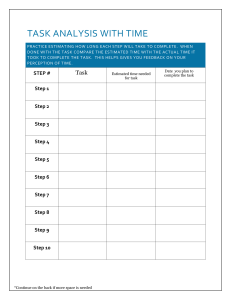

The role of safety culture in safety performance measurement Pedro M. Arezes and A. SeÂrgio Miguel Pedro Arezes is Assistant Professor at the Human Engineering Group in School of Engineering of University of Minho in Portugal. He holds a PhD in Production Engineering and is author of about 30 journal papers and international conference proceedings. He is involved in several research projects in the Ergonomics and Health and Safety domain. E-mail: parezes@dps.uminho.pt A. SeÂrgio Miguel is an invited Full Professor of Industrial Health and Safety at the Human Engineering Group of the University of Minho in Portugal. He has authored more than 100 scienti®c papers in international journals and proceedings. He is a member of the editorial board of two international journals in the Health and Safety domain and leader of several projects in this area. He is also an industry consultant and, presently, the President of the North Section of the Portuguese Engineers Association (OE). E-mail: asmiguel@dps.uminho.pt PAGE 20 | Abstract The emergence of implementation and certi®cation of structured management systems, such as the occupational health and safety management system, implies that companies should be able to measure the results and achievements from such implementation. This paper focuses on the description and comparison of the traditional indicators of health and safety performance and the use of different safety performance indicators, such as the companies' safety culture. The purpose of this paper is to summarize the safety measurement performance process and analyze what is the potential role of safety culture in this process. Keywords Health and safety, Performance measurement (quality), Health and safety requirements Measuring performance In the last decade, companies' management has widely agreed on the importance of the implementation and certi®cation of structured management systems, such as quality management systems, environment management systems, and recently, occupational health and safety (OH&S) management systems (NP 4397, 2001). The implementation of such systems requires that companies can be able to measure their results and achievements concerning each particular system. As a part of the OH&S management system, the performance measure is as important as other issues, such as ®nancial, production or service delivery management. As mentioned previously, measuring performance is an integrated part of any management system (Figure 1), and has several goals. As far as it concerns OH&S management systems, the safety performance measurement (SPM) can provide information, help in introspection, in decision-making, and in addressing different information needs (HSE, 2001). The primary purpose of SPM is to provide information on the progress and current status of the strategies, processes and activities used by an organization to control risks to OH&S. Measurement information sustains the operation and development of the OH&S management system, and consequently risk control, by providing information on how the system operates in practice, identifying areas where remedial action is required, establishing a basis for continual improvement and providing feedback and motivation. MEASURING BUSINESS EXCELLENCE | VOL. 7 NO. 4 2003, pp. 20-28, ã MCB UP Limited, ISSN 1368-3047 DOI 10.1108/13683040310509287 Figure 1 Performance measurement within the OH&S management system (adapted from HSE, 2001) policy development Policy Organizing Auditing Planning and implementing MEASURING PERFORMANCE Reviewing Performance feedback loop to improve performance As a way for introspection, SPM should seek to answer questions, such as: What is the position relative to the overall OH&S aims and objectives? How is the company in comparison with others? Does the management system improve the OH&S? Is the management of OH&S effective? Is the OH&S management reliable? Is the OH&S management ef®cient? Is the company culture supportive of OH&S, particularly pressed by competing demands? These questions should be asked not only at the highest level but also at the different management levels and across the organization. The aim should be to provide a complete picture of the organization's OH&S performance. In what concerns decision making the measurement information helps in deciding what goals can be achieved in relation to the initial proposal, what progress is needed and reasonable to expect in some circumstances, how it might be achieved against particular restraints (for example resources or time), and how to prioritize and have an effective use of resources. The type of information achieved by SPM is of primary importance for people in organizations who have particular responsibilities within the OH&S management system. These will include directors, senior managers, line managers, supervisors, OH&S professionals and employees/ safety representatives. It is also important to have an overall coherence in approach so that individual measuring activities are aligned within the overall performance measurement framework. As a matter of fact, this coherence should result in a hierarchical set of linked measures which re¯ect the organization's structure. Because performance measures should be derived principally to meet an internal need, there will be a limit to the number which can be used meaningfully from organization to organization (i.e. for external benchmarking purposes) rather than within the context of a particular organization. VOL. 7 NO. 4 2003 | MEASURING BUSINESS EXCELLENCE | PAGE 21 Although the primary focus for performance measurement is to meet the internal needs of the organization, there is an increasing need to demonstrate to external stakeholders (regulators, insurance companies, shareholders, suppliers, contractors, members of the involving community etc.) that arrangements to control OH&S risks are in place, operating correctly and effectively. While some ``high-risk'' industries may have recognized that they had been ``accepted'' by their local community and society, pressure for accountability is reaching other sectors through some concepts such as corporate social responsibility (HSE, 2001). Organizations will need to communicate their performance in ways that are meaningful to their various stakeholders. Traditional safety performance indicators If managers were asked how they measured their companies' performance, they would probably mention several economic indicators, such as liquid pro®t, return on investment or market share. A common feature of these indexes would be that they are generally positive in nature, re¯ecting achievement, rather than negative, which re¯ects failure. If the same managers were asked how they measured their companies' OH&S performance, it is likely that they only expressed accidents and illness, or diseases, related statistics. While the general business performance of an organization is subject to a range of positive measures, for OH&S it is frequently done with a few negative measures (lost time injuries, total injuries, lost work days rates, etc.) (Williams, 1999). Some companies also report, as a performance measure, the OH&S compliance indicating, for example, how many citations and penalties or ®nes relating to safety issues the company had in the period being measured. OH&S differs from many areas measured by managers because success results in the absence of an outcome (accidents or illness) rather than a presence. A low accident or ill-health rate, even over a period of years, is no guarantee that risks are being controlled and will not lead to accidents or professional diseases in the future. This is particularly true in companies where there is a low probability of accidents but where major hazards are present. Here the historical records of accidents and illnesses can be a deceptive indicator of safety performance. Organizations need to recognize that there is no single reliable measure of OH&S performance. What is required is a variety of measures, providing information on a range of OH&S activities. As organizations recognize the importance of managing OH&S they become aware of the problems with using accidents and ill-health statistics alone as the unique measure of OH&S performance. The use of accident rates, particularly when related to reward systems, can lead to such events not being reported in order to ``maintain'' performance, or to reduce accident assurance classi®cation. Additionally, whether a particular event results in an injury or accident is often a matter of chance, so it will not necessarily re¯ect whether or not a hazard is under control. In small or low-risk companies, these inconveniences could be accentuated, because a hypothetical low accident rate can lead to complacency, and also result in a few data points available. Because of the disadvantages associated with the use of accident and ill-health data alone when measuring performance, some organizations have recognized the need of more proactive measures of performance. Generally, this is translated into a search for things, which can be easily counted, such as number of training courses or number of inspections. Some authors (Pardy, 1999) argue that SPM indicators have been developed in three different phases: traditional, transitional and modern phases. The ®rst one is, as mentioned previously, characterized by traditional indicators, such as the statistical issues and the percentage of the budget allocated to OH&S. The second one, as the name may suggest, represents a transitional phase and is characterized by the use of indicators of trends and other PAGE 22 | MEASURING BUSINESS EXCELLENCE | VOL. 7 NO. 4 2003 economic indicators, such as the savings obtained through prevention. Finally, the last one is characterized by the use of positive indicators in measuring OH&S. This represents the approach which will be described in this paper. What is often absent is a systematic approach to deriving these measures and how they link to the risk control or mitigation process. The random approach, which is based purely on what is easiest to measure, is of limited value. The resultant data provide no information on how these values were achieved, whether they are ``acceptable'' (i.e. good/bad) or represented the quality and effectiveness of the activity. A more disciplined approach to SPM is required. This is important not only to ensure that measurement is effective but also to ensure effective use of the resources used to measure performance. Using safety culture Despite the minor theoretical development, a growing number of investigators and practitioners, in particular within the occupational safety area, has been emphasizing the importance of the organizational culture in individual perception and in risk behavior in workplaces. The terms ``safety culture'' or ``safety climate'' have been used to describe the output of an organization in terms of such an assumption of the value given to safety issues by individuals or groups of individuals. The use of the term ``climate'' seems to indicate a temporary or seasonal characteristic (Rundmo et al., 1996). On the opposite, the use of ``culture'' assumes the existence of an acquired and developed knowledge, and in this way, implying some stability. Zhang et al. (2002), in a comprehensive review of the concept of safety culture, establish the following de®nitions: J Safety culture: the enduring value and priority placed on worker and public safety by everyone in every group at every level of an organization. It refers to the extent to which individuals and groups will commit to personal responsibility for safety; act to preserve, enhance and communicate safety concerns. J Safety climate: the temporal state measure of safety culture, subject to commonalties among individual perceptions of the organization. It is therefore situationally based, refers to the perceived state of safety at a particular place and time, is relatively unstable, and subject to change depending on the features of the current environment or prevailing conditions. Despite the possible differences between concepts, the term culture will be used as designating both concepts. For authors working in this area, the most important in¯uence in the de®nition of safety behavior is the safety culture of the organization they belong to (HSE, 1997). This is, presently, one of the major investigation areas related to risk perception in occupational environments. While the empirical evidence of the culture's effect on risk behavior remain limited, some research seems to demonstrate that the presence of a ``complete'' knowledge of the risk among workers could be considered, at least by inference, as being suggestive of the cultural in¯uence on the risk behavior. In fact, in contrast with most of the studies in the perception of the risk area, the results of some studies on safety culture have contributed with a suf®ciently signi®cant number of empirical evidences suggesting that individuals have a perception, substantially precise, of risks in their occupational environments (Rundmo, 1992; Flin et al., 1996). However, these conclusions are, to a large extent, related to physical risk perception in high-risk environments, such as, the off-shore environment in oil and gas exploitation, nuclear and chemical plants. However, only a few available studies exist in occupational environments with less risk, or more trivial risks (Arezes, 2002). Other conclusions that can be drawn by these studies suggest that this effect can be substantially lesser for risk perception associate with dangerous substances exposure and in workers operating in complex environments, where the immediate risks are less observed (Weyman et al., 1999). VOL. 7 NO. 4 2003 | MEASURING BUSINESS EXCELLENCE | PAGE 23 Although some of the results, found in many of these studies, are not always consistent and present some variability, it seems to emerge a relative consensus in what concerns the factors that could in¯uence safety culture, such as, safety management, work force enrolment, risk attitudes, personal responsibility, safety rules violations and workplace physical environment (Cox et al., 1998). Safety culture is deeply related with organizational culture. The existence of such a culture supposes an organization where people share values, which will affect and in¯uence the attitudes and behavior of its members (Cooper, 2000a). The safety culture is a sub-dimension of this organizational culture, which supposedly in¯uences the attitude and behavior of the organization members in relation to an occupational OH&S performance (Donald, 1998; Cooper, 2000b). The safety culture is, according to Lee et al. (2000), understood as the product of multiple interactions between people (psychological), functions (behavioral) and organizations (contextual). The safety culture, risk perception, workers attitudes, safety concern and other organizational factors can affect the acceptability of breaking safety rules and, in that sense, being able to affect risk behavior. The safety climate and workers attitude contribute, signi®cantly, to the variability found in workers risk behavior in occupational settings (Rundmo, 2000). According to Groover (2001), one of the challenges that organizations face is the risk recognition and the appropriate reply by its collaborators. If risk is not well perceived or recognized, the safety performance continuous improvement is hardly achieved. The knowledge of workers' risk perception and its attitudes concerning safety is needed for the development and understanding of safety culture (Williamson et al., 1997). On the other hand, the safety culture seems to have a signi®cant effect in risk behavior (Rundmo et al., 1997). In this respect, Vries et al. (2000), in a study carried out in occupational environments, concludes that workers with more evident risk behavior are the ones who have a lesser bene®ts perception, who have found lesser social support and, mainly, the ones who have had bigger barriers to ``compliance'' behaviors. These barriers are, generally, related to how the organizations face and deal with the occupational safety, or in other words, by their own safety culture. In the standardized guidelines for implementation of OH&S management systems (for example OHSAS 18002, 2000 and prNP 4410, 2002), a wide range of measures to monitoring and measuring performance are proposed, which includes the use of several methods, such as: J results from risk identi®cation, assessment and control; J systematic inspections using checklists of workplaces; J previous analysis of new installations, equipment, materials, etc. J inspection in order to verify if all machines and safety systems are operational; J assessment of occupational exposure to physical, chemical and biological agents and comparison with established threshold or recommended values; J evaluation of workers behaviors in order to identify unsafe work practices which could be corrected; J documentation and record analysis; J benchmarking of OH&S practices; and J identi®cation of workers' attitudes towards the implementation of the OH&S management system. PAGE 24 | MEASURING BUSINESS EXCELLENCE | VOL. 7 NO. 4 2003 Some of these methods could be obtained through the application of a safety culture evaluation. As an evaluation method of SPM, safety culture evaluation consists of questioning workers about their attitudes to facing risk, the safety management or the safety procedures (Flin et al., 1998). OH&S climate is amenable to measurement, and recently, some questionnaire packages and other tools have been developed, in order to allow organizations to canvass the views of their employees on some key aspects of OH&S within their organization, as well as diagnosis, or to assess the safety culture levels of each company. Some of those packages are commercially distributed (HSE, 1997) and others are, partial or totally, published in scienti®c papers, such as those mentioned in Davies et al. (1999) and Cox et al. (2000). The safety culture evaluation results can have a wide range of uses, ranging from the conception of speci®c training programs to corrective actions based on these evaluations or, as it is pretended to illustrate in this paper, as a safety performance measurement indicator of companies or organizations. The measurement of safety culture, as mentioned previously, can be done in several ways and using several tools. Nevertheless, there are some common dimensions in a great number of safety culture or climate assessment tools. Within the set of developed tools with the purpose of the safety culture evaluation, it is possible to verify that the most frequent evaluated dimensions are related with management and managers (72 percent of the cases), OH&S management systems (67 percent) and risk control (67 percent), followed by less frequent subjects such as work pressure and work capacity which appear approximately in one third of the studies (Flin et al., 2000). This conclusion seems to con®rm the importance of management and its concern to safety issues, as a factor of paramount importance in organizations' safety culture. Davies et al. (1999), analyzing several safety culture/climate tools, group the more frequent items in some ``general subject'' groups, such as: J training and competence; J job security and job satisfaction; J pressure for production; J communications; J perceptions of personal involvement in health and safety; J accidents (including incidents and near misses); J perception of organizational/management commitment to OH&S; J merits of the OH&S procedures/instructions/rules; J rule breaking; and J workforce view on state of safety culture. Although safety culture can be measured and used as an important indicator of safety performance, and despite the fact of the consensual acceptance of an organizational culture concerning safety, its in¯uence in safety performance is not so consensual. The utility of safety culture is based, essentially, in the assumption that this could have an in¯uence in workers' behavior changing and, through that, in¯uence the safety performance. However, it should be noted that this assumption is not always observed and consensual, Hale et al. (2000) for example, veri®ed that safety performance could be improved, however without any signi®cant change in safety culture. These authors go further, pointing out that there is little evidence that the opposite can occur, i.e. a changing in safety culture could improve safety performance. VOL. 7 NO. 4 2003 | MEASURING BUSINESS EXCELLENCE | PAGE 25 From various studies, it is possible to conclude that the OH&S culture of an organization is an important factor in ensuring the effectiveness of risk control. The OH&S management system has an important in¯uence on the safety culture, which in turn impacts on the effectiveness of the OH&S management system. Measuring aspects of the safety culture is, therefore, part of the overall process of measuring OH&S performance. Many of the activities which support the development of a positive safety culture need to be measured. The safety culture measurement can gather information through several ways. The use of questionnaires is frequently used, but talking to people to elicit facts and their experiences as well as gauging their own opinions are also important. Beyond the possibility of using safety culture in SPM, it should be noted and emphasized the main goal of OH&S management systems, and that is minimizing risks in occupational environments. For this purpose, and beyond the individual information mentioned previously, SPM should also address other information, by examining written reports, documents and records and through direct observation of work conditions and peoples' behavior. Direct observation includes inspection activities and monitoring of work environment, namely physical, chemical and biological environment (e.g. thermal environment, noise, vibration, dust and chemical concentrations, biological risks) and people's OH&S related behavior. Summary and conclusion Recent years have witnessed a growing concern over the issue of safety culture within the research on occupational safety issues. The purpose of the present paper is to summarize the safety measurement performance process and analyze how this measurement can be done using safety culture, as well as the highly related concept of safety climate. From this review, it is possible to reveal that SPM is a crucial aspect of the OH&S management system. The traditional safety performance indicators, such as the accident statistics indices, seem to have a limited application and may not re¯ect with precision the company's safety performance. The efforts to de®ne and assess safety culture have arisen, most of the times, from high-risk or high complex industries, such as nuclear, chemical, oil and gas industries. Furthermore, the application of safety culture evaluation within OH&S management systems is relatively recent. In despite of the importance of the analyzed concepts, there is a considerable disagreement among safety professionals, both within and across industries, in de®ning how safety culture should be de®ned and whether or not safety culture is inherently different from the concept of safety climate. It is expected that this paper will enable researchers and safety practitioners to understand better how concepts, such as safety culture, can be also used to measure companies' safety performance. This application will facilitate the measurement process as well as its precision. This will permit companies to assess and compare safety performances, even if data on accidents and illness are scarce, which ultimately will help in improving the de®nition of strategies for the development of working conditions. References Arezes, P.M. (2002), Risk Perception of Occupational Noise Exposure, PhD Thesis, University of Minho, Portugal, November. Cooper, M. (2000a), ``Towards a model of safety culture'', Safety Science, Vol. 36 No. 2, pp. 111-36. Cooper, M. (2000b), ``Safety training ± a special case?'', Journal of European Industrial Training, Vol. 24 No. 9, pp. 481-90. PAGE 26 | MEASURING BUSINESS EXCELLENCE | VOL. 7 NO. 4 2003 Cox, S. and Cheyne, A. (1998), ``Hazard perceptions and attitudes to safety'', Proceedings of Society for Risk Analysis-Europe Annual Meeting. Cox, S. and Cheyne, A. (2000), ``Assessing safety culture in offshore environments'', Safety Science, Vol. 34 No. 1-3, pp. 111-29. Davies, F., Spencer, R. and Dooley, K. (1999), ``Summary guide to safety climate tools'', Offshore Technology Report No. 063/99, Health and Safety Executive, UK. Donald, I. (1998), ``Going beyond occupational safety: relating safety attitudes and other indicators of safety performance'', Proceedings of Society for Risk Analysis-Europe Annual Meeting. Flin, R., Mearns, K., Gordon, R. and Fleming, M. (1996), ``Risk perception by offshore workers on UK oil and gas platforms'', Safety Science, Vol. 22, pp. 131-45. Flin, R., Mearns, K., Gordon, R. and Fleming, M. (1998), ``Measuring safety climate on UK offshore oil and gas installations'', Proceedings of the 4th International Conference on Health, Safety and Environment in Oil and Gas Exploration and Production, Society of Petroleum Engineers, Richardson, Caracas. Flin, R., Mearns, K., O'Connor, P. and Bryden, R. (2000), ``Measuring safety climate: identifying the common features'', Safety Science, Vol. 34 No. 1-3, pp. 177-92. Groover, D. (2001), ``Why can't employees see risk?'', Personal Communication at AIHce Conference, New Orleans, LA. Hale, A.R., Guldenmund, F. and Swuste, P. (2000), ``Are safety culture and safety performance related?'', Proceedings of the First International Conference ORP 2000 on Occupational Risk Prevention, Spain. HSE ± Health and Safety Executive (1997), Health and Safety Climate Survey Tool, Information Pack, HSE Books, 1997, ISBN 0 7176 1462 X, available online at ww.hse.gov.uk/pubns/misc097.pdf HSE ± Health and Safety Executive (2001), Web-based Guide to Measuring Health and Safety Performance, available online in www.hse.gov.uk/opsunit/perfmeas.htm Lee, T. and Harrison, K. (2000), ``Assessing safety culture in nuclear power stations'', Safety Science, Vol. 34 No. 1-3, pp. 61-97. NP 4397 (2001), Sistemas de GestaÄo da SegurancËa e SauÂde no trabalho (OSHSAS 18000), IPQ/CEN, Lisboa. OHSAS 18002 (2000), Occupational Health and Safety Management Systems ± Guidelines for the Implementation of OHSAS 18001. Pardy, W. (1999), ``Performance measurement for workplace safety'', Vermont Safety Information Resources on the Internet, Powerpoint presentation available online in siri.uvm.edu/ppt/perfmeas/ pr NP 4410 (2002), Sistemas de gestaÄo da segurancËa e sauÂde do trabalho ± Linhas de orientacËaÄo para a implementacËaÄo da norma NP 4397, IPQ/CEN, Lisboa. Rundmo, T. (1992), ``Risk perception and safety on offshore petroleum platforms. Part I. Perception of risk'', Safety Science, Vol. 15 No. 1, pp. 39-52. Rundmo, T. (2000), ``Safety climate, attitudes and risk perception in Norsk Hydro'', Safety Science, Vol. 34 No. 1-3, pp. 47-59. Rundmo, T., Mearns, K., Flin, R., Fleming, M. and Gordon, R. (1996), ``Safety status, job situation and perceived risk in Norwegian and UK offshore workers ± a comparative study'', Proceedings of Society for Risk Analysis-Europe Annual Meeting. Rundmo, T., Ulleberg, P. and Bjerke, W. (1997), ``Safety attitudes and risk behaviour ± employee assessments'', Proceedings of Society for Risk Analysis-Europe Annual Meeting. Weyman, A. and Kelly, C. (1999), ``Risk perception and risk communication: a review of the literature'', Health and Safety Executive Contract Research Report No. 248/1999, 76 pp, UK. Williams, W. (1999), Local Government Occupational Noise Management Implementation Strategy, Final Report GR 97/0016, Workcover NSW. VOL. 7 NO. 4 2003 | MEASURING BUSINESS EXCELLENCE | PAGE 27 Williamson, A., Feyer, A., Cairns, D. and Biancotti, D. (1997), ``The development of a measure of safety climate: the role of safety perceptions and attitudes'', Safety Science, Vol. 25 No. 1-3, pp. 15-27. Vries, H. and Lechner, L. (2000), ``Motives for protective behavior against carcinogenic substances in the workplace: a pilot study among Dutch workers'', Journal of Occupational Environmental Medicine, Vol. 42 No. 1, pp. 88-95. Zhang, H., Wiegmann, D.A., von Thaden, T.L., Sharma, G. and Mitchell, A.A. (2002), ``Safety culture: a concept in chaos?'', Proceedings of the 46th Annual Meeting of the Human Factors and Ergonomics Society, Human Factors and Ergonomics Society, Santa Monica. PAGE 28 | MEASURING BUSINESS EXCELLENCE | VOL. 7 NO. 4 2003