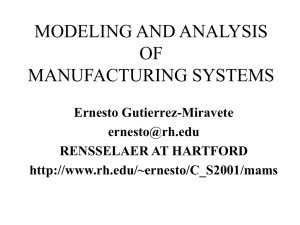

Energy Conversion and Management 208 (2020) 112593 Contents lists available at ScienceDirect Energy Conversion and Management journal homepage: www.elsevier.com/locate/enconman Comparative analysis and improvement of grid-based wind farm layout optimization T Giovanni Gualtieri National Research Council, Institute of Bioecomony (CNR-IBE), Via Caproni 8, 50145 Firenze, Italy ARTICLE INFO ABSTRACT Keywords: Wind farm layout optimization Gridded layout Literature case study Wind turbine database Levelized cost of energy Self-organizing map Among the main grid-based wind farm layout optimization studies addressed in the literature, 14 layouts have been recomputed by selecting the levelized cost of energy as a primary objective function. Relying on 120 wind turbine combinations, a previously developed optimization method targeting best turbine selection has then been applied. All literature layouts were optimized, as capacity factors were (slightly) increased (78.89–80.90 to 83.02–83.07%), while levelized costs of energy were (significantly) reduced (130.37–370.42 to 54.01–142.64 $/MWh). This study concluded that neither the discrete nor the continuous optimization model can be recommended in all scenarios. In general, a capacity factor increase does not necessarily imply a decrease in levelized cost of energy. The latter may be minimized by decreasing the overall wind farm capacity, the number of turbines, or selecting turbines with lower rotor diameters or rated powers. By contrast, capacity factor may be maximized by installing turbines with higher hub heights or lower rated speeds. Contradicting various findings, using turbines with different rotor diameters, rated powers or hub heights is not recommended to minimize the levelized cost of energy. Although addressed within several optimization studies, maximization of energy production is a misleading target, as involving the highest costs of energy. 1. Introduction Wind farm layout optimization (WFLO) is commonly intended as optimal positioning of wind turbines (WTs) in a wind farm (WF) through minimization of power losses due to wake interferences between the WTs to maximize the annual energy yield (AEY) [1]. In reality, this is a limiting definition, as AEY is not the only factor to take into account [2]. Since WF planning is an economic project, AEY maximization should be combined with the minimization of the cost of energy [3]. 1.1. Addressing wind farm layout optimization When addressing the WFLO problem, two WF layout models are generally applied [4]: (i) the continuous model, allowing WTs to be positioned anywhere in the WF, subject to constraints; (ii) the discrete model, only allowing WTs to be positioned at a finite number of locations. When applying the continuous model (i), WTs may either be irregularly placed (e.g. [5]), or positioned according to aligned (e.g. [6]) or staggered (e.g. [7]) arrays. In the discrete approach (ii), the domain is divided into a discrete grid with WTs positioned in the centre of specific cells (e.g. [8]). Depending on the layout scheme, the best WTs positioning is pursued by seeking, respectively: (i) optimal downwind and crosswind spacing between the WTs; (ii) most suitable grid cells to place the WTs. According to various Authors (e.g. [4]), since enabling to continuously vary the WTs placement, the continuous space search is more capable of achieving global optimal solutions. Conversely, unless when dealing with particularly dense grids (e.g. [9]), searching in a discrete space generally leads to a significant WFLO computational simplification [10]. An improved approach has been addressed by various Authors (e.g. [11]) by combining both discrete and continuous models into a single framework in an attempt to incorporate the advantages offered by each model: less model-solving complexity the former, and more flexible WT positioning the latter. To this aim, Long et al. [12] performed a thorough comparison of the advantages and drawbacks in planning WF layout deriving from applying the discrete vs. the continuous model. The WFLO problem is non-convex (involving many optimal solutions) and cannot be solved using traditional optimization methods, but requires heuristic optimization techniques, which were implemented by most Authors [2]. Heuristic techniques include, e.g., Genetic Algorithms (GA) [13], Particle Swarm Optimization (PSO) [3], Evolutive Algorithm (EA) [14], Viral System Algorithm (VSA) [8], or Extended Pattern Search (EPS) [15]. GAs are used in more than 75% of WFLO studies [4]. All these algorithms are strongly affected by the size of the solution space. For example, if considering a gridded layout divided E-mail address: giovanni.gualtieri@ibe.cnr.it. https://doi.org/10.1016/j.enconman.2020.112593 Received 11 November 2019; Received in revised form 7 February 2020; Accepted 8 February 2020 0196-8904/ © 2020 Elsevier Ltd. All rights reserved. Energy Conversion and Management 208 (2020) 112593 G. Gualtieri Nomenclature LCoE levelized cost of energy [$/MWh], Eq. (25) horizontal and vertical WF full sizes [m] Lh, Lv overall number of generated WF layouts [–] NLAY NLIT number of literature WF layouts [–] NP, ND, NH number of combinations in the WF with WTs having different Pr, D or Hhub [–] NT, NTH number of WTs, and number of WT combinations [–] NWF number of WF layouts for each literature case study [–] P total wind power installed in the WF [kW] Pe electric power output from a WT [kW], Eqs. (8), (13) Pr WT rated power [kW] wake radius downstream a WT [m], Eq. (1) r0 rw radius of wake expansion caused by an upstream WT [m], Eq. (3) v(z) wind speed at generic height z AGL [m/s], Eq. (20) v, vm wind speed, and mean wind speed [m/s] v0 free stream wind speed [m/s] actual wind speed approaching the WT [m/s], Eq. (7) vact vhub actual wind speed approaching the WT at Hhub [m/s] vi, vr, vo WT cut-in, rated and cut-off wind speeds [m/s] z, z1, z2 height AGL, and height at z1 and z2 AGL [m] z0 site’s aerodynamic surface roughness length [m] zref wind reference height AGL [m] site elevation ASL [m] zsite α wake expansion coefficient of upstream WT [–], Eq. (4) wind shear coefficient [–] δ wind speed deficit [–], Eqs. (5), (6) Δh, Δv horizontal and vertical WF grid cell sizes [m] η WF efficiency [%], Eqs. (12), (15) Φ WT design ratio [–], Eq. (21) Ω mean-to-rated wind speed [%], Eq. (22) Abbreviations AGL AGL AGL PL SOM WF WFLO WT above ground level above ground level above ground level power law self-organizing map wind farm wind farm layout optimization wind turbine Variables a A AEY CF Ci Cini CT D Fsite Ftot Fwake FWT Hhub WT axial induction factor [–], Eq. (2) WT swept area [m2] annual energy yield [MWh/y], Eq. (9) capacity factor [%], Eq. (10) annual cost at year i [$/kW/y] initial capital cost [$] WT thrust coefficient [–] WT rotor diameter [m] power losses of a single WT depending on the site type [%], Eq. (17) total power losses of a single WT experienced in the WF [%], Eq. (18) power losses of a single WT due to all wake interactions in the WF [%], Eqs. (11), (14) power losses of a single WT depending on the WT system [%], Eq. (16) WT hub height [m] into Ncell cells where NWT WTs are to be installed, the number of possible solutions is: Ncell!/[NWT!(Ncell–NWT)!] [2]. The WFLO problem is also complicated by the turbulence loads experienced by the WTs due to their mutual wake interactions in the farm. These increase the fatigue degradation of WTs, thus shortening their expected lifetime and consequently increasing the overall project’s cost. Therefore, a proper balance between the maximization of energy production and the minimization of structural loads should be targeted [16]. On the other hand, both the positive and negative environmental impacts involved by the installation of a grid-connected WF should not be ignored. For example, Tao et al. [17] demonstrated that, since integration of the WF into the electrical network reduces air pollutant emissions thus saving remarkable expenditures on pollutant penalty costs, neglecting these costs undervalues the profit deriving from the WF connection to the grid. By contrast, a relatively small amount of economic benefit should be sacrificed for reducing the noise disturbance of the WF to neighbouring residents and animals. approach in [18], i.e. the limited number of installed WTs, and thus the waste of land resource [4]. These studies targeted the same goals of Mosetti et al. [18], i.e. maximization of AEY [21] (also via maximization of WF array efficiency [22]), and/or minimization of a fitness value, given by the ratio of WF costs to AEY [23]. Regardless, the following deficiencies should be pinpointed in all such studies due to the use of: (i) the same WT model; (ii) a theoretical WT power curve; (iii) a constant value for WT thrust coefficient (CT); (iv) a simplified objective function (the fitness value), also relying upon (v) an overly-simplistic cost model. Actually, as Chowdhury et al. [3] pointed out, the WFLO problem should address two synergistic issues: (i) optimal WT allocation, and (ii) optimal WT selection. While several literature studies exist on heuristic algorithms, merely representing best WTs allocators (e.g. [24]), a minority of works focused on seeking the best-suited characteristics of commercial WTs [3], as in most cases only one single model was used, either when adopting the discrete [25] or the continuous [26] WFLO model, or a combination of both [11]. In other words, rather than a further WFLO assumption, WT characteristics should be treated as an array of variables to be carefully analysed for detecting the unique combination required to solve the WFLO problem. To this aim, for example, Hayat et al. [27] analysed the advantage of alternating 2- and 3blade WTs in a WF, while the benefits of vertically-staggered WFs were explored placing small WTs between large WTs by Chatterjee and Peet [28], as well as using different hub heights by Stanley et al. [29] or Wu et al. [30]. A 3-variable analysis was addressed, e.g., by Mirghaed and Roshandel [31], who targeted the minimization of WF costs through variation of WT hub height, rotor diameter and rated power, while parameters at WF-level such as the number of WTs and total installed power were also taken into account by Pookpunt and Ongsakul [32]. Following this survey, it is clear that all key factors – both at WT- 1.2. Literature survey Mosetti et al. [18] first addressed the optimal positioning of WTs in a WF, applying a GA algorithm and Jensen’s wake model [19]. They dealt with: (i) a flat onshore site; (ii) three ideal wind conditions; (iii) the same (theoretical) WT model installed over the whole WF; (iv) a square (2 km × 2 km) gridded layout with 200-m square cells [18]. WFLO was pursued by maximizing AEY and minimizing the installation costs of WTs [2]. Following and in the framework of this seminal work, several grid-based WFLO studies were addressed, either using the same assumptions as in [18] (e.g. [20]), or slightly different ones that involved a denser grid up to 20 × 20 [1] or even 50 × 50 [9] cells. All of these studies attempted to address a recognized drawback of the 2 Energy Conversion and Management 208 (2020) 112593 G. Gualtieri and WF-level – should be concurrently analysed to actually perform a WFLO comprehensive study. studies and implemented in several WFLO software, including WAsP [37] and WindPro [38]. According to Jensen’s model, the wake expands linearly behind a WT and a constant wind speed deficit in the radial direction x occurs [39]. If considering an upstream WTi having a rotor radius Ri, the radius of the wake spreading downstream WTi is [14]: 1.3. Goals and contributions of the paper The goals of the present study are the following: (i) to comparatively analyse main grid-based WFLO studies addressed in the literature after their recomputation using more real-world settings; (ii) to optimize them by applying a previously developed method [33] which targets an optimal selection of commercial-scale WTs; (iii) to provide insights into optimization functions and parameters that mostly influence WFLO. 1 1 r0, i = Ri ai 2ai (1) where ai is WTi axial induction factor [39]: ai = 0.5(1 1 (2) CT , i ) with CT,i the WTi thrust coefficient. At radial distance xij of a downstream WTj, the radius of wake expansion due to WTi is [39]: Literature studies where an optimal 10 × 10 (2 km × 2 km) gridbased layout was achieved against wind scenario ‘c’ defined in [18] have been recomputed. According to goal (i), the first contribution of the present paper is to overcome deficiencies (detailed in section 1.2) affecting such studies, for which the following were never applied: (i) 120 combinations of commercial WTs rather than using a single WT model; (ii) experimental (instead of theoretical) power curves for each WT; (iii) a continuous function of wind speed rather than a constant value for CT; (iv) the levelized cost of energy (LCoE) as an objective function instead of the simple fitness value; (v) the thorough NREL cost model rather than the simplified cost model proposed in [18]. Performing optimization of such studies by applying the method developed in [33] (goal ‘ii’) enables to deliver the paper's second contribution: since the WTs best selection rather than the WTs best positioning is pursued, layout optimization – contrary to those studies – has been performed by varying the type of WTs while retaining the number of WTs and their placement as assumed. Since the WFLO method presented in [33] was previously applied to the continuous WF layout model, a paper's further contribution is not only to test its applicability to the discrete model, but also to make a straight comparison – since application conditions are similar – between the discrete and the continuous WFLO model: this offers the opportunity to possibly determine whether one approach is superior to the other. An additional contribution while targeting goal (iii), is a multipurpose and a multi-variable analysis of grid-based WFLO studies that have never been addressed before: to concurrently consider all possible optimization functions (power production, WF efficiency, capacity factor or cost of energy) and parameters that mostly influence WFLO – both at WT- and WF-level – allows to genuinely achieve a comprehensive WFLO study. rw, ij = r0, i + (3) i x ij where αi is WTi-induced wake expansion coefficient [14]: i = 0.5 ln(Hhub, i z 0 ) (4) with Hhub,i the hub height of WTi and z0 site’s roughness length. A single wake between two WTs causes a velocity deficit given by [39]: ij r0, i rw, ij = 2ai 2 Aoverlap, ij Aj (5) where Aj is WTj swept area, and Aoverlap,ij the overlapping area between Aj and WTi-induced wake area at xij. Aoverlap,ij can be calculated by applying the method described in [39]. Summarizing, for a WTj subject to multiple wakes induced by Ni upstream WTi, the total velocity deficit can be calculated by summing up the Ni contributions provided by Eq. (5) [39]: Ni j 2 ij = Ni = 2ai i=1 i=1 r0, i rw, ij 2 Aoverlap, ij 2 Aj (6) Ultimately, actual wind speed approaching the downstream WTj is given by: vact , j = v0 (1 (7) j) 2.2. Wind power output and wind farm efficiency 2. Methods The electric power Pe(v) generated by a real WT is defined as [40]: Wake losses between the WTs were calculated by using Jensen’s model, while all other losses were assessed through an analytic method. A previously-developed curve as a function of wind speed was used for CT, while the NREL model was applied for WF cost analysis. SOMs were used to provide insights into WF layout optimization functions and parameters that influence WFLO the most. Pe (v ) = m e Pm (v ) = m e Cp P ( v ) = 1 Cp 2 m e A v3 = 1 2 T A v3 (8) where Pm(v) is the mechanical power extractable from wind power P(v) available for a WT with swept area A affected by a wind speed v [41], ρ is site’s air density, Cp is the WT power coefficient, ηm and ηe are mechanical transmission and electric conversion efficiencies of the WT, andηT = Cpηmηe is total power efficiency [42]. Annual energy yield (AEY) of a WT over a 1-year period (t =8760 h) is [43]: 2.1. Wake losses: Jensen’s model When a uniform free wind speed v0 hits a WT, a cone of slower and more turbulent air develops behind the WT, causing the so-called ‘wake effect’ [26]. Wake interactions between WTs are accounted for by the wake models. Jensen's analytical wake model, although one of the oldest, is still very effective in WFLO because of its simplicity [4]. Evidence that Jensen's model outperformed other wake models has been provided at both onshore (e.g. [34]) and offshore (e.g. [35]) locations. Originally proposed by Jensen [19] and later developed by Katic et al. [36] for studying WFLO, the model is applied within most AEY = t Pe (v ) f (v ) dv = t 0 m e Pm (v ) f 0 (v ) dv = t 0 1 2 T A v 3f (v ) dv (9) Capacity factor CF is the ratio of AEY to the energy (Er) that the WT could have produced if operated at its rated power over the same period [44]: 3 Energy Conversion and Management 208 (2020) 112593 G. Gualtieri CF = AEY Er attempted to deal with this issue, proposing a CT continuous curve as a function of Cp following a best-fit procedure. Very few WFLO studies considered CT as a value varying with wind speed [2], as for example the study performed by Ali et al. [45]. Based on CT experimental curves provided by manufacturers for 50 onshore commercial WTs [46], a further improvement has been proposed in [33] by applying a best-fit procedure, which returned the following CT(v) curve: (10) Overall power losses a generic WTj undergoes in the WF caused by all wake interactions are: Pact , j Fwake, j = 1 (11) P0 where Pact,j and P0 represent the power productions corresponding to vact,j and v0 in Eq. (7). WF efficiency, returning the amount of energy extracted from total available energy, is the ratio of total actual power output to total ideal power output. For a WF including N WTs, it yields [44]: N = Pact = Pideal j=1 CT = (5.47581845 (12) Mosetti et al. [18] introduced a WT theoretical model whose power output as a function of wind speed resulted from applying the laws of Betz and the momentum in the airflow passing through the WT swept area [2]. Assuming ηT = 40%, ρ = 1.225 kg/m3, and D = 40 m, Eq. (8) can thus be expressed through the following theoretical equation [14]: The PL is the wind speed vertical extrapolation model most widely used in wind energy applications (73.5%) because of its simplicity and greatest accuracy [47]. Based on the PL, a known wind speed value at height z1 is extrapolated to height z2 (i.e., WT hub height) by [47]: with Pe(v) in kW. Eq. (13) was used in all grid-based WFLO literature studies analysed. In the special case of the WT theoretical model, a modified expression for Eq. (11) can be derived by using Eq. (13): Pact , j Fwake, j = 1 P0 = 1 v (z2 ) = v (z1) (14) Accordingly, combining Eq. (13) into Eq. (12) yields [14]: N P = act = Pideal N Pact , j j=1 N P0 = j =1 N 3 0.3 vact ,j (15) Specific WT parameters, derived from basic parameters, may be calculated to better analyse WT characteristics, and thus assess how their particular regulation may influence WT performances. For example, the WT design ratio [42]: For any WT, power losses other than wake losses can be quantified by applying the method reported in [41]. Losses linked to gearbox, generator, converter, and unavailability & repair are calculated as depending on the WT system; losses due to electric grid connection, icing/ soiling, and other generic factors are calculated as a function of the type of site. WT-related losses FWT are calculated as: [(1 fgearbox ) (1 fgenerator ) (1 fconverter ) (1 by: fgrid ) (1 fice ) (1 fother )] This mean-to-rated wind speed Ω quantifies the percentage of the site’s wind speed the WT exploits on average when operating at rated conditions. funav )] 2.7. Wind farm cost estimation (17) Summarizing, total losses Ftot affecting any WT in the farm are given Ftot = 1 [(1 Fwake) (1 FWT ) (1 Fsite )] (22) = vm vr (16) [(1 (21) = vr vi quantifies the range of the region a WT operates between its vi and vr values. A further WT parameter is the ratio of the site’s mean wind speed to the WT rated wind speed [33]: while site-related losses Fsite are calculated as: Fsite = 1 (20) 2.6. Specific wind turbine parameters (0.3 v03 ) 2.3. Turbine-related, site-related and total losses FWT = 1 z2 z1 where v(z1) and v(z2) are wind speeds at heights z1 and z2, respectively, and is the wind shear coefficient. Although is a function of various parameters (e.g., atmospheric stability, terrain roughness, height range) and experiences significant inter-daily and inter-annual variations [48], when the site’s estimates are not available a rough value as a sole function of the landscape can be used (e.g. [49]). 3 vact ,j v03 (19) 2.5. Wind speed vertical profile (13) Pe (v ) = 0.3 v 3 1 Eq. (19) has been compared against the CT values averaged from the considered 50 WTs, eventually returning the scores summarized in Table S1 of the Supplementary material. Eq. (19) is particularly accurate when the WTs operate above their rated speed. Across the full wind speed range (3–25 m/s), a mean bias of 0.007 m/s, root mean square error of 0.027 m/s, and R2 of 0.993 are achieved. Pact , j N P0 10 6v 5.00641402 + 1.132584887) An optimization function (the fitness value) was introduced to address the WFLO problem [50]: (18) (23) Objective = Cost Pe where Pe is the total yearly power output extracted from the WF and Cost is the overall yearly cost of the WF, defined as [18]: 2.4. Turbine thrust coefficient One of the major WT operational parameters, thrust coefficient CT is also crucial for achieving an accurate wake analysis [7]. In the large majority of WFLO studies (e.g. [32]), a constant value of 0.88 is assumed for CT. However, as remarked by Serrano et al. [2], a CT fixed value may lead to significant errors in evaluating the wake effect. Relying on CT curves from 13 commercial WTs, Abdulrahman et al. [7] Cost = N 2 1 + e 3 3 0.00174 N2 (24) with N the number of WTs installed in the WF. As noted in section 1.2, both a rough objective function (Eq. 23) and a simplified cost model (Eq. (24)) were used within most grid-based WFLO studies (e.g. [23]). A more economically accurate approach was 4 Energy Conversion and Management 208 (2020) 112593 G. Gualtieri proposed, e.g., by Castro et al. [13], who suggested considering the project’s net present value (NPV) as an optimization function since taking into consideration crucial parameters such as the initial capital cost, its discount rate and the WF full lifetime. In addition to NPV, Shamshirband et al. [51] proposed that the project’s interest rate of return (IRR) should also be considered. According to this perspective, LCoE is probably the most reliable metric to be used for assessing the economic performances of a WF project [3]. The LCoE is the ratio between lifetime costs and lifetime electricity production, both discounted back to a common year through a discount rate reflecting the average capital cost [52]. For a WF project, LCoE may be calculated as [41]: LCoE = Cini + n i=1 n i=1 similar feature values are arranged close to each other on the map, while dissimilar data result in neurons allocated on different map edges. Therefore, the grid of neurons allows to easily detect the relationships between the variables and, possibly, the cluster structure in the original data [55]. The SOM algorithm performs an iterative training process where any input neuron is connected to all output neurons. Once the single winner neuron is identified, neurons are connected to adjacent neurons by a neighbourhood function. Gaussian, Cut Gaussian, bubble, and Mexican hat are the most commonly used neighbourhood functions. Another two parameters that control this learning procedure are the learning rate and the neighbourhood radius, both decreasing monotonically with the training steps [55]. Ci (1 + d )i AEY (1 + d )i (25) 3. Layouts from literature studies with Cini the initial capital cost, Ci the annual cost at year i from installation, d [%] the investment’s interest rate, and n the operational lifetime [years]. More accurate analytical models than Eq. (24) since also taking Pr into account were proposed (e.g. [53]). The most reliable cost model is likely the one developed at NREL by Fingersh et al. [54], where the cost for each single WT component and subsystem are calculated. This model is fully detailed in Table 5 of [32], where: (i) Cini is expressed as a function of R, Pr and Hhub by means of 23 equations; (ii) Ci is expressed as a function of Pr and AEY based on 3 equations. A total of 14 grid-based layouts developed in the literature have been comparatively analysed (Fig. 1). Their characteristics and scores are summarized in Table 1. All layouts have been built-up based on Mosetti et al. [18], who proposed a square gridded domain divided into 10x10 possible WT locations. Assuming the installation of a theoretical WT with D = 40 m, Hhub = 60 m, yielding a power output as in Eq. (13), they assumed square grid cells with a size of 5D = 200 m, with an overall layout extent therefore equal to 50D × 50D (2 km × 2 km). Only layouts based on wind scenario ‘c’ defined in [18] have been considered herein. Mosetti et al. [18] achieved an optimal layout comprising 15 WTs (Fig. 1a). Only Ulku & Alabas-Uslu [10], proposing a layout with WTs positioned along the first and last rows (Fig. 1k), used the same number of WTs, while all studies following [18] largely increased this number. All Authors employed WTs with the same Hhub value (60 m), except MirHassani & Yarahmadi [26], who also used WTs with Hhub = 78 m (Fig. 1h), and a combination of 8 WTs with Hhub = 50 and 17 WTs with 2.8. Self-organizing map The SOM is an unsupervised learning artificial neural network model that operates a nonlinear projection from a large data space to a small grid of neurons [55]. The original data space (input layer) is projected to a grid of neurons (output layer) while maintaining the topological and metric relationships in the original data. The SOM can recognize groups of similar input variables so that neurons having Fig. 1. Analysed literature gridded layouts (Δh = Δv = 200 m; Lh = Lv = 2 km): (a) Mosetti et al. [18]; (b) Grady et al. [50]; (c) Emami & Noghreh [56]; (d) Turner et al. [57]; (e) Patel et al. [25]; (f) Parada et al. [1]; (g) MirHassani & Yarahmadi [26]; (h) MirHassani & Yarahmadi [26]; (i) MirHassani & Yarahmadi [26]; (j) Abdelsalam & El-Shorbagy [20]; (k) Ulku & Alabas-Uslu, ‘a’ [10]; (l) Ulku & Alabas-Uslu, ‘b’ [10]; (m) Ulku & Alabas-Uslu, ‘c’ [10]; (n) Ulku & Alabas-Uslu, ‘d’ [10]. Hhub is 60 m for all layouts except 78 m (h) and 50 & 78 m (i). Wind conditions as in Fig. S1 apply for all layouts. 5 Energy Conversion and Management 208 (2020) 112593 G. Gualtieri Table 1 WFLO literature studies analysed and compared.a,b,c,d Layout Study Ref. Design Hhub (m) No WTs η (%) Pe (kW/y) Fitness (×10−4) (b) (c) (d) (e) (f) (g) (h) (i) (j) (k) (l) (m) (n) Mosetti et al. Grady et al. Emami & Noghreh Turner et al. Patel et al. Parada et al. MirHassani & Yarahmadi MirHassani &Yarahmadi MirHassani &Yarahmadi Abdelsalam & El-Shorbagy Ulku & Alabas-Uslu, ‘a’ Ulku & Alabas-Uslu, ,’b’ Ulku & Alabas-Uslu, ‘c’ Ulku & Alabas-Uslu, ‘d’ [18] [50] [56] [57] [25] [1] [26] [26] [26] [20] [10] [10] [10] [10] Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. 60 60 60 60 60 60 60 78 50 & 78 60 60 60 60 60 15 39 28 39 39 40 39 25 25 41 15 28 39 46 84 86.62 91 3,695 32,038 32,262 32,453 33,810 34,173 50,639 36,832 34,132 34,461 12,103 20,776 26,932 30,424 36.1 8.031 1a 1b 1c 1d 1e 1f 1g 1h 1i 1j 1k 1l 1m 1n 91.40 93.62 7.96 7.875 8.155 10.5 9.5 10.0 10.4 a For each layout, original characteristics and scores are reported. Values are missing where not reported in the works. c Eq. (15) used to calculate η. d Wind conditions as in Fig. S1 apply for all layouts; for normalization purposes, they also apply for layouts (g), (h) and (i), although in the original work zref = 78 m was set [26]. b Hhub = 78 m (Fig. 1i) being the only case with multiple Hhub values. As a result of the optimization algorithms that aimed at maximizing the downwind distance between the WTs, in layouts (e) and particularly (j) the majority of WTs are positioned towards the outer boundaries of the WF [25]. In layout (d) WTs are positioned according to a quite regularly staggered design very similar to that of an array layout. Conversely, layout (f) is scattered and irregular, with WTs mostly located in the outermost zone of the WF, particularly on the prevailing wind directions (270–350°) [1]. The optimized layouts proposed by Ulku & Alabas-Uslu [10], particularly (m) and (n), are structured in arrays with WTs aligned along the grid columns. Apart from layout (a), the fitness value – where available – exhibits a narrow range (7.875–10.5x10-4), with layout (f) returning the lowest value. Table 2 Assumptions and constraints for WF layouts. Section Site Description Location Topography Elevation Roughness length Wind shear coefficient Air density Parameter zsite z0 Reference height Vertical profile Assumptions and constraints, derived from the literature, apply for both (i) recomputation and (ii) optimization of WFLO literature layouts (Table 2). Wind turbines No. models (i) layouts recomputation (ii) layouts optimization No. combinations (i) layouts recomputation (ii) layouts optimization Thrust coefficient 4.1. Site characteristics and wind conditions Site characteristics and wind conditions are basically the same as those assumed in [33]. Following [49], =0.15 was considered herein. Wind scenario ‘c’ defined in [18] – plotted in Fig. S1 of the supplementary material – has been assumed, which refers to a height (zref) of 60 m AGL. To normalize all compared studies, zref = 60 m was also assumed for layouts (g), (h) and (i), although in the original work zref = 78 m was set [26]. Wind values at zref are adjusted to the proper Hhub of any WT by applying the PL (Eq. (20)) with = 0.15. Although a theoretical one, this wind scenario is an accepted reference for most grid-based WFLO studies (e.g. [58]). It was assumed herein to normalize comparison among all literature studies and to retain the scores originally achieved therein. In any case, this wind scenario is the most realistic among the three defined in [18]. On the other hand, refined wind condition settings such as the one proposed by Haces-Fernandez et al. [59], where wind speed and direction were segmented into bins to create a 2-D matrix with all possible combinations, were not considered since they are beyond the scope of this work. 1.225 kg/m3 zref v(z) multi-directional wind with variable wind speed (vm = 14 m/s, Fig. S1) 60 m AGL varying based on PL (Eq. (20)) NT NTH a 6 1 (2)a 120 CT Power curve The WT database developed in the computation tool detailed in [60] was used. This database has since been upgraded to include over 350 1 39 WF layout Design Size (Fig. 1) horizontal full size Lh vertical full size Lv horizontal grid cell size Δh vertical grid cell size Δv WT placement WT minimum spacing WT selection criteria (i) layouts recomputation Manufacturer and model (ii) layouts optimization Manufacturer(s) Model(s) 4.2. Wind turbines onshore flat 0 m ASL 0.30 m 0.15 ρ Wind conditions Wind case study 4. Assumptions and constraints Value(s) varying with wind speed (Eq. (19)) experimental gridded (row/column) 2000 m 2000 m 200 m 200 m study-dependent (Fig. 1) 4 rotor diameters the WT as in Table 4 (case ‘a’) the same for the whole WF the same WT along the row, and varied along the column Values in brackets refer to layout (i) in Table 1. Energy Conversion and Management 208 (2020) 112593 G. Gualtieri onshore commercial models. WT characteristics were retrieved from manufacturers’ websites as well as from online WT databases such as Wind turbines models [46] and WindPower [61]. It is accepted (e.g. [32]) that minimum crosswind and particularly downwind WT spacing should be observed in order to mitigate wake interactions between WTs in the WF. This constraint should also be considered for any wake model’s application. For example, Jeon et al. [34] demonstrated that the errors in predicting velocity deficit by Jensen’s wake model can be accepted for a downstream WT spacing above 3.75D. Therefore, consistently with Pookpunt and Ongsakul [32], a minimum downwind distance of 4D was assumed between adjacent cells in the gridded layout: since Δh = Δv = 200 m, this constraint yielded a maximum D = 50 m (Table 2). Furthermore, a minimum Pr = 200 kW was set for withdrawing the very small WT models. Eventually, a total of NT = 39 WTs have been used, extracted from the WT database after setting D ≤ 50 m and Pr ≥ 200 kW. Their characteristics are reported in Table 3. Notably, for any WT, experimental power curves have been used rather than approximated (e.g. [32]), best-fitted (e.g. [3]), or theoretically-constructed (e.g. [18] and all following grid-based WFLO studies) power curves. Since WTs with multiple hub heights were handled as distinct WTs, the overall number of WT combinations was actually NTH = 120. 2002–2020 inflation rate. For WT-related losses, the fx percentages depending on WT system, derived from [41] and given in Table S2, were used in Eq. (16); for site-specific losses, fgrid = 2%, fice = 2% and fother = 0% were set in Eq. (17). To calculate LCoE, d = 5% and n = 20 years were set in Eq. (25). This procedure generates two outputs: (i) a summary spreadsheet (with NWF records), listing characteristics and scores of all generated layouts; (ii) NWF spreadsheets, one for each layout, reporting characteristics and scores of each WT in the farm. Summarizing, NWF = 1,758 layouts are generated and analysed by the WFLO procedure for each of NLIT literature layouts. Since NLIT = 14, the overall number of layouts is: NLAY = NWF*NLIT = 1,758*14 = 24,612. A far more simplified WFLO procedure is activated when recomputing the original literature studies as, for each case, only one single WT (at most with two Hhub values) is imported from the WT database, and only one layout (NWF = 1) is generated and then analysed: in this case, the number of processed layouts (NLAY = NWF*NLIT) is 14. 6. Results and discussion The considered literature layouts have been recomputed and then optimized. In doing so, real WT models (exhibiting experimental power curves supplied by manufacturers) have been considered instead of the theoretical WT model (featuring the theoretical power curve defined in Eq. (13)) originally used in each of those studies. For the same reason, the more general Eq. (12) rather than Eq. (15) was used to calculate WF efficiency. Key factors that influence layout optimization the most have also been investigated. 4.3. Wind farm layouts WF layouts are presented in Fig. 1. When literature studies are recomputed, a single WT model is used. When layouts are optimized, the same WT selection criterion proposed in [33] is followed, which is detailed in the following. Once each WT is retrieved from the database, all possible WT combinations obtained by varying model, D and Hhub are implemented. For any layout instance, a common manufacturer is chosen for all WTs to be installed in the farm. WTs are the same for each row, while they are varied from one row to the other. The particular case where a unique WT model is installed throughout the farm is considered, too. 6.1. Recomputation of literature layouts The optimal layouts achieved in the original studies (Table 1) have been recomputed by considering the same application conditions (Table 2). In doing so, the Nordex N43-600 wt has been selected, proving to be the model within the WT database that best-fits the characteristics of the theoretical WT defined in [18]. WT characteristics are detailed as (a) in Table 4, while the WT power curve is shown in Fig. S3a. Although not the same model as in [18], this WT offers the advantage of having two Hhub values in addition to 60 m (i.e. 50 and 78 m) which enable to also run the layouts (h) and (i) proposed in [26]. Table 5 summarizes the scores achieved after recomputing all literature layouts by employing the Nordex N43-600 wt It is apparent that, irrespective of the number of installed WTs, the overall WF capacity and corresponding energy production, all layouts return very similar scores of η and CF, as shown by their very narrow ranges: 98.81–99.61% (η), and 78.89–80.90% (CF). By contrast, a very wide range is returned for Pe (7,101–21,773 kW/y) and LCoE (130.37–370.42 $/MWh). Overall, it should be noted that – except for layout (a) – significantly higher power output was achieved in layouts optimized in the original studies (Table 1). These findings support the hypothesis that the heuristic algorithms implemented within each study likely optimized all such layouts while targeting both Pe and CF maximization rather than LCoE minimization. Layout (a) returns the lowest LCoE (130.37 $/MWh), while layout 5. Wind farm layout optimization procedure The applied WFLO procedure (Fig. S2) consists of two stepwise Fortran modules: a layout generator, and a layout analyser. The same procedure is used to perform both layout recomputation and optimization. This procedure is a variation of the one developed in [33]. In the most general case (i.e., the optimization approach), based on the WT selection criteria, the layout generator ingests from the database all WTs with D ≤ 50 m and Pr ≥ 200 kW. Each layout in Fig. 1 is then loaded to enable allocation of each WT accordingly. After processing all available WT combinations, the module generates NWF layouts, each including sequential code, database identifier and coordinates of all allocated WTs. During the second stage, all previously generated layouts are ingested by the layout analyser, with characteristics of any WT retrieved from the database. The layout analyser performs the computation of CT(v), vertical extrapolation of wind speed, Jensen’s model and corresponding losses/efficiency, losses linked to the site and WT, energy output scores, and cost model. The NREL cost model [54] was used to calculate LCoE after setting [$] as the currency and the average Table 3 Summary of characteristics of all processed onshore WTs.a Score Median value Range a Rated power Rotor diameter Hub height Wind speeds Pr (kW) D (m) Hhub (m) Cut-in vi (m/s) Rated vr (m/s) Cut-off vo (m/s) Φ 600 220–900 43 26–50 50 30–78 3.5 2.5–5.0 14.0 11.0–18.0 25.0 20.0–28.0 4.3 3.1–5.3 Total WT models: NT = 39. Total WT combinations (sorted by Hhub): NTH = 120. 7 Design ratio Energy Conversion and Management 208 (2020) 112593 G. Gualtieri Table 4 Characteristics of WTs used or achieved while running all WFLO literature layouts.a Approach (case) Application condition (i) layouts recomputation (a) Recomputing (ii) layouts optimization (b) Minimizing LCoE (c) a b Maximizing CF Model Layout(s) Pr (kW) D (m) Hhub (m) vi (m/s) vr (m/s) vo (m/s) Systemb Nordex N43-600 All 600 43 50 60 78 3 13.5 25 A Vergnet GEV 26/220 Windtec 650 (a) 220 26 60 3.5 17 20 A (a) 600 50 71.5 3.5 11 20 C Power curves for each WT are plotted in Fig. S3. Coding for WT systems is reported in Table S2 [41]. (h) the highest CF (80.90%). The number of installed WTs significantly affects the results, as shown by the near matching scores from 28- wt layouts (c) and (l), as well as those from 39- wt layouts (b), (d), (e), (g) and (m). Scores from 15- wt layout (k) are very similar to those from 15- wt layout (a), too, particularly as minimum Pe and LCoE are basically the same, and values of all other indicators are only slightly worse. Pe scores are also a strict function of the number of installed WTs. Contrary to suggestions by MirHassani and Yarahmadi [26] that using WTs with different Hhub leads to an increase in the power output, with Pe = 11,962 kW/y layout (i) does not improve performances of the layout (h), which has the same design but WTs with identical Hhub. From the scores in Table 5, it is apparent that LCoE is a much more straightforward economic indicator than the fitness value, because not only does it exhibit a wider variation range than the latter (Table 1), but it also completely reverses the ranking of (a) from the worst (Table 1) to the best (Table 5) layout. Significantly improved η values are achieved with respect to the original applications (Table 1, where reported), where, however, Jensen’s wake model was applied using CT = 0.88. To assess the differences against the present study where the CT(v) approach is implemented, the CT = 0.88 option has been also analysed herein (see Table S3). It is apparent that η values are lower (overall ranging 94.69–98.18%), thus indicating that using CT = 0.88 is more conservative than using CT(v). The impacts are however quite marginal on Pe (7,025–21,512 kW/y), CF (77.94–80.50%), and LCoE (130.50–371.29 $/MWh). 6.2. Optimization of literature layouts For each literature layout, a total of NWF = 1758 layout instances have been generated, ultimately allowing the detection of only one solution that satisfies the selected optimization function. Table 6 shows the comparative results of layouts that minimize LCoE, while Table 7 shows those of layouts that maximize CF. All recomputed literature layouts (Table 5) have been optimized by the present optimization method, as both LCoE values have been reduced and CF values increased. While LCoE reduction is substantial (130.37–370.42 to 54.01–142.64 $/MWh, Table 6), CF increase is marginal (78.89–80.90 to 83.02–83.07%, Table 7). It is worth noting that for all literature case studies and both optimization conditions, all optimal layouts have been achieved by using identical WTs over the whole WF: this means that a unique combination for Pr, D and Hhub (NP = ND = NH = 1) applies. Furthermore, for all case studies, the same WT model proved to minimize LCoE, and the same WT model to maximize CF. As shown in Table 4, LCoE minimization is accomplished by using the Vergnet GEV 26/220 wt (whose power curve is plotted in Fig. S3b), while CF maximization is achieved by using the Windtec 650 wt (power curve in Fig. S3c). With respect to layouts recomputation, LCoE minimization is accomplished by reducing Pr and D, and concurrently increasing vr in the selected WT (Table 4), while CF maximization is accomplished – for the same Pr – by increasing D and decreasing vr . These outcomes agree with suggestions, e.g., by Abdulrahman and Wood [7], that small-medium sized WTs with low hub height should be installed to minimize LCoE. Table 5 Comparative results of WF literature layouts recomputed using a single WT model.a,b,c,d Layout (a) (b) (c) (d) (e) (f) (g) (h) (i) (j) (k) (l) (m) (n) Ref., and Hhub Mosetti et al. [18], 60 m Grady et al. [50], 60 m Emami & Noghreh [56], 60 m Turner et al. [57], 60 m Patel et al. [25], 60 m Parada et al. [1], 60 m MirHassani & Yarahmadi [26], 60 m MirHassani & Yarahmadi [26], 78 m MirHassani & Yarahmadi [26], 50 & 78 m Abdelsalam & El-Shorbagy [20], 60 m Ulku & Alabas-Uslu [10], ‘a’, 60 m Ulku & Alabas-Uslu [10], ‘b’, 60 m Ulku & Alabas-Uslu [10], ‘c’, 60 m Ulku & Alabas-Uslu [10], ‘d’, 60 m Cumulated Mean Cumulated Mean Cumulated No WTs P (MW) η (%) Pe (kW/y) AEY (MWh/y) CF (%) LCoE $/MWh) 15 39 28 39 39 40 39 25 25 41 15 28 39 46 9 23.4 16.8 23.4 23.4 24 23.4 15 15 24.6 9 16.8 23.4 27.6 99.61 99.21 99.35 99.23 99.08 99.13 99.04 99.41 99.53 99.05 98.90 98.81 98.95 98.82 7116 18,480 13,273 18,481 18,473 18,950 18,471 12,135 11,962 19,419 7,101 13,253 18,466 21,773 62,335 161,884 116,271 161,897 161,826 165,998 161,806 106,301 104,784 170,112 62,209 116,094 161,766 190,732 79.06 78.97 79.01 78.98 78.95 78.96 78.94 80.90 79.74 78.94 78.91 78.89 78.92 78.89 130.37 316.16 231.00 316.16 316.18 323.92 316.19 207.38 207.70 331.67 130.43 231.08 316.21 370.42 a Characteristics of each WF layout are depicted in Fig. 1. Eq. (12) used to calculate η. c Wind conditions as in Fig. S1 apply for all layouts; for normalization purposes, they also apply for layouts (g), (h) and (i), although in the original work zref = 78 m was set [26]. d The same WT (Table 4, case ‘a’) is used for all WFLO studies. b 8 Energy Conversion and Management 208 (2020) 112593 G. Gualtieri Table 6 Comparative results of WF literature layouts optimized by LCoE minimization.a,b,c,d Layout (a) (b) (c) (d) (e) (f) (g) (h) (i) (j) (k) (l) (m) (n) a b c d Ref., and Hhub Mosetti et al. [18], 60 m Grady et al. [50], 60 m Emami & Noghreh [56], 60 m Turner et al. [57], 60 m Patel et al. [25], 60 m Parada et al. [1], 60 m MirHassani & Yarahmadi [26], 60 m MirHassani & Yarahmadi [26], 78 m MirHassani & Yarahmadi [26], 50 & 78 m Abdelsalam & El-Shorbagy [20], 60 m Ulku & Alabas-Uslu [10], ‘a’, 60 m Ulku & Alabas-Uslu [10], ‘b’, 60 m Ulku & Alabas-Uslu [10], ‘c’, 60 m Ulku & Alabas-Uslu [10], ‘d’, 60 m Cumulated Mean Cumul. Mean Cumul. No WTs P (MW) η (%) AEY (MWh/y) CF (%) LCoE ($/MWh) 15 39 28 39 39 40 39 25 25 41 15 28 39 46 3.30 8.58 6.16 8.58 8.58 8.80 8.58 5.50 5.50 9.02 3.30 6.16 8.58 10.12 99.63 99.22 99.37 99.25 99.10 99.14 99.05 99.36 99.39 99.07 98.90 98.82 98.96 98.83 21,928 56,945 40,902 56,950 56,924 58,392 56,917 36,519 36,522 59,839 21,882 40,835 56,902 67,090 75.86 75.76 75.80 75.77 75.74 75.75 75.73 75.80 75.80 75.73 75.69 75.67 75.71 75.68 54.01 122.61 91.17 122.60 122.62 125.47 122.62 82.59 82.59 128.33 54.05 91.20 122.63 142.64 Mean Cumul. Mean Cumul. Characteristics of each WF layout are depicted in Fig. 1. Eq. (12) used to calculate η. Wind conditions as in Fig. S1 apply for all layouts. The same WT (Table 4, case ‘b’), installed over the whole WF, achieved to optimize all layouts. Table 7 Comparative results of WF literature layouts optimized by CF maximization.a,b,c,d Layout (a) (b) (c) (d) (e) (f) (g) (h) (i) (j) (k) (l) (m) (n) a b c d Ref., and Hhub Mosetti et al. [18], 60 m Grady et al. [50], 60 m Emami & Noghreh [56], 60 m Turner et al. [57], 60 m Patel et al. [25], 60 m Parada et al. [1], 60 m MirHassani & Yarahmadi [26], 60 m MirHassani & Yarahmadi [26], 78 m MirHassani & Yarahmadi [26], 50 & 78 m Abdelsalam & El-Shorbagy [20], 60 m Ulku & Alabas-Uslu [10], ‘a’, 60 m Ulku & Alabas-Uslu [10], ‘b’, 60 m Ulku & Alabas-Uslu [10], ‘c’, 60 m Ulku & Alabas-Uslu [10], ‘d’, 60 m Cumulated No WTs P (MW) η (%) AEY (MWh/y) CF (%) LCoE ($/MWh) 15 39 28 39 39 40 39 25 25 41 15 28 39 46 9.00 23.40 16.80 23.40 23.40 24.00 23.40 15.00 15.00 24.60 9.00 16.80 23.40 27.60 99.63 99.25 99.38 99.28 99.14 99.18 99.10 99.38 99.41 99.11 98.98 98.90 99.02 98.90 65,494 170,232 122,231 170,236 170,216 174,587 170,211 109,134 109,137 178,941 65,459 122,182 170,200 200,729 83.07 83.05 83.06 83.05 83.04 83.04 83.04 83.06 83.06 83.04 83.03 83.02 83.03 83.02 125.03 309.33 224.86 309.33 309.33 317.01 309.34 201.82 201.82 324.69 125.04 224.87 309.34 363.10 Characteristics of each WF layout are depicted in Fig. 1. Eq. (12) used to calculate η. Wind conditions as in Fig. S1 apply for all layouts. The same WT (Table 4, case ‘c’), installed over the whole WF, achieved to optimize all layouts. Table 6 shows that layout (a) (termed “L1”) returns the lowest LCoE value (54.01 $/MWh), yet only slightly lower than layout (k) which achieves a score very close to this. This value is consistent with the global average LCoE value (60 $/MWh) reported for 2017-updated onshore wind projects by IRENA [52]. Using observed wind data and applying the NREL cost model, at the real site of Khaf in Iran (40-m vm = 10.5 m/s) Mirghaed and Roshandel [31] designed a square (1.73 km × 1.73 km) layout with crosswind/downwind WT distances of 3D × 6D: notably, they obtained an LCoE value of 55 $/MWh very close to the minimum values (54.01–54.05 $/MWh) obtained in the current study (40-m vm = 13.2 m/s). Conversely, current LCoE minima are larger than those (21–31 $/MWh) calculated by Rahbari et al. [5] at a real site in Teheran based on observed wind data (10-m vm = 6.38 m/ s), where they designed four different rectangular layouts (sized 1.5 km × 2.5 km) with WTs irregularly allocated. Current LCoE scores are either lower or higher than minimum LCoE value (103.46 $/MWh) achieved in the previous WFLO study, based on the continuous model and run under quite similar application conditions (i.e. same site features, layout shape and size, and wind conditions) [33]. This indicates that the discrete model can perform either better or worse than the continuous model and that, consistent with reviews, e.g., by Serrano et al. [2] or Shakoor et al. [4], a superior model cannot be clearly ascertained. The CF values maximized in Table 7 match among all the considered studies (83.02–83.07%), thus reinforcing the hypothesis raised in section 6.1 that optimization of such literature layouts tends to a common value, corresponding to maximum CF. Regardless, layout (a) (termed “L2”) also proves to be the best solution for maximizing CF. Comparing Tables 6 and 7, it is apparent that the LCoE minimization target combines with satisfactory scores of CF (75.67–75.86%, Table 6), while this is not the case for CF maximization, which overall is not associated to particularly profitable scores of LCoE (125.03–363.10 $/MWh, Table 7). Current CF values are lower than the maximum CF value (92.17%) achieved in the previous WFLO study based on the continuous model [33]: although indirectly, this outcome is consistent with findings by Long et al. [12] that the continuous model is better than the discrete model when maximizing the power output is set as WFLO target. Characteristics and performances of WTs installed in layouts optimized by LCoE minimization and CF maximization are detailed, 9 Energy Conversion and Management 208 (2020) 112593 G. Gualtieri respectively, in Table S4 (L1) and Table S5 (L2), while their placement within the WFs is depicted in Fig. S5. It is apparent that L1 and L2 correspond to the same layout (a), except that they employ two different WT models. As reported in Table 4, such WT models belong to systems A and C as defined in Table S2, i.e. those accounting for the lowest overall WT-specific losses. If considering characteristics of all available WTs (Table 3), LCoE minimization (Table S4) is achieved using a WT exhibiting the lowest Pr and D, and almost maximum vr. These outcomes agree with suggestions by Chen et al. [40] that higher vr values are required by sites with higher vm and result in lower WTrelated LCoE, and that larger WTs do not necessarily reduce LCoE. The values of Ω (84.29–84.47%) indicate that on average the WT operates below its rated speed. By contrast, CF maximization (Table S5) is achieved through a WT of medium Pr, with minimum vr and Φ, and Hhub close to the maximum (Table 3). Corresponding Ω values (130.73–131.00%) indicate that to a remarkable extent (over 30%) the WT operates above its rated speed, thus largely exceeding the threshold over which the WF overall cost increase is adequately compensated for by the revenues deriving from energy production. Cini/Pr (Fig. S4n), and CF (Fig. S4p), meaning that – for any WT combination in the WF – all these parameters are insensitive to the selected layout design. This outcome is particularly meaningful for CF, as it confirms that whatever the chosen literature layout, this score does not appreciably change. Conversely, patterns are layout-dependent for P (Fig. S4d), total losses (Fig. S4m), AEY (Fig. S4o), and LCoE (Fig. S4q), meaning that choosing a specific layout dramatically affects WF power production and particularly the project’s economic viability. 15- wt layouts (a) and (k) exhibit a similar pattern for P, AEY, and LCoE, with main discrepancies apparent in η. For layouts (k) and (l) there is a relevant frequency of layout instances built-up with a twofold combination of Pr (Fig. S4a) and D (Fig. S4b), while for layout (k) this also involves Hhub values (Fig. S4c). Layout (a) proves to be the best solution overall for maximizing η, minimizing total losses, and – most importantly – minimizing LCoE. By contrast, layout (a) returns the lowest overall AEY values. It is worth noting that the plots of AEY and LCoE can almost perfectly be overlapped. In terms of total power losses (Fig. S4m), wake losses are almost negligible (Fig. S4k), particularly if compared to losses linked to the site and WT (Fig. S4l). Furthermore, in the majority of layout instances, WTs operate in wind regimes below their rated speed (Fig. S4j). After lumping all literature layout instances together, a correlation analysis between all parameters has been performed (Table S6). Since no correlation exists between CF and LCoE (r = −0.03), increasing CF can either reduce or increase LCoE. As shown by Figs. S2o and S2q, AEY and LCoE are strongly correlated (r = 0.99): therefore, for a high wind potential site, WFLO is surprisingly achieved by reducing the total energy production. LCoE is also strongly correlated to P (r = 1.00), thus indicating that the overall installed power rather than the mere number of WTs (r = 0.84) should be reduced for reducing LCoE. Pr affects LCoE more than vr (r of 0.51 vs. –0.02), which contrasts with suggestions by Chen et al. [40] that vr is more influential on LCoE than Pr. Distributions of Ci and AEY are strongly correlated as well (r = 1.00), meaning that annual expenditures increase with WF energy production. Total losses 6.3. Insights into wind farm layout optimization key factors Optimization functions and key factors that mostly affect WFLO have been investigated after applying kernel density plots, correlation analysis and self-organizing maps to main WFLO parameters. 6.3.1. Kernel density and correlation analysis All layout instances generated per literature study have been analysed in terms of the distribution of main WFLO parameters. The result of this analysis is summarized through the kernel density plots shown in Fig. S4, drawn by using the “sm.density.compare” tool [62] implemented in the “sm” R package [63]. For all literature layouts, quite similar distributions may be observed for Pr (Fig. S4e), D (Fig. S4f), Hhub (Fig. S4g), vr (Fig. S4h), Φ (Fig. S4i), Ω (Fig. S4j), Fsite & FWT (Fig. S4l), Fig. 2. SOM component planes obtained while optimizing literature layouts for the following parameters: No. WTs, NP, ND, NH, P, Pr, D, Hhub, vr, Φ, Ω, η, Fsite & FWT, Ftot, Cini/Pr, AEY, CF, and LCoE. Cumulated values are plotted for No. WTs, P and LCoE, while WF-averaged values for all other parameters. A total of 1,758 layouts by 14 literature case studies (NLAY = NWF*NLIT = 24,612) were processed. 10 Energy Conversion and Management 208 (2020) 112593 G. Gualtieri are strongly correlated to site- and WT-related losses (r = 0.96), and poorly correlated to η, and thus to array losses (r = 0.33): since sitespecific losses do not change, WT-related losses are the component that primarily affects total losses, meaning that the system the selected WT belongs to (see Table S2) is pivotal in affecting WF overall losses. On the other hand, a significant correlation (r = 0.86) was ascertained between Ω and CF, yet it was not as strong (e.g., r > 0.95) as to imply that Ω gives the same level of information as CF. 6.3.1), the SOMs of Ftot basically match with those of Fsite & FWT. Since the SOMs of η confirm that wake losses are almost negligible, it is also confirmed that WF total losses are mainly driven by losses depending on WT characteristics: therefore, the selection of WTs returning the lowest losses (see Table S2) should be prioritised. In any case, reducing total losses positively affects CF but not LCoE, as CF increases do not necessarily result in LCoE decreases. The highest energy production may be obtained by the most expensive layouts, i.e. those that maximize the overall WF installed capacity and employ WTs with the highest values of Pr, D and Hhub. However, AEY maximization is economically disadvantageous as they correspond to the highest values of LCoE. This means that maximizing the overall WF power output, as pursued within several studies (e.g. [57]), is a misleading WFLO goal. Summarizing, the SOMs proved useful in improving the multivariable investigations addressed in the past literature either dealing with WFLO (e.g. [31]), or WT optimal site matching (e.g. [40]). They are also particularly helpful when WFLO problems involving multiple objective functions (as performed, e.g., by Abdulrahman and Wood [7]) are addressed. Since they are capable of representing the relationships among main WF layout parameters through a single, compact plot, the SOMs allow to achieve a straightforward WFLO pattern, thus efficiently coping with the non-convex, highly complex, multi-purpose and multivariable nature of the WFLO problem. 6.3.2. The self-organizing maps To more thoroughly investigate WFLO key factors, an advanced analysis than both kernel density and correlation analysis (Section 6.3.1) was accomplished through the use of SOMs. A dataset including NWF = 1758 layout instances multiplied by NLIT = 14 case studies, for a total of NLAY = NWF*NLIT = 24,612 layouts, was used. The following 18 variables were selected as component planes of the SOMs: No. WTs, NP, ND, NH, P, Pr, D, Hhub, vr, Φ, Ω, η, Fsite & FWT, Ftot, Cini/Pr, AEY, CF, and LCoE. Ci was not considered since its distribution is the same as AEY (r = 1.00, Table S6). The following final SOM structure was achieved for the above 18 variables: (i) an input layer, including 24,612 neurons corresponding to all layout instances; (ii) an output layer, including 100 neurons, represented through 10x10 gridded hexagons. Before SOM training, all variables’ values were normalized such that their mean was 0 and their variance was 1 [64]. The SOMs were trained following the requirements of the Kohonen’s algorithm [55]: thus, 60,000 iterations (over 500 times the number of gridded neurons) were used, along with initial values of 0.9 (close to 1) for learning rate and 7 units (higher than grid’s radius) for neighbourhood radius. The Mexican hat was selected as neighbourhood function since it results in a larger variables’ variation range than the most widely used Gaussian function, while the goodness of SOM was assessed using the Kaski and Lagus error metrics [65], that combine quantization and topographic errors. The graphical output of SOM application, performed by using the Living For SOM tool (http://livingforsom.com), is shown in Fig. 2. In SOM topology of LCoE, lower-to-higher neurons are arranged bottom to top, with minimum and maximum values located centrally. A similar topology is exhibited by SOMs of P and AEY, and – to a lesser extent – Pr, D, and No. WTs: this means that LCoE may be minimized by decreasing the overall WF installed capacity, the energy production, rated powers, rotor diameters or the number of WTs. These scores confirm findings achieved in section 6.2 that lie behind the optimization of layout L1 (Table S4). The association of LCoE with NP, ND and NH is weaker, as shown by their different SOM topologies: LCoE minima are associated to lower but not minimum values of NP, ND and NH, which are located in the centre of their respective maps. In any case, this means that LCoE could be reduced by avoiding to install WTs with multiple Pr, D or Hhub (as accomplished for layout L1). This finding seems to contradict those from various Authors, suggesting that it is more profitable to suitably combine different WTs rather than installing identical WTs, particularly having different D [66] or different Hhub [58]. Since the WT combinations in the farm reduce to just one for each WT per manufacturer, WT selection criteria set in section 4.3 are dramatically simplified. Notably, CF neurons do not arrange in a mirrored fashion with respect to LCoE neurons, suggesting that maximizing CF does not imply minimizing LCoE: confirming the null correlation between CF and LCoE (section 6.3.1), a CF increase may either result in an LCoE increase or decrease. Rather, SOM clustering of CF shows a neurons arrangement quite similar to the ones of Hhub, Φ, Ω, and (mirrored) vr, suggesting that an increase (decrease for vr) in such variables leads to an increase in CF. These results were anticipated in section 6.2 when analysing the characteristics of optimal layout L2 (Table S5). As for the SOM of Ω, it is confirmed that values close to 100% do increase CF, but also involve an overall energy waste, since resulting in an energy over-production (see AEY) not adequately compensated by a corresponding revenue (see LCoE). Consistent with findings from the correlation analysis (section 7. Conclusions A total of 14 grid-based layouts addressed in the literature and run based on wind scenario ‘c’ defined in Mosetti et al. [18] have been recomputed. Several application improvements have been performed to the original settings, including the use of: (i) commercial-scale WTs instead of a theoretical WT; (ii) experimental instead of theoretical WT power curves; (iii) CT varying with wind speed rather than the 0.88 constant value; (iv) LCoE as an objective function rather than the simple fitness value; (v) the detailed NREL cost model in place of the overlysimplistic cost model defined in [18]. All layouts returned very similar scores of farm efficiency (98.81–99.61%) and CF (78.89–80.90%), but widely varying scores of LCoE (130.37–370.42 $/MWh): this indicates that CF maximization rather than LCoE minimization was the actual target pursued by the heuristic algorithms implemented within each WFLO study. Results indicated the 15- wt layout by Mosetti et al. [18] as the optimal in minimizing LCoE (130.37 $/MWh), and the 25- wt layout by MirHassani and Yarahmadi [26] as the optimal in maximizing CF (80.90%). As such, results achieved from this layout recomputation proved to be a novelty in themselves, as they were quite different from those returned from the original studies, which adopted energy yield maximization and/or fitness value minimization as an objective function. In the present study, relying on 39 commercial WTs, a previously developed optimization method [33] was applied which targets optimal WT selection while retaining the original number of WTs and their placement as an assumption. Previously applied to the continuous WF layout model, the method has also been successfully applied to the discrete layout model. For each literature case study, a total of 1,758 layout instances were generated, overall resulting in 24,612 layouts. Method’s application proved to optimize all literature layouts, as CF values were (slightly) increased (78.89–80.90 to 83.02–83.07%), while LCoE values were (significantly) reduced (130.37–370.42 to 54.01–142.64 $/MWh). It is worth noting that the layout by Mosetti et al. [18] proved to be the best both in minimizing LCoE (54.01 $/MWh) and in maximizing CF (83.07%). Furthermore, for all literature case studies and both optimization conditions, all optimal layouts were achieved by using identical WTs: this means that only one combination of rotor diameter, rated power and hub height applies over the whole WF. For all case studies, the same WT model (Vergnet GEV 26/ 220) minimized LCoE, and the same WT model (Windtec 650) 11 Energy Conversion and Management 208 (2020) 112593 G. Gualtieri maximized CF. LCoE scores were either better or worse than those achieved in the previous WFLO study, implementing the continuous model and run under similar application conditions [33]: therefore, a model – be it discrete or continuous –cannot be recommended since neither clearly outperforms the other. A thorough analysis has been performed to investigate optimization functions and the parameters that mostly influence WFLO. Although specifically applying to high wind potential sites where mid-sized WTs are supposed to be installed, various conclusions can be made: Acknowledgments No funds were received to support the research conducted in this paper. Appendix A. Supplementary data Supplementary data to this article can be found online at https:// doi.org/10.1016/j.enconman.2020.112593. • the two optimization conditions are not associated, as a CF increase does not necessarily imply an LCoE decrease; • LCoE can be minimized by decreasing farm overall capacity or the • • • • • References [1] Parada L, Herrera C, Flores P, Parada V. Wind farm layout optimization using a Gaussian-based wake model. Renew Energy 2017;107:531–41. [2] Serrano González J, Burgos Payán M, Riquelme Santos JM, González-Longatt F. A review and recent developments in the optimal wind-turbine micro-siting problem. Renew Sustain Energy Rev 2014;30:133–44. [3] Chowdhury S, Zhang J, Messac A, Castillo L. Optimizing the arrangement and the selection of turbines for wind farms subject to varying wind conditions. Renew Energy 2013;52:273–82. [4] Shakoor R, Hassan MY, Raheem A, Wu YK. Wake effect modeling: a review of wind farm layout optimization using Jensen’s model. Renew Sustain Energy Rev 2016;58:1048–59. [5] Rahbari O, Vafaeipour M, Fazelpour F, Feidt M, Rosen MA. Towards realistic designs of wind farm layouts: application of a novel placement selector approach. Energy Convers Manage 2014;81:242–54. [6] Mustakerov I, Borissova D. Wind turbines type and number choice using combinatorial optimization. Renew Energy 2010;35(9):1887–94. [7] Abdulrahman M, Wood D. Investigating the power-COE trade-off for wind farm layout optimization considering commercial turbine selection and hub height variation. Renew Energy 2017;102:267–78. [8] Ituarte-Villarreal CM, Espiritu JF. Optimization of wind turbine placement using a viral based optimization algorithm. Procedia Comput Sci 2011;6:469–74. [9] Yang Q, Hu J, Law SS. Optimization of wind farm layout with modified genetic algorithm based on boolean code. Wind Eng Ind Aerodyn 2018;181:61–8. [10] Ulku I, Alabas-Uslu C. A new mathematical programming approach to wind farm layout problem under multiple wake effects. Renew Energy 2019;136:1190–201. [11] Long H, Zhang Z. A two-echelon wind farm layout planning model. IEEE Trans Sustainable Energy 2015;6(3):863–71. [12] Long H, Zhang Z, Song Z, Kusiak A. Formulation and analysis of grid and coordinate models for planning wind farm layouts. IEEE Access 2017;5:1810–9. [13] Castro Mora J, Calero Barón JM, Riquelme Santos JM, Burgos Payán M. An evolutive algorithm for wind farm optimal design. Neurocomputing 2007;70(16–18):2651–8. [14] Rajper S, Amin IJ. Optimization of wind turbine micrositing: a comparative study. Renew Sustain Energy Rev 2012;16(8):5485–92. [15] DuPont B, Cagan J, Moriarty P. An advanced modeling system for optimization of wind farm layout and wind turbine sizing using a multi-level extended pattern search algorithm. Energy 2016;106:802–14. [16] Réthoré PE, Fuglsang P, Larsen GC, Buhl T, Larsen TJ, Madsen HA. TOPFARM: Multi-fidelity optimization of wind farms. Wind Energy 2014;17(12):1797–816. [17] Tao S, Xu Q, Feijoo A, Hou P, Zheng G. Bi-hierarchy optimization of a wind farm considering environmental impact. IEEE Trans Sustainable Energy 2020. https:// doi.org/10.1109/TSTE.2020.2964793. [18] Mosetti G, Poloni C, Diviacco B. Optimization of wind turbine positioning in large wind farms by means of a genetic algorithm. J Wind Eng Ind Aerodyn 1994;51:105–16. [19] Jensen NO. A note on wind generator interaction. Risø-M-2411, Risø National Laboratory, 1983. [20] Abdelsalam AM, El-Shorbagy MA. Optimization of wind turbines siting in a wind farm using genetic algorithm based local search. Renew Energy 2018;123:748–55. [21] Zergane S, Smaili A, Masson C. Optimization of wind turbine placement in a wind farm using a new pseudo-random number generation method. Renew Energy 2018;125:166–71. [22] De-Prada-Gil M, Alías CG, Gomis-Bellmunt O, Sumper A. Maximum wind power plant generation by reducing the wake effect. Energy Convers Manage 2015;101:73–84. [23] Marmidis G, Lazarou S, Pyrgioti E. Optimal placement of wind turbines in a wind park using Monte Carlo simulation. Renew Energy 2008;33(7):1455–60. [24] Wu Y, Zhang S, Wang R, Wang Y, Feng X. A design methodology for wind farm layout considering cable routing and economic benefit based on genetic algorithm and GeoSteiner. Renew Energy 2020;146:687–98. [25] Patel J, Savsani V, Patel V, Patel R. Layout optimization of a wind farm to maximize the power output using enhanced teaching learning based optimization technique. J Cleaner Prod 2017;158:81–94. [26] MirHassani SA, Yarahmadi A. Wind farm layout optimization under uncertainty. Renew Energy 2017;107:288–97. [27] Hayat I, Chatterjee T, Liu H, Peet YT, Chamorro LP. Exploring wind farms with alternating two-and three-bladed wind turbines. Renew Energy 2019;138:764–74. [28] Chatterjee T, Peet Y. Exploring the benefits of vertically staggered wind farms: Understanding the power generation mechanisms of turbines operating at different scales. Wind Energy 2019;22(2):283–301. number of WTs, as well as selecting WTs with lower rotor diameters or rated powers; conversely, CF maximization can be achieved by installing WTs with higher hub heights or lower rated speeds; LCoE can be minimized even using WTs operating on average (slightly) below their rated speed; by contrast, matching or exceeding their rated speed increases CF, but also results in overall energy waste, since it leads to an over-production of energy that is not adequately compensated by the corresponding revenue; contradicting various findings, using WTs with different rotor diameters, rated powers or hub heights is not the best approach for minimizing LCoE: this dramatically impacts on WT selection criteria, as only one WT combination per manufacturer (i.e. the same model) is suggested as being installed in the farm instead of other possible combinations; WF total losses are mainly driven by losses depending on WT characteristics, while wake losses are almost negligible: however, reducing total losses results in CF increases, but not necessarily in LCoE decreases; maximization of WF power generation is a misleading WFLO target, as it is achieved at the expense of a dramatic LCoE increase: therefore, when AEY maximization and LCoE minimization became two competing (and conflicting) goals, the latter should be prioritised. The following limitations affect the study, based on considering: (i) an ideal onshore flat and sea-level site; (ii) a theoretical wind scenario; (iii) grid-based layouts with fixed (square) shape, grid density (10x10), and overall size (2 km × 2 km); (iv) the simplified Jensen’s wake model; (v) a set of mid-sized WTs (D = 26–50 m and Pr = 220–900 kW). Also, wake-induced fatigue degradation of WTs, and thus more complex cost functions (as addressed, e.g., by Réthoré et al. [16]), have been disregarded since they are beyond the scope of this work. In the future, this method could be applied to onshore sites with complex topography or offshore sites, hopefully being real and not ideal sites. Furthermore, to generalize the results achieved thus far, it could be helpful to deal with more real-world wind scenarios (e.g. [59]), representative of a wider range of locations or, following DuPont et al. [15], to analyse the effects resulting from considering different atmospheric stability conditions. CRediT authorship contribution statement Giovanni Gualtieri: Conceptualization, Data curation, Investigation, Methodology, Supervision, Validation, Visualization, Writing - original draft, Writing - review & editing. Declaration of Competing Interest The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. 12 Energy Conversion and Management 208 (2020) 112593 G. Gualtieri [29] Stanley AP, Ning A, Dykes K. Optimization of turbine design in wind farms with multiple hub heights, using exact analytic gradients and structural constraints. Wind Energy 2019;22(5):605–19. [30] Wu YT, Liao TL, Chen CK, Lin CY, Chen PW. Power output efficiency in large wind farms with different hub heights and configurations. Renew Energy 2019;132:941–9. [31] Mirghaed MR, Roshandel R. Site specific optimization of wind turbines energy cost: iterative approach. Energy Convers Manage 2013;73:167–75. [32] Pookpunt S, Ongsakul W. Design of optimal wind farm configuration using a binary particle swarm optimization at Huasai district, Southern Thailand. Energy Convers Manage 2016;108:160–80. [33] Gualtieri G. A novel method for wind farm layout optimization based on wind turbine selection. Energy Convers Manage 2019;193:106–23. [34] Jeon S, Kim B, Huh J. Comparison and verification of wake models in an onshore wind farm considering single wake condition of the 2 MW wind turbine. Energy 2015;93:1769–77. [35] VanLuvanee DR. Investigation of observed and modelled wake effects at Horns Rev using WindPRO. Technical University of Denmark, Department of Mechanical Engineering; 2006. [36] Katic I, Hojstrup J, Jensen NO. A simple model for cluster efficiency. In: Proceedings of the European Wind Energy Association Conference and Exhibition, 1986, 407–10. [37] Mortensen NG, Heathfield DN, Myllerup L, Landberg L, Rathman O. Wind atlas analysis and application program: WAsP 8 help facility. Roskilde, Denmark: Risø National Laboratory; 2005. [38] Nielsen P. The WindPRO Manual Edition 2.5. EMD International A/S, 2006. [39] Wang L, Tan AC, Cholette M, Gu Y. Comparison of the effectiveness of analytical wake models for wind farm with constant and variable hub heights. Energy Convers Manage 2016;124:189–202. [40] Chen J, Wang F, Stelson KA. A mathematical approach to minimizing the cost of energy for large utility wind turbines. Appl Energy 2018;228:1413–22. [41] Gualtieri G. Improving investigation of wind turbine optimal site matching through the self-organizing maps. Energy Convers Manage 2017;143:295–311. [42] Pallabazzer R. Parametric analysis of wind siting efficiency. J Wind Eng Ind Aerodyn 2003;91(11):1329–52. [43] Chang TJ, Wu YT, Hsu HY, Chu CR, Liao CM. Assessment of wind characteristics and wind turbine characteristics in Taiwan. Renew Energy 2003;28:851–71. [44] Manwell JF, McGowan JG, Rogers AL. Wind energy explained: theory, design and application. 2nd ed. Chippenham, UK: John Wiley & Sons; 2010. [45] Ali M, Matevosyan J, Milanović JV. Probabilistic assessment of wind farm annual energy production. Electr Power Syst Res 2012;89:70–9. [46] Wind turbines models. https://en.wind-turbine-models.com; 2019 [accessed 03/ 11/19]. [47] Gualtieri G. A comprehensive review on wind resource extrapolation models applied in wind energy. Renew Sustain Energy Rev 2019;102:215–33. [48] Gualtieri G. Atmospheric stability varying wind shear coefficients to improve wind resource extrapolation: a temporal analysis. Renew Energy 2016;87:376–90. [49] Sun H, Yang H, Gao X. Investigation into spacing restriction and layout optimization of wind farm with multiple types of wind turbines. Energy 2019;168:637–50. [50] Grady SA, Hussaini MY, Abdullah MM. Placement of wind turbines using genetic algorithms. Renew Energy 2005;30:259–70. [51] Shamshirband S, Petković D, Ćojbašić Ž, Nikolić V, Anuar NB, Shuib NLM, et al. Adaptive neuro-fuzzy optimization of wind farm project net profit. Energy Convers Manage 2014;80:229–37. [52] International Renewable Energy Agency (IRENA). Renewable Power Generation Costs in 2017. IRENA, ISBN 978-92-9260-040-2. Abu Dhabi, Jan. 2018. Available at: https://www.irena.org/publications/2018/Jan/Renewable-power-generationcosts-in-2017 [accessed 03/11/19]. [53] Zhang J, Chowdhury S, Messac A, Castillo L. A response surface-based cost model for wind farm design. Energy Policy 2012;42:538–50. [54] Fingersh LJ, Hand MM, Laxson AS. Wind turbine design cost and scaling model. Golden, CO: NREL Report No. TP-500-40566, Dec. 2006. [55] Kohonen T. Self-organizing maps. 2nd ed. Heidelberg, Germany: Springer; 2001. [56] Emami A, Noghreh P. New approach on optimization in placement of wind turbines within wind farm by genetic algorithms. Renew Energy 2010;35(7):1559–64. [57] Turner SDO, Romero DA, Zhang PY, Amon CH, Chan TCY. A new mathematical programming approach to optimize wind farm layouts. Renew Energy 2014;63:674–80. [58] Chen Y, Li H, Jin K, Song Q. Wind farm layout optimization using genetic algorithm with different hub height wind turbines. Energy Convers Manage 2013;70:56–65. [59] Haces-Fernandez F, Li H, Ramirez D. Improving wind farm power output through deactivating selected wind turbines. Energy Convers Manage 2019;187:407–22. [60] Gualtieri G. Development and application of an integrated wind resource assessment tool for wind farm planning. Int J Renew Energy Res 2012;2(4):674–85. [61] WindPower. The wind turbines and wind farms database, http://www.thewindpower.net; 2019 [accessed 03/11/19]. [62] Bowman AW, Azzalini A. Applied smoothing techniques for data analysis: the kernel approach with S-plus illustrations. Oxford: Oxford University Press; 1997. [63] Bowman AW. ‘sm’ package: Smoothing Methods for Nonparametric Regression and Density Estimation. Version 2.2-5.6, 2018/09/27. Available at: https://cran.r-project.org/web/packages/sm/index.html [accessed 03/11/19]. [64] Luyssaert S, Janssens IA, Sulkava M, Papale D, Dolman AJ, Reichstein M, et al. Photosynthesis drives anomalies in net carbon-exchange of pine forests at different latitudes. Glob Change Biol 2007;13:2110–27. [65] Kaski S, Lagus K. Comparing self-organizing maps. In: Proceedings of the International Conference on Artificial Neural Networks (ICANN '96), Springer, Berlin, Germany, 1996:809–14. [66] Chowdhury S, Zhang J, Messac A, Castillo L. Unrestricted wind farm layout optimization (UWFLO): Investigating key factors influencing the maximum power generation. Renew Energy 2012;38(1):16–30. 13