SOLAR ENERGY FOR COOKING AT CENTER FOR COMMUNITY YOUTH

SUPPORT

Prepared by Sydney Kambalikena

10 October 2021

1

INTRODUCTION

Project background

Center for Community Youth Support (CCYS) is a community-based organization located in the out

skirt of Lilongwe city, Malawi. The organization has been implementing a number of community

development initiatives since 2012. Fore among the community development initiatives is the feeding

program, which caters for 380 pupils and 48 secondary school female students proving them with

breakfast, lunch and supper. The program has been instrumental in motivating students to remain in

school. Despite many other expenditures associated with the program, one of the biggest expenses

associated with the program is purchasing firewood for cooking. The Malawi government has been

discouraging people from using firewood for cooking to reduce deforestation and global warming

which has greatly affected the country. CCYS made a request with electricity supply corporation of

Malawi (ESCOM) to get electricity, but that request has remained unattended to for the past six years

now. As things stand, exploring other options to get energy for cooking is the best way forward.

Location

CCYS is located in Area 25 Lilongwe, Malawi. The catchment area covers five villages namely; Tsale,

Pheleni, Mzumanzi 1, Mzumanzi 2, and Galeta. Below is the satellite image of the site.

PROJECT MAIN OBJECTIVE

The project main objective is to come up with the solar system which will provide power for cooking.

2

Specific Objectives

To come up with a solar system size to provide power for cooking

Select the type and size of electric pots to be used for cooking

Layout drawing for the system setup

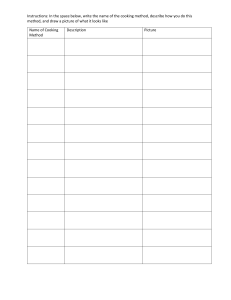

METHODOLOGY

General methodology

A visit was made to CCYS to obtain the basic data which will be used to design the system. The

following basic data were obtained during the visit;

Number of pupils/ students fed with porridge, lunch and supper

Size of pots used for cooking

Time and period for preparing food

Selection of electric pots

Based on the assessment two 60-liters electric pots were selected to be used for cooking of 12kw each

3 phase.

LOAD POWER ANALYSIS FOR THE SYSTEM

Food

# of

people

fed

Breakfast

385

(Porridge)

Lunch

Supper

48

48

Size of pot

used

Coking

period

Times

(hrs.)

Pot

wattage

1.5

12000

0.8

14400

9am-10:30am

1.5

12000

0.5

9000

(9am-10am)

1

12000

0.5

6000

3pm-4:30pm

1.5

12000

0.5

9000

3pm-4pm

1

12000

0.5

6000

1

18

1

108

60L pot (1pot) 7am-9am

40L

pot

(Nsima/ rice)

20L

pot

(relish)

40L

pot

(Nsima/relish)

20

liters

(relish)

Loading

factor

Used power

(Kwh)

Additional

loads

Indoor

9

lights

2

Security

9

lights

12

Total

required

power

The total daily energy requirement to power the loads per day 44536wh

3

44526

BATTERY STORAGE

Considerations

The PV plant will provide all the power for cooking considering that all the cooking activities will be

done during the day when there is the sun, but in case of times when there is low power output from

solar system then, the battery will support the solar panels. The battery will be designed to provide

half of the required power to support the solar panels during low power output.

Daily energy requirement= 44526wh

Designed daily battery capacity=44526wh/2=22263wh

Days of autonomy=1

Depth of discharge (DoD)=80%

DC input battery input=48V dc

Required battery capacity= (daily energy requirement ×days of autonomy)/ (system voltage× DoD)

=22263h ×1) / (48×0.8)

= 579Ah @48v DC

Option

Battery

type

Battery

life span

1

Lead

acid

GEL

Lithium

ion

3 years

Battery

system

capacity

579ah

10 years

579ah

2

Battery

capacity

System

voltage

200ah @ 48v DC

12v

200ah

@48v

48v DC

Number

of

batteries

12

Unit cost

(U$)

Total cost

(U$)

365.86

4,390.32

3

3,048.78

9,146.34

INVERTER

The inverter size is determined by adding the AC loads and then multiply with safety factor.

Inverter capacity=daily load demand (w) ×safety factor

= ({0.8 x 12000+0.5 X 12000} ×1.25

=19500w

Therefore, 30kva inverter capacity is selected to power the AC loads.

4

PV ARRAY CAPACITY

Considerations

Required dairy energy demand: 44526wh

Selected PV module:300w, 36V,8.3A; Isc =8.9, VOC =44.

Selected PV input voltage :350v DC

Design sunshine hours for Lilongwe:6 hours per day

Battery voltage: 48V

PV capacity= Dairy energy demand / (sun shine hours ×de-rating factors)

=44526w/ (6h×0.8)

=9276.25w

Number of Panels in series Nps=350v/36v

=10

Number of series strings Npp

=9276.25/ (10 ×300)

=3

Total number of panels = Nps × Npp =3×10

=30 panels

Adjusted system capacity for the system =30×300w=9kw

CHARGE CONTROLLER

Considerations

Selected PV module:200w, 30V,8.2A; Isc =8.9, VOC =44.

Model: GTE -300W-P-72-(Vmp=36V)

Type: Monocrystalline

Charge controller size=Number of modules in parallel × Isc × safety factor

=3×8.9×1.25

=34A

5

SYSTEM SUMMARY

The proposed system design consists of the following details:

SOLAR PV SYSTEM

Components

Description

Solar Panels

Lithium-Ion Batteries

Inverter

Combiner box

Battery isolator

PV structure

Cables

and

accessories

Total

6

other

300w

–

Monocrystalline

200AH @48V DC

30kva

Fused, surge and

isolator type

QTY Unit price (U$)

Total Price

(U$)

30

6600

3

1

220

3659

9756.1

2

243

486

metal type

2

1

121

609.8

242

609.8

bunch

1

621

621

10977

9756.1

29291.9

SCHEMATIC LAYOUT DIAGRAM OF THE SYSTEM

PV Array

DC Bus

Inverter

Battery

Bank

Pot 1

Kitchen layout

5m

2m

6.5m

Power Room

veranda

7

4m

Pot

1

2m

Pot

2

Pot 2

Site for Extension 6.5 meters by 11meters

8