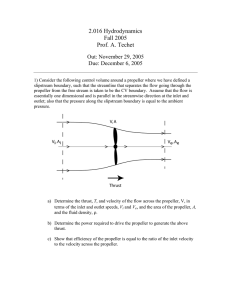

Proceedings of the Institution of Mechanical Engineers, Part M: Journal of Engineering for the Maritime Environment http://pim.sagepub.com/ Hydrodynamic analysis of puller and pusher of azimuthing podded drive at various yaw angles Reza Shamsi and Hassan Ghassemi Proceedings of the Institution of Mechanical Engineers, Part M: Journal of Engineering for the Maritime Environment published online 30 April 2013 DOI: 10.1177/1475090213481417 The online version of this article can be found at: http://pim.sagepub.com/content/early/2013/04/29/1475090213481417 Published by: http://www.sagepublications.com On behalf of: Institution of Mechanical Engineers Additional services and information for Proceedings of the Institution of Mechanical Engineers, Part M: Journal of Engineering for the Maritime Environment can be found at: Email Alerts: http://pim.sagepub.com/cgi/alerts Subscriptions: http://pim.sagepub.com/subscriptions Reprints: http://www.sagepub.com/journalsReprints.nav Permissions: http://www.sagepub.com/journalsPermissions.nav >> OnlineFirst Version of Record - Apr 30, 2013 What is This? Downloaded from pim.sagepub.com at University of Sydney on April 30, 2013 Original Article Hydrodynamic analysis of puller and pusher of azimuthing podded drive at various yaw angles Proc IMechE Part M: J Engineering for the Maritime Environment 0(0) 1–15 Ó IMechE 2013 Reprints and permissions: sagepub.co.uk/journalsPermissions.nav DOI: 10.1177/1475090213481417 pim.sagepub.com Reza Shamsi and Hassan Ghassemi Abstract The research explained in this article was carried out to investigate the hydrodynamic characteristics of the puller and pusher azimuthing podded drive propulsion at various yaw angles and different operating conditions. The method is finite volume–based Reynolds-averaged Navier–Stokes. The renormalization group k-e model is employed using the differential viscosity model and swirl-dominated flow to simulate turbulence. For the purposes of this research, two different propellers (B-series and David Taylor Model Basin (DTMB)) are analysed in pusher and puller of azimuthing podded drive configurations. The performance curves of the propellers obtained by numerical methods are compared and verified by the experimental results. Characteristic parameters including torque and thrust of propeller and axial force and side force of the unit are presented as functions of advance coefficients and yaw angles. Keywords Propeller, azimuthing podded drive, Reynolds-averaged Navier–Stokes, yaw angles Date received: 20 May 2012; accepted: 18 January 2013 Introduction One of the main objectives of this research was to find the hydrodynamic characteristics and flow field around the azimuthing podded drive (AZIPOD). For the past 10 years, the AZIPOD systems have been widely used in the marine industry, not only for passenger ships but also for offshore drilling units and naval vessels. The main components of podded propulsor are strut, pod, and propeller. In this system, an electrical motor is located inside a steerable pod housing that drives a fixed pitch propeller. The total unit is hung below the stern of the ship by strut and can be rotated through 360° around its vertical axis. Therefore, thrust is generated in any direction that gives the better manoeuvrability. This device combines propulsion and manoeuvring functions mutually.1 Two main configurations of the podded systems are the puller and pusher types. In the puller type, the propeller is located in the forward face of the pod and on the upstream of the strut, but in the pusher type, the propeller is located in the downward face of the pod and on the downstream of the strut. In general, the efficiency of the podded propulsor is lower than openwater propeller. This is due to the resistance of the pod and strut. Therefore, the resistance of unit is an important factor that cannot be ignored. The pushertype propeller has lower efficiency than the puller type. In the pusher type, the propeller works in the wake of the strut. Selection of podded propulsor’s type depends on ship performance, speed, and comfort criteria.2 The AZIPOD systems have many advantages over conventional propulsion systems such as more uniform flow, good manoeuvrability, better seakeeping performance characteristics than the conventional vessel, low noise and vibration, fuel saving, space saving in ship arrangement, and rudder and shaft elimination.3,4 The conventional propulsion systems or propeller–rudder system (PRS) is working behind a ship hull where they encounter a large wake flow. Due to the presence of the hull, the flow distribution into the propeller is nonuniform and unsteady. The most significant hydrodynamic advantage of the AZIPOD system is that the Department of Ocean Engineering, Amirkabir University of Technology, Tehran, Iran Corresponding author: Hassan Ghassemi, Department of Ocean Engineering, Amirkabir University of Technology, Hafez Ave, No. 424, P.O. Box 15875-4413, Tehran, Iran. Email: gasemi@aut.ac.ir Downloaded from pim.sagepub.com at University of Sydney on April 30, 2013 2 Proc IMechE Part M: J Engineering for the Maritime Environment 0(0) propeller is set in a more uniform and axisymmetric flow. This regular flow reduces unsteady forces and the propeller radiated hull surface pressures that reduce cavitation risk on the propeller blades.5 Alternatively, the AZIPOD has a few disadvantages. These problems may be considered in three sections: hydrodynamic performance, operational problems, and environmental aspects.6 The ship’s lateral area is decreased by using the AZIPOD systems. Therefore, directional stability of the ship is decreased. Also, reduced lateral area and increased steering forces generate a large rolling motion for the ship. This may restrict the ship performance in the turning manoeuvres. The AZIPOD systems have a few operational problems such as failure of mechanical and electrical components of the podded propulsor, electrical power limitation, accommodating a large motor inside the pod, and high capital cost relative to conventional propulsion systems. Also, hydrodynamic impacts on the environment in terms of ship wash effect and wave propagation should be considered in these systems.7 More recently, due to the market needs and in order to gain more efficiency by the AZIPOD systems, marine researchers (such as Ma et al.,8 Islam et al.,9 Bal et al.,10 Lijun and Yanyin,11 and Carlton12,13) have rigorously pursued this topic, and much effort has been devoted to explore it numerically and experimentally.14,15 Because of the problems in testing AZIPOD, limited experimental work has been performed. Experimental studies of Szantyr16 were one of the early works for AZIPOD in azimuthing condition. They measured axial and transverse force and moment for AZIPOD to 615° yaw angle. Grygorowicz and Szantyr17 measured force and moments for the puller and pusher podded propulsor models. Woodward et al.18 proposed a practical method for predicting the global forces and moments acting on a podded propulsor at any different load condition and yaw angle. This method is validated with model test. They used these data for the study of the various modes that may be employed to stop a poddriven ship. Reichel19 also presented results of comprehensive manoeuvring open-water tests of a pusher AZIPOD. Steering forces were measured in the range of yaw angles from 245° to +45°. Another important study is the work carried out by Islam et al.20,21 Particular test equipment was designed, and several different measurements were considered. The AZIPOD was tested in the puller and the pusher conditions in different yaw angles from 230° to +30°. Their results showed that the unit force and moment coefficients depend on the propeller advance coefficient, yaw angle, and yaw direction. In the recent work, Amini and Steen22 reported systematic model test results of the podded drives in different advance velocities and different yaw angles. The tests were performed on the pulling and pushing models for both open-water and in behind conditions.23 It is a common practice to perform a model test to evaluate the hydrodynamic performance of a marine propeller or propulsion system. However, the model test is usually expensive and time-consuming. An alternate approach computational fluid dynamics (CFD) is a powerful tool for analysing the performance of ship propulsion system. Numerical analysis of the podded drive in azimuthing condition has not thus far been adequately explored. For this reason, a wide numerical analysis is used in order to understand the flow pattern around the podded drives in azimuthing condition and interaction between the propeller, pod, and strut. In this work, the finite volume–based Reynolds-averaged Navier–Stokes (RANS) solver is applied to predict the hydrodynamic performance of propeller alone and a new design AZIPOD system. By these simulations, the characteristics of flow around the marine propeller and AZIPOD are presented including pressure distribution and open-water performance curves in zero angle and oblique flow. Previous work To date, both inviscid and viscous solvers are used in hydrodynamic analysis of marine propellers. The viscous method has traditionally been employed for flow problems, where turbulence, boundary layer, wake, and viscous resistance are important. The viscous solvers are based on the solutions of the RANS equations and are now commonly used in the design of turbomachinery components. In 2002, RANS method was employed by Funeno24 for analysis of marine propellers. The most important advantage of RANS method is that the viscous effects decreasing the propeller efficiency could be directly captured, and the flow near the hub and tip of propeller is well investigated. In 2003, Rhee and Joshi25 used RANS method with unstructured and sliding mesh for analysing a marine propeller in unsteady conditions. In order to study the effect of yaw angle on AZIPOD performance, different numerical methods have been used from potential method or potential/ viscous method to pure viscous method. Figure 1 shows the numerical methods for the hydrodynamic analysis of the AZIPOD. In azimuthing condition, there is interaction between pod, propeller, and strut. Therefore, the viscous effect is an important phenomenon in hydrodynamic analysis. The numerical methods based on potential flow theory have been used widely and successfully to predict the performance of conventional propellers. The modified wake model must be assumed in order to predict the performance of podded propellers using potential flow–based numerical method. Ghassemi and Ghadimi5 predicted AZIPOD performance using potential flow method. Achkinadze et al.26 presented a velocity-based panel method improved with semiempirical viscosity corrections for lift and drag of propeller blade and strut sections. Liu et al.27 applied unsteady panel method code for predicting unsteady Downloaded from pim.sagepub.com at University of Sydney on April 30, 2013 Shamsi and Ghassemi 3 Figure 1. Numerical methods for hydrodynamic analysis of AZIPOD. BEM: boundary element method; RANS: Reynolds-averaged Navier–Stokes; VLM: vortex lattice method. forces, torques, and bending moments for an AZIPOD unit model at various yaw angles. Their results showed that at large yaw angles, there is a discrepancy between numerical results and experimental data. Due to viscous effects at large yaw angles, the interaction between propeller, pod, and strut increases. Also at these angles, drag forces of propeller, pod, and strut increase to high values because of flow separation. For this reason, potential results should be corrected at large yaw angles by estimating a proper value for AZIPOD drag. Different hybrid methods were used to predict flow characteristics around podded propulsors. In hybrid potential/viscous approach, the flow around propeller is simulated by boundary element method (BEM) or vortex lattice method (VLM) and pod and strut are modelled by RANS or Euler solvers. Body force approach is used for coupling these methods. Main studies in this field have been done by Gupta,2 Mishra,3 and Bal and Guner.28 RANS simulation for AZIPOD has been done by Sanchez-Caja et al.29,30 They presented a fully viscous method for analysis of these systems. Koushan and Krasilnikov31 applied unsteady RANS solver for simulating the flow around pulling and pushing pod propeller in azimuthing condition from 245° and +45° yaw angles. Although in recent years AZIPOD systems are installed in many ships, efficient research schemes are needed to provide more details of the performance at various operational design conditions. This research focused on the variation of forces generated by the propeller, pod, and strut at different azimuth conditions and yaw angles for both pusher and puller types. The numerical results included are the open-water characteristics of the propeller alone and hydrodynamic performance of the pusher and puller types of the AZIPOD at various yaw angles. Comparisons of these two types are also presented and discussed at various operating conditions. Governing equations The governing equations for viscous flow in this study are the Navier–Stokes (NS) equations for momentum transport and continuity equation for mass conservation and can be stated as ∂r +r ðr~ vÞ = 0 ∂t ∂ ðr~ vÞ+r ðr~ v~ vÞ = rp+r ðt Þ ∂t ð1Þ ð2Þ where ~ v denotes the velocity vector, p is the static pressure, and t represents the stress tensor given by 2 vI t = m r~ v+r~ vT r ~ 3 ð3Þ where m is the molecular viscosity and I denotes the unit tensor. Using the Reynolds averaging approach, the NS equations can be expressed as ∂r ∂ + ðrui Þ = 0 ∂t ∂xi ∂ ∂ ∂p ðrui Þ+ rui uj = ∂t ∂xj ∂xi ∂ ∂ui ∂uj 2 ∂uI ∂ + m + dij ru9i u9j + ∂xj ∂xj ∂xj ∂xi 3 ∂xI ð4Þ ð5Þ where dij is the Kronecker delta and ru9i u9j shows the Reynolds stresses. It is rather difficult to model the components of the Reynolds stress tensor because it requires detailed and unavailable data about turbulent structures in the flow. When a turbulence model is to be chosen, it is worth considering whether a complicated or a simple model should be used. The k-e and k-v models are the most widely used turbulence models for external aerodynamics and hydrodynamics analyses. The continuous flow problem is to be discretized for the numerical solution of the governing equations in CFD. This can be Downloaded from pim.sagepub.com at University of Sydney on April 30, 2013 4 Proc IMechE Part M: J Engineering for the Maritime Environment 0(0) Figure 2. Model of solution field for propeller alone. Figure 3. Model of solution field for puller and pusher types of AZIPOD. done by four different techniques: finite volume, finite difference, finite element, and finite analytic method. The most popular technique for discretization of governing equations in marine hydrodynamics is finite volume method, but finite difference and finite analytic methods are also employed.32 Numerical method In order to model the propeller in the fluid environment, the solution field is divided into dynamic and static cylindrical frames, as depicted in Figure 2. The dynamic frame simulates the propeller rotation and employs the Coriolis acceleration terms in the governing equations for the fluid. The dimensions of this frame are related to the propeller diameter. The static frame surrounds the dynamic frame. In this study, the domain size was chosen based on our previous work33 and some other CFD works on marine propellers.32–34 The proposed dimensions proved to be the proper ones to achieve this end. The static frame is a cylinder with 3D diameter. The distance between the dynamic frame and inlet is nearly 2D, while it is nearly 5D for the outlet and dynamic frame. The same method is used for the AZIPOD, but the dimensions of frames are selected related to the pod length. Figure 3 shows the sketch of computational domain for the puller and pusher of the AZIPOD. In addition, a mesh convergence study was performed for a single propeller. In this study, different element sizes are considered. The best compromise Downloaded from pim.sagepub.com at University of Sydney on April 30, 2013 Shamsi and Ghassemi 5 between element size and accuracy has been obtained from the results of this work. For a single propeller and the AZIPOD, the solution field is divided into six blocks. (Figures 2 and 3). Unstructured tetrahedral cells are used in rotating blocks for both the single propeller and the AZIPOD. Surface of the propeller and hub are meshed with the size of 0.01D. Four prismatic cells with the size of 0.001D are selected for the boundary layer on the propeller surface. In the single-propeller case, the other blocks are meshed with structured hexahedral cells, and in the AZIPOD models, unstructured tetrahedral cells are used. Number of cells for a single propeller and an AZIPOD is about 1.5 and 1.8 million, respectively. Value of wall Y-plus parameters for both cases are in range 30 \ Y+ \ 100. The advance coefficient is set by altering the inlet velocity. Here, the propeller rotating speed remains constant during calculations.32 The inlet boundary condition for the static frame is set as inlet velocity. The outlet boundary condition can be set as either ‘outflow’ or ‘pressure outlet’ for this frame. The propeller blades, pod, strut, and the static cylinder are assumed as wall boundary conditions. The governing equations of this problem are solved by the finite volume method based on the RANS equations. The Fluent 6.3 software was used to solve the RANS equations. On the basis of the literature published in the application of Fluent in the simulation of the flow around conventional propellers,2,3,14,15,25,32 in this study, it is used to investigate the open-water hydrodynamic performance of the podded propeller. The discretized equations are solved using Green– Gauss cell-based gradient option. The simple algorithm is used for solving the pressure–velocity coupling equations. The second-order upwind discretization scheme is utilized for the momentum, turbulent kinetic energy, and turbulent dissipation rate in this problem. The rotation of the propeller is modelled using the moving reference frame (MRF), and the turbulent fluid is modelled by k-e method. The renormalization group (RNG) k-e model is employed using the differential viscosity model and swirl-dominated flow. For the near-wall treatment, the standard wall functions are applied to wall boundaries. More detailed description of the numerical method is presented by Kim et al.35 Resulting unit thrust from AZIPOD is the sum of three components TUnit = TPro +TPod +TStrut ð7Þ where TPro, TPod, and TStrut are the component thrust from the propeller, pod, and the strut, respectively. For AZIPODs, coefficients of propeller thrust, unit thrust, and axial and side forces are defined as TPro TUnit , KTUnit = 2 4 2 4 rn D rn D Fx Fz KFx = 2 4 , KFz = 2 4 rn D rn D KTPro = ð8Þ where Fx and Fz are the total forces on the whole unit in x and z directions, respectively. These coefficients are important factors in the design of the AZIPODs affecting propulsion and manoeuvring specifications. Also, the propeller efficiency and the AZIPOD unit efficiency can be defined as J KTPro 2p KQ J KTUnit hUnit = 2p KQ hPro = ð9Þ Results and discussion The numerical method mentioned above is employed for the simulation of viscous flow around conventional marine propellers and new AZIPOD systems. At first, we conducted initial studies to investigate the influence of boundary conditions and computational control parameters on the results. Therefore, two different propeller models are analysed in open-water condition in the absence of the pod and strut. Assuming the constant rotational velocity for the propellers, their performance is investigated for different inlet velocities to obtain the characteristics of the propellers in openwater conditions. Then, the flow around and the total of units are studied in zero yaw angle and azimuthing condition. The Cartesian coordinates are used, where x, y, and z denote the downstream, upward, and starboard directions, respectively. The origin of the coordinates is located at the centre of the propeller hub. Propeller alone Hydrodynamic characteristics The performance characteristics of the propeller can be defined using the non-dimensional coefficients such as the advance coefficient, thrust coefficient, and torque coefficient, which can be computed, respectively, as follows KT = T , rn2 D4 KQ = Q , rn2 D5 J= V nD ð6Þ In this section, two propeller models are selected. The first propeller test case is designed based on the conventional B-series sections. The characteristic curves and performance data of the propeller are determined by the experimental tests in the cavitation tunnel and can be calculated according to Carlton.1 The second propeller test case is a propeller model that was used by Liu.36 Table 1 gives the main dimensions of two propeller models A and B. Here, Figures 4–13 are presented and discussed for the calculations of the propeller alone. Downloaded from pim.sagepub.com at University of Sydney on April 30, 2013 6 Proc IMechE Part M: J Engineering for the Maritime Environment 0(0) Table 1. Main dimension of propeller models. Propeller models Model A Model B Profile type B-series No. of blades Diameter (mm) Hub ratio Pitch–diameter ratio (P/D) EAR Skew angle (°) Rake angle (°) 4 508 0.2 1 0.65 21 10 NACA 66 (DTMB modified) 4 270 0.26 1 0.6 0 0 EAR: expanded area ratio; NACA: National Advisory Committee for Aeronautics. Figure 4. Variation of error value for thrust and torque coefficient at J = 0.6. The grid dependency study is conducted for propeller model A. Six models for the same domain with different element sizes and cell numbers are generated (Table 2). These models were simulated at J = 0.6, and the results were compared to the experimental results. The variations of error values for the propeller thrust and torque coefficients are shown in Figure 4. As shown, the errors were reduced by an increase in the numbers of element. The numerical simulations for two propeller models A and B were carried out in similar working conditions to experimental conditions. Propeller model A was simulated at advance velocity coefficients J = 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9, 1.0 and model B at J = 0.2, 0.4, 0.6, 0.8, 1.0. Figures 5 and 6 represent the pressure distribution on back side and face side of the propeller models A and B, respectively. As observed in the figures, high pressure is at face side and low pressure is at back side. Also, the pressure and axial velocity distributions for propeller models A and B in transverse and longitudinal planes are shown in Figures 7 and 8, respectively. As shown in Figure 8, it is clearly observed that the velocity at the propeller downstream position is high, which is shown by red contour line. Quantitatively, the pressure distribution coefficient for propeller models A and B at four radii (r/R = 0.3, 0.5, 0.7, and 0.9) is shown in Figure 9. The blade sections of both the propellers are well shaped to generate the moderate pressure distributions to avoid or mitigate cavitation. Figures 10 and 11 show the hydrodynamic characteristic curves obtained by analysis and its comparison with the experimental data for propeller models A and B, respectively. The results show that there is a good agreement between the experimental and CFD results particularly for advance ratio 0.2–0.8. The results show that at very high–speed condition (J . 1), there is a discrepancy between numerical results and experimental data. At light-loaded condition, advance speed value is close to the value of pitch–diameter ratio, J/(P/ D) ’ 1.0. It means that the propellers work with Figure 5. Pressure distribution on back (left) and face (right) side of the propeller A at J = 0.5. Downloaded from pim.sagepub.com at University of Sydney on April 30, 2013 Shamsi and Ghassemi 7 Figure 6. Pressure distribution on (a) back and (b) face side of the propeller B at J = 0.6. Figure 7. Pressure distribution in transverse plane at J = 0.5 for (a) propeller A and (b) at J = 0.6 for propeller B. Figure 8. Axial velocity distribution in longitudinal plane (a) at J = 0.5 for propeller A and (b) at J = 0.6 for propeller B. Downloaded from pim.sagepub.com at University of Sydney on April 30, 2013 8 Proc IMechE Part M: J Engineering for the Maritime Environment 0(0) Figure 9. Pressure coefficient distribution for propeller A (a) at J = 0.5 and (b) for propeller B at J = 0.6. Figure 10. Experimental and computational characteristic curves of the propeller model A. positive rotational speed and produce a positive (forward) thrust in the first quadrant.27 In this range of advance ratio (J = 0.2–0.8), the error percentage for thrust coefficient, torque coefficient, and efficiency for propeller models A and B at different advance ratios (J) are shown in Figures 12 and 13, respectively. According to these figures, the error is slight in design condition. In lifting bodies like propellers, the effect of viscosity is much smaller on the thrust but significant on the torque. The maximum force is due to pressure that may be determined by potential methods based on lifting surfaces and panel methods. Tables 3 and 4 present the viscous force/pressure force and viscous moment/pressure moment for propeller models A and B, respectively. It can be seen that the viscous force contributes a greater part in the torque than in the thrust of the blades. Figure 11. Experimental and computational characteristic curves of the propeller model B. Performance of AZIPOD system In this section, a model of propeller including pod and strut has been established and the whole of the unit has been analysed in RANS solver. Flow characteristics around the propeller, pod, and strut were evaluated. The AZIPOD is studied in zero yaw angle and azimuthing condition. These investigations are performed for two AZIPOD configurations: puller and pusher. The propeller model A was selected and set with a pod and strut. The non-dimensional data of the pod and the strut are presented in Table 5. Profiles of the Downloaded from pim.sagepub.com at University of Sydney on April 30, 2013 Shamsi and Ghassemi 9 Figure 12. Error percentage for propeller model A at different J. Figure 13. Error percentage for propeller model B at different J. Table 2. Element number of grid dependency cases. Cases Element no. 1 2 3 4 5 6 128,856 296,469 654,901 1,028,906 1,567,804 2,492,314 pod and the strut are similar to the one used by Szantyr,16 but its dimensions are adjusted to propeller size. More details about the profiles of the pod and the strut can be found in the study by Gupta.2 Table 3. Comparison between viscous and pressure force and moment for propeller model A. Advance velocity (J) Viscous force/ pressure force (%) Viscous moment/ pressure moment (%) 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 0.35 0.40 0.47 0.56 0.70 0.94 1.45 3.10 7.54 1.55 1.77 2.01 2.31 2.71 3.34 4.50 7.30 12.71 Downloaded from pim.sagepub.com at University of Sydney on April 30, 2013 10 Proc IMechE Part M: J Engineering for the Maritime Environment 0(0) Figure 14. Pressure distribution on pod, strut, and (a) face and (b) back sides of the propeller at zero yaw angle for puller propeller (J = 0.6). Table 4. Comparison between viscous and pressure force and moment for propeller model B. Advance velocity (J) Viscous force/ pressure force (%) Viscous moment/ pressure moment (%) 0.2 0.4 0.6 0.8 1.0 0.62 0.83 1.24 2.62 6.71 2.72 3.50 4.67 7.43 11.45 Table 5. Non-dimensional main particulars of pod and strut. Parameters Value Maximum pod diameter ratio, Dpod/Dprop A Pod length ratio, Lpod/Dprop A Strut height ratio, Sheight/Dprop A Strut chord ratio, Schord/Dprop A Strut width ratio, Swidth/Dprop A 0.295 1.624 0.551 0.433 0.187 The model was first studied in puller configuration. The total forces on unit in each direction and propeller thrust and torque are computed for a range of advance coefficients from 0.2 to 1. Yaw angles of the pod are changed from +15° to 215° with 5° increments. Then, the podded model was tested in pusher condition. These tests include studies on pusher podded propeller at yaw angles from +15° to 215° with varying advance coefficients from 0.2 to 1. Figures 14 and 15 show pressure distribution on pod, strut, and propeller at zero yaw angle at an advance coefficient of J = 0.6 for puller and pusher types, respectively. High pressure is on the face side and low pressure is on the back side. Also, the velocity pathlines at downstream of the puller and pusher AZIPOD for zero yaw angle at an advance coefficient of J = 0.6 are shown in Figure 16. In puller type, since the strut and the pod are located in the downstream of the propeller, the induced velocities from the propeller change the inflow to the strut and pod. In pusher type, those elements are located in the upstream of the propeller and the propeller works in the wake of the strut and pod. The propeller thrust and torque coefficients for a range of advance coefficients and yaw angles are shown in Figures 17 and 18. In puller type, for all advance coefficients, the propeller thrust coefficient increases with increasing yaw angle. This behaviour is similar for negative angles and positive angles, and the propeller thrust coefficients are symmetrical at positive and negative yaw angles. The same behaviour is found in the propeller torque coefficient. In this simulation, the advance velocity coefficient is defined in the x direction of the coordinate system. Therefore, the effective advance velocity in the direction of the propeller axis is J cos c, where c is the yaw angle. This means that when yaw angle is changed from straight condition to positive or negative angle, the effective advance coefficient in the direction of the propeller axis is reduced. This results in higher thrust in the corresponding operating conditions. But in pusher type, for all advance coefficients, the propeller thrust coefficient decreases when yaw angle is increased from negative angles to positive yaw angles and the propeller thrust coefficients are not symmetrical at positive and negative yaw angles. Alternatively, in pusher type, propeller works in the wake of strut, and the inflow on the propeller is strongly non-uniform.37 Due to differences in the inflow condition for positive and negative yaw angles, asymmetry is seen in the propeller thrust curves. Also, the effect of the propeller direction of rotation should be considered in this asymmetry. The same trend can be seen for the torque coefficient, as shown in Figure 18. At any yaw angle, for all advance coefficients, the propeller thrust Downloaded from pim.sagepub.com at University of Sydney on April 30, 2013 Shamsi and Ghassemi 11 Figure 15. Pressure distribution on pod, strut, and (a) face and (b) back sides of the propeller at zero yaw angle for pusher propeller (J = 0.6). Figure 16. Velocity pathlines on pod, strut, and propeller at zero yaw angle for (a) puller propeller and (b) pusher propeller at J = 0.6. Figure 17. Variation of propeller thrust coefficient with yaw angle for puller and pusher AZIPOD. Figure 18. Variation of propeller torque coefficient with yaw angle for puller and pusher AZIPOD. Downloaded from pim.sagepub.com at University of Sydney on April 30, 2013 12 Proc IMechE Part M: J Engineering for the Maritime Environment 0(0) Figure 19. Variation of total unit axial force coefficient with yaw angle for puller and pusher AZIPOD. Figure 20. Variation of pod and strut axial force coefficient with yaw angle for puller AZIPOD. coefficient of the pulling AZIPOD is greater than the pushing one. Figure 19 shows the total unit axial force coefficient for the puller and pusher AZIPOD. The maximum value is obtained at yaw angle 25° for all advance velocities. Also, variation of the pod and strut axial force coefficient with yaw angle for the puller and pusher AZIPOD are shown in Figures 20 and 21, respectively. In puller type (Figure 20), the inflow on the pod and the strut is influenced by propeller-induced wake flow and the interaction between the propeller wake and the strut is dominated. This results in asymmetry in total unit axial force curve. In pusher type (Figure 21), the inflow on the pod and the strut is uniform. For this reason, the axial force of the pod and the strut is almost symmetric. Figure 21. Variation of pod and strut axial force coefficient with yaw angle for pusher AZIPOD. Figure 22. Total unit efficiency for puller AZIPOD at different yaw angles. The total unit efficiency for the puller and pusher AZIPOD at different yaw angles is presented in Figures 22 and 23. As shown, for all advance coefficients, total unit efficiency is not equal at opposite yaw angles. Total unit efficiency for the puller and pusher AZIPOD increases with yaw angle variation in the following manner: +15, +10, +5, 215, 210, 0, and 25. Figure 24 shows the side force coefficient for the puller and pusher AZIPOD. In puller and pusher types, for all advance coefficients, the side force coefficient increases when yaw angle is increased to the left (negative yaw angle) or right (positive yaw angle). Also, side force coefficients for puller and pusher pod increase with increasing advance coefficient. The side force components are propeller transverse force and pod and strut side forces. These components are presented in Downloaded from pim.sagepub.com at University of Sydney on April 30, 2013 Shamsi and Ghassemi 13 Figure 26. Variation of propeller side force coefficient with yaw angle for puller and pusher AZIPOD. Figure 23. Total unit efficiency for pusher AZIPOD at different yaw angles. Figure 27. Variation of strut side force coefficient with yaw angle for puller and pusher AZIPOD. Figure 24. Variation of total unit side force coefficient with yaw angle for puller and pusher AZIPOD. Figures 25–27. In puller and pusher AZIPOD, zero side force is found at the small yaw angle about 1°. Due to the propeller wake rotation and strut interactions, there is a small side force in straight condition (zero yaw angle) for both puller and pusher types. Conclusion In this article, the hydrodynamic analysis of a propeller alone and pusher/puller of the AZIPOD at various yaw angles and operating conditions was investigated. A finite volume–based RANS solver has been used to evaluate the performance of these systems. Based on the numerical findings, the following conclusions can be drawn: 1. Figure 25. Variation of pod side force coefficient with yaw angle for puller and pusher AZIPOD. Open-water characteristics of the propeller show that the numerical results are in good agreement with the experimental data. Downloaded from pim.sagepub.com at University of Sydney on April 30, 2013 14 2. 3. 4. 5. 6. Proc IMechE Part M: J Engineering for the Maritime Environment 0(0) In puller type of AZIPOD, propeller thrust and torque coefficient curves are symmetrical to yaw angles. But, in pusher type, propeller thrust and torque coefficients decrease when yaw angle is increased from negative angles to positive angles. Comparison of the pusher/puller types show that the puller types make more thrust, torque, and axial force coefficients than pusher type at yaw angles investigated. The thrust, torque, and unit force coefficients showed a strong dependence on the propeller advance coefficient and azimuth angle. These coefficients were decreasing with the increasing advance coefficients for both azimuth directions (615°). The variation of the pod and strut axial force coefficient against yaw angle is asymmetric for the puller and symmetric for the pusher type of the AZIPOD. In puller and pusher types, for all advance coefficients, the side force coefficient increases when yaw angle is increased to the left (negative yaw angle) or right (positive yaw angle). Zero side force is found at the small yaw angle of about 1°. 8. 9. 10. 11. 12. 13. 14. Funding This research was supported by High Performance Computing Research Center (HPCRC) at Amirkabir University of Technology. 15. Acknowledgements The authors wish to thank the reviewers for their valuable comments and suggestion. 16. 17. References 1. Carlton JS. Marine propeller and propulsion. 2nd ed. Oxford: Butterworth-Heinemann, 2007. 2. Gupta A. Numerical prediction of flows around podded propulsors. MSc Thesis, University of Texas at Austin, Austin, TX, 2004. 3. Mishra B. Prediction of performance of podded propulsors via coupling of a vortex-lattice method with an Euler or a RANS solver. MSc Thesis, University of Texas at Austin, Austin, TX, 2005. 4. Sarioz K, Atlar M, Sarioz E, et al. Operability of fast podded RoPax vessels in rough seas. Proc IMechE, Part M: J Engineering for the Maritime Environment 2005; 219(1): 37–46. 5. Ghassemi H and Ghadimi P. Computational hydrodynamic analysis of the propeller rudder and the AZIPOD systems. Ocean Eng 2008; 35(1): 117–130. 6. Atlar M, Woodward MD, Besnier F, et al. FASTPOD project an overall summary and conclusions. In: Proceedings of 2nd T-POD conference, Brest, France, 3–5 October 2006. Brest: University of Brest. 7. Atlar M, Wang D and Glover EJ. Experimental investigation into the impact of slipstream wash of a podded propulsor on the marine environment. Proc IMechE, 18. 19. 20. 21. 22. Part M: J Engineering for the Maritime Environment 2007; 221(2): 67–79. Ma C, Qian Z, Yang C, et al. Research on wake model of pod propulsion. In: Proceedings of 1st T-Pod conference, Newcastle upon Tyne, UK, 14–16 April 2004. Newcastle upon Tyne: Newcastle University. Islam M, Taylor S, Quinton J, et al. Numerical investigation of propulsive characteristics of podded propellers of pusher configuration. In: Proceedings of 1st T-Pod conference, Newcastle upon Tyne, UK, 14–16 April 2004, pp.513–526. Newcastle upon Tyne: Newcastle University. Bal S, Akyildiz H and Guner M. Preliminary results of a numerical method for podded propulsors. In: Proceedings of 2nd T-POD conference, Brest, France, 3–5 October 2006. Brest: University of Brest. Lijun Z and Yanyin W. Discussion on the hydrodynamic performance for podded propeller in steady flow by using surface panel method. In: Proceedings of 2nd T-POD conference, Brest, France, 3–5 October 2006. Brest: University of Brest. Carlton JS. Podded propulsors: some design and service experience. In: Proceedings of the Motor ship marine propulsion conference, Copenhagen, Denmark, 9–10 April 2002, p.7. London: Motor Ship. Carlton JS. Podded propulsors: some results of recent research and full scale experience. J Mar Eng Technol 2008; 11: 1–14. ITTC. The specialist committee on azimuthing podded propulsion. Final report and recommendations to the 24th ITTC. In: Proceedings of the 24th ITTC, Edinburgh, UK, 5–10 September 2005, vol. 2, pp.543–600. Newcastle upon Tyne: Newcastle University. ITTC. The specialist committee on azimuthing podded propulsion. Final report and recommendations to the 25th ITTC. In: Proceedings of the 25th ITTC, Fukuoka, Japan, 14–20 September 2008, vol. 2, pp.563–603. Fukuoka: JASNAOE. Szantyr JA. Hydrodynamic model experiments with pod propulsor. Ocean Eng Int 2001; 5(2): 95–103. Grygorowicz M and Szantyr JA. Open water experiments with two pods propulsor models. In: Proceedings of the 1st international conference on technological advances in podded propulsion, Newcastle upon Tyne, UK, 14–16 April 2004, pp.357–370. Newcastle upon Tyne: Newcastle University. Woodward MD, Atlar M and Clarke D. Comparison of stopping modes for pod-driven ships by simulation based on model testing. Proc IMechE, Part M: J Engineering for the Maritime Environment 2005; 219(2): 47–64. Reichel M. Manoeuvring forces on azimuthing podded propulsor mode. Polish Marit Res 2007; 14: 3–8. Islam MF, Veitch B and Liu P. Experimental research on marine podded propulsors. Journal of Naval Architecture and Marine Engineering 2007; 4(2): 57–71 Islam MF, Veitch B, Akinturk A, et al. Experiments with podded propulsors in static azimuthing conditions. In: Proceedings of the 8th CMHSC, St John’s, NL, Canada, 16–17 October 2007. St. John’s, NRC. Amini H and Steen S. Shaft side force and bending moment on steerable thrusters in off-design conditions. In: Proceedings of the 11th international symposium on practical design of ships and other floating structures, Rio de Janeiro, Brazil, 19–24 September 2010. Rio de Janeiro: PRADS. Downloaded from pim.sagepub.com at University of Sydney on April 30, 2013 Shamsi and Ghassemi 15 23. Amini H and Steen S. Shaft loads on azimuth propulsors in oblique flow and waves. Int J Marit Eng 2011; 153(Part A1): 9–22. 24. Funeno I. On viscous flow around marine propellers-hub vortex and scale effect. J Kansai Soc Nav Archit Jpn 2002; 238: 17–27. 25. Rhee SH and Joshi S. CFD validation for a marine propeller using an unstructured mesh based RANS method. In: Proceedings of FEDSM’03, Honolulu, HI, 6–11 July 2003. Honolulu: ASME 26. Achkinadze AS, Berg A, Krasilnikov VI, et al. Numerical analysis of podded and steering systems using a velocity based source boundary element method with modified trailing edge. In: Proceeding of the propellers/shafting 2003 symposium, Virginia Beach, VA, 17–18 September 2003. Virginia Beach: SNAME. 27. Liu P, Islam M and Veitch B. Unsteady hydromechanics of a steering podded propeller unit. Ocean Eng 2009; 36(12–13): 1003–1014. 28. Bal S and Guner M. Performance analysis of podded propulsors. Ocean Eng 2009; 36: 556–563. 29. Sanchez-Caja A, Rautaheimo P and Siikonen T. Computation of the incompressible viscous flow around a tractor thruster using a sliding-mesh technique. In: Proceedings of 7th international conference on numerical ship hydrodynamics, Nantes, France, 1999. Nantes: Ecole Centrale de Nantes. 30. Sanchez-Caja A, Ory E, Salminen E, et al. Simulation of incompressible viscous flow around a tractor thruster in model and full scale. In: Proceedings of the 8th Conference on numerical ship hydrodynamics, Busan, Korea, 22– 25 September 2003. Busan: ONR. 31. Koushan K and Krasilnikov VI. Experimental and numerical investigation of an open thruster in oblique flow conditions. In: Proceedings of the 27th symposium on naval hydrodynamics, Seoul, Korea, 5–10 October 2008. NY: Curran Associates, Inc. 32. Kulczyk J, Skraburski L and Zawislak M. Analysis of screw propeller 4119 using fluent system. Arch Civ Mech Eng 2007; 7(4): 129–137. 33. Shamsi R, Soheili S and Hamooni A. Hydrodynamic analysis of marine propellers using computational fluid dynamics. In: Proceedings of the 17th international conference on mechanical engineering, Tehran, Iran, 12–14 May 2009. Tehran: ISME. 34. Guo C, Ma N and Yang C. Numerical simulation of a podded propulsor in viscous flow. J Hydrodyn 2009; 21(1): 71–76. 35. Kim SE, Mathur SR, Murthy JY, et al. A Reynolds-averaged Navier-Stokes solver using unstructured mesh-based finite-volume scheme. In AIAA 98–0231, 36th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, January 12–15, 1998. Reston: AIAA. 36. Liu P. The design of a podded propeller base model geometry and prediction of its hydrodynamics. Report, Report no. TR-2006-16, June 2006. St. John’s: Institute for Ocean Technology, National Research Council Canada (IOT-NRC). 37. Molland AF and Turnock SR. Marine rudders and control surfaces. 1st ed. Oxford: Butterworth-Heinemann, 2007. Appendix 1 Notation D Fx Fz J KFx KFz KQ KT n p Q TPod TPro TStrut TUnit V ~ v propeller diameter axial force side force propeller advance ratio axial force coefficient side force coefficient propeller torque coefficient propeller thrust coefficient propeller angular velocity (r/s) static pressure propeller torque pod thrust propeller thrust strut thrust unit thrust axial velocity velocity vector dij hPro hUnit m r c t Kronecker delta propeller efficiency total unit efficiency molecular viscosity fluid density yaw angle stress tensor Downloaded from pim.sagepub.com at University of Sydney on April 30, 2013 View publication stats