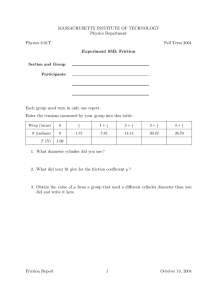

THERMAL PHYSICS LABORATORY Dr.Nourhan Kawni Dr.Salem Marhaba Student: Roua Etry ID: 202203078 Experiment4: Mechanical Equivalent of Heat Aim of the experiment: Determination of the mechanical equivalent of heat. Theory: Mechanical energy from friction is fully converted into thermal energy. As both forms of energy are given in the same unit of 1J=1 N.m, and as heat is a form of energy, the total amount of mechanical energy must be transformed into an equal amount of heat energy according to the law of conservation of energy. Thus, the mechanical equivalent of heat must amount to: ∆𝑊/∆𝑄 = 1 In this experiment, a metallic body is rotated and heated. As the cylinder turns, the friction between the cylinder and the rope converts the work into thermal energy, which raises the temperature of the cylinder. The work due to friction on the cylinder: W = 2πn(F2 − F1 ) The work is converted into thermal energy: Q = crm(T2 − T1 ) Where: Q: heat W: work done due to friction n: number of rotations C: specific thermal capacity of the cylinder r: radius of cylinder m: mass of the cylinder F1: weight of the object = 10 N T2: final temperature F2: force on the spring T1: initial temperature of the cylinder Apparatus: 1. Friction cylinder CuZn, m = 1.28 kg, m = 0.64 kg (C= 385 j/kg.C) 2. Friction cylinder Al, m = 0.39 kg (C= 900 J/Kg.C) 3. Plastic friction band 4. Crank handle 5. Thermometer 6. Thermally conducting paste 7. Screw clamps 8. Spring balance 10 N 9. Commercial weight 1kg Method: 1- Fix the friction cylinder and the crank handle to the journal bearing 2- Hang a spring balance from the holder. 3- Attach the friction band to the spring balance. 4-Wrap the band 2.5 times around the cylinder so that the load on the balance is relieved if the crank handle is turned to the right. 5-Attach a weight to the lower end of the friction band. 6-To measure temperature, the thermometer is held with a universal clamp and carefully introduced into the bore hole of the friction cylinder. The thermometer and the bore hole of the cylinder must be carefully aligned, so the thermometer will not break while the cylinder is rotating. To improve thermal contact, the bore hole is filled with heat conducting paste. 7-The temperature of the cylinder should be measured before and after a given number (25, 50) of rotations. Notice: For small and large friction cylinder CuZn, the specific thermal capacity c is equal to 385 J/KgC. whereas c for friction cylinder Al is equal to 900 J/kgC. 8-After collecting the measurements calculate Q and W and then the mechanical equivalent of heat. Data & Calculations: F1=10 N r=2.45cm CuZn(small) T1=20℃ 25 50 rotations rotations T2(C) 20.3 22.5 CuZn(large) T1=22℃ 25 50 rotations rotations 22.2 21.5 Al Cylinder Spring balance CuZN Cylinder Crank handle Plastic friction band Thermometer Commercial weight Fig 1 Al T1=20.5℃ 25 rotations 20.6 50 rotations 21 F2(N) 53 50 51 53 42 40 W(J) 165.48 308.876 157.78 330.966 123.15 230.9 Q(J) 123.2 542.08 98.56 246.4 70.2 140.4 ∆W/∆Q 1.3 0.6 1.6 1.3 1.7 1.6 Table 1 Conclusion: 1. First conclusion we can take from table 1 is that both work and heat increase when increasing the number of rotations. 2. The mechanical equivalent of heat is always around 1 (the only reason it's not equal to one is experimental errors and that's normal considering that this experiment is not easy to execute), which means that most of work is converted into heat.