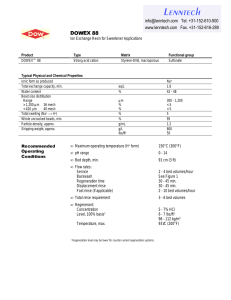

TECHNICAL PAPER 192 Treatment of Coal Bed Methane Produced Water Using Short Bed Ion Exchange MICHAEL SHEEDY AND PAUL ROBINSON, Eco-Tec Inc., Pickering, Ontario IWC-08-XX KEYWORDS: ion exchange, coal bed methane, produced water ABSTRACT: The water produced during the recovery of natural gas from coal beds, coal bed methane - CBM, is often a major problem in developing this resource. A pilot study of a short bed ion exchange process treating CBM produced water is presented. The paper will discuss background issues related to CBM produced water, alternate treatment methods, short bed technology, pilot plant test data, and design of a full scale system. BACKGROUND Coal bed methane, CBM exists in coal deposits throughout North America and at the turn of this century was estimated to supply 7% of US natural gas demand. The importance of this source of gas has only continued to grow over the subsequent years. Natural gas in the coal seams is trapped by the ground water pressure. Production wells are drilled into the coal seam and once a sufficient amount of water is removed the well goes into gas production. Withdrawal of this ground water is one of the major concerns related to utilizing this source of energy and has been the focus of federal and state regulators, local landowners, and other special interest groups. Consequently beneficial use of this water is of great importance. Alternate uses for this water include the following: agriculture – for livestock and irrigation, municipal supply, underground injection to recharge ground water supply, surface discharge to streams or soil, impoundment storage and as a SM/Technical Paper 192 supply for industrial use. Water quality standards vary depending on the use. CBM produced water is primarily composed of sodium bicarbonate. A typical analysis for produced water in the Powder River Basin in Wyoming is shown in Table 1. Table 1: Typical Analysis of Produced Water Component Range (mg/L) Na 470 – 1,100 as Na Ca 8 – 41 as Ca Mg 2 – 18 as Mg Fe 0.1 – 0.35 as Fe Ba 0.1 – 1 as Ba HCO3 1,400 – 2,900 as HCO3 SO4 10 as SO4 Cl 20 as Cl TSS 5 – 25 SAR 100 - 513 Recovered water for surface use typically has limits placed on conductivity, pH, in some case suspended solids and turbidity, and the sodium absorption ratio, SAR. SAR, also known as sodicity, is calculated using Eq.(1). SAR = Nameq/L/((Cameq/L + Mgmeq/L)/2)1/2 Eq.(1) October 2008 TECHNICAL PAPER 192 Target levels for conductivity and SAR are set to ensure water uptake by plant roots and proper soil porosity. Jangbarwala(1) presents a good review of this topic. An example of a typical water quality target for surface discharge in the Powder River Basin is given in Table 2. Table 2: Typical Water Quality for Surface Discharge Component Range Conductivity 1,000 – 2,000 µS/cm SAR 3 – 7.5 pH 6.5 - 9 Na 200 – 500 mg/L as Na Cl <70 mg/L as Cl Turbidity or TSS Quantitative limits not always defined. Should be no visible turbidity counter-currently upwards into a backwash, rinse and regeneration zone. Between pulses the resin is regenerated using HCl. Advantages of this system include continuous operation, which should help to minimize the need for large feed and product storage tanks, counter-current regeneration to minimize acid and rinse water requirements, and an ability to handle some suspended solids via the backwashing process. Disadvantages include the overall height as shown in Figure 1, a relatively more complicated process compared to a conventional IX column, and resin attrition due to the pumping and crushing in the isolating valves between the different loop sections. TREATMENT TECHNOLOGIES In many cases the quality of the produced water must be improved to permit its beneficial use. For SAR and conductivity control the most commonly used technology is ion exchange, but various other technologies exist, as do different methods of ion exchange, IX. A partial list of alternate technologies would include electrodialysis reversal-EDR, distillation, reverse osmosis, and freeze-thaw evaporation. The list of ion exchange methods includes the following: short bed IX (described in a separate section), continuous fluidized IX, conventional deep bed IX, and a novel fluidized IX process for selective Na removal. CONTINUOUS FLUIDIZED IX - The well known Higgins Loop(2,3) technology is used for Na removal from CBM water and is shown in Figure 1. In this system the produced water is pumped downward through an adsorption bed of SAC resin, while the resin is periodically pulsed SM/Technical Paper 192 Figure 1: Higgins Loop CONVENTIONAL IX - In this process a standard fixed bed IX column is used to exchange the Na from produced water. Normally these processes are regenerated co-currently and are regenerated with either H2SO4 or HCl. The advantages of this process are its simplicity. However, regenerant operating costs will be higher and larger volumes of waste will be produced. The Catalyx(4) process appears to be an example of a conventional system with a slight modification to the valving and process steps that permit some waste minimization. October 2008 TECHNICAL PAPER 192 Generally SAC resin is used for Na removal, but at least one reference(5) was found that describes the use of WAC resin. Normally WAC resins will not work in an acid cycle for Na removal because the low pH that results from the Na exchange forces the weak carboxylic group to remain in the acid form. However, the very high levels of bicarbonate in CBM water buffer the pH and permit the exchange to occur. The benefit of using a WAC resin is a reduction in regenerant consumption to almost the stoichiometric amount due the ease of converting the carboxylic group back to the acid form. Higher levels of Cl and SO4, while not expected, will result in Na leakage when using a WAC resin. Furthermore, if a counter-currently regenerated SAC resin is used in a packed or short bed type system there should be no difference between the acid consumed by either resin. Also, the SAC resin will be less expensive and will not be as sensitive to increases in Cl and SO4. Na SELECTIVE IX - This continuous IX process is shown in Figure 2 was developed with Montana State University(6) and adjusts an IX reactor volume, residence time, and the amount and state of the IX resin to control the rates of exchange such that the higher Na concentration increases the Na removal rate and leaves more Ca in the withdrawn reactor solution than would result if the mixture was allowed to come to equilibrium. Normally when using SAC resin in a more conventional IX process Ca and Mg removal are strongly preferred relative to Na and the product water will contain no hardness. Leaving Ca and Mg in solution helps to achieve the SAR target level without the need to replace hardness in the final product water. This appears to be the principal benefit of this process. Unfortunately, no case study data or examples in the patent application could be found to support the claims of this process. Also, the patent application describes a relatively complex process consisting of a fluidized reactor, fluid distributor, elutriation lines, resin separators (possibly a hydrocyclone), rotary valves, a separate regeneration system, and provision for make-up of fresh resin. All of these components must then be operated to carefully balance resin regeneration level, water and resin mix ratio, resin withdrawal rates and other parameters to ensure the relative exchange rates favourable to selective divalent exchange are achieved. SPECIAL PROCESS CONCERNS Compared to oil field produced water, CBM water is more easily treated since it is not necessary to separate oil, control silica, or achieve low hardness levels from high TDS waters. However, CBM water does require special attention with regards to the following: Ba control, Fe control, waste disposal, and remote location operation. Ba CONTROL - Table 1 indicates that Ba levels ranging from 0.1 – 1 ppm are typical. The solubility of BaSO4 is approximately 1 ppm as Ba. Such a low level can pose a problem when the treatment technology being used concentrates the Ba. Cation exchange resins have a high selectivity for Ba, which readily concentrates on the resin. Figure 2: Continuous IX Process SM/Technical Paper 192 The lower cost of sulphuric acid makes it an attractive IX regenerant chemical however, October 2008 TECHNICAL PAPER 192 when used with a Ba loaded resin insoluble BaSO4 is almost immediately produced. This results in fouling of the resin bead surface and the accumulation of solid material within the resin bed. A microscopic photograph of a Ba fouled resin bead is shown in Figure 3. In this case the resin had only been in service for 3 days when treating a stream containing 1 ppm-Ba and regenerated with sulphuric acid. It was possible to remove some of the BaSO4 by taking the resin out of the column and immersing it in HCl. Other cleaning chemicals such as EDTA and NaCl were found to be ineffective. The first method simply involves dosing sulphuric acid into the feed stream. The patent(9) indicates that the invention can be used as pretreatment for cation exchange or reverse osmosis to reduce fouling. As already noted the solubility limit of BaSO4 is 1 ppm as Ba, which like Ca does not depend on the level of SO4 present. Therefore, adding sulphuric acid will not drop the Ba level below 1 ppm. When using sulphuric acid the Ba level in the feed to the IX unit needs to be <0.1 ppm. Therefore, this method is not a viable pretreatment method for an IX unit regenerated with sulphuric acid. The patent abstract for the second method indicates the invention is particularly useful for BaSO4 scale control in acid cycle water softeners. Beaker scale tests were conducted by dosing PESA into 50 g/L sulphuric acid and then adding BaCl2. There was no increase in the soluble level of Ba in any of these tests regardless of dosage or contact time. Essentially all the solutions became turbid immediately upon dosing of the Ba. This indicates that this chemistry will not prevent Ba fouling during sulphuric acid regeneration. Figure 3: Fouled Ba Resin Bed Of course the most obvious way to avoid BaSO4 fouling is to use HCl or if using sulphuric to first remove Ba using a Na cycle softener. The selection is governed by the overall economics of the system. Alternate methods that have been proposed for Ba control when using a sulphuric acid regenerant include a “Rapid Barium Removal” process(7), scale inhibitors such as polyepoxysuccinic acid, PESA(8), and so called “trickle filters”. SM/Technical Paper 192 The final method is reported to involve passing the CBM stream through a channel of particulate gypsum. Possibly the sulphate in the gypsum or surface exchange on the gypsum particle would be responsible for Ba removal. Another beaker scale test was conducted using a large excess of freshly prepared gypsum and a solution containing 1 ppm Ba. The liquid was filtered after mixing for more than 24 hours. There was no change in the Ba concentration. This suggests that this method may also not be viable. No information concerning design or performance of these “trickle filters” could be found. October 2008 TECHNICAL PAPER 192 Fe CONTROL - Fe fouling of softener resins is a common problem. It occurs when insoluble ferric iron is carried into the softener bed or forms on the resin as a result of oxidation of ferrous ion previously exchanged onto the resin. The use of HCl as the regenerant or periodic cleaning solution helps to prevent Fe fouling by redissolving any colloidal ferric iron. Beaker scale cleaning tests of Fe fouled resin have shown that sulphuric acid is not nearly as effective as HCl. It would also be possible to remove Fe upstream of an IX unit by treatment with manganese greensand filtration. Other common practices include adding chemicals to the regenerant salt such as hydrosulphite, preventing solution exposure to oxygen and using oxygen scavengers such as ammonium bisulphite. Figure 4 is a picture of a pilot plant filtrate tank. The filtrate was clear upon leaving the filter. The photograph shows the tank contents after sitting exposed to air for only a few hours. The stored filtrate became very turbid and had a yellow/orange colour characteristic of colloidal iron. Obviously processing such a fouled solution would result in rapid fouling of IX resin. Figure 5 shows the same filtrate solution before and after acidification with HCl. The Fe level in this feed was 3 – 4 ppm. Figure 4: Pilot Plant Filtrate Tank SM/Technical Paper 192 Figure 5: Filtrate Solution Before and After Acidification with HCl REMOTE LOCATION AND WASTE DISPOSAL - In many cases the CBM well sites are in remote locations and therefore consideration must be given to processes and equipment that are reliable and require minimal operator attention. All processes that are used to improve the quality of CBM water result in the production of waste. For example, this would be the spent regenerant and rinse streams in the case of ion exchange, the reject stream from an RO, or the concentrate stream from an EDR process. Generally this waste is stored onsite and evaporated in lined holding ponds that must ultimately be remediated or it is shipped offsite for deep well injection. Both options are costly and therefore consideration must be given to minimizing the volume of waste produced. In the case of IX regenerant streams the recovery of the waste salts (NaCl or Na2SO4) have been proposed. In most cases this requires additional processing to purify and crystallize the material and then establishment of a market. The additional capital equipment, the logistics of shipment, and the difficulty in marketing relatively small quantities of salt makes waste recovery uneconomic relative to the current practices. October 2008 TECHNICAL PAPER 192 SHORT BED ION EXCHANGE Short bed ion exchange is a packed bed system that can be described as a compressed, short bed (CSB) ion exchange process. An overview of packed bed technology and some of the theory of short bed systems is presented in reference (10). It is characterized by the combination of a number of design features and benefits: Fine Mesh Resins (Fig 6 – Using resin beads having a mean diameter of 20% of that commonly used in ion exchange processes (Figure 7), results in a very high surface area. This means that a greater proportion of exchange sites are at the surface of the resin particles. Since the rate of ion exchange is dependant on the rate of diffusion of ions to exchange sites, a greater proportion of surface exchange sites can be accessed rapidly through diffusion of ions through the liquid film around the resin particles rather than through the much slower process of intra-particle diffusion to access internal resin sites. Consequently, contact time required in the resin bed is short. This allows flow velocities of 30 - 50 gpm/ft2 (73 – 122 m/hr). Figure 7: Conventional Ion Exchange Resin Low Resin Loading Depending on the application only 10% - 40% of the resin capacity is used in the process. This favours use of the surface exchange sites, which have the highest kinetics. Short Beds of Compressed Resin The high ion exchange kinetics of fine mesh resins, allows resin bed heights of only 3-6 inches (75 –150 mm). Resin is packed into resin columns under slight compression with no freeboard. This provides excellent flow distribution and eliminates any possibility of channeling. Low resin loading minimizes resin shrinking and swelling. Countercurrent, Short Regeneration Since the resin beds are fully packed, with no freeboard, countercurrent regeneration, which is the most chemically efficient approach, is employed using simple equipment designs. The short resin beds, and low loading permits regeneration of a resin bed in 30-90 seconds. Figure 6: Short Bed Ion Exchange Resin SM/Technical Paper 192 While these features offer many benefits the technology does require special attention with regards to pretreatment for the removal of suspended solids. Any solids that pass into the resin bed are readily trapped by the fine mesh resin and since no freeboard space exists they cannot be October 2008 TECHNICAL PAPER 192 removed via backwashing within the column. The accumulation of solids results in a steady increase in pressure drop and a corresponding drop in flowrate and loss of system capacity. In practice, suspended solids should be removed from all streams being treated by ion exchange processes in order to prevent resin fouling and to address product water turbidity and TSS target limits. The greater sensitivity of packed bed systems necessitates higher levels of filtration efficiency. One of the most economic methods for removing suspended solids is via dual media filtration. A high efficiency filter of this type has been developed for use with short bed IX systems(10). A specialized polishing filtration media is used to achieve filtrate turbidity levels of 0.1 NTU. Pretreatment to this level prevents fouling of short bed systems. SHORT BED CBM PRODUCED WATER PROCESS FLOWSHEET Short bed technology is now been applied to the treatment of a CBM produced water stream in the Powder River Basin in Wyoming. FEED WATER AND TARGET VALUES The composition of the CBM produced water stream is demonstrated in Table 3. The effluent target values that must be achieved are shown in Table 4. SHORT BED CBM PRODUCED WATER SYSTEM - The process flowsheet is shown in Figure 8. The feed is collected in a holding pond and then pumped to the process. Given the feed composition and the final water quality target values only 721 gpm needs to be treated. The remaining 329 gpm bypasses the system and is recombined with the treated water, checked to confirm that the target values have been achieved and is then discharged to a river. SM/Technical Paper 192 After splitting the flows the first step in the treatment process is the removal of suspended solids using high efficiency dual media filters(10) (Spectrum filters). A coagulant (normally PAC) is used to ensure a low turbidity value in the filtrate. The filter backwash waste is recycled to the feed pond. Table 3: CBM Produced Water Stream Composition Value or Range Parameter Unit Flowrate gpm 1,050 Alkalinity mg/L as 2,010 HCO3 Sodium mg/L as Na 785 Chloride mg/L as Cl 17 Sulphate mg/L as SO4 11 Calcium mg/L as Ca 12 Magnesium mg/L as Mg 5 Conductivity µS/cm 2,800 pH --8.5 Iron mg/L as Fe 0.350 Barium mg/L as Ba 0.722 TSS mg/L <5 DOC mg/L as C 2 o Temperature C 2 – 21.5 Table 4: Target Values Parameter Units Value SAR --≤6 Chlorides mg/L as Cl 70 Dissolved µg/L as Fe 320 Iron pH pH --6.5 – 9.0 Specific µS/cm 1,215 Conductance Dissolved mg/L as Na 420 Sodium mg/L 810 Total Dissolved Solids October 2008 TECHNICAL PAPER 192 Figure 8: Process Flowsheet for Short Bed CBM Produced Water System The filters are followed by a short bed Na cycle Softener, Figure 9, that is used for Ba removal. The softener has a bed diameter of 5.5 ft, a depth of 0.5 ft and utilizes SAC resin. To avoid Fe fouling this softener is periodically rinsed with HCl. The softened water is then fed to another short bed system (decationizer) where Na is removed and the resin is regenerated using sulphuric acid. Figure 9: Na Cycle Softener SM/Technical Paper 192 The decationizer bed is 6 ft in diameter and 1 ft in depth and also uses SAC resin. Sulphuric acid was selected because it resulted in a lower overall cost per barrel of water (relative to the use of HCl) even when the additional softener capital and regenerant salt were included. During pilot testing regenerant consumption for this system was only 1.15x the stoichiometric minimum. Figure 10 shows the decationizer in the foreground with the inline softener of Figure 9 in the background. The spent regenerant and rinse solutions from both units are directed to an evaporation pond. The effluent stream leaving the Na removal unit is fed to a decarbonator for the removal of carbon dioxide. This raises the pH and minimizes the amount of lime that must be used to adjust the final pH and hardness level. This short bed process typically results in ≤ 2% of the stream being lost through operation of the softener and decationizer units. October 2008 TECHNICAL PAPER 192 PERFORMANCE DATA At the time of writing this paper the plant was still in the process of being commissioned and no performance data were available. The design of the ion exchange system was based on pilot plant operation and the results of these tests are shown below in Table 6. Table 6: Short Bed Pilot Plant Softener Data Cycle Time (min): 58 Figure 10: Decationizer The final step in the process is the recombination of the processed and bypassed streams, the inline addition of lime (or in some cases CaCl2) for pH and SAR adjustment and measurement of pH, hardness and conductivity before discharge. Out of compliance water is recycled back to the feed holding pond. Feed Regenerant Brine (150-g/L) Product Waste Regenerant Wash Ca Mg Na (mg/L) (mg/L) (g/L) 7.6 2 2.7 0.2 1.1 57.5 703.7 0.781 1.25 1130 1 549 n/a n/a 22 188.000 3.0 1250 305 n/a 161,800 Bed Volume 703.7 0.78 Ba (ug/L) 938 PROCESS ECONOMICS – Table 5 demonstrates the process economics for the Short Bed CBM Produced Water System. Table 5: Short Bed CBM Produced Water Economics Total CBM Water FeedFlowrate (gpm) Treated Flowrate (gpm) Feed Composition as per previous table Unit Units Consumption Price $0.24 $/lb 100% 0.272 Sulphuric Acid $3.54 $/gal 100% 0.0012 Coagulant (PAC) $0.39 $/lb 100% 0.00311 Hydrochloric Acid $0.08 $/lb 100% 0.04399 Sodium Chloride $0.08 $/lb 0.10305 Lime $0.06 $/kWh 0.06534 Electricity $0.54 $/bbl waste 0.009 Waste Total *bbl = 42 gal barrel of total CBM water feed **Waste based on financed cost for evaporation pond SM/Technical Paper 192 1,050 721 Units lb-100%/bbl lb-100%/bbl lb-100%/bbl lb-100%/bbl lb-100%/bbl KWh/bbl bbl-waste/bbl Cost/1000 gal of total CBM feed $1.55 $0.01 $0.03 $0.08 $0.20 $0.09 $0.12 $2.08 October 2008 TECHNICAL PAPER 192 It should be noted that since the softener process objective was only to remove Ba significant amounts of Ca and Mg were allowed to leak into the product stream. These levels could be lowered by a reduction of the feed volume treated. The results of the Decationizer are demonstrated in Table 7. Table 7: Short Bed Na Removal Decationizer – Pilot Plant Data Cycle Time (min): 7.34 Feed Conc.H2SO4 Regenerant (96%) Onstream Regen Bed Volume 18.2 0.028 17.3 1.0 Na Ca Mg H+ (mg/L) (mg/L) (g/L) (eq/L) 1158 n/a n/a n/a n/a 35.5 17.6 18612.9. n/a n/a 5. Bob Bradely, Mark Reinsel, “An Economical Process to Treat Produced Water From Coal Bed Methane Deposits in the Powder River Basin”, Proceedings of the 2001 International Water Conference - IWC, Paper# IWC-01-15. 6. Ronald Neil, US Patent Application 20060261010, November 23, 2006. 7. Applications Bulletin – CleanSweepBarium, http://www.tbeconline.com/id6.html 8. J. Michael Brown, US Patent 5,486,294, January 23, 1996. 9. Bruce W. Bandorick et al, US Patent 7,081,204, July 25, 2006. 10. Michael Sheedy, Peter Kuzora, “The Use of Short Bed Ion Exchange Technology for the Production of High Purity Water at WE Energies’ Pleasant Prairie Power Plant”, Proceedings of the 2004 International Water Conference – IWC. n/a n/a SUMMARY A short bed ion exchange process has been developed for the treatment of CBM produced water. The first system has been installed and is currently in the process of being commissioned. Field performance data are not yet available and may be the subject of a future paper or report. REFERENCES 1. Juzer Jangbarwala, “CBM-Produced Water A Synopsis of Effects and Opportunities” Water Conditioning and Purification, December 2007. 2. I. R. Higgins, US Patent 2,815,322, December 3, 1957. Irwin R. Higgins, Mark S. Denton, “CSA Continuous Countercurrent Ion Exchange (CCIX) Technology” Separation Science and Technology, v 19, March 1987 p 997 - 1015. 3. 4. Juzer Jangbarwala, US Patent 6,776,913, August 17, 2004. SM/Technical Paper 192 October 2008