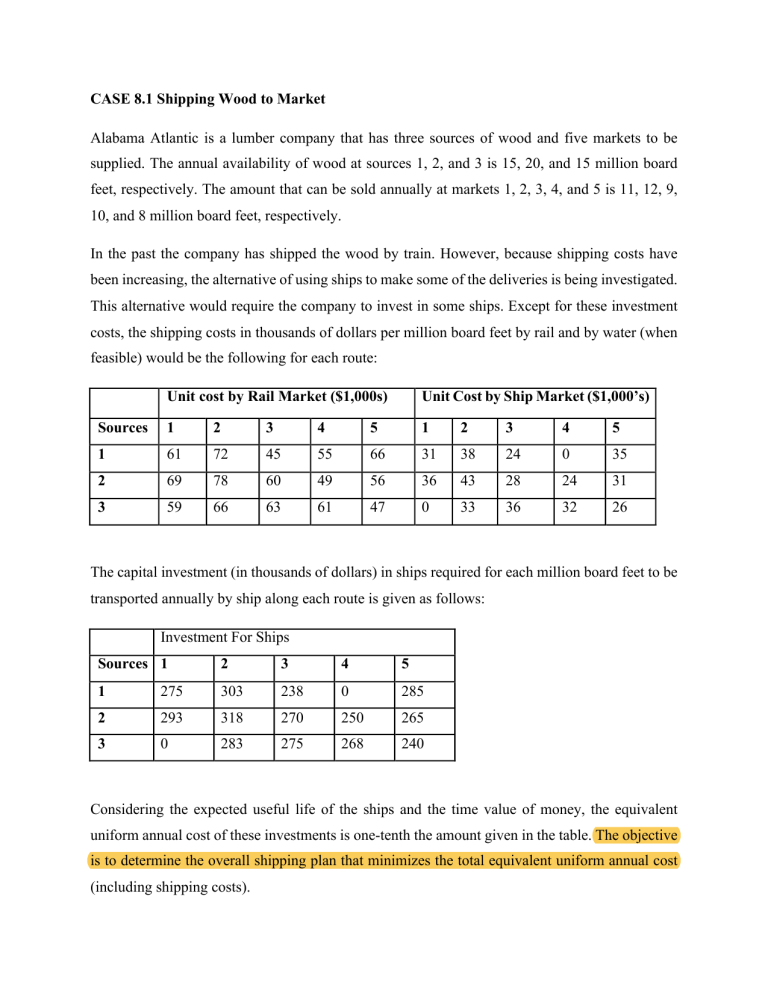

CASE 8.1 Shipping Wood to Market Alabama Atlantic is a lumber company that has three sources of wood and five markets to be supplied. The annual availability of wood at sources 1, 2, and 3 is 15, 20, and 15 million board feet, respectively. The amount that can be sold annually at markets 1, 2, 3, 4, and 5 is 11, 12, 9, 10, and 8 million board feet, respectively. In the past the company has shipped the wood by train. However, because shipping costs have been increasing, the alternative of using ships to make some of the deliveries is being investigated. This alternative would require the company to invest in some ships. Except for these investment costs, the shipping costs in thousands of dollars per million board feet by rail and by water (when feasible) would be the following for each route: Unit cost by Rail Market ($1,000s) Unit Cost by Ship Market ($1,000’s) Sources 1 2 3 4 5 1 2 3 4 5 1 61 72 45 55 66 31 38 24 0 35 2 69 78 60 49 56 36 43 28 24 31 3 59 66 63 61 47 0 33 36 32 26 The capital investment (in thousands of dollars) in ships required for each million board feet to be transported annually by ship along each route is given as follows: Investment For Ships Sources 1 2 3 4 5 1 275 303 238 0 285 2 293 318 270 250 265 3 0 283 275 268 240 Considering the expected useful life of the ships and the time value of money, the equivalent uniform annual cost of these investments is one-tenth the amount given in the table. The objective is to determine the overall shipping plan that minimizes the total equivalent uniform annual cost (including shipping costs). You are the head of the OR team that has been assigned the task of determining this shipping plan for each of the following three options. Option 1: Continue shipping exclusively by rail. Option 2: Switch to shipping exclusively by water (except where only rail is feasible). Option 3: Ship by either rail or water, depending on which is less expensive for the particular route. Present your results for each option. Compare. Finally, consider the fact that these results are based on current shipping and investment costs, so the decision on the option to adopt now should take into account management’s projection of how these costs are likely to change in the future. For each option, describe a scenario of future cost changes that would justify adopting that option now. Solution: Introduction: The Given Case of “Shipping wood to Market” is a Transportation problem. Where, Alabama Atlantic, a lumber company which has three sources of wood and five markets to be supplied. The annual availability of wood at sources 1, 2, and 3 is 15, 20, and 15 million board feet, respectively. Whereas, the amount that can be sold annually at markets 1, 2, 3, 4, and 5 is 11, 12, 9, 10, and 8 million board feet, respectively. The company so far has used Rails to supply woods. However due to increase in shipping cost, Atlantic is looking for alternatives to minimize cost, requiring company to invest in ships. As a head of OR Team, we will be evaluating the independent cost of shipping exclusively through rail, cost of switching to shipment, and cost of making use of rail or water transportation, depending on which is less expensive for the particular route. For Minimizing cost of shipment, VAM model has been used in evaluating three different alternatives. All the alternatives have been processed using QM for Windows V4 software. Option 1: Objective: Minimum cost of shipping Exclusively by Train. Initial Problem: Unit cost by Rail Market ($1,000s) Sources 1 2 3 4 5 Supply 1 61 72 45 55 66 15000 2 69 78 60 49 56 20000 3 59 66 63 61 47 15000 Requirement 11000 12000 9000 10000 8000 50000 There are 3 different sources of wood and 5 different markets. The annual availability of wood at sources 1, 2, and 3 is 15, 20, and 15 million board feet, respectively. Whereas, the amount that can be sold annually at markets 1, 2, 3, 4, and 5 is 11, 12, 9, 10, and 8 million board feet, respectively. All the cost has been presented in thousands. Initial Solution: Initial Solution calculated using VAM model suggested that, the cost of shipment from, railways is 2.834 Billion. Cost =2834000 Source 1 Source 2 Source 3 Destination Destination Destination Destination Destination 1 2 3 4 5 6000 -2 9000 -14 -15 5000 5000 -7 10000 ( -3 ) -2 7000 -22 -24 8000 However it is not an optimal solution. Hence further iteration is required, Iterations: Iteration 1 Source 1 Source 2 Destination 1 Destination 2 Destination 3 6000 5000 -2 5000 9000 -7 Destination 4 Destination 5 -14 10000 (-3) -15 Source 3 Iteration 2 Source 1 Source 2 Source 3 Iteration 3 Source 1 Source 2 Source 3 -2 7000 -22 -24 8000 6000 5000 -5 -3 12000 9000 -7 -19 -14 10000 -21 -18 5000 3000 6000 2000 3000 -4 -2 12000 9000 -7 -20 -14 10000 -22 -18 8000 -1 (-1) Minimum cost of shipment from the railways have been calculated by using QM for Windows V4 software and VAM model. It requires 3 Iteration to achieve the optimal solution. After 3 Iterations we receive our optimal solution. Optimal Solution: Optimal solution value = $2816000 Source 1 Source 2 Source 3 Destination Destination Destination Destination Destination 1 2 3 4 5 6000 9000 2000 10000 8000 3000 12000 The Optimum cost of shipping goods from Railways is $2.816 Billion as the cost can no longer be minimized any further. Shipping List: From Source 1 Source 2 To Destination 1 Destination 3 Destination 1 Destination 4 Destination 5 Shipment Cost per unit Shipment cost 6000 61 366000 9000 45 405000 2000 69 138000 10000 49 490000 8000 56 448000 Destination 1 Destination 2 Source 3 3000 59 177000 12000 66 792000 As shown in the above figure, the optimum cost of shipping from railways is $2.816 Billion. This is obtained by allocating 6000 units of woods to Destination 1 and 9000 units to Destination 3 from source 1. Similarly, 2000 units of wood has been Transported to Destination 1, 10000 units to Destination 4 and 8000 units to Destination 5 from Source 2. Further on 3000 units of wood has been shipped to Destination 1 and 12000 units of wood to Destination 2 from source 3. Justification of Using Railways: 1. Railway is best means of shipment for land locked location, 2. No further investment is necessary as required infrastructure has already been developed. 3. Option: 2 Objective: To determine the overall shipping plan that minimizes the total equivalent uniform annual cost, including shipping costs. In the past the company has shipped the wood by train. However, because shipping costs have been increasing, the alternative of using ships to make some of the deliveries is being investigated. This alternative would require the company to invest in some ships. The capital investment (in thousands of dollars) in ships required for each million board feet to be transported annually by ship along each route is given as follows: Sources 1 2 3 1 275 293 0 Investment For Ships in 1000’s 2 3 4 303 238 0 318 270 250 283 275 268 5 285 265 240 However, after considering the expected useful life of the ships and the time value of money, the equivalent uniform annual cost of these investments turns out to be one-tenth the amount given in the table. Sources 1 2 3 Investment For Ships per year 1 2 3 27.5 30.3 23.8 29.3 31.8 27 0 28.3 27.5 4 0 25 26.8 5 28.5 26.5 24 Fig: Per year cost of investment Initial Problem: Total Shipping Cost Unit Cost by Ship Market ($1,000’s) Sources 1 2 3 4 5 Supply 1 58.5 68.3 47.8 55 63.5 15000 2 65.3 74.8 55 49 57.5 20000 3 59 61.3 63.5 58.8 50 15000 Requirement 11000 12000 9000 10000 8000 50000 Fig: Shipment cost after adding Initial Cash Outlay While calculating Total Shipping cost, Unit cost by ship to market has been added with Initial cash outlay after considering the time value of money. However, shipping goods to all market is not completely possible through sea ways. Hence, Railways have to be considered for markets where goods cannot be shipped through seas. Hence, Railways cost of transportation has been considered at places where we cannot ship. In this case, it is not possible to ship goods from source 3 to destination 1 and from source 1 to destination 4. This route has been considered as not feasible zone of shipment from sea ways and hence railways must be used to reach those destinations. Hence, while calculating optimum cost of transportation through seas cost of railways have been used for those places where shipping through seas is not feasible. Initial Solution: Cost =2,800,800 Source 1 Source 2 Source 3 Destination Destination Destination Destination Destination 1 2 3 4 5 6000 -0.3 9000 -12.8 -6.8 5000 5000 -0.4 10000 ( -6 ) -7.2 7000 -22.4 -23.3 8000 The initial cost of shipping woods from sea ways calculated using VAM model is $2.8 Billion. However it is not an optimal solution. Hence further iteration is required, Iterations: Iteration 1 Source 1 Source 2 Source 3 Iteration 2 Source 1 Source 2 Source 3 Destination 1 Destination 2 Destination 3 Destination Destination 4 5 6000 5000 -7.2 -0.3 5000 7000 9000 -0.4 -22.4 -12.8 10000 -23.3 -6.8 -6 8000 6000 5000 -1.2 -6.3 -6 12000 9000 -0.4 -16.4 -12.8 10000 -17 -12.8 5000 3000 Minimum cost of shipment from the seaways have been calculated by using QM for Windows V4 software and VAM model. It requires 2 Iteration to achieve the optimal solution. After 2 Iterations we receive our optimal solution. Optimum Solution: Optimal solution value = $2770800 Source 1 Source 2 Source 3 Destination Destination Destination Destination Destination 1 2 3 4 5 6000 9000 5000 10000 5000 12000 3000 The Optimum cost of shipping goods from Railways is $2.77 Billion as the cost can no longer be minimized any further. Shipping List: From Source 1 Source 2 Source 3 To Destination 1 Destination 3 Destination 1 Destination 4 Destination 5 Destination 2 Destination 5 Shipment Cost per unit Shipment cost 6000 58.5 351000 9000 47.8 430200 5000 65.3 326500 10000 49 490000 5000 57.5 287500 12000 61.3 735600 3000 50 150000 As shown in the above figure, the optimum cost of shipping from railways is $2.77 Billion. This is obtained by allocating 6000 units of wood to destination 1 and 9000 units of wood to destination 3 from source 1. Similarly, 5000 units of wood is supplied to destination 1, 10000 units of wood to destination 4 and 5000 units of wood to destination 5 from source 2. At last, source 3 is used to supply 12000 units of woods to destination 2 and 3000 units of wood to destination 5. Justification of Using Waterways: 1. Even after adding present value of initial cost outlay to shipping cost, Optimum cost of shipping through seaways is lower than that of Railways. Hence, waterways must be used. 2. After 10 years, the initial investment should no longer be added; hence the cost of shipment will further decrease. 3. Option: 3 Objective: Minimize Total cost, by selecting alternative that is less expensive for the particular route from either Railways or Seaways. Initial Problem: The objective of this transportation problem is to minimize Total cost of Transportation by using both the means of Shipping. Hence, by comparing shipment cost of delivering goods from various sources to various destinations, through both means, we have selected those cost, that is minimum. Unit Cost by means where cost is minimum ($1,000’s) 1 2 3 4 5 Supply 58.5(S) 68.3(S) 45(R) 55(R) 63.5(S) 15000 65.3(S) 74.8(S) 55(S) 49(S) 56(S) 20000 59(R) 61.3(S) 63(R) 58.8(S) 47(R) 15000 Sources 1 2 3 Requiremen t 11000 12000 9000 10000 8000 50000 Initial Solution: Cost =2751600 Source 1 Source 2 Source 3 Destination Destination Destination Destination Destination 1 2 3 4 5 6000 -0.3 9000 -12.8 -9.8 5000 5000 -3.2 10000 -4.5 -7.2 7000 -24.7 -23.3 8000 The initial cost of shipping woods from both ways calculated using VAM model is $2.752 Billion. However it is not an optimal solution. Hence further iteration is required. Iterations: Iteration 1 Source 1 Source 2 Source 3 Iteration 2 Source 1 Source 2 Destination 1 Destination 2 Destination 3 Destination 4 Destination 5 6000 5000 -7.2 -0.3 5000 7000 9000 -3.2 -24.7 -12.8 -9.8 10000 (-4.5) -23.3 8000 6000 5000 -4.8 -4.5 9000 -3.2 -12.8 10000 -14.3 5000 Source 3 -2.7 12000 -20.2 -18.8 3000 Minimum cost of shipment from both ways has been calculated by using QM for Windows V4 software and VAM model. It requires 2 Iteration to achieve the optimal solution. After 2 Iterations we receive our optimal solution. Optimum Solution: Optimal solution value = $2729100 Source 1 Source 2 Source 3 Destination Destination Destination Destination Destination 1 2 3 4 5 6000 9000 5000 10000 5000 12000 3000 The Optimum cost of shipping goods both ways is $2.729 Billion as the cost can no longer be minimized any further. Shipping List: From Source 1 Source 2 Source 3 To Destination 1 Destination 3 Destination 1 Destination 4 Destination 5 Destination 2 Destination 5 Shipment Cost per unit Shipment cost 6000 58.5 351000 9000 45 405000 5000 65.3 326500 10000 49 490000 5000 56 280000 12000 61.3 735600 3000 47 141000 As shown in the above figure, the optimum cost of shipping from railways is $2.77 Billion. This is obtained by allocating 6000 units of wood to destination 1 and 9000 units of wood to destination 3 from source 1. Similarly, 5000 units of wood is supplied to destination 1, 10000 units of wood to destination 4 and 5000 units of wood to destination 5 from source 2. At last, source 3 is used to supply 12000 units of woods to destination 2 and 3000 units of wood to destination 5. Even though allocation made, while calculating Transportation cost using both ways is similar to Sea ways, Cost is further reduced by use of railways while shipping goods from Source 1 to Destination 3, similarly from Source 2 to destination 5 and Source 3 to destination 5. This further reduces cost by 41.7 Million. Justification of Using both ways: 1. The Ultimate objective of Transportation model is to minimize cost, using both ways results in minimum Transportation cost. Hence, mixture of both railways and seas ways must be used to minimize cost. 2. It is wise to use this model for next 10 years, until the day, the initial cash outlay for investing in shipment is fully recovered. Conclusion: Means of Transportation Optimum Cost Railways 2,816,000,000 Sea ways 2,770,800,000 45,200,000 Both 2,729,100,000 41,700,000 Reduction in cost - In the nutshell it can be concluded that, it is wise for Alabama Atlantic to make use of both means of shipment for transporting woods from its 3 different sources to 5 different destinations, as collectively both means minimizes the total cost of transportation. If that is not possible Alabama Atlantic should use seaways rather than Railways, as it minimizes cost of shipment. Making Use of Sea ways instead of Railways helps Alabama Atlantic save 45.2 Million dollars. Similarly using both means help Alabama Atlantic save 86.9 Million dollars that they are spending right now, while using railways.