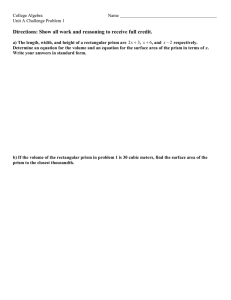

![Total Station and its application in Mine Surveying[1]](http://s2.studylib.net/store/data/025715526_1-f25fc1f07e6d0d1b8a450fd3ae8feadf-768x994.png)

Total Station Dheeraj Kumar Introduction A total station is an optical instrument used in modern surveying. With this device, as with a transit and tape, one may determine angles and distances from the instrument to points to be surveyed. With the aid of trigonometry, the angles and distances may be used to calculate the actual positions (x, y, and z or northing, easting and elevation) of surveyed points in absolute terms. It is a light weight, compact and fully integrated electronic instrument combining the capability of an EDM and an angular measuring instrument such as wild theodolite. It can perform the following functions. – Distance measurement – Angular measurement – Data processing – Digital display of point details – Storing data is an electronic field book A standard transit is basically a telescope with cross-hairs for sighting a target; the telescope is attached to scales for measuring the angle of rotation of the telescope (normally relative to north as 0 degrees) and the angle of inclination of the telescope (relative to the horizontal as 0 degrees). After rotating the telescope to aim at a target, one may read the angle of rotation and the angle of inclination from a scale. The electronic transit provides a digital read-out of those angles instead of a scale; it is both more accurate and less prone to errors arising from interpolating between marks on the scale or from mis-recording. The readout is also continuous; so angles can be checked at any time. The other part of a total station, the electronic distance measuring device or EDM, measures the distance from the instrument to its target. The EDM sends out an infrared beam which is reflected back to the unit, and the unit uses timing measurements to calculate the distance traveled by the beam. With few exceptions, the EDM requires that the target be highly reflective, and a reflecting prism is normally used as the target. The reflecting prism is a cylindrical device, at one end is a glass covering plate and at the other is a truncated cone with a threaded extension. It is normally screwed into a target/bracket on the top of a pole; the pointed tip of the pole is placed on the points to be surveyed. The total station also includes a simple calculator to figure the locations of points sighted. The calculator can perform the trigonometric functions needed, staring with the angles and distance, to calculate the location of any point sighted. Many total stations also include data recorders. The raw data (angles and distances) and/or the coordinates of points sighted are recorded, along with some additional information (usually codes to aid in relating the coordinates to the points surveyed). The data thus recorded can be directly downloaded to a computer at a later time. The use of a data recorder further reduces the potential for error and eliminates the need for a person to record the data in the field. The determination of angles and distance are essentially separate actions. One aims the telescope with great care first; this is the part of the process with real potential for human error. When the telescope has been aimed, the angles are determined. Only then does one initiate the reading of the distance to the target by the EDM. That takes only a few seconds; the calculations are performed immediately. The total station is mounted on a tripod and leveled before use. Meanwhile, the prism is mounted on a pole of known height; the mounting bracket includes aids for aiming the instrument. The prism is mounted so that its reflection point is aligned with the center of the pole on which it has been mounted. Although the tip of the pole is placed on the point to be surveyed, the instrument must be aimed at the prism. So it will calculate the position of the prism, not the point to be surveyed. Since the prism is directly above the tip, the height of the pole may be subtracted to determine the location of the point. That may be done automatically. (The pole must be held upright, and a bubble level is attached to give the worker holding the pole a check. It is not as easy as one might expect to hold the pole upright, particularly if there is any wind; as a result, multiple readings may be required. When the instrument is set up and turned on, it sets itself to be pointing to zero degrees (north) when power is first supplied. The user must then re-set the instrument to zero degrees when it is actually pointing north There are two adjustment knobs for rotating within the horizontal plane. One rotates the telescope to make a sighting, with the readout of angles displaying changes. The other, however, permits the user to rotate the entire instrument and to keep the current angle unchanged during the process. That effectively re-orients the zero or north setting. That can be very helpful when setting up or re-setting the instrument, but, of course, it can be devastating if one makes that adjustment by mistake and thereby changes the north setting. This particular instrument was designed in such a way that it was too easy to re-set the instrument when one only wanted to make a sighting.) The pole is designed to be placed on the survey point in a vertical position; it cannot be placed on a point on the face of a wall. In fact, a prism pole can rarely be placed against the face of a wall because of the bulk of the prism, the pole, and the target to which the prism is attached. For siting a point on the wall, one can use reflecting sheet or even prism can be kept without its pole and target. The instrument measures to within 1-5 seconds for vertical and horizontal angles. The electronic distance measuring device (EDM) measures to within 2 mm. and 3 parts per million; so the error will be no more than the sum of 5 mm. and 3 parts per million of the measured distance from instrument to prism. Instruments are available which measure to tighter tolerances, but for shortrange work baseline backsight Total station foresight Fig. 1 : Measurement using a total station Salient features • Dynamic angle – Scanning System ensures highest measuring accuracy. • With standard telescope. • Two – axis compensator automatically determines and corrects standing – axis tilt. • The data can be recorded and stored in a cassette or Card or Internal memory of the instrument, and can be downloaded to or up loaded from a computer by supplied software from manufactures (Leica Survey Office’ for Leica Model, T-com for Topcon and Sokkialink for Sokkia Total station). The data is recorded in a format compatible to Software programme and computer evaluation of the data, so that the out put can be obtained in desired usable form. • Online control by computer • Total Station can be operated with a multi function Keyboard, which is associated with a display screen which is some cases, gives a graphic display also. • Built-in Co-ordinate geometry functions for ancillary calculation. • Key-board-control o All the functions are controlled by operating key board. • Digital panel o The panel displays the values of distance, angle, height and the co-ordinates of the observed point, where the reflector (target) is kept. • Remote height object o The heights of some inaccessible objects such as towers can be read directly. The micro-processor provided in the instrument applies the correction for earth’s curvature and mean refraction, automatically. • Traversing program o The co-ordinates of the reflector and the angle or bearing on the reflector can be stored and can be recalled for next set up of instrument. • Setting out for distance, direction and height o Whenever a particular direction and horizontal distance is to be entered for the purpose of locating the point on the ground using a target, then the instrument displays the angle through which the theodolite has to be turned and the distance by which the reflector should move. Use With a total station one may determine angles and distances from the instrument to points to be surveyed. With the aid of trigonometry, the angles and distances may be used to calculate the coordinates of actual positions (X, Y, and Z or northing, easting and elevation) of surveyed points, or the position of the instrument from known points, in absolute terms. The data may be downloaded from the theodolite to a computer and application software will generate a map of the surveyed area. Some total stations also have a GPS interface which combines these two technologies to make use of the advantages of both (GPS - line of sight not required between measured points; Traditional Total Station - high precision measurement especially in the vertical axis compared with GPS) and reduce the consequences of each technology's disadvantages (GPS - poor accuracy in the vertical axis and lower accuracy without long occupation periods; Total Station - requires line of sight observations and must be setup over a known point or within line of sight of 2 or more known points). Total Stations are popular for the following reasons: • One can work in an area where GPS units won’t work due to trees or other obstacles. The total station doesn’t require any satellite coverage. • The most accurate measurements are possible. The survey-grade GPS unit will give around 20mm precision, but the total station, if used properly will give 5-10mm precision. Field Checklist for Total Station work • tripod with cover • Total Station • Lens cover • Back sight rod/tripod and prism and lens cover • Foresight rod/tripod and prism and lens cover • Manufacturer’s manual • List/maps of points • Field notebook • Survey tape • Binoculars • Hammer and nail indent maker • Clippers (for removing vegetation for line of sight) if necessary Working Procedure Physical Set-Up Total station • Stand yellow wooden/metallic tripod over the chosen point (this varies depending on scenario), and loosen bottom screws on all the legs. Unclip the strap. • Without spreading the legs, pull the tripod up to chin level and tighten the screws. • Spread the legs of the tripod so that they are evenly positioned over the point. Unscrew the yellow cap on the top. Arrange the tripod so that the openings between the legs are facing the area where you will take most of the foresight shots. • Remove the total station from the case, keeping one hand on the top handle and one hand on the bottom at all times. Place the total station on the silver flat surface on the tripod and attach it using the screw underneath the tripod. Be sure to set the total station so that Face 1 of the total station is facing you, and the tribrach is situated so that the bubble is also facing you (see pictures at the end of the manual) Backsight • There are two options for the backsight. You can use either a pole with prism OR tripod with adaptor and prism. • Attach prism to the top of the tripod/pole. Make accurate centering & leveling so as to position the pole/tripod exactly on the ground point. • Note down the height of prism centre from ground point (height of foresight) • Make sure that the rod and prism are facing approximately the direction of the total station. The operator will give you directions to make sure that it is perfectly pointed later on. Foresight • There are two options for the fore sight. You can use either a pole with prism OR tripod with adaptor and prism. Attach prism to the top of the tripod. • Stand the rod/tripod and prism, and place the tip of the rod/tripod on the unknown point of interest that you want to shoot (foresight shot). Make accurate centering & leveling so as to position the pole/tripod exactly on the ground point Note down the height of prism centre from ground point (height of foresight) • Make sure that the rod and prism are facing approximately the direction of the total station. The operator will give you directions to make sure that it is perfectly pointed later on. Instrument Orientation There are two orientations to be carried out a. Station Orientation b. Back sight Orientation In station orientation the absolute coordinates of the station (which is occupied by the total station) is fed to the total station. In backsight orientation either bearing of the base line or coordinate of the back station is fed to the total station. This is done only after the perfect sighting to the backsight point. This is required in order to orient the total station with respect to the known azimuth. Measurement The inclined distance and horizontal & vertical angles to target (Fore sights) are measured automatically at a push of button. Angle The angle measurement system of the total station in similar to that of an electronic theodolite, the dynamic angle-measuring system used in the total station makes use of a large number of graduation for each reading of the angle on Horizontal or Vertical circle of the instrument. This helps to eliminate as for as possible the effects of graduation errors. Most modern Total Station instruments measure angles by means of electro-optical scanning of extremely precise digital bar-codes etched on rotating glass cylinders or discs within the instrument. The best quality total stations are capable of measuring angles down to 0.5 arcsecond. Inexpensive "construction grade" total stations can generally measure angles to 5 or 10 arc-seconds. Distance Measurement of distance is accomplished with a modulated microwave or infrared carrier signal, generated by a small solid-state emitter within the instrument's optical path, and bounced off of the object to be measured. Electromagnetic modulated beam or wave is generated in the main instrument held at one end of the line to be measured. This modulated beam is directed toward a reflector held at the other end of the line from where it is reflected back toward the main instrument, in a parallel path, where the distance traveled by the electronic signal is determined by measuring the “phase-difference” between the transmitted and reflected signals. The modulation pattern in the returning signal is read and interpreted by the onboard computer in the total station, and the speed-of-light lag between the outbound and return signal is translated into distance. Most total stations use a purpose-built glass prism as the reflector for the EDM signal, and can measure distances out to a few kilometers, but some instruments are "reflectorless", and can measure distances to any object that is reasonably light in color, out to a few hundred meters. The typical Total Station EDM can measure distances accurate to about 0.1 millimeter, but most land surveying applications only take distance measurements to 1.0 mm. Some modern machines are 'robotic' allowing the operator to control the machine from a distance via remote control. This eliminates the need for an assistant staff member to hold the reflector prism over the point to be measured. The operator holds the reflector him/herself and controls the machine from the observed point. The other parameters like horizontal distance, co-ordinates, levels etc. are also calculated automatically and displayed digitally. The display may be alphanumeric and graphic as well. A number of trigonometrical functions and setting out parameters can also be performed. Initial setting parameters like bearing of a line, co-ordinates and height of the station occupied, the height of instrument and that of the reflector height needs to be input in the instrument memory before starting the actual measurement. It can also be used in trekking mode for continuous measurement on a moving reflector for setting out points of interest. Observations • A number of functions, settings and adjustments are available in the control panel mounted on the system to set up the Total Station for specific tasks. • Co-ordinates, height, and horizontal direction (angle) of instrument stations can be stored in the theodolite and are then available as station co-ordinates for the next traverse stations. Applications Total stations are the primary survey instrument used in many mining applications. Underground Mining As the development drifts in an underground mine are driven, a total station will be used to record the absolute location of the tunnel walls (tope), ceilings (backs), and floors. This data can then be loaded into a CAD program, such as SURPAC, AutoCAD, and compared to the designed layout of the tunnel. At regular intervals, the survey party will install stations. These are small steel plugs that are drilled into the walls or the back. The plugs are installed in pairs. For wall stations, two plugs are installed in opposite walls, forming a line perpendicular to the drift. For back stations, two plugs are installed in the back, forming a line parallel to the drift. When the survey crew wants to set up the total station in a drift, they use a set of plugs to locate the total station. Surface applications 1. Establishing National Grid bases at new areas: 2. Establishing boundaries in case of mining lease areas 3. Documentation of land holdings 4. Establishing control stations around OCPs 5. Training the present generation to face future challenges 6. Other applications a. Surveying the positions of benches b. Surveying the positions of the working faces, (to monitor the production) c. Monitoring the Positions of Machines in the Mine, d. Measurement of O.B. Dumps. e. Measurement of Stock piles, f. Detail Surveying on the Surface, g. Monitoring the pit slopes for Stability, h. Delineating the position of water in the sump. i. Updating the mine’s Information System (IS) j. Surveying the positions of boreholes, drilling sites etc. k. Strengthening the Survey Control Network. Manpower Requirements • One operator and one person for each prism. At least one prism is necessary. • There are systems that can be operated by one person. • Once the data is collected, it must be uploaded onto a computer to process Components of a Total Station EDM Electronic theodolite On-Board Micro-processor Data Collector (built in or separate unit) Data Storage (internal or memory card) Prisms Tri-pod Survey Rod (adjustable height) Micro-processor • Averages multiple angle measurements • Averages multiple distance measurements • Computes horizontal and vertical distances • Corrections for temp, pressure and humidity • Computes inverses, polars, resections • Computes X, Y and Z coordinates Fig. 2: Components of Total station A “RESECTION” P C B Fig. 3: Method of Angular measurement at a point Field to Finish Operations Memory card USB and Compact Flash Automatic target recognition Control/operation (robotic) Specifications 1. Range a. Reflectorless: b. Single Prism 2. Accuracy a. Angles b. Distance 3. 4. 5. 6. L.C L.C Data Storage Display Transfer remotely (radio/cell phone) Measurement and basic comps Fig. 4: Field to finish operation Final Comps, checks and outputs upto 1200 meters upto 5500 m 1” - 5” 3mm + 2ppm (prism) 4mm + 3ppm (reflectorless) 0.5” (Angular) upto 0.2mm (Distance) 20000 points / flash card with 256MB memory 11 digits Continuing Evolution of Measurement Technologies Leica Smartstation Merging TS and GPS Broadcast of Real-Time Corrections Topcon Imaging TS Merging TS and Lidar Terrestrial Photogrammetry Google Earth High Resolution Satellite Imagery Fig. 5: State of the art measurement techniques Major Manufactures PENTAX Total Stations : http://www.pentax.co.jp Nikon Total Stations : http://www.tdsway.com/products/nikon_tstations Leica total station : http://www.leica-geosystems.com/corporate/en/products/total_stations/ Trimble total stations : http://www.trimble.com/totalstations.shtml Sokkia total stations : http://www.sokkia.net/eu-index.html Topcon total stations : http://www.topconpositioning.com Smartstation • Recent developments include a GPS unit with the total station • Fully integrated data storage and data processing, Bluetooth data transfer or GPRS • It is a total station with integrated GPS receivers. All commands, displays, functions, operations and computations relating to GPS reside in the total station. With Smartstation there is no need to setup control points, long traverses or resections. Just Smart Station is set up at chosen point and GPS determine the position. The survey work becomes easier, quicker and it needs only few setups. • Total stations need local control points over which they can be set up, from which they can traverse, and to which they can measure to resect their positions. • On the other hand, GPS receivers can determine their positions within a few seconds to centimeter-level accuracy using data from GPS reference stations that may be 50km or more away. • GPS rover receivers are fast and efficient to use but need an open view of the sky in order that they can receive the satellite signals. They are at their most advantageous in wide, open areas. By contrast, total stations can measure and stakeout where GPS cannot be used: underground, to points under trees and bushes, in city canyons, on construction sites where there are large obstructions. Fig. 6: Smartstation Errors in Total Station Telescope errors Observation errors Levelling errors Manufacturing errors Fig. 7: Errors in Total station The Telescope • Parallax error • Collimation error Fig. 8: Error due to Telescope Parallax error The affect can be large. The solution is simple: • Focus the telescope on an object at optical infinity (say over 200m) • Then focus the eyepiece so that the cross-hair is crisp • Move your head and watch if the cross-hair moves Collimation Error • An error of adjustment • Occurs when the centre of the cross-hair is not aligned with the optical axis of the instrument Fig. 9: Collimation Errors • Can be detected by observing the difference between face left and face right – For Horizontal angles, the difference is 180° – For Vertical angles, they should sum to 360 ° • Can be removed by adjusting the cross-hair • Can be eliminated by taking the average of the face left and face right readings! Plate Bubble Error • There are two level bubbles The pill or bulls-eye bubble – The horizontal plate bubble – (and the vertical index bubble) Pill bubble • Is only approximate, to be used as a guide only • Can be corrected by adjustment once the instrument is correctly levelled Fig. 10: Tribrach Plate Bubble • Is the serious one • Is subject to errors of adjustment • The affect can be greatly reduced by averaging the displacement of the bubble during setup Plumbing Errors • Difficult to detect, we need to test the tribrach/instrument combination in the workshop • The optical plummet is still a telescope, we need to focus the cross-hair and image correctly • Errors are reduced by interchanging the jigger with targets when traversing Observation Errors • These are treated as random and can be modelled by the Normal Distribution • They can be reduced by repeated measurement • This improves accuracy and precision • Pointing to the wrong target is NOT an error! • Reading the display incorrectly is NOT an error! n xmean = σx mean ∑x i =1 n n = σx n