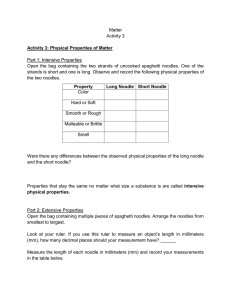

TRIBHUVAN UNIVERSITY INSTITUTE OF ENGINEERING Western Regional Campus Department of Electronics and Computer Engineering A Report On Instrumentation Case Study Visit Undertaken At Narayani Noodles Industry Chitwan, Nepal Submitted By Sandip Shrestha Santosh Raj Bhandari Ozan Wagle Sumit Pant TABLE OF CONTENT 1. 2. Acknowledgment Abstract 3. Objectives 4. Introduction 5. Generating Process 6. Units operation 7. Recommendations i. ii. 8. A system block Proposed system Conclusion 1. ACKNOWLEDGMENT "How much you will use effort; you will get that much-helping hands to do that work and according to your effort used you will get the success". This case study report of a field visit on industrial automation is a joint work from team members of students under Electronics stream: 076(WRC). We are delighted to express our hearty thankfulness to our teacher Mrs. Smita Adhikari, HOD of the Department of electronics and computer engineering respected sir Ramesh Thapa for granting such a marvelous opportunity to us for exploring the real-world problems and works and we would like to thank teachers who have guided us in the entire 3 days educational visit. We also express our thankfulness to our teachers who have fully provided warm guidance on the continuation of our field. Any suggestions in this regard are heartily welcomed. 2. ABSTRACT It is crucial for a student in the electrical engineering stream to learn and get acquainted with design principles and their implementation in a suitable field. Basically, the available resource and environment are inadequate to fulfill the requirement. With the sole aim to perceive a basic overview of practical implementations, we have been asked to conduct a case study on a production industry related to our field of study. The reports indulge all the associated fundamentals along with the description, diagrams, mechanism, and blocks of plants practiced on "ABC Noodles": one of the most reputed industries in Nepal. It includes detailed information on the manufacturing scheme of noodles. There lack some hindrances that cause imperfection in any production industry. We have pointed out some and presented the most effective measures for betterment and way for the best quality product. We are hopeful that our proposed scheme can contribute to uplift overall efficiency of the current plant. 3. OBJECTIVES The main objective of this case study was to get detailed information about industrial automation and to get acquainted with the use of instrumentation in the real field. We researched a lot to select which part of the system has to be automated and we have proposed a design to solve the problems related to the operation and manufacturing of various categories of noodles. Hence, the main objective of our visit can be summarized as follows: • To visit the chosen organization and learn its operation under the supervision of senior engineers and techniques. • To get a clear idea about industrial automation. • To study the existing management system and technology of the company. • To get acquainted with the use of instrumentation in the real field. • To learn the vital role of engineering in a particular company. • To be familiar with various engineering aspects demanded by that particular company. • To observe the current system and detect the fault in the engineering system if any. • To propose solutions to boost the efficiency of the system. 4. INTRODUCTION Smart Food and Snacks Pvt. ltd. was established in 2005 AD (2062 BS). The company has been established under the glorious leadership of an eminent industrialist in the country, Mr. Shovakar Neupane, who runs the Ambe Group. The mission of this company is to enhance value creation for the stakeholder can only be achieved through the quality and commitment of our people. It has the aim to produce the best quality noodles which are good in taste, nutritious, and accessible to all. It has the main objective of creating the best noodles for the ultimate customer satisfaction. Mostly these noodles have the market in the far-western and mid-western development region. 5. MANUFACTURING PROCESS 1. MIXER According to the need, a suitable amount of water and flour is added to the mixture, and the dough is prepared. 2. SHAPER 1 The dough is passed through the shaper and the dough is sliced in the shape of the sheet having a thickness of about I cm. 3. SHAPER 2 This shaper slices the sheet from shaper I into about 60% of the thickness. 4. SHAPER 3 This shaper slices the sheet from shaper 2 again about 60% of thickness to get a very fine thickness. 5. NOODLE SHAPER This shaper cuts the sheet from shaper 3 into the noodle shape by a specially designed mechanical key, This key also provides the final shape placement of the noodle. 6. STEAM TUNNEL In this tunnel, the noodle is cooked at a temperature of 92-95 degrees Celsius. 7. FLAVOUR PLANT From the chamber containing the mixture of chicken seasoning, the mixture is dropped continuously and the noodle is absorbed in the seasoning liquid to give flavor and color. 8. FRYING PLANT The noodle so soaked is then fried in the palm oil at 170-180 degrees Celsius. 9. HEATING OVEN AND COOLING SYSTEM The noodle is first heated and then cooled instantly so that the noodle remains crispy. 10. PACKING PLANT : With suitable digital technology consisting of several micro-controller, control instructions, noodle is packed. Hence, the noodle is prepared and packed for the consumers. Noodle Shaper Heating Oven Packing Plant Noodles Fig: General Block Diagram of Production Plant 6. PRODUCTION UNIT OPERATION For the production of the noodles, the whole system can be broken down into different units and can be analyzed in parts. The components of the system are described below: 1. MIXING UNIT The mixing of flour with other ingredients is done in this unit, The required amount of the raw material is measured by the operator and is fed to the unit manually. 2. Thickness control unit This unit consists of pairs of rollers that are kept apart at a certain distance. The thickness of the mixed paste is controlled manually by the operator by rotating proper gears for desired thickness. The speed of the roller pair is synchronous with the other roller pair. As the mixed paste is passed through the roller pair, the thickness of it gets lesser, and finally, when it comes out from the final roller pair the dough is of the required thickness. 3. Shaping Unit After obtaining the mixed paste of required thickness, the actual noodle shape is given to it by passing it through the roller with graves which gives the noodle shape. 4. Steam baking Unit The shaped noodles coming out from the shaping unit is half cooked around 90 to 95 degree Celsius. Temperature setting is done by the operator manually. 5. Cutting Unit In the cutting unit, the noodle groves are cut in the actual size of the noodles. The weight of the noodles is determined by the length to be cut. The blade is adjusted to obtain the appropriate sue. 6. Flavoring Unit The noodles once cut are sprayed with the soup. The chicken flavor is sprayed with the chicken soup which comes from the boiler. The noodles absorb around 12 gm of the soup and the remaining soups are collected in the container which is refused. 7. Frying Unit The frying unit consists of the furnace where palm oil is boiled. There are two burners, which are separately controlled, are supplied by kerosene fuel. The noodle which was soaked in the soup is fried in the furnace. If the proper color is not obtained then increasing the fuel in the furnace Increases the temperature of the furnace more. 8. Drying Unit The unnecessary oil from the noodle is removed by blowing it with cool air. This prevents the noodle from being too oily. Th1S unit consists of two high-capacity fans. 7. RECOMMENDATIONS Although the present system IS made In digital technology, there are some parts where the procedure is done manually. The mixing unit is the initial stage of the whole plant which is done manually. The required weight of the flour is measured manually. The required amount of water to be mixed with flour is also measured manually. At the final stage, the surplus things like soup, onion oil, and chili powder are attached manually and the weighting of the finalized dry foods is also done by the people who are in stand-by positions. Therefore, some parts can be improved, such as: The packet of the soup can be made automatically not manually. The defective packets can be detected automatically not manually. The steam from the steam plant can be stored again so that it can be re-utilized. The main defect of the present system is that the mixing procedure is done manually so that it has to be monitored from time to time by the human being. To solve this problem, the system should be allowed to operate automatically with the help of micro-controllers and sensors. Customs Formalities Customs formalities are different in different countries. Also, these formalities are very lengthy, timeconsuming, and complicated. Nepalese noodles have to be exported to the international market through India. So, Nepalese noodles have to fulfill the customs formalities of India too. This takes a very long time and not only increases complexities in exporting the noodles but also increases the cost of noodles, making it more expensive when it reaches the international market. Payment Difficulties Different countries have different currencies and different conversion rates. These rates keep on fluctuating every day. An exporter may suffer loss sometimes due to the fluctuation in exchange rates. The Nepalese noodles industry also suffers this kind of loss due to the change in the exchange rate. While exporting the noodles to a foreign market, the Nepalese noodles industry gets paid only after the supplier in the foreign market receives the noodles consignment. This takes a long time as international trade is a lengthy process with all the barriers and problems involved in it. During this time there can be heavy fluctuation in exchange rates sometimes and the noodles exporter in Nepal can suffer loss sometimes. Documentation Formalities There are several documents to be filed with various authorities while exporting the goods. Nepalese noodles industry also has to produce several documents while exporting noodles to a foreign market. It is also a lengthy and complicated process but the documents must be prepared to meet the requirements of the importing and exporting countries. 7.1 PROPOSED SYSTEM BLOCK DIAGRAM 7.2 INSIGHTS ON PROPOSED SYSTEM In the above blocks of the proposed system plant, efforts are focused to perform the controlled operation with microcontrollers and precise sensors. Introducing the use of a programmable peripheral interface like 8255A is intended to establish sound communication between the microcontroller and slow peripherals like counter, keyboard, etc. High current appliances are driven through relays with sensed current output from AT89S52 (family of 8051/52 microcontroller). Packaging system is digitized and operated through devices that were manually done in the production house. Upon overviewing the above system it is visible that the system is far more aimed to make controlled and self-operating with the aid of improved module of digital and electronic circuitry. 8. CONCLUSION The prime objective of our case study was to gain the fundamental ideas and understand any process which contributes to fluent visualization regarding implementation of any digital or controlled system where the application of instrumentation system is a must criterion. The field visit under the coordination of our teacher and department has proven to be worthy for the understanding scheme of the microprocessor-based industrial system in this regard. Obviously, this is the era of industrial advancement and modernization where commodities are expected to be qualitative, sanitized and should meet the demand of consumers accordingly. Considering the preeminence truth, we have presented some effectual recommendations for overall betterment and efficient operating design scheme in our case study. THANK YOU!!!