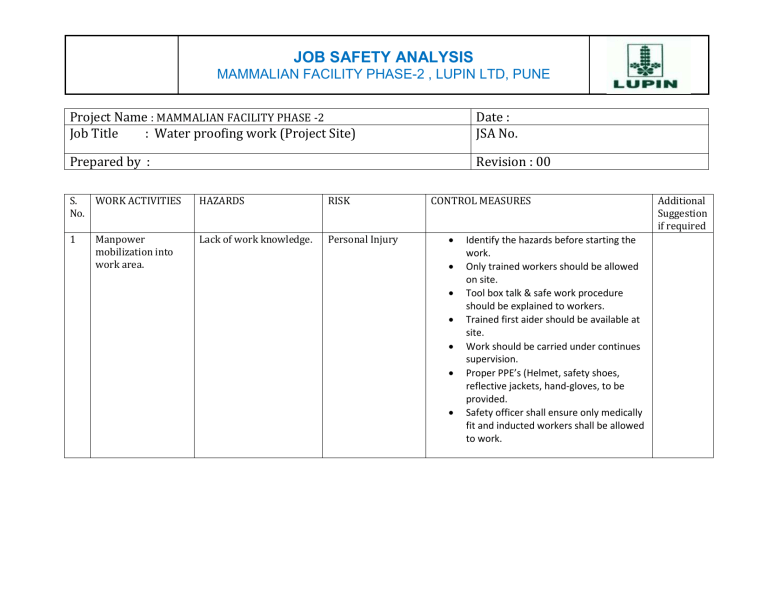

JOB SAFETY ANALYSIS MAMMALIAN FACILITY PHASE-2 , LUPIN LTD, PUNE Project Name : MAMMALIAN FACILITY PHASE -2 Job Title : Water proofing work (Project Site) Date : JSA No. Prepared by : Revision : 00 S. WORK ACTIVITIES No. HAZARDS RISK 1 Lack of work knowledge. Personal Injury Manpower mobilization into work area. CONTROL MEASURES Identify the hazards before starting the work. Only trained workers should be allowed on site. Tool box talk & safe work procedure should be explained to workers. Trained first aider should be available at site. Work should be carried under continues supervision. Proper PPE’s (Helmet, safety shoes, reflective jackets, hand-gloves, to be provided. Safety officer shall ensure only medically fit and inducted workers shall be allowed to work. Additional Suggestion if required JOB SAFETY ANALYSIS MAMMALIAN FACILITY PHASE-2 , LUPIN LTD, PUNE 2 Material shifting /Handling by manually/wheel barrow Mis-handling, fall of person on same level, Fall of material while shifting Physical injury 3 Cleaning by tar brush and grinder machine Hand cut hazards and electrical hazards. Physical injury 4 Mixing of water Fosroc X421IC chemical, cement and sand and applying. Cut injury, person may fall while applying waterproofing chemical incorrectly, electrical hazards, Inhalation and Eye irrigate Physical injury material damaged. Supervisor/engineer shall ensure the material shall be shifted safely on wheel borrow. Supervisor/engineer shall ensure shifted materials are stacked properly in a safe manner. Worker must be use nose mask and safety glass safety hand gloves during material shifting work. Supervisor/engineer shall ensure person using grinder must have inspected and mandatory PPE’s. Shall be use. Access and egress must be clear/free from obstruction before start the work. Worker must be use nose mask and safety glass safety hand gloves during cleaning work. Supervisor/engineer shall ensure person mixing of Fosroc X421IC and cement, sand and water is using dust mask and Rubber/PVC hand gloves other than mandatory PPE’s. Supervisor shall prepare standing platform. Supervisor/engineer shall ensure proper housekeeping before and after completion of job on each day. Electrician shall be ensuring mixing machine shall be inspected. Supervision shall be ensuring during JOB SAFETY ANALYSIS MAMMALIAN FACILITY PHASE-2 , LUPIN LTD, PUNE 5 In case of emergency Confusion & fear will be created in workers Personal injury the applying of Fosroc X421IC chemical person must have use safety Goggle and nose mask. Supervisor and safety officer shall be ensuring secondary contentment shall be present during the mixing work. Assembly points should be located at site Emergency contact number shall be displayed at site. Briefing shall be given at the time of induction & at regular intervals. Emergency vehicle should be ready at site. Trained first aider should be available at site. JOB SAFETY ANALYSIS MAMMALIAN FACILITY PHASE-2 , LUPIN LTD, PUNE Sr. No Specific Recommended Safe Job Procedures 1 Work Permit 2 Tool box talk for work 3 PPE’s Ensure and Area barricading Name of Responsible Persons Prepared by Prepared by Designation Signature Reviewed and approved by Reviewed by Reviewed by Approved by