Ohaus Explorer Balances Service Manual

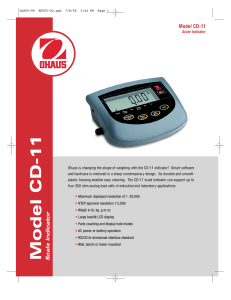

advertisement