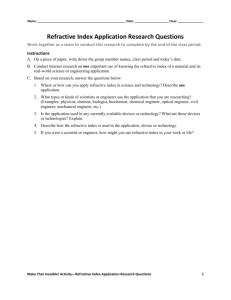

1. A researcher will check the dry parameter value of a bitter leaf simplicia using the gravimetric method. Explain the steps! Answer: The steps are as follows: The a. extract is weighed carefully as much as 1 g to 2 g and put into a shallow weighing bottle with a lid which has previously been heated at 105°C for 30 minutes and has been calibrated. b. Before being weighed, the extract was flattened in a weighing bottle, by shaking the bottle, until it formed a layer of approximately 5 mm to 1 O mm thick. If the extract being tested is a thick extract, mix it with the help of a stirrer. Then put in the drying chamber, open the lid, dry at 105°C until the weight remains. c. Before each drying, allow the closed bottle to cool in the desiccator to room temperature. If the extract is difficult to dry and melts on heating, add 1 g of desiccant silica which has been carefully weighed after drying and stored in a desiccator at room temperature. d. Mix the silica evenly with the extract when it is hot, then dry again at the determination temperature to a constant weight. Source: Ministry of Health RI. 2000. Standard Parameters of Medicinal Plant Extracts. Jakarta : Director General of POM, Director of Traditional Medicine Supervision. 2. In a measurement of one of the non-specific parameters of an extract, namely the water content with toluene distillation, the value is 15%. What do you think about these results and whether these values can meet the criteria for quality raw materials? Explain the reason (Use the correct reference) Answer: according to FHI 2000 generally the required water content is less than 10%, so it can be concluded that the water content of the extract does not meet the criteria for quality raw materials. Source: ● Indonesian Herbal Pharmacopoeia 3. The result of measuring the ash content parameter of an extract of raw materials for traditional medicine is 9%. What is the meaning of that value. Answer : This means that the remaining amount of internal and external mineral content of an extract (other part of the sample) after the igniting process is 9% of the total mineral content. Source: ● Indonesian Herbal Pharmacopoeia 4. Staff of a company will measure the refractive index of menthol oil. Explain the steps for determining it! j Answer: The refractive index is determined based on direct measurement of the refractive angle of the oil by maintaining the oil temperature at a constant temperature. The instrument used to measure the refractive index is a refractometer. The oil sample must be at the same temperature as the ambient temperature in which the refractive index test is performed. Source: ● Safwani, Luni Aulia. 2015. Profile of Volatile Components of Eucalyptus Essential Oil from Various Regions and Their Effect on the Flavor Profile of Cajuput Candy. Essay. Faculty of Agricultural Technology. IPB ● Anonymous. Pharmacopeia Indonesia V 2014 Edition. Jakarta : Ministry of Health of the Republic of Indonesia 5. A traditional medicine company is experiencing a shortage of raw materials for citronella oil (Cymbopogon nardus L.). So make a reorder on another supplier. In the test of the refractive index value obtained a value of 1.490 at a temperature of 25oC. What do you think about the measurement results and explain the benefits of measuring the refractive index of essential oils. Answer: According to EAO No.7, it is explained that the refractive index value of Citronella Oil is 1.488-1.495. So it can be concluded that the measurement results meet the requirements. Factors that affect the measurement results include: 1. Raw materials determine the quality of essential oils. The optimal condition of the material affects the quality of the essential oil, for example the appropriate way of picking and determining the level of aging of the material. 2. Post-harvest handling Post-harvest handling of essential oils is not the same for each part, be it leaves, flowers, stems, bark, rhizomes, or seeds. The non-uniformity of post-harvest handling will reduce the quality of the essential oil. 3. Production process As in the supply of raw materials and post-harvest handling, errors in the production or processing process will have a negative effect. Production errors can reduce the yield and quality of the essential oil produced. 4. Storage Essential oils should be stored in dark glass bottles and tightly closed. Essential oils stored in metal containers can result in a change in the color of the oil from clear to brownish due to the rust reaction of the metal. The benefits of measuring the refractive index are: Measurement of the refractive index of a liquid is important in assessing the nature and purity of the liquid in the sample we are testing. And as a comparison of the speed of light in air with the speed of light in the substance. Source : ● http://digilib.unila.ac.id/7354/15/15.%20BAB%202.pdf ● http://eprints.undip.ac.id/66470/6/bab_2.pdf ● Anonymous. Indonesian Pharmacopeia V 2014 Edition. Jakarta : Ministry of Health of the Republic of Indonesia