Gas Development Project for the

Unitization of the Jambaran-Tiung Biru

Field

PROJECT EXECUTION PLAN

Doc No.

A

Rev

28 Dec 15

Rev Date

Issued For Bid

Description

DTS

JY

SS

SS

Prepared By

Checked By

Endorsed By

Approved By

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 2 of 72

Document Information

Revision History

Revision

Section

A

All

Description

Issued for Bidding

Distribution List

Master Controlled copy

Honeywell Document Control

Controlled Copy

Customer

Controlled Copy

Honeywell Projects

Copyright Statement

This document contains information that is confidential and proprietary to Honeywell and may not be

reproduced or given to third parties without the express written permission of Honeywell.

Copyright 2022, Honeywell

Source

This document was developed and prepared by Honeywell.

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 3 of 72

TABLE OF CONTENTS

1

REFERENCE DOCUMENTS.......................................................................................................8

1.1

1.2

2

Pertamina EP CEPU:...................................................................................................................... 8

Codes/Standards ............................................................................................................................. 8

ABBREVIATIONS, DEFINITIONS AND NOMENCLATURE ....................................9

2.1

2.2

3

Terms.............................................................................................................................................. 9

Abbreviations ................................................................................................................................. 9

INTRODUCTION ...............................................................................................................12

3.1

3.2

3.3

3.3.

3.4.

3.5.

3.7.

3.8.

4.

Purpose of the Document ............................................................................................................. 12

Project Overview .......................................................................................................................... 12

HONEYWELL as a MAC............................................................................................................ 12

HONEYWELL Value Proportion .............................................................................................. 13

Honeywell Mission Statement ................................................................................................. 14

Quality Statement ...................................................................................................................... 15

Honeywell Executive sponsor .................................................................................................. 15

Confidentiality ............................................................................................................................. 15

PROJECT OVERVIEW .............................................................................................................16

4.1.

4.2.

4.3.

4.4.

5.

Basis of the Execution Plan ..................................................................................................... 16

Key factors for Success of the Project ................................................................................... 16

MAC Scope of Work Overview ................................................................................................ 17

Project Locations and Sourcing............................................................................................... 19

PROJECT EXECUTION STRATEGY ..........................................................................................20

4.5.

Project Execution Work Flow ................................................................................................... 20

4.5.1.

4.5.2.

Manufacturing Process for ICSS - JTB MAC ............................................................ 20

Detailed Explanation on Implementation ................................................................... 23

4.6.

4.7.

4.8.

4.9.

Manufacturing & Software development Process for IECS - JTB MAC............................ 23

Detailed design phase .............................................................................................................. 24

Project Implementation phase ................................................................................................. 24

Commissioning Phase .............................................................................................................. 24

4.9.1.

Installation & Commissioning Support ....................................................................... 24

4.10.

4.11.

4.12.

Post Commissioning / Long term Support ............................................................................. 24

Project Milestones ..................................................................................................................... 25

Proposed Project Schedule ..................................................................................................... 25

6.

PROJECT ORGANIZATION ..............................................................................................26

4.13.

Project Organization.................................................................................................................. 26

Project Members and Their Roles and Responsibilities. ...................................................................... 26

6.1.

Honeywell Site Team ................................................................................................................ 31

6.2.

Responsibilities Matrix (Between MAC and CONTRACTOR/Company) .......................... 31

7.

PROJECT MANAGEMENT PLAN ...............................................................................33

6.3.

6.4.

Global Project Management Methodology ............................................................................ 33

Global Project Engineering Methodology .............................................................................. 33

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 4 of 72

6.4.1.

Customer satisfaction survey ...................................................................................... 34

6.5.

Project Communication Plan ................................................................................................... 34

6.5.1.

6.5.2.

6.5.3.

6.5.4.

6.5.5.

6.5.6.

6.5.7.

6.5.8.

6.5.9.

Objectives ....................................................................................................................... 35

Project Correspondence .............................................................................................. 35

Communication links and channels ............................................................................ 35

Language ........................................................................................................................ 36

Contact Name(s) and Address of Client .................................................................... 36

Contact Name(s) and Address of Honeywell ............................................................ 37

Correspondence Identification .................................................................................... 37

Correspondence and Telephone/Facsimile Communication ................................. 37

Project authority............................................................................................................. 37

6.6.

Project Controls ......................................................................................................................... 37

6.6.1.

Project Cost Control ...................................................................................................... 38

6.6.1.1.

Purpose....................................................................................................................... 38

6.6.1.2.

Methodology............................................................................................................... 38

6.6.2.

Project Schedule Control ............................................................................................. 38

6.6.2.1.

Purpose....................................................................................................................... 39

6.6.2.2.

Areas of Responsibility ............................................................................................. 39

6.6.2.3.

Scheduling Criteria .................................................................................................... 39

6.6.2.4.

Scheduling Technique .............................................................................................. 39

6.6.2.5.

Progress Updating .................................................................................................... 39

6.6.2.6.

Internal Planning Meetings ...................................................................................... 39

6.6.3.

Reporting ........................................................................................................................ 39

6.7.

Project Change Control ............................................................................................................ 40

6.7.1.

6.7.2.

6.7.3.

6.7.4.

6.7.5.

6.7.6.

Change Management Plan .......................................................................................... 40

Change Management Flow Chart ............................................................................... 40

Change Management Plan Implementation ............................................................. 40

Change Verification and Approval .............................................................................. 41

Approval of PO amendment ........................................................................................ 41

Change Implementation ............................................................................................... 41

6.8.

Customer Progress Reporting / Meetings ............................................................................. 43

6.8.1.

6.8.2.

Progress Reports .......................................................................................................... 43

Customer Kick Off / Progress Meetings .................................................................... 43

6.9.

Document Control...................................................................................................................... 43

6.9.1.

6.9.2.

6.9.3.

6.9.4.

Document Handling Procedure ................................................................................... 43

Electronic Filing System ............................................................................................... 44

Electronic Data Exchange ........................................................................................... 44

Document Transmittals ................................................................................................ 44

8.

ENGINEERING PLAN ..............................................................................................................45

6.10.

6.11.

General........................................................................................................................................ 45

Detailed design phase .............................................................................................................. 45

6.11.1. FEED verification........................................................................................................... 45

6.11.2. Detailed design .............................................................................................................. 46

6.12.

Implementation Phase .............................................................................................................. 47

6.12.1. Engineering Work Packages ....................................................................................... 47

6.12.2. Use of Standard Builds (Toolkit) ................................................................................. 47

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 5 of 72

6.12.3.

6.12.4.

6.12.5.

6.12.6.

6.12.7.

6.12.8.

6.12.9.

PCS Hardware ............................................................................................................... 48

PCS Applications........................................................................................................... 48

ESD/FGS Hardware...................................................................................................... 48

ESD/FGS Applications ................................................................................................. 48

HMI .................................................................................................................................. 48

Third Party Interfaces ................................................................................................... 49

Network & High Level System Design ....................................................................... 49

6.13.

Testing......................................................................................................................................... 49

6.13.1. Design Validation Tests ............................................................................................... 49

6.13.1.1. Software Prototype (Typical) test ........................................................................... 49

6.13.1.2. Hardware Prototype (Typical) Test......................................................................... 50

6.13.2. Communication Interface / Handshaking Test ......................................................... 50

6.13.3. Internal Testing .............................................................................................................. 50

6.13.4. System Readiness Review .......................................................................................... 50

6.13.5. Factory Acceptance Test ............................................................................................. 51

6.13.6. Third party interface testing ......................................................................................... 51

6.13.7. Integrated Factory Acceptance Test .......................................................................... 51

6.13.8. Certificate of Acceptance ............................................................................................. 51

6.13.9. Site Acceptance Test .................................................................................................... 52

6.13.10. Pre-Commissioning / Commissioning .................................................................... 52

6.14.

Documentation ........................................................................................................................... 52

6.14.1.

6.14.2.

6.14.3.

6.14.4.

6.14.5.

6.14.6.

INtools Instrument Database ....................................................................................... 52

Loop Schematics ........................................................................................................... 53

Bill Of Materials.............................................................................................................. 53

System Self Documentation ........................................................................................ 53

Technical Query Forms ................................................................................................ 53

Standard System Manuals........................................................................................... 53

6.15.

Packing and Shipping ............................................................................................................... 53

6.15.1. Packing and Preparation for Shipment ...................................................................... 54

9.

INTERFACE MANAGEMENT METHODOLOGY .....................................................56

9.2.

9.3.

9.4.

9.5.

9.6.

9.7.

9.8.

Interface Management Plan .......................................................................................................... 56

Project Responsibilities for Interfaces .......................................................................................... 56

Client Responsibilities ................................................................................................................. 56

MAC Responsibilities .................................................................................................................. 56

CONTRACTOR or Third Party Responsibilities ......................................................................... 57

Potential Interfaces Issues ............................................................................................................ 57

Interface Procedures ..................................................................................................................... 58

9.8.1.

9.8.2.

9.8.3.

9.8.4.

9.8.5.

9.8.6.

Defining ICSS Interfaces ................................................................................................. 58

MAC ICSS 3rd Party Interface ......................................................................................... 58

ICSS Interface Coordination ............................................................................................ 59

Interface Coordination Meetings ..................................................................................... 59

Interface Work Packages ................................................................................................. 59

Interface miles tones within Project Schedule ................................................................. 60

10.

10.2.

QUALITY PLAN ...................................................................................................................61

Quality Plan.................................................................................................................................. 61

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

11.

PROJECT EXECUTION PLAN

Rev A

Page 6 of 72

PROCUREMENT PLAN......................................................................................................64

11.2.

11.3.

General ......................................................................................................................................... 64

Breakdown of Work activities...................................................................................................... 64

11.3.1.

11.3.2.

11.3.3.

11.3.4.

11.3.5.

6.15.2.

11.3.6.

Engineering Phase ............................................................................................................ 64

System Integration Phase ................................................................................................. 64

Installation Phase ............................................................................................................. 64

Organisation and Staffing ................................................................................................ 65

Procurement Management ............................................................................................... 65

Subcontract Management ............................................................................................ 71

Materials Coordination .................................................................................................... 73

12.

HEALTH SAFETY ENVIRONMENT (HSE) PLAN ...................................................................74

13.

SITE EXECUTION PLAN .................................................................................................75

13.2.

13.3.

13.4.

13.5.

13.6.

13.7.

13.8.

13.9.

13.10.

13.11.

13.11.1.

13.12.

13.12.1.

14.

14.2.

14.3.

14.4.

Site Scope ..................................................................................................................................... 75

Site Organization and Responsibilities ........................................................................................ 75

Pre-Commissioning Plan .............................................................................................................. 75

Pre-Commissioning Strategy........................................................................................................ 75

Pre-Commissioning Scope ........................................................................................................... 76

Permit to Work (PTW) ................................................................................................................. 76

Pre-Commissioning Responsibilities ........................................................................................... 77

Pre-Commissioning Activities ..................................................................................................... 77

HSE and QA................................................................................................................................. 78

Deficiency List Completion ......................................................................................................... 78

Site Changes and Control............................................................................................. 78

COMMISSIONING AND START-UP PLAN ............................................................................ 78

Commissioning and Start-up Scope ............................................................................. 78

PROJECT COMPLETION PLAN ................................................................................................79

General ......................................................................................................................................... 79

Knowledge Transfer to Customer ................................................................................................ 79

Project Closeout Package ............................................................................................................. 79

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

Project Execution Plan

PROJECT EXECUTION PLAN

Rev A

Page 7 of 72

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 8 of 72

1 REFERENCE DOCUMENTS

1.1 Pertamina EP CEPU:

Document number

JTB-SF-T-SPE-900-00006

JTB-SF-T-SPE-900-0005

JTB-SF-Z-DBS-900-0001

1.2

Document Description

Main Automation Contractor Technical Proposal

MAIN AUTOMATION CONTRACTOR (MAC) REQUIREMENT AND

SCOPE OF WORK

Project Design Basis

Codes/Standards

Term Name

Acronym

American National Standards Institute

ANSI

American Petroleum Institute

API

Institute of Electrical and Electronic Engineers

IEEE

International Electrotechnical Commission

IEC

The Instrument, Systems and Automation Society

ISA

International Standards Organisation

ISO

Technische Uberwachungs Verein

TUV

Underwriters Laboratories, Inc.

UL

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 9 of 72

2 ABBREVIATIONS, DEFINITIONS AND NOMENCLATURE

2.1 Terms

Context

COMPANY

CONTRACTOR

SUB CONTRACTOR

Project

MAC

VENDOR

Meaning

Pertamina EP CEPU

Appointed by Company who shall be responsible for detail engineering

design, material and equipment procurements and construction.

Appointed by Contractor to provide services to Contractor

Gas Development Project for Jambaran – Tiung Biru Field (JTB Project)

Main Automation Contractor- Honeywell.

Supplier of services, equipment fabrication or materials

2.2 Abbreviations

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 10 of 72

Acronyms

Descriptions

AMS

Asset Management System

AS

Alarm System

BMS

Bypass Management System

BOM

Bill of Material

C&E

Cause and Effect

CCR

Central Control Room

CCTV

Closed Circuit Television

CER

Central Equipment Room

CPF

Central Processing Facilities

DCC

Document Control Centre

DCS

Distributed Control System

DDS

Detailed Design Specification

ESD

Emergency Shutdown System

EPKS

Experion PKS System

FAT

Factory Acceptance Test

FDS

Functional Design Specification

FEED

Front End Engineering Design

FGS

Fire and Gas System

FTA

Field Termination Assembly

FSO

Floating, Storage and Offloading vessel

GPE

Global Project Engineering (Honeywell)

GPM

Global Project Management (Honeywell)

GPS

HART

Global Positioning System

Highway-Addressable Remote Transmitter Communication

Protocol

HMI

Human Machine Interface

HSE

Health, Safety and Environment

HVAC

Heating, Ventilation and Air Conditioning

IAMS

Instrument Asset Management System

ICSS

Integrated Control and Safety System

IFAT

Integrated Factory Acceptance Test

IMS

Information Management System

ISA

The Instrumentation, Systems and Automation Society

LAN

Local area Network

LER

Local Equipment Room

LSS

Load Shedding System

MCC

Motor Control Centers

OLE

Object Linking and Embedding

OPC

OLE for Process Control

OTS

Operator Training Simulator

PAEAS

Public Address / Emergency Alarm System

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 11 of 72

PCS

Process Control System

PDCS

Power Distribution Control System

P&ID

Piping and Instrumentation Drawings

PEP

Project Execution Plan

PFD

Process Flow Diagram

PLC

Programmable Control System

PMS

Power Management System

PPF

Production Processing Facilities

QA/QC

Quality Control/Quality Assurance

QMS

Quality Management System

RIETIS

Remote Instrument Enclosure

SAT

Site Acceptance Test

SIL

Safety Integrity Level

SIT

Site Integration Test

SM

Safety Manager

SUDS

SPI

Shared User Database Structure (data exchange)

Smart Plant Implementation by Intools (instrument

database)

UCP

Unit Control Panel

TAT

Typical Acceptance Test

UPS

Un-interruptible Power Supplier

WBS

Work Breakdown Structure

WP

Project Work Package

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 12 of 72

3 INTRODUCTION

3.1

Purpose of the Document

The MAC Project Execution Plan document describes the Honeywell processes, activities and

contractual arrangements associated with delivery of the JTB Project to achieve the project objectives.

This document defines the plan, minimum administration requirements, project organization, project

progress, roles and responsibilities. In addition, this document will define the execution of each phase

of the project and each work package including engineering, assembly, sub-contracting, interface

management, system integration, testing, construction, commissioning and start-up support and safety

management.

3.2 Project Overview

The JTB project is expected to produce 178 MMSCFD (169.1 MMSCFD annual average) of pipeline

quality sales gas for export. Solid sulphur removed from the gas sweetening process is produced at

rate of 60 to 120 metric tons/day for export. Condensate is recovered and pumped to ExxonMobil Cepu

limited Banyu Urip Central Processing Facilities (EMCL BU CPF) at a rate of 3,750 bbls/day. Produced

water is recovered and pumped to EMCL BU CPF at a rate of 8,253 bbls/day.

3.3 HONEYWELL as a MAC

The MAC scope of work shall be consistent with the requirements described in COMPANY’s Instruction

to Tenderness and Scope of Work for Main Automation Contractor (MAC) Technical Proposal,

document no: JTB-SF-T-SPE-900-00006, Rev.1 date 14th July 2015.

Honeywell as the MAC will work closely and directly with the CONTRACTOR and the COMPANY

throughout the project from inception to commissioning. MAC will also provide the required interface to

enable COMPANY/CONTRACTOR to liaise with other EPC’s (if Any), the EPC sub-contractors as

needed and to ensure standardization objectives and overall ICSS integration objectives of the

COMPANY are met with.

As MAC, Honeywell will be required to design, engineer, supply, assemble, test and implement the

Integrated Control and Safety System (ICSS) and Integrated Enterprise Control System (IECS) which

includes supply of hardware and software for selected Manufacturing Operation Management

System(MOMS). More detailed scope of work has been included in the Honeywell proposal document.

The MAC concept will help in consistency and standardization of the hardware, software, integration,

training and spare parts. The concept also ensure single point ownership for all ICSS & IECS related

systems under MAC scope and ensure smooth integration and commissioning at site.

The MAC anticipates and proposes the following phases during the project execution to meet the scope

and objectives of this project:

3.2.1. Phase-1:

Detailed Design Phase

During this phase key team members of the MAC shall be mobilized and located in CONTRACTOR’s office

in Jakarta or any other places. The team will be led by Project manager and engineering team which consist

of lead engineer, and lead discipline engineers: ICSS and IECS system. During this phase MAC vendor

will verify the FEED documents already developed by the COMPANY as part of a separate FEED contract.

The MAC vendor shall also work with the CONTRACTOR to establish design basis and project

fundamentals and agreed upon as possible. Those include compliance to scope,

conformance/options/exceptions, Minimize customization/use of vendor standards, Document Deliverable

List, functional design specifications (FDS), Graphic sketches basis, standard report format, data base

format finalization (InTools) – if any, System Architecture review with L4/L5 interface requirements/security,

project timeline, design freeze and project milestones, customer input design data, prototyping as

applicable, package vendor schedule, project specifications, PEP approval etc. If any changes are required

to the FEED documents the same will be discussed and agreed to ensure it is in line with the final ICSS &

IECS system selected. Review and agree on the Project Execution Plan shall also be carried out during

the FEED verification phase. Project manager shall be available in CONTRACTOR’s office as required

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 13 of 72

during the FEED verification phase and ensure it is executed as per plan. Project manager shall be mostly

located at Honeywell office in Jakarta driving the project activities and interfacing with the CONTRACTOR

and Company. An Overall lead engineer and other key engineers will be located at CONTRACTOR office

full time during the detailed design phase will also provide necessary interface support to CONTRACTOR

and Honeywell engineering team.

3.2.2. Phase-2:

Implementation Phase

Detailed engineering bulk drawings, Prototype (Typical) testing, Design Freeze, Approval, bulk building

and generation, procurement, hardware manufacturing, CITs at vendor location, testing (FAT/IFAT). MAC

will provide the office space, for COMPANY and CONTRACTOR personnel during FAT, IFAT and Review

Sessions. This activity shall be done in Honeywell Jakarta office.

MAC will deliver the cabinets to site after IFAT done and accepted by CONTRACTOR And COMPANY

with receiving FAT/IFAT Acceptance report and Inspection Release Note, soon once Test completed.

MAC will supervise the Cabinet Installation at COMPANY’s site if agreed by CONTRACTOR.

3.2.3. Phase-3:

Commissioning Phase

During this phase the system delivered to customer site will be verified and inspected upon receipt and

stored at ware house of customer, installation by customer’s contractor, SAT, pre-commissioning and

commissioning & start-up assistance.

The following block diagram illustrates the various phases of the project.

Phase-1

Detailed

Design

MAC

Selectio

n

Phase-2

Phase-3

Implementation

Procure, Build,

Test

Commissioning

Install, SAT, Precommission

& Commissioning

- MAC Purchase Order issued

End of

Project

Commencement of Life

time support phase

3.3.

HONEYWELL Value Proportion

As experiences of MAC package, Honeywell has the following value proportion that will give advantages and

meet the requirements of Contractor and COMPANY requirements:

3.3.1.

Technology

Proven-in-use ICSS Platform

Universal I/O Technology to reduce field cabling, marshalling and accommodate late design

inputs.

Virtualisation Technology & Wireless for hardware platform optimisation.

VEP engineering for accelerating schedule.

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

3.3.2.

3.3.3.

3.3.4.

3.4.

PROJECT EXECUTION PLAN

Rev A

Page 14 of 72

Seamless Integration with existing Banyu Urip ICSS system.

Experiences/Capability

Leverage on MAC project capabilities in Indonesia (BU MICC, Jangkrik FPU ICSS)

Familiarity with Banyu Fields (EPF, MICC)

Experienced resources in global and SEA for support

Large staging area available in Jakarta

Extensive ICSS and 3rd Party system Integration/non-DCS scope

Vast Upstream Installed Base Worldwide

Proven methodology, tools and global Lesson Learn

Values

Experience from Banyu Urip ICSS design(typical/HMI)for optimizing repeat functions for JTB

MAC Project

Single window integrated MAC approach

Backup by Regional and Global MAC experience and resources

GPM 2012 Best Practices, Standard Builds and Integrated Tools

Global Quality and HSE policies enforced

Financially Strong & Sound

Minimize Risk

Regional & Global Management commitment – Executive sposorship

Proven track record in meeting delivery schedule

Experienced Project Management & engineering team members

Familiar with multiple EPCs engagement and MAC delivery

Honeywell Mission Statement

To achieve recognition as the best Automation Systems Integrator that pro-actively attains the project

goals for the Customer through:

On-schedule and on-budget delivery of the project within scope and Quality requirements.

Implementation to ensure standardization throughout the project, as possible.

An Integrated Control and Safety System (ICSS) which is engineered, manufactured and tested

to the highest standards and fully meeting the functional requirements of the project

Trouble free and safe start up by seamless provision of skilled resources for each location and

phase of the project

The Vision is to provide an integrated Control and Safety System (ICSS) that is best in class for:

SAFETY:

Confident operators guided by the best system, to recognize, understand and

respond to process upsets in a safe manner.

OPERABILITY:

Design strategies shall achieve for the operators, the best integration of

process safety, marine and package systems to a single Human-Machine

Interface.

MAINTAINABILITY:

Maintenance technicians shall regard the system’s engineering tools, its

access, its redundancy and its commonality as an asset for reliable and safe

facilities.

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

PERFORMANCE:

3.5.

PROJECT EXECUTION PLAN

Rev A

Page 15 of 72

All systems and equipment designed, manufactured, supplied and

commissioned under Honeywell scope will perform to the highest level of

system availability and reliability throughout the life of the project.

Quality Statement

It is the intention of Honeywell to deliver defect-free competitive products and services, on time, to both

internal and external customers by performing exactly to requirements. Our name must represent

excellence to our customers, our vendors and ourselves.

It is the policy of Honeywell to achieve continual improvement by:

3.6.

Identifying improvement possibilities

Setting appropriate objectives and targets

Implementing programs to meet the objectives and targets

Supplying appropriate QMS training and guidance

Seeking ways to improve the Quality Management System

Quality management shall be consistent with requirements of Project Quality Plan of

CONTRACTOR and COMPANY.

Health Safety & Environment Statement

Honeywell policies, commitments and responsibilities to Health Safety and the Environment are stated in

Doc Health Safety Environment (HSE) Plan.

3.7.

Honeywell Executive sponsor

In recognition of the importance of the JTB project to both CONTRACTOR and COMPANY, Honeywell

will nominate an Executive Sponsors for the project. The Executive Sponsors will act as Champion within

Honeywell for this critical project, and facilitate resolution of issues that might require their attention.

3.8.

Confidentiality

Honeywell will ensure that all project team members are familiar with the Confidentiality requirements

contained within the contract and that all project team members comply with the procedure as detailed in

document Honeywell Project Quality Plan.

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 16 of 72

4. PROJECT OVERVIEW

This section specifies the Project Execution Model that will be adopted for the Integrated Control and Safety

System (ICSS) and Integrated Enterprise Control System (IECS) for Jambaran Tiung Biru Project,

Indonesia. Honeywell believes that the proposed execution model will be most suited to this project scope

and location as well as to deliver the best commitment to our customer.

The Project Execution Plan (PEP) describes project methodologies, project organization, roles and

responsibilities, change management, resource loading, locations of manufacturing, communication

channel, procurement management, system integration and site commissioning activities in order to

achieve on-time delivery of the project.

The PEP also provides an overview of the quality controls and administration planned for the project

including engineering and design audits, manufacturing audits, etc. The PEP is a live document and will

be updated as required during project execution to reflect any changes in implementation methodology

and philosophy as mutually agreed between MAC,CONTRACTOR and COMPANY.

4.1.

Basis of the Execution Plan

The Project Execution Plan is developed based on the Jambaran Tiung Biru project specification

documents listing out the requirements and furnishing basis for developing applications and hardware

engineering for ICSS and IECS system.

4.2.

Key factors for Success of the Project

Experienced Project Manager providing single window contact to CONTRACTOR for managing

all the contractual requirements of scope, schedule, resources and quality

Program management approach to guide close coordination with COMPANY, CONTRACTOR,

EPCs, Project team and other Stake holders.

Ensure standardization amongst all systems supplied by different parties.

Dedicated EPKS and SIS engineers from local affiliate to be full time with CONTRACTOR to

verify FEED and involvement of MAC lead engineer to ensure proper coordination amongst all

EPC’s and COMPANY.

Continuity of Key personnel from start to finish.

Engaging experienced consultant with domain knowledge during key phases of the project.

Effective management of all interfaces achieved through key personnel engagement

Honeywell will adopt a Program management approach to ensure close coordination between Honeywell

and other stakeholders of the project for achieving standardization of all systems integrated in the ICSS

and IECS. This approach provides strength to the Honeywell project team and comes as a benefit to the

COMPANY. A Project Director will be driving the approach and provide the necessary guidance to the

MAC Project manager, and the team, taking the overall stewardship of the project. He will be based at the

Singapore project centre and be available for all key meetings during the project life cycle. He will also

coordinate with the Honeywell Global Program Management team as necessary to cover the overall

expectations on the Jambaran Tiung Biru Project.

Honeywell understand that the success of the Jambaran Tiung Biru project depends very much on an

experienced team of Project Management, Engineering and Consultant resources to be deployed in the

project. Key resources are critical for the success factor of the project and Honeywell will assure the

availability of such resources from project start to commissioning and handover to COMPANY. Honeywell

also plans to ensure participation of resources from local affiliate service organization who will later be

involved in site commissioning and long term support to COMPANY. Even though Honeywell has a rich

history of project execution and engineering for such projects, we plan to engage an experienced

engineering consultant with rich background in upstream oil and gas facilities, during the key design phases

and preparation of functional design specification documents till freeze. Such consultant support is

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 17 of 72

expected to pay rich dividends in the success of the project. Honeywell also plan to engage experts in

review and validation of network architecture and setup in line with Honeywell’s global best practices and

design guidelines which is another critical factor in the success of implementation.

4.3.

MAC Scope of Work Overview

Detailed Engineering Services: Review and finalization of preliminary controls engineering

specifications provided in Instructn to Bidder (ITB) package for all instrumentation, control and

safety systems on the Project. Design of Integrated Control and Safety System (ICSS) and its

interfaces.

Supply of Goods and Services: supply of goods for specified instrumentation and control systems

during Detailed Engineering design. Provide construction support, commissioning support, startup support and after market training and on-site assistance.

The MAC's responsibilities include the following and as per mutually agreed contract scope and

proposal/costing basis:

Resulting automation deliverables, participation in review meetings, and collaboration via

comments and/or input into the development of other automation CONTRACTOR deliverables.

Supply the hardware and software components for Integrated Control And Safety Systems

(ICSS) and all related services.

Supply the hardware and software component for selected Manufacturing Operation

Management System (MOMS) as part of IECS and all related services.

Provide the PROJECT management, procurement, cost and schedule control, engineering,

services as described in this document associated with the systems supplied by the MAC.

Provide services related to automation and resolve interface issues between MAC supplied

systems and other instrumentation and control systems, including package system supplied by

others. MAC will be acted as automation system interfaces leader.

Work closely with the CONTRACTOR, equipment package VENDORs, and COMPANY to

reduce duplicated activities and to compress schedule.

Produce as-built instrumentation and control systems documentation, drawings and data bases

for use by COMPANY.

Develop TAT, FAT and integrated FAT (IFAT) plan, stage equipment, and perform

prototype/typical test, FATs and IFAT

MAC will provide training to COMPANY personnel as defined in contract.

Provide spare parts for start up, commissioning and two-year (optional) operations.

Provide certain inspection, construction support, and commissioning services as defined in

Project Specifications.

The MAC scope of work shall be performed by Honeywell Process Solutions (HPS), Jakarta office and

includes Design, Implementation and Test of ICSS and IECS System Infrastructure facilities as spelt

out in our proposal.

MAC Scope of Work – By Honeywell

The following is brief description on ICSS/IECS system that will be provided by Honeywell as a MAC:

Process Control System (PCS)

: Experion PKS C‐300 Series ‐ Universal IO

SIS

: Safety Manager ‐ Remote Universal Safety IO

F&G

: Safety Manager ‐ Remote Universal Safety IO

RTU

: Safety Manager ‐ Remote Universal Safety IO

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 18 of 72

OTS

: Honeywell Unisim or equal

Alarm Management

: Honeywell Dynamo Alarm Manager or equal

APMS

: Honeywell Asset Management or Equal

EPMS

: Honeywell Uniformance Process or Equal

CMMS

: Honeywell FMEA Tools or Equal

E‐LOG BOOK

: Honeywell E‐Log Book or Equal

IMS

: Honeywell Inspection Management

RTIS

: Honeywell PHD

Futuristic Operator Workstation

: TBA

ESD and F&G Matrix Console

: Local Made

Engineering Workstation

: Dell or Equal.

MAC Scope of Work – By NON- Honeywell

MMS

: Bruel Kjaer Vibro or Equal or Equal

Weather Monitoring System

: Climatronic or equal

EDMS

: Integraph or Equal

LIMS

: LabMate Enterprise or Equal

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

4.4.

PROJECT EXECUTION PLAN

Rev A

Page 19 of 72

Project Locations and Sourcing

Honeywell will control the execution of this project from the central location of MAC Front office (FO) in

Jakarta, Indonesia for the smoother implementation of the project and based on past experience. The

Project Manager, who is based in MAC Front Office (FO), is the single point of contact with responsibility

for the execution of the project. The core engineering team will be based at the MAC FO implementation

Centre.

During Detailed design phase a team of key team engineers (for ICSS and IECS) will be co-located with

CONTRACTOR in his office. In addition a team of project engineers will be located at Honeywell’s front

office (FO) to provide necessary FEED support. This in line with the MAC capacity and to leverage

expertise and ensure cost effectiveness. The Key engineers located at CONTRACTOR office will be led

by the Project Manager (PM) to establish a minimum team at CONTRACTOR office. The PM will provide

leadership and carry out interface responsibilities (with support by MAC lead Engineer as required). The

need for a dedicated interface Lead engineer will be determined with the COTRACTOR. Interface role

will be primarily acting as coordinator and interface with COMPANY, CONTRACTOR other EPC

contractors, vendors, 3rd party suppliers of EPC’s etc .required at CONTRACTOR office. This role along

with the MAC Lead Engineer will also attempt to achieve consistency in design across the plant systems

under MAC responsibility.

After detailed design phase the key engineers located at CONTRACTOR office will move to MAC FO for

implementation and testing phase. PCS/ESD/FGS hardware will be supplied through Honeywell’s Global

Customer Solution Centre (CSC). The factory allocated for this project shall be Tianjin Factory, China.

Network equipment/Components for ICSS and IECS shall be sourced as per Honeywell Factory

Approved manufacturers.

All 3rd party hardware, software, cabinets, consoles etc in MAC scope shall be sourced as per Honeywell

approved vendors per Honeywell global supply chain sourcing guidelines as well as meeting Customer

specifications and Approved Vendor List.

All marshalling, power distribution, auxiliary cabinets, console furniture will be assembled, wired and

tested in Jakarta. DCS/ESD/FGS systems shall be assembled and wired in Honeywell Factory and

shipped to Jakarta for integration and testing.

In the capacity of MAC and to leverage expertise and cost effectiveness, Honeywell plans to utilize

Honeywell Graphics Development Centre (GDC), Indonesia for the implementation of graphics

generation work packages. Design, Integration and testing of these packages will remain the

responsibility of MAC FO Engineering Team.

All project integration testing, staging and prototype/typical test, Factory Acceptance Tests (FAT/IFAT)

will be carried out at the Jakarta staging facilities.

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

5.

PROJECT EXECUTION PLAN

Rev A

Page 20 of 72

PROJECT EXECUTION STRATEGY

5.1.

Project Execution Work Flow

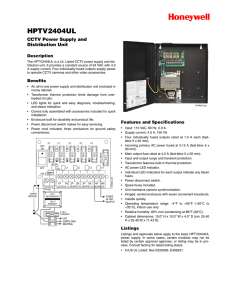

5.1.1. Manufacturing Process for ICSS - JTB MAC

The Honeywell factories are ISO 9001 certified and covers the complete range of HPS (Honeywell

Process Solutions) offerings, including the Series C standard build, integration of Experion® Process

Knowledge System (PKS), safety systems and Total Plant Solution systems.

Honeywell executes to a global policy where we only build Safety Manager SIS cabinets at certified

locations. These locations are certified by TUV and use the same processes and materials in all locations

to ensure global consistency. So, there would be no difference in the specification and certification of an

SM built in any of the certified locations including Honeywell’s Tianjin factory in China. We will provide

TUV certificate copies for the factory used to support IEC61508 and SIL compliance .

For successful strategy for MAC, the execution for ICSS and IECS-MOMs will:

1) Closely follow the EPC’s master schedule milestones for close alignment and establishing of

Common Objectives. As such the MAC project schedule milestones shall complement the

overall schedule the EPC is looking for starting from KOM, Design Freeze, Manufacturing,

Testing, delivery and post delivery site support up to start up and warranty period.

2) Design documentation schedule, format, numbering philosophy, review cycles etc will take

into account EPC and COMPANY requirements and aligned to milestones

3) Identification of testing philosophy, interface design strategy and prototype testing upfront to

avoid risks and delays

4) Strong scope change management to contain cost and productivity

5) Use of Robust Methodology, Lessons Learned, Proven Technology and Tools available (LEAP

concepts) to extend flexibility during execution. This is to accommodate late design inputs in

some cases and to perform system configuration where possible without target hardware being

available, quicker recovery for slippage etc

6) Staggered delivery of equipment to meet construction schedule as priority during execution

7) Proactive planning and mobilisation of resources throughout the project to ensure timely

support. Full time Resident Engineers at EPC office from KOM up to start of FAT will be

deployed as needed to enhance coordination and accelerate work

8) Regular reviews of Risks and opportunities and involve customer team members as needed to

identify and mitigate risks that will impact progress

9) Reporting accuracy and avoidance of gaps in progress measurement

10) Safety and Quality as top priority throughout the MAC life cycle

The following diagram illustrates the overall project execution work flow.

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 21 of 72

ICSS/IECS

System

Hardware

Design Spec

MAC

Contract

Award

FEED

verification

Kickoff

Meeting

ICSS/IECS

System

Software

Design Spec

Detail Design

Freeze

ICSS/IECS

Define

System

Interfaces

IECS/MOMS/LDS

Procurement, Design, Manufacture

PCS System cabinet

assembly and factory quality

checks @ Tianjin, China

factory.

PCS System

cabinet Order Global Order

Process

SIS System

cabinet OrderGlobal Order

Process

Marshalling/Aux

Cabinet

Prototype mfg&

Approve

@Jakarta

Detailed

cabinet

drawings

Internal FAT

@ Jakarta

staging

@Jakarta

staging

Manufacturing

Marshall/Aux

Cabinets

@Jakarta

SW Prototype

Develop/Test

and approve

Perform

FAT/IFAT

@Jakarta

System

Staging for

FAT/IFAT

SIS System cabinet Assembly

and validation checks

(Waterford, Ireland for SM

boards & Tianjin factory,

China.

S/W Bulk

Generation

Receive the

System

at Site *

Packing &

Shipping

Site

Supervise

Installation *

As-Built Prep and submit

Detailed design Phase

Implementation Phase

Perform

SAT *

Project Execution Plan

Plant

Start-up *

Supervision

Project *

Close-out

After market

Service *

Commissioning Phase

* By Honeywell, Indonesia

# By Contractor

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 22 of 72

Below are the steps involved in PCS/SIS/Marshalling cabinet manufacturing and testing processes and

the relevant locations where they will happen.

PCS System cabinets

1. Upon completion of approval of I/O list and BOM (Bill of Material) for construction, the factory order is

placed for system cabinets through global factory order process using TPC (Total Plant Configuration)

software tool for build quality and consistency.

2. Upon receipt of order, the order processing will review the order for correctness and look at the region

where supply to be delivered and allocate order to Honeywell factory.

3. Tianjin Factory, China will be receiving order and will determine delivery time as per order request and

confirm order receipt and delivery.

4. Tianjin Factory, China assembles the system inside the cabinet and carries out quality checks as per

mandatory internal factory procedure (Steps 1 to 4 belong to Honeywell internal process)

5. Tianjin Factory, China ships system to project execution location in Jakarta, Indonesia for staging and

IAT, FAT/IFAT.

SIS System cabinets

1. After having drawings approved for construction, the factory order is placed for system cabinets

through global factory order process using SM tool for build quality and consistency.

2. Upon receipt of order, the order processing will review the order for correctness and look at the region

where supply to be delivered and allocate order to Honeywell factory.

3. Tianjin Factory, China will be receiving order and will determine delivery time as requested and

confirm order receipt and delivery.

4. Tianjin factory, China will obtain the required critical SM boards/components of the order from

Honeywell’s Waterford, Ireland factory

5. Tianjin Factory, China assembles the system inside the cabinet and carries out quality checks as per

mandatory internal factory procedure.

6. Tianjin factory, China ships the assembled system to Singapore Factory for validation checks as per

Solution Binder.

7. Singapore Factory carries out the required validation checks as per Honeywell Solution Binder

procedure. (Customer will be informed of this test schedule but witness is not mandatory as, the

activities from steps 1 to 7 belongs to the Honeywell internal process).

8. Singapore Factory ships system to project execution location in Jakarta, Indonesia for staging and

IAT, FAT/IFAT.

Marshalling cabinets

1. After design freeze order is placed on Local Indonesian suppliers for marshalling cabinets, terminals,

other accessories that go into marshalling cabinets.

2. Upon receipt of materials the same is issued to qualified cabinet assembly vendor factory in Jakarta,

Indonesia selected as per supply chain procurement procedures.

3. Cabinets are assembled and wired with all components by qualified cabinet assembly vendor factory

in Jakarta, Indonesia.

4. Cabinets are tested by cabinet assembly vendor factory in Jakarta, Indonesia for continuity checks

and layout checks as per approved drawings.

5. Cabinets are checked for internal quality control by project team.

6. Cabinets are delivered to Honeywell staging area in Jakarta, Indonesia

7. Cabinets are hooked up to System cabinets using pre-fabricated cables and tested as per IAT,

FAT/IFAT.

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 23 of 72

5.1.2. Detailed Explanation on Implementation

Honeywell would like to furnish further explanation on the Project Execution plan regarding manufacturing

and testing of SIS and DCS systems.

Honeywell complies with the TUV requirements on functional safety management for SIS system as

follows:

Engineering and design - Honeywell adopts engineering and design according to IEC61508/11

requirement and the work is performed by competent engineers (whom TUV FS certified perform the

work). Honeywell standard Safety Binder is used for SIS implementation which consists of all

documentations to support verifications and validation activities.

SIS system assembly - Honeywell approved factory is TUV approved for SM assembly. Technicians

assemble the system according to the approved engineering drawings provided by project team (using

standard drawings configuration). The system is then internally tested in Singapore against the approved

engineering drawings and configuration as part of the verification and validation process. This is to ensure

when the cabinets arrive in Jakarta for FAT/IFAT testing with customer, the SIS has passed the stringent

internal processes.

Below are the validation checks done in Singapore factory as part of validation process:

1. Layout & Mechanical Check

2. Tagging Checks

3. Wiring checks

4. Power distribution Checks

5. Earth connection checks

6. Dielectric & resistance test

7. Redundancy Checks

8. Simulation Input & Output Signal Test

Testing (FAT, IFAT) - This is performed by TUV certified engineers to verify the SIS system against the

customer approved design drawings, logic configuration, specifications for JTB MAC

project. Management of changes, checklists and testing records are managed by the project team

thorough out the whole FAT/IFAT process. If critical hardware rectifications are required during

FAT/IFAT, qualified SM technician from Singapore will be dispatched to Jakarta as required to perform

the required changes under the coordination Lead SM. This support is similar to critical rectifications

carried out for RIE and site location faults.

Staging Facilities- The staging facilities established in Jakarta follow Honeywell global staging

management system in goods receiving, HSE, tools, power distribution, HAVC, cable railings, facilities

maintenance, defects rectification, meeting rooms, rest rooms and shipment procedure. All testing tools

will be properly calibrated as per ISO requirement. The staging area provides space, basic utilities and

staging management support while the actual testing is handled by qualified and experienced project

team engineers.

5.2.

Manufacturing & Software development Process for IECS - JTB MAC

After kick off meeting, MAC will appoint one lead IECS/MOMS that will be acting as interface with

customer to define the requirements of IECS/MOMS together with CONTRACTOR and COMPANY.

The outcome of defining the requirements of MOMS are: selecting the hardware and software that will

be implemented as MOMS applications that defined on the project specification.

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 24 of 72

IECS/MOMS hardware that will provide by MAC mostly are ONLY server/PC that already recommended

by HONEYWELL or other 3rd party vendors; So that hardware purchase will be part of vendor MOMS

software that NOT Honeywell’s supply.

Meanwhile for software side, once the FDS of IECS approved by CONTRACTOR/COMPANY; Lead

IECS/MAC will monitor the software implementation as per schedule agreed;

A detailed implementation plan for MOMS packages will be determined and reviewed for further

execution at this early stage when the right stake holders are established.

5.3.

Detailed design phase

During Detailed Engineering phase of the Project, the MAC will be required to work closely with the

Detailed Engineering Services Contractor(s). As such, the MAC’s objective will be to build upon the

specifications provided in the ITB package and refine the design of the Integrated Control and Safety

System (ICSS) and Integrated Enterprise Control System (IECS) which the MAC will in turn procure, build,

install and commission.

The MAC will provide input concerning the control, monitoring and safety systems for the basic facilities

design as well as the interfaces to all packaged equipment.

Some salient features of Implementation phase include (more details in section 6):

5.4.

Key team members from MAC are mobilized and collocated in CONTRACTOR office

Finalize project execution plan and schedule.

FEED verification and necessary updates.

Develop and finalize Functional design specifications.

Define and finalize interface issues with other EPC contractors

Define and finalize design basis for bulk drawing generations and detailed engineering drawings.

Project Implementation phase

Some salient features of Implementation phase include (more details in section 6):

5.5.

Key team members of MAC Jakarta office continue with the implementation and testing phase of

the project.

Develop detailed project drawings, cabinet layouts, wiring schedules, databases and other

detailed engineering drawings.

Use of appropriate methodologies, tools, standards (GPM) and ‘Honeywell standard build’ –

building blocks ready for use – for consistency, standardisation, maintainability and optimal

quality.

Honeywell will execute the project utilizing its local competences and global resource pools.

The use of Web-based Intranet Project Work spaces to support proper communications between

teams in various locations.

Commissioning Phase

5.5.1. Installation & Commissioning Support

Installation and commissioning support will be provided in accordance with the provisions in the

CONTRACTOR contract. This support will be generally provided on a time and material basis.

5.6.

Post Commissioning / Long term Support

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 25 of 72

Long-term technical support will be provided in accordance with the provisions in the contract and will be

covered under a separate agreement with Honeywell local affiliate in Indonesia.

5.7.

Parts Management Program

Software Support Program

Optional Support Services including Training

Project Milestones

The following table highlights the project milestone assumed in the RFQ response.

MAC

Contract

Award

KOM with

selected

CONTRACTOR

FEED

Verification

&detail

design

Detail

Design

Freeze

Manufacturing /

Bulk generation

Internal

Test

FAT

IFAT

Shipment

SAT

Commissioning /

Project Closure

The tentative duration for the above milestone activities will be updated upon receiving the integrated

project schedule from CONTRACTOR.

5.8.

Proposed Project Schedule

Please refer to document Project schedule. The detail schedule will be prepared upon confirmation of

project milestone dates during Kick-Off meeting, Customer input design data, Hardware Design Freeze,

Prototyping, Software Design Freeze milestones, System Readiness Review, FAT/IFAT start, SAT and

Commissioning.

Honeywell will develop a Level 3 Project Schedule, then updated at the end of the KOM and thereafter

on a monthly basis. The progress updated schedule will be issued with the monthly report and discussed

during regular coordination meetings. The MAC schedule shall comply the overall project schedule of the

contractor for the timeline of overall installation.

The schedule will identify any deliverables required from Owner/CONTRACTOR for Honeywell to

complete the System design and configuration. In addition, any design interface required or provided by

Honeywell will be identified.

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 26 of 72

6. PROJECT ORGANIZATION

6.1.

Project Organization

The key considerations in developing the organization structure for the Implementation phase of the

Jambaran Tiung Biru project include:

Program management approach to ensure close coordination and manage interfaces between

Honeywell and COMPANY, CONTRACTOR and other EPC’s, sub-system suppliers and other

stakeholders. The key objective is to ensure use of vendor standards and best practices and

minimize customization as applicable. This will drive consistency in design between different

honeywell systems supplied and interfaces with other 3rd party sub-systems supplied by others

so that operator has a standard view of all systems and displays, consistent implementation

method, consistency in documentation, ease of long term maintenance etc. A Project Director

located at the Singapore project centre will oversee and drive this approach and providing

necessary guidance to the MAC Project manager and Lead Engineer.

Main MAC execution centre located in Jakarta with core project team resources, engineering

execution and implementation in Jakarta.

Location of Key team members of the project at CONTRACTOR office for the detailed design

phase.

Involvement of Specialist consultant with extensive experience in upstream oil and gas facilities.

Involvement of local affiliate resources during project implementation phase to provide seamless

support during commissioning and post commissioning support.

Objective and efficient use of experienced pool of resources in Global Engineering Services

centre.

Honeywell’s prior experience in similar MAC projects

Mobilization of Subject Matter Experts within Honeywell and from relevant Third Party Systems/

Interface Vendors to support the design/detailed engineering

Interface management to ensure smooth information exchange and resolution of issues between

all parties and strict adherence to work processes so as to provide consistency and to avoid

delays due to re-work

Refer to document of project organization chart.

The Project Team will be responsible for the timely delivery of all project deliverables and for ensuring

customer satisfaction.

Technical design of the ICSS and IECS.

Implementation of control strategies as defined by the process unit designers

Implementation of Project and operations requirements (e.g. operator interface)

Consulting to CONTRACTOR on other design criteria as required

Execution of the Project, including focus on the following:

o

Schedule, cost, deliverables, documentation, Quality and Safety

o

Integration across the EPC’s and the other participants in the Project

o

Completion and stewarding of Project design standards

o

Procurement, work releases for ICSS equipment and services

Integration and interface management with the CONTRACTOR Teams which will:

o

be resident, or have sufficient assignment at CONTRACTOR office,

o

have tight integration with the CONTRACTOR workflow,

Project Members and Their Roles and Responsibilities.

Project Execution Plan

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 27 of 72

Function

Primary role

Support role

1. Project Director

Overall stewardship of the project

Interact with Honeywell Global

Program Management team

Based in Project centre in Singapore

Guidance and mentoring of Project

Manager.

Coordination with executive

sponsors as required

Attends all key meetings with

CONTRACTOR, COMPANY

As an escalation path for the project

team and customers alike.

2. MAC Project

Manager

Project Manager shall be responsible

for the entire project execution and

control. He holds overall project

management responsibilities

Assigned at Contractor’s office during

detailed design phase(FEED review)

Overall responsible for Project HSE

planning and management

Responsible for development, update

and adherence to the Project Execution

Plan

Responsible for overall project success

criteria (schedule, budget, quality,

customer satisfaction)

Focal point for interface to

CONTRACTOR and COMPANY.

Responsible for effective coordination

amongst multiple teams and EPC’s

located in different geographies.

Selection and staffing of the Project

team with quality resources

Guidance and mentoring of

Engineering Team.

Team Building activities

Arrange logistics

Arrange and lead regular internal

review meetings.

Procurement of hardware and

software

Internal/ external audits

Quality assurance to ensure all

deliverables are consistent.

Sets targets for project members

and ensure they are met.

Raising invoices, payments etc..

Setting up internal project cost

monitoring systems and tracking.

Issue resolution

Risk monitoring and mitigation

Based in Honeywell Project office in

Jakarta

Attend all meetings with customers.

Tracks progress and reports progress

on agreed time line to CONTRACTOR

and COMPANY.

Work closely with Project Director and

project team.

3. MAC Lead Engineer

MAC Lead engineer holds technical

responsibility for all ICSS scope

Reports to the Project Manager

Responsible for HSE

Development, maintenance and

adherence to project engineering

standards and procedures

Project Execution Plan

Supports the PM and Engineers in

Contractor’s office during Detailed

Design

Training and mentoring engineers.

Adopting new tools available with

Honeywell development centres.

Adopting best engineering

practices.

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 28 of 72

Responsible for engineering

consistency across different contracts

Technical roles and responsibility

definition

Overall technical accountability and

control of design and implementation

activities

Technical risk identification,

assessment and control

Based in Honeywell Project office but

will be located in Contractor office

during key periods of detailed design

phase.

Develop and maintain check

sheets to be used during

implementation and testing phase

to ensure quality.

Technical audits.

Assist PM to track progress.

Assist PM in procurement

activities.

Set target to engineers and ensure

they are met with.

Arrange regular internal review

meetings between different engineering

teams and subcontractors.

Coordinates with CONTRACTOR and

other EPC’s on all technical issues.

Coordinates with Engineering

consultants and design specialists.

Coordinates with Technical assistance

centres.

Leads and Drives the Testing phase.

4. Specialist Consultant

Specialist consultant will support the

project team during key design phase

to develop and review functional design

specifications which will form the back

bone of design and development

Specialized background experience in

upstream oil and gas facilities

Design engineering support to MAC

Lead engineer and his team which

needs specific domain knowledge,

experience and background

Attend critical Design review meetings

with customer

5. Project Controls

Development of project schedule and

tracking of project tasks

Set up and manage costing system

Progress collection and reporting within

Honeywell

Help prepare monthly progress report

to customer

Handle scope changes and change

management.

Update and monitor regularly the

Deliverable Control Index tool

Update and monitor customer input

data

Project Execution Plan

Coordination with CONTRACTOR

and COMPANY during design

reviews.

JIMBARAN

TIUNG BIRU

PROJECT

PROJECT EXECUTION PLAN

Rev A

Page 29 of 72

Schedule and flag delays immediately.

Reports to Project manager.

6. EPKS Engineers/

SIS Engineers

Other engineers

Assigned at Contractor’s office as

required during detailed design

phase(FEED review)

Attending training and obtaining

certification in EPKS and SIS

modules.

Report to MAC Lead engineer

Checking engineering inputs for quality.

Develop design documents and

drawings.