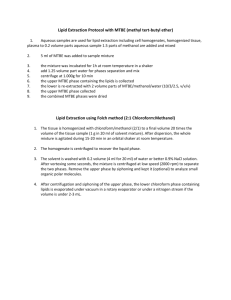

EXPERIMENT 3 SEPARATION BY LIQUID-LIQUID EXTRACTION Table of Contents I. II. III. IV. Page Reading/Video Assignments Overview Reagent Table Requirements Experimental Details Part A: Separation of a Mixture Part B: Melting Point Determination 1 2 2 7 7 9 I. READING/VIDEO ASSIGNMENTS Reading: Techniques in Organic Chemistry 2nd edition: pages 75-100 (especially section 8.6: microscale extractions) 3rd edition: pages 113-141 (especially section 11.5: microscale extractions) 4th edition: pages 142-173 (especially section 10.6: microscale extractions) Video: MIT Digital Lab Techniques Manual http://www.youtube.com/watch?v=ciWpS6SetdY II. OVERVIEW Liquid-liquid extraction is a separation method based upon differential solubility of components of a mixture in two immiscible solvents. The distribution of compounds between two immiscible solvents is expressed as a “distribution” or “partition” coefficient (K). K is defined as the grams/mL of a compound in an organic solvent divided by the g/mL of the compound in water (at equilibrium). In this experiment, you will experimentally determine the partition coefficient of benzoic acid when distributed between water and methyl tert-butyl ether (MTBE) at room temperature. The process of liquid-liquid extraction involves (1) dissolution of a mixture in a suitable solvent followed by addition of an immiscible solvent, (2) thorough mixing of the immiscible layers, (3) separation of the layers, (4) drying of the organic solution, and (5) isolation of the separated components. The vessel used for conducting liquid-liquid extractions depends upon scale. Larger scale extractions (as you will do in this experiment) utilize a separatory funnel. Separatory Funnel The following describes the important experimental details for each step: 2 (1) Dissolve a mixture in a suitable solvent, then add an immiscible solvent: • The most commonly used solvent pairs in liquid-liquid extractions involve an organic solvent and water. Of course, organic solvents that are totally miscible with water (such as ethanol or methanol) are not suitable for use with this method. • As always, the solution with the lower density will be on the top and the more dense solution will be on the bottom. • The components of the mixture will be distributed between the layers based upon their distribution (partition) coefficient. In order for the method to succeed, the partition coefficient must be greater than 1.5 for each component. (2) Thoroughly mix the immiscible layers: • Adequate mechanical agitation is required since the layers are immiscible. Good mixing allows the components to encounter each of the immiscible liquids and to partition themselves according to their partition coefficients. • Whatever the container chosen for this mixing, it must be tightly closed. • With a separatory funnel, close the stopcock and cap the funnel with the correct stopper. With a snap-cap centrifuge tube, be sure to seat the cap carefully. Always hold the stopper or cap in place with a thumb or hand while mixing. • Because many organic solvents are volatile, vapors will build during mixing, increasing the internal pressure of the container. For this reason, one must vent the mixing container frequently to relieve this pressure. To vent with a separatory funnel, turn it upside down, allow the liquid to drain away from the stopcock, point it away from any personnel and open the stopcock to vent. With a centrifuge tube, allow the liquid to drain away from the top of the tube and carefully remove the cap. Repeat this several times during the mixing process. If you fail to do this, the pressure may build up and force the cap off, releasing the liquid contents violently. Be sure to always point the funnel or tube opening away from yourself and others, in case the contents are released. (3) Separation of the layers • The immiscible layers can readily be physically separated using a separatory funnel. • Sometimes, an emulsion forms during the mixing stage which impairs the formation of two distinct layers. Emulsions are difficult to handle but can sometimes be resolved by adding salt (sodium chloride) to the aqueous layer or by centrifugation filtration. • Determining which layer is the organic and which is the aqueous is readily accomplished by adding a drop of water to each layer and observing what happens. (4) Drying of the organic solution • Most often, the desired component of an extractive separation will be more soluble in the organic solvent. • Before isolating the component extracted into the organic layer, it is important to “dry” the organic solution. This is required since most organic solvents have some 3 • miscibility with water and will therefore contain trace quantities of water. To dry the organic layer, “wash” the layer with a brine (saturated NaCl in water) solution. This removes the majority of the water. After removing the brine layer, treat the organic solution with a “drying agent” to remove last traces of water. Typical drying agents are magnesium sulfate and sodium sulfate. Magnesium sulfate is the more efficient and faster-acting of the two. When it absorbs water its physical form changes from a free-flowing powder to a clumped solid. Therefore, it is easy to know when excess drying agent has been added as one will observe a “snow-globe” effect due to free-flowing solid when the flask is swirled. (5) Isolation of the separated components • The desired compound is readily isolated by evaporating the solvent from the dried solution. • The material obtained may require further purification, as liquid-liquid extraction is a separation technique, not a purification technique. Purification can be accomplished through recrystallization or distillation. Unfortunately, most organic compounds have limited solubility in water. This fact would seem to severely limit the utility of liquid-liquid extractions in the organic laboratory. However, this is not the case due to the fact that some organic compounds can be chemically transformed into ones that have significant water solubility. This can readily be accomplished with organic acids or bases. We can convert these hydrophobic compounds into their more hydrophilic salt forms by reacting them with bases or acids. Following separation, we can also return the salts to their non-salt forms using similar acid-base chemistry. Acidic organic compounds contain the carboxylic acid functional group (pKa ~3 – 5) or the phenol group (pKa ~8 – 10). Both can be converted to their salt forms using inorganic bases. It is important that the bases used are inorganic so that they will be water soluble. It is also an advantage that there exists both strong (NaOH) and weak (NaHCO3) inorganic bases. This will allow for the selective conversion of strong and weak acids to their respective salt (water soluble) forms. Basic organic compounds are characterized by the presence of an amine group. This group can be converted to its salt form using inorganic acids. Unfortunately, a usable range of water soluble strong and weak acids are not available so the separation of weak bases from strong bases is not feasible. The following shows how the solubility of organic acids and bases can be modified by changing their chemical compositions. 4 R-CO2H + NaHCO3 (aq) R-CO + Ar-O- Na+ NaOH (aq) + 2 2O + H 2O very water soluble insoluble or slightly soluble in water R-NH2 + CO + H very water soluble insoluble or slightly soluble in water Ar-OH - Na+ 2 HCl (aq) R-NH + Cl- 3 + H 2O very water soluble insoluble or slightly soluble in water As stated above, an aqueous solution of NaHCO3 converts carboxylic acids to their sodium carboxylates, but NaHCO3(aq) is not a strong enough base to form sodium salts of phenolic compounds. Due to this difference in acidity, two organic acids can be partitioned or separated, providing their pKa values differ by five or so pKa units and the aqueous base used in the deprotonation is not basic enough to remove the hydrogen from the weaker organic acid. Note, if aqueous NaOH were used instead of NaHCO3(aq) in the extraction of a mixture containing a carboxylic acid and a phenol, the strong base would deprotonate both the carboxylic acid and the phenol and subsequently, both the carboxylate and phenolate would reside in the aqueous base layer and therefore no separation would be achieved. The diagram below depicts the same information but in a different presentation format. 5 The process of extraction and separation can be best understood by constructing a flow chart. Figure 1 shows the separation of a carboxylic acid from a neutral organic compound. It is important to always construct a flow chart before conducting a complex liquid-liquid extraction. R-CO2H + R-CH3 dissolved in MtBE 1N NaOH (aq) organic - R-CO2 R-CH3 ether R-CO2H Figure 1 6 Na+ 1N HCl (aq) no organic compound III. REAGENT TABLE REQUIREMENTS Compounds to Include: • All compounds in Table 1 and Table 2 • Water • Methyl t-butyl ether (MTBE; also tBME and TBME) • Magnesium sulfate • Sodium sulfate Information Required for Each Compound: • Chemical names • Chemical structures (not for charcoal) • Hazards (from the Safety Data Sheet, SDS) IV. EXPERIMENTAL DETAILS PART A: Separation of a Mixture Transfer ~500 mg of a mixture containing a carboxylic acid, an amine, and a neutral compound to a separatory funnel containing ~10 mL of MTBE. Cap and gently shake the solution until the solid dissolves. Remember to frequently vent the separatory funnel during mixing. If the solid does not completely dissolve, you can add the 5% HCl for the next step and mix the two layers. Isolation of the Amine Extract the unknown mixture with dilute acid. Add ~5 mL of 5% HCl to the separatory funnel cap and shake for 30 seconds (remember to vent). Remove the stopper and allow the layers to separate. Remove the bottom layer (aq) to a vial or test tube labeled “HCl aq.” Extract the organic layer with two additional portions of 5% HCl, (2 x ~5 mL) and combine the aqueous layers. This process will provide two vials or tubes: the original “unknown mixture” vial containing the mixture in MTBE and a tube containing ~15 mL HCl aq. Back-extract the aqueous layer with MTBE. Return the aqueous HCl solution to the separatory funnel. Add ~5 mL of fresh MTBE to the separatory funnel. Stopper and shake the funnel for 30 seconds (remember to vent). Remove the stopper and allow the layers to separate. This “back-extraction” removes any neutral and carboxylic acid molecules that were dissolved in the aqueous solution during the extractions. Basify the aqueous solution. Add 10% NaOH dropwise with continuous stirring to the aqueous HCl solution and frequently check the pH of the mixture with a pH paper. To check the pH, do NOT dip the pH paper directly into the solution; take a 7 drop of the solution (with a stirring rod) and touch the rod to the one spot on the pH paper. Use the same paper for several tests. Take the pH to well into the basic range (pH ~ 11) This will require about 3-5 mL of 10% NaOH. A precipitate of the free amine may form during this pH adjustment (if this occurs, the solid will dissolve when the MTBE is added). Extract the aqueous solution with three portions of ~5 mL MTBE. Combine the MTBE fractions and wash the combined organics with 6 mL brine, remove the aqueous layer, and dry the MTBE layer over magnesium sulfate. Filter and transfer the MTBE solution to a tared flask containing a few boiling chips. Evaporate the solution to dryness in the hood. Record the mass for the isolated amine. Isolation of the Carboxylic Acid Extract the unknown mixture with dilute strong base. Extract the remaining MTBE solution labeled “unknown mixture” three times with 5% NaOH (3 portions of ~5mL each). This process will provide two tubes: the original “unknown mixture” tube containing the mixture in MTBE and a tube with ~15 mL aqueous NaOH. Back-extract the aqueous layer with MTBE. Back-extract the combined NaOH solutions with 5 mL of fresh MTBE. Transfer the organic layer to the original “unknown mixture” tube containing the mixture. The back-extraction removes any neutral compound that was dissolved in the aqueous solution during the extractions. Acidify the aqueous solution. Add 10% HCl dropwise with continuous stirring to the NaOH aq solution and frequently check the pH of the mixture with a pH paper. Take the pH well into the acid range (pH ~ 2). This usually will require 4-6 mL. A precipitate of the free carboxylic acid may form during this pH adjustment (if this occurs, the solid will dissolve when the MTBE is added). Extract the aqueous solution with three portions of ~5 mL MTBE. Combine the MTBE fractions. Wash the combined organics with 6 mL brine, remove the aqueous layer, and dry the MTBE layer over magnesium sulfate. Filter and transfer the MTBE solution to a tared conical vial containing a few boiling chips. Evaporate the solution to dryness in the hood. Record the mass of the isolated carboxylic acid. Isolation of the Neutral Compound Add the “unknown mixture” solution to the separatory funnel and add ~10 mL of water. Shake and separate the organic layer from the water (remember to vent). This step is known as a “wash” since any water-soluble impurities are removed (“washed away”) from the organic layer. Wash the organic layer with ~10 mL brine, remove the aqueous layer, and dry the MTBE layer over magnesium sulfate. Filter and transfer the MTBE solution to a tared flask containing a few boiling chips. Evaporate the solution to dryness in the hood. Record the mass of the isolated neutral compound. Store the separated compounds in a desiccator. 8 PART B: Melting Point Determination Using the melting point analysis methods previously employed, identify the three components of the mixture. Be sure to calibrate the thermometer by selecting a compound from Table 2 that has a melting point near your crude melting point. If the unknown identification is questionable, it would be wise to purify the sample via recrystallization or perform a mixed melting point analysis. The possible unknowns are provided in Table 1, below. Table 1: Possible Unknowns COMPOUND Benzoic acid trans-Cinnamic acid m-Nitrobenzoic acid m-Bromobenzoic acid p-Toluic acid p-Bromoaniline p-Chloroaniline Ethyl p-aminobenzoate 2-Aminobenzophenone 4-Aminoacetanilide 9-Fluorenone Benzil Phenanthrene Fluorene 1 CAS number 65-85-0 140-10-3 121-92-6 585-76-2 99-94-5 106-40-1 106-47-8 94-09-7 2835-77-0 122-80-5 486-25-9 134-81-6 85-01-8 86-73-7 MP (°C)2 121 – 125 132 – 135 141 – 144 155 – 158 177 – 180 60 – 64 67 – 70 88 – 90 103 – 107 164 – 167 80 – 83 94 – 95 98 – 100 111 – 114 Sigma Aldrich Catalog: www.sigmaaldrich.com Table 2: Standard Chemicals for Thermometer Calibration COMPOUND Vanillin Acetanilide Benzamide Salicylic acid Succinic acid Dimethylglyoxime 1 2 CAS number 121-33-5 103-84-4 55-21-0 69-72-7 110-15-6 95-45-4 MP (oC)1 81(1) 114.35(0.04) 128(1) 158.6(0.5) 185(3) 245.5 MP (°C)2 81 – 83 113 – 115 125 – 128 158 – 161 184 – 186 240 – 241 CRC Handbook of Chemistry and Physics 96th ed. (uncertainty in parentheses) Sigma Aldrich Catalog: www.sigmaaldrich.com 9