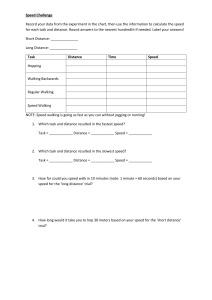

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/228701840 Heat loss from a thermal manikin during wet tests with walking simulation Article CITATIONS READS 2 42 1 author: Kalev Kuklane Instituut Fysieke Veiligheid (IFV) 155 PUBLICATIONS 2,954 CITATIONS SEE PROFILE Some of the authors of this publication are also working on these related projects: It is a part of a general work under the theme HEAT View project Thermprotect View project All content following this page was uploaded by Kalev Kuklane on 05 June 2014. The user has requested enhancement of the downloaded file. 7th International Thermal Manikin and Modelling Meeting - University of Coimbra, September 2008 HEAT LOSS FROM A THERMAL MANIKIN DURING WET TESTS WITH WALKING SIMULATION Kalev Kuklane Lund University, Dept. of Design Sciences, EAT, Thermal Environment Laboratory Sölvegatan 26, Box 118, HS 69, SE-22100 Lund, Sweden email: kalev.kuklane@design.lth.se http://wwwold.eat.lth.se/Research/Thermal/ Summary: The walking tests with a thermal manikin TORE were carried out with THERMPROTECT WP2 clothing. The test conditions simulated the human tests of the same work package, including ambient conditions (10 and 25 °C), clothing (impermeable and permeable), wetting of cotton underwear (wet and dry) and setting the walking speed to approximately the same level. Additional tests in homogenous conditions (Ta=Tsk=34 °C) were carried out. The results agree with previous studies and form a good basis for further analysis together with human test results. Keywords: walking manikin, wet underwear, heat loss, evaporation, evaporative efficiency Category: Sweating manikins and moving manikins 1 Introduction EU-project THERMPROTECT did extensively study heat and mass transfer through textile materials and clothing ensembles [1]. However, throughout whole project the walking manikin tests were not carried out and that left a gap in explaining and comparing walking subjects’ tests [2] based on manikin measurements. In order to catch up and exploit the available THERMPROTECT data from the subject tests a test series were carried out on a walking manikin TORE. The conditions were chosen to get as close to the actual subject test conditions as possible. This paper describes the walking manikin tests and compares them with values collected during static measurements reported before [3]. 2 Methods The conditions were chosen to follow a subject series of THERMPROTECT WP 2 Moisture [2]. Additional conditions were chosen for testing in order to gather needed background information as described by [3]. Thermal manikin Tore was used for testing. Detailed information on the manikin parameters is available in [4]. Both standing and walking tests were carried out, however, only walking results are given in this paper. During THERMPROTECT tests on Tore a thin plastic film was wrapped around manikin surface. During these tests the film was skipped in order to reduce the errors. Walking of the manikin was simulated with pneumatic system and was adjusted by frequency and step length as close as possible to the walking speed of the subjects (4.5 km/h). During walking tests at 10 °C several zones had maximum heat losses and surface temperature dropped below 34 °C. THERMPROTECT permeable (PERM) and impermeable (IMP) coverall together with wet or dry cotton underwear were used for testing. Material properties of these clothing pieces are available in [3]. The same socks (Ullfrotté, material 400 g/m2) and shoes (sports shoes from Arbesko AB) as the subjects had, were also used on manikin. For wet tests the cotton underwear was put through a short rinsing (4 minutes) and centrifuging (8 seconds) cycle. After the procedure underwear held in average 1034±35 g of moisture. Air velocity in the chamber was set to 0.35±0.10 m/s. Tests were carried out at 3 ambient temperatures: 10, 25 and 34 °C. Two first conditions were used according to subject tests and the third one was carried out for defining wet heat loss in homogenous conditions (manikin surface temperature was kept at 34 °C). The relative humidity in the chamber was set to 80, 31, and 18 % humidity for 10, 25 and 34 °C respectively in order to achieve an ambient water vapour pressure of 1000 Pa. Fig. 1. Heat loss components from manikin areas that were fully covered by wet underwear (head, hands and feet excluded). 7th International Thermal Manikin and Modelling Meeting - University of Coimbra, September 2008 3 Results and discussion The heat loss pattern (Figure 1) followed the results described by Havenith [3]. The walking resulted in higher heat losses. This effect compared to static tests was expected. Evaporative cooling potential (Emass) and apparent evaporative heat loss (Eapp, Figure 2) showed similar patterns as observed by Havenith [3]. Even similar peak in Emass for PERM at 25 °C was observed as by Havenith [3] at 20 °C. Although, the clothing weight was corrected for evaporation during dressing, this peak might have been caused by measuring uncertainties related to dressing and undressing, and weighting the clothing before and after the tests. The apparent evaporative efficiency (ηapp) for PERM stayed just around 1 for all walking tests, while for IMP it almost doubled compared to [3], and reached close to 7 at 10 °C (Figure 3). It could be in a way expected as the walking should increase both internal (pumping) and external convection and thus also the effectiveness of the heat pipe effect. On the other hand, ηapp values for 20 or 25 °C expected from the curves in both studies did not differ very much when considering somewhat different measuring conditions and setups. The values of real evaporative efficiency (ηreal, Figure 3) for PERM differed to some extent compared to Havenith [3], while for IMP ηreal was much lower for walking and the difference increased with increasing temperature. A reason for this may be correcting clothing weight for moisture losses during dressing. From IMP evaporation was low, and not correcting or wrong correction could have had a large influence on final results. Finally, these results need to be analysed further in combination with static tests with the same setup. Further, the walking manikin data need to be analysed in combination with the subject results [2]. Fig. 2. Evaporative cooling potential and apparent evaporative heat loss from the manikin (excluding head, hands and feet). a) b) Fig. 3. Apparent evaporative cooling efficiency and apparent latent heat of evaporation (a), and real evaporative cooling efficiency (b). Acknowledgements The study was supported by SCA Hygiene Products AB, Sweden. References [1] Havenith, G., Holmér, I., Meinander, H, den Hartog, E., Richards, M., Bröde, P., Candas, V., 2006, Final technical report. THERMPROTECT, Assessment of Thermal Properties of Protective Clothing and Their Use. EU-project, contract G6RD-CT-2002-00846. [2] Kuklane, K., Gao, C., Holmér, I., Bröde, P., Candas, V., den Hartog, E., Meinander, H., Nocker, W., Richards, M. and Havenith, G. 2007. Physiological responses at 10 and 25 °C in wet and dry underwear in permeable and impermeable coveralls. In: Mekjavic, I. B., Kounalakis, S. N., Taylor N. A. S. Environmental Ergonomics XII, Proceedings of the 12th International Conference on Environmental Ergonomics (ICEE 2007), August 19-24, 2007, Grand Hotel Bernardin, Piran, Slovenia. [3] Havenith, G.; Richards, M.G.; Wang, X.; Bröde, P.; Candas, V.; den Hartog, E.; Holmér, I.; Kuklane, K.; Meinander, H.; Nocker, W. 2008. Apparent latent heat of evaporation from clothing: attenuation and "heat pipe" effects. Journal of Applied Physiology 104(1), 142-149 [4] Kuklane, K., Heidmets, S. and Johansson, T. 2006. Improving thermal comfort in an orthopaedic aid: better boston brace for scoliosis patients. The 6th International 7th International Thermal Manikin and Modelling Meeting - University of Coimbra, September 2008 Thermal Manikin and Modeling Meeting (6I3M), 16 - 18 October 2006, The Hong Kong Polytechnic University, Hong Kong SAR. View publication stats