Uploaded by

Briones, Christian Marjhun M.

Screw Fastenings & Rivets: Thread Design & Power Screws

advertisement

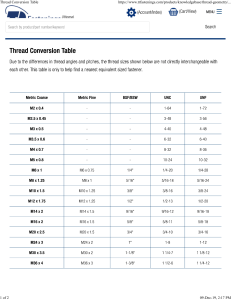

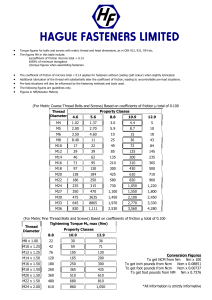

SCREW FASTENINGS AND RIVETS 1. THREADS Threaded bolts and screws are used to hold machine parts. The common thread forms for screws are: Pitch, P is the axial distance between corresponding points on adjacent threads and is equal to the reciprocal of the no. of threads per inch. Lead, L is the axial distance a thread advances in one revolution, hence: L = P for a single thread L = 2P for a double thread L = 3P for a triple thread 2. DESIGN OF BOLTS Types of bolts and screws (see page 173-175, Faires) For your assignment, submit to me the images of the types of bolts & screws. The safe external tensile load for bolts in tension is; English Metric Where: Fe = external tensile load ; N As = Stress area ; Table AT14 and Table 5.1, Faires ; mm2 Sy = yield strength ; N/mm2 3. INITIAL TENSION AND TIGHTENING TORQUE Initial Tension The stress or load induced by the tightening operation. The relation between the applied torque T(N-mm), and the initial tension F(N), proposed by Maney is: T = CDFi ; N-mm Where: Fi = S i As ; N C = torque coeff; pages 159-160 = 0.20 (as received) = 0.15 (as lubricated) T = tightening torque Fi = initial tightening force ; N D = nominal bolt size ; mm Si = initial stress in bolt due to tightening = Sy for high strength material = 0.9 Sp when proof stress available = 0.85 Sy no proof stress Sp = proof stress Sy = yield stress Su = ultimate stress 4. POWER SCREWS A power screw is a device used in machinery to change the angular motion into linear motion and usually to transmit power. Familiar applications include the lead screws of lathes, and the screws for vises, presses and jacks. Square Thread Acme Thread Buttress Thread Where: P=pitch of thread h= height of thread 5. SQUARE THREAD Where: λ = Lead angle h = (1/2)P to (7/16)P Do = outside dia. of screw Di = inside diameter of screw Dm = Do-h (Mean Diameter) For square thread ; For Acme Thread ; For Buttress Thread ; h = (7/16)P h = (1/2)P h = 0.663P (Forces on a body moving up an incline) ƩX = 0 ; Q - R sin(β + λ) = 0 Q = R sin(β + λ) ƩY = 0 ; W – R cos(β + λ) = 0 W = R cos(β + λ) Then: Or EQUATION 1 Also from the figure above: EQUATION 2 From Equation 1 and 2 we have: Raising the load (Square Thread) Where: W = Axial Load Q = Force that pulls the weight up the plane Ff = frictional force β = angle of friction tan β = f ; the coeff. of friction or β = tan-1 f λ = Lead angle R= resultant, the total plane reaction N = normal plane reaction (Forces on a body moving down an incline) Then: ƩX = 0; Q = R sin (β - λ) ƩY = 0 ; W = R cos (β - λ) EQUATION 3 From equation 2 and 3 we have; Lowering the Load (Square Thread) Note: For lowering the load, the screw must be self-locking. If β > λ, the screw is self locking. If β < λ, the screw is not self locking. Torque required to overcome collar friction: Torque required to overcome thread & collar friction: Torque without Thread Friction: Efficiency of Screw: Combined Efficiency: Where: fc = coeff. of collar friction Q= force to raise or lower the load Dc = mean collar diameter Lead = np Lead =axial distance travelled by a nut or thread per revolution. n= 1.0 single thread n= 2.0 double thread n= 3.0 triple thread n= 4.0 quadruple thread Power Input to the screw: N = rpm of screws 6. ACME THREAD Torque required to overcome thread friction; A. Raising the load Since tan β = f, then; or (Raising the load) see page 249, Faires B. Lowering the Load Where: φ = 14.5 for a standard Acme thread = pressure angle in a plane normal to the thread. Note: for the value of f, refer to page 250, Faires 7. TYPES OF THREADS A. UNC (Unified National Coarse Series) - Recommended for general use B. UNF (Unified National Fine Series) - Used in automobile and aircraft C. UNEF (Unified National Extra Fine) - Useful in aeronautical equipment D. 8UN (Unified 8-Thread Series) - Used on bolts for high-pressure pipe flanges, cylinder head, studs, etc.