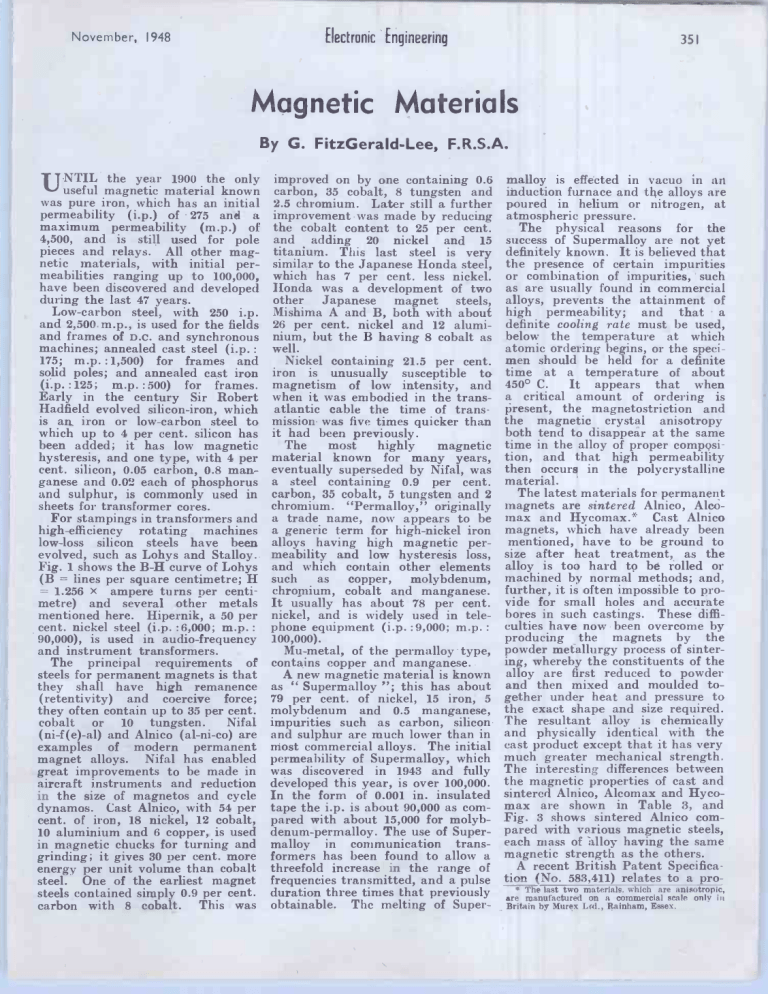

November, 1948 Electronic Engineering 351 Magnetic Materials By G. FitzGerald-Lee, F.R.S.A. NTIL the year 1900 the only improved on by one containing 0.6 malloy is effected in vacuo in an carbon, 35 cobalt, 8 tungsten and induction furnace and the alloys are 2.5 chromium. Later still a further poured in helium or nitrogen, at improvement was made by reducing atmospheric pressure. The physical reasons for the the cobalt content to 25 per cent. 4,500, and is still used for pole and adding 20 nickel and 15 success of Supermalloy are not yet pieces and relays. All other mag- titanium. This last steel is very definitely known. It is believed that netic materials, with initial per- similar to the Japanese Honda steel, the presence of certain impurities meabilities ranging up to 100,000, which has 7 per cent. less nickel. or combination of impurities, such have been discovered and developed Honda was a development of two as are usually found in commercial during the last 47 years. other Japanese magnet steels, alloys, prevents the attainment of Low -carbon steel, with 250 i.p. Mishima A and B, both with about high permeability; and that a and 2,500 m.p., is used for the fields 26 per cent, nickel and 12 alumi- definite cooling rate must be used, and frames of D.C. and synchronous nium, but the B having 8 cobalt as below the temperature at which atomic ordering begins, or the specimachines; annealed cast steel (i.p.: well. 175; m.p. :1,500) for frames and Nickel containing 21.5 per cent. men should be held for a definite solid poles; and annealed cast iron iron is unusually susceptible to time at a temperature of about (i.p. :125; m.p. :500) for frames. magnetism of low intensity, and 450° C. It appears that when Early in the century Sir Robert when it was embodied in the trans- a critical amount of ordering is Hadfield evolved silicon -iron, which atlantic cable the time of trans- present, the magnetostriction and is an, iron or low -carbon steel to mission was five times quicker than the magnetic crystal anisotropy both tend to disappeir at the same which up to 4 per cent. silicon has it had been previously. been added; it has low magnetic The most highly magnetic time in the alloy of proper composihysteresis, and one type, with 4 per material known for many years, tion, and that high permeability cent. silicon, 0.05 carbon, 0.8 man- eventually superseded by Nifal, was then occurs in the polycrystalline ki useful magnetic material known was pure iron, which has an initial permeability (i.p.) of 275 and a maximum permeability (m.p.) of ganese and 0.02 each of phosphorus a steel containing 0.9 per cent. and sulphur, is commonly used in carbon, 35 cobalt, 5 tungsten and 2 sheets for transformer cores. chromium. "Permalloy," originally For stampings in transformers and a trade name, now appears to be high -efficiency rotating machines a generic term for high -nickel iron material. The latest materials for permanent magnets are sintered Alnico, Alcomax and Hycomax.* Cast Alnico magnets, which have already been alloys having high magnetic per- mentioned, have to be ground to evolved, such as Lohys and Stalloy. meability and low hysteresis loss, size after heat treatment, as the Fig. 1 shows the B -H curve of Lohys and which contain other elements alloy is too hard to be rolled or low -loss silicon steels have been (B = lines per square centimetre; H = 1.256 X ampere turns per centimetre) and several other metals mentioned here. Hipernik, a 50 per cent. nickel steel (i.p. :6,000; m.p.: 90,000), is used in audio -frequency and instrument transformers. The principal requirements of steels for permanent magnets is that they shall have high remanence (retentivity) and coercive force; they often contain up to 35 per cent. cobalt or 10 tungsten. Nifal (ni-f(e)-al) and Alnico (al-ni-co) are examples of modern permanent magnet alloys. Nifal has enabled great improvements to be made in aircraft instruments and reduction as copper, molybdenum, machined by normal methods; and, chromium, cobalt and manganese. further, it is often impossible to pro- such It usually has about 78 per cent. vide for small holes and accurate nickel, and is widely used in tele- bores in such castings. These diffi- culties have now been overcome by producing the magnets by the Mu -metal, of the permalloy type, powder metallurgy process of sintering, whereby the constituents of the contains copper and manganese. A new magnetic material is known alloy are first reduced to powder phone equipment (i.p. :9,000; m.p. : 100,000). and then mixed and moulded together under heat and pressure to the exact shape and size required. The resultant alloy is chemically and sulphur are much lower than in and physically identical with the Most commercial alloys. The initial cast product except that it has very permeability of Supermalloy, which much greater mechanical strength. was discovered in 1943 and fully The interesting differences between as "Supermalloy "; this has about 79 per cent. of nickel, 15 iron, 5 molybdenum and 0.5 manganese, impurities such as carbon, silicon developed this year, is over 100,000. the magnetic properties of cast and in the size of magnetos and cycle In the form of 0.001 in. insulated sintered Alnico, Alcoraax and Hycodynamos. Cast Alnico, with 54 per tape the i.p. is about 90,000 as com- max are shown in Table 3, and cent. of iron, 18 nickel, 12 cobalt, pared with about 15,000 for molyb- Fig. 3 shows sintered Alnico com- denum-permalloy. The use of Superin magnetic chucks for turning and malloy in communication transgrinding; it gives 30 Der cent. more formers has been found to allow a energy per unit volume than cobalt threefold increase in the range of steel. One of the earliest magnet frequencies transmitted, and a pulse steels contained simply 0.9 per cent. duration three times that previously carbon with 8 cobalt. This was obtainable. The melting of Super10 aluminium and 6 copper,,. is used pared with various magnetic steels, each mass of alloy having the same magnetic strength as the others. A recent British Patent Specification (No. 583,411) relates to a pro- 7KT.& last two materials. which are anisotropie, are manufactured on a commercial scale only in Britain by Murex Lfd., Itainham, Essex. 352 Fig. I. November, 1948 Electronic Engineering B -H Curves for various magnetic 20 materials (a) From H=0-1.2, B=0-250 (b) From H=1.2-160, B=250-9,000 (c) From H=I60-1,000, B=9,000-20,000 18 Reference a. Permalloy b. Hipernik c. Pure Iron e. Cast steel, annealed iron, annealed g. Lohys. Carbon annealed steel d. Low 1. Cast 16 dg C ab 14 6 12 Rx 03 600 4 b 2 800 1000 cess of making an anisotropic permanent magnet in which an iron base alloy containing about 9 per cent. aluminium, 25 nickel and 21 cobalt is subjected to the action of a magnetic field while cooling from 25 50 75 100 125 150 f 10 per cent. The cooling in the magnetic field is effected at an average 200 rate of 0.5-15° C. per second, the maximum cooling rate of the guar ternary alloy of iron, aluminium, 6 L 150 solution temperature of may contain up to 5 per cent. of copper, titanium or silicon, or up to 1 per cent. zirconium, or any two or more of these elements un to 250 rl a 1,240° C. down to 650° C., and a precipitation or ageing heat -treatment is applied to the alloy before it is finally magnetised. The alloy nickel and cobalt being 10° per second with 21 per cent. nickel and 15° with 30 nickel. If silicon is present the cooling rate is less than 10° per second, and is slower still as the silicon content is increased; with zirconium present the cooling 2 Qc, rate should not exceed 1° per second. 100 Table 1 shows the coefficients of magnetic permeability and susceptibility of certain materials, those in a the first column being established by dividing' the magnetic induction produced by the magnetising force; and in the second column by dividing the magnetic intensity by the 5 magnetising force. 41 2 (.4rr 4 -npere-turn 6 )er CM 8 1.0 1.2 Table 2 gives the hysteretic contants, or Steinmetz coefficients, for various materials. November, 1948 TABLE I.-COEFFICIENTS OF MAGNETIC PROPERTIES Material very Annealed Perm. . 3,080 2,590 280 245 200 beneficial effect of purification of the material with respect to non-metallic substances such as carbon and oxygen was used to considerable advantage. It will be interesting during 25 10 439 ... manganese steel 280 18 170 1.4 11 Fig. 2 graphically recapitulates the development of magnetic materials from iron to Supermalloy; in Neumann's " 1040 " alloy the 37 Glass hard piano wire Annealed Norway iron 100 Susc. soft iron wire ... Annealed soft iron wire ... Moderately soft iron wire Annealed steel wire Hard -drawn steel wire Cobalt Hadfield 353 Electronic Engineering the next few years to see whether this progress can be maintained. TABLE 11.-HYSTERETIC CONSTANTS Material Hys. Con. Very soft iron wire Very thin soft sheet iron ... Thin good sheet iron Thick sheet iron ... Ordinary sheet iron Transformer cores ... Soft annealed cast steel Soft machine steel ... Cast steel Cast iron Hardened cast steel 0.002 0.0024 0.003 0.0033 0.004 0.005 0.038 0.0094 0.012 0.016 0.025 ... TABLE III.-COMPARATIVE MAGNETIC PROPERTIES 103 Br. in Coercivity Hc, in gauss oersteds product BH max. C 7100-7900 580-480 I.4 -1.8x 106 S 6400-7700 550-450 6300-7200 660-550 1.4-1.8x 108 Remanence Alloy 90 BO Standard "Alnico " 70 High Coercive 60 Fig. 2. Sixty years' development in 50 magnetic permeability. C - Energy . 1.4-1.66 x 106 " Alnico " S 5800-6400 640-590 1.4-1.66 x 106 High C 8000-8800 420-320 1.3-1.7 x 106 S 7300-8000 450-350 1.25-1.45 x 106 C 12700 570 4.3 x 106 S 11200 560 3.3 x 106 C 8500 790 2.7 x 106 7600-8200 820-760 2.4-2.8 x 106 Remanence 40 " Alnico " 30 " Alcomax 11 " 20 k' " Hycomax " 10 /9/4 IRON -- 1900 1690 /9 7 1952 /934 S SI. STEEL 1910 1920 1930 1940 1950 C = Cast S = Sintered Power Valve Protective C ircuit is common practice to protect ITthe grid or anode circuits of respect to A. A resistor R3 is current but not the grid current, arranged in the cathode circuit of the current flowing in such a direr. power valves with relays, whereby the valve so that it carries the anode tion that the potential of D is below that of the point C. The values of a change in current in either of R3 and 112 are in the same ratio as these circuits causes the anode the maximum permissible ratio supply to be cut off. This method, between the grid and anode curhowever, has the disadvantage that rents. Thus, during normal operathe relay may operate during the tion the potential of B is not above adjustment of the valve load or that of D, but if the grid current when transients are caused by falls or if the anode current rises switching in an associated part of CIRCUIT then B becomes less negative than BREAKER the circuit. D, then the diode V1 conducts, The accompanying diagram shows allowing relay RI, to open the key a simple and efficient safety circuit K. The circuit breaker comes into that does not suffer from the usual MAINS operation and removes the anode disadvantage outlined above, as it supply from the valve, thus preventoperates only when the ratio of grid ing damage. current to anode current falls below a RL When the load is being adjusted, predetermined safe operating value. or when transients occur, the grid A triode power valve obtains its bias and anode currents rise together, by means of the grid current flowand the circuit continues to operate ing in the grid resistor 111, and a normally. resistor, R2, is placed in series with -Communicated from the E.M.I. it so that the grid current places Laboratories. point B at a negative potential with