Generation of a Tachometer Signal from a

Smart Vibration Sensor

Eric Bechhoefer, GPMS

Ed Spence, The Machine Instrumentation Group

Presented at the MFPT 2018

Virginia Beach, VA, 15-17 May 2018

Introduction

TSA, commonly applied for shaft, gear and bearing

analysis, requires a Tach

A Tach cannot be applied in some applications

A novel, 2-process is introduced to generate a high

quality Tach signal from the vibration data

– Cyclic rate of the shaft is reconstructed by removing extraneous

vibration data with an idealized BPF

– Then remove jitter from the resulting signal

Tach signal can then be used for TSA averaging and

TSA resampling algorithms

Technique is demonstrated on two data sets

Generation of a Tachometer Signal from a Smart

Vibration Sensor

Some History

– S. BRAUN. The extraction of periodic waveforms by time

domain averaging. Acustica, 32 (1975)

TSA

– R, Stewart: Some Useful Data Analysis Techniques for

Gearbox Diagnostics, Institute of Sound and Vibration

Research, Proceeding of Meeting on Application of Time

Series Analysis, Sept. 1977

FM0/1/2/3/4,Residual, Envelope Analysis

– Foundation for Modern Gearbox Analysis.

Note: Stewart Comments on Tach Jitter, states that

there is a limit to the number of Revs for the TSA

3

The Need for a Tachometer

• Common to use FFT for Condition

Monitoring Analysis

– Frequency Magnitude and Phase

– Idealized Filtering for Residual Analysis

– Hilbert Transform for Amplitude and

Frequency Modulation, Envelope analysis.

• FFT Assumptions

– Infinitely Long Signal (e.g. Gibb’s Effect)

• Finite effects mitigated by windowing

(Hamming, Hann, etc.)

– Signal is Stationary – e.g. Exhibits

Stationarity

4

Stationarity and Stationary Signals

Implies that the conditions of the signal do not

change

Shaft rate always changing

– Bandwidth limits of the feedback from controller

Lack of Stationarity degrades spectral analysis

– Spectral smearing

Reduces the probability of fault detection

5

The Resample Algorithm

• Restores Stationarity by

resampling

• TSA removes nonsynchronous noise

– Reduces Asynchronous

Signals by 1/Sqrt(n) is

“consistent”

– Usually Radix-2

– One Rev based on number

of samples measured by the

key phasor, e.g. the Tach

– ex: 824 samples in a rev is

resampled to 1024

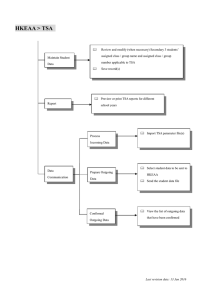

TSA Algorithm

Set TSA Length

m = 2ceil(log2(r))

tsa = zero(m ,1)

For i = 1:N

Revolutions

Resample r data

points into M data

points

tsa = tsa + M

Resam ple Algorithm

Set Segment Length

ceil(log2(r))

m=2

samp = zero(m*N,1)

For i = 1:N

Revolutions

indx = i*m + 1:m

Resample r data

points into M data

points

samp(indx ) = M

tsa = tsa/ N

Get Apparent Sam ple Rate

TSA = DFT(tsa)

Spectrum = Welches(sam p)

6

The Tachometer Signal

Taken as the rising edge of a Key Phasor

– Variable Reluctance (e.g. Generator Signal)

– NPN or PNP (e.g. Hall or Optical Sensor)

Two Method for calculating Zero Cross Time

– ADC: Sample the signal and post process for zero cross.

Limited to sample rate (e.g. 100,000 sps)

– Comparator on Microcontroller GPIO Pin. Essentially the

clock speed of the Micro (50 MHz, etc.)

Jitter reduces the “consistency” of the Tach signal

– Generally, more Revs does not improve TSA

7

Why “Tachless” Vibration Monitoring

Some applications cannot implement a Tach

– e.g. Glandless Pump due to high temperature and

pressure (see BCP paper, MFPT 2018)

– Introduction would require expensive re-certification

(e.g HUMS)

HUMS adoption is an ROI calculation.

– Removing Tach reduces cost

– One less sensor reduces weight (less rotorcraft fuel)

– Smart vibration sensors

Local Processing of tachometer and vibration to reduce cost

and weight

8

Generating Tach from Vibration is a 2-step

process...

Tach derived from the vibration signal still includes jitter

– Need to reprocess to remove

Theory: Vibration is synchronous with a shaft

– Pick a Vibration Signal, say a gear mesh (27 tooth)

– Count 27 zero crossings, and call that time the ‘Tach Zero

Cross’

– Unfortunately, time domain signal is superposition of many

signals...

Thesis: process the signal to...

– Remove extraneous signals (ex. Noise, shaft harmonics, gear

mesh frequencies, etc)

– Use the Analytic Signal for calculating the Zero Crossing

9

Using Analytic Signal for deriving Time of Zero Cross

• Hilbert Transform

defined as

Gs

0

0

-0.5

-0.5

-1

-1

0

0.4

0.2

0.6

0.8

0

1

0.4

0.2

0.6

1

0.8

Time (sec)

Reconstructed Zero Cross

Time (sec)

(Sa))

unwrap(atan(as))

• Ex: 2 Hz Sine

1

10

0.8

Radians

– Imaginary Part of Sa

is Signal + π/2

– Zero Cross is the

Interpolated Time

every 2π

0.5

0.5

Time (sec)

S = F{s(t)}

Sa(f) = S(f), f = 0

Sa(f) = 0, f < 0

Sa(f) = 2Sa(f), f > 0

sa(t) = F-1 (Sa(f))

1

Real

Image

Gs

–

–

–

–

–

Analytic Signal

2 Hz Sine, 1000 sps

1

8

6

4

2

0.6

0.4

0.2

0

0

0

2

4

Angle (Radians)

6

0

2

4

6

Angle (Radians)

10

Prior Art

•

Bonnardot et. al (2007) demonstrated

tach from vibe using the analytic signal

–

•

Implemented a band pass filter filter centered

on a gear mesh

Band pass filters “leak”

– 29 Hz shaft, 32 tooth: 928 Hz Gear Mesh

– 120 tap FIR filter

– Filter does not reject 1/Rev side bands,

corrupts zero cross signal, reducing SNR

•

•

•

Phase Error (e.g. zct) is a function of SNR

σ[δ]=1/sqrt(2)10-snr/20

6-8dB SNR is typical, or about 6 to 10

degrees of phase error

11

Improved Tach from Vibe Using Idealized Filter

(Recipe*)

• Calculate radix-2 length for the

FFT.

• Calculate the low and high

bandwidth index (bwlow, bwhigh),

which are centered are a know

gear mesh

• Take the zero padded FFT of the

vibration data

• Zero the FFT from zero to bwlow,

and from bwhigh to nRadix

• Take the inverse FFT

• Calculate the unwrapped argument

of the signal from 1 to n time series

• Normalize the time series of radians

by the number of teeth of the gear

(assuming 1st harmonics)

• Interpolate the number of indexes

for every 2 radians

• Normalized to tachometer zero

crossing times by sr.

*Much more tractable with a distributed processing approach...

12

Example of Idealized filter vs. FIR filter

• 97,656 sps x 6 x sec

– 585,936 -> 1,048,576 pt FFT

• 29 Hz Shaft, 32 tooth Gear

– 928 Hz +/- 29 Hz

– Bandwidth of Filter 910 and

960 Hz

– bwlow = 920/sr x 1,048,576 =

9771

– bwhigh = 960 / 97,656 *

1,048,576 = 10,308.

– Sa(f) = 0, f < bwlow, f > bwhigh

13

Controlling Jitter – Prior Art

A previous paper* described a 25% Improvement in

analysis by reducing jitter – with Tach...

Developed a zero phase IIR filter procedure to remove

noise not associated with changed in shaft speed

IIR filters are not ideal

– New procedure uses Idealized filter...

*Improving Gear Fault Detection by Reducing Tachometer Jitter, AHS 2015

14

Application of a New and Improved Jitter

Reduction Procedure (Recipe)

•

•

•

•

•

•

•

•

•

•

Take the pseudo derivative of the tachometer

signal

Calculate the the radix-2 length of the pseudo

derivative signal of length n

Zero pad the array from n to the radix-2 length

Calculate the bandwidth index of the FFT

Idx = floor(bandwidth * radix-2 length / 2);

Bandwidth is a normalized value, typically 0.12

Take the real FFT of the zero padded derivative

signal

Set the real and imaginary parts of the FFT

from Idx to the radix-2 length

Take the inverse real FFT.

Reconstruct the tachometer signal by taking

the pseudo integral of the signal

Data set from a wind turbine with 8 targets per revolution.

The periodic peaks are due to spacing error in the tachometer

target, which introduces non-random jitter error.

The idealized filter removes all the spectral power (jitter)

15

Ex 1. High Speed Pinion on a Wind Turbine

Wind turbine conditions:

• SR: 97,656

• 30 Hz Shaft

• Cracked Tooth On Pinion

• Tach from Hall Sensor

Using Comparator

• 6 dB SNR data prior jitter

reduction

Comparison of Tach signal vs. Tach-less Solution

16

TSA Comparison

17

Tach vs. Tachless for Standard CIs

Analysis

Tach

Tach from Vibe

SO1

0.0100 g

0.0104 g

SO2

0.0013 g

0.0016 g

SO3

0.0019 g

0.0018 g

TSA RMS

0.5091 g

0.4828 g

TSA P2P

2.0887 g

1.8430 g

FM0

4.278

4

AM RMS

0.100 g

0.099 g

AM Kurtosis

4.242

4.217

FM RMS

0.428 radians

0.426 radians

FM Kurtosis

4.995

4.844

18

Tail Rotor Intermediate Gearbox Pinion Fault

Comparison of Tach vs. Tach-less Solution

• SR: 100,000

• VR Tach on 500 Hz Shaft,

22 tooth

• Shaft Under Analysis is

~68.5 Hz

• 12 dB SNR

• Tach time generated via

ADC

Note the high level of Jitter on the VR tach

19

TSAs differ only in phase

20

Tach vs. Tachless for Standard CIs

Analysis

SO1

Tach

0.043g

Tach from Vibe

0.043g

SO2

0.283 g

0.282 g

SO3

1.855 g

1.85g

TSA RMS

81.646 g

81.591g

TSA P2P

222.77g

223.02g

FM0

16.94

15.38

AM RMS

17.06g

17.06g

AM Kurtosis

4.126

4.126

FM RMS

3.037 radians

3.048 radians

FM Kurtosis

2.46

2.45

21

Implementation Issues

Very Difficult to Implement Long FFT

on an Embedded System

– Floating point (32b)

• breaks at 32K points

– Double precision (64b)

• Uses 2x RAM

• 5x slower

– Naive implementation (first

attempt) 15 minutes; improved

to run in 3 minutes

22

Conclusion

• Tach-less TSA was demonstrated

on two fault cases

• Analysis Results Between Tach

and Tach-less TSA were

indistinguishable

• Tach-less Smart Vibration Sensor

can be implemented to reduce

the cost of a HUMS installation

• Goal: lower cost HUMS

installation for Type 27 AC

(<9,000 lbs)

Smart

Vibration

Sensor

23

24