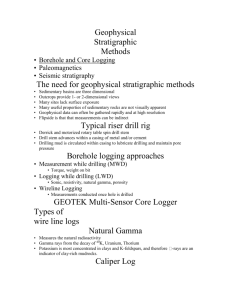

Basics well logging (fields Applications( Abbas Radhi Abbas عباس راضي عباس Iraq 2016 Contents 1. Introduction Define of well logging Uses of well logging in petroleum engineering Who use logs? who responsible for well logging? 2. Type of well logging Open hole logging -Conventional logs ( SP , GR , CAL , DLL , MSFL , Density , Neutron , sonic) -High tech logs : ( NMR , FMI , MDT ,SWC , VSP ) Cased hole logging - Cement bond log ( CBL and Image log ) - Production logging tools ( PLT ) - Reservior saturation log ( RST ) - casing inspection log ( MIT , MFC) 3. Log interpretation interpretation Procedure interpretation steps Calculation Petrophysical parameters (Vsh , φ , K , SW ) 4. Some pictures for logging truck and logging tools 2 1 Contents 1. introduction 2. Type of well logging 3.Log interpretation 4.Some pictures for logging truck and logging tools 3 2 Well Logs : are measurements of physical properties of the rock type ( porosity , permeability , volume of shale , water saturation ) related to depth by using ( Resistivity , Density , neutron , acoustic , SP , GR properties , etc ). 4 3 2-Uses of well logging in petroleum engineering 1. 2. 3. 4. 5. 6. 7. 8. 9. 5 Rock typing Identification of geological environment Reservoir fluid contact location Fracture detection Estimate of hydrocarbon in place Estimate of recoverable hydrocarbon Determination of water salinity Reservoir pressure determination Porosity/pore size distribution determination 4 Many Engineers use logging depend his requirements : 1. 2. 3. 4. 5. 6. 7. 6 Geologist Geophysics Petrophysics Engineer Reservoir Engineer Drilling Engineer Workover Engineer Completion Engineer 5 Petrophysics Engineer responsible for all logging : 1. design types of logging ( open Hole and cased Hole ) in vertical and directional wells . 2. Supervision during run logging tools in well site 3. Check all Quality of logging in well site 4. Do log interpretation by using interpretation software 7 6 Contents 1. introduction 2. Type of well logging 3.Log interpretation 4.Some pictures for logging truck and logging tools 8 7 Vertical well Horizontal well nI ofm r atoin Management, DrilnigEngnieernig, DaatMudolggnig, Rgi-SiteSupervsioin DrilnigDynamcis DrilnigFul diSysetms High Tech logs Conventional logs Fom r atoin EvaulatoinMWD Hgih Perofm r anceBits Seterabel Drilnig Systems 9 8 Conventional logs 1. Lithology logs : SP GR 2. Porosity logs : Density Neutron Sonic High tech logs Cased Hole logging 1. Nuclear magnetic resonance log (NMR) 2. Modular formation dynamic tester (MDT) 3. Micro resistivity Imaging 4.Sidewall core 5. Vertical seismic profile (VSP) 1. Cement evaluation log : (A) normal CBL , VDL , GR , CCL (B) Image cement evaluation SBT URS CBMT 2. production logging tools ( PLT) 3. Oil saturation log 4. Casing inspection log 3. Resistivity logs : Resistivity Induction 4. Caliper log 10 9 Open Hole logging Vertical well Horizontal well Information Management, DrillingEngineering, DataMudlogging, Rig-SiteSupervision DrillingDynamics DrillingFluidSystems Formation EvaluationMWD High Tech logs 11 Convention al logs 10 High PerformanceBits Steerable Drilling Systems Conventional logs 1. Lithology logs : SP GR 2. Porosity logs : Density Neutron Sonic 3. Resistivity logs : Resistivity Induction 4. Caliper log 12 11 -100 SP 0 100 5185 5195 Useful for: 5205 Detecting Shale 5215 permeable beds and it thickness. 5225 5235 5245 5255 Determining Sandstone 5265 formation water salinity . 5275 5285 5295 Qualitative Shale 5305 indication of bed shaliness. 5315 5325 5335 5345 Sandstone 5355 5365 5375 5385 5395 5405 5415 13 12 Shale GAMMA RAY LOG (GR) -100 • • • • • • Gamma ray log is measurement of natural radioactivity in formation 5185 It measures the radiation emitting from naturally occurring U, Th, and K. 5225 GR log is indictor for shale Correlation between wells, 0 GR 100 200 5195 5205 5215 Shale 5235 5245 5255 5265 Sandstone 5275 5285 5295 5305 Shale 5315 5325 Depth control for log all logs and perforation 5335 GR log can be run in both open and cased hole 5365 5345 5355 5375 Sandstone 5385 5395 5405 5415 14 13 Shale Correlation between wells by GR 15 14 SP , GR , CAL -Log 16 15 The acoustic/sonic log is a porosity log that measures the interval transit time of a compressional wave traveling through one foot of formation. The logging sonde consists of one or more transmitters, and two or more receivers. Modern acoustic/sonic logs are borehole compensated devices. 17 16 The formation density log is a porosity log that measures the electron density of the formation. The density logging tool consists of a radioactive source that emits gamma rays into the formation and one or more gamma ray detectors, located a fixed distance from the source. وهذا المجس يقيس كثافة الصخور والتي لها عالقة عكسية مع المسامية اذا كلما ازدادت المسامية كلما قلت الكثافة ويعتبر االنهيدرايت من اكثر الصخور كثافة اما . اقلها كثافة فهي الحجر الكلسي المسامي والدلومايت ذو الفجوات 18 17 Neutron logs are porosity logs that essentially measures the hydrogen concentration in a ”formation. In “clean formations, where the pore spaces are filled with water or oil, the neutron log measures liquid-filled porosity. وهذا المجس يقيس المسامية ايضا ولكن بصورة غير مباشرة اذا انه يقيس عدد ذرات الهيدروجين في الصخرة والتي لها عالقة بالمسامية عن طريق مصدر سيل من النيوترونات التي تصطدم بالهيروجين الموجود في الصخرة وكل ذرة هيدروجين موجودة في الصخرة تؤدي الى اصطياد نيوترون يصطدم بها وهكذا من معرفة عــدد النيوترونات التي اصطيدت نستطيع تقديــر عدد ذرات الهيدروجين في الصخرة وبالتالي المسامية لتلك الصخرة . 18 19 20 19 Lithology Using Porosity Log Combinations 21 20 Lithology Using Neutron-density cross plot Cross plot of Neutron-Density -Sandstone) 22 21 cross plot of Neutron-Density Limestone) Density and neutron behavior 23 22 Use to measure the resistivity of the formation, and thus the possibility of hydrocarbon shows. Many types of resistivity log use , but the famuse are ( MSFL , DLL) DLL : Dual Laterolog Resistivity( long “ RD” , short “ RS” ) MSFL : Micro Spherical Focused Laterolog 24 23 MSFL 1. • • High resistivity mean: Hydrocarbon Tight zone ( low porosity ) 2. Low resistivity mean: • Shale • water 3. Separation between resistivites mean • Formation fluid is different from drilling fluid . SFL Formation Fluid different from Drilling Fluid Formation Fluid similar to Drilling Fluid 25 24 26 25 Induction logs are used in wells that do not use water or mud, but oil-based drilling fluids or air. They are nonconductive and therefore cannot use electric logs instead they use magnetism and electricity to measure resistivity. 27 26 Rm – resistivity of the drilling mud Rmc – resistivity of the mud cake Rmf – resistivity of mud filtrate Rs – resistivity of shale Rt – resistivity of uninvited zone(true resistivity) Rw – resistivity of formation water Rxo – resistivity of flushed zone 28 27 Caliper Log 1-A caliper log is a well logging tool that provides a continuous measurement of the size and shape of a borehole along its depth The measurements that are recorded can be an important indicator of caving 2- this log use by cementing engineer to calculate the volume of cement . 29 28 30 29 A caliper log in horizontal well can not get it by wire line because wireline can cover to about 60 degree , after 60 degree can use another tools by LWD called ultra sonic caliper , this tools can give caliper log 2D and 3D 31 30 ultra sonic caliper , Example : this tools can give caliper log 2D and 3D 32 31 33 32 Classification of the wells Well types Drilling purpose - Exploration well Appraisal well Developmen t well ( - producer , water injection well) 34 Drilling depth - - short depth Medium depth Deeper 33 Well trajectory - Vertical well - Directional well Example :wire line logging program ( in vertical wells) No. 1 Interval 17-1/2" (OH) 13.375”(CH) 2 12-1/4" (OH) 9.625”(CH) 8-1/4"(OH) Depth(m) 120-2287 0-2287 2287-2893.8 -2893.8 2893.8-3208 Logging items 1) DLL*/MSFL/DT/GR/SP/CAL 1)CBMT/VDL/CCL/GR 1) DLL*/MSFL/DT/GR/SP/CAL 1)CBMT/VDL/CCL/GR 1) DLL*/MSFL/XDT/DEN/CNC/GR /SP/CAL 3 6.625”(CH) 35 -3208 1)CBMT/VDL/CCL/GR 34 DLL : Dual Laterolog Resistivity MSFL : Micro Spherical Focused Laterolog DT : Digital sonic GR : Gamma Ray SP : spontaneous potential log CAL : Caliper Log CBMT : Cement Bond Imaging log VDL : Variable Density log CCL : casing-collar locator XDT : Cross Dipole Sonic DEN : Density Log CNC : Compensated Neutron log 36 35 Run(1): GR/SP/CAL/DLL/MSFL/XDT Run(2): GR/DEN / CNS 37 36 Depth of investigation of logging tools 38 37 Common logs and what they measure 39 38 Open Hole logging Vertical well Horizontal well Information Management, DrillingEngineering, DataMudlogging, Rig-SiteSupervision DrillingDynamics DrillingFluidSystems Formation EvaluationMWD High Tech logs 40 Convention al logs 39 High PerformanceBits Steerable Drilling Systems 1. Nuclear magnetic resonance log (NMR) 2. Modular formation dynamic tester (MDT) 3. Micro resistivity Imaging (FMI) 4.Sidewall core (SWC) 5. Vertical seismic profile (VSP) 41 40 Application -Effective Porosity - Capillary Bound Water - Free Fluid - Clay Bound Water - Total Porosity 42 41 43 42 Micro Resistivity imaging log (FMI) Application 44 Fracture identification and characterization Thin-bed analysis Characterization of sedimentary bodies Structural analysis Secondary porosity evaluation 43 Example :Micro Resistivity imaging log In this interval XRMI fractures are fitted with coring fractures 45 44 MDT ( Modular formation dynamic tester) 46 45 MDT • MDT:Modular Dynamic Formation Tester is the tool through which we can test the formation and measure the formation pressure, temperature and get the pure reservoir fluid and water samples. Many name of this tools depend of companies (MDT, RFT RDT, RCI) Application 1. 2. 3. 4. 47 Identify the pressure test Identify the permeability Identify the fluid contact (OWC) Identify fluid type (Oil or Water) 46 MDT System 48 47 MDT Tool 49 48 MDT Technique 50 49 MDT Job Planning MDT job is designed after evaluating the open hole logs. There are few main points which should be keep in mind before planning the job. 1. Select the depth points for formation pressure. 2. Select at least three (3) pressure points in one bed. 3. Pressure points should fall in oil/gas zones and water bearing zone. 4. Select the oil/gas sample point, which should be clean and try to get it from top of the reservoir. 5. Also select a point for water sample in water bearing zone. 6. MDT oil/gas sample is very suitable for PVT analysis. 51 50 MDT INTERPRETATION Interpretation of MDT data is very interesting. For interpretation you have to make a graph between the formation pressure and depth. When you plot the formation pressure against the depth you will get the density gradient, values of which are given as under: Oil, Gas and Water has different gradients. 1-Gas = 0.55 g/cc 2-Oil = 0.88 g/cc 3-Water = 1.0 g/cc 52 51 Density calculation by MDT 53 52 Identify OWC by MDT MDT 54 53 Identify Fluid Type by MDT 55 54 56 55 57 56 Rotary Sidewall Coring system 58 57 59 58 60 59 Core analysis can be divided into two types: 1. Conventional core analysis . 2. Special core analysis . 1. Conventional core analysis . Provide information about lithology , residual fluid saturation , porosity and permeability . 61 60 2. Special core analysis . • • • • • • 62 Porosity and permeability at elevated confining stress . Electrical properties such as formation factor and. resistivity index . Capillary pressure. Wettability and relative permeability. Mechanical rock properties such as compressibility. Water food sensitivity for infectivity and well performance. 61 Drilling coring SWC Advantage: Advantage: the core is regular, cylindrical and little formation pollution. Easy, fast ,Low cost. The core can be used for many different analysis. Disadvantage: Disadvantage: High cost In the most case the core is irregularly ,small and destroyed. Complex The explosive device must be used in SWC operation, which is dangerous. Affecting drilling speed Low recovery rate, Especially in hard formation. 63 62 VSP : Vertical seismic profiles, as the name suggests, are run vertically in a wellbore to obtain detailed seismic response near the wellbore. After correcting for the very different geometry of such a survey, the results are presented in seismic section format. They can be correlated with conventional seismic data and with synthetic seismograms made from the sonic and density logs in the same wellbore. 64 63 Open Hole logging Vertical well High Tech logs 65 Convention al logs 64 Horizontal well Information Management, Drilling Engineering, Data Mudlogging, Rig-Site Supervision Drilling Dynamics Drilling Fluid Systems Formation Evaluation MWD High Performance Bits Steerable Drilling Systems 66 65 Logging design and procedure 67 66 Logging design and procedure 68 67 69 68 Some available measurement in LWD technology 1. Gamma Ray 2. Resistivity 3. One porosity log (Density & neutron & sonic) 4. Borehole caliper (Ultra sonic azimuthal caliper) Information Management, DrillingEngineering, DataMudlogging, Rig-SiteSupervision DrillingDynamics DrillingFluidSystems Formation EvaluationMWD High PerformanceBits Steerable Drilling Systems 70 69 The following is a list of available measurement in LWD: 1-Natural gamma ray 2-Spectral gamma ray 3-Azimuthal gamma ray 4-Gamma ray close to drill bit. 5-Density and photoelectric index 6-Neutron porosity 7-Borehole caliper 8-Ultra sonic azimuthal caliper 9-Density caliper 10-Attenuation and phase shift resistivities at different transmitter 11-spacings and frequencies 71 12-Resistivity at the drill bit 13-Deep directional resistivities 14-Compressional slowness 15-Shear slowness 16-Density borehole images 17-Resistivity borehole images 18-Formation tester and sampler 19-Formation pressure 20-Nuclear magnetic resonance 21-Seismic while drilling 22-Vertical seismic profile 70 72 71 73 72 GR & Resistivity distance from bit 74 73 Example : LWD for SLB LWD procedure : 1. Real time ( GR , Resistivity ) 2. Porosity trip log (one porosity log )/ GR, sonic or neutron) 75 74 Vertical well Horizontal well nI ofm r atoin Management, DrilnigEngnieernig, DaatMudolggnig, Rgi-SiteSupervsioin DrilnigDynamcis DrilnigFul diSysetms High Tech logs Conventional logs Fom r atoin EvaulatoinMWD Hgih Perofm r anceBits Seterabel Drilnig Systems 76 75 77 76 (2)Cased Hole logging Cement evaluation log : (A) normal CBL , VDL , GR , CCL (B) Image cement evaluation SBT ,URS ,CBMT 1 2 production logging tools ( PLT) Cased Hole logging reservoir saturation 3 log (RST) 4 78 Casing inspection log (MIT) 77 Cement Bond Log (CBL &CBMT) 79 78 Three types for cement log run in missan oil bellow table: fields , see No 80 LOG Long name Casing size Company 1 CBL Cement Bond Log 13-3/8” BHDC , COSL , WFD 2 CBM T 9- 5/8” 6-5/8” BHDC , COSL 3 URS Ultra sonic redial scanner 9- 5/8” 6-5/8” WFD Cement Bond Image Tool 79 13-3/8” CBL , VDL , GR , CCL Evaluation Criterion: • V.Good Cement CBL≤5% • Good Cement 5%< CBL≤15%; • Medium Cement 15%< CBL≤25% • Poor Cement CBL>25%. 81 80 (CBL) Cases 82 81 Cement Bond Image Log (CBMT) Evaluation Criterion: depend on ( ATAV) Free pipe ( 0 to≤ 2) db/ft · Poor cement (>2 to≤ 6) db/ft · Medium cement (>6 to≤10)db/ft · Good cement (>10 to≤12) db/ft · Very Good cement (>12 to 20) db/ft 83 82 Example : (CBMT) Attenuation Array Variable Attenuat ion Map VDL Variable Density Log Casing wave Bad cement Medium cement Bad cement Medium cement Bad cement Very Good cement Formation wave 84 83 Ultra sonic redial scanner(URS) Evaluation Criteria: depend on IMPD • • • • • • 85 ( IMPd<=0.38,"gas“ ( IMPd>0.38, IMPd<=2.3),"liquid gas-Fresh Wtr", ( IMPd>2.3, IMPd<=2.7),"Heavy drill fluid", ( IMPd>2.7, IMPd<=3.85),"low IMPd", ( IMPd>3.8, IMPd<=5),"medium IMPd", ( IMPd>5),"good IMPd") 84 Production Logging Tools -PLT 86 85 Production Profile Log Purpose a. Calculate water, oil and gas rate of each pay zone. b. Judge whether the sliding sleeve shuts or not and estimate which zone is primary water production layer. c. Determine gas production zone. d. Make sure the fluid level and production pressure by measuring whole interval. e. Make sure whether there is crossflow in the shut-in state. Three-phase flow 87 86 Shut-in Production Profile Log Production profile logging : Obtain the variation of the flow rate in each perforation, water production intervals and gas inlets etc, thus providing basis for taking stimulation treatments. Injection profile logging : Obtain the movement of the inject fluid or gas, the absorption quantity in each perforation and analysis of injection-production relation. 88 87 Production Profile Log 89 88 PLT-Quantitative interpretation 90 89 PLT-Quantitative interpretation 91 90 PLT-Quantitative interpretation 92 91 PLT-Tool introduction Flowmeter Continuous spinner flowmeter Fullbore spinner flowmeter Basket spinner flowmeter Radioactivity fluid density Water hold-up Temperature and Pressure Spontaneous Gamma ray and Cased Collar Located Caliper, Electromotion Centralizer and so on Surface Read-Out Production Logging Memory Production Logging 93 92 PLT-Quality control GR: Repeat measurements curves have similar shape, and the curves are consistent with the original gamma curves CCL: Curves change significantly, downhole tools such as sleeves and packers have obvious characteristics. Spinner: Good correlation, stability logging speed and no cross and abnormal. Density: Good repeatability, curves change significantly around the interface of oil and water, gas and water, oil and gas and the gas outlet orifice. Capacitance: Curves change stable in the zero-flow interval, in the oil-water interface, gas-water interface have significant changes. Pressure: Good repeatability, no significant abnormality. Temperature: Have significantly change in the liquid outlet orifice, shut-in curves have the same trend with the temperature curves when the well is produce . 94 93 PLT-Qualitative analysis spinn er Flowmeter second Main production zone: flowmeter curves change great main The greater the flowmeter curves change, the more liquid it produces or absorbs. third 95 94 PLT-Qualitative analysis Density & Capacitance Oil & Gas: Density decrease and capacitance increase Water: Density increase and capacitance decrease 96 95 Example for PLT Perforation interval Interpretation interval Zone A Oil B/D B/D 5.8 409.2 Contributions by phase Top m Bottom m 2972.0 2993.0 3016.0 2984.0 2996.0 3019.0 3045.0 3055.0 3045.0 3055.0 462.0 322.5 784.5B/D 3083.0 3066.0 3072.4 3079.9 3069.9 3077.0 3083.0 3.0 43.1 495.3 89.1 197.9 1697.6 92.1B/D 241.0B/D 2192.9B/D B 3065.0 97 Water Top m Bottom m SSD 0.0 2000.0 4000.0 415.0B/D Water 96 OIL Prepare PLT-tools in well site 98 97 reservoir saturation log (RST) the reservoir saturation log (RST) makes both formation sigma and C/O ratio measurements that allow the calculation of water saturation without the need for a resistivity log.. 99 98 reservoir saturation log (RST) Reservoir saturation tools such as the pulsed neutron (TDT) are still widely used. the reservoir saturation log (RST) makes both formation sigma and C/O ratio measurements that allow the calculation of water saturation without the need for a resistivity log.. In formations with high-salinity formation water, the sigma measurement has been used for several decades to determine water saturation. The C/O ratio measurement can accurately evaluate water saturation in moderate to high porosity formations regardless of water salinity. This calculation is particularly helpful if the water salinity is low or unknown. If the salinity of the formation water is high, the Dual-Burst Thermal Decay 100 99 Reservoir saturation log (RST) Time measurement is used. A combination of both measurements can be used to detect and quantify the presence of injection water of a different salinity from that of the connate water. Time-lapse measurements of water saturation can be used to monitor the performance of a well or reservoir over time. TDT logs have gone throufg many evolutionary changes over the years so reservoir monitoring is difficult, especial;;y in low porosity reservoirs. Some age related normalization and bore hole corrections are often needed to makes sense of the data. 101 100 Application of RST 1. 2. 3. 4. 5. 6. 7. 8. 9. 102 Formation evaluation behind casing Sigma, porosity, and C/O measurement in one trip in the wellbore Water saturation evaluation in old wells where modern open hole logs have not been run Measurement of water velocity inside casing, irrespective of wellbore angle (production logging) Measurement of near-wellbore water velocity outside the casing (remedial applications) Formation oil volume from C/O ratio, independent of formation water salinity Capture yields (H, Cl, Ca, Si, Fe, S, Gd, and Mg) Inelastic yields (C, O, Si, Ca, and Fe) Borehole salinity 101 Casing inspection log (MIT) 103 102 Casing insertion log (MIT) MIT= multi – Finger imaging tool (24 , 40 ,60 ) finger Applications • Monitoring internal casing corrosion or scale buildup • Evaluation of drilling wear • Identification of split, parted, or deformed casing • Evaluation of deformation caused by geomechanical factors 104 103 Example :Casing insertion log (MIT) 105 104 Contents 1. introduction 2. Type of well logging 3.Log interpretation 4.Some pictures for logging truck and logging tools 106 105 (3) Log interpretation 107 106 Petrophysical Interpretation Qualitative: Assessment of reservoir properties, fluid type form log pattern. Quantitative: Numerical estimation of reservoir properties of oil, water etc. 108 107 Qualitative interpretation of well logging • Estimation of effective porosity & permeability. • Estimation of volume of shale. • Estimation of hydrocarbon saturation. • Determination of the depth and thickness of net pay • Estimation of reserves of hydrocarbon. 109 108 interpretation Procedure The basic logs, which are required for the adequate formation evaluation, are: 1. Permeable zone logs (SP, GR, Caliper) 2. Resistivity logs (MFSL, Shallow and Deep resistivity logs),DLL 3. Porosity logs (Density, Neutron and Sonic). Generally, the permeable zone logs are presented in track one, the resistivity logs are run in track two and porosity logs on track three. Using such a set of logs, a log interpreter has to solve the following problems, (I). Where are the potential producing hydrocarbons zones? (II). How much hydrocarbons (oil or gas) do they contain? 110 109 interpretation steps First step: The first step in the log interpretation is to locate the permeable zones. Scanning the log in track one and it has a base line on the right, which is called the shale base line. This baseline indicates shale i.e., impermeable zones and swings to the left indicate clean zones- e.g., sand, limestone etc. The interpreter focuses his attention immediately on these permeable zones. Next step: To scan the resistivity logs in track 2 to see which of the zones of interest gives high resistivity readings. High resistivities reflect either hydrocarbons in the pores or low porosity. Next step: Scan the porosity logs on the track 3 to see which of the zones have good porosity against the high resistivity zones. Discard the tight formations. Select the interesting zones for the formation evaluation 111 110 Petrophysical parameters Petrophysical parameters determined From logs : 1.Vol. of shale (Vsh) 2.Porosity (φ) . 3.Permeability (K). 4.Water saturation (SW) 112 111 Porosity: Is the percentage of voids to the total volume of rock. It is measured as a percent and has the symbol The amount of internal space or voids in a given volume of rock is measure of the amount of fluids a rock will hold. The amount of void space that is interconnected, and so able to transmit fluids, is called effective porosity. Isolated pores and pore volume occupied by adsorbed water are excluded from a definition of effective porosity. 113 112 Permeability: Is the property a rock has to transmit fluids. It is related to porosity but is not always dependent upon it. Permeability is controlled by the size of the connecting passages (pore throats or capillaries) between pores. It is measured in darcies or millidarcies absolute permeability : the ability of a rock to transmit a single fluid when it is 100% saturated with that fluid Effective permeability : refers to the presence of two fluids in a rock, and is the ability of the rock to transmit a fluid in the presence of another fluid when the two fluids are immiscible Relative permeability : is the ratio between effective permeability of fluid at partial saturation, and the permeability at 100% saturation (absolute permeability). 114 113 Permeability can determined from : 1. Core analysis 2. From log 3. Well test analysis ( Build up test ) 4. Formation Tester (MDT , RFT ) 5. NMR Water saturation: Is the percentage of pore volume in a rock which is occupied by formation water. 115 114 Well logging data should provide LAS file in open hole to use it in software . 116 115 1.Shale volume from GR 117 116 1.1Shale volume from sp 118 117 2. porosity calculation Ø = ((ØD 2 + ØN 2)/2)1/2 ØD =(ᵨma - ᵨb)(ᵨma - ᵨf) – Vsh – (ᵨma - ᵨsh) / (ᵨma - ᵨf) ØN =(CN-LCOR-0.5*Vsh*Nsh)*0.01 -Nsh = Neutron value in shale -ᵨma =Matrix density of formation -ᵨb = Bulk density of formation -ᵨf = Fluid density in borehole -ᵨsh =Shale density -CN-LCOR= Value of matrix -ØD = Density porosity -ØN = Neutron porosity 119 118 3. permeability calculation Swb is set at (15 % - 25%) 120 119 4. water saturation calculation Use Archie Equation 121 120 Effective porosity Effective Porosity :The second step of shaly sand analysis is to determine the effective porosity of the formation i.e. determining porosity of the formation if it did not contain clay minerals. Effective Porosity from Neutron-Density Combinations: These values of neutron and density porosity corrected for the presence of clays are then used in the equations below to determine the effective porosity (-effective) of the formation of interest 122 121 123 122 Result after interpretation by software Well logging data 124 123 ormation hrif MA No. Interval m Thickness GR m API RT Ω.m DT us/ft Neutron Density % g/cc Por % Perm mD Sw % Vsh % Result 31 3735.4 3736.6 1.2 22.2 10.8 62.2 10.9 2.52 9.8 6.5 45.6 5.8 Oil 32 3744.5 3751.7 7.2 24.1 17.1 70.0 16.7 2.4 15.2 52.4 27.1 6.9 Oil 33 3771.9 3774.3 2.4 26.5 9.1 66.4 15.7 2.5 13.4 28.8 41.4 8.7 Oil 34 3809.2 3811.3 2.1 15.7 17.1 61.6 10.8 2.6 9.6 5.7 39.8 2.3 Oil MB21 35 3811.3 3825.7 14.4 11.3 102.2 73.8 18.0 2.4 18.6 99.4 7.6 1.0 Oil 36 3825.7 3903.9 78.2 27.5 7.6 70.8 17.5 2.4 15.4 43.9 31.2 9.3 Oil 37 3930.6 3939.2 8.6 14.6 3.2 68.8 18.0 2.4 17.8 82.6 40.8 1.7 Oil MC1 38 3939.2 3940.8 1.6 19.9 1.1 67.1 17.2 2.4 15.3 42.8 78.6 4.4 Oil & Water 39 3942.3 3946.5 4.2 18.1 1.6 64.7 16.3 2.5 13.7 27.7 75.2 3.5 Oil & Water 40 3978.7 3982.1 3.4 20.8 3.2 64.5 13.5 2.5 11.6 12.6 66.7 4.9 Oil & Water MC2 41 3983.4 4014.5 31.1 23.2 1.7 68.4 15.7 2.4 14.4 33.1 65.8 6.3 Oil & Water 42 4022.4 4030.5 8.1 21.5 2.0 61.2 12.6 2.6 9.6 5.5 86.5 5.3 Oil-bearing water MB11 125 124 Contents 1. introduction 2. Type of well logging 3.Log interpretation 4.Some pictures for logging truck and logging tools 126 125 127 126 128 127 129 128 130 1 2 4 3 129 131 130 132 131 133 132 134 133