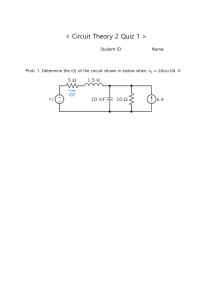

ELE1911 Electrical & Electronic practice A Practice book Semester 2 2015 Student name: __________________________________________________________________ Student number: _________________________________________________________________ Program: _______________________________________________________________________ Published by University of Southern Queensland Toowoomba Queensland 4350 Australia http://www.usq.edu.au © University of Southern Queensland, 2015.2. Copyrighted materials reproduced herein are used under the provisions of the Copyright Act 1968 as amended, or as a result of application to the copyright owner. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means electronic, mechanical, photocopying, recording or otherwise without prior permission. Table of Contents Practice courses for electrical, electronic & computer engineering programmes . 1 Introduction ....................................................................................................................... 1 External students ............................................................................................................. 3 Claiming exemption ......................................................................................................... 4 Course content and pre-requisite knowledge .............................................................. 4 External students ...................................................................................................................................... 4 Day students.............................................................................................................................................. 5 Staff associated with this practice course .................................................................... 5 Requisite materials........................................................................................................... 5 Assessment....................................................................................................................... 6 Lab completion log – record of competency ................................................................ 7 Digital lab ......................................................................................................................... 10 Revision (part 1): Introduction to Micro-Cap digital simulation ............................... 10 2. Introduction .......................................................................................................................................... 13 3. Action of lamps and switches ............................................................................................................. 13 4. Inverters............................................................................................................................................... 13 Revision (part 2) – AND, OR, NAND and NOR gates .................................................. 15 1. NAND gates......................................................................................................................................... 15 2. AND gates ........................................................................................................................................... 16 3. OR gates.............................................................................................................................................. 16 4. NOR gates ........................................................................................................................................... 16 5. Questions ............................................................................................................................................ 18 Activity 1: XOR, equivalence, half adder & comparator ............................................ 20 1.1 The exclusive OR circuit ................................................................................................................... 20 1.2 Simple comparator ............................................................................................................................ 21 1.3 An exclusive OR gate using four NAND gates ................................................................................ 22 1.4 The half adder ................................................................................................................................... 22 1.5 A simple logic block .......................................................................................................................... 23 1.6 Questions .......................................................................................................................................... 24 Activity 2: Flip-flops ....................................................................................................... 27 2.1 Two cross coupled NAND gates; the simple latch .......................................................................... 27 2.2 The simple clocked RS flip-flop ........................................................................................................ 28 2.3 Application – simple data memory or type ‘D’ flip-flop .................................................................... 30 2.4 The principle of the master slave ‘JK’ flip-flop ................................................................................. 30 Activity 3: Serial counter ............................................................................................... 33 3.1 A four-bit serial counter using J-K flip-flops ..................................................................................... 33 3.2 Altering the natural count sequence ................................................................................................ 34 Activity 4: Team project, part A – PRBS generator design ....................................... 36 Revision ................................................................................................................................................... 37 Activity 5: Part 1 – Introduction to the THRSim11 software...................................... 43 Procedure ................................................................................................................................................ 43 Simulation ................................................................................................................................................ 45 Target 68HC11 microprocessor board................................................................................................... 47 Activity 5: Part 2 – Introduction to programming the 68HC11 .................................. 48 Procedure ................................................................................................................................................ 50 Activity 5.6: Use of a clock to program a delay .......................................................... 54 Procedure ................................................................................................................................................ 55 Activity 5.7: Seven segment display ............................................................................ 55 Procedure ................................................................................................................................................ 56 Activity 5.8: PRBS generator design – part B ........................................................................................ 58 Revision ................................................................................................................................................... 59 Activity 9: Introduction to PLCs ................................................................................... 62 Activity 10: PLC application .......................................................................................... 62 Electronics lab ................................................................................................................ 63 Activity 1: Familiarisation with test equipment .......................................................... 63 Activity 2: Introduction to breadboarding ................................................................... 64 Activity 3: Electronics project construction ............................................................... 64 Activity 4: Electronics project testing ......................................................................... 65 Electrical technology activities .................................................................................... 66 Electrical safety – rules ................................................................................................. 66 Electricity supply and accidents ............................................................................................................. 66 Factors affecting electric shock .............................................................................................................. 66 Human body as conductor...................................................................................................................... 67 Effect of magnitude of current ................................................................................................................ 68 Main effects on the body ........................................................................................................................ 68 Resuscitation ........................................................................................................................................... 69 University of Southern Queensland ............................................................................. 70 Energy systems laboratory: safety rules................................................................................................ 70 Safety instructions: please read and observe ....................................................................................... 71 Using instruments in electrical laboratories ........................................................................................... 72 Using A.C. measuring instruments .............................................................................. 72 Activity A1: Kirchhoff’s laws......................................................................................... 75 Aims ......................................................................................................................................................... 75 Theory...................................................................................................................................................... 75 Activity A2: Resistance measurement of DC machine windings ............................ 77 Activity A3: D.C. shunt motor performance ................................................................ 78 Activity A3: D.C. shunt motor performance pre-determination ............................... 88 Experiment A3: D.C. shunt motor performance pre-determination ...................................................... 89 Activity B1: Transformer tests...................................................................................... 91 Activity B2: Three-phase transformer connections................................................. 103 Activity C1: Power factor improvement .................................................................... 107 Activity C2: Series resonance..................................................................................... 112 Activity C3: Capacitor-start single phase induction motor: load test ................... 116 Activity D1: Three-phase circuits: star and delta connected loads ...................... 121 Activity D2: Three-phase induction motor – DC generator tests........................... 123 Appendix A: Reading analog multimeter scales ...................................................... 135 Reading analog multimeter scales............................................................................. 135 1 ELE1911 Electrical and electronic practice A Practice courses for electrical, electronic & computer engineering programmes Introduction The purpose of the system of practice courses is to develop practical skills, the ability to function effectively as part of a team, and in the case of Bachelor of Engineering students, an understanding of the responsibilities of a professional engineer. Practice courses are zero unit, zero tuition cost courses which are assessed on a pass/fail basis i.e. no other grades are possible. Their nominal duration is 40 hours, of which 35 hours will be laboratory work, group projects or other structured activities. The remainder is set aside for assimilation, report writing and assessment. For day mode students, practice activities will usually be synchronised with relevant academic units, and distributed over one semester. Day students will normally complete two practice courses a year. For external students, the practice courses are available as intensive on-campus residential schools, normally of one week duration. Students will usually complete one residential school per year. However, the timing of these has been arranged such that the more critical courses can be completed in pairs over a two week period, in order to minimise visits to campus. The practice courses which apply to Electrical and Electronic engineering programmes are shown in table 1, and those for Computer Systems Engineering (including BEng/BIT), Instrumentation and Control Engineering and Software Engineering are shown in table 2. Table 1: Practice courses for electrical and electronic majors Practice course Number Name Residential school for external students Usage ADEE BEng Tech (EE) BEng (EE) Year Month and week ENG1901 Engineering practice 1 ✓ ✓ ✓ 1 Feb, wk 13 (note 5) ELE1911 Elec. & electr. prac. A ✓ ✓ ✓ 2 Feb, wk 13 (note 1) ELE2912 Elec. & electr. prac. B ✓ ✓ ✓ 3 Feb, wk 14 ELE2913 Elec. & electr. prac. C ✓ ✓ ✓ 4 Sept, wk 9 (note 2) ELE3914 Elec. & electr. prac. D ✓ ✓ 5 Sept, wk 10 (note 3) ELE3915 Elec. & electr. prac. E ✓ 6 Sept, wk 10 (note 4) ENG3902 Professional practice 1 ✓ 7 Sept, wk 9 ENG4903 Professional practice 2 ✓ 8 Sept, wk 9 2 ELE1911 Electrical and electronic practice A Table 2: Computer systems, instrumentation and control, and software engineering majors Practice course Residential school for external students Usage Number Name AD CS BET (CS) BEng BEng/ BEng BEng (CS) BIT (IC) (SW) ENG1901 Engineering practice 1 ✓ ✓ ✓ ✓ ✓ ✓ 1 S3, week 13 (5) ELE1911 Elec. & electr. prac. A ✓ ✓ ✓ ✓ ✓ ✓ 2 S3, week 13 (1) ELE2912 Elec. & electr. prac. B ✓ ✓ ✓ ✓ ✓ ✓ 3 S3, wk 14 ELE3913 Comp. sys. eng. prac. ✓ ✓ ✓ ✓ 4/5 Sept, 9 (2) ELE3914 Elec. & electr. prac. D ✓ 5 Sept, 10 (3) ELE3915 Elec. & electr. prac. E 6/7 Sept, 10 (4) ELE3916 SWEng. team practice 6 Sept, 10 (4) ENG3905 Mechatronic practice 6 Sept, 10 ENG3902 Professional practice 1 ✓ ✓ ✓ ✓ 7 Sept, 9 ENG4903 Professional practice 2 ✓ ✓ ✓ ✓ 8 Sept, 9 ✓ ✓ ✓ ✓ ✓ Yr Month, week ● Numbers in parentheses refer to notes below. ● As far as possible, students should follow the recommended enrolment pattern for their programme, as shown in the University handbook. Notes on tables regarding residential schools for external students 1. ELE1911 may be delayed for one year and completed together with ELE2912 over a two-week period. 2. ELE2913 (or ELE3913) may be delayed for one year and completed together with ELE3914 over a two-week period. 3. ELE3914 can be delayed and completed together with ENG3902 over a two-week period. 4. ELE3915 (or ELE3916) can be delayed and completed together with ENG4903 over a two-week period. 5. ENG1901 is also available in the September recess, in week 9. 6. Information regarding year in which residential schools should be undertaken does not apply to the BEng/BIT in external mode. This may only be undertaken by students who are eligible for at least two years advanced standing. Hence the year in which practice courses are undertaken will depend very much on individual enrolment patterns. 3 ELE1911 Electrical and electronic practice A External students Students studying in external mode will complete each practice course by attending a one week intensive residential school, and submitting written reports as required. The practice courses should not be completed until all pre-requisite courses have been completed. Students should either have completed the co-requisite courses, or be currently enrolled in them. Students are normally expected to attend for the full duration of the nominated residential school period. This should be the whole of the week, i.e. 8 am Monday to 5 pm Friday, except where alternative arrangements have been made because a Public Holiday falls within the week. Students planning to attend should check the USQ web site for the final timetable 2 or 3 weeks before the residential school. Prior to attendance at residential schools, students should refresh their knowledge of any courses listed as pre- or co-requisites. It is advisable to bring to the residential school the study books for these courses, as you will probably wish to refer to them during the week. During the on-campus Orientation programme at the start of the residential school, students will be given details of: ● any changes to the timetable ● what groups they might be in ● any other relevant information. Because of space constraints in the USQ Handbook it has not been possible to describe the pre- and co-requisite requirements in great detail. These are described more fully in the practice books provided to you when you enrol in these courses, and you should check these carefully. Each practice course should be completed at the stage in your programme where you will gain maximum benefit from attendance. This will be made easier if students follow the recommended Enrolment pattern for their programme. External students will not normally complete more than one practice course per year. However, the completion of some practice courses can be delayed by one year, to allow two residential schools to be completed end to end over a two-week period. This feature is designed to assist external students who travel to USQ from remote locations or from overseas. External students in the Electrical and Electronic Engineering, Power and Instrumentation and Control majors should note that there are two practice courses in their fourth year, one in February and one in September. In the case of Associate Diploma students following the recommended enrolment pattern, this will correspond to their final year. Day students Day students will normally complete practical activities in association with related academic courses, and these will be credited to the relevant practice courses. However, there may be a few activities which do not occur in parallel with a related academic course e.g. printed circuit board activities for Bachelor of Engineering students. 4 ELE1911 Electrical and electronic practice A Claiming exemption As is the case with any other course, you may apply for exemption from a practice course, on the basis of previous equivalent study, training or work experience. When making any application for exemption it is your responsibility to provide: ● proof of completion ● details of what you have completed previously, with regard to subject matter and also contact hours or workload. In some cases this may take the form of a letter from your employer on company letterhead, verifying that you have had relevant experience or training. It is recommended that you draw up a table of all the activities within the practice course, and then summarise beside each your relevant experience or training. This should then be attached to the letter of verification from your employer. Do not submit original certificates. Copies should be verified as true copies by a Justice of the Peace (or an official of equivalent standing in the case of an overseas application). If you are granted an exemption from a course, then this will appear on your academic record, and you will not have to enrol in the course. If you have already been granted exemption from practice courses, as part of a block of exemptions in recognition of previous study, then further claims for exemption from subsequent practice courses will not normally be considered. This is because the awarding of a block of exemptions involves a trade-off between work the student has completed but has not been given credit for, and work the student has not completed but has been given credit for. The awarding of further exemptions will upset this balance. Course content and pre-requisite knowledge This practice course contains activities relevant to the following academic courses, which are specified as co-requisites: ● ELE1301 Computer engineering ● ELE1502 Electronic circuits ● ELE1801 Electrical technology. External students The residential school for this course is in the week of February. External students following a standard enrolment pattern should complete this residential school at the end of their second year of enrolment, after completion of all of the courses specified as above as co-requisites. It is advisable to bring to the residential school the study books and texts for the co-requisite courses listed above. 5 ELE1911 Electrical and electronic practice A It is permissible to delay the residential school for one year so that it can be completed in conjunction with the residential school for ELE2912 Electrical and electronic practice B over a two-week period. Day students Day students following one of the standard enrolment patterns shown in the USQ Handbook or Faculty Guide to Programmes should enrol in practice courses as indicated in the enrolment pattern. Staff associated with this practice course Examiner: Mr Mark Norman Phone: (07) 4631 2912 Fax: (07) 4631 2526 Email: <Mark.Norman@usq.edu.au> Moderator: Dr Hong Zhou Other staff closely associated with this practice course will be the examiners of the academic courses which are supported by these practical activities. These are: ELE1301 Mr Glenn Harris ELE1502 Mr Mark Norman ELE1801 Mr Ron Sharma and Mr Gordon Hampson Many other full time and part time staff will assist with the running of laboratory sessions for day students, and with residential schools for external students. Requisite materials ● A cheap scientific calculator (which need not be programmable or have graphics) ● A cheap protractor; scale ruler; dividers and drawing compass; HB pencil and eraser ● A pad of A4 graph paper with 2 mm squares. 6 ELE1911 Electrical and electronic practice A Assessment No separate formal laboratory reports are required for this practice course. All that is required is that you complete the practical work to the satisfaction of the laboratory supervisor. Some of the activities require you to fill in data or answer questions on the activity sheets. At the conclusion of each practical session you must present this practice book to your supervisor for his signature, which certifies that you have completed the activity. If you wander out of the laboratory without checking with the supervisor, there may be no record that you have completed the activity, and you may have to repeat the activities. This course is assessed on a Pass/Fail basis. To obtain a Pass you must have completed at least 80% of the activity hours associated with the course, which will be interpreted as 80% of each group of activities. This flexibility is intended to allow for sickness and unforeseen accidents or emergencies. It is not acceptable to omit a complete group of activities. In normal circumstances it is expected that students should complete all of the activities. You will be required to produce the Lab Completion Log from this practice book to verify that you have completed (or been exempted from) all of the activities required to achieve a pass in this course. 7 ELE1911 Electrical and electronic practice A Lab completion log – record of competency Student name: ________________________________________ Student number: _____________________ Program: ______________________________________________________________________________________ Approx. duration Activity title Digital Lab Supervisor’s name/s: Activity 1: XOR, equivalence, half adder & comparator 2 Activity 2: Flip-flops 2 Activity 3: Serial counter 2 Activity 4: PRBS generator logic design, part A 2 Activity 5: Introduction to THRSim11 2 Activity 6: Using a clock to program a delay 2 Activity 7: Seven segment display 2 Activity 8: PRBS generator software design, part B 2 Activity 9: Introduction to PLCs 2 Activity 10: PLC application 2 Electronics lab Supervisor’s name/s: Activity 1: Introduction to test equipment 2 Activity 2: Introduction to bread-boarding 2 Activity 3: Electronic project construction 4 Activity 4: Electronic project testing 2 Electrical technology lab Supervisor’s name/s: Activity A1: Kirchhoff’s laws 0.5 Activity A2: DC shunt motor performance 1.5 Activity B1: Transformer tests B1.1 Preliminary tests B1.2 No-load test B1.3 Short-circuit test Activity B2: Three-phase transformer connections Activity C1: Power factor improvement Activity C2: Series resonance Activity C3: Capacitor-start single-phase – Induction motor: load test 2 0.5 1 1.5 1 Activity D1: Three-phase circuits: star and delta-connected loads 0.5 Activity D2: Three-phase induction motor – DC generator tests 1.5 Competency demonstrated (Supervisor to sign) Date 8 ELE1911 Electrical and electronic practice A University of Southern Queensland Faculty of Engineering and Surveying Safety briefing To comply with the Workplace Health and Safety Act, the Faculty Safety Officer requests that all students are given a safety briefing during the first week. A record is kept of those present at the safety briefing as proof that an attempt has been made to meet the Workplace Health and Safety obligations. 1. Z-Block building evacuation plan and emergency procedures University buildings are to be evacuated when the building evacuation siren sounds. In Z Block, this alarm consists of two separate tones. The first tone is a warning tone indicating that the building may be about to be evacuated. The second tone is more urgent in sound and has a voice-over telling occupants to evacuate the building. On hearing an alarm or the call ‘evacuate’, all occupants should: ● Cease all activities without delay. ● Leave the building immediately by the designated fire or emergency exits to be used by all students and staff on that floor. Do not use lifts. Leave personal possessions behind. ● Proceed to the designated assembly area, western side of Z Block, well away from the building. ● Keep clear of entry/exit ways. Give assistance, if required, to persons who use a walking aid. ● Comply with the directions of Emergency Squad members, who wear orange hard hats. 2. Emergency telephone numbers and how to summon help For all emergencies, telephone: Work hours (8.30am – 5pm) (on campus) 2222 After hours (on campus) 2222 The phone number of the University Nurse is listed on the emergency phones. To call for emergency assistance or raise a fire alarm, yell for help; e.g. – ‘Help!’ or ‘Fire!’ First-aid and emergency-trained personnel are rostered to be available in the vicinity. 3. Location of first aid kits First Aid kits may be found in the following locations: Z Block First floor Z109 (not accessible after hours) Z Block Second floor Foyer Z Block Third floor Foyer Z Block Fourth floor Z475 – Sick Room – (not accessible after hours) 4. Personal protection Fully covered shoes must be worn in laboratories; no loose, long hair; no loose clothing or loose jewellery. DECLARATION: I have read and understood the above safety instructions. STUDENT NAME (Please Print): STUDENT NUMBER: ........................................ SIGNATURE: DATE: ................................ ................................ ......../......../........ 9 ELE1911 Electrical and electronic practice A Faculty of Engineering and Surveying THE ENERGY SYSTEMS ELECTRICAL LABORATORIES CONTAIN SAFETY HAZARDS WHICH MUST BE TREATED WITH DUE CAUTION AT ALL TIMES. YOUR SAFETY, WHILE YOU ARE AT USQ, IS PARAMOUNT TO THE UNIVERSITY. USQ also has obligations under the Workplace Health and Safety Act. You can assist the University to meet its obligations under the Act, and to ensure that your health and your safety are protected. Please complete the form below, so that the University can put in place protective measures to ensure your health and safety whilst you use the facilities in the Energy Systems Laboratory. To assist your supervisor to ensure your safety, please complete the following questionnaire. Any information disclosed will be held in confidence. Do you suffer from any of the following disabilities: YES NO 1. Colour-blindness or any visual disability. 2. Hearing problems. 3. Dexterity problems. 4. Inability to stand comfortably during practical classes. Are you currently taking any medication or drugs, prescribed or otherwise, which may impair your ability to concentrate, to follow instructions, or to operate the laboratory equipment safely? Do you have any other condition that may affect your ability to work safely during practical classes? If ‘YES’, please give details: ___________________________________________________ __________________________________________________________________________ __________________________________________________________________________ Contact information: _________________________________________________________ These matters may be discussed with you confidentially in relation to your work in the laboratories. I understand that I should inform USQ of any medical condition during my course to assist in ensuring my safety. I can inform the Head of Discipline confidentially, in writing, to that effect. Student name (please print): _______________ Signature: ____________ Date: Student number: ____________________________ / / Safety form 001/03 10 ELE1911 Electrical and electronic practice A Digital lab Note: Write down all workings as these will be checked in order for activities to be marked as completed. Revision (part 1): Introduction to Micro-Cap digital simulation Aim To familiarise students with digital circuit simulation using Micro-Cap simulation software To introduce digital concepts associated switching circuits and logic elements. Objectives Upon successful completion of this activity, students should: have demonstrated the operation of simple circuit consisting of switches and lamps be familiar with the use of simulation software to perform basic digital functions. 1. Getting started To start Micro-Cap double-click the desktop icon or click the Windows ‘Start’ button to select MicroCap from the programs menu. This will bring up the following program window, in which you build your circuit. Micro-Cap is supplied with a large number of circuit components, both digital and analogue. To learn how to build and simulate digital circuits using these components it is best to start with a small project. To begin, familiarise yourself with the menus and toolbars. 11 ELE1911 Electrical and electronic practice A The pull down menus are used primarily to: load and save files access circuit components select circuit analysis (simulation) tools. The toolbars enable quick access to the more frequently used features. You will now build a simple circuit consisting of a battery, a switch and a lamp. For the switch and the lamp you will use animated components. This will allow you to operate the switch to light the lamp. Figure 1: Analogue LED circuit To place an animated switch on the drawing, select the Component > Animation > Animated SPST Switch menu option. Once the component is selected from the menu the component symbol will replace the cursor. You can then place as many of that component onto the drawing as required. Each copy will have its own unique identifier. You only need one switch, so move the component to the desired position (near the center of the workspace). Click and hold the left-mouse button, while still holding the left mouse button down click the right mouse button one or more times to rotate the component in 90 degree steps. Once the desired rotation is obtained release both buttons. The switch is now positioned on the drawing. The cursor will remain in the component mode, ready to place another switch. Select the Component > Animation > Animated Analog LED menu option and place a LED on the drawing about 2cm to the right of the switch. At this point the LED’s component properties dialogue box will open. This dialogue box allows you to set various component attributes. Click OK to exit the box. 12 ELE1911 Electrical and electronic practice A Now click the Battery button on the components toolbar. Place the battery to the left of the switch, with the correct orientation, as shown in figure 1. When this component is placed the component properties dialogue box will open. Enter 9v in the Value box then click OK. Now click the Ground button on the components toolbar. Place this component on the negative end of the battery. The final task is to wire the components together. To do this you need to enter the wire mode. Click the Wire mode button. Once again the cursor will change indicating that you are in the wire mode. Move the cursor to the positive end of the battery, click and hold the left mouse button. Move to the left side of the switch and release the mouse button. A wire should now exist between the two points. Note that this wiring mode allows you to place one or two segments of wire at 90 degrees to each other. If you place a small right angle segment by mistake it is easily removed. To remove a component or wire segment, first enter the select mode by clicking the Select mode button then click the left mouse button on a blank area of the diagram to ensure no components or wires are highlighted. Next, using the left mouse button click the component or wire segment to be removed. The object should now be highlighted. Press the Delete button on the keyboard. Return to the wire mode and continue to wire the circuit as shown in figure 1. To exit the wire mode click the Select mode button. The circuit can now be analysed using one or more of the circuit analysis tools. For this circuit you will carryout a Dynamic DC analysis. This analysis tool allows you to change parts of the circuit and to observe the effect of that change. In particular, you are able to close the switch and observe the change of state of the LED. In other words, turn the LED on. Ensure that you are in the Select mode. Now select Analysis > Dynamic DC menu option. When the Dynamic DC dialogue box appears, press OK. If node voltages appear turn them off by clicking the Node Voltages button. The LED can now be turned on by double-clicking the switch. Point the cursor near the switch lever then double-click the left mouse button. The LED will change colour indicating the ON state. Doubleclick the switch again to turn the LED off. You must be in the select mode to do this. Micro-cap is a powerful circuit simulator and for this course you will barely touch on its full capabilities. However, the few features you do use will provide an invaluable learning tool for this course. Each home activity for the digital logic part of this course will be based on Micro-Cap. If you have any difficulty using the software or would like to learn more about its features select Help from the main menu to find the answer. 13 ELE1911 Electrical and electronic practice A You will now build on figure 1 for the first logic activity. 2. Introduction In Boolean Algebra – the algebra of logic – each variable can have either of two possible values ‘0’ and ‘1’. These two values represent two contrary states. The value ‘1’ can be used to mean ‘TRUE’ and then the value ‘0’ will mean not true or ‘FALSE’. Similarly ‘1’ can mean ‘HIGH’ and ‘0’ will mean ‘LOW’ as shown in the table below: ‘1’ TRUE YES ON HIGH OUTPUT HOT WET ‘0’ FALSE NO OFF LOW NO OUTPUT COLD DRY In this activity you will produce these logic levels using a switch and test the logic levels with a lamp (LEDs). The output of a switch will be ‘0’ or ‘1’ according to the switch position and if you connect a lamp to the switch, it will light (change colour) if the output is ‘1’ and not light if the output is a ‘0’. 3. Action of lamps and switches Using the circuit of figure 1 you were able to check the function of the switch and the lamp (LED). When the switch is open it will produce a logic ‘0’ at its output. This logic ‘0’ is indicated by the lamp being OFF (white or no colour). When the switch is closed it will produce a logic ‘1’ at its output. This logic ‘1’ is indicated by the lamp being ON (yellow in colour). To be able to perform this and future activities using digital logic components you need to change the circuit of figure 1 to the following. Delete the Animated Analogue LED and replace it with an Animated Digital LED. Remove the wire link to ground. Figure 2: Digital LED circuit When this circuit is analysed, using Dynamic DC analysis, opening the switch results in a logic ‘0’ being applied to the LED causing it to be OFF (black). Closing the switch results in a logic ‘1’ being applied to the LED causing it to be ON (red). 4. Inverters An inverter is a device that has one input and one output but the output logic level is always the opposite of the input logic level. Connect an inverter and another digital LED to the right of the current digital LED as shown in the following diagram. To do this, select the inverter from the component toolbar and position it to the right of the LED. When the component properties dialogue box appears select the DO_GATE timing 14 ELE1911 Electrical and electronic practice A model then click OK. Select an animated digital LED from the Components menu and place it to the right of the inverter. Insert a wire between the current LED and the inverter input and between the inverter output and the new LED. Ensure the cursor is in the select mode then run the Dynamic DC analysis and observe the effect of opening and closing the switch. Note the logic level at the output of the inverter is opposite to the logic level at the input. Figure 3: Inverter circuit Figure 3 can be further simplified by replacing the battery and switch with a digital switch as shown in figure 4. The animated digital switch can be found under the Component > Animation menu option. Figure 4: Modified inverter circuit 15 ELE1911 Electrical and electronic practice A Revision (part 2) – AND, OR, NAND and NOR gates Equipment required 1 large digital circuit board 1 power supply Logic blocks A logic block is a unit which combines and manipulates the binary inputs to perform some logic function and produce one or more outputs. Each output will be a ‘0’ or ‘1’ depending on the combination of input values. Fundamental logic blocks There are four fundamental logic blocks, AND, OR, NAND, NOR and their properties are summarised in the table below: The NAND gate is the logic gate most readily available in integrated circuit form but the other three basic gates may be constructed from NAND gates and inverters. 1. NAND gates Connect the three input NAND gate to switches and lamps as shown in figure 1 (over next page). (a) Check through the truth table of a NAND gate (b) Disconnect one input to the NAND gate. Complete a truth table for the remaining two inputs. Does a NAND gate respond to an unconnected input as if it were connected to logic ‘1’ or logic ‘0’? Answer . 16 ELE1911 Electrical and electronic practice A 2. AND gates The NAND function is Z A B ; if the output of a NAND gate is inverted we get W Z A B A B With the same layout as in item 1, use a second NAND gate module as an inverter as shown dotted in figure 1. Confirm the truth table of an AND gate. 3. OR gates By inverting the inputs to a NAND gate the system becomes an OR gate. By De Morgan’s theorem A B A B Connect the logic circuit shown in figure 2. Check the circuit truth table against that of an OR gate. 4. NOR gates If the output of an OR gate is connected to an inverter the circuit becomes a NOR gate. Use another inverter (or NAND) gate to change the circuit of item 3 into a NOR gate and check its truth table. A B A B 0 0 1 0 1 1 1 0 1 0 0 0 Z (= output of your circuit for item 4) 17 ELE1911 Electrical and electronic practice A Figure 2 Figure 1 18 ELE1911 Electrical and electronic practice A 5. Questions (a) Complete this truth table A 0 B 0 0 1 1 0 1 1 A B A B (b) Consider the following logic block. The inputs to the AND gate are A and B. The output Z is therefore A B The logic block is represented by the function Z=A B Circle the answer that represents the function of the following logic block. Answer: (a) Z = A B , (b) Z = A B , (c) Z = A B , (d) Z = A B 19 ELE1911 Electrical and electronic practice A (c) Complete this truth table A 0 B 0 0 1 1 0 1 1 A+B A+B (d) Circle the answer that represents the function of the following logic block. Answer: (a) Z = A B , (b) Z = A B , (c) Z = A B , (d) Z = A B 20 ELE1911 Electrical and electronic practice A Activity 1: XOR, equivalence, half adder & comparator Equipment required 1 large digital circuit board 1 power supply Simple combinational logic 1.1 The exclusive OR circuit The Exclusive OR circuit is a logic block with two inputs and the output is true if either (but not both) of the inputs is true. The truth table is: A 0 0 B 0 1 Z 0 1 1 1 0 1 1 0 Z = ‘1’ if A = ‘1’ OR B = ‘1’ but not both i.e. Z AB AB Consider the logic circuit figure 1.1. Figure 1.1 Connect this circuit on the patchboard, check that the circuit performs according to the truth table given above. 21 ELE1911 Electrical and electronic practice A 1.2 Simple comparator A minor modification to the circuit of item 1.1 will enable it to compare two binary digits and produce an output ‘1’ where they are the same and ‘0’ when different. Writing this in truth table form gives: A 0 0 B 0 1 Z 1 0 1 1 0 1 0 1 i.e. Z = ‘1’ if A = B i.e. Z AB AB Consider the logic circuit of figure 1.2. Figure 1.2 Connect this circuit on the patchboard and check that the circuit performs according to the truth table given above. 22 ELE1911 Electrical and electronic practice A 1.3 An exclusive OR gate using four NAND gates Figure 1.3 The logic circuit shown in figure 1.3 also acts as an Exclusive OR circuit. Wire the circuit on the patchboard, check the truth table to show that this is so. Also theoretically derive Z as a function of A and B and simplify to Z AB AB . Solution Z A AB B AB A A B B A B AB AB 1.4 The half adder A half adder is a logic block which accepts two binary digits as inputs and produces two outputs. One output is the sum of the two digits and the other is a carry digit. The truth table will be: A B Sum Carry (Co ) 0 0 0 1 0 1 0 0 1 0 1 0 The first output column follows the same sequence as the Exclusive OR circuit (item 1.1) while the second column has the same output as that of an AND circuit (item 1.2). A half adder can be constructed from an exclusive OR circuit together with an AND circuit. The logic circuit is shown in figure 1.4. Connect the circuit on the patchboard and check its performance against the truth table. 23 ELE1911 Electrical and electronic practice A Figure 1.4 1.5 A simple logic block Determine the truth table and Boolean expressions for the outputs of this circuit, and check that they are consistent. Figure 1.5 24 ELE1911 Electrical and electronic practice A 1.6 Questions (a) Refer to the following diagram What are the Boolean expressions for Y and Z? Y= Z= If A = 0, B = 0 and C=1, then Y= Z= (b) Refer to the following diagram What is the Boolean expression for Z in terms of A, B & C? Z= Complete the truth table for this logic diagram. 25 ELE1911 Electrical and electronic practice A A 0 0 B 0 0 C 0 1 X = AB 1 1 1 1 0 0 0 0 1 1 0 1 1 1 1 0 0 1 1 1 0 0 0 1 1 1 1 1 0 1 Y = BC Z = XY (c) Simplify the following expressions using De Morgan’s Theorems. i. Z ABC ii. Z (A B) C iii. Z ABC (d) Determine whether or not the output of the following logic diagram is the same as Z (A B)CD 26 ELE1911 Electrical and electronic practice A To solve this problem determine, from the logic diagram above, an expression for Z. Simplify the expression using De Morgans Theorems. 27 ELE1911 Electrical and electronic practice A Activity 2: Flip-flops Scope Types of flip-flop; simple latch set – reset, clocked set – reset D-type, master-slave JK. Equipment required 1 digital circuit board for items 1, 2, 3 1 power supply or 2 digital circuit boards for item 4 1 power supply Flip-flops 2.1 Two cross coupled NAND gates; the simple latch Two cross coupled NAND gates form a simple latch or flip-flop. Connect two NAND gates as shown in figure 2.1a. Figure 2.1a Check and complete the truth table of the system. 28 ELE1911 Electrical and electronic practice A With a logic ‘1’ input on A and B simultaneously, the outputs at QA and QB may be ‘0’ and ‘1’ or ‘1’ and ‘0’ respectively. This can be easily verified by putting ‘1’ on A and ‘1’ on B and reducing A or B to ‘0’ alternately. This circuit is sometimes referred to as an SR flip-flop (set – reset flip-flop), where a logic ‘0’ on input A will set the output QA to logic ‘1’ and a logic ‘0’ on input B will reset the output QA to logic’0’. 2.1.1 Application This simple latching circuit forms the basic anti-bounce circuit figure 2.1b, used to prevent the train of pulses formed by bouncing switch contacts, from being applied to a sequential logic system where it is likely to give rise to a malfunctioning of that system. Figure 2.1b With the switch in position A the logic levels are as shown in the diagram. When the switch lever breaks away from A, an input of the upper NAND gate changes to ‘1’ but the output remains unchanged. The lever may bounce on contact A many times without affecting the logic level at Q. When the switch lever changes to B, the output will reverse at the first contact and will remain unchanged if the contacts bounce at B. 2.2 The simple clocked RS flip-flop Adding two gates on the input side of the cross coupled NAND gates prevents the inputs on the R and S terminals from being applied to the latching circuit unless the clock is in the high or ‘1’ state. The circuit is unable to respond to the RS input until a clock pulse is applied. The clock pulse may be generated by a change over switch (followed by an anti-bounce circuit), or just a simple switch. Connect the circuit shown in figure 2.2. Note: the additional NAND gates invert the SR inputs. 29 ELE1911 Electrical and electronic practice A Figure 2.2 Check and complete the truth table. Note: Qn is the state of Q before a clock pulse is applied. (i.e. Now) Qn+1 is the state of Q after a clock pulse is applied. (i.e. After clock pulse) When R = S = ‘1’, Qn+1 can be ‘0’ or ‘1’ depending on the speed of the individual gates. The truth table can be summarised in a shorter form as shown below: 30 ELE1911 Electrical and electronic practice A The first row in the truth table states that there will be NO CHANGE in the logic state of the output when logic ‘0’ is applied to both R and S inputs. 2.3 Application – simple data memory or type ‘D’ flip-flop This is a modified RS flip-flop with only a single D input, the second input to the RS flipflop being obtained via an inverter. The truth table will be: Construct this flip-flop from the logic circuit diagram figure 2.3. Check the truth table. Figure 2.3 2.4 The principle of the master slave ‘JK’ flip-flop The truth table of an RS flip-flop is: 31 ELE1911 Electrical and electronic practice A Note: for an RS flip-flop ‘Qn+1’ occurs on the rising edge of the clock pulse. This flip-flop suffers from the severe restriction in that an input R = ‘1’, S = ‘1’ is not permitted as the resultant output is indeterminate. The way this is overcome can be verified on the logic board. Figure 2.4 Note: If you do not have enough spare gates to complete this diagram, remember that other gates can be transformed as necessary. i.e. 3 input NAND 2 input NOR + 2 NOTs 2 input NAND 2 input NAND (refer to the study book for ELE1301 or confirm through application of DeMorgan’s Theorems) Connect two clocked RS flip-flops to form a JK flip-flop as shown in figure 2.4 then check and complete the following truth table: 32 ELE1911 Electrical and electronic practice A Check carefully that this is equivalent to: By using an anti-bounce circuit for the CLOCK input, the internal states of the ‘master’ flipflop can be studied while the CLOCK is held high and this will illustrate more clearly the master-slave action and show that the ‘slave’ flip-flop takes up its new state as the CLOCK goes down again. That is, Qn+1 will occur on the falling edge of the clock pulse. Connect a lamp to the CLOCK line to indicate its state at any time. 33 ELE1911 Electrical and electronic practice A Activity 3: Serial counter 1. The study of a four-bit serial counter. 2. Methods to alter the natural count sequence. 3.1 A four-bit serial counter using J-K flip-flops Notes 1. JK flip-flops wired serially in a toggle mode will naturally count in binary. 2. The output frequency of the second FF is half the frequency of the first FF, etc. 7. The total number of natural states that a serial counter has is 2n where n is the number of FFs in the counter. (a) Referring to the diagram shown in figure 6.1 for a four-bit serial counter: 1. complete the truth table (B) 8. complete the timing table (C) 9. configure the four J-K flip-flops as shown in diagram (A). Connect test lamps to the outputs A, B, C and D and verify that with an appropriate clock input, the counter outputs change as predicted. 34 ELE1911 Electrical and electronic practice A (A) JK flip-flops wired to work as a four-bit serial counter; (B) truth table of the four-bit serial counter; (C) timing diagram for the four-bit serial counter. Figure 3.1 3.2 Altering the natural count sequence The natural counting sequence of a serial counter can be changed. For example, the 3-bit counter in figure 3.2 naturally counts through eight states. If some application demands a counter say with seven states, one of the natural states can be skipped. The circuit of figure 3.2 shows how this can be done. The circuit in figure3.2 is wired to skip a state, the state with outputs A, B and C all HIGH (equivalent to decimal 7). That is, the use of the NAND gate does not permit all outputs to stay HIGH between clock pulses. Thus the modified 3-bit counter arrives at the state that is equivalent to decimal 7, outputs A, B, and C do go HIGH but only for an instant. At this instant three HIGHS are applied to the input of the NAND gate, causing its output, the RESET signal, to go LOW> The ACTIVE LOW RESET signal output from the NAND resets all the FFs, causing their outputs A through C to go LOW and stay that way until the next clock pulse. Thus, as shown in the timing diagram for this circuit, outputs A, B and C are all HIGH only momentarily, long enough to cause a LOW going RESET pulse to each FFs CD (direct clear) input. Therefore, immediately after the seventh pulse, but before the eighth, outputs A through C are all LOW. 35 ELE1911 Electrical and electronic practice A Figure 3.2 36 ELE1911 Electrical and electronic practice A Activity 4: Team project, part A – PRBS generator design Equipment required Equipment required: MicroCap8 demo software Logic board Flip-flop board Plug pack Power supply Task 1. To design from first principles a pseudo-random binary sequence generator (PRBS) based on parallel counter design techniques. Your supervisor will provide the required binary sequence. The generator should: Use J-K flip-flops. Be clocked by a single switch. 2. Use the count sequence provided by your supervisor and the form attached to this activity to generate your design. 3. Simulate the design using MicroCap8 (transient analysis). 4. Implement the design on the hardware boards. 5. Demonstrate the design to your supervisor. 6. Retain the design for part B of the project. In part B of this project the pseudo-random binary sequence generator will be interfaced with the 68HC11 microprocessor to provide a visual indication of the binary sequence. Attachments 1. Revision material, including a design example. 2. Blank karnaugh maps to use for your design. 37 ELE1911 Electrical and electronic practice A Revision Designing a PRBS generator A pseudo-random binary sequence, (PRBS) generator is simply a parallel counter that generates a sequence of binary digits that appear to be random or have no pattern. Strictly speaking the sequence is not truly random as it repeats itself over and over again. These PRBS signals are often used to test a data transmission system for errors in the transmitted signal. Several methods have been evolved, some analytical, some using map techniques. The main advantage of a map technique is its simplicity and ease of understanding. This activity is designed to illustrate this technique. Before commencing the activity you may find it helpful to review the following example. Example: PRBS generator design using J-K flip flops Table 1: PRBS generator code sequence table It is important to note that for parallel counters all flip flops change state simultaneously, so the input to each flip flop must be prepared in advance for the clock. Consider the Q output change of a clocked JK flip flop under various input conditions. 38 ELE1911 Electrical and electronic practice A Table 2: JK flip-flop change table X = Don’t care The PRBS generator being described in this example requires 4 flip flops (one for each binary digit, ABCD) to construct. In this case the four are marked FFA, FFB, FFC and FFD. If we first consider the operation of FFA we see from the code sequence table that its output is zero for all counts up to decimal 5. That is, the change from step 5 to 6 is 0 to 0. From step 6 to 7 the change is from 0 to 1, at 7 it returns back to 0, at 8 back to 1 and at 9 returns back to 0 again (ie. loops back to the start). These observations can now be marked on another map called a code change map for flip flop A corresponding to the steps shown in map 1 above. Map 2: Code change map for FFA Counts 0 to 5, FFA = 0, show as 0 → 0 on code change map. After count 6, FFA → 1, show as 0 → 1 on code change map. After count 7, FFA → 0, show as 1 → 0 on code change map. After count 8, FFA → 1, show as 0 → 1 on code change map. After count 9, FFA → 0, show as 1 → 0 on code change map. The code change above is now used to determine what the J and K inputs will be for FFA. This is normally done by marking the characteristics of a JK flip-flop onto two karnaugh maps, one for the J input and one for the K input. These are called JK input logic maps. Referring to both the JK change table and the code change map for FFA place the corresponding values for J & K in the corresponding karnaugh map positions. That is, wherever 0 → 0 appears in the code change map for FFA, place a ‘0’ in the J-map and an ‘X’ in the K-map (the values for J & K are taken from the JK change table for 0 → 0). Then wherever 0 → 1 appears in the code change map, place a ‘1’ in the J-map and an ‘X’ in the K-map. Finally, wherever 1 → 0 appears in the code change map, place a ‘X’ in the J-map and an ‘1’ in the K-map. Fill the remaining squares with ‘X’s. Now loop the ‘1’s. Include ‘X’s where possible to obtain the largest loop. 39 ELE1911 Electrical and electronic practice A Map 3: JK input maps The input signals for FFA have now been determined. A similar procedure is now followed to obtain the input signals for FFB, FFC and FFD. The results should be: Table 3: JK input logic JA = B C D + B C D KA = l JB = C KB = C JC = B + D KC = 1 JD = B C + A B C KD = A + B C Implementation: 40 ELE1911 Electrical and electronic practice A The PRBS circuit above may look complex, but if you analyse each input separately the input logic should correspond to table 3 above. Transient analysis Now run a transient analysis. Set up the transient analysis limits page as follows. 41 ELE1911 Electrical and electronic practice A Click the run button. If your design is correct you should see the waveforms for each output, the stimulus generator and the hexadecimal value for each time interval. These hex values should correspond to the designed code sequence, beginning at 0. 42 ELE1911 Electrical and electronic practice A The following activities will combine a number of computer processes to illustrate microprocessor software design techniques. Combining a personal computer (having at least one serial port) with the EZ-MICRO CPU-11 microprocessor development board, the user is able to prototype hardware, develop, execute, and debug software using the Motorola MC68HC11D0 microcomputer chip (which is the heart of the MICRO CPU-11). The main components of the EZ-MICRO CPU-11 package that we will make use of are: EZ-MICRO CPU-11 (based on the MC68HC11D0 CPU) THRSim11 Simulator software for the PC. 43 ELE1911 Electrical and electronic practice A Activity 5: Part 1 – Introduction to the THRSim11 software The first activity will involve exercises to become familiar with the THRSim11 simulator software, edit and assemble sample code, and download, execute and debug the code. The most important outcome of this activity is that an appreciation of the overall process is attained, even if an in-depth understanding of the procedures is not achieved. Procedure 1. To provide power to the EZ-MICRO CPU-11 microprocessor board, connect the 9-Volt AC wall transformer that is provided into a power-point and connect the 9-Volt plug into the EZ-MICRO CPU-11 power jack connector. 2. Connect one end of the serial cable that is provided to the COM port (or serial port) of the PC. Connect the other end of the cable to the serial port (9-pin make ‘DB’ connector) of the EZ-MICRO CPU-11 microprocessor board. 3. Boot up the PC, and run the THRSim11 Simulator software. The THRSim11 program allows you to accomplish several tasks. It allows the serial communication between the EZ-MICRO CPU-11 microprocessor board (target) and the PC. It allows you to assemble 68HC11 assembly code, download the assembled code to EZ-MICRO CPU-11 microprocessor board and execute/debug the code. The following snapshot shows the start up screen for the THRSim11 Simulator. The THRSim11 Simulator software establishes serial communications with the EZ- MICRO CPU-11 microprocessor board and sends initial data to the CPU. In order to create the assembly source code file ‘XXXLAB1.ASM’ for this activity, you must select the New command from the File menu and the simulator will create a new edit window. A 68HC11 assembler program can be written in this edit window. It is also possible to cut and paste to/from this window from/to other text documents. 44 ELE1911 Electrical and electronic practice A Note: Your initials will replace XXX when you save the program. Enter the following source code: After you have finished entering the above assembly language source code use the Save As command from the File menu to save the information you have just entered. 4. The next step is to assemble your source code using the THRSim11 Simulator software. With the Assemble command from the File menu or the related toolbar button the contents of the edit window can be assembled into machine language. A list window will be opened and the machine code will be loaded in the simulated memory. The green line shows you where the PC register is pointing to. Any errors encountered during assembly will be highlighted. Such errors are probably due to typographical mistakes. Correct any errors in the XXXLAB1.ASM file and re- assemble until there are no errors. 45 ELE1911 Electrical and electronic practice A The program can be now simulated within the THRSim11 Simulator software or downloaded to a target 68HC11 microprocessor board. Both methods will be used in the following steps. Simulation 5. Before running the assembled program within the THRSim11 Simulator open two memory list boxes using the Memory List command from the View > Memory menu options. For the first list box set the starting address to $0000 (data), and for the second list set the starting address to $E000 (program). Arrange the windows so that the assembled program and the memory list boxes are visible, as shown below. Note, the memory locations starting at $0000 should contain the initial value $ff and those starting at $E000 should contain the machine code program, ready to run. 46 ELE1911 Electrical and electronic practice A 6. Run the program using the Run button or F9. Note, the ARRAY memory locations $0000 to $0009 now contain the values $00 to $09. If these values do not appear, there must be an error in the program. The THRSim11 Simulator will execute the program and continuously loop on the last instruction ‘LOOP2 JMP LOOP2’ until the STOP button on the toolbar is pressed. Once the program has stopped the simulated 68HC11 should be reset. To do this, press the RESET button on the toolbar. 7. Modify the ARRAY memory locations so that they contain $ff again. To do this you first have to select the line where you want to enter the new value. Once the line is highlighted, type in the new value. Press return after entering the value or click the next line to be changed. The down arrow on the keyboard can also be used to enter the new value and move to the next line. 8. The program could be executed again, however the program flow is not very clear. The THRSim11 Simulator offers several features that can aid in the following program flow. These features work together to support tracing program flow, monitoring register and memory contents, and setting up breakpoints. The following exercise will use the CPU Registers box and Step commands to step through the program one instruction at a time. The CPU Registers box can be used to display and modify the contents of the A, B, X, Y, C (condition code), S (stack pointer), and PC (program counter) registers. Registers are memory locations that are closely bound to the core microprocessor. Registers have a variety of special functions that regular memory locations do not share. The registers that are used by this program are B, X, C, and PC. The B register is a general purposed 8-bit wide register that is used to hold the variable that controls the loop count, index into the ARRAY and the data that is stored in the ARRAY. The X register is a 16-bit register that is used to address or point to the array element that will be changed. The C register, often called the flags register, has bits that are set or reset depending on various conditions that result from program execution. For this activity the Z (zero) flag is used (bit 2 in the C register). The Z flag is set to 1 (true) when the execution of certain instructions results in zero, otherwise it is reset to 0 (false). Consider the effects of the ‘CMPB #10’ instruction. This instruction compares the contents of the B register to the decimal value 10. If they are equal, the Z flag is set. If not, the Z flag is reset. This flag setting is used in the following instruction ‘BNE LOOP1’ to determine if the loop should be executed again or if it has finished. The PC register contains the address of the next instruction that will be fetched. The PC register is initialised to the program’s start address when the program is assembled. It is now a simple matter to step though the program. To do this, press the STEP button on the toolbar. Stepping through the program one instruction at a time is a powerful way to analyse the program flow. However, it can be noted that stepping through a code section that loops many times could become very tedious. The THRSim11 Simulator offers another command called Set Breakpoint that allows the program to run until it reaches the instruction where the breakpoint has been established. You will learn how to use breakpoints in the next activity. 47 ELE1911 Electrical and electronic practice A Target 68HC11 microprocessor board 9. To run the program on the target microprocessor board, a few changes must be made to the program. The changes are required to ensure that the program and data memory locations coincide with the microprocessor board’s memory map. 10. Make the following changes to the XXXLAB1.ASM program: Remove the last two lines of code, as the reset vector of the target microprocessor is already set. Change the ORG $0000 statement to ORG $1100 Change the ORG $E000 statement to ORG $1120 Save the program under a different name using the Save As command. 11. Assemble the program, then click the Download to target button on the toolbar (light blue down arrow). The THRSim11 Simulator will download the machine code only to the target microprocessor board. 12. Open two list boxes using the Target Memory List command from the Target > Target Memory menu options. Set the start address of the first box to $1100 and the second to $1120. The first box will display the data and the second will contain the program code. Open the Target CPU Registers box as well, as shown below. 48 ELE1911 Electrical and electronic practice A 13. Run the program using the Target Go button (light blue forward arrow) or Ctrl+F9. Note, the ARRAY memory locations $1100 to $1109 now contain the values $00 to $09. The THRSim11 Simulator will execute the program and continuously loop on the last instruction ‘LOOP2 JMP LOOP2’ until the RESET button on the target microprocessor board is pressed. 14. Modify the ARRAY memory locations so that they contain $00. To do this you first have to select the line where you want to enter the new value. Once the line is highlighted, type in the new value. Press return after entering the value or click the next line to be changed. The down arrow on the keyboard can also be used to enter the new value and move to the next line. 15. Execute the program again. Press the RESET button on the target microprocessor board to stop the program. If the ARRAY memory locations do not change, click in the memory list box to force the update. It may be necessary to click on each line to update its value. 16. To shut down the system, unplug the 9-Volt AC power supply, and disconnect the serial cable from the EZ-MICRO CPU-11. Activity 5: Part 2 – Introduction to programming the 68HC11 The following activity is designed for gaining familiarity with the THRSim11 Simulator debugging tools. The program adds five decimal numbers using accumulator A and stores the final result in a particular memory location. 49 ELE1911 Electrical and electronic practice A The five decimal numbers to be added 1, 2, 3, 4, and 5 are to be stored in locations $0000 to $0004 respectively and the answer is to be stored at location $0005. A flow chart describing the program is shown below. The program listing is as follows: 50 ELE1911 Electrical and electronic practice A The program as listed contains a faults that will be used to demonstrate the editing facilities available with the THRSim11 Simulator. Procedure A detailed procedure for entering (programming) and fault finding (debugging) follows: 1. Start Up and enter the program A. Start the THRSim11 Simulator software. B. In order to create the assembly source code file ‘XXXLAB2.ASM’ for this activity, select the New command from the File menu. C. Enter the assembly language source code as shown above then save the file, using Save As from the File menu. Note: Your initials will replace XXX. 2. Assemble the source code A. To do this, select the Assemble from the File menu or press the Assemble button on the toolbar. The assembled program listing will appear in a new dialogue box. Look at the assembled listing file. Two errors should have been generated. Correct the first error in the XXXLAB2.ASM file and re-assemble. The second error should disappear as it was caused by the first. B. Open two memory list boxes using Memory List from the View > Memory menu. For the first list box set the starting address at $0000 (data), and for the second list set the starting address to $E000 (program). Arrange the windows so that the assembled program and the memory list boxes are visible, as shown below. 51 ELE1911 Electrical and electronic practice A Figure 5.2.2: Memory lists Note that memory locations starting at $0000 contain the initial values $01 to $05 and those starting at $E000 contain the machine code program, ready to run. 3. Run the program A. Run the program using the Run button or F9. The THRSim11 Simulator will execute the program and continuously loop on the last instruction ‘LOOP2 JMP LOOP2’ until the STOP button on the toolbar is pressed. Once the program has stopped the simulated 68HC11 should be reset. To do this, press the RESET button on the toolbar. B. Note, the memory location labelled ANS ($0005) now contain the value $0A (decimal 10). The correct answer is $0F or decimal 15; therefore there is a problem in the program as originally defined. The following steps should help isolate the problem and correct it. 4. Breakpoint and register display A. It might be useful to see what the program was doing each time it went through the loop. Therefore, set a breakpoint at the beginning of the loop, location $E009. To do this, use the Set command from the Breakpoint menu. Enter $E009 as the breakpoint value. 52 ELE1911 Electrical and electronic practice A B. Note, a yellow bar appears to indicate a break point has been set. C. Run the program again. The program will run to the breakpoint and then pause. At this point the program is suspended, and on detecting this breakpoint, the contents of the registers may be viewed. The registers should contain the following values: D. To resume the execution of the program, select the Run button. Since the breakpoint at location $E006 is in a loop it will again be the next breakpoint and the program will pause. At this point the registers will contain: Note that Accumulator A contains the partial sum and Accumulator B has been decremented. The X Register has been incremented since the last breakpoint. 53 ELE1911 Electrical and electronic practice A E. Select Run, and once again the registers may be examined: F. Select Run, and once again the registers may be examined: G. Select Run, and the program has now successfully completed the loop four times and Accumulator A contains the incorrect sum. 5. Correcting the program A. From above it is evident that although the program was supposed to add five numbers, the loop was executed only four times. Therefore the LDAB#4 instruction at locations $E001 – $E002 should have been initialised to five (5). B. To remove the breakpoint, select Remove from the Breakpoint menu. Highlight the breakpoint to be removed and click OK. C. Edit the XXXLAB2.ASM file and update the value of the operand for the LDAB D. mnemonic. Save the assembly language program. Re-assemble the program and run it. D. The following should now be displayed, indicating the correct value stored in location $0005. 54 ELE1911 Electrical and electronic practice A Activity 5.6: Use of a clock to program a delay Counting is a good way to create a programmable delay in your program. The 68HC11 in the EZ-MICRO architecture is running at 2 MHz and yet our application may be required to blink a light once every 5 seconds. In any given microprocessor each instruction in each addressing mode takes a precise and deterministic amount of time to execute. This means we can calculate how long it takes to make a certain number of passes through a loop. By looking at each instruction’s information sheet, we can identify the ‘execution time’, a value given in terms of cycles. The cycle time of the 68HC11 on-board the EZ-MICRO Board running from an 8 MHz crystal is 500ns. The LDAA instruction requires 2 cycles to execute in the immediate addressing mode. This means that is takes 1 usecs for LDAA #5 to execute on the EZ-MICRO system. Execution times of a few common looping instructions are provided: LDAA DECA BNE NOP LDX DEX (imm) 2 cycles 2 cycles 3 cycles 2 cycles 3 cycles 3 cycles (imm) Consider the following code segment that executes a loop five times. The code segment has two NOP instructions inside the loop, and these are used to provide additional delay. LDAA DECA NOP NOP BNE COUNT #6 COUNT The initialisation of the loop only occurs once. The LDAA instruction requires 1 usec. The time for 6 passes through the interactive part of the loop can be computed as 6 passes × 4.5 usec/pass = 27 usec. So the total time required for one execution of the loop is 28 usecs. The largest loop counter that we can create with a single byte of memory or a single byte register is 256. However if we use a 16-bit register as a loop counter we can count up to (or down from) 65 535. For a loop that requires 10 cycles per iteration, the total time required for one execution of the loop is now 327 675 usec plus 1 usec to initialise the loop. Notice that as the time required for all the iterations grows large the time required to initialise the loop becomes less and less significant. The index register is a 16-bit register that is very well suited for a loop counter. The instructions LDX, INX, and DEX make it easy. For example, consider the following code segment that creates a delay of almost exactly 0.25 seconds. COUNT LDX DEX NOP BNE #62 500 *3 cycles *3 cycles *2 cycles COUNT *2 cycles 55 ELE1911 Electrical and electronic practice A Procedure Write a program that creates a delay of approximately 1 second and then increments the contents of Accumulator A and delays again. This delay-then-increment process should continue indefinitely (when simulated only). While developing your program, use the following guidelines. 1. Choose $E000 as the origin of your program code segment. 2. Create a nested loop; use index register X as the inner loop counter and ACCB as the outer. Note: The simulator runs much slower than the EZ-MICRO board. It is also not practical to calculate the delay based on the number of machine cycles. Determine the value to be placed in the index register by trial and error. A typical starting value for a 0.2 second delay may be $0100 in the index register. 3. Run the program for 10 seconds then stop it. The value in accumulator A should be $0A. 4. Modify your program to run on the target board. Change the starting address to $1000. Estimate the value to be placed in the index register based on the number of machine cycles within the loops and a cycle time of 500nsec. 5. Test the value of accumulator A in your program so that the program can be stopped when accumulator A reaches the count of 10. To stop the program, insert a ‘NOP’ instruction just before the end of the program. This will allow a target breakpoint to be set. 6. Download the code to the 68HC11 microprocessor board. Set the target breakpoint, then measure the time the program takes to run, it should be close to 10 seconds. 7. Examine the target CPU registers. You should see a value of $0A in Accumulator A. Activity 5.7: Seven segment display The aim of this activity is to illustrate two interfacing techniques that may be used to drive a seven segment display. 1. The first technique utilises the peripheral interface adapters B and C of the 68HC11 microprocessor. The segments of the display are connected to the output pins of peripheral register B. In this way, the character displayed will depend on the bit pattern stored in peripheral register B. The illumination of the display is controlled by one output pin of peripheral register C. This ensures that the display is not illuminated until valid data appears in peripheral register B. This technique will be simulated using the THRSim11 Simulator software. 5. The second technique utilises a BCD to 7 segment display decoder circuit built into the EZ-MICRO Board. This technique is easier to program, but requires more circuitry than the first. The character to be displayed is simply stored to a specified memory address that represents the BCD to 7 segment decoder. So placing the required character on the data bus will cause the appropriate segments to light when the address of the decoder appears on the address bus. Since the address bus provides the display enable signal, illumination of the display will only occur while the specified address is on the bus. For this reason the display decoder must be continually written to. In this way our brain ‘sees’ the display as being continuously lit. 56 ELE1911 Electrical and electronic practice A This technique will be illustrated using the EZ-MICRO board. Procedure 1. To illustrate the first technique, enter the following program into the THRSim11 Simulator. The program will display the number 3 on a 7 segment display. However, before simulating the operation of the program it is necessary to connect the display to the simulated 68HC11 output ports. To do this, select 7-Segments display from the Connect > 7-Segments Displays menu options. A 7 segment display box will appear in the workspace. Move the display to avoid obscuring other open dialogue boxes. To connect the display, right click within the display. Select the Connect option to display the Connect dialogue box, as shown below. Connect the 68HC11 pins to the component (display) pins by highlighting the two nodes to be connected then click the Connect button. When all pins are connected, as shown above, click OK. Save the program file as XXXLAB6a.ASM. Assemble and run the program. If there are no errors, the number 3 should appear in the display box. 57 ELE1911 Electrical and electronic practice A 2. Modify the program to display the number 5 for a few seconds then turn the display off. Confirm the program works as expected then stop it. Close all open dialogue boxes. 3. Create a new program using New from the File menu. 4. To illustrate the second technique, enter the following program. 5. Assemble the program then download it to the target EZ-MICRO board using the Download to Target Board button on the toolbar. Run the program on the target using the Target Go button on the toolbar. Confirm that the number 3 is displayed for about 1 second. 6. Modify the program to display the number 5 for 5 seconds. 58 ELE1911 Electrical and electronic practice A Activity 5.8: PRBS generator design – part B Equipment required 68HC11 development board Logic board Flip-flop board Plug packs Power supply Task 1. To interface the pseudo-random binary sequence generator designed in part A with the 68HC11 microprocessor development board and to provide a visual indication of the binary sequence on the development board. The generator should: use J-K flip-flops be clocked by a single switch (on the logic board). Procedure 1. Construct the generator designed in part A. 2. Connect the generator to the 68HC11 uP development board. 3. Write a program that will, when interrupted, read the output of the generator. 4. Download the program to the 68HC11 uP development board (target board). 5. Run the program on the target board. 7. Clock the generator with the switch and observe the target display. Attachments 1. Revision – Interrupts. 2. Initial code. Reference ELE1301 study book, module 11 – MC68HC11 instruction set (In particular, tables 11.1, 11.3 & 11.4). 59 ELE1911 Electrical and electronic practice A Revision 1. Interrupts A major difference exists between most peripherals when they are connected to a CPU and that is ‘speed of operation’. In general most peripherals are very slow compared with a CPU. Signals between the CPU and the peripheral indicating when each other is ready to transfer data, are known as ‘Interrupts’. An interrupt can also be a signal to a CPU to halt its normal operations and do something more important. These signals are used for alarm inputs, external control of processes or debugging aids in software development. Generally interrupts fall into three categories: internal external software. For this activity we need to use an external interrupt. External interrupts are generated by signals from peripheral devices. They may be requesting data transfers or indicating a failure has occurred. A good example of this is a machine error. In this case the interrupt may be used to initiate a special routine to quickly store and display an error code in the few milliseconds before the machine shuts down. When an interrupt is received by the CPU it: Completes the current instruction in its program Stores all of its registers contents in memory Executes a special program called the Interrupt Service Routine (ISR) Returns to the point where it left the original program. Various methods are used to transfer control to the ISR. On interrupt, the 68HC11 obtains a 16-bit interrupt vector from 2 fixed memory locations ($FFF2 and $FFF3). This interrupt vector ($01EE for the ìP development board) is then loaded into the program counter as the address of where the first instruction of the ISR resides. For this activity the program will go to the vector address $01EE for the first instruction of the interrupt service routine, which is actually a jump to another location in the program area of memory. To do this the following code may be included at the end of a program. ORG $01EE JMP IRQISR An interrupt from the PRBS generator will cause CPU to suspend its current execution and perform a special ISR and when finished return to the main program. After executing the ISR, how does MPU know where to return to? As outlined previously, this is taken care of automatically by the CPU as it temporarily stores the current address of the PC on the stack before it branches to the ISR. Actually it stores PC, Index Reg, AccA, AccB and CCR in that order, on the stack. When the RTI is executed it restores these values to their respective sources in the reverse order as the stack is a Last In First Off (LIFO) device. The following flowcharts may be used as a guide for this activity. 60 ELE1911 Electrical and electronic practice A Note: ‘loop’ is designed to continually refresh the display while waiting for an IRQ. So, no instructions are associated with the ‘wait for interrupt’ block. 61 ELE1911 Electrical and electronic practice A 2. Initial code 62 ELE1911 Electrical and electronic practice A Activity 9: Introduction to PLCs Equipment required To be advised by the instructor. Activity 10: PLC application Equipment required To be advised by the instructor. 63 ELE1911 Electrical and electronic practice A Electronics lab Please bring your electronic construction breadboard to residential school. You can use it to build your circuit on and avoid the need to construct your circuits more than once on the shared breadboards here. Activity 1: Familiarisation with test equipment Spend the first hour or so of your time here getting used to the test equipment on the bench. Use the following activities to ensure that you know the basic capabilities and limitations of the equipment: Power supply and multimeter: Measure the following voltages with the digital multimeter set on a d.c. volts range. ● Voltage between +5V terminal and common ● Voltage between +5V terminal and the common on the other side of the supply ● Voltage between +5V terminal and ground ● Voltage between +Variable terminal and common. ● Ensure that you know how to adjust the voltage. Oscilloscope and function generator: ● Set up the function generator output to be a sine wave at about 1kHz, with no d.c. offset. ● Connect the output to channel 1 of the oscilloscope. ● Trigger the display to achieve a stable trace. You may need to get help with this – be sure you know how to do it properly. ● Measure the period of the signal with the oscilloscope and compare it to the nominal period of the function generator signed. ● Measure the voltage of the signal with both the oscilloscope and the meter set on a.c. volts. Make sure that both give similar values. ● Vary the settings of the function generator, frequency, level, wave form, and d.c. offset, and observe the oscilloscope trace. Ensure that you can measure the d.c. offset value by selectivity d.c. coupling. 64 ELE1911 Electrical and electronic practice A Activity 2: Introduction to breadboarding To be advised by the instructor. Activity 3: Electronics project construction 3.1 Build the circuit comprising the comparators (LM339), logic circuit IC2a and IC2b (74LS00) and the LED. Vary the input voltage and ensure that the circuit works to indicate when the input voltage is within a fixed range. Measure the following: ● The voltages defining the voltage range. ● The voltage range of the input at which in-range/out-of-range indication occurs. ● The voltages of the logic levels at all three pins of the IC. Estimate the current in the LED. Is this acceptable? 3.2 Build the lower frequency oscillator based on the 555 timer and ensure that it works. Sketch approximately to scale and in correct time relationship, the waveforms at the threshold and output pins of the 555. Compare the period of the output signal with that obtained by calculation. 3.3 Build the higher frequency 555 oscillator. Repeat the procedure of 3.2. Pin RES will have to be high for oscillation. 3.4 Add the logic circuity comprising IC6a and IC6 b (74LS00) to the oscillators. When will there be a signal at the output of IC6b? Sketch this output waveform. 3.5 Build the amplifier based on the LM741 op amp. You may choose to adjust some values here. Adjust the potentiometer to achieve an output voltage which swings both positive and negative. Record your final output waveform with the previous circuit connected. Measure the voltage gain and compare it to theory. 3.6 Build the circuit driving the 8 ohm load or speaker. Connect the amplifier. Sketch the waveform across the speaker. Check that the transistors are capable of supplying the current and that the 741 can supply the required base current. 3.7 Ensure that the whole circuit operates to detect a certain voltage range and indicate it with a sound output. 65 ELE1911 Electrical and electronic practice A Activity 4: Electronics project testing To be advised by the instructor. ELE1911 – Electronic circuit 66 ELE1911 Electrical and electronic practice A Electrical technology activities Electrical safety – rules Electricity supply and accidents The use of electricity is of immense importance and benefit to the industry, the home, and the welfare of the community generally. However, the possibility of electric shock, which can cause injury and death, is always there. An analysis of electrical accidents indicates that in most cases the victims contacted the normal supply of 240 volts. There were also some accidents involving contact with high voltage transmission lines and aerial distribution conductors with a line voltage of 415 volts. Death from electric shock has occurred from contact with the electrodes of leads of electric welders, in which the voltage was less than 100 volts. The question that may be asked then is, why supply at 240 V and not a lower value (e.g. 32 V)? The reason is that if the ordinary supply were 32 volts, it certainly would be safer, but the cost of electricity supply would be much greater due to the heavier and more expensive cables and other equipment required by both the supply authority and the householder. Electrical accidents are often the result of misadventures of careless persons undertaking make-shift repairs (to domestic appliances and workshop equipment which become faulty due to misuse and lack of proper care and maintenance). They can be avoided by a commonsense approach in observing the rules of personal safety. Strict adherence to the safety regulations and recommended working procedures in using adequate safety devices (such as protective clothing, gloves, goggles, face-masks, helmets), warning notices, safety-barriers, security locks, rescue-observer, insulated tools etc., is recommended. Domestic electrical installations and equipment rated at 240 V are quite safe if installed and used in accordance with the various methods, procedures and regulations which have been adopted by the Electricity Boards and the State Electricity Commission. Lower voltages, particularly 32 volts, are used in industry for such applications as inspection lead-lights. The supply for these is obtained from 240/32 V transformers. Factors affecting electric shock To receive a shock a person must contact two points between which there is a difference of potential, for example between the active conductor and the earthed metal frame of an electric iron. The resulting current flow through the body causes the damage. Investigations have shown that the following electrical and physiological factors, determine the severity of the shock. 67 ELE1911 Electrical and electronic practice A Table 1: Factors affecting electric shock Electrical Duration of current Frequency of current Physiological General physical condition of victim e.g. Weak heart Wave shape of current Body resistance Magnitude of current Skin resistance Voltage applied initially Path of current Phase of heart cycle Table 2: Body current and physiological effect Current (50 Hz) Physiological phenomena <1 mA None 1 mA Perception threshold Feeling or lethal incidence Imperceptible 1–3 mA Mild sensation 3–10 mA Painful sensation 10 mA Paralysis threshold of arms Cannot release hand grip, if no grip, victim may be thrown clear 30 mA Respiratory paralysis Stoppage of breathing (frequently fatal) 75 mA Fibrillation threshold 0.5% Heart action discoordinated (probably fatal) 250 mA Fibrillation threshold 99.5% (>5 s exposure) 4A Heart paralysis threshold (no fibrillation) Heart stops for duration of current passage. For short shocks, may restart on interruption of current (usually not fatal from heart misfunction) >5A Tissue burning Not fatal unless vital organs are burnt Human body as conductor Alternating voltage at 50 Hz reaches maximum value at intervals of 0.01 second. When such a voltage is applied to the human body, the nerve-muscle system is still attempting to recover 68 ELE1911 Electrical and electronic practice A from one peak when it is subjected to the next. Consequently with an a.c. current of sufficient magnitude the muscles remain in spasm and the victim remains locked to the a.c. supply. Direct current causes momentary locking (at make or break) but not continuous spasm. If the frequency is raised, the body is able to tolerate more current. The shock effect is detectable up to about 50 kHz. Above this frequency, only heating is experienced, and this effect is used in diathermy where 1 MHz or more is used. The electric resistance of the human body varies with the condition of the skin, which is responsible for most of the resistance, and the situation of the body. Obviously when a person is perspiring his resistance is lowered. Also, if part of the body is immersed in water, resistance is lowered. Once the skin is punctured, body resistance decreases greatly. Consequently, prolonged time of application of current, by causing sweating and blistering and finally destruction of the skin, is more dangerous than a brushing contact. The average resistance of the body, from hand to hand, with intact dry healthy skin is approximately 3000 ohms. This figure can be reduced to about 500 ohms by soaking the hands in water. Body resistance is also reduced when the contact area and the contact pressure with a conductor is increased. Effect of magnitude of current Current of 1 to 3 milliampere magnitude can be felt by the person without shock condition. The ‘let-go’ voltage at which an individual can release himself from contact varies in individuals from 15 to 19 volts a.c. and the ‘let-go current’ is in the range of 8 to 14 milliamperes and leads to micro-shock conditions. Alternating currents from ‘let-go’ values and up to 25 milliamperes cause muscular cramps and may lead to exhaustion, loss of consciousness and ability to breathe. Muscular convulsions will cease when the current is removed, but the inability to breathe may persist, requiring artificial resuscitation (macro-shock condition). If the body current exceeds 25 milliamperes, the severity of the shock situation is intensified to ventricular fibrillations. It is a condition where the heart loses its rhythm and the heart muscles quiver in an uncoordinated manner, diminishing the possibility of reviving the victim. The heart is vulnerable because currents, whether from hand to hand, or hand to foot, travel principally in the blood vessels and so reach and traverse the heart. Artificial respiration in itself, does nothing to restore heart rhythm. The time of contact for fibrillation to occur is related to the cardiac cycle and the current for fibrillation: I 60 / t Main effects on the body Current through the body may cause one or more of the following effects: a. Paralytic injury to the brain. b. Injury to the heart and hence circulatory failure. c. Damage to tissue and organs by severe burns. d. Respiratory failure. e. Muscular convulsions. 69 ELE1911 Electrical and electronic practice A Resuscitation Attempts to revive victims of electric shock are often successful if a person with a knowledge of resuscitation methods is available to immediately apply them. Prompt action by a rescuer is essential as the chances of death increase with each minute of delay in commencing resuscitation. Course of action A quick appraisal of the situation should be made by a rescuer when approaching a victim. If the victim is still in contact with a live conductor, then the supply should be immediately switched off, or the flexible cord pulled out of the socket of the wall outlet. In some situations, such as a fallen conductor in the street, the means of switching off supply are not readily accessible. The rescuer, in this case, must move the victim from the conductor without himself becoming the second victim. Dry wood, dry clothing, rope, blankets, rubber mats and rubber gloves provide sufficient insulation for 240 volts. The rescuer must decide on the spot how to effectively use these materials to shift the electric conductors. If an unconscious person has to be moved before artificial respiration is commenced, he may be carried, rolled or dragged. The uppermost thought in a rescuer’s mind should be to commence resuscitation with minimum delay. Medical assistance should be fetched as soon as possible, but commencement of artificial respiration should not be delayed for this purpose. Methods of resuscitation Obtain Safety and Resuscitation Publications. Thoroughly study and learn the most effective and normally-preferred resuscitation methods. 70 ELE1911 Electrical and electronic practice A University of Southern Queensland Faculty of Engineering and Surveying Energy systems laboratory: safety rules 8. Before proceeding to conduct any Energy Systems Laboratory work, as directed, students must firstly provide written notification to the instructor if they: ● have a physical disability ● have a history of physical illness ● have a current medical condition or ● are on medication that may cause impairment of judgement or slow reaction time, so that appropriate safety procedures and precautions can be arranged and implemented. Students who are presently unwell (i.e. feel faint or dizzy, etc.) must notify the instructor (in private) before proceeding with any Energy Systems Laboratory work. All information given is confidential and is disclosed only to the instructor and Laboratory Technician in Charge as necessary to ensure personal safety in the Laboratory at all times. 9. Do not proceed to set up an activity unless you have prepared proper circuit diagrams with a detailed equipment listing and these have been approved by the instructor. 10. Connect according to the approved circuit diagrams, using colour-coded cables for easy identification. If any changes are made to the connections, these must be recorded in the report. If major changes were made, then draw revised circuit diagrams. 11. Never switch on the power supply unless: ● you have thoroughly checked the connections, starting settings of controls, instrument ranges and supply details ● you have carefully studied the safety requirements and precautionary measures, starting and stopping procedures and operational sequences ● you have consulted the instructor and clarified all your doubts ● the instructor has checked and approved your connections and set up. 12. Use appropriate protective measures (fuses, switches, and circuit breakers). Protect measuring instruments from surge currents. If anything appears to be wrong switch off the supply at the circuit breaker or switch. 13. In case of emergency, promptly inform the instructor and proceed to follow his/her instructions in a calm and orderly manner. 14. Lay out the equipment on the test bench in a safe and easily accessible manner. Do not crowd the test bench. Remove all unwanted items, spare cables and your own possessions to another unused bench. 15. Since you will be working on exposed live parts at 240 V and 415 V, think before you do anything. Prevent electrical accidents to persons and equipment by carefully observing safety instructions. 71 ELE1911 Electrical and electronic practice A Safety instructions: please read and observe When connecting leads 1. Avoid using test-leads and connecting cables with damaged insulation or loose terminations. 2. Avoid connecting more than two leads to any terminal. 3. Avoid spreading cables over rotating or hot parts. 4. Avoid over-tightening terminals, screws and nuts (finger-tightness is sufficient). 5. Avoid joining (or piggy-backing) connecting leads to obtain extended connection. (Use a single cable of adequate length). 6. Avoid overloading cables by applying excessive currents. (Use thicker cables for currents in excess of 7 A, thin cables for currents up to 7 A and thinner cables for currents less than 1 A). 7. Avoid plugging and unplugging connector cables when the supply is switched on. When working in the laboratory 1. Do not work in thongs, sandals or bare-feet. 2. Do not leave your energised circuit unattended. 3. Do not wear hanging chains and bracelets. 4. Do not hold metallic rulers and pens near live circuits. 5. Do not touch any bare conductors, terminals or rotating parts. 6. Do not pull or twist power cables. 7. Do not touch or shift hot lamps and resistors. 8. Do not meddle with equipment and notices. 9. Do not play tricks on other students. 10. Do not kick objects or push buttons with your foot. 11. Do not tap, shake, drag or drop instruments. 12. Do not rest your feet or arms on equipment. 13. Do not place paper pads over ventilating screens. 14. Do not lean over panels, trolleys or persons. 15. Do not place equipment on the floor or standing space. Be safety conscious. Know what to do in case of emergency. __________________________________________________ Neatly remove this section and hand to the laboratory supervisor. I shall abide by the energy systems laboratory safety rules and instructions which I have read and understood. Name: Signature: Date: 72 ELE1911 Electrical and electronic practice A Using instruments in electrical laboratories Please read and observe 1. Inspect the instruments. Do not use if faulty or damaged. 2. Handle all instruments with gentleness and care. Do not jar or drag meters on bench tops. Do not pull wires connected to meters. Do not tap the meter or subject it to vibration. Do not write on the meter or use ball-point pen on the glass. 3. Before using any instrument consult its instruction manual. Double-check meter usage and the correct method of connections. Ascertain and observe the polarity markings of terminals. Use d.c. meters in d.c. circuits and a.c. meters in a.c. circuits. 4. Check zero errors before using the instruments. If the mechanical zero requires resetting, ask the instructor to do it for you. Do not use coins, blunt screw drivers, etc. on Set-Zero screw. 5. Check accuracy class of the instrument, scale multiplying factors and subdivisions of scale graduations for the range connected. 6. Check the correct positioning of the instrument. Most laboratory instruments are positioned flat on the table. Meters marked with must be placed vertically on the table. 7. Do not place meters close to the edge of the table or on the floor. Arrange meters in the front, so that their scales can be correctly read with ease. 8. Do not use meter terminals as junction posts. Do not over-tighten terminals but check for loose connections. 9. Double-check the selected Range Setting for voltages and currents. Read the meter indication on the correct scale. First select the range higher than the value being measured. If the reading is very low, then lower the scale range. 10. Current coils of ammeters, wattmeters, power factor meters and energy meters are likely to be easily damaged. When switching-in circuits which may draw surge currents, shortcircuit the current coils using shorting switches. Do not exceed the rated current. If you notice the instrument to be faulty or damaged before you use it, or if any wrong connection or accident occurs, report to the Supervisor without delay. Do not use multimeter with test prongs on energised circuits in CURRENT and OHMS settings. Do not switch on power without checking range setting of meters and controls. Using A.C. measuring instruments 1. A.C. voltmeters A.C. voltmeters are calibrated to indicate the effective (r.m.s.) value of sine-wave voltages. The selected range of a multi-range instrument must be always higher than the expected voltage in the test circuit and the setting may be changed to the next lower range if the reading is too low on the selected range. Always check the range before using the meter. 73 ELE1911 Electrical and electronic practice A Always connect the voltmeter in parallel with the circuit element, the voltage across which is being measured. Where a single multi-range voltmeter is used to read the voltages across a number of terminals, insulated leads with prongs or touch-clips are used and the meter need not be permanently connected. Most laboratory instruments are placed horizontally on the table ( ). 2. A.C. ammeters A.C. ammeters are calibrated to indicate the effective (r.m.s.) values of sinusoidal currents. Always connect the ammeter in series with the circuit element, the current through which is being measured. Choose a range setting higher than the expected circuit current. NEVER connect an ammeter in parallel with a circuit element or across a supply source, as the meter will be permanently damaged. DO NOT USE TEST-PRONG LEADS. Polarity of connection to the ammeter terminals has no effect on the indication of the meter. If using a multi-range instrument, always set it on the higher range and change the range to a lower one if necessary. 3. A.C. wattmeters A.C. wattmeters are calibrated to indicate the average real or active power supplied to a circuit element. A wattmeter has one set of current terminals, (usually marked M or ±, and L for the current range), and one set of voltage terminals (usually marked V+, and the voltage range). Connect the current terminals in series with the circuit element, M to the mains side and L to the load side. Check the meter cover and select the correct current range setting so that the meter range value is higher than the expected load current; one of the voltage terminals (V+) is usually connected to M (or L). Always record the multiplying factor corresponding to the selected voltage and current ranges. Always check the current/voltage ranges connected before switching the power on. Use the shorting switch to protect the current coil from surge currents. Correct polarity connections must be observed, otherwise the pointer may be kicking below zero. If the pointer is below zero when the circuit is switched off, then there is a zero error. Ask the instructor to correct this zero error. If the meter is connected correctly and the pointer reads below zero, then use the reversing switch and record the reading as negative in sign. For highly inductive or capacitive loads, the power factor is less than 0.2 and a low-powerfactor (l.p.f.) wattmeter is to be used. If the load power factor is 0.5 or more, use a wattmeter calibrated at unity power factor (u.p.f.). 4. Power factor meter 74 ELE1911 Electrical and electronic practice A A power factor meter indicates the cosine of the angle between a voltage and the current. It is connected in the same way as a wattmeter. Since it has no spring control, the pointer may drift when the supply is off. Note that the scale is not uniform. Always indicate whether the p.f. value is lead or lag. If the voltage-coil or current-coil connections are reversed, the pointer may deflect outside the scale range. 5. Energy meter (kilowatt-hour meter) An energy meter is an integrating type instrument. It has a rotating disc the speed of which is a measure of the energy supplied to the load. The meter has a constant (K revolutions per kWh). Energy metered = (no. of revolutions of the disc) / K. The meter is connected in the same way as a wattmeter. It is mounted in a vertical position. 6. Cathode ray oscilloscope A cathode ray oscilloscope (CRO) is used to observe the time variations or waveforms of voltages and to measure their properties. To observe the waveform of a current, the current is passed through a resistor of known value and the voltage drop across the resistor is measured using the CRO. Note: An isolation transformer should be used to supply the 240-V power to the CRO in tests where a circuit voltage is floating and common earth connection is not permissible. 75 ELE1911 Electrical and electronic practice A Activity A1: Kirchhoff’s laws Aims 1. To apply Ohm’s law and Kirchhoff’s current and voltage laws. 2. To verify the calculations by test measurements. Theory Refer to study book 1, chapter 4. For the circuit is shown in figure 1: I1, I2 and I3 are branch currents; b and d are the only nodes; a and c are merely terminations; abda and bcdb are the closed loops. Figure 1: Circuit Node and terminal voltages Using double subscript notation, the voltage differences between terminals can be written. Applying Ohm’s law to the branches, using d as the common reference point: Vad = E1 Vab = Vad – Vbd = R1.I1 Vad = E2 Vcb = Vcd – Vbd = R2.I2 Vbd = V3 = R3 ⋅ I3 From the equations above, the branch currents are: I1 = Vab / R1 = (Vad – Vbd ) / R1 = (E1 – V3) / R1 I2 = Vcb / R2 = (Vcd – Vbd ) / R2 = (E2 – V3) / R2 I3 = Vbd / R3 = V3 / R3 Applying KCL at node b: I1 + I2 = I3 ( E1 V3 ) / R1 ( E2 V3 ) / R2 (V2 / V3 ) 1 1 1 ( E1 / R1 ) ( E2 / R2 ) V3 R1 R2 R3 The branch conductances are: G1 = 1 / R1; G2 = 1 / R2; G3 = 1 / R3 1 1 1 V3 [( E1 / R1 ) ( E2 / R2 )] / R1 R2 R3 or V3 = [G1.E1 + G2.E2] / [G1 + G2 + G3] – Millman’s Parallel Generators Theorem 76 ELE1911 Electrical and electronic practice A Parallel generators theorem analysis 77 ELE1911 Electrical and electronic practice A Activity A2: Resistance measurement of DC machine windings Aims To conduct tests on a d.c. machine to determine: 1. The armature circuit resistance. 2. The shunt-field winding resistance. Circuit diagrams and apparatus Figure 1: Armature circuit Figure 2: Shunt-field winding Table 1: Measurement of resistances in a D.C. machine Detail Detail M D.C. machine, 230 V, 21.75 A, 1 500 r/min, MacFarlane Eng. Co. S Supply fuse switch 220 V, 30 A, d.c. RL Variable resistance, 250 Ω, 240 V, 20 A, GK Electrical Rf Variable resistance, 324 Ω, British Electric Resistance Co., 1.3 A Va Voltmeter, AVO 8 Mk III, 0–25 V d.c., 2% F.S.D., 20 kΩ /V Vf Voltmeter, AVO 8 Mk III, 0–100 V d.c., 2% F.S.D., 20 kΩ /V Aa Ammeter, 30–0–30 A d.c. A.J. William Elec. Inst., Type P.C. 6, Class 1M A Ammeter, AVO 8 Mk III, 0–1 A d.c., 1% F.S.D. Instructions 1. Armature circuit resistance (Ra) Note that armature circuit includes interpole winding and brush contacts. Connect the circuit as in figure 1. Set RL to limit the current to the rated value. Close S. Adjust RL so that the rated current flows through the armature circuit. 78 ELE1911 Electrical and electronic practice A If the armature starts to rotate, hold it still. Note the voltage drops and currents for three positions of the armature. Record the readings in table 2. Calculate the mean value of Ra1 at θ1 = 20°C and then the value of Ra at θ2 = 75°C. Ra Ra1av 1 1 75 1 1. 0.004 / K 1 20C temperature coefficient of resistance at 1 ambient temperature 2. Shunt-field resistance (Rf) Connect the circuit as in figure 2. Since the resistance of the winding is high, make sure the current If does not include the current taken by the voltmeter. Take three readings. Record readings in table 2. Calculate the mean value of Rf1 at θ1. Determine the Rf value at 75°C. Calculations Table 2: Test data: resistances in a D.C. machine Armature circuit Field circuit Va V Vf V Ia A If A Ra1 Ω ---- ---- Rf1 Ω ---- ---- Ra1av Ω ---- average value at temp. 20°C Rflav Ω ---- average value at temp. 20°C Ra Ω ---- at temp. 75°C Rf Ω ---- at temp. 75°C ---- Activity A3: D.C. shunt motor performance Aims 1. To run the d.c. shunt motor at the rated voltage and rated speed on no-load. 2. To predetermine the load characteristics of the motor from no-load test. ---- 79 ELE1911 Electrical and electronic practice A Circuit diagram and apparatus Figure 1: D.C. shunt motor: no-load run test Table 1: No-load run test: D.C. shunt motor list of apparatus Detail Detail M D.C. motor: 5 kW 230 V, 21.75 A, 1 500 r/min N Tachometer 0–2 000 r/min R1 Variable resistance 50 Ω, 5 A, wire-wound Rf Variable resistance 330 Ω, 1.1 A Va Voltmeter, D.C. 0–300 V Vt Voltmeter, D.C. 0–300 V A1 Ammeter, D.C. 0–5 A A2 Ammeter, D.C. 0–3 A F1 Fuse, 30 A, 250 V D.C. F2 Fuse, 5 A, 250 V D.C. Instructions Shunt Motor No-Load Run Test Decouple the motor from the shaft load. Connect the motor for no-load run as in figure 1. Use a variable resistance R1 for starting. Keep R1 at maximum and Rf at minimum resistance. Close S after ensuring the starting and stopping procedures. Check the meters for polarity and range. Check the direction of rotation of the motor. Note the direction marked on the end-frame. (If the direction is wrong, open S. Interchange the wires connected to Z and ZZ. Close S. The motor should run in the correct direction.) Adjust R1 gradually until Va = Vt . 80 ELE1911 Electrical and electronic practice A Adjust Rf to obtain the rated speed. Record the readings in table 3. Reduce speed. Stop the motor. Open S. Analysis Calculations (refer to the practice example which follows this activity) Calculate the rotational and fixed losses (table 3). Assume a value of line current IL = x.ILr where x = load factor. x is a variable: x = (0.25, 0.5, 0.75, 1 and 1.25) and the rated line current = ILr. See sample calculations. Complete the calculations for each IL in table 4. Graphs 1. Plot the predetermined characteristics: efficiency (η), speed (N), torque (T) and line current (IL) vs power output (Pout) on the same graph. 2. Plot torque (T) vs line current (IL) and torque (T) vs speed (N). 3. Draw the power flow diagram (to scale) at full load. Table 2: D.C. shunt motor Rated details of motor Vt: V Ilr: A N: r/min Pout: kW Ω Armature resistance Ra = Table 3: No-load light running test: data and calculations Supply voltage Vt = V No-load armature loss = Ra.Iao2 W Field current If = A No-load armature input = (Va.Iao) W Armature voltage Va = V Iron, friction and windage losses (rotational) Pr = Vt.Iao – Ra.Iao2 = W No-load armature current Iao = Field circuit loss = Vt.If = W Speed No = A r/min Fixed losses PF = Pr + Vt.If = W 81 ELE1911 Electrical and electronic practice A Table 4: D.C. shunt motor: efficiency calculation by summation of losses x Load factor No-load Vt Supply voltage V IL Line current x.ILr A If Field current A Ia Armature current (IL – If) A Ia2Ra Armature losses W PF Fixed losses W PL Total losses PF + Ia2Ra W Pin Power input VtIL W Pout Power output (Pin – PL) W η Efficiency (Pout/Pin) × 100 % Ebo No-load back e.m.f. Va – Ra.Iao V Eb Back e.m.f. Va – Ra.Ia V N Speed = Eb.(No/Ebo) r/min T Torque = Pout/(2πN/60) N.m * At no-load, IL = Iao + If * 0.25 0.5 0.75 1 1.25 82 ELE1911 Electrical and electronic practice A D.C. shunt motor performance characteristics SAMPLE CALCULATIONS (At load factor x = 1): Ra = Ω Ia = A W PF = W = W PL = W Pout = W η = % Eb = V N = r/min T = N.m Vt = V x = IL = A If = I2aRa = Pin A Discussion 1. Efficiency vs Power Output _________________________________________________ _______________________________________________________________________ _______________________________________________________________________ 2. Speed vs Power Output ____________________________________________________ _______________________________________________________________________ _______________________________________________________________________ 3. Torque vs Power Output and Torque vs Speed __________________________________ _______________________________________________________________________ _______________________________________________________________________ 4. Line Current vs Power Output _______________________________________________ _______________________________________________________________________ _______________________________________________________________________ 5. Power Flow Diagram (Scale: 10 mm ≡ 2 kW) (See page 118) 83 ELE1911 Electrical and electronic practice A D.C. shunt motor performance characteristics 84 ELE1911 Electrical and electronic practice A Conclusions 1. Full-load performance _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ 2. What would happen to a d.c. shunt motor if the d.c. supply is switched on: (a) with no series resistance in the armature circuit? (b) with a high resistance in series with the shunt field? _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ 3. Limitations of the test method — Assumptions (a) _____________________________________________________________________ (b) _____________________________________________________________________ (c) _____________________________________________________________________ (d) _____________________________________________________________________ 4. Advantages of the test and predetermination (a) _____________________________________________________________________ (b) _____________________________________________________________________ (c) _____________________________________________________________________ (d) _____________________________________________________________________ References (Harvard format) 1. _______________________________________________________________________ _______________________________________________________________________ 2. _______________________________________________________________________ _______________________________________________________________________ 85 ELE1911 Electrical and electronic practice A Practice example: D.C. shunt motor performance A d.c. shunt motor is rated at 5 kW, 1 500 r/min, and line current of 24 A at 200 V. The armature circuit resistance is 0.8 W. It is run from a 200-V supply at 1 500 r/min. There is no load on the shaft. The armature current is 1.5 A. The shunt field current is 1.0 A. 1. Assuming fixed supply and field settings, determine: (a) No-load armature power loss: Ra.Iao2 = 0.8 × (1.5)2 = 1.8 W (b) No-load armature power input: Vt.Iao = 200 × 1.5 = 300.0 W (c) Rotational power losses: Pr = 300 – 1.8 = 298.2 W (d) Shunt field circuit power loss: Vt.If = 200 × 1.0 = 200 W (e) Fixed losses: PF = Pr + VtIf = 298.2 + 200 = 498.2 W (f) No-load line current: ILo = Iao + If = 1.5 + 1.0 = 2.5 A (g) Full-load armature current: Ia = ILr – If = 24 – 1 = 23 A 2. Predetermine the following items at half-load (i.e. load factor x = 0.5): (a) Line current: IL = x.ILr = 0.5 × 24 = 12 A (b) Armature current: Ia = IL – If = 12 – 1 = 11 A (c) Armature power loss: Pa = Ra.Ia2 = 0.8 × 112 = 96.8 W (d) Total power losses: PL = PF+ Pa = 498.2 + 96.8 = 595.0 W (e) Electrical power input: Pin = Vt.IL = 200 × 12 = 2 400 W (f) Mechanical power output Pout : = Pin – PL = 2 400 – 595 = 1 805 W (g) Efficiency: (h) η = Pout / Pin = 1 805 / 2 400 = 0.752 No-load back e.m.f Ebo . = Vt – Ra.Iao = 200 – 0.8 × 1.5 = 198.8 V (i) Back e.m.f.: Eb = Vt – Ra.Ia = 200 – 0.8 × 11 = 191.2 V (j) Speed: N = (No/Ebo).Eb = (1 500/198.8) × 191.2 = 1 443 r/min (k) Angular velocity: ω = (2π/60).N = (2π/60) × 1 443 = 151.07 rad/s (l) Torque output: = Pout/ω = 1 805 / 151.07 = 11.95 N.m T 86 ELE1911 Electrical and electronic practice A Power flow diagram for a D.C. shunt motor 87 ELE1911 Electrical and electronic practice A 88 ELE1911 Electrical and electronic practice A Activity A3: D.C. shunt motor performance pre-determination Table 3: No-Load light running test: data and calculations Table 4: D.C. shunt motor: efficiency calculation by summation of losses 89 ELE1911 Electrical and electronic practice A Experiment A3: D.C. shunt motor performance pre-determination 90 ELE1911 Electrical and electronic practice A ELE1801 Electrical Technology appendix parts of a D.C. machine Carefully examine the d.c. machine provided. Identify the parts listed and study the following table: Note: The d.c. machine can be either a MOTOR (converts electrical energy into mechanical energy) or a GENERATOR (converts mechanical energy into electrical energy). Part Constructional details Function Remarks 1. stator frame Cast iron, hollow, square/ cylindrical. Stationary. Supports pole pieces, end shields, and terminal box. Provides part of the path for the working magnetic field. Size varies according to machine rating. Often finned to assist machine cooling. 2. pole piece Laminated steel bolted or dove-tailed to stator core. Supports the field coils. Provides part of the path for the working magnetic field. Air-gap between pole piece and armature core kept to a minimum. 3. field coil Insulated copper wire. Carries field current that provides the working magnetic field for the d.c. machine. Can be connected in series of parallel. 4. armature core < 1 mm thin laminations containing slots, keyway. Supports armature coils: slots accommodate the Air-gap between armature teeth and pole piece windings. kept to a minimum. Central keyed hole Provides part of the path for the working accommodates shaft. magnetic field. 5. armature wind An assembly of coils made Carries armature current which provides a field Coil active parts reside in slots: non-active ing of insulated copper wire. that interacts with the working magnetic field to parts form end windings. Skewed slots give torque. minimize cogging. 6. commutator Copper segments insulated Provides electrical connection between by mica strips: form band. stationary and moving conductors. Fastened to but insulated from shaft. Allows current direction in armature conductors to change as coils pass from N to S poles and v.v. 7. brushes Carbon: a good conductor; soft to prevent scoring. Low brush pressure causes arcing. Carbon particles attack insulation, causing shorting of comm. segments. 8. brush yoke Steel assembly that holds Fixed to stator core. the brushes under pressure. Contains the spring that is used to adjust brush pressure. Motor: adjusting brush angle adjusts speed. Generator: adjusting brush angle adjusts voltage. 9. shaft Made of strong, relatively low-permeability steel. Supports the armature and the bearings. Provides a means of connection to mechanical load. Provides a means of mechanical coupling. Not part of the path for the working magnetic field. 10. bearings Ball-type (roller/taper depending on application). Reduces mechanical friction between stationary Replaced as part of routine maintenance, or as and moving parts. required (approximately every three years). 11. end shields Made of cast iron. Support the bearings. Supports bearings and shaft. Houses the bearings. Gives protection for windings against mechanical damage. Electrical connection between stationary and moving conductors. Excessive pressure adds friction and causes commutator scoring. In totally-enclosed machines, given protection for windings against the environment. 91 ELE1911 Electrical and electronic practice A Activity B1: Transformer tests B.1.1 Preliminary tests Aims 1. To be familiar with the constructional features of shell-type and core-type small power transformers. 2. To test the continuity of windings. 3. To test the insulation resistance of windings. Instructions 1. Inspection Draw neat sketches to illustrate the constructional features of core-type and shell-type transformers. Refer to ELE1801 study book, section 10.1. Note how leakage inductive reactance of windings can be minimised by sandwich windings. 2. Continuity test Using an ohmmeter, identify the terminals belonging to the same winding. If the winding is open-circuited or not connected, the resistance between two terminals would be very high (infinity). If a winding has a short-circuit, the resistance between its terminals would be very low (close to zero). Record the results in table 1. 3. Insulation resistance test Learn to use the Megger insulation tester. Refer to ELE1801 study book, chapter 9, section 2, for Megger details. Connect the two primary terminals together to one test lead and the other test lead to the core (or shield) terminal of the transformer. Rotate the handle and record the readings in table 2 as values >2 MΩ or <2 MΩ. Repeat the test on each of the windings and the core, and between the windings as well. Record the results in table 2. If any value is greater than 2 MW, then the insulation is ‘safe’. If any value is less than 2 MW, then the insulation is ‘not safe’. (Note in table 2.) Analysis 1. State the purposes of the transformer preliminary test. 2. Briefly comment on the results with respect to the minimum ‘safe’ level of insulation. 3. Neatly sketch constructional features of shell-type and core-type small power transformers on the graph paper provided. 92 ELE1911 Electrical and electronic practice A Table 1: Continuity test Winding Resistance (Ω) Ω ≡ Ohmmeter Secondary-1 Secondary-2 Primary Figure 1 Table 2: Insultation resistance test (Megger test) Tested between Value (MΩ) Note M ≡ Megger G and A1 & A2 together G and 21 & 22 together G and 22 & 23 together A1 & A2 and 21 & 22 A1 & A2 and 22 & 23 A1 and G Figure 2 22 and G Discussion of results/conclusions 1. State the purposes of the transformer preliminary tests: to test: (a) ____________________________________________________________________ (b) ____________________________________________________________________ 2. Briefly explain the term ‘minimum SAFE level of insulation’; comment on the results obtained: _______________________________________________________________________ _______________________________________________________________________ 3. Indicate how leakage inductive reactance of windings can be minimised: _______________________________________________________________________ _______________________________________________________________________ 93 ELE1911 Electrical and electronic practice A Reference (Harvard format) 1. _______________________________________________________________________ _______________________________________________________________________ 94 ELE1911 Electrical and electronic practice A 95 ELE1911 Electrical and electronic practice A B.1.2 No-load test Aims 1. To conduct a no-load test on a single-phase transformer. 2. To determine: the iron-loss and magnetising components of no-load current; the voltage transformation ratio; and the no-load equivalent circuit parameters. 3. To measure the e.m.f. per turn, and hence estimate the number of turns in the primary and the secondary windings. Instructions 1. Record the rating-plate details of the test transformer in table 1. Note: the low voltage (L.V) winding is used as the primary. Connect the test set-up as in figure 1. Check instrument ranges and scale factors. Close S1. Open the wattmeter current-coil shorting switch (if not already open). Adjust VAT to apply the rated supply voltage to the low-voltage (240-V) winding. Record all the readings in table 2. 2. The tertiary test winding (search coil) has Nt =10 turns. See figure 3. Connect a voltmeter across the test winding terminals. Record the voltage (Vt) induced across the test winding in table 3. 3. Reduce the voltage to zero. Switch off S1. Analysis 1. Calculate the transformation ratio, the components of no-load current and the no-load equivalent circuit parameters (table 2). Refer to study book. 2. Calculate the voltage per turn, and the number of turns in the primary and the secondary windings, using Voltage per turn Et = (Vt / Nt); N1 (V1 / Et); and N2 = (V2 / Et). 3. Draw below the transformer no-load phasor diagram showing voltages V1 and V2 and currents Io, Ic and Im using the flux Φ as the reference. Indicate the no-load power-factor angle ɸo. Use the scales: 10 mm ≡ 150 V; 10 mm ≡ 25 mA. Transformer no-load phasor diagram 96 ELE1911 Electrical and electronic practice A Table 1: List of apparatus T kVA Test Transformer S= VA; L.V. primary V1 A.C. Voltmeter 0–300 V f = 50 Hz V2 A.C. Voltmeter 0–600 V H.V. secondary Ao A.C. Ammeter 0–1–3 A Wo Wattmeter 0.5 A, 250 V, 0.2 p.f. Nt Test winding of 10 turns VAT Variable auto-transformer Voltage V1 = V V2 = V Current I1 = A I2 = A Table 2: No-load test data Figure 1: No-load test circuit Table 3: E.M.F. per turn test Figure 2: E.M.F. per turn test Figure 3: Simple equivalent circuit diagram for transformer on no load 97 ELE1911 Electrical and electronic practice A Discussion 1. State the purposes of the transformer no-load test: (a) ____________________________________________________________________ (b) ____________________________________________________________________ (c) ____________________________________________________________________ (d) ____________________________________________________________________ 2. Indicate the following key equations: The apparent power balance: ________________________________________________ The m.m.f. balance: _______________________________________________________ The voltage, current and turns ratios: _________________________________________ 3. Draw the no-load equivalent circuit diagram showing measured and calculated values. Transformer no-load equivalent circuit diagram 4. Briefly explain what Ro and Xo represent. _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ Conclusions _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ Reference (Harvard format) 1. _______________________________________________________________________ _______________________________________________________________________ 98 ELE1911 Electrical and electronic practice A B.1.3 Short-circuit test Aims 1. To conduct a short-circuit test on a single-phase transformer and determine the rated-load copper loss. 2. To determine the equivalent circuit parameters. 3. To pre-determine the efficiency. Instructions 1. Study the circuit shown in figure 1. Check the connections. Set the auto-transformer for minimum output voltage. Close switch S1. Very carefully adjust the auto-transformer output (about 8–10 V only) to circulate the rated current in the short-circuited high voltage (H.V) secondary winding. Record the readings (table 1). 2. Reduce the voltage to zero. Switch off S1. Analysis 1. Calculate the short-circuit power factor; the equivalent impedance, resistance and reactance of the transformer (table 1). All values are referred to the low-voltage side, in the equivalent circuit (figure 2 in table 2). 2. From both the NO-LOAD and SHORT-CIRCUIT TESTS, complete table 2 and 3 to predetermine the transformer efficiency for load factors between 0.25 and 1.25. 3. Plot graphs of efficiency versus output power, for power factors of unity and 0.8 lagging. 4. Draw the transformer equivalent circuit below, showing all symbols and all measured and calculated values at rated voltage and current, i.e. at rated load. 5. Draw the rated-load phasor diagram to scale (10 mm ≡ 500 mA) on the graph paper supplied. Transformer equivalent circuit diagram (show test data at rated load) 99 ELE1911 Electrical and electronic practice A Determination of transformer equivalent circuit Figure 1: Short-circuit test circuit diagram Table 1: Short-circuit test data Vs I1 (Pc) VAT Variable auto transformer 240 V/0–260 V, 5 A 12 s cos s Ws (V) (A) (W) Ze Ws Vs I1 Vs I1 (Ω) Ws Wattmeter 0– 25 V, 5 A, UPF (A) Vs A.C. voltmeter; 0–30 V As A.C. ammeter, 0–5 A ɸs = cos–1(λs) = cos–1( A2 A.C. ammeter, 0–5 A Re = Ze . cos ɸs = × = Ω T Test transformer Xe = Ze . sin ɸs = × = Ω lagging = ° ) Table 2: Transformer equivalent circuit (transfer data from the no-load test) Refer all values to the 240-volt side I '2 = I2(N2/N1) : V '2 = V2(N1/N2) V1 = V N1/N2 = V2 = V = n R0 = kΩ P0 = W X0 = kΩ cos ɸs = lagging Re = Ω Pc = W Xe = Ω cos ɸs = lagging Ze = Ω Xe/Re = Figure 2: Transformer equivalent circuit xm = P0 / Pc = 100 ELE1911 Electrical and electronic practice A Sample calculations (show working) (a) Load factor x = ..... Power factor λ = 0.8 lagging S = Rated VA (from No-load test) = VA Pc = Rated-load copper loss = W Iron loss Po = W Copper loss at load factor x x2.Pc = = W Total loss PL = P + x2.P o c = = W Output power Pout = x.S.λ = = W Input power Pin = Pout + PL = = W Efficiency (%) η = Pout / Pin = = % (b) Maximum efficiency condition xm2.Pc = Po λ = 1: = xm Po / Pc ∴ Pout = xm.S.λ = = W PL = 2Po = = W Pin = Pout + PL = = W ∴ ηmax = Pout / Pin = = or % Table 3: Predetermination of efficiency λ = cos ɸ = 1 Po x (W) 0.25 0.5 0.75 1.0 1.25 2 x Pc xS (W) (VA) λ = cos ɸ = 0.8 lagging Pout Pin η Pout Pin η (W) (W) (%) (W) (W) (%) 101 ELE1911 Electrical and electronic practice A Discussion 1. State the purposes of the transformer short-circuit test: to determine: (a) ____________________________________________________________________ (b) ____________________________________________________________________ (c) ____________________________________________________________________ (d) ____________________________________________________________________ Primary Secondary Load _______________________________________________________________________ 2. Briefly explain what Re and Xe represent. _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ 3. Briefly indicate any precautions and safety measures taken. _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ 4. Briefly explain the condition for maximum efficiency. _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ Conclusions _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ Reference (Harvard format) 1. _______________________________________________________________________ _______________________________________________________________________ 102 ELE1911 Electrical and electronic practice A 103 ELE1911 Electrical and electronic practice A Activity B2: Three-phase transformer connections Aims 1. To check the correct and the incorrect star and delta connections of windings; and 2. To verify the relationships between line/phase voltages and line/phase currents for deltawye connection. Instructions 1. For each of the three identical single-phase transformers, ensure that terminals are marked with correct polarities. 2. The transformers are connected as in figure 3. Check that the connections and the voltage ratings are correct. Open the load switch S2. Close the supply switch S1. Ensure the voltmeter range setting is 600 V. Record the phase and the line voltages (table 2). Close S2. Record the line and the phase currents (table 2). Analysis 1. For each three-phase connection, verify the relationships: (a) VL Vp , and IL 3.I p for -connection (b) VL 3.Vp , and I L I p for Y -connection 2. Draw the phasor diagram to scale showing all the phasors (optional). 3. Complete the three-phase transformer exercise. Discussion __________________________________________________________________________ __________________________________________________________________________ __________________________________________________________________________ __________________________________________________________________________ __________________________________________________________________________ __________________________________________________________________________ 104 ELE1911 Electrical and electronic practice A Exercise: Three-phase transformers Three identical single-phase transformers, arranged in a Δ–Y configuration, take power from a three-phase supply at a line voltage of 415 V and deliver it to a three-phase load at a line voltage of 120 V. The total load draws 15 kVA. Sketch a circuit diagram of the transformer and load and determine the following values (show working): Circuit diagram 1. The primary phase voltage. 2. The primary line current. 3. The primary phase current. 4. The secondary line voltage. 5. The secondary phase voltage. 6. The secondary line current. 7. The secondary phase current. 8. The transformation ratio of each transformer. 9. The kVA supplied by each transformer. 105 ELE1911 Electrical and electronic practice A Table 1: Lists of apparatus T Single-phase power transformer A Digital ammeter or clip-on ammeter V Multi-range voltmeter R Loading resistor bank, 3-phase, ______ A S1 Three-phase, V, / V, _______/______ A 50 Hz, _______ A supply Voltmeter reads twice the phase voltage. Figure 1: Wrong delta connection Figure 3: Three-phase transformer ΔY connection Voltmeter reads low (≈ 0 V) Figure 2: Correct delta connection 106 ELE1911 Electrical and electronic practice A Table 2: Delta-wye connected transformer Primary Δ Y Secondary Verification Voltages VL1 VL2 VL2 = ____ VP2 VP1 VP2 VP1 n VP 2 IL1 IL2 I L1 3.I P1 IP1 IP2 Line Phase Currents Line Phase 107 ELE1911 Electrical and electronic practice A Activity C1: Power factor improvement Aim To calculate the power factor for the mercury vapour lamp circuit, and draw the phasor and power diagrams. Figure 1: Mercury vapour lamp circuit: power factor improvement Theory Refer to study book topic on power factor improvement. Precautions When the lamp is first switched on, its resistance is relatively low and a large current tends to flow in the circuit. Close S2 to switch in 25 μF in parallel with the lamp. This will limit the inrush current thereby avoiding any overload of the instrument current coils. After the lamp has reached its operating temperature, the current will stabilise at a lower value. Once the lamp attains its operating conditions, do not switch off the supply. Switching on the supply will not restart the lamp until the hot vapour has cooled to room temperature. Table 1: List of apparatus V A.C. voltmeter, _______V S2 Capacitor switch A1 A.C. ammeter, _______A C Capacitor box A2 A.C. ammeter, _______A W Wattmeter ______μF to _______μF, _______V R ______A,_____V____ S1 Supply _______V,_______A Mercury vapour lamp _______V,_______A,_______W Switch, L Ballast inductor 108 ELE1911 Electrical and electronic practice A Instructions 1. Check the circuit set up. Record details of apparatus used in table 1. 2. Switch in the capacitors as indicated in table 2 and record meter values. Note 1: When S2 is open, IL = I. Note 2: When operating conditions have stabilised, IL will remain constant since V, R, and XL are constant. Table 2: Power factor improvement Measured values C (μF) V (V) I (A) IC (A) IL (A) Calculated values P (W) Q (var) S (VA) cos P VI 0 ....... lagging ........... 20 ....... ............ _____ 55 ....... ............ _____ Note: Record measured and calculated values to three (3) significant figures. Analysis 1. Complete the calculations in table 2. 2. Draw to scale (20 V and 500 mA to 10 mm), on graph paper, a phasor diagram for V, I, IC and IL values in table 2, with V as reference, and showing I = IL + IC for each of the three capacitance values. (see page 113) 3. Draw to scale, (10 mm ≡ 100 W) on graph paper, power diagrams for P, Q and S values from table 2, at C = 20 μF and 55 μF. 4. Calculate the value of capacitance required for unity power factor in the circuit. State this value on the phasor diagram. 109 ELE1911 Electrical and electronic practice A Sample calculations For C = ....μF Apparent power S = V.I = × Power factor λ = cos ɸ = P / (V.I) = Reactive power Q = S. sin ɸ = × = S 2 P2 = VA /( × = var = ) Figure 1: Phasor diagram for power factor improvement applied to an inductive-resistive load (a mercury-vapour lamp and its associated iron-cored ballast) = = var 110 ELE1911 Electrical and electronic practice A Steps 1. Using a protractor, draw Io = IL to scale, lagging V by angle ɸo (calculate from p.f.). 2. Draw IC20, ...IC55 to scale, leading reference V by 90°, from the origin 0. 3. Complete the parallelograms on 0A ... 0B. 4. By phasor addition, IL + Icn = In: draw in phasors I20 ... I55 and estimate the value of C needed for operation at unity p.f. Discussion (itemise) _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ Conclusions _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ Reference (Harvard format) 1. _______________________________________________________________________ _______________________________________________________________________ 2. _______________________________________________________________________ _______________________________________________________________________ 111 ELE1911 Electrical and electronic practice A 112 ELE1911 Electrical and electronic practice A Activity C2: Series resonance Aim To determine the current-frequency curve of a series R-L-C circuit theoretically and experimentally. Preparation 1. Study the theory and examples in the relevant study paper. Use the nominal values given in figure 1 to complete the exercise in table 1 on the following page. 2. Calculate the resonance frequency (fr), using the values of R, L and C in figure 1. 3. For the seven (7) values of frequency f in table 1 calculate and plot the values of I versus f in graph 1. Label this response ‘Theoretical’. Instructions 1. Using the digital L-C-R meter provided, measure the values of required inductance, capacitance and resistance. Measure the d.c. resistance Rdc of the inductor. R= Ω L= mH C= nF Rdc = Ω Figure 1: Series resonance circuit 2. Connect the circuit as shown in figure 1. Short leads are essential. 3. Adjust the sine wave output of the signal generator to exactly 16 volt peak-to-peak as measured on Channel 1 of the CRO. Vary the signal generator frequency in 5-kHz steps from 40 kHz to 15 kHz. Set the frequency accurately using the CRO timebase. At each frequency, measure the peak-to-peak amplitudes of V1 and V0 on the CRO. V1 may change, so adjust the amplitude to ensure that it remains constant. Record f, V1 and V0 in the table. Calculate I0 = V0 / ( 2 2.R ). Plot I versus f, as you take readings, superimposing on the theoretical graph. Label this response ‘Measured’. 113 ELE1911 Electrical and electronic practice A Resonance curves: preparatory work Date: Given: R = 600 Ω L = 10 mH; C = 4.7 nF; V1 = 16.0 Vpp (a) For the R-L-C series circuit, complete the table below. Note: ω = 2πf (b) Plot R, |XC|, XL, X, Z and I versus f, on the graph paper supplied, in graphs 1 and 2. (c) Verify: I V / R ; r 0 I1 X Lr X Cr L / C V1 2 2.Z I0 V0 2 2.R Table 1: Series resonance: calculation of current from theoretical values and measured values 114 ELE1911 Electrical and electronic practice A 115 ELE1911 Electrical and electronic practice A 116 ELE1911 Electrical and electronic practice A Activity C3: Capacitor-start single phase induction motor: load test Aims 1. To conduct a load test on a capacitor-start single-phase induction motor. 2. To determine its performance characteristics: Current I, Input Power Pi, Power factor p.f, Speed N, Slip S, Torque T and Efficiency η versus Power Output Po. Circuit diagram Figure 1: Circuit diagram for the capacitor-start single-phase induction motor load test Table 1: List of apparatus F.H.P. Brake Motor Test Set – (Jay Jay Instruments type FH1/4) consisting of – V A.C. voltmeter 0–250 V, AVO 8 A A.C. ammeter 0–2.5–10 A, AVO 8 M Induction motor, single-phase, capacitor-start, 240-V, 50-Hz, 1/8-h.p., 1 425-r/min, 1.4-A coupled to – W Wattmeter, 250 V, 2.5 A, u.p.f., 0–625 W, overcurrent protection, 50 Hz, class 1.0, A.J. William B Eddy-current brake with variable torque and dynamometer calibrated 0–2 N.m PT Photo-tachometer, 0–2 000 r/min digital type C Capacitor, 16μF, 350 V a.c. 117 ELE1911 Electrical and electronic practice A Procedure 1. Inspect the circuit: check the wiring using the diagram provided. Check the motor rating-plate details. Check the list of apparatus used (table 1). 2. Precautions to be observed before starting the motor: Set the dynamometer scale to zero using the knurled thumb screw behind the scale. Protect the meters from overcurrent on start. Use 16-μF capacitor only. Set the torque control rheostat to OFF for the ‘no-load’ condition. 3. Switch on the a.c. supply at the main switch S1. Set the motor spring-loaded start/off/mn switch S2 to the START position then, once the motor is running, smartly set switch S2 to the RUN position. 4. Reset meter scales. Release overcurrent protection on the current coils. 5. Record the voltage V, current I, input power Pi, speed N and torque T at ‘no load’ (table 2). 6. Increase the load on the motor by adjusting the torque control so that the dynamometer indicates 0.2 N.m. Record the readings in table 2. 7. Repeat for torques of 0.4, 0.6, 0.8 and 1.0 N.m. Record the readings. Do not operate the motor for load torques above 1.1 N.m. Release the load. 8. Switch off the motor run/off/start switch and the a.c. supply. Calculations Determine the power output Po, efficiency η, power factor p.f and slip S, for each load torque T and neatly record in table 2. Full-load output power Po = Rated brake horse power (B.H.P.) × 746 Rotational velocity ω = 2π.N/60 Full-load torque T = Po / (2π.N/60) Graph On the same graph, plot current I, power factor p.f., torque T, speed N, percent slip S(%) and percent efficiency η(%) versus power output Po. 118 ELE1911 Electrical and electronic practice A Capacitor-start single-phase induction motor performance characteristics Sample calculations V = _____ V; I = _____ A; Pi = _____ W; f = _____ Hz; p = _____ poles T = _____ N.m; N = _____ r/min Power factor p.f. = Pi / (V.I) = ___________ = _________ lagging Rotational velocity ω = 2π.N / 60 = ___________ = _________ rad/s Output power Po = T.ω = ___________ = _________ W Efficiency η (%) = 100.(Po /Pi ) = ___________ = _________ % Synchronous speed Ns = 120.f / p = ___________ = _________ r/min Slip S (%) = 100.(Ns – N) / Ns = ___________ = _________ % Table 2: Load test data and calculations Test observations T V I Pi (N.m) (V) (A) (W) Calculations N ω Po η p.f. S (W) (%) (p.u.) (%) No. 1 2 3 4 5 6 Note: ‘p.u.’ stands for ‘per unit’. (r/min) (rad/s) 119 ELE1911 Electrical and electronic practice A 120 ELE1911 Electrical and electronic practice A Graph 1 – Capacitor-start single-phase induction motor: performance characteristics 121 ELE1911 Electrical and electronic practice A Activity D1: Three-phase circuits: star and delta connected loads Aims ● ● To connect a balanced, 3-phase load consisting of three resistors in (a) star, and (b) delta To measure line and phase values of current and voltage, and verify that: I L 3.I p for delta: ● and VL 3.Vp for star and To measure the total power in each case, using a three-phase wattmeter and to compare these values: PC 3.I pVp ; and PC 3.I LVL Instructions 1. Connect the three resistors in star. Measure and record ‘IL’ VL and Vp and PM. IL,IP VL Vp PM PC (A) (V) (V) (W) (W) Does VL = 3.Vp ? _________________ Calculate PC and compare with PM. _________________________________ 2. Connect the three resistors in delta including an ammeter to measure IP. Measure and record IL, PM and VL. IL IP VL, Vp PM PC (A) (A) (V) (W) (W) Does IL = 3.I p ? _________________ Calculate PC and compare with PM. _________________________________ 122 ELE1911 Electrical and electronic practice A 3. Compare the power used in star and delta. ______________________________________________________________________ ______________________________________________________________________ 123 ELE1911 Electrical and electronic practice A Activity D2: Three-phase induction motor – DC generator tests Aims ● To inspect the constructional features of an induction motor, a d.c. shunt generator and an auto-transformer ● To conduct a load test on a three-phase induction motor-generator set ● To determine the induction motor performance characteristics and ● To verify three-phase voltage, current and power relationships. Apparatus Figure 1: Three-phase induction motor – D.C. generator load test circuit Table 1: Apparatus: Three-phase induction motor – D.C. generator tests Detail M Detail Induction motor, three phase, Δ, 4.0 kW, G 415 V, 8.1 A, 1 420 r/min, 50 Hz W1 Wattmeters, single-phase, 600 V, 10 A, RL W2 0–1.5 kW, scale × 4, 50 Hz, Type P.W.6, A.J. William Elec. Variable resistance load, 3-f, 230 V, 5 kW in 0.5 kW switched increments, Creswell England. Vg Voltmeter, D.C. AVO 8, Mk V, 0–300 V VP Voltmeter A Ammeter, D.C., 30–0–30 A, class 1.0, Type P.C.6, A.J. William Elec. A1 Ammeter, A.C., AVO 8, Mk V, 0–10 A N Tachometer, 0–2 000 r/min, digital EMTEK, auto-range A2 Ammeter AT Auto-transformer (Variac), 50 Hz, 240 V, 8 A, model type W20H Warburton Franki VL Voltmeter, A.C., AVO 8, Mk III, 0–1 000 V D.C. shunt generator, 5.0 kW, 230 V, 21.8 A, 1 500 r/min 124 ELE1911 Electrical and electronic practice A Instructions 1. Check the circuit connections. Check the meter ranges and scale factors. Prepare a list of apparatus used (table 1). Record the rating plate details. Adjust the two spring balances so that the machine frame has even clearance from its bed. 2. Couple the motor with the d.c. shunt generator. Note the marked direction of rotation on the machine frame. Set the auto-transformer for minimum voltage. Set field regulator RF at maximum resistance (i.e. for minimum current). Switch off load resistor RL. Ensure that the ammeters and wattmeters are set correctly. Confirm what to do to reverse the direction of rotation. 3. Close switches S1 and S. Carefully adjust the auto-transformer to start the motor. Check the phase sequence and direction of rotation. If the direction is wrong, switch off S1 and S. Interchange any two of the supply connections at the auto-transformer. Close switches S1 and S. Restart. Do not exceed 10 A line current on starting. Check that the direction of rotation is now correct. Check the d.c. meters for correct polarity. Gradually adjust the auto-transformer output to the rated voltage of the motor. 4. Using RF, adjust the d.c. generator output voltage Vg to 230 V. Switch in RL in steps, adjusting RF to maintain Vg at about 230 V so that the motor draws the rated line current. Adjust the spring balances so that the machine frame does not touch the bed. Take the readings (line voltage, line current, power input, speed and spring balances) at full-load and record them in table 2. Measure the motor line current and the phase current and record them in table 3. Measure the line and the phase voltages at the auto-transformer and record them in table 3. 5. Reduce the load in steps and take four evenly-spaced sets of readings between full-load and no-load (as indicated in table 2) resetting RF as necessary to keep Vg at 230 V. 6. Finally, switch out RL, adjusting RF to reduce Vg to a minimum. Reduce the a.c. voltage to a minimum. Switch off and stop the motor. Decouple the motor from the generator using the wingnuts on the bed. Restart the motor and run it at the rated voltage on no-load. Record the no-load readings (line voltage, line current, power input and speed) in table 2. Three-phase induction motor performance characteristics Sample calculations (at line current setting ≈ 3.8A) 125 ELE1911 Electrical and electronic practice A 1. Calculate the power input, power factor, torque, power output, efficiency and slip for the motor for each load setting and tabulate the values (table 2). Power input: Pi = (W1 + W2) Power factor: λ = Pi / ( 3 VL .I L ) = cos ɸ = W = lagging Synchronous speed N s : = 120 f / p = r/min Slip: S = 100 × (Ns – N) / Ns = % Torque: T = (F1 – F2) × 0.305 = N.m Power output: Po = 2πNT / 60 = W Efficiency: η = (Po / Pi) × 100 = % 2. Calculate the capacitance rating (μF, VA and V) of the capacitor bank required to improve the no-load motor supply power factor to a value of unity. 3. Verify that in star connection: line voltage = 3 × phase voltage. 4. Verify that the two wattmeter readings are given by: W = VLIL cos (30° ± ɸ) Graphs 1. Plot the induction motor characteristics: efficiency (η), speed (N), slip (S), line current (IL), power factor (λ), and torque (T) versus output power (Po), on the same graph. 2. Plot torque against slip on a separate graph sheet (see page 134). 3. Draw a phasor diagram to scale, headed as shown, for the induction motor at no load. (see study book 2, p. 11.25, Summary: Three-phase A.C. system, delta connection) Title: Phasor diagram for a delta-connected induction motor at no load Scale Voltage – 10 mm s: ≡ 75 V Sequence: a-b-c Current – 10 mm ≡ 2.0 A p.f. = cos ɸ0 = ............ lagging 126 ELE1911 Electrical and electronic practice A Table 2: Three-phase induction motor load test data Observations and results Test readings IL Approx. line current setting (A) Unit Line current A VL Line voltage V W1 Wattmeter-1 W W2 Wattmeter-2 W F1 Spring balance-1 N F2 Spring balance-2 N N Speed ≈ 8.3 ≈ 7.4 ≈ 6.5 ≈ 5.6 ≈ 4.7 ≈ 3.8 r/min Observations and results Approx. line current setting (A) Pi Power input W λ Power factor (p.f.) s Slip T Torque N.m 0 Po Power output W 0 η % 0 lagging % Efficiency Table 3: Star and delta circuits verification (use rated-load values) Circuit Star Auto-transformer Delta Induction motor Line value Phase value Vab = VL = Vas = VP = Vbc = VL = Vbs = VP = Vca = VL = Vcs = VP = Ia = IL = Iab = IP = Ib = IL = Ibc = IP = Ic = IL = Ica = IP = Verification VL 3. Vp VL/VP = ........... I L 3. I p IL/IP = ........... 127 ELE1911 Electrical and electronic practice A Three-phase induction motor performance characteristics Three-phase, ..... V, ..... kW, ..... r/min induction motor 128 ELE1911 Electrical and electronic practice A Discussion (itemise) _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ Conclusions _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ Reference (Harvard format) 1. _______________________________________________________________________ _______________________________________________________________________ continued 129 ELE1911 Electrical and electronic practice A Appendix A: Example investigation: three-phase induction motor 1. A 5-kW, 415-V, 50-Hz, Calculate 1 440-r/min, delta-connected, cage-rotor motor has a full-load (a) Power input current of 8.75 A at 0.866 (b) Power output lagging p.f. 2. Determine the full-load polar expressions of all the phase and the line voltages and currents. Write them in matrix form. = = = = (c) Efficiency = = (d) Torque = = (e) Synchronous speed = = (f) Slip = = Line voltages = Phase voltages V ab V bc V ca V Reference: Vab Sequence: a-b-c Line currents I a Ib I c Phase currents I ab I bc I ca A 3. The no-load test-data for the motor are given: VL = 4.15 V; ILo = 1.72 A Pio = 340 W (a) cos o Pin / ( 3.VL .I L ) (b) I o I Lo / 3 Determine and indicate the equivalent circuit paramters for the no-load condition. (c) Ro VL / ( I o .cos o ) (Note: The induction motor equivalent circuit per phase at no-load is similar to the (d) single-phase transformer equivalent circuit at no-load.) Xo VL / ( I o .sin o ) A 130 ELE1911 Electrical and electronic practice A 4. Draw all the phasors in (2) in a neat diagram and identify them with correct letter symbols. Title: Phasor diagram for a delta-connected induction motor at full load Scales: Voltage – 10 mm ≡ V Sequence: Current – 10 mm ≡ A p.f. = cos ɸ = 5. The power supplied to the 5-kW deltaconnected induction motor is measured using two wattmeters. Determine the indications of the two wattmeters, at full-load. |Vab | = |Vcb | = VL = |Ia | = |Ic| = IL = cos ɸ = ɸ= Two-wattmeter method: circuit Wattmeter indications W1 Vab .1a.cos Vab Ia VL .I L cos (_ _ _ _) W2 Vcb .1c.cos Vcb Ic VL .I L cos (_ _ _ _) Total active power: P = W1 + W2 P 3(VL .I L cos ) P W1 W 2 3(VL .I L cos (_ _ _ _)) 131 ELE1911 Electrical and electronic practice A Appendix B: Parts of an induction machine Carefully inspect the induction motor provided. Identify the parts listed and complete the following table. Part Constructional details Function 1. stator frame Cast iron, hollow, square/cylindrical. Stationary. Supports motor parts. 2. stator core Laminated sheet set. Holds stator winding in position. Remarks Plays an important role with the cooling/ventilation. 3. stator windings Three identical, insulated copper coils, mounted on the stator pole pieces. Windings terminated in Y or Δ in terminal box. 4. rotor core Laminated sheet steel circular Holds rotor windings in disks, each insulated and pinned position. into a cylinder. Must be well insulated to prevent short circuit and leakage currents. 5. rotor windings Wound rotor has an assembly of Carries the current that creates coils made of insulated copper the torque which causes rotation. wire. 6. slip-rings (if any) Wound rotor has phosphor bronze copper alloy rings, concentric with the shaft, and terminating rotor windings. To enable current to be correctly distributed. 7. cooling system Fan mounted on shaft inside housing. Fins on outside of motor casing. Blows air past windings and over case fins. Fins of impeller fan are easily broken if malfunction or roughly handled. 8. terminal box Insulated (plastic or other material) to house connections securely. Provides connection to stator windings and, as applicable, wound rotor brushgear. Important to keep well insulated. 9. shaft Made of strong, relatively lowpermeability solid steel. Supports rotor. Enables drive rotation. Shaft to bearing fit to be at close tolerance. 10. bearings Ball-type (roller/taper depending To enable easy shaft and rotor on application) white metal. rotation. 11. end-shields Made of cast iron. Support the bearings. Must be kept in good condition; lubricated; no wear; correct use of loads. Shaft bearings mounted in them. Bearing position concentric with shaft. 132 ELE1911 Electrical and electronic practice A 133 ELE1911 Electrical and electronic practice A Three-phase induction motor performance characteristics Three-phase, 415 V, 4 kW, 1500 r/min induction motor 134 ELE1911 Electrical and electronic practice A 135 ELE1911 Electrical and electronic practice A Appendix A: Reading analog multimeter scales Reading analog multimeter scales When DC voltage measurements are made on an analog multimeter, it is important to look at the correlation between the range selector switch position and meter scale indication. For example, when the range switch is in the 2.5-V position, the 0 to 250 scale is used, but the scale value must be divided by 100. For example, 1.75 volts DC would be indicated as shown in figure A.1. Figure A.1: Reading 1.75 volts DC on the multimeter scale When the range switch is in the AC 10-V position, the AC 0 to 10 scale is used. For example, 4.8 volts AC would be indicated as shown in figure A.2. Figure A.2: Reading 4.80 volts AC on the multimeter scale 136 ELE1911 Electrical and electronic practice A When the range switch is in the DC 250-V position, the 0 to 250 scale is used. For example, 160 volts DC would be indicated as shown in figure A.3. Figure A.3: Reading 160 volts DC on the multimeter scale When the range switch is in the DC 50-V position, the 0 to 50 scale is used. For example, 34.0 volts DC would be indicated as shown in figure A4. Figure A.4: Reading 34.0 volts DC on the multimeter scale 137 ELE1911 Electrical and electronic practice A When the range switch is in the DC 500-V position, the 0 to 50 scale is used, but the scale value must be multiplied by 10. For example, 350 volts DC would be indicated as shown in figure A.5. Figure A.5: Reading 350 volts DC on the multimeter scale In all of the examples given above, the pointer indicated exactly a particular scale division. When the pointer rests between two scale divisions, an estimate as close as possible to the true reading must be made. For example, a reading of 128 volts DC would be indicated as shown in figure A.6. Figure A.6: Reading 128 volts DC on the multimeter scale 138 ELE1911 Electrical and electronic practice A In the previous multimeter examples, the top scale indicates resistance readings. Note figure A.7. Figure A.7: Multimeter ohms (resistance) scale When the range switch is in the R × 1 position, the resistance reading is referenced to the scale numbers. When the range switch is in the R × 100 position, the scale numbers must be mentally multiplied by 100. When the range switch is in the R × 1 000 position, the scale numbers must be mentally multiplied by 1 000 etc. Before any resistance readings are taken, a calibration procedure must be followed. The ohmmeter section of the multimeter applies a test voltage (from 1.5 to 22 volts) across a component whose resistance is to be measured. The meter then indicates the test current that is drawn in terms of ohms units. Since the multimeter’s battery voltage decreases with use and time, the zero-adjust control must be adjusted to bring the needle to the zero point on the ohms scale when the test leads are shorted together. This calibration procedure must be done when first using the multimeter for resistance measurements and whenever the resistance range position is changed, i.e. R × 1 range would be calibrated separately from the R × 100 range etc. When the zero-adjust control is turned to its maximum position and the needle will not reach zero on the ohms scale, the internal battery should be replaced. Volume (decibel) level measurements are made from the bottom scale of the meter and readings are usually in dBm; i.e. dB reference is 1 mW into 600 ohm. The multimeter A.C. ranges are used in conjunction with a decibel conversion graph or table supplied by the manufacturer to enable its use over an extended range of impedances.