means of two sus­ pension lugs, dwg 1252628, threaded into the top of the hull. The bomb is hoisted into the aircraft by means of a hoisting lug, dwg 1686182, threaded into the top of the hull midway between two suspension lugs. The manual switch is mounted flush with the side of the hull in an opening 2 % inches in diameter with a flanged mounting seat. The switch is properly oriented by an aligning pin in the mounting seat and a mating notch in the switch housing. Inside the forward section of the hull, a steel disk is welded across the diameter. This steel disk makes the weight, center of gravity, and the moment of inertia of the practice- bomb equivalent to those of the service bomb. The practice bomb also simu­ lates closely the magnetic properties of the service bomb. The after bulkhead of the hull has an opening near the top 2 % inches in diameter, and four tapped holes which provide mount­ ing and attachment points for the weapon connector of the practice weapon. Two tapped holes near the perimeter of the same bulkhead provide attachment points for H 3106 lifting lugs used in vertical handling of the hull. A grooved flange around the after edge of the hull fits against a similar flange around the forward edge of the afterbody. The hull and the afterbody are held together by means of a segmented clamp band which mates with these two grooved flanges. The clamp band, dwg 1476493-12, is made up of three seg­ ments secured with self-locking screws. The hull and the afterbody are properly aligned on assembly by means of an align­ ing pin projecting from the upper edge of S U SP E N S IO N LUGS W EAPO N CO N N EC T O R CLAM P BAND B U LK H E A D M A N U A L SW ITCH Figure 11-54.— Cutaway of Assembled Practice Bomb. 11-77 N A V W E P S OP 2216 (V O L U M E 1) the hull and a mating hole in the forward edge of the afterbody. Afterbody. Practice Weapon Afterbody, Mk 5 Mod 0 is a conical aluminum shell, 47 % inches long, pierced with flooding and vent holes. Shrouded fins stabilize the air and underwater trajectory. An oval opening in the top of the after­ body gives access to the weapon connector and the fault switch when the afterbody is installed on the hull. The forward edge of the afterbody has a grooved flange which mates with the clamp band, and an aligning hole which mates with the aligning pin of the hull on assembly. Weapon Response Simulator Assembly. General . The weapon response simula­ tor assembly consists of two major compo­ nents: a manual switch and a weapon con­ nector, figure 11-54. Although the manual switch of the practice bomb is only a single component, it simulates the functions of two components of the service bomb: Manual Safety Switch Mk 45 Mod 0 and Rotary Switch Control Mk 1 1 Mod 0. Externally the manual switch of the practice bomb resem- Figure 11-55.— Manual Switch Mk 52 Mod 0, Installed. 11-78 Figure 11-56.— W eapon Connector Mk 22 Mod 0, Installed. bles the rotary switch control of the service bomb. The weapon connector in the prac­ tice bomb simulates the Weapon Connector Mk 21, the MC-725 switch and the monitor circuits of the service bomb. The manual switch is mounted on the side of the hull, figure 11-55. The weapon con­ nector is mounted on the after bulk­ head of the hull, figure 11-56. The upper surface of the weapon connector is accessible through the opening in the top of the after­ body and is approximately flush with the surface of the afterbody. A cable, dwg 1541079, electrically connects the manual switch to the weapon connector and fault switch, figure 11-54. M anual S w itch . Practice Weapon Man­ ual Switch, Mk 52 Mod 0, figure 11-55, con­ sists of a single pole, double throw rotary switch that is operated by an attached con­ trol mechanism. The manual switch is en­ cased in an aluminum housing and is mounted in an opening in the side of the hull. It is held in place by two steel tabs fastened to the hull with self-locking screws, dwg 1476493-23. A notch in the side of the P R A C T IC E B O M B A SSE M B L IE S and switches of the service bomb by rotating the fault switch to a desired position in set­ ting up a training problem. The service bomb is described in NAVY SWOP B101-1. Postloading, pre-takeoff, and inflight procedures are the same for the practice bomb as for the service bomb. Practice Depth Bomb Mk 102 Mod 0 has three major components: a hull assembly, an afterbody, and a weapon response simulator assembly. The simulator assembly consists of a weapon connector and a manual switch for the practice bomb. Hull. The hull assembly, figure 11-54, is a blunt-nosed steel cylinder, 45% inches long 18 inches in diameter. A steel bulk­ head is welded into the after-end of the hull as a closure and provides a mount for the weapon connector. The practice bomb sus­ pended in a bomb rack by means of two sus­ pension lugs, dwg 1252628, threaded into the top of the hull. The bomb is hoisted into the aircraft by means of a hoisting lug, dwg 1636182, threaded into the top of the hull midway between two suspension lugs. The manual switch is mounted flush with the side of the hull in an opening 2 % inches in diameter with a flanged mounting seat. The switch is properly oriented by an aligning pin in the mounting seat and a mating notch in the switch housing. Inside the forward section of the hull, a steel disk is welded across the diameter. This steel disk makes the weight, center of gravity, and the moment of inertia of the practice- bomb equivalent to those of the service bomb. The practice bomb also simu­ lates closely the magnetic properties of the service bomb. The after bulkhead of the hull has an opening near the top 2 % inches in diameter, and four tapped holes which provide mount­ ing and attachment points for the weapon connector of the practice weapon. Two tapped holes near the perimeter of the same bulkhead provide attachment points for H 3106 lifting lugs used in vertical handling of the hull. A grooved flange around the after edge of the hull fits against a similar flange around the forward edge of the afterbody. The hull and the afterbody are held together by means of a segmented clamp band which mates with these two grooved flanges. The clamp band, dwg 1476493-12, is made up of three seg­ ments secured with self-locking screws. The hull and the afterbody are properly aligned on assembly by means of an align­ ing pin projecting from the upper edge of i ADAPTER PLUG CO N N EC T O R AFTERBODY C LAM P BAND CABLE S U SP E N S IO N LUGS HULL \ B U LK H EA D M A N U A L SW ITCH Figure 11-54.— Cutaway of Assembled Practice Bomb. 11-77 N A V W E P S OP 2216 (V O L U M E 1) the hull and a mating hole in the forward edge of the afterbody. Afterbody. Practice Weapon Afterbody, Mk 5 Mod 0 is a conical aluminum shell, 47 % inches long, pierced with flooding and vent holes. Shrouded fins stabilize the air and underwater trajectory. An oval opening in the top of the after­ body gives access to the weapon connector and the fault switch when the afterbody is installed on the hull. The forward edge of the afterbody has a grooved flange which mates with the clamp band, and an aligning hole which mates with the aligning pin of the hull on assembly. Weapon Response Simulator Assembly. G en e r al . The weapon response simula­ tor assembly consists of two major compo­ nents : a manual switch and a weapon con­ nector, figure 11-54. Although the manual switch of the practice bomb is only a single component, it simulates the functions of two components of the service bomb: Manual Safety Switch Mk 45 Mod 0 and Rotary Switch Control Mk 11 Mod 0. Externally the manual switch of the practice bomb resemS E C U R IN G SC R E W LO CKIN G TAB Figure 11-55. Manual Switch Mk 52 Mod 0, Installed. 11-78 Scanned by MilSpecManuals Figure 11-56.— W eapon Connector Mk 22 Mod 0, Installed. bles the rotary switch control of the service bomb. The weapon connector in the prac­ tice bomb simulates the Weapon Connector Mk 21, the MC-725 switch and the monitor circuits of the service bomb. The manual switch is mounted on the side of the hull, figure 11-55. The weapon con­ nector is mounted on the after bulk­ head of the hull, figure 11-56. The upper surface of the weapon connector is accessible through the opening in the top of the after­ body and is approximately flush with the surface of the afterbody. A cable, dwg 1541079, electrically connects the manual switch to the weapon connector and fault switch, figure 11-54. M a n u a l S w i t c h . Practice Weapon Man­ ual Switch, Mk 52 Mod 0, figure 11-55, con­ sists of a single pole, double throw rotary switch that is operated by an attached con­ trol mechanism. The manual switch is en­ cased in an aluminum housing and is mounted in an opening in the side of the hull. It is held in place by two steel tabs fastened to the hull with self-locking screws, dwg 1476493-23. A notch in the side of the P R A C T IC E B O M B ASSEM B LIES housing matches an alignment pin in the flanged mounting seat in the hull. The back of the housing is fitted with a male plug and threaded sleeve for making connection with the cable from the weapon connector. The entire unit is sealed with O-rings. The switch has two positions, SAFE and ARMED, indicated by engraved lettering on the outside of the control mechanism. When the control mechanism is rotated to either the SAFE or ARMED position, it is locked in place by spring loaded balls inside the mechanism. To operate the control mechanism, Arm­ ing Wrench H-3113 is inserted against a spring-loaded piston in the center of the con­ trol mechanism, figure 11-57. This releases the locking balls and the mechanism can be rotated by turning the wrench. Turning the wrench clockwise arms the switch and counterclockwise safes the switch. When the new position is reached, the wrench is forced out of the piston and the springloaded balls again lock the mechanism in place. As an added safety factor, when the con­ trol mechanism is not locked in either of its two positions, the arming wrench cannot be pulled out. Figure 11-57.— Manual Switch Mk 52 Mod 0 and Arming Wrench. Figure 11-58.— Weapon Connector Mk 22 Mod 0 and Adapter Plug. W eapon Co n n ec to r . Practice Weapon Connector Mk 22 Mod 0, figure 11-58, pro­ vides access to the electrical circuits in the practice bomb. The connector assembly consists of an aluminum housing, adapter plug, and Motor Driven Switch Mk 53. A rotary fault switch is mounted in the same housing for con­ venience of access but does not function as part of the connector. The fault switch is described separately. The connector housing is mounted in an opening in the after bulkhead and is secured by four self-locking screws, dwg 147640419. One end of the adapter plug mates with the receptacle in the weapon connector, and the other end mates with a cable from the aircraft. In operation, a wire bail on the adapter plug is attached to the aircraft. If the weapon is released from the aircraft, the adapter plug is pulled out of the connector receptacle and remains with the aircraft. The connector receptacle consists essen­ tially of two parts: a female receptacle and three steel retainer balls. The female re­ ceptacle mates with its male counterpart in the adapter plug. The outside surface of the adapter plug sleeve has three L-shaped grooves which engage the retainer balls in 11-79 N A V W E P S OP 2216 (V O L U M E 1) the connector receptacle. The adapter plug has two positions, LOCKED and UN­ LOCKED as engraved on top of the plug, figure 11-58, which are determined by the position of the stop pin in the slot between these indicated positions. The adapter plug must be in the UNLOCKED position before it can be installed in the weapon connector. Turning the adapter plug clockwise locks the weapon connector by means of the retaining balls. The stop pin halts the rotation of the sleeve when it is in the LOCKED position and a set screw secures the sleeve in that position. When the adapter plug must be removed from the weapon connector for testing or other purposes, the set screw must be loosened and the sleeve turned to the UN­ LOCKED position. However, if the bomb is dropped from an aircraft, the weight of the bomb will pull the locked adapter plug from the connector. A rubber boot on the adapter plug seals the joint between plug and receptacle. A protective dust cover is installed on the ex­ posed threads of the adapter plug when the bomb is in storage or shipment. When the dust cover is removed from the adapter plug, it is secured under a spring clip located on top of the weapon connector; to prevent loss it is attached to the clip by a short chain. Motor Driven Switch Mk 53 simulates the MC-725 switch in the service bomb. Mounted in the forward part of the con­ nector housing, it consists of a rotary wafer switch and a small electric motor. When the motor operates, the switch is rotated to either of two positions. In one position it closes a simulated ARMED circuit and in the other a simulated SAFE circuit. The switch has two sets of contacts, one for monitoring the armed and safe position and one for operation of the motor. A 32-inch cable electrically connects the manual switch with the weapon connector. The cable is clamped to the forward end of the weapon connector housing and passed into the housing where it is permanently connected to various, terminals. The other 11-80 end of the cable is fitted with a standard female AN connector, which mates with the plug in the back of the manual switch. F ault S w it c h . The fault switch is lo­ cated in the connector housing, figure 11-58, and is protected by a dust cap when the switch is not in use. It is a rotary, fiveposition switch, operated by turning the slotted rotor with a screwdriver. The fault switch simulates defects in the service bomb by opening certain circuits in the practice bomb. Dummy Bomb Depth Dummy Bomb, Mk 108 Mod 0 is an expendable dummy form of the Mk 102 bomb and is used for fit tests on aircraft prototypes and for nonrecoverable drops from aircraft. It is a duplicate of the Mk 10 2 with the following exceptions: 1. It does not contain any of the switches or associated wiring. 2. It contains a Weapon Dummy Con­ nector, Mk 23 Mod 0 which is unwired but is capable of receiving an adapter plug. 3. The hull has no opening for a manual switch or a weapon connector. Functioning The practice bomb simulates the manual switch, the MC-725 switch, the series moni­ tor circuit, and the pressure monitor switch circuit of the service bomb. The practice bomb also incorporates a fault switch that can simulate various faults which might ap­ pear in the service bomb. Operation of the practice bomb consists of applying voltage to its circuits and operating its switches in conjunction with either a monitor test set or an aircraft control box. A schematic wiring diagram of the practice bomb ap­ pears in figure 11-59. In this section, all the pins referred to are on the weapon con­ nector receptacle. Simulated Manual Safety Switch and Series Monitor Circuit. The manual safety switch and rotary switch control of the serv­ ice bomb are simulated in the practice bomb by Manual Switch Mk 52, previously de­ scribed. This switch simulates the SAFE and P R A C T IC E B O M B A SSEM B LIES ARMED conditions of its service counter­ part. The associated wiring in the practice bomb simulates the rest of the series monitor circuit in the service bomb. Operation of the manual switch consists of rotating it to the SAFE or ARMED position, thus chang­ ing the circuit configuration of the practice bomb. M a n u a l S w i t c h i n S a f e P o s i t i o n . When the manual switch is rotated to the SAFE position and the fault switch is in position 1, a circuit is completed from pin G and pin M to pin T through the fault switch and the manual switch. The circuit from pin G to pin T simulates the series monitor circuit with the high-voltage power supply installed in the weapon, and the circuit from pin M to pin T simulates the series monitor circuit when the high-voltage power supply is not installed. If the fault switch is in position 4 both simulated circuits are open. This simulates a fault in the service weapon as indicated in the following table. Manual Sw it c h in A rm ed Fault Switch Simulations P osition S im u late d S er v ic e W eapon F au lt of S w itch 1 2 3 4 P o s it io n . When the manual switch is rotated to the ARMED position and the fault switch is in position 1 , a circuit is completed from pin V to pin T through the fault switch and the manual switch. This simulates that part of the monitor circuit seen by the aircraft control b ox : the manual safety switch ARMED monitor and the pull-up switch monitor contacts closed. If the fault switch is in position 5, the circuit is open. This simulates a fault in the service weapon as indicated in the pre­ ceding table. M o to r D r iv e n S w i t c h . Motor Driven Switch Mk 53, described previously is lo­ cated in the housing of the weapon con­ nector for the practice weapon. The switch has two sets of contacts which operate simul­ taneously : the power contacts which act as limit switches controlling the power to the motor, and the monitor contacts which in­ dicate the ARMED and SAFE positions of the switch. The motor driven switch simu­ lates the MC-725 switch (in-flight safety switch) of the service weapon. 5 None— does not interfere with circuits. MC-725 switch unable to move to ARM ED position because: a. Timer not in home position. b. Low voltage power supply has been initiated. c. MC-725 switch motor or wiring is faulty. d. Connector Cable CF-3011 or M C 725 Switch is faulty. M C-725 Switch unable to return from ARM E D to SAFE position because motor or wiring is defective. Open series monitor circuit because: a. Pull-up switch has operated or is faulty. b. Manual safety switch is not in SAFE position or is faulty. c. X-unit connector is not connected or is faulty. d. Weapon connector cable CF-3011 is faulty. Open monitor circuit seen by control box (pull-up switch and ARM ED Manual Safety Switch) because: a. Pull-up switch has operated or is faulty. b. Manual safety switch is not in ARM E D position or is faulty. c. Weapon connector cable CF-3011 is faulty. A r m in g t h e S w i t c h . T o move the switch to the ARMED position voltage is applied to the motor circuit through pin K or J. Since a ground on pin S is applied to the motor through the fault switch and the power contacts of the motor-driven switch, the motor operates and drives the switch to­ ward the ARMED position indicated by the dotted lines in figure 11-59. After four to seven seconds of operation the power con­ tacts open and the ground is removed from the motor. The motor stops and the switch remains in the ARMED position. At the outset of the arming operation, a 11-81 N A V W E P S OP 2216 (V O L U M E 1) r i j Figure 11— 59.— Schematic Wiring Digram Practice Depth Bomb Mk 102 Mod 0. circuit is complete from pin L to pin F through the monitor contacts. As the switch moves toward the armed position, the circuit from pin L to pin F is opened by the chang­ ing position of the monitor contacts and a circuit from pin L to pin H is completed. For a brief interval during the travel of the switch the circuit from pin L is com­ pleted to both pin F and pin H. If the fault switch is in position 2 before beginning the arming operation, the circuit from pin S to the motor is open and the motor will not operate. This simulates the faults indicated in the preceding table. 11-82 S afing t h e S w it c h . T o move the switch from the ARMED to the SAFE position, voltage is applied to the motor circuit through pin P, the fault switch, and the power contacts of the motor driven switch. Since a ground on pin K is applied to the motor, the motor operates but in the oppo­ site direction because of the reversed po­ larity of the applied voltage. The switch is driven toward the SAFE position. After four to seven seconds of operation, the cir­ cuit from pin P to the motor is broken and the motor stops. The switch remains in the SAFE position. P R A C T IC E B O M B A SSEM B LIES At the outset of the safing operation a closed circuit exists from pin L to pin H through the monitor contacts. As the switch moves toward the SAFE -position, the cir­ cuit from pin L to pin H is opened by the changed position of the monitor contacts and the circuit from pin L to pin F is com­ pleted. For a brief interval during the travel of the switch the circuit from pin L is completed to both pin F and pin H. If the fault switch is in position 3 before beginning the safing operation, the circuit from pin P to the motor is open and the motor will not operate. This simulates a fault in the service weapon as indicated in the simulations table. Simulated Pressure Monitor Switch. The pressure monitor switch of the service weapon is simulated in the practice weapon by a jumper from pin R to pin B of the weapon connector. This simulates the nor­ mal closed condition of the pressure monitor switch in the service weapon. The practice weapon does not simulate an open condition of the pressure monitor switch. Unpackaging and Testing The procedures to be followed in preparing the practice bomb for use consist of two major steps: removing the bomb from its packaging, and testing the electrical circuits and switches in the bomb. When defective components are discovered follow the re­ placement procedures described later. Unpackaging the Bomb. The bomb is shipped completely assembled. No spare components or accessories are packaged with the bomb. The practice bomb is shipped on a wooden skid secured by three metal bands. Un­ packaging the bomb consists of removing the bomb from the skid and placing it on a truck dolly: 1. Cut the three metal bands with metal cutting shears. 2. Attach an H-3102 sling to the bomb suspension lugs and to a hoist ( 200 0 -pound minimum capacity). 3. Lift the bomb from the skid and place it on an H-3103 truck dolly with the nose of the bomb resting against the pillow block. 4. Remove the sling. NOTE: All inspecting, testing, and parts replacement may be done with the weapon on the H-3103 dolly. Unpackaging Spare Components. If test­ ing shows that a component of the bomb is defective it is replaced by a spare component. Spare components are individually packaged in reusable aluminum containers. The con­ tainers are lined with foam plastic to cushion the component during shipment. Four latches secure the cover of each container and, during shipment, two of the latches are secured by lead car seals. Desiccant is included in each container. The container may be shipped individually or in quantity. When shipped in quantity they will normally be overpacked in wooden boxes. A spare component is unpacked as fol­ lows : 1. Remove the wooden overpacking, if present. 2. Remove the lead car seals from the con­ tainer latches, open the latches and remove the container cover. 3. Inspect the humidity indicator card. If excessive humidity is indicated, inspect the component with particular care to insure that it has not been adversely affected. In addition examine the container to determine if the humid condition resulted from con­ tainer failure. Defective containers should not be reused unless the cause of their failure is readily correctable. 4. Lift out any loose cushioning and re­ move the component. 5. Replace the cushioning and the cover. Set the container aside for future use or return it to the issue point. A rejected component may be packed in the container from which its replacement was removed, and the container appropri­ ately tagged. Testing. The components to be tested in the bomb are the manual switch, weapon 11-83 N A V W E P S OP 2216 (V O L U M E 1) connector, adapter plug, motor driven switch, fault switch, and their associated wiring. The testing is done with the Monitor Test Set T-3-24 and with the Safety Switch Test Set T-3026. One position of the fault switch is tested with an ohmmeter. CAUTION: Do not attempt to apply voltage to the practice bomb from any source other than those mentioned in this publication. The correct voltage and polarity is sup­ plied only by the monitor test set, safety switch test set, or the air­ craft control box. The test sets indicate by lights that con­ tinuity exists in the weapon circuits. Each test set can be self-checked for possible de­ fects. Procedures for the self-check and for the weapon tests are described in the following paragraphs. P r e p a r a t io n o f t h e M o n it o r T e s t S e t . Initial preparation of the monitor test set is the same for the self-check and the weapon test. NOTE: This test set is selfpowered and therefore needs no external source of power. The test set is prepared as follows: 1. Remove the top case and open the hinged lid inside the top case. 2. Remove the cables and ground strap. 3. Connect the lug end of the ground strap to the GROUND post on the test set panel. 4. Connect the clip end of the ground strap to a good earth ground. All these connections are maintained for both the self-check and the weapon test. S e l f -C h e c k o f M o n it o r T e s t S e t . For the purpose of self-checking, the T-3024 is provided with two connectors mounted on the hinged panel in the top half of the con­ tainer. Two cables are provided with the test set: CT-3057 and CT-3058. If the set is to be fully checked tests must be conducted with both cables as indicated in the follow­ ing paragraphs. If the lights do not come on or go off as 11-84 specified during the self-check, the test set is defective. For trouble shooting proce­ dures, refer to NAVY SWOP T3024-2. The self-check is performed as follows: USING CABLE CT-3057. 1. Plug the standard male AN connector on CT-3057 into the connector on the front panel of the test set. Plug the female con­ nector on the other end of the cable into the CT-3057 TEST connector on the hinged lid in the top case of the test set. 2. Operate the POWER switch to the ON position. The W /H SAFE, BATTERY-ON, and PRESSURE lights should come on. If all three lights do not come on, there is a de­ fect in the test set. USING CABLE CT-3058. 1. Plug the standard male AN connector on CT-3058 into the connector on the front panel of the test set. Plug the special con­ nector on the other end of the cable into the CT-3058 TEST connector on the hinged lid in the top half of the container. 2. Operate the POWER switch to the ON position. All four lights on the panel should come on. If all four lights do not come on, there is a defect in the test set. T e s t in g Pr a c tic e W e a p o n W i t h M o n i­ T e s t S e t . The T-3024 checks the con­ to r tinuity of the simulated series monitor cir­ cuit, and the operation of the manual switch. The test set is powered by its own 6 -volt battery. Cable CT-3057 is used when test­ ing through the adapter plug and cable CT3058 is used when testing directly through the weapon connector. Tests must be per­ formed with both cables. The procedures followed in testing the weapon are described in the following paragraphs. USING CABLE CT-3057. 1. Plug the standard male AN connector on cable CT-3057 into the connector on the front panel of the test set. Plug the female connector on the other end of the cable into the adapter plug on the weapon. Rotate the manual switch to the SAFE position. Ro­ tate the fault switch to position 1. The weapon now is ready to be tested. 2. Operate the test set POWER switch to the ON position. The BATTERY-ON, W /H P R A C T IC E BO M B A SSEM B LIES SAFE, and PRESSURE lights should come on. 3. Rotate the manual switch to the ARMED position. The test set BATTERYON light should go out. 4. Rotate the manual switch to the SAFE position. The test set BATTERY-ON light should come on. Rotate the fault switch to position 4. The BATTERY-ON light should go out. U se o f S a f e t y S w i t c h T e s t S e t . The T-3026 is used to functionally test Motor Driven Switch Mk 52 during assembly pro­ cedures or trouble shooting of the practice bomb by assembly organizations. CAUTION: The T-3026 should be used with the practice bomb main­ taining the same safety precautions as used with the service bomb. Re­ fer to NAVY SWOP B101-1 for proper service bomb usage. Initial preparation of the safety switch test set is the same for the self-check and the weapon test. The test set is prepared as follows: 1. Remove the top case and open the hinged panel inside the top case. 2. Remove the power cord, the ground strap, and cable CT-3061. The other cable, CT-3063, is not used in testing the practice bomb. 3. Connect the lug end of the ground strap to the GROUND post on the front panel of the test set. 4. Connect the clip end of the ground strap to a good earth ground. 5. Connect one end of the power cord to the 3-pin male connector on the panel and the other end to a 95-130V 55-65 CPS power source. S e l f - C h e c k o f S a f e t y S w i t c h T e s t Se t . For purposes of self-checking, the T-3026 is provided with a test receptacle and test light mounted on the hinged panel in the top half of the container. If the lights do not come on or go off as specified during the self-check, the test set is defective. For trouble shooting procedures, refer to NAVY SWOP T3026-2. The self-check is per­ formed as follows: 1. Set the test set rotary switch in the OFF position. 2. Connect one end of cable CT-3061 to the standard AN receptacle on the test set panel and the other end to the CON­ TINUITY TEST receptacle on the hinged panel. 3. Operate the POWER switch to the ON position. The POWER light should come on and stay on while making the following tests. 4. PRESS-TO-TEST the BATTERY-ON, MONITOR, W /H SAFE, and W /H ARMED lights. Each light should come on when its shield is pressed and go out when its shield is released. 5. Turn the selector switch to the W /H SAFE position. The BATTERY-ON, MON­ ITOR, and W /H SAFE lights should come on. 6 . PRESS-TO-TEST the test light that is mounted on the hinged panel in the top half of the case. The light should come on when its shield is pressed and go out when its shield is released. 7. Turn the selector switch to the W /H ARMED position and hold the switch in that position. The BATTER Y-ON and MONI­ TOR lights should stay on. The W /H SAFE light should go out. The W /H ARMED light and the test light on the hinged panel should come on. 8 . Release the selector switch. The switch should return automatically to the W /H SAFE position; the BATTERY-ON and MONITOR lights should stay on, the W /H SAFE light should come on, and the W /H ARMED light and the test light on the hinged panel should go out. 9. Turn the selector switch to OFF. All lights except the POWER light should go out. 10. Operate the POWER switch to OFF. The POWER light should go out. T e s t i n g P r a c t i c e W e a p o n w i t h Sa f e t y S w i t c h T e s t S e t . The T-3026 checks the continuity of the simulated safety switch circuits, the operation of the safety switch motor, and the operations of the fault switch. 11-85 N A V W E P S OP 2216 (V O L U M E 1) The test set supplies 28-volt DC to the cir­ cuits under test. The procedures followed in testing the weapon are described in the fol­ lowing paragraphs. 1 . Connect one end of cable CT-3061 to the AN receptacle on the test set panel and the other end directly to the weapon con­ nector. (The adapter plug is not used with this test set.) 2. Rotate the manual switch of the prac­ tice weapon to the SAFE position. Rotate the fault switch to position 1 . 3. Operate the test set POWER switch to the ON position. The POWER light should come on. 4. Turn the test set test selector switch to the W /H SAFE position. The W /H SAFE, MONITOR, and BATTERY-ON lights should come on. NOTE : From step 5 through step 8 the BATTERY ON and MONITOR lights should remain on. 5. With the fault switch in position 2, turn the test selector switch to the W/H ARMED position and hold it there four to seven seconds. The W /H ARMED light should remain out and the W /H SAFE light should remain on. 6 . With the fault switch in position 1, turn the test selector switch to the W /H ARMED position and hold it there. After four to seven seconds the W /H ARMED light should come on and the W /H SAFE light should go out. 7. While holding the rotary switch in the W /H ARMED position, turn the fault switch to position 3. Release the test selector switch, allowing it to return automatically to the W /H SAFE position. The W /H SAFE light should remain out and the W /H ARMED light should remain on. 8 . Return the test selector switch to the W /H ARMED position and hold it there. Return the fault switch to position 1. Re­ lease the test selector switch, allowing it to return automatically to the W /H SAFE position. After four to seven seconds the W /H SAFE light should come on and the W /H ARMED light should go out. 11-86 9. Before the test set selector switch is turned to the OFF position, the W /H ARMED light must be allowed to go out and the W /H SAFE light to come on, as indicated in the preceding paragraph. Then turn the selector switch to the OFF posi­ tion. The MONITOR, BATTERY-ON, and W /H SAFE lights should go out. 10. Operate the POWER switch to the OFF position. The POWER light should go out. T e s t i n g P o s it io n 5 op F a u l t Sw i t c h . Position 5 of the fault switch does not enter into any of the circuits checked by the two test sets and must be tested with an ohmmeter as follows: 1. Insert the adapter plug into the weapon connector. 2. Rotate the manual switch to the ARMED position. Rotate the fault switch to position 5. 3. Connect an ohmmeter across pins P and V of the adapter plug. The meter should indicate an open circuit. 4. Rotate the fault switch to any other position. The meter should indicate a closed circuit. Troubleshooting. Users of this publica­ tion must not repair defective components but must replace them with new ones. Therefore troubleshooting consists simply of localizing an indicated trouble to one of three replaceable components: the adapter plug, the manual switch, or the weapon con­ nector. (The fault switch and the motor driven switch are included in the weapon connector.) Procedures for removing and replacing components follow under Disas­ sembly and Assembly. The following steps should localize any trouble. 1. Replace the adapter plug with a new one and re-run that part of the test which indicated trouble. If trouble is still indi­ cated, reinstall the original adapter plug and proceed to step 2 . 2. Replace the manual switch with a new one. With the manual switch connected to the cable but not mounted, re-run that part of the test which indicated trouble. If P R A C T IC E BO M B A SSEM B LIES trouble is still indicated, proceed to step 3. 3. Connect a new weapon connector to the original manual switch, without mounting either component on the hull. Re-run that part of the test that indicated trouble. If the trouble has been corrected, mount the original manual switch and the new weapon connector on the hull. 4. If, after these three steps, trouble is still indicated, it is possible that more than one component of the bomb is defective. In such a case, replace all the components with new ones and then substitute all the old components one at a time until the trouble reappears. This will identify the defective components. Assembly. It is assumed that all assem­ bly is taking place on the H-3103 dolly. As­ sembly procedure consists of three steps in this order: the weapon connector is mounted on the after bulkhead of the hull; the manual switch is joined to the weapon connector cable and mounted in the side of the hull; the afterbody is fastened to the hull. W e a p o n C o n n e c t o r I n s t a l l a t i o n . In­ stallation of the weapon connector requires a piece of stiff wire at least 32 inches long for fishing the cable through the hull to the manual switch opening. The weapon con­ nector is installed as follows: 1. Insert the guide wire through the man­ ual switch opening in the hull and bring the end of it out through the weapon connector opening in the after bulkhead. 2. Attach the guide wire to the end of the weapon connector cable. 3. Draw the cable through the weapon connector opening and insert the weapon connector housing in the opening. 4. Fasten the weapon connector housing to the after bulkhead with four self-locking screws, dwg 1476493-19, tightening them with a torque of 42 to 50 foot-pounds. M a n u a l S w i t c h I n s t a l l a t i o n . Install the manual switch as follows: 1. With the weapon connector installed, draw the cable through the manual switch opening in the side of the hull with the guide wire. 2. Install the cable connector on the man­ ual switch and secure it with the threaded sleeve on the cable connector. 3. Orient the manual switch in the open­ ing in the hull by matching the aligning pin in the flanged seat with the notch in the switch housing and install the switch. 4. Locate the two locking tabs with the crescent ends toward the switch, figure 1155, and secure the assembly with self-lock­ ing screws, dwg 1476493-23. Tighten the screws with a torque of 15 to 20 inch-pounds. A f t e r b o d y I n s t a l l a t i o n . Three men are needed to attach the afterbody to the hull. Two men lift the afterbody and a third man installs the clamp band. The afterbody is attached as follows: 1. Lift the afterbody into position against the after bulkhead of the hull. An align­ ment pin on the hull fits into a corresponding hole in the afterbody. 2. Secure the afterbody to the hull by in­ stalling the three clamp band segments on the grooved flanges. Use assembly wrench H-3115, and self-locking screws, dwg 1476493-12, tightening all screws with a torque of 12-15 foot-pounds. Disassembly. Replacement of components may require some disassembly of the bomb. Disassembly is carried out only as far as is necessary for replacing the defective com­ ponent. The order of disassembly is as follows: detach the afterbody from the hull: remove the manual switch; remove the weapon con­ nector. If the manual switch alone is de­ fective, it can be replaced without removing the afterbody. All disassembly may be conveniently done with the weapon on an H-3103 dolly. A fter b o d y R e m o v a l . Three men are needed to detach the afterbody from the hull. Two men support the afterbody while a third man removes the clamp band. The afterbody is detached as follows: 1. Using assembly wrench H-3115 re­ move the screws from the clamp band seg­ ments and remove the segments from the weapon. 2. Remove the afterbody from the hull. Raise the afterbody slightly as it is moved 11-87 N A V W E P S OP 2216 (V O L U M E 1) away from the hull in order to clear the weapon connector. M a n u a l S w i t c h R e m o v a l . The manual switch is removed as follows: 1. Insert an arming wrench into the switch and rotate it to a point midway be­ tween the ARMED and SAFE, positions. 2. Remove the two mounting screws that fasten the tabs to the hull. 3. Pull the switch out of the hull by means of the arming wrench. 4. Disconnect cable from switch. W eapon 11-88 Co n n ecto r Rem oval. Th e weapon connector cannot be removed from the hull until the afterbody has been taken off and the manual switch has been discon­ nected from the cable. The weapon con­ nector is removed as follows: 1. Remove the four socket-head screws that secure the weapon connector to the after bulkhead of the hull. 2. Withdraw the connector and attached cable from the opening in the bulkhead. Avoid scraping the cable on the edge of the opening. Chapter 12 SAFETY PRECAUTIONS General Safety Precautions Under no circumstances should any Naval activity attempt to render inert live-loaded bombs and fuzes to fill an order for inert material. Under no circumstances shall am­ munition be modified or changed without specific authority from the Bureau of Naval Weapons. It must be assumed that fuzes may func­ tion at some indeterminate time after the dumping of bombs, regardless of the method of disposal. Lower the bombs over the side to the water surface. Keep them off the hull to the fullest extent practicable. Re­ lease bombs into the water with the least amount of fall that circumstances permit. Fuzes, bombs, igniters, and bursters are not to be unpacked in advance of require­ ments. If unpacked and not used, return them to their original packings. Do not use a fin assembly if it cannot be properly secured to the bomb. If the fin assembly is loose and turns while on the bomb, it will pull the arming wire from the tail fuze and the fuze may arm before the bomb is dropped. Never use an arming wire that is twisted, kinked, or burred. These conditions are caused by mishandling. Burrs may result when cutting the arming wire to its required length or at any other point in the opera­ tion. File or recut to remedy the condition. Safety Precautions for Fuzes The use of certain World War II fuzes is restricted; refer to NAVORDINST 8024.25. Under no condition will any attempt be made to unarm an impact nose fuze of the AN-M158 type which is suspected of being armed. No attempt should be made to unarm im­ pact tail fuzes of the AN-M100A2 type by turning the arming vane backwards. If the threads on the arming stem fail to en­ gage the threads on the firing plunger, the firing plunger will be pushed into the primer with probable initiation of the explosive components. Prevent the arming-vane assembly of im­ pact tail fuzes of the AN-M115 type from rotating by inserting a cotter pin or wire through the holes in the arming-stem cup and the bearing-cup eyelet. This will not make the fuze any safer if it is fully armed, but will prevent partially armed fuzes from becoming completely armed. Once installed, no attempt shall be made to remove long-delay tail fuzes of the A N M123 type from bombs. The following precautions must be ob­ served at all times when handling long-delay tail fuzes of the AN-M123 and AN-M132 type. 1. Do not assemble the detonator holder to fuzes or fuzes to bombs in anticipation of future needs. 2. Take particular care to protect these fuzes from heat and shock. 3. Examine the indicator vials when the fuze packing box is opened. If all fuzes in the box are not used, leave the vials in the box with the remaining fuzes and reinspect them when the box is reopened. 4. When engaging threads of mating parts in assembling these fuzes to a bomb, do not turn one part back and forth until the threads engage. Use a screwing-in motion only. The antiwithdrawal device will cause the fuze and bomb to detonate if the fuze is rotated counterclockwise while in the adapter-booster, even before the threads are engaged. Bombs fuzed with AN-M123A1, A N M124A1, or AN-M125A1 fuzes cannot be released SAFE. Impact will cause the sol­ vent ampoule to shatter and to initiate the delay train, even with the arming wire in place. In the event of incomplete missions, these fuzed bombs are to be jettisoned over enemy territory or deep water. Once in­ stalled, no attempt shall be made to remove the fuzes from the bombs. 12-1 N A V W E P S OP 2216 (V O L U M E 1) Once installed, no attempt shall be made to remove long-delay tail fuzes of the A N M132 type from bombs. Any attempt to remove them will cause the antiwithdrawal device to detonate the fuze instantaneously. Do not remove the warning tag attached to these fuzes when the fuze is assembled to the bomb. When fully armed, the antidisturbance side fuze (M131 or M131A1) is extremely sensitive and very dangerous. Only a slight vibration is needed to initiate the antidis­ turbance mechanism and explode the bomb. DO NOT HANDLE armed or questionably armed fuzes of this type; they are to be destroyed by authorized personnel, together with the bomb. With Nose Fuzes AN-M103A1, A N M139A1, and AN-M140A1, do not remove the cotter pin that locks the vane strap and eyelet strap until the bomb is installed in the bomb rack. Before attempting to remove any fuze from a bomb, be sure it is in the unarmed condition or safe to handle. The following conditions apply to the individual fuzes des­ ignated. 1. Nose Fuzes AN-M158 and AN-M159 must be considered armed if the striker has risen more than V4, inch above the vane nut. 2. Nose Fuze AN-Mk 219 Mods 3 and 4 will be regarded as armed if the striker flange has advanced % G inch from the outer sleeve. From outward appearances it is practically impossible to obtain a definite indication as to whether the fuze is partially or fully armed. 3. Nose Fuzes Mk 243 Mod 0 and Mk 244 Mod 1 are armed if the arming assembly (arming vanes, vane cup, and reduction gears) is missing. If the arming assembly is not missing, measure the distance between the flange of the vane cup and the flange of the vane cup support. If this distance is 14 inch or more, the fuze is fully armed. If less than 1 4 inch, the fuze is partially armed. 4. Check Mechanical Time Nose Fuzes AN-M145A1 and AN-M146A1 and Mechani­ cal Time Fuze M155A1 for clearance between 12-2 the striker and safety block. If the striker should snap down or tightly against the safety block, or if the safety block should fall out, replace the block, secure it with tape, remove the fuze from the bomb or cluster, and set it aside for disposal by authorized and qualified personnel. 5. Impact Tail Fuzes AN-M100A2, A N M101A2, AN-M102A2, M172, AN-M184, AN-M185, AN-M194, AN-M195, and the AN-M115 series are armed if the armingvane assembly and reduction-gear mecha­ nism are missing. If these are not missing, the fuze is not necessarily in the unarmed or SAFE condition. Measure the distance between the eyelet and the bearing cup and the flange on the arming-stem cup. If the distance is less than inch, the fuze is partially armed; if 1/2 to % inch, arming is questionable; if more than % inch, the fuze is definitely armed. 6. The degree of arming of Impact Tail Fuze AN-Mk 228 Mods 0 and 1 can be de­ termined through a small glass window in the side of the fuze by examining the relative positions of the striker, cover, and outer sleeve. If the upper surface of the striker and the lower edge of the cover are about flush with the top edge of the sleeve, the fuze can be considered unarmed. If the position of the striker is not more than 3/ 10 inch away from the outer sleeve, the fuze can be considered only partially armed. If the striker has moved away from the outer sleeve about 1/32 inch, the fuze is to be con­ sidered fully armed. 7. If the arming-vane assembly and the arming screw of Tail Fuze AN-Mk 247 Mod 0 are missing, or if the arming-vane assem­ bly is raised from the fuze y% inch or more, the fuze is armed. 8. There is no way of telling from visual inspection of Hydrostatic Tail Fuze AN-Mk 230 Mods 4, 5, and 6 whether or not it is armed. 9. If the anemometer hub of Multi-Posi­ tion Fuze M157 or AN-M173A1 has sepa­ rated from the fuze head by Ys inch or more, or if the anemometer vanes are completely removed from the fuze, the fuze is armed. SA FETY P R EC A U T IO N S Do not attempt to remove an armed, un­ armed, or questionably armed Side Impact Fuze M129 from a bomb. Do not attempt to remove an armed, un­ armed, or questionably armed Side Time Fuze M130 or M130A1 from a bomb. Fuze M131, which is very similar in appearance to the M130 and M130A1 fuzes, has an anti­ disturbance feature which will detonate an armed bomb when slightly vibrated. Do not attempt to remove an armed, un­ armed, or questionably armed Side Anti­ disturbance Fuze M131 from a bomb. The antidisturbance mechanism in the fuze will detonate the bomb if the fuze is armed. Use extreme care in handling Impact Tail Fuze AN-Mk 228 Mods 0 and 1; some lots are dangerously sensitive. Do not remove the safety cotter pin that locks the arming mechanism of AN-Mk 228 fuzes. Make no attempt to install detonators in Long-Delay Tail Fuzes AN-M123A1, A N M124A1, AN-M125A1, AN-M132, A N M133, or AN-M134. Fuzes must be disposed of by authorized personnel. Long-Delay Tail Fuzes AN-M123A1, A N M124A1, or AN-M125A1 will detonate if their extensions are unscrewed by any amount. Once an AN-M123A1, AN-M124A1, A N M125A1, AN-M132, AN-M133, or A N M134 fuze is inserted in the adapter-booster, the fuze must not be turned backward (counterclockwise) by any amount, how­ ever slight. Engage the threads by a screw­ ing-in motion only. Do not attempt to unscrew the fuze; screwing-out motion will cause the locking ball to become wedged against the wall of the adapter-booster and any further turning will detonate both the fuze and the bomb. If any thing interferes with the comple­ tion of a fuzing operation involving an A N M123A1, AN-M124A1, AN-M125A1, A N M132, AN-M133, or AN-M134 fuze, no attempt shall be made to defuze the bomb. The bomb, with the fuze in place, shall be disposed of by authorized and qualified per­ sonnel. Do not partially pre-arm Hydrostatic Tail Fuze AN-Mk 230 to insure arming at low altitudes. The extent of arming cannot be determined by visual examination. If the fuze is already in a state of partial arm­ ing, additional rotation of the vanes may complete arming and render the fuze dan­ gerous since fluid pressure (air or water) applied through parts in the body may build up sufficiently to detonate the fuze. If an AN-M166E1 VT fuze container (used with the Mk 77 Mod 0 fire bomb) is damaged or if the seal is broken in any way, the fuze is to be considered unservice­ able. Safety Precautions for Bomb Components Other Than Fuzes All M15 and AN-M16 igniters now in stock, with the exception of those procured during or after 1950, have Arming-Wire Assemblies C-10 packed in the same ship­ ping box. Because of reported malfunc­ tions, these wires are to be used only in the event that standard arming wires are not readily available. If used, precautions must be taken to crimp the ferrule, or slide, with pliers and to bend back the short length of the loop attached to the swivel 180 degrees on itself. Rough handling of Practice Bomb Signal Mk 4 Mods 3 and 4, Mk 6 Mod 0, or Mk 7 Mod 0 may cause immediate functioning, or may damage the signal so that it will not function properly. Avoid dropping or jar­ ring these signals at all times. Practice Bomb Signals Mk 4 Mods 3 and 4, Mk 6 Mod 0, and Mk 7 Mod 0 must not be unpacked in advance of requirements. If unpacked and not used, return them to their original packings. Swollen or deformed practice bomb sig­ nals are not to be used. The primer must be flush with or slightly below the base of the signal. Defective signals will be turned over to a bomb disposal officer. Under no circumstances should a signal case containing Practice Bomb Signals Mk 4 Mods 3 and 4 be opened or tampered with. If cartons containing Practice Bomb Sig­ 12-3 N A V W E P S OP 2216 (V O L U M E 1) nals Mk 6 Mod 0 or Mk 7 Mod 0 are punc­ tured, split, or badly damaged, or if the seals are broken, the contents are considered unserviceable. This does not apply to sig­ nals repacked in the field and sealed with adhesive tape for temporary protection. These assemblies must be examined carefully for serviceability by qualified personnel. Stow Practice Bomb Signals Mk 6 Mod 0 and Mk 7 Mod 0 in a dry, ventilated location, out of the direct rays of the sun. If necessary to disassemble Practice Bomb Signal Mk 6 Mod 0 or Mk 7 Mod 0, the safety cotter pin must be installed in the body of the fuze before the arming wire is removed. Safety Precautions for Armor-Piercing and Semi-Armor-Piercing Bomb Assemblies Use only fin assemblies that are in good condition. Reject fin assemblies that are rusted, dented, bent, or have loose fins. Inspect suspension and hoisting lugs for damage or defects before securing them to the bomb body. Replace if necessary. If fuze containers are found to be punc­ tured, split, or if the seal is broken in any way, the fuzes contained therein are con­ sidered unserviceable. This does not apply to fuzes replaced in the field and resealed with adhesive tape for temporary protection. Such fuzes should be examined carefully for serviceability. One of the fuzes used with the 500-lb SAP Bomb AN-M58A2 is the AN-M124A1 tail fuze which incorporates the use of an anti­ withdrawal device. The 1000-lb SAP Bomb AN-M59A1 and the 2000-lb SAP Bomb M103 use the AN-M125A1 and the A N M134 tail fuzes which also have an anti­ withdrawal device. Nondetonation of bombs using these fuzes cannot be relied upon when released SAFE because the glass solvent ampoule in the fuze may be broken upon im­ pact of the bomb. Once one of these fuzes is installed, no attempt should be made either to remove the fuze from the bomb or to return the bomb to an airfield or aircraft carrier upon an incomplete mission. Do not turn the fuze back and forth to engage 12-4 threads; use a screwing-in motion only. The antiwithdrawal device will cause the fuze and the bomb to detonate if the fuze is rotated counterclockwise while in the adapter-booster, even before the threads are engaged. Safety Precautions for General Purpose Bomb Assemblies The 100-lb GP Bomb AN-M30A1 and the 250-lb GP Bomb AN-M57A1 use the AN M123A1 and the AN-M132 tail fuzes which incorporate the use of an antiwithdrawal de­ vice. The 500-lb GP Bomb AN-M64A1 uses the AN-M124A1 and the AN-M133 tail fuzes, and the 1000-lb GP Bomb A N M65A1 and the 2000-lb GP Bomb A N M66A2 use the AN-M125A1 and the A N M134 tail fuzes, all of which also have anti­ withdrawal devices. Nondetonation of bombs using these fuzes cannot be relied upon when released SAFE because the glass solvent ampoule in the fuze may break upon impact of the bomb. Once one of these fuzes is installed, no attempt should be made to remove the fuze or to return the bomb to an airfield or aircraft carrier upon an incom­ plete mission. Do not turn the fuzes back and forth to engage the threads; use a screwing-in motion only. The antiwith­ drawal device will cause the fuze and bomb to detonate if the fuze is rotated counter­ clockwise while in the adapter-booster, even before the threads are engaged. Safety Precautions for Aircraft Depth Bomb Assemblies The body of the 350-lb ADB AN-Mk 54 Mod 1 is damaged easily because of its light construction. Inspect it for damage. Safety Precautions for Fragmentation Bomb Assemblies No attempt should be made to remove the fuzes of 4-lb Frag Bomb M83, to change the setting, or to work on them in any way. No attempt should be made to reservice AN-M145A1 or AN-M145 mechanical time fuzes which are used, respectively, with the 90-lb Frag Bomb M82 and the 220-lb Frag SAFETY PR EC A U T IO N S Bomb AN -M 88 . The AN-M145A1 fuze is considered armed when one or more of the following conditions exist: absence of the safety block; complete or partial ejection of the firing pin; and failure of the trigger arm assembly to support the striker and pre­ vent it from snapping down tightly against the safety block. Safety Precautions for Fragmentation Bomb Clusters and Adapters Boxed frag bomb clusters should be handled carefully. When set down, place them in a horizontal position. Do not slide, tumble, or strike the packings. Upon unpacking, inspect clusters to be sure that the fuze safety devices are in place. If a fuze is armed, the cluster will be destroyed by authorized personnel. Bind­ ing straps which hold the bombs in place should be tight and unbroken. Broken straps may be replaced and the cluster used. Do not disassemble the 100-lb Frag Bomb Cluster M28A2 or any of its components. The locking cup screws of bombs in the M28A2 cluster must be tight before the nose cup retainers are removed. Protect unpacked clusters from moisture. Inspect the 500-lb Frag Bomb Cluster M26A2 for serviceability. Be sure that the cotter pins and shear wires are secure in the band clamps. Bands which hold the bombs in place should be tight and un­ broken. When using the 500-lb Frag Bomb Cluster M29A1, do not handle wafers by the strap­ ping. When the adapter is closed, its cover may cut some of the strings with which the wafers of the M29A1 cluster are tied. The cover must not be opened or the untied bombs will spring out. A case locking bush­ ing shall be used with all M29 clusters. If adapters do not gage properly and cannot be adjusted, they should not be used on frag bomb clusters. Store loaded M29A1 clusters off the ground and under a tarpaulin. Store for as short a period as possible, since this ma­ terial is susceptible to damage by atmos­ pheric moisture. When once loaded, the cluster adapter will not be reopened. The locking cups must be in a fully locked posi­ tion before the time fuze is inserted. Safety Precautions for Chemical (Gas), Smoke, and Incendiary Bomb Assemblies As WP (white phosphorus) munitions ig­ nite spontaneously upon contact with the air, they should not be handled roughly. If a fire does occur, personnel should wear gloves and keep both gloves and shoes wet. WP smoke is toxic on prolonged and re­ peated inhalation, but is not likely to be harmful in the concentrations found in smoke screens in the open air. Gas masks afford complete protection from concen­ trated WP smoke, but they tend to become clogged and therefore should not be worn except where serious exposure in enclosed spaces is involved. WP in contact with the skin will cause severe and lingering burns. Places of con­ tact should be washed immediately and kept wet until the phosphorus has been removed. Washing the affected area with a soda solu­ tion, followed by a 5 percent copper sulphate solution, is very effective. Greasy oint­ ments should never be used since they merely spread the contamination. Incendiary bombs and components have satisfactorily withstood tests simulating the normal handling expected to be received dur­ ing loading, shipment, unloading, and stow­ age. However, they can easily be damaged by unnecessarily rough treatment and should be handled with care at all times. Sodium-loaded igniters should be handled very carefully to prevent leakage of the sodium, which ignites spontaneously and with great violence when it comes into con­ tact with moistures. Sodium-loaded (Na) igniters shall be stowed only with other water-activated munitions and in accordance with OP 5, Ammunition Ashore, or OP 4, Ammunition Afloat, whichever is appropri­ ate, and OP 1631, Ammunition Hazard Classification List. WP-loaded igniters should be handled very carefully to prevent 12-5 N A V W E P S OP 2216 (V O L U M E 1) leakage of the white phosphorous, which ig­ nites spontaneously when it comes into con­ tact with the atmosphere. Water must never be used on burning sodium or on burning buildings or equipment in which sodium is stored or used. Dry soda ash, dry graphite, or dry sand will quickly smother sodium fires. Chemical solution type, vaporizing liquid type, or carbondioxide extinguishers are not effective, and their use will add to the hazard instead of reducing it. The chemical solution type of extinguisher (soda acid) contains water, while the vaporizing liquid type (carbon tetrachloride) and carbondioxide both react violently with sodium. The fumes of burn­ ing sodium are essentially caustic and there­ fore irritating. An approved type of respi­ rator should always be available, and per­ sonnel should always put on the respirator before attempting to fight a sodium fire. The pipe plugs in the igniter and the filling plugs in the body of the 500-lb incendiary bomb AN-M76 should not be removed under any circumstances. Bombs and components must be handled as little as possible. Do not drop them or subject them to bumps, shocks, or blows. Protect them from rain, spray, and the direct 12-6 rays of the sun. Stored bombs should be in­ spected frequently so that leakers may be detected and properly processed. Safety Precautions for Fire Bomb Assemblies Once a fire bomb is filled, it must be used or destroyed. All fire bombs not expended shall be jettisoned prior to landing afloat or ashore. Safety Precautions for Practice Bomb Assemblies Do not apply pressure to force the firingpin assembly into the bomb. The assembly may collapse and fire the signal. Be extremely careful when handling prac­ tice bombs loaded with signals. Jarring or dropping the bomb may detonate the signal. Do not, under any circumstances, point either end of the signal toward other per­ sonnel. Loaders must not place their bodies in line with the nose or tail ends of the bombs. Do not remove the safety cotter pin from the body of the fuze before the bomb is se­ cured in the aircraft and the arming wire is completely installed. INDEX Page A AD Bomb A N -M k 54 ______ _____ __________ 6-1 AD bombs— safety precautions ....... _ ...... ... 12-3 A P Bomb A N -M k 1 ................................................ . 4-6 A N -M k 33 ......... ........................... ............... 4-1 AP bombs— safety precautions ________ ____ 12—4 Adapter-Booster M102A1 ......... ..........................- __ ____ ___ 3-1 M115A1 ........................ ................................ 3-2 M l 17 .............................................................. 3-3 T45E1 ............................................................ 3-4 T46E4 __ _____________ _____________ ____ 3-5 adapter-boosters ___________ _________________ 1-11 adapter, cluster ......................... ........................ 1-13 Aircraft Depth Bomb A N -M k 54 ___________ 6-1 aircraft depth bombs ............... ....... .......... 1-6, 6-1 Amatol ------------------------------- ----------------------1-13 ammonium picrate ................... .......................... 1-14 ammunition code ................... ............................ 1-19 ammunition data card ....... .............. ................ 1-21 antidisturbance side fuze ______________ 2-97 arming wire .... ................................................... 1-11 armor piercing bombs ........... .................. 1-6, 4-1 Arm y-Navy numbers ........... ....... ...................... 1-19 Army n um bers............................ ......................... 1-19 Auxiliary Booster Mk 1 ................................ .............................. 3-6 Mk 4 .............................................................. 3-7 auxiliary boosters .................. ............................. 1-12 B band, shipping ........................................ band, suspension ................................... base plug ...................................... blast, bomb ........................................... body, b o m b ............................................... Bomb AN-M 30A1 ............... ..................................... 5-1 AN-M41A1 .................................... 7-4, 8-1, 8-9 AN-M 47A2 ............ 10-15 AN-M 47A3 ........ 10-15 AN-M 47A4 ....................... 10-12 AN-M57A1 .................................. AN-M 58 ............... ......................_................ 4-11 AN-M58A1 ..................................... AN-M 58A2 .................................... AN-M59 ....................................... AN-M59A1 ..................................... AN-M64A1 __________________ Page Bomb— continued AN-M65A1 ... ............. 5-18 AN-M 66A2 ... .......... 5-24 __ ____ 10-19 AN-M 76 ...... ..... . 10-4 AN-M 78 ....... _______ 10-8 AN-M 79 ...... _______ 7-16 AN-M81 ...... ........ _ _ 7-11 AN-M 88 ...... ________ 4-6 AN -M k 1 .... _______ 11-1 A N -M k 23 ... ________ 4-1 A N -M k 33 ... _______ 6-1 AN -M k 54 _ _______ 10-1 M70A1 _____ ............. 7-7 M82 ........... .. 7-1, 8-5, 8-19 M83 ............. ......... _______ 4-18 M103 ______ ________ 9-1 M117 ..... . ......... 9-5 M118 ........ . ......-.... 11-1 Mk 5 ....... .. .............. 11-21 Mk 15 _____ _______ 11-5 Mk 19 .......... ............ 11-1 Mk 43 .... . ....... 11-33 Mk 65 ....... . Mk 66 ....... ..................................................... 11-42 Mk 67 ...... ................ ............................... -- 11-51 Mk 76 . " . . . .............................................. 11-12 Mk 77 Mod 0 ______________ ____________ 10-29 Mk 77 Mod 1 _____ ____ ___ ________ ____ 10-25 Mk 78 ______________ 10-38 Mk 79 ________ ______ _______________ — 10-42 Mk 81 ....... 5-31 Mk 82 ______ 5-32 5-39 1-18Mk 83 ______ Mk 84 ........ 5-43 1-18 Mk 1-13 86 _________________________ 11-29 Mk 87 — ________ 11-38 1-6 Mk 88 ________ 11-47 1-13 Mk 89 _____ 11-16 Mk 1 0 0 ___ 11-61 Mk 102 ________ 11-76 Mk 104 ............ 11-56 Mk 106 ..................— ..............- ............. ...... 11-9 bomb body ____________________________ bomb5-7 components .. ..................................... 1-11, 3-1 safety precautions ____________________ 12-3 bomb 4-11conversion kit (See conversion kit) 4-10operation ___________________ bomb booster, 4-14 adapter (See adapter booster) 4-14 auxiliary (See auxiliary booster) booster, 5-12 fin assembly ................................. box-type 1-1 1-13 1-3 1-15 N A V W E P S OP 2216 (V O L U M E 1) Page Burster AN-M12 AN-M13 AN-M14 AN-M1B AN-M16 AN-M18 AN-M20 M10 ...... bursters ____ 3-9 3-10 3-11 3-11 3-11 3-12 3-13 3-8 1-13 C card, ammunition data ....... .............................. 1-21 charge, explosive ............. ............................... 1-13 chemical bombs ......... ....... ...................... ..... 1-8 safety precautions ...... 12-5 Chemical (Gas) Bomb AN-M78 ............ ............. ....... . ........ 10-4 AN-M79 _____ ____ ____ ________ ____ 10-8 M70A1 ....... ..... ................................. .......... 10-1 Classification, Federal Supply ............... ...... .1—19 classification o f bombs .... ................................. 1-6 classification o f fuzes .............. 1-8 closing plug _____________ _____________ ___ _ 1-13 Cluster AN-M1A1 _____________________ ____ .... 8-1 AN-M 1A2 __________ 8-1 M26A1 __ _ ____________ _______ _______ 8-12 M26A2 ............... .............. ........................... 8-9 M27 ........ ...................................................... 8-15 M27A1 ... _______ ____ _____________ 8-14 M28 ____ _______ _______ ___ _____ ______ 8-6 M28A1 ........... ...... ......................................... 8-6 M28A2 __________________ ______________ 8-5 M29 ............ 8-20 M29A1 ......... ...... ..... ................... ........... 8-19 Cluster Adapter AN-M 1A3 .................................................... 8-1 M13A2 ...... .................................................... 8-9 M14A1 ________ ____ _____ ____ __ ____ ___ 8-14 M15A2 ........... ........... ................................... 8-5 M16A1 ........... .......................................... __ 8-19 cluster adapters ________________ 1-13 code, ammunition ..... .......................................... 1-19 color coding ......... 1-19 components, bomb .................. ._............... 1-11, 3-1 Composition B ...................................................... 1-13 conical fin assembly ........ ........................ .... 1-15 Conversion Kit Mk 19 . ................................... 10-34 D defective ammunition disposal ................. ...... delay arming ....... ........................................ ....... delay time fuze, long .......................................... Demolition Bomb M117 ....... ...................1............... ..... ...... M118 ______ __________________ ___ ______ demolition bombs ............. ...............1 ............... 1-2 1-24 1-8 1-11 9-1 9-5 1-8 Page Depth Bomb AN -M k 54 ............... ................. . 6-1 Depth Bomb, Practice Mk 100 _____________ __ ______ __ 11-61 Mk 102 .......... ..................................... ...... 11-76 depth bombs ......... .............. ....................... 1-6, 6-1 detonator, primer (See primer detonator) detonator safe ......... .......................................... 1-8 disposal o f ammunition .............. ................... 1-24 dumping of ammunition ........ ...... ............. ...... 1-24 E Ednatol __ _______ ____ ____________________ explosive charge ................................ ....... .... Explosive D ......................................... ...... .... explosive train ....... ......................................... 1-14 1-13 1-14 1-6 F Federal Supply Classification _______ ___ 1-19 fin assemblies ......... ............. ........................... 1-15 Fin Assembly AN-M103A1 . 5-1, 7-11, 7-16, 10-1 AN-M106A1 .............. ..... . 5-7 AN-M109A1 .... ...... 5-12, 10-4, 10-19 AN-M110A1 .... ________ 4-10 AN-M113A1 __ __ ________ 5-18, 10-8 AN-M114A1 .... .......... ............. — 4-14 AN-M116A1 .... ___ __ _________ 5-24 M117A1 ______ _______________ 4-18 M126 ________ _____ ______ 5-11 M128A1 ........... ......... ......... 5-16, 10-23 ...... ..................... 5-22 M129 ............. . ............................ 5-29 M130 - .... ....... ..... .............._.... 9 -1 M131 ...... . M132 ........... . .......... ........ . 9 -5 .......... 5-5, 7-11, 7-16 M135 ........ ....... ................ 4-10, 4-14 Fin Locknut Mk 1 ............... ............ 1-16 fin locknuts ........... Fire Bomb Mk 77 Mod 0 ........... ....... ................... ........ 10-29 Mk 77 Mod 1 ................_.............................. 10-25 Mk 78 __ __________ ________ ____ _______ 10-38 Mk 79 .....................................- ............ .... 10-42 fire bombs ......... .......................... - ..... - ................ 1-8 safety precautions ............ ............ ... .... 12-6 Frag Bomb AN-M 41A1 ............. ............. ... 7-4, 8-1, 8-9 AN-M 81 ............. ..............- .......................... 7-16 AN-M 88 _________________ __ ___ ______ 7-11 M82 ................. .........................— ........... 7-7, 8-14 M83 .... ............................... ..... 7-1, 8-5, 8-19 Frag Bomb Cluster AN-M 1A1 ______________________ A N -M 1A2 ................................................ .... 8-1 M26A1 .................... 8-12 M26A2 .......................... ................................. 8-9 M27 _______ 8-15 M27A1 ............ 8-14 M28 ............ ................................................. 8-6 8-2 IN D E X Page Page Frag Bomb Cluster— continued Fuze— continued M28A1 ............................................................ 8-6 M28A2 ___ ________ _____ _______ _______ 8-5 M29 ......... ................................................. - . . 8-20 M29A1 .......... ................... ........................... 8-19 fragmentation bomb clusters ............... .......... 8-1 safety precautions ........... .......................... 12-5 fragmentation bombs .............................— 1-8, 7-1 safety precautions ........ ......................... —. 12-4 AN -M k 247 .................................................. 2-55 Ml 29 ...... ........................................ .............. 2-89 M130 ......................_ _.......... ................. ...... 2-93 M130A1 L................... ..................._............... 2-93 M131 ..... 2-97 M131A1 ................... ...................................... 2-97 M155A1 ................ ...... .......................... ...... 2-30 M157 __________________ __________ ___... 2-R3 M160 ______ 2-36 M161 ..................... 2-36 Ml 62 ___ ________ _______ ___ __ ______ 2-36 M172 .......... 2-36 M176 .... 2-36 M178 ..._J .......... 2-43 M179 _ ............... .......... 2-43 M l80 ....... ............^ ................................ 2-43 M181 .................. 2-43 Ml 82 ___________ 2-43 M183 .................... 2-43 Mk 243 ........ ................................................ 2-17 Mk 244 ................... ................... .................... 2-17 T50E1 ............................................................ 2-33 T50E4 ______ ________ _______ ___ _______ 2-33 T51E1 _____________ 2-33 T91 _5|_________ 2-33 T93 .........................—....... .........— .............. 2-33 fuze, antidisturbance side ............... .................. 2-97 fuze, hydrostatic ..... . ..... ....................... .......... 1-11 fuze, impact nose ..... 1-11, 2-1, 2-7, 2-12, 2-17 fuze, impact side ________ 2-89 fuze, impact tail ......... 1-11, 2-1, 2-43, 2-50, 2-55 fuze, long-delay tail ..................... 1-11, 2-59, 2-68 fuze, mechanical time .... 1-11, 2-22, 2-30 fuze, multi-position ..................... ...... 1-11, 2-83 fuze safety precautions .............. .............. 12-1 fuze, side ______________ ____ ___ _____ _____ 1-11 fuze, time side ..................................................... 2-93 fuze, VT ............... .......................... ....... 1-11, 2-33 fuzes, classification of ............... .................... 1-8 Fuze AN-M 100A2 ................................ A N -M 1 0 1 A 2 ........................................... AN-M 102A2 ................ AN-M103A1 ____ _____ ___ ______________ AN-M110A1 .................. ............................. AN-M 112 ...................................................... AN-M112A1 ................... AN-M113 ......... AN-M113A1 ...... ............................. ............. AN-M114 _____ AN-M114A1 .................................................. AN-M 115 ..................... AN-M 116 ............... AN-M117 ________________ AN-M123 ................................................ AN-M123A1 ............ ..................................... AN-M 124 ________________ ________ _____ AN-M124A1 ............... AN-M125A1 ____ AN-M 126 |................................................ AN-M126A1 ................ ...................... ...... AN-M 132 .............. AN-M133 ............ AN-M 134 .... AN-M139A1 ______ ____________________ AN-M140A1 ............ .................... ................ AN-M145A1 ............. AN-M146A1 ........ ................................ AN-M158 __________________ ________ AN-M159 ............... ............. ............. ........... AN-M166 .... . AN-M166E1 _____ AN-M166E3 ____ AN-M168 .............. AN-M168E1 ......... ....................................... AN-M168E2 .......... AN-M173 ............ ............................. AN-M173A1 ............ AN-M175 ......................................... .... AN-M177 ............ ......................................... AN-M184 ........... ....................................... AN-M185 .................................................... AN-M194 ............. ................... .... ........ AN-M195 ............ ............................. ...... A N -M k 219 ....... ....................................... A N -M k 228 ........... ..................................... A N -M k 230 ........ ......................................... 2-36 2-36 2-36 2-1 2-7 2-43 2-43 2-43 2-43 2-43 2-43 2-43 2-43 2-43 2-59 2-59 2-59 2-59 2-59 2-7 2-7 2-68 2-68 2-68 2-1 2-1 2-22 2-22 2-7 2-7 2-33 2-33 2-33 2-33 2-33 2-33 2-83 2-83 2-36 2-36 2-36 2-36 2-36 2-36 2-12 2-50 2-77 G GP Bomb AN-M30A1 ..................... 5-1 AN-M57A1 .............. 5-7 AN-M 64A1 ____________________________ 5-12 AN-M 65A1 ..... 5-18 AN-M 66A2 .................................................. 5-24 Mk 8 1 ....... ............................................ ...... 5-31 Mk 8 2 ......... ......................... ........................ 5-32 Mk 83 __ _______ _______ _______ _______5-39 Mk 84 ..... ................................................... 5-43 general purpose bombs ............................. 1-3, 5-1 GP bombs— safety precautions ..................... 12-4 '''gas bombs .... ......... .................................... 1-8, 10-1 gas bombs— safety precautions ............ 12-5 1-3 N A V W E P S OP 2216 (V O L U M E 1) Page P age H H B X ..................... ............... ............................. H -6 ............................................. ............................ handling explosives ........................................... hydrostatic tail fuze ........ ........................ 1-11, 1-14 1-15 1-24 2-77 I Igniter AN -M 5 ....... ...._............................................ 3-14 AN-M 9 .......................................................... 3-15 AN-M16 ............................. ...._.................... 3-18 M15 ........ ............... ...................................... 3-16 M23 ........... ................................................... 3-20 igniters ..... .......... ................ ..................... .......... 1-17 impact nose f u z e ....... —.. 1-11, 2-1, 2-7, 2-12, 2-17 impact side fuze .................................................. 2-89 impact tail fuze ..... . 1-11, 2-1, 2—43, 2-50, 2-55 Incendiary Bomb A N -4 7 A 2 ......... .................................. ........... 10-15 AN -47 A3 - ........ ........................................... 10-15 AN-M47A4 __________ _______ __________ 10-12 AN-M76 ........................................................ 10-19 incendiary bombs ......................... ..................... 10-1 safety precautions ................ .................. 12-5 J jettisoning bombs ................................_......... 12-6 K Kit, conversion (see conversion kit) L liner, fuze seat .................................................. locking web ......... ................................................ long-delay tail fuze .................... 1-11, 2-59, locknut, fin ......... ........................................ . 1-16, Low Drag Bomb (GP) Mk 81 ........................................ Mk 82 ......... ....................................... ......... Mk 83 ................ Mk 84 ............................................................ 1-17 1-17 2-68 1-17 5-31 5-32 5-39 5-34 M mark numbers ...................... marking ........... ................................................... mechanical time fuze ........................ ............... miniature practice bombs ............... 1-8, 11-1, multi-position fuze .................................... 1-11, 1-19 1-19 1-11 11-5 2-83 N Navy numbers ......... ......... ................. ....... ...... 1-19 nose fuze, im pact.... 1-9, 1-11, 2-1, 2-7, 2-12, 2-17 O obsolescent items ............................................... obsolete items ............................... ...................... 1-3 1-3 P packaging ........... ................................................. Picratol ........ .............................. .......................... 1-4 1-21 1-15 plug, base ........................................ .........— ......... plug, closing ..................._................................... Practice Bomb A N -M k 23 ..... ..... ........................................ Mk 5 ....... ............... ...................................... Mk 15 ............................................................ Mk 19 .................................................. ........ Mk 43 ................................................ ............ Mk 65 ........ ................................................... Mk 66 ..... .................. ................................... Mk 67 ............. ................................._........ Mk 76 ............ Mk 86 ......... ............................................ ...... Mk 87 ............. Mk 88 - ..... .................................................... Mk 89 ............ ............................... ................ Mk 100 ...................................................... Mk 102 ............................................. ............. Mk 104 ............... .......................................... Mk 106 .......................................................... Practice Bomb Signal Mk 4 ..... Mk 5 ...... ..................- ................................... Mk 6 ................. Mk 7 ......... practice bombs ........ ...........................—..... 1-8, safety precautions ................ ................ Practice Depth Bomb Mk 100 ....... ............................................ .. Mk 102 ............ .....................................Primer Detonator M14 ............ M16 _________ _____ - ................................. M16A1 ....................- ....................._............ .. primer-detonators ....... 1-13 1-13 11-1 11-1 11-21 11-5 11-1 11-33 11-42 11-51 11-12 11-29 H -3 8 H -47 H -16 11-61 11-76 11-56 11-9 3-21 3-23 3-24 3-26 11-1 12-6 11-61 11-76 3-28 3-30 3-30 1-18 R RDX _____________ ____ - .............................-...... regulations, stowage ..................... ................. relays ........... ....... ....................................... .......... restrictions, fuze ............................................... ricochet .................................................................. 1-14 1-21 1-18 12-1 1-6 S SAP Bomb AN-M 58 ....................... AN-M 68A1 ........ ........... AN-M 68A2 .................... AN-M 59 ....................... AN-M59A1 ____ ____ M103 .............................. safety precautions ____ __ scope o f OP 2216_____ __ seat, fuze .... ......................... seat liner, fuze _______ ___ semi-armor-piercing bombs shear safe .............................. shipping band ......... ............ ... ... ... .... .... ... 4-11 4-11 4-10 4-14 4-14 4-18 12-1 ... 1-3 1-13 .... 1-17 1-6, 4-1 .. 1-8 .... 1-18 IN D E X Page Page aide fuze .... -................. signal ............ ............. signal, practice bomb (See signal) Smoke nomb AN -47A3 ............. AN-M47A2 .......... AN-M47A4 ......... smoke bombs ............. . safety precautions stowage, explosive ... suspension band _____ 1-11, 2-89, 2-93, 2-97 ______ ________ 1-18 practice bomb 1-11, 2-1 , 2-43, 2-50, 2-55 1-11. 2-59, 2-68 time fuze, mechanical... 1-11, 2-22, 2-30 ..... 2-93 time side fuze............... train, explosive _____ - 1-6 Tritonal ____ ____ ___ ...... 1-16 ............ ......... 10-15 .......... ............ 10-15 U _______________ 10-12 _________ 1-8, 10-1 unpacked fuzes ................ .......... 12-5 V ........................... 1-24 ................ ............................. VT 1-18 fuze ................. ..... T TNT ............................. tail fuze, hydrostatic.. tail fuze, impact...... .... 1-24 1-11, 2-33 W ........................... 1-15 .......... -..... - 1-11, 2-77 web, locking ............. .................... wire, arming (See arming wire) ..... 1-17 1-5 DISTRIBUTION SNDL Part 1 (No. 72) and Part 2 (No. 29) Two copies each unless otherwise excepted: 21(CINC); 22(COMSECONDFLT); 23A(COMNAVFOR); 24A(COMNAVAIR); 24B (COMPHIBFOR); 24F(COMSERVFOR); 24J(CGFMFOR); 26A(COMPHIBTRA); 26D( UDT ); 26F(OPTEVFOR); 26G( DESLANTSCOLGRU ); 26K(CJTF); 26U (MORDSERVU); 26GG(EODU); 27A(COMSERVFOR); 27C(COMSEAFRON Carib­ bean, Hawaiian, Alaskan); 28A(COMCARDIV Nos 2, 4, 16, 17, 18, 19, 20); 28J (COMSERVRON); 29G(CVS); 29H(CVA, C V A (N )); 29K(DL); 29L(DLG); 31B(AKA); 31C(APA); 31J(LSD); 32HH(AV); 32JJ(AVP); 32KK(AVS); 42A (COMFAIR); 42B(COMFAIRWINGS); 42D(FAETU); 42F(COMNAVAIR); 42I(ATTACK WINGS); 42J1(C0MCARAIRGRU); 42K1(ATKR0N); 42L1 (FITRON); 42N(AIRANTISUBRON); 42P(PATRON); 42S( AIRDEVRON); 42V(AIRSHIPRON); 45AA(EODCO); 46A(CGAIRFMFPAC); 46B(CGMAW); 46C1(MAG); 46C2(MARWGHQGRU); 46D1(MARFITR0N); 46D2(MARATKRON); 46J(MACRON); 46K (MASRON); 46R(MABRON); 46Z (MARCOM PRECON RON); A3(CNO); A5(BUSHIPS, BUWEP); A6(MARCORP); B3(AFSC); B5(CG) Cl(NLO APG, Md); C4(FC DASA); F2(ND except 3rd, PRNC); F3(NAVBASE); F9(NAVSTA San Diego); J28(USNRTC); J30(NAVTRAPUBCEN); J31 (NAVRETRACOM); J33(SERVSCOL); J37(NTC); •J60(NSAA); J71(NAVSCOLEOD); J94(NROTCU); J95(NAVWARCOL); J97(Merchant Marine Academy); LI (NAVSHIPYD); M17(NAVORDSUPDEP); M26(SUPANX); M27(NSC); M28(NSD); M46(NAVORDSUPO); M61(ASO); RIO(MARCORPSUPCEN); R20(MARCORSCOL); W lA l(N A S ); W1A2(NAS); W IB(NAAS); W IC(NAF); W IE(M CAS); WIF(MCAAS); WIG(MCAF); W2A(COMNAB all except 3rd, 8th, 13th, and Japan); W3A(CNATRA); W3B(CNAVANTRA); W3E(CNARESTRA); W3F (CNATECHTRA); W3G(MARTC); W4A(NATTC); W4B(NATTU); W4C(NARTU/; W4E(MARTD); W4F(NAVTECHTRAU); W5J(MARDET); W6A(BUWEPSGENREP); W6B(BUWEPSREP); W7B(AIRMATCEN); W7C(AIRTESTCEN); W7E (AIRDEVCEN); W7F(EODTECHCEN); W7H(AIRENGRFACSHIPINSTL); W7K (NAVAIRSPWPNFAC); W7M (AIRDEVU); W7P(WPNLAB); W 7Q(LAB); W7R (NOLTESTFAC); W7S(NOTS); W7Y(NAVORDU); W8B(NAVMISCEN); W9B(NOP Louisville Code Adf); W9G(NAVORDFAC); W11A(NAD except Fort Mifflin); W11B (NAND); W llC(W PN STA); WllE(Skiffes Creek Annex); W llH (N AVM AG ); W12C(MORDSERVU); FRC, GSA, Alexandria, Va. Requests for additional copies of NAVWEPS OP 2216 (VOLUME 1) should be sub­ mitted on DD Form 1149 to the appropriate forms and publications supply point. 8 August 1960/3000/1 « U. S. GOVERNMENT PRINTING OFFICE : [963 O - 680622