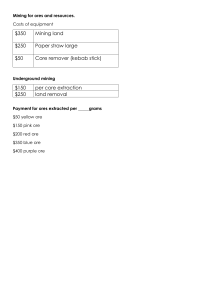

Article Quantitative Analysis of Iron and Silicon Concentrations in Iron Ore Concentrate Using Portable X-ray Fluorescence (XRF) Applied Spectroscopy 2020, Vol. 74(1) 55–62 ! The Author(s) 2019 Article reuse guidelines: sagepub.com/journals-permissions DOI: 10.1177/0003702819871627 journals.sagepub.com/home/asp Shubin Zhou1 , Zhaoxian Yuan2, Qiuming Cheng1, David C. Weindorf3, Zhenjie Zhang1, Jie Yang1, Xiaolong Zhang4, Guoxiong Chen5, and Shuyun Xie5 Abstract As a technique capable of rapid, nondestructive, and multi-elemental analysis, portable X-ray fluorescence (pXRF) has applications to mineral exploration, environmental evaluation, and archaeological analysis. However, few applications have been conducted in the smelting industry especially when analyzing the metal concentration in ore concentrate samples. This research analyzed the effectiveness of using pXRF in determining the metal concentration in Fe concentrate. For this proof of concept study, Fe ore samples dominated by Fe and Si were collected from the Northeastern University Mineral Processing Laboratory (Shenyang, China) and directly analyzed using pXRF, laboratory-based XRF, and titration methods. The compactness (density) of the ore concentrate was found to have very little effect on pXRF readings. The pXRF readings for Fe and Si were comparative to laboratory-based XRF results. Based on the strong correlations between the pXRF and XRF results (Fe: R2 > 0.99, Si: R2 > 0.96), linear calibrations were adopted to improve the accuracy of pXRF readings. Linear regression equations derived from the relations between XRF results and pXRF results of 21 Fe ore concentrate samples were used to calibrate the pXRF, and then validation was performed on five additional samples. Results from this preliminary study suggest that ordinary least squares (OLS) regression improves the accuracy dramatically, especially for Fe with relative errors (REs) decreasing to 0.03%–3.27% from 4.26%–8.32%. Consequently, pXRF shows strong promise for rapid, quantitative analysis of Fe concentration in Fe ore concentrate. Based on the results obtained in this study, a larger, more comprehensive study is warranted to confirm the results obtained. Keywords Portable X-ray fluorescence spectra, pXRF, quantitative analysis, compactness effect, calibration method, ore concentrates Date received: 5 March 2019; accepted: 16 July 2019 Introduction Iron concentrates are common commercial products used in the steel smelting industry. The concentrations of Fe in the Fe concentrate not only establish the values and prices of concentrate but also affect the smelting process and the quality of smelting products.1 Presently, titration is commonly used to determine the Fe concentrations in Fe ore concentrates.2 However, the traditional titration method is both time-consuming and uneconomical. Considering this, several researchers previously applied X-ray fluorescence (XRF) spectrometry and prompt gamma–neutron activation analysis system in the analysis of metal concentrations in ore concentrates.1,3–8 XRF spectrometry was suggested as a viable option for determining the concentration of major, minor, and trace elements in ore concentrates using proper calibration methods. By comparison, 1 State Key Lab of Geological Processes and Mineral Resources, China University of Geosciences, Beijing, China 2 Institute of Resource and Environmental Engineering, Hebei Geo University, Shi Jiazhuang, China 3 Department of Plant and Soil Science, Texas Tech University, Lubbock, TX, USA 4 School of Resources & Civil Engineering, Northeastern University, Shenyang, China 5 State Key Lab of Geological Processes and Mineral Resources, China University of Geosciences, Wuhan, China Corresponding author: Zhaoxian Yuan, No. 136, Huaian East Road, Shijiazhuang City, Hebei Province 050031, China. Email: sdyzx86@126.com 56 inductively coupled plasma–mass spectrometry is an alternate approach for the determination of minor and trace elements in ore concentrates.9 These analytical methods made multi-elemental analysis possible and simplified the analysis process to some extent. Compared with conventional analysis methods, portable XRF (pXRF) not only provides the advantages of nondestructive and multi-elemental analysis, but also simplifies the analysis process and reduces the expense by offering field portability.10–15 To date, it is widely accepted as a tool for data collection in mineral exploration, environmental quality assessment, and archaeological analysis.10,11,13,15–21 The results of pXRF measurements are influenced by many factors. For example, particle size, matrix effect, beam (dwell) time, moisture content, and sample homogeneity can all influence reported results.18,22–28 Thus, the pXRF analyzer may produce different results when analyzing samples with different physical properties (e.g., matrix density) such as rocks, soil, water, or plants.15,18,29–32 The calibration or response of pXRF to different sample types is dependent on the analytical mode used in various pXRF models; hence, several approaches, including ordinary least squares (OLS) regression calibration, nonlinear, and segmented calibration have been proposed to calibrate the pXRF readings for improved accuracy.29,30–33 Generally, pXRF is capable of quantitatively determining the elemental concentration of homogeneous samples with a higher degree of certainty such as polluted waters.28,31 Even for soil analysis, pXRF provides strong correlation with conventional analysis methods.12,34 Furthermore, predictive accuracy in soils can be improved using rudimentary sample preparation such as homogenizing, drying, grinding, and sieving.26 Ore concentrates are commonly dry, with fine particle size and a high degree of homogeneity. Given the demonstrated effectiveness of pXRF in analyzing water and soil samples, the purpose of this study is to develop a quantitative analysis method to obtain elemental information of Fe concentrates via pXRF and establish its effectiveness for industrial practices. Materials and Methods Applied Spectroscopy 74(1) Laboratory Analysis Analytical Instrument The instrument employed in this study was a Niton XL3t 950 (Thermo Fisher Scientific). The instrument is equipped with a silicon drift detector and an X-ray tube with a maximum voltage/current of 50 kV/40 mA and an Ag anode target excitation source. The diameter of the detection window is 8 mm. Three test modes, the mining mode, soil mode, and ‘‘test all’’ mode, are available for analyzing different types of samples. The mining mode is suitable for analyzing elements at higher concentrations (i.e., for major elements >0.2–0.5%), and soil mode is for minor and trace elements.21 According to Thermo Fisher Scientific (USA), the producer of the Niton XL3t 950 analyzer, the ‘‘test all’’ mode more rapidly obtains a comprehensive result than the other two modes, but with relatively poor accuracy. In this study, the ‘‘mining mode’’ was used since the concentrations of Fe were very high in ore concentrates. Film Analysis Due to the extremely small size of Fe concentrate particles, the particles can easily attach to other objects. Thus, the polyethylene films or paper bags needed to be used to prevent the ore concentrates from contaminating the pXRF detecting window. The effect of polyethylene films and paper bags on pXRF readings has been previously investigated by many scholars.23,28,32,35 The attenuation is generally linear with respect to concentration but highly dependent on the element.32 Polyethylene films generally deliver lower attenuation than paper packet and Mylar films. The penetration depth of the fluorescence signal is also affected by film thickness. For example, at a thickness of 2.5 mm, the Mylar film transmits 79% of the Si signal, which decreases to 57% at a thickness of 6.0 mm.23 Considering the X-ray transmission rate, availability, and economy, the same thin polyethylene film used in a previous study (tens of mm, with nearly no compositional interference), causing little attenuation of X-rays,28 was employed in this study. Sample Collection A total of 29 Fe ore samples were collected from the Northeastern University Mineral Processing Laboratory (Shenyang, China). These samples were mineral products produced in different mineral processing experiments of Fe ores with different ore grades. Thus, these Fe concentrates represent those commonly produced in an industrial setting. Due to the drying and grinding process during the mineral processing period, the collected Fe ore samples were dry and the particle size was very small (80% passing 74 mm). The Fe concentrates were stored in plastic bags to preserve desiccation and sent to the China University of Geosciences, Beijing, China, for further analysis. Compaction Effect Even though the fine particle size of ore concentrates was optimal for pXRF analysis, the compactness (density) of the sample was still of concern. Due to the particle size of ore concentrates, the volume of a certain weight of ore concentrate may vary significantly. Specifically, the compactness of ore concentrates could vary considerably when exposed to different levels of pressure in processing. Moreover, this kind of difference is very common and unavoidable in an industrial setting. For example, the ore concentrate stored at the bottom of the packing bags is generally more compacted than ore concentrates in the upper section due to Yuan et al. simple, gravitational effects. Thus, an experiment was conducted in this paper in order to determine whether the compactness of ore concentrates would affect the pXRF readings. In the first step, the three loose Fe ore concentrates were analyzed 20 times using pXRF. Next, pressure was applied, and the volumes of Fe ore concentrate were compacted to approximately one-third of their previous volumes. The compacted Fe ore concentrates were again analyzed 20 times using pXRF and used to evaluate the effect of compaction on pXRF elemental readings. 57 functions of concentration. The relative precision near detection limits is low.36–38 The relative standard deviation (RSD) of 20 measurements reflected the stability of the pXRF readings (precision). The RSD is described per Eq. 1 RSD ¼ SD 100% AM ð1Þ where SD is the standard deviation and AM is the arithmetical mean. Lower RSD values represent higher reliability of the results. Measurement of Iron Ore Concentrates In total, 26 Fe ore samples were analyzed in the laboratory via pXRF. The pXRF analyzer was placed vertically (aperture up) in the support stand. A small plastic tube (the bottom was covered with one layer of polyethylene film) was placed vertically on the pXRF aperture in the support stand. According to previous studies,22,23 the penetration depth was limited to a few hundred mm for different rocks, and 5 mm of soil was considered to be infinitely thick. The thickness of the Fe ore sample mass in the plastic tube was >8 mm. All measurements were controlled using NDT software. Mining mode was used to analyze the ore concentrates 20 times with a beam time of 60 s. Factory calibration, a self-calibration function of the Niton XL3t 950 analyzer, was performed after every 20 samples. The results of 21 samples were used for model calibration, and the remaining five samples were used for model validation. These samples later underwent X-ray fluorescence (ME-XRF21m) and titrimetric analysis (Fe-VOL82) at ALS Minerals (ALS Chemex, Ltd., Guangdong, China). For the X-ray fluorescence (ME-XRF21m) analysis, the Fe ore sample was mixed with fusing agents (Li2B4O7 and Li2CO3) and cobalt internal standard. The fusion pieces were then prepared using a Vulcan Fusion Machine (IMP Automation). The X-ray fluorescence spectrometer was a PW2424 (Malvern Panalytical). In titrimetric analysis, the Fe concentrates were dissolved in HNO3–HF and dissolved with a mixture of sulfuric acid–phosphoric acid (H2SO4– H3PO4). Fe3þ was then reduced to Fe2þ using stannous chloride/titanium trichloride. The total Fe in Fe concentrate was titrated using potassium dichromate standard solution with sodium diphenylamine sulfonate as indicator. Statistical Analysis Accuracy and Precision The accuracy in this study was the description of systematic errors and a measure of statistical bias. Typically, accuracy can be reflected in the linear regression equation between certified values and pXRF readings. The precision was the description of random errors, a measure of statistical variability. The precision (and to an extent accuracy) are Calibration and Performance Verification A linear regression model was used to establish the relationship between pXRF and XRF results. The linear regression model was described using Eq. 2: y ¼ mx þ b ð2Þ where x is the Fe or Si concentration reported using XRF and y is the pXRF reading for Fe. The value of m represents the slope of the line and b is the y intercept; m and b are used to calculate the response factor and the offset correction values, respectively. Therefore, the regression equation can be expressed as Eq. 3: ½pXRF readings ¼ m½certified concentrations þ b ð3Þ This equation enables calibration of the pXRF readings for optimized accuracy. Following on, Eqs. 4 and 5 are given as ½calibrated pXRF reading ¼ 1 ð½pXRF readings bÞ m ð4Þ which we simplified to: ½calibrated pXRF reading ¼ p½pXRF reading þ c ð5Þ where p ¼ m1 and c ¼ mb Measurement Times Versus Absolute Errors The absolute error (AE) for n measurements is given as Eq. 6 " # n 1 X AEn ¼ ð r i ci Þ n i¼1 ð6Þ where ri is the pXRF reading after OLS calibration and ci represents the results measured using XRF. 58 Applied Spectroscopy 74(1) Results and Discussion Compactness Effect As shown in Table I, two groups of data which were produced by analyzing the same samples with different compaction (density) were compared. A paired-sample t-test was also conducted to determine the significant difference between the samples. The two groups of data revealed only modest differences. The calculated P values (two-tail) for G-0914-28 and T-0807-14-24 were 0.21 and 0.07, Table I. Portable X-ray fluorescence of Fe content (%) of loose/ compacted Fe ore concentrate. Sample description Fe content (G-0914-28) Fe content (G-0116-15) Fe content (T-0807-14-24) Loose Compacted 47.73 47.86 9.84 9.67 51.05 50.85 Figure 1. Scatter plots of Fe contents reported using XRF versus Fe content reported using titration for Fe ore concentrate in China. respectively, which indicates no significant difference between loose and compacted samples with relatively high Fe concentrations. However, the P values (two-tail) for G-0116-15 was 0.00, suggesting a significant difference for loose and compacted ore concentrate with low Fe concentration. Even so, the average mean of Fe readings for loose and compacted samples was generally the same, indicating that it is not necessary to control the compactness of homogeneous Fe ore samples for pXRF measurements. This is likely due to the inherent high particle density of Fe oxides (e.g., hematite 5.3 g cm–3) and relatively uniform, small particle size. Undoubtedly, the study of compactness effects broadens the potential application of pXRF in industrial practices, suggesting only simple sample preparation methods are needed. Accuracy and Precision According to the laboratory analysis, the Fe ore concentrate was Fe and Si dominated. As shown in Fig. 1, the XRF data were in perfect correlation with elemental data produced by titration. The Fe content reported using titration is generally slightly higher (0.17%–0.66%) than that reported using XRF. Due to the relatively high detection limit of titration, e.g., ciron > 10%, elemental data for five samples (G-0914-27, G-2714-27, G-0116-8, G-0714-29, and G-1111-29) was not possible through titration. Therefore, the data produced using XRF (in perfect correlation to titration) were used for comparison with pXRF results. Prior to model development, five samples of different Fe ore concentration ranges were chosen as the validation set. The relationship between the pXRF readings of the remaining 21 samples and the XRF results is displayed in Figs. 2a and b. Linear regression analysis was used to compare the pXRF data with the XRF data. The slope and the square of the correlation coefficient (R2) of the regression line close to 1 indicate accurate pXRF results. As shown in Fig. 2a, Figure 2. Scatter plots of pXRF readings versus XRF-determined Fe or Si concentrations (a, b) display the results for Fe and Si, respectively, in Fe ore concentrate from China. Yuan et al. the slope of the regression line for Fe is 1.042 and the R2 value is 1.000, which indicates robust pXRF performance. The pXRF data for Fe were comparable with certified values and calibrated through the linear regression. However, as shown in Fig. 2b, the slope of the regression line for Si is 0.858 and the R2 value is 0.963, suggesting slightly less accurate results for Si compared to Fe. Such results were expected, as pXRF is more sensitive for heavier elements due to its higher excitation energy.39,40 Twenty replicate measurements were conducted for each sample, making it possible to calculate the RSD of pXRF data. Thus, the RSD values reflect the stability of pXRF results. Yuan et al.16 reported that pXRF offers good performance when analyzing samples with relatively high elemental concentrations. Figure 3 illustrates the variation in RSDs with increasing Fe and Si concentrations. The RSD values for Si generally decrease with the increasing Si concentrations. Even so, all RSD values are <8%. In contrast, RSD values for Fe were mostly <2% (except one with a RSD of 2.16), which indicates relatively better stability. 59 The solid stability results obtained likely reflect high homogeneity of the ore concentrate. Calibration and Performance Verification Considering the good correlation between pXRF readings and XRF results for both Fe and Si, an attempt was made to calibrate the pXRF readings through the formulas obtained from the measurements of the 21 samples. According to the equations described in Figs. 4a and 4b, the calibration formulations for Fe and Si are given as Eqs. 7 and 8, respectively. yFe ¼ xFe 0:057 1:042 ð7Þ ySi ¼ xSi 0:75 0:858 ð8Þ The xFe and xSi values represented original readings for Fe and Si, respectively. The yFe and ySi represent calibrated readings for Fe and Si, respectively. To determine the effectiveness of the calibration, the REs for original errors and errors after calibration were compared. The REs were defined per Eq. 9. REFe=Si ¼ Figure 3. The RSDs of pXRF readings for Fe or Si versus XRFdetermined Fe or Si concentrations in Fe ore concentrate from China. j pXRFFe=Si XRFFe=Si j XRFFe=Si ð9Þ The REs of the calibrated readings were calculated through the same method. Figs. 4a and 4b display the results. The line indicated by triangles and the line using squares represent the errors after linear calibration and original errors, respectively. As shown in Fig. 4a, the REs for Fe decrease to 0.03%–3.27% from 3.81%–8.32%, suggesting that the OLS calibration for Fe can effectively improve the accuracy. However, as shown in Fig. 4b, Figure 4. Improvement in accuracy of portable X-ray fluorescence (pXRF) readings using OLS regression calibration, (a, b) display the results for Fe and Si, respectively, for Fe ore concentrate in China. 60 Applied Spectroscopy 74(1) Table II. Portable X-ray fluorescence replicate measurements versus absolute errors (%) for Fe ore concentrate in China. MT AE-(G-2714-27) AE-(G-0914-24) AE-(G-0714-28) AE-(G-2714-20) AE-(G-1111-31) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 0.17 0.20 0.23 0.25 0.26 0.24 0.24 0.26 0.26 0.26 0.26 0.27 0.27 0.27 0.27 0.27 0.26 0.26 0.26 0.27 1.28 0.65 0.51 0.34 0.43 0.27 0.22 0.24 0.34 0.33 0.26 0.20 0.24 0.21 0.20 0.18 0.23 0.23 0.22 0.22 0.50 0.63 0.64 0.40 0.38 0.52 0.44 0.46 0.52 0.46 0.46 0.46 0.41 0.42 0.41 0.40 0.36 0.36 0.33 0.31 0.54 0.29 0.06 0.13 0.09 0.19 0.19 0.20 0.14 0.19 0.10 0.13 0.11 0.17 0.16 0.12 0.10 0.09 0.10 0.10 0.19 0.05 0.00 0.31 0.35 0.33 0.24 0.12 0.09 0.03 0.04 0.04 0.02 0.15 0.13 0.05 0.03 0.00 0.00 0.02 MT: measurement time; AE: absolute error. the effect of calibration for Si was less robust. The OLS calibration improved the accuracy for four samples with Si contents >8.8%. For sample G-1111-31 with a Si content of 5.6%, the OLS calibration failed to reduce the error probably due to the relatively low Si content. Measurement Times versus Absolute Errors As shown in Table II, the AEs for one time of measurement are from 0.17% to 1.28%. The results with such accuracy are mostly attributed to the high homogeneity of the ore concentrate. Generally, the AEs decrease with increasing replicate measurements, suggesting the necessity to perform repeated measurements. The errors would keep relatively stable after certain minimum measurement times (MTs). In fact, as shown in Fig. 1, different laboratorybased methods such as XRF or titration produce different readings on the same sample with AEs ranging from 0.17% to 0.66%. Thus, calibrated pXRF readings were found to be comparable to the elemental data produced using XRF or titration. Based on the consideration of both MT and accuracy, at least four replicate scans for averaging are recommended in further measurements of ore concentrates which share similar physical properties (particle size, moisture, and homogeneity) as the ore concentrates described herein. Conclusion In this preliminary study, the feasibility of using pXRF to quantitatively analyze Fe and Si concentrations was assessed. The effect of the compaction of Fe ore concentrate on the pXRF readings was also evaluated. Based on high correlations between pXRF readings and certified elemental data reported using XRF, OLS calibration equations were built and used to directly predict unknown samples. Results indicated that the OLS calibrations can substantively improve pXRF predictive accuracy and provide reliable elemental data in the rapid analysis of ore concentrate. Declaration of conflicting interests The authors declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article. Funding This research was supported by the National Key Research and Development Program of China (No.2016YFC0600501), the National Basic Research Program of China (2015CB452605), Yuan et al. 61 the China Geological Survey Project (No.DD20160045, No. DD20190459), the National Natural Science Foundation of China (No. 41602338, No. 41302263, No. 41430320, No.41702075, No. 41702355 No.51734005), the Research Program of Hebei Education Department (No. ZD2017011), the Fundamental Research Funds for the Central Universities, China University of Geosciences, Wuhan (No. CUG170104), and the BL Allen Endowment in Pedology at Texas Tech University. ORCID iD Shubin Zhou https://orcid.org/0000-0003-4104-1688 References 1. F. Wang, Z. Li, B. Qian. ‘‘Rapid Analysis of Iron Concentrates by X-ray Fluorescence Spectrometry with Sol-Gel Sample Preparation Technology’’. J. Xray. Sci. Technol. 2011. 19(3): 417. 2. The National Standards of the People’s Republic of China. ‘‘Iron Ores: Determination of Total Iron Content – Titanium (III) Chloride Reduction Methods (GB/T 6730.5-2007). 2007. (In Chinese). 3. W.C. Lai, L.Q. Ge, Y.P. Wu, et al. ‘‘Application of Light XRF Analyzer in Rapid Testing of Iron Concentrate Quality’’. Metal Mine. 2003. 7: 15. 4. L. Zhao, X. Xu, J.B. Lu, et al. ‘‘Study on Element Detection and its Correction in Iron Ore Concentrate Based on a Prompt GammaNeutron Activation Analysis System’’. Nucl. Sci. Tech. 2019. 30(4): 58. 5. G. Budak, A. Karabulut. ‘‘X-ray Fluorescence Analysis of Malachite Ore Concentrates in the Narman Region’’. Spectrochim. Acta, Part B. 1999. 54(6): 985–988. 6. R. Polat, A. Gürol, N. Ekinci, et al. ‘‘Determination of Ore Concentrates by Energy Dispersive X-ray Fluorescence Spectrometry’’. J. Trace Microprobe Tech. 2003. 21(1): 63–71. 7. J. Liu, B. Qiao. ‘‘Quantitative Analysis of Lead Ores Using Sepharose for Sample Preparation by X-ray Fluorescence Spectrometry’’. Anal. Lett. 2010. 43(5): 836–842. 8. S. Turmel, C. Samson. ‘‘X-ray Fluorescence Analysis of Iron Ore Concentrates’’. X-Ray Spectrom. 1984. 13(2): 87–90. 9. S.F. Boulyga, J.A. Cunningham, Z. Macsik, et al. ‘‘Development, Validation and Verification of an ICP-MS Procedure for a MultiElement Analysis of Uranium Ore Concentrates’’. J. Anal. Atom. Spectrom. 2017. 32(11): 2226–2237. 10. D.J. Kalnicky, R. Singhvi. ‘‘Field Portable XRF Analysis of Environmental Samples’’. J. Hazard. Mater. 2011. 83(1–2): 93–122. 11. C. Kilbride, J. Poole, T.R. Hutchings. ‘‘A Comparison of Cu, Pb, As, Cd, Zn, Fe, Ni, and Mn Determined by Acid Extraction/ICP–OES and Ex Situ Field Portable X-ray Fluorescence Analyses’’. Environ. Pollut. 2006. 143(1): 16–23. 12. Y.D. Zhu, D.C. Weindorf, W.T. Zhang. ‘‘Characterizing Soils Using a Portable X-ray Fluorescence Spectrometer: 1. Soil Texture’’. Geoderma. 2011. 167: 167–177. 13. D.C. Weindorf, Y.D. Zhu, S. Chakraborty, et al. ‘‘Use of Portable X-ray Fluorescence Spectrometry for Environmental Quality Assessment of Peri-Urban Agriculture’’. Environ. Monit. Assess. 2012. 184(1): 217–227. 14. D.C. Weindorf, Y.D. Zhu, B. Haggard, et al. ‘‘Enhanced Pedon Horizonation Using Portable X-ray Fluorescence Spectrometry’’. Soil Sci. Soc. Am. J. 2012. 76(2): 522–531. 15. A.G. Caporale, A. Paola, C. Fiore, et al. ‘‘Monitoring Metal Pollution in Soils Using Portable-XRF and Conventional Laboratory-Based Techniques: Evaluation of the Performance and Limitations According to Metal Properties and Sources’’. Sci. Total. Environ. 2018. 643: 516–526. 16. N. Craig, R.J. Speakman, R.S. Popelka-Filcoff, et al. ‘‘Comparison of XRF and PXRF for Analysis of Archaeological Obsidian from Southern Peru’’. J. Archaeol. Sci. 2007. 34(12): 2012–2024. 17. Z.X. Yuan, D.Y. Xu, Z.J. Chen, et al. ‘‘Application of Portable XRF Technology for Hand Specimen Scale Geochemical Imaging and Identification of Sequences of Mineralization’’. J. Jilin University (Earth Sci. Ed.) [Jilin Daxue Xuebao (Diqiu Kexueban)]. 2012. 42: 216–223. 18. Z.X. Yuan, Q.M. Cheng, Q.L. Xia, et al. ‘‘Spatial Patterns of Geochemical Elements Measured on Rock Surfaces by Portable X-ray Fluorescence: Application to Hand Specimens and Rock Outcrops’’. Geochem.: Explor. Environ. Anal. 2014. 14(3): 265–276. 19. D.C. Weindorf, L. Paulette, T. Man. ‘‘In-Situ Assessment of Metal Contamination via Portable X-ray Fluorescence Spectroscopy: Zlatna, Romania’’. Environ. Pollut. 2013. 182: 92–100. 20. M. Rouillon, M.P. Taylor. ‘‘Can Field Portable X-ray Fluorescence (pXRF) Produce High Quality Data for Application in Environmental Contamination Research?’’ Environ. Pollut. 2016. 214: 255–264. 21. L.L. Burley, S.J. Barnes, C. Laukamp, et al. ‘‘Rapid Mineralogical and Geochemical Characterisation of the Fisher East Nickel Sulphide Prospects, Western Australia, Using Hyperspectral and pXRF Data’’. Ore Geol. Rev. 2017. 90: 371–387. 22. P.J. Potts, O. Williams-Thorpe, P.C. Webb. ‘‘The Bulk Analysis of Silicate Rocks by Portable X-ray Fluorescence: Effect of Sample Mineralogy in Relation to the Size of the Excited Volume’’. Geostand. Newslett. 1997. 21(1): 29–41. 23. G.E.M. Hall, A. Buchar, G. Bonham-Carter. ‘‘Quality Control Assessment of Portable XRF Analysers: Development of Standard Operating Procedures, Performance on Variable Media and Recommended Uses’’. Canadian Mining Industry Research Organization (CAMIRO). CAMIRO Project 10E01, Phase I. 2011. https://www.appliedgeochemists.org/images/stories/XRF/pXRF% 20Report%20Phase%20I%20Report%20rev%20Oct%202013.pdf [accessed Aug 2 2019]. 24. R. Ravansari, L.D. Lemke. ‘‘Portable X-ray Fluorescence Trace Metal Measurement in Organic Rich Soils: pXRF Response as a Function of Organic Matter Fraction’’. Geoderma. 2018. 319: 175–184. 25. B.T. Ribeiro, D.C. Weindorf, B.M. Silva, et al. ‘‘The Influence of Soil Moisture on Oxide Determination in Tropical Soils via Portable X-ray Fluorescence’’. Soil Sci. Soc. Am. J. 2018. 82(3): 632–644. 26. K. Tian, B. Huang, Z. Xing, et al. ‘‘In Situ Investigation of Heavy Metals at Trace Concentrations in Greenhouse Soils via Portable X-ray Fluorescence Spectroscopy’’. Environ. Sci. Pollut. R. 2018. 25(11): 11011–11022. 27. A. Turner, C.C. Chan, M.T. Brown. ‘‘Application of FieldPortable-XRF for the Determination of Trace Elements in Deciduous Leaves from a Mine-Impacted Region’’. Chemosphere. 2018. 209: 928–934. 28. S.B. Zhou, Z.X. Yuan, Q.M. Cheng, et al. ‘‘Rapid In Situ Determination of Heavy Metal Concentrations in Polluted Water via Portable XRF: Using Cu and Pb as Example’’. Environ. Pollut. 2018. 243(Pt B): 1325–1333. 29. D. Sacristán, R.A.V. Rossel, L. Recatalá. ‘‘Proximal Sensing of Cu in Soil and Lettuce Using Portable X-ray Fluorescence Spectrometry’’. Geoderma. 2016. 265: 6–11. 30. C. McGladdery, D.C. Weindorf, S. Chakraborty, et al. ‘‘Elemental Assessment of Vegetation via Portable X-ray Fluorescence (PXRF) Spectrometry’’. J. Environ. Manage. 2018. 210: 210–225. 31. D. Pearson, D.C. Weindorf, S. Chakraborty, et al. ‘‘Analysis of MetalLaden Water via Portable X-ray fluorescence Spectrometry’’. J. Hydrol. 2018. 561: 267–276. 32. M. Rincheval, D.R. Cohen, F.A. Hemmings. ‘‘Biogeochemical Mapping of Metal Contamination from Mine Tailings Using Field-Portable XRF’’. Sci. Total. Environ. 2019. 662: 404–413. 33. D.R. Cohen, E.J. Cohen, I.T. Graham, et al. ‘‘Geochemical Exploration for Vertebrate Fossils Using Field Portable XRF’’. J. Geochem. Explor. 2017. 181(1): 1–9. 62 34. M.B. Bernick, D.J. Kalnicky, G. Prince, et al. ‘‘Results of Field-Portable X-ray Fluorescence Analysis of Metal Contaminants in Soil and Sediment’’. J. Hazard. Mater. 1995. 43(1–2): 101–110. 35. P.A. Morris. Field-Portable X-ray Fluorescence Analysis and its Application in GSWA. Perth: Geological Survey of Western Australia, 2009. 36. C.R. Stanley. ‘‘On the Special Application of Thompson–Howarth Error Analysis to Geochemical Variables Exhibiting a Nugget Effect’’. Geochem.: Explor. Environ. Anal. 2006. 6(4): 357–368. 37. M. Thompson, R.J. Howarth. ‘‘Duplicate Analysis in Geochemical Practice (Parts 1 and 2)’’. Analyst. 1976. 101(1206): 690–709. Applied Spectroscopy 74(1) 38. M. Thompson, R.J. Howarth. ‘‘A New Approach to the Estimation of Analytical Precision’’. J. Geochem. Explor. 1978. 9(1): 23–30. 39. V. Orfanou, Th. Rehren. ‘‘A (Not So) Dangerous Method: pXRF vs. EPMA-WDS Analyses of Copper-Based Artefacts’’. J. Anthropol. Archaeol. 2014. 7(3): 387–397. 40. D.C. Weindorf, S. Chakraborty. ‘‘Portable X-ray Fluorescence Spectrometry Analysis of Soils’’. Meth. Soil Anal. 2016. 1(1). doi: 10.2136/methods-soil.2015.0033.