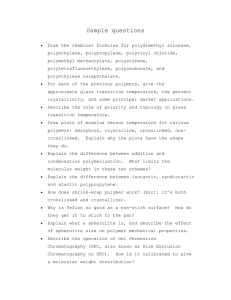

Polypropylene Degradation Control 1 Contents: Introduction: ............................................................................................................................................ 3 Structures of polypropylene: ...................................................................................................................... 4 Properties of Polypropylene:...................................................................................................................... 6 Polypropylene classified in relation to Polyethylene: .................................................................................... 9 Structures and Synthesis of polypropylene: ............................................................................................... 11 Polypropylene Manufacturing Process: ..................................................................................................... 15 Modifications: ........................................................................................................................................ 17 Effect of Degradation on Molecular Structure and Properties of PP: ............................................................. 20 In general - the relationship between Polymer Degradation and Properties: ................................................. 24 Stabilization of PP by Additives: ................................................................................................................ 25 Protective Effects of Stabilizer Additives: ................................................................................................... 28 Reduction of Polymer Degradation during Processing: ................................................................................ 32 Influence of multiple reprocessing cycles on the rheological and mechanical properties of PP: ........................ 35 Summary: .............................................................................................................................................. 38 Bibliography: .......................................................................................................................................... 39 2 Introduction: Polypropylene (PP) is the fourth main bulk plastic produced in the world after polyethene, poly (viny1 chloride), and polystyrene. After polymerization, polyolefins are subjected to one or more processing steps involving, molding, and extrusion. Combinations of high pressure and shear provide the elevated temperature necessary for each of these steps. Once, polyolefin are exposed to conditions that tend to degrade their polymer chains and change their properties. The heat and shear of the processing environment can initiate degradation and oxidation processes in the polymer well before the finished product has been packed for shipment. Degradation can be initiated by heat shear, oxygen, catalyst residues or any combination of them. The thermal oxidation of polyolefins includes initiation, propagation, and chain branching and termination steps. Compared with PE, unsterilized PP is especially susceptible to oxidative degradation because of the high reactivity of hydrogen atoms attached to tertiary carbon atoms. The degradation of PP, initiated either by UV irradiation or through thermal activation, causes change in crystallization and melting behaviors of PP. Degradation also leads to chain scission or cleavage, leading to a decrease in the durability of the product. Loss in molecular weight (molar mass) also occurs. There are several types of chain scission in PP. The most common is a unimolecular scission of carbon- and oxygen-centred radicals. The reduction in the molecular weight of the PP polymer leads to a change in many of its corresponding properties. One of the most detrimental is the loss of durability and ductility, thus a drastic decrease in toughness of the polymer. In addition, the chain scission will produce products that will tend to cause an increase in the color of the polymer and the generation of oxygenated compounds, which will adversely affect the durability, strength and physical properties of the final PP products. Unsterilized PP is very prone to oxidation and degradation in the presence of air. Further thermal and oxygen exposure in the application itself gradually leads to degradation unless adequate antioxidants (AOs) and heat stabilizers have been added. To maintain a resin’s original molecular weight and mechanical properties throughout its planned processing and designed lifetime, AOs and stabilizers are essential ingredients. The aim of this paper is to understand why are antioxidants and heat stabilizers needed for PP, and how do they work? 3 Structures of polypropylene: PP as a commercially used material and in its most widely used form is made with catalysts that produce crystallisable polymer chains. These give rise to a product that is a semi crystalline solid with good physical, mechanical and thermal properties. There are three polypropylene structures produced during polymerization: isotactic, syndiotactic, and atactic: Isotactic polypropylene exhibits four crystalline structures: Alpha Beta Gamma Mesomorphic Each of these structures forms under specific processing conditions and defines the properties of the polypropylene. In polypropylene containing the alpha, beta, and gamma structures, the final material is typically opaque due to the scattering of light by spherulites with sizes similar to the wavelength of visible light. 1. The most common polypropylene crystalline form is the alpha structure, in which the polypropylene chain exhibits either a left or right handed helical conformation. Crystallites grow to form sheet-like lamellae due to the preferential growth of the crystalline regions perpendicular to the principle axis of the helices. Secondary lamellae grow tangentially from pre-existing lamellae, resulting in a characteristic crosshatched microstructure. These tangential growth structures can interact with neighboring lamellae to create a farspreading supermolecular structure. Molecular helix of alpha crystalline form of isotactic polypropylene. Crosshatched microstructure of alpha crystalline isotactic polypropylene 2. Beta Crystallinity - The beta crystalline form of isotactic polypropylene differs from the alpha form by having a lower crystalline density and lower melting point. The beta form is metastable to the alpha form and will rearrange to the alpha structure when heated to approximately 100 °C or placed under strain. Beta lamellae form parallel stacks. 4 3. Gamma Crystallinity - Isotactic polypropylene’s gamma structure rarely forms under standard processing conditions. It is believed that this form arises when an alpha crystalline material is sheared in the growth direction as crystals form. Gamma crystallites form a crosshatched structure that is similar to that of the alpha form. It differs, though, in that the crystallites grow in two directions simultaneously. The resulting structure is more uniform than that seen in alpha crystalline isotactic polypropylene. The density of the gamma crystallites exceeds that of both the alpha and beta crystallites. 4. Smectic or Mesomorphic Crystallinity - structure in rapidly quenched isotactic polypropylene products. In these materials, the polymer chains do not have the necessary time to orient, preventing them from forming the large crystalline domains seen in the other three forms. This means that the crystalline regions are small and that there is poor alignment among the individual crystallites. The small crystallites are surrounded by amorphous regions. The behavior of smectic isotactic polypropylene falls between that of alpha crystalline polypropylene and the atactic form. The poorly organized crystallites do not effectively scatter light resulting in a transparent material. This form of isotactic polypropylene is metastable Syndiotactic polypropylene: is produced by the monomer units inserted alternately head-to-tail. This structure is more flexible with better impact resistance and clarity than the isotactic structure. Atactic Polypropylene –Atactic polypropylene’s irregular structure inhibits the regular packing required to create crystallites. The polymer exhibits poor strength, high tackiness and is, in general, not terribly useful as a thermoplastic resin in its pure state. It does, though, find a wide range of applications as a component of some adhesives and as filler in asphalt, for some of the same reasons that make it ineffective in polymer applications. Impact Modified Isotactic Polypropylene - Even though isotactic polypropylene has poor impact strength, its other properties and low costs attract engineers. For this reason, impact modifying agents have become a common ingredient in polypropylene products that require high impact strength, especially at low temperatures. Soft rubbers that are incompatible with the polymer matrix are effective impact modifiers. In the solid state, a two-phase structure forms. Small discrete rubber particles are surrounded by a continuous matrix of polypropylene. The rubber particles enhance the material’s impact strength by blunting the cracks that propagate during the impact event. The rubber also absorbs and helps dissipate the impact energy. 5 Properties of Polypropylene: The properties of polypropylene depend on the molecular weight and molecular weight distribution, crystallinity, type and proportion of comonomer (if used) and the isotacticity. Polypropylene is sold commercially as homopolymers, random copolymers, or impact resistance copolymers. Physical properties range from high strength, stiffness, to a flexible polymer with lower strength but greater toughness. Properties of iPP, sPP and aPP: polypropylene structures isotactic degree of crystallinity melting point density [g/cm3] 40 to 70% Has the highest melting point, greatest crstallinity, superior mechanical properties. 160 to 180 °C Syndiotactic Atactic ˜30% crystallites have a much more complex structure than the isotactic form polypropylene Comparisons of stereoisomer 0.855,amorphous approximately 138 °C 0.946, crystalline crystallizes very slowly Atactic polypropylene has no commercial application because it's pretty much a gooey, messy blob. Have better impact strength than isotactic. Soft and rubbery, amorphous and relatively weak. Low density and low tensile strength but high degree of flexibility. Some of the most significant properties of polypropylene are: 1. Isotactic homopolymer polypropylene - has a high degree of crystallinity thereby creating a material that is strong, with low permeability to vapor or solvents, and high chemical resistance. With the exception of the mesomorphic crystalline form – is typically opaque, due to the high concentrations of crystalline regions. 2. Syndiotactic polypropylene, which has lower crystallinity, is transparent and not as strong 3. Atactic form, due to its lack of crystallinity, has poor physical strength with lower resistance to dissolution in solvents and greater permeability to low molecular weight gases such as oxygen and water vapor. Polypropylene’s melting temperature is high, useful material for many high-temperature applications. It also has a high glass transition temperature. The result of this is that polypropylene is prone to brittle failure on impact, which is especially noticeable at low temperatures. To address the engineering issues created by the high propensity for brittle failure, polypropylene is often compounded with an impact modifying agent. 6 Polypropylene is produced as homopolymers and copolymers. The physical properties range from good tensile strength and stiffness to a tough, flexible, and low strength polymer: 1. Polypropylene copolymers incorporate small amounts of ethylene which lower the crystallinity rate, producing higher impact strength even at low temperatures, and more flexibility, but a lower melting point and low melt mass-flow rate properties. Polypropylene Random Copolymer is produced by polymerizing together ethene and propene. It features Ethene units, usually up to 6% by mass, incorporated randomly in the polypropylene chains. These polymers are flexible and optically clear making them suitable of applications requiring transparency and for products requiring an excellent appearance Polypropylene Block Copolymer, ethene content is larger (between 5 and 15%). It has comonomer units arranged in regular pattern (or blocks). The regular pattern hence makes thermoplastic tougher and less brittle than the random co-polymer. These polymers are suitable for applications requiring high strength, such as industrial usages. 2. Polypropylene homopolymer has the highest melting point with a wide range of melt flow rates and stiffness. PP Homopolymer vs. Copolymer: PP Homopolymer a) High strength to weight ratio and stiffer & stronger than copolymer b) Good chemical resistance and weldability c) Good process ability d) Good impact resistance e) Good stiffness f) Food contact acceptable g) Suitable for corrosion resistant structures h) Melting Point - 160 - 165°C i) Density - 0.904 – 0.908 g/cm3 PP Copolymer a) Bit softer but has better impact strength; tougher and more durable than homopolymer b) Better stress crack resistance and low temperature toughness c) High process ability d) High impact resistance e) High toughness f) Not preferable for food contact applications g) Melting Point - 135 - 159°C h) Density (Random Copolymer)- 0.904 – 0.908 g/cm3 In addition, other types of Polypropylene: Material PP impact copolymer PP terpolymer PP high melt strength (HMS PP) Expanded polypropylene (EPP) Description and benefits It is a PP homopolymer with a co-mixed PP random copolymer phase, containing between 45 – 65% ethylene. With its high impact resistance, it is suitable for packaging, pipe and automotive applications. It is a combination of propylene segments and randomly positioned monomers of ethylene and butane. It has high optical transparency and low crystalline uniformity and is a suitable material for sealing film applications. A long chain branched PP that has both high melt strength and stretchability. This polymer has a wide range of mechanical properties and high thermal and chemical properties, making it suitable to be used as low-density foams for various applications. It is a greatly versatile closed-cell bead foam with low density. It exhibits distinctive properties, such as high impact resistance, energy absorption, thermal insulation, and high strength-to-weight ratio. It is also used in many industries, such as automobiles, construction, and packaging. 7 Advantages and Disadvantages of Polypropylene: Advantages Low Cost Excellent flexural strength Good impact strength Processable by all thermoplastic equipment Low coefficient of friction Excellent electrical insulation Good fatigue resistance Excellent moisture resistance Service Temperature to 126 C Very good chemical resistance Disadvantages High thermal expansion UV degradation Poor weathering resistance Subject to attack by chlorinated solvents and aromatics Difficulty to bond or paint Oxidizes readily flammable Typical Applications: a) Flexible packaging films b) Biaxially oriented packaging films c) Stretched and oriented monofilament, tapes for textiles, carpeting, insulated medical fabrics and woven carpet backing d) Automotive interiors, bumpers, spoilers, air vent systems, under the hood components, internal wheel guards, and bellows e) Hygiene products, household goods and medical application trays, strainers, and containers f) Consumer products, such as closures, over caps, trigger sprayers, rigid and semi-rigid packaging, video cassette cases, toys, and electrical hardware g) Appliance housings and components, outdoor furniture, and luggage h) Injection blow molded stretch bottles with excellent stiffness, impact resistance, and clarity Automobile injection molded dash panel Hot water dispenser bottles Electric rice cooker 8 Compact disk jewel boxes Variety of injection molded products Polypropylene classified in relation to Polyethylene: Polyolefin LDPE (Lowdensity Polyethylene) HDPE (Highdensity )Polyethylene LLDPE (linear low-density )polyethylene PP Homopolymer Molecular structure Preparation method Radical, with autoclave or tubular reactor Produced by polymerization of ethylene using Ziegler-Natta or supported chromium ("Phillips") catalysts. Small amounts (4%of) a-olefin comonomers are used in many of the commodity grades to introduce low concentrations of short chain branching, primarily to enhance processability but also to improve toughness and environmental stress crack resistance produced by copolymerization of ethylene with a-olefins using: Ziegler-Natta supported chromium catalysts (Phillips catalysts) single site catalysts Mechanical properties Non-Newtonian melt rheology, good impact strength High tensile strength, low impact strength None - Small amount of aolefin incorporated to improve polymer properties Intermediate strength with elasticity, melt rheology more Newtonian than LDPE Butene-1 hexene-1 octene-1 4-methyl- 1 - pentene No branches - High tensile strength, brittle, temperature ,resistance Transparent high-strength and temperature-resistant glossy films Ziegler-Natta catalysis Polypropylene copolymer with ethylene, block or random Ziegler-Natta catalysis Polypropylene and copolymers with ethylene Single-site or metallocene-catalysed Tough with high melting Temperature (block) or softer with lower melting temperature(random) Tough films, with more milky colour Narrow molar mass distribution, random comonomer distribution and high isotacticity Flexible, elastic transparent films 9 Comonomer Is often blended with linear low density polyethylene and high density polyethylene to improve processability. No branches Ethylene Ethylene Comparison of mechanical and physical properties between PP and PE: Polyolefin LDPE HDPE LLDPE Polypropylene homopolymer, PP-H Polypropylene random polymer, PP-R Polypropylene block copolymer, PP-B Polypropylene glass-fiber reinforced polymer, PPGF30 Polypropylene, PP + Ethylene-propylene-(diene) copolymer, EPDM thermal coefficient of expansion in longitudinal at 23 - 55 °C 23 - 25 14 - 18 18–20 density (g/cm3 ) Tm [C°] yield strain )%( Tensile modulus (MPa) HDT at 1.8 MPa (°C) 0.915 - 0.930 0.940 - 0.970 0.915 - 0.940 105–115 130–138 120–130 ca. 20 8 - 12 20–30 200 - 400 600 - 1400 300–700 38 - 50 ca. 40 12 - 15 0.90 - 0.915 162 - 168 8 - 18 1300 - 1800 55 - 65 12 - 15 0.895 - 0.90 135 - 155 10 - 18 600 - 1200 45 - 55 12 - 15 0.895 - 0.905 160 - 168 10 - 20 800 - 1300 45 - 55 6 1.21 - 1.14 162 - 168 - 5200 - 6000 90 - 115 15 - 18 0.89 - 0.92 160 - 168 10 - 35 500 - 1200 40 - 55 Though Polyethylene and Polypropylene are similar in physical properties but here are key points to consider selecting the polymer suitable to needs: a) b) c) d) e) f) g) Polypropylene (PP) It can be produced optically clear It is lighter in weight PP exhibits a high resistance to cracking, acids, organic solvents and electrolytes It has high melting point and good dielectric properties PP is non-toxic It is stiffer and resistant to chemicals and organic solvents compared to polyethylene PP is more rigid than polyethylene a) b) c) d) e) 10 Polyethylene (PE) Polyethylene can only be made translucent like a milk jug Its physical properties allow it to stand up better in cold temperatures, particularly when using it as signs It is a good electrical insulator PE offers good tracking resistance Polyethylene is sturdy as compared to Polypropylene Structures and Synthesis of polypropylene: The propylene molecule is the monomer unit of polypropylene. There are a number of different ways to link the monomer together, depending on the stereo arrangement. Three major factors control the stereo regularity of PP: The first factor is the degree of branching. The molecular chain of PP will be straight (or linear) if the next monomer unit always attaches to the chain end. If the next monomer may add on to the backbone, this results in the formation of branches, as seen in. The pendant methyl sequence can also change the stereo regularity of PP. The addition of propylene to the growing PP chain can be regiospecific or non-regiospecific. The addition of monomer can be in a head-to-tail manner or in other ways such as head-to-head or tail-to-tail. Still another way to control the stereo regularity is the position of the tertiary hydrogen. There exist two possibilities for the arrangement of the tertiary hydrogen. If the propylene monomer is always added in the same stereo arrangement, the alignment of the tertiary hydrogen will be in a same hand way, either righthanded or left-handed. Any change in the stereo arrangement of the adding monomer can result in an opposite hand distribution of the tertiary hydrogen. Synthesis of polypropylene: Monomers are produced by the cracking of petroleum products such as natural gas or light oils. For the preparation of polypropylene the C3 fraction (propylene and propane) is the basic intermediate and this may be separated from the other gases without undue difficulty by fractional distillation. Polymerization of polypropylene is a coordination polymerization of monomer propylene. The monomer propylene undergoes polymerization in the presence of catalyst such as Ziegler-Natta catalyst (or) metallocene catalyst. homopolymers produced by Ziegler-Natta catalysis block copolymers produced by Ziegler-Natta catalysis random copolymers produced by Ziegler-Natta catalysis rubber-modified blends of the above homopolymers and copolymers produced by metallocene catalysis 11 Ziegler-Natta is chain-growth polymerization is an alternative method that does not involve radicals. Ziegler-Natta and metallocene catalysts are used commercially, the choice between the two depends largely on the desired molecular weight distribution: 1. Ziegler-Natta catalysts are predominantly isotactic, with a comparatively broad molecular weight distribution (Mw/Mn ≈ 3.5) 2. Metallocene catalysts have only one active polymerization site, which results in a narrower molecular weight distribution (Mw/Mn ≈ 2.0). Some characteristics of Metallocene catalysts and Ziegler-Natta catalysts polypropylene: Characteristic Melt flow (g/10 min) molecular weight (g/mole) Tm [C°] Polydispersity mi-PP 75 148000 150 ̴2 ZN-PP 15.4 430000 165 ̴9.2 The conditions of polymerization such as pressure, temperature, and concentrations of the reactants are given by the grade of the polymer which is to be produced. Using Ziegler Natta catalyst, there are two major processes for synthesizing of polypropylene. The properties of polypropylene are affected by tacticity of polypropylene, the orientation of the methyl group. Based on the type of catalyst that is used for the polymerization, the tacticity of the propylene could be selected. The tacticity of a polymer affects the packing between molecules (crystallinity) and thus affects its physical properties such as the melting temperature, mechanical strength and elasticity. Structure regularity: Isotactic > Syndiotactic > Atactic 12 Zeigler Natta catalyst could form isotactic polypropylene (or) syndiotactic polypropylene. One type of metallocene catalyst could form isotactic polypropylene and another type of metallocene catalyst forms syndiotactic polypropylene. An amorphous rubbery material is atactic polypropylene. It is synthesized with the help of special kind of Zeigler-Natta catalyst (or) with certain type of metallocene catalyst. Two types of coordination polymerization are: 1. Heterogeneous Ziegler-Natta polymerization: Coordination polymerization is carried out in the presence of heterogeneous Ziegler Natta catalysts that are based on oregano aluminum co-catalyst and titanium tetrachloride. 2. Homogeneous Ziegler-Natta polymerization: Certain homogeneous Ziegler-Natta polymerization such as Kaminsky catalyst is used as catalyst in coordination polymerization. Nonpolar ethene and nonpolar propene are the monomers that are used along with homogeneous Ziegler-Natta polymerization. Heterogeneous Ziegler-Natta polymerization: The monomer propylene would be polymerized at high temperatures and high pressures. The polymerization could be effective only in the presence of inert solvent carried moderate pressure in presence of stereospecific catalyst like TiCl4. In the Zeigler Natta polymerization of polypropylene, TiCl4 is the catalyst and Al(Et)3 is the cocatalyst. The polymer formed by the method of Ziegler Natta polymerization could have high molecular weights. The polymerization reaction could be given as Homogeneous Zeigler Natta polymerization of propylene: Atactic polypropylene are formed when metallocene are reacted with methylaluminoxane. Here, the metals could be titanium, zirconium, and hafnium. Methylaluminoxane in short is known as MAO. The reaction of metallocene with methylaluminoxane to give atactic polypropylene is written as, 13 Example for Isotactic Polymerization by Ziegler-Natta catalyst: Ziegler-Natta catalyst is a mixture of Titanium Tetrachloride and Triethyl Aluminium. The mechanism begins with the formation of a complex between Titanium and Aluminium. Isotactic Polymerization: 1. Formed bond between the CH2 group of propylene and the Titanium and giving second carbon of the propylene a positive charge. 2. Migration - The alkyl group of the aluminium transfers to the carbocation. This transfer happens so rapidly that the carbocation formed in the previous step doesn't have time to rearrange. Thus, the titanium stereo specifically inserts the propylene group between itself and the ethyl group. 3. The titanium complex continues to stereo specifically insert additional propylene monomers between itself and last ethyl group added to the chain. 4. To end the reaction, chemists destroy the complex by treating it with methanol. 14 Polypropylene Manufacturing Process: The PP manufacturing process can be divided into three generations: 1. the first generation (deashing and AP removal) 2. second-generation (non-deashing or non-solvent) and 3. third-generation (non-deashing and non-AP removal) AP (atactic Polymers): non crystalline polymers where the methyl groups of propylene units are arranged irregularly on the chain The operation for eliminating the catalyst is known as deashing. Solvent polymerization process Solvent polymerization process (Nondeashing) Bulk polymerization process (Non-solvent) Vaper phase polymerization process (Nondeashing, Non-AP) Chronology of development in Ziegler-Natta catalysis: Generation first generation second-generation third-generation Fourth generation Catalyst TiCl4/AlEt2Cl TiCl4/ether/AlEt2Cl/ester TiCl4 Al-oxame activated metallocene complexes Support Activated MgCl2 Silica gel 15 Process steps Remove catalyst residues Remove catalyst residues No purification No purification No palletizing extrusion In addition, classification can be done according to the polymerization method into: 1. Slurry Process Polymerization of Polypropylene - In the slurry process, propylene monomer is dissolved in a hydrocarbon diluent in which the polymerization process occurs. The polymerization products are either soluble (the highly atactic components) or insoluble. Both the insoluble and soluble components are collected and form separate product streams. Insoluble species form slurry in the solvent, from which they are removed by centrifugation. Soluble, atactic component is removed with the solvent as another product stream. To separate the atactic polymer from the solvent, the solution is heated allowing the solvent to flash off, leaving the atactic polymer behind. Any unreacted monomer is degassed from the solution and recycled to the start of the polymerization process. 2. Liquid Propylene Polymerization of Polypropylene - employs the liquid monomer as the polymerization solvent. This process, known as the liquid propylene or bulk-phase process has a major advantage over the slurry method in that the concentration of the monomer is extremely high. The high concentration increases the rate of the reaction relative to that seen in the slurry process. In addition, the heat of polymerization can be removed from the process by the vaporization of the monomer. The gaseous monomer is then recycled to the reactor, after liquefaction, as condensed monomer. Just as in the slurry process, the polypropylene forms an insoluble phase in the propylene diluent. The insoluble phase is isolated from the liquid propylene. Unlike the slurry process, the insoluble phase contains both the atactic and isotactic fractions. Separation of these two components requires an additional step in which the soluble portion is dissolved into an organic solvent. 3. Solution Polymerization of Polypropylene - During solution polymerization the monomer, catalyst, and diluent are introduced to a reactor maintained at a temperature between 175 and 250 °C. The resulting polymer forms a viscous solution in the solvent, which is pumped out of the reactor. If necessary, the solution can be filtered to remove the catalyst residue. Solvent is removed from the solution and recycled, leaving behind a mixture of isotactic and a small amount of atactic polypropylene. 4. Gas Phase Polymerization of Polypropylene - In gas phase reactors, the monomer is introduced to the bottom of reactor where it percolates up through a fluidized bed of polymer granules and inert-media supported catalyst. A fraction of the monomer reacts to form more polymer granules, the remaining monomer being drawn from the top of the reactor, cooled, and recycled. Polymer granules are continuously withdrawn from the bottom of the fluidized bed and the catalyst is replenished. 16 Modifications: The property ranges of all reactor-made homo- and copolymers so far described can further be modified by nonreactive or reactive compounding. Three types of modification are most relevant in practice: 1. Increasing stiffness and heat resistance by addition of mineral fillers or reinforcing fibers 2. Improving toughness and flexibility by addition of external elastomers or PE plastomers 3. Modifying the process ability by radical-based reactive modification Fillers: Using inorganic fillers in PP helps both in expanding the property profile of the materials, but also in reducing the formulation cost. The most used inorganic fillers for PP are calcium carbonate (CaCO3), talc, and kaolin, while wollastonite is used if a high dimensional stability of the compound is required. The end-use properties of a compound are determined not only by the chemical type or composition of the filler, but also by the particle shape and surface area which especially define the reinforcement quality. The highest modulus and heat deflection temperature (HDT) are reached for anisotropic particles of fine particle size equally distributed in the polymer. This property together with its capacity for crystal nucleation makes talc the most commonly used inorganic filler for PP impact copolymers. The compounds exhibit a balanced property profile including increased modulus, higher HDT, and better dimensional stability . PP-talc compounds may contain up to 50 wt% of the mineral, but its absorption can cause surface appearance problems. Additionally, the impact strength decreases with increasing filler content due to the anisotropic nature of the filler. PP homo- and copolymers reinforced with glass fibers (GF) or carbon fibers (CF) are industrially used in the automotive and other technically challenging areas to replace polycarbonate, polyamide, or acrylonitrileebutadieneestyrene (ABS) terpolymers. Coupling agents to increase the adhesion between fiber and polymer are needed, but also fiber coating (sizing) to avoid fiber breakage and further promote the adhesion. Positioning: 17 Elastomers: Blending PP with various impact modifiers such as EPR, EPDM, or polystyreneblock-poly(ethylene-co-but-1-ene)block-polystyrene (SEBS) was the earliest route for producing impact-modified PP. In blends of heterophasic PP with polymeric modifiers the end-use properties such as mechanical performance and optical properties strongly depend on the phase structure formed; this depends on structural factors (as for reactor-based systems), but also on the compounding and even the processing step. Commonly used factors to describe these parameters are the viscosity ratio l between dispersed phase and matrix, the phase compatibility, and the deformation history in processing; most of these are relevant for both reactor-based and compounded systems. For example PP+EPDM Elastomer Blends: These structures do not necessarily have to be connected to each other in a chain, but can be achieved by blending PP with EPDM. These products exhibit high stiffness and softening temperatures, are easily modified by copolymerization of PP, and are compatible with EPDM. The properties of PP + EPDM elastomers depend on their blend ratio: 1. 90% PP results in the properties of conventional PP with slightly lower stiffness and softening temperature, but also with increased impact resistance at −40 °C. 2. Blends with 40% PP exhibit the typical properties of thermoplastic rubbers. Other determining factors are crystallinity, molecular weight, and molecular weight distribution of the PP. In addition, it is important whether a homo- or a copolymer, random or sequential PP is used. It is also possible to create blends with PE. Reactive Processing: Finally, structural modification is also possible by reactive post reactor processes. The earliest version is targeted at modifying the MMD, where controlled radical degradation allows a tailored production of narrow MMDs. This process known as visbreaking or controlled rheology process can be applied best in case of PP homopolymers or random copolymers, leading to higher MFR and a broader Newtonian region of the viscosity curve. Mostly liquid peroxides are used which are sprayed under nitrogen onto the warm reactor powder before it is fed to the pelletization extruder. In large-scale plants, visbreaking also allows the production of a multiplicity of grades from one reactor setting. Transparency and surface gloss are improved and these grades have significant advantages in fiber spinning or cast film processes. Further reactive modification steps for PP are also mostly based on radical-initiated grafting reactions, applications ranging from the production of long-chain branched PP with high melt strength (strain hardening) (offering advantages, e.g., in foaming, via stabilization) or partial cross-linking of phase structures (to the production of thermoplastic vulcanizates) to polar modifiers (e.g., by grafting with maleic anhydride). Blends of PP-I and, e. g., methyl methacrylate or styrene are produced by reactive blending. They have the following advantages: low density (0.91–0.96 g/cm3), weather resistance, scratch resistance, little processing shrinkage (little warpage) and moisture absorption. 18 Compounds with 3–6% hydrocarbon resins, for example, hydrogenated dicyclopentadiene (DCPD), increase the glass transition temperature of PP films by up to 25 K and thus the modulus of elasticity by up to 50%, while reducing water vapor permeability by up to 30%. Properties for number modified PP Grades: Property Density Tensile modulus of elasticity Yield stress Elongation at yield Elongation at break Melting temperature Heat deflection temperature HDT/A 1.8 MPa Unit PP + EPDM PP-T 20 Talcum PP-T40 Talcum PP-GF30 Glass fiber g/cm3 0.89–0.92 1.21–1.24 1.12–1.14 MPa 500–1200 3500–4500 5200–6000 5500–6000 1850 MPa % 10–25 10–35 1.04–1.06 2200– 2800 32–38 5–7 PP-GFC30 Glass fiber, chem. coupled 1.12–1.14 30–35 3 - - 26 - % - 15–20 3–15 3–5 3–5 - °C 160–168 162–168 162–168 162–168 162–168 - °C 40–55 60–80 70–90 90–115 120–140 53 19 PP-B25 Barium 1.13 Effect of Degradation on Molecular Structure and Properties of PP: The terms “durability” and “degradation”, as well as “long-term properties” and “end-of-life” of polymers, are related to one another. Degradation refers to a process which results in the deterioration of any physical property of a polymer. In general, the said process starts at the amorphous/crystalline interface, and affects the mechanical properties, thermal stability, distribution of lamellar thickness, as well as crystallinity. Each aforementioned component is subject to environmental effects individually or in combination. Accordingly, various factors in a typical habitat – sun-based radiation, temperature, moisture, oxidative conditions, and mechanical toxins – can act intelligently via a debasement procedure. Therefore, the general impact of degradation can be greatly complex. With reference to the basis above, polymer degradation is categorized into: 1. 2. 3. 4. 5. 6. 7. Thermal debasement (heat) Thermo-oxidative debasement (heat and oxygen) Thermomechanical debasement (heat and stress) Photo degradation (light) Photo-oxidative corruption (light and oxygen) Biodegradation (natural operators) Mechanical debasement (mechanical stress) Virgin PP (due to the presence of a tertiary hydrogen) obtained directly from a commercial process is very susceptible to UV irradiation and air oxidation. If stored un-stabilized at room temperature, the durability, strength and physical properties of the PP product deteriorate rapidly over a period of weeks or months depending on the physical form, temperature, available oxygen, intensity of UV radiation and other conditions. At elevated temperatures, such as during summer storage, the degradation process can be accelerated. When organic materials such as polyolefins are exposed to conditions such as heat, ultraviolet light, or mechanical stress in the presence of atmospheric oxygen, free radicals are formed which initiate the oxidation process. Degradation of Thermoplastics: 20 This process is characterized degradation of PP can be divided into three steps: 1. Initiation 2. Propagation 3. Termination Importance of AOs and Stabilizers for Polyolefins - Polymers are heat-, shear-, and oxygen-sensitive materials, and exposure to the heat and shear of processing alone can cause chain scission—the breaking and shortening of molecular chains. Upon exposure to oxygen, auto-oxidation, or autoxidation, is initiated by the creation of free radicals (reactive molecular species with unpaired electrons). Autoxidation is a circular, self-propagating process that, unless interfered with by AOs, gradually leads to increasing degradation of the polymer. Polyolefins are susceptible to degradation by free radicals via breaking or cleavage of their polymeric chains (i.e., chain scission) or by cross-linking between chains. These reactions lead to changes in molecular weight, molecular weight distribution, mechanical properties, and appearance. Because of molecular structure differences, the tendency toward chain scission and reduced molecular weight is more pronounced in polypropylene (PP) than in polyethylene (PE), while cross-linking tends to predominate especially in unbranched types of PE. Degradation cycle by Thermo-oxidative: 1. Heat, shear, and catalyst residues tend to strip hydrogen from the polymer chain (RH) to form alkyl free radicals (R•) 2. Oxygen combines with the free-radical species to create new reactive species, including peroxy radicals and hydroperoxides (O2 + R• ROO• + RH ROOH + R•) and other fragment species (H2O, H2, H2O2) 3. The hydroperoxides (ROOH) in turn are themselves reactive, creating new free-radical species, such as hydroxy and alkoxy radicals (ROOH •OH + RO•). UV Degradation of Polyolefins – Because of the chemical structure of polypropylene, it has a high degradation rate when exposed to UV light like the Sun. The light causes the bonds holding the polymer together to break which weakens the plastic. This makes polypropylene unsuitable for uses that require longterm exposure to sunlight. The initiation of polymer degradation via UV light depends mainly on the presence of UV-absorbing species (chromophores) mixed in with the polymer. Since saturated polyolefin molecules do not themselves absorb much UV light directly, the most damaging UV effects are from absorption by chromophores such as catalyst residues, pigments, processing aids, flame retardants, or generally any organic molecules containing double bonds. These molecules release some of the UV energy they absorb by breaking bonds and releasing free radicals, which begin a degradation cycle similar to the autoxidation processes. Degradation cycle by Photo-oxidative: 1. UV energy is absorbed by chromophores, creating broken bonds and free radicals (R•) in the polymer. 2. Oxygen combines with free-radical species to create new species, including peroxy radicals and hydroperoxides, which are reactive with the polyolefin chain (RH) itself (O2 + R• ROO• + RH-ROOH + R•), as well as other fragment species (H2O, H2, H2O2). 3. The hydroperoxides (ROOH) in turn are themselves reactive and create new free-radical species such as hydroxy and alkoxy radicals (ROOH•OH + RO•). 21 Photo-oxidation mainly takes place at the surface of an unprotected resin, but it can occur deep within the solid material if the UV energy is not blocked by elements within the resin. Either way, the resin changes induced by this degradation can range from minor to catastrophic; for example, it has been proposed that chain scission leads to increased crystallization in the polymer and creates internal and surface voids, resulting in cracks, embrittlement, and loss of gloss. Different polyolefin structural forms react differently to UV. Overall, degradation takes place more easily within the amorphous phase of a polymer than in the crystalline phase. Moreover, PE and PP photo-oxidation behaviors are different enough that the same additives approach for protecting PE may not work the same in PP, even in the same applications. And even different forms of PP—homopolymer and copolymer—can differ in their sensitivity to UV when using the same stabilizer. Example of Oxidation: Polymer oxidation occurs through a free radical chain reaction. Mechanical stress, heat, or the presence of oxygen or metal catalyst residues results in homolytic cleavage of the carbon-hydrogen or carbon-carbon covalent bond in the polypropylene chain; each atom receives one electron from the two-electron covalent bond, producing two free radicals, each with an unpaired electron. An example of a chain initiation reaction in the presence of oxygen is given below: The chain reaction is propagated through the formation of a hydroperoxide, accompanied by the formation of another free radical The oxidation rate is determined by the rate of the slow step in the chain propagation reactions. Due to the presence of the pendant methyl group, polypropylene contains tertiary (3°) hydrogen atoms, in which the carbon atom covalently bonded to the hydrogen is also bonded to three other carbon atoms. The free radical (PP·) formed from abstraction of a tertiary hydrogen is more stable than those formed from abstraction of a primary (1 ° carbon atom attached to one other carbon) or secondary (2° carbon atom attached to two other carbons) hydrogen, due to the tendency of carbon atoms along the chain to electronically donate electrons to the electron-deficient radical. 22 The higher probability of reaction with the tertiary hydrogen considerably increases the susceptibility of polypropylene to oxidation. In further reactions (chain branching reactions that increase the amount of free radicals), the hydroperoxide decomposes in the presence of heat or metal catalyst residues to form an alkoxy radical. Oxidative chain scission is believed to occur through disintegration of this alkoxy radical: The decrease in molecular weight resulting from chain scission produces a gradual loss in mechanical properties. One of the most detrimental is the loss of durability and ductility, thus a drastic decrease in toughness of the polymer. In addition, the chain scission will produce compounds such as carboxylic acids, lactones, aldehydes, and esters are also produced during oxidation reactions, resulting in chemical modifications such as yellowing. Products that will tend to cause an increase in the colour of the polymer and the generation of oxygenated compounds, which will adversely affect the durability, strength and physical properties of the final PP products. Chain reactions are terminated when two radicals combine to form an inactive species. In the solid form, PP is a semi crystalline polymer with a crystalline content that is normally between 40% and 60%. The crystalline regions are essentially impervious to oxygen, so the oxidation only occurs in the amorphous region. It has been reported by that the diffusion rate of oxygen is much slower than the reaction rate, so that the oxidation process is basically a surface phenomenon. In most cases, the surface can become dull, crazed, or even powdery. Obviously, unstabilised PP is very prone to oxidation and degradation in the presence of air. Therefore, adding appropriate stabilizer's is necessary to convert PP into a durable, useful material. 23 In general - the relationship between Polymer Degradation and Properties: Changes of the molecular structure of polymers Degradation reactions can cause molecular weight reduction, a change of molar mass distribution or the formation of chain branches or crosslinks. These molecular parameters can influence rheological properties of the polymer melt (like viscosity) and the mechanical or optical properties of the processed granules or finished parts. Changes of mechanical properties Possible influence on some key polymer properties. The molecular composition and homogeneity of the mixture after compounding of polymers with fillers or after mixing of different polymers can have an influence on mechanical properties, like tensile strength or bending strength, as well as on brittleness or impact strength. Change of flow behavior (rheological properties) In addition to mechanical properties, molecular weight degradation may also change rheological properties of polymer melts. This changed flow behavior might result in changed processing behavior within the extruder. In addition to changes of the mean molecular weight, the width of the molecular weight distribution can be narrowed through degradation or widened through crosslinking reactions. Other parameters related to molecular weight distribution are the zero shear viscosity, solution viscosity or melt flow index (MFI) and melt volume index (MVI), respectively. Already small changes of mean molecular weight via degradation can lead to a significant change of viscosity: with decrease of mean molecular weight by a factor of 2, the zero shear viscosity is diminished by a factor of 10. Rheological methods are therefore a very sensitive indicator for changes of the molecular structure of polymers. Molecular weight degradation can influence mechanical properties significantly: below a critical molecular weight the tensile strength and impact resistance are drastically reduced. An example of the critical molecular weight is for polypropylene around 170,000 g/mol. 24 Optical properties Other properties Optical properties comprise color changes (e. g. yellowing, discoloration) that might be caused by oxygen-containing functional or chromophoric groups (conjugated double bonds). Color changes can be determined and quantified via optical or spectroscopic methods. Crosslinks might lead to gels or spots (punctiform impurities) that can influence optical properties in addition. Depolymerization leads to detachment of monomers, which can lead to odor formation, and related molecular weight changes can lead to mechanical property changes. Side group elimination can lead to emissions of undesired or toxic substances, e. g. emission of hydrochloric acid from polyvinyl chloride (PVC). Aside from mechanical properties, polymer degradation may also cause changes of dielectric properties or electrical conductivity Stabilization of PP by Additives: Plastics additives can be classified into three main groups: 1. Additives that stabilize plastics against degradation and aging during processing or in use: Degradation usually involves chain cleavage of the macromolecules and can proceed through the addition of energy (e.g., shear forces, heat, UV light) or chemical attack (e.g., oxidation, hydrolysis). These additives are called antioxidants, light stabilizers, or heat stabilizers. 2. Additives that facilitate or control processing (e.g., lubricants, mold-release agents, or blowing agents) 3. Additives that impart new, desirable qualities to plastics, such as resistance to burning, transparency or color, improved mechanical or electrical properties, dimensional stability, and degradability. Such additives include flame retardants, fillers, dyes, pigments, antistatic agents, nucleating agents, optical brighteners, impact modifiers, and plasticizers. A variety of additives are used to overcome some of the limitations in plastic materials. Some of the common additives used in compounding and their functions are given below: 1. Antioxidants: Prevent oxidative degradation of the polymers. 2. Heat stabilizers: Prevent the polymers from heat-induced breakdown, and degradation, when the plastic product is exposed to high temperatures. 3. UV stabilizers: Prevent polymer deterioration when the plastic product is exposed to UV light. 4. Internal lubricants: Improve the processing ability of the polymer by lowering melt viscosity. 5. Plasticizers: Enhance the polymer flexibility, resiliency, and melt flow. 6. Antifogging agents: Prevent fogging that obscures viewing through clear plastic films or sheets. Protective additives are characterized by their: Chemistry (e.g. hindered phenols, phosphites) and/or Function (e.g. radical scavengers, peroxide decomposers, UV absorbers). Different families of additives are reactive with different intermediates in the oxidation process (e.g. free radicals vs. hydroperoxides), present different levels of reactivity (e.g. at different temperatures), and have different degrees of stability during exposure to environmental conditions such as high temperatures or UV light. As a result of their inherent reactivity and stability, some additives function primarily as melt processing stabilizers at high temperatures, some as thermal stabilizers but at lower temperatures (i.e. in the solid state), and still others as light stabilizers. Some common families of stabilizer additives used in polypropylene: a) b) c) d) e) f) g) Hindered phenols Phosphites and phosphonites Thioethers Hydroxylamines Hindered amine light stabilizers (HALS) Benzoates, and Ultraviolet (UV) absorbers 25 Additives that stabilize plastics against from degradation how they work? Organic stabilizers can react with molecular oxygen in a process called autoxidation, initiated by heat, light (high-energy radiation), mechanical stress, catalyst residues, or reaction with impurities, to form alkyl radicals. The free radicals can, in turn, react to cause the polymer to degrade, causing embrittlement, melt flow instability, loss of tensile properties, and discolouration. Oxidation can be slowed by chain-breaking antioxidants, to reduce rate of propagation, or preventative anti-oxidants, which prevent initial formation of free radicals. Antioxidants deactivate the sites by decomposing the hydroperoxide or by terminating the free radical reaction. There are many different stabilizer systems for plastics, depending on the type and products of oxidation. Traditional stabilizer systems for polyolefins are based on a combination of a phenolic anti-oxidant and a phosphorus-based melt processing stabilizer, the phenolic providing melt processing stability as a donor of hydrogen atoms and a scavenger of free radicals, and a level of thermal stability. The phosphorus-based additive functions as a hydroperoxide decomposer during the melt compounding stage. Three forms of stabilization are used: prestabilization, stabilization during processing, and long-term stabilization. Numbers of requirements apply to antioxidants: 1. 2. 3. 4. 5. 6. 7. They must be thermally stable and nonvolatile at processing temperatures They must be soluble in polymers and no chalking should occur at service temperatures They must not have an intrinsic color, and their oxidation products must have minimal color Any acidic hydrolysis products must not corrode machinery They must resist extraction They must be odorless and tasteless They must not create toxicity problems (many must be approved as indirect food additives) Chemical Classes of antioxidants: Antioxidants are divided into two classes on the basis of their mode of action: 1. Primary antioxidants : sterically hindered phenols, secondary aromatic amines, and sterically hindered amines (HALS) 2. Secondary antioxidants: phosphites, phosphonites, thioethers (sulfides), and metal salts Primary antioxidants can be used by themselves for prestabilization and long-term stabilization. Secondary antioxidants are used in combination with primary antioxidants, especially for stabilization during processing and for long-term stabilization under severe thermal conditions. Synergistic effects often occur in such systems (e.g., phenol and phosph (on)ites or phenol and thioethers). Antagonistic effects are also observed, however (e.g., between thioethers and HALS). The stabilizer system often includes other components that complex or neutralize degradation-promoting catalysts or acid traces. 26 Mechanism of Action: 1. Primary antioxidants (free-radical scavengers) have reactive hydrogens which react with free radicals (examples: hindered phenols, sterically hindered amines, and aromatic amines) - They interrupt the primary oxidation cycle by removing the propagating radical. Hindered phenols donate hydrogen to chain-propagating radicals such as alkoxy, peroxy, and hydroxy radicals. 2. Secondary antioxidants (peroxide scavengers) decompose hydroperoxides and prevent chain branching of photochemical reactions (examples: phosphites, phosphonites, and thioesters). Another class of secondary antioxidants is thioethers or organic sulfides. They decompose two molecules of hydroperoxide into the corresponding alcohols and are transformed to sulfoxides and sulfones. These are very effective peroxide decomposers during long-term thermal aging. These are also referred to as Thiosynergists. Both functions are in some cases combined into one compound. Antioxidants are usually added in concentrations from 0.03 to 0.3%. Demonstrate the role of primary and secondary antioxidants in the degradation process. Each antioxidant plays an important role as described in the following section: This reaction converts the chain propagating radical into inert alcohol and water, respectively. Hindered phenols are very effective radical scavengers both during processing and longterm thermal aging. Secondary antioxidants decompose hydroperoxides (ROOH) into nonreactive and thermally stable products before they decompose into alkoxy and hydroxy radicals. 27 Protective Effects of Stabilizer Additives: Order to provide the most effective protection against oxidation it is beneficial to combine additives acting by different mechanisms, i.e. by attacking the oxidation process at multiple steps. These combinations often exhibit a level of performance far superior to that of their individual components used alone. Polymers and parts produced from them can be oxidized under a wide range of conditions encountered in their manufacturing and end use. Combinations of additives (often referred to as systems) are usually needed to provide effective protection. Hindered phenol antioxidants are highly effective to prevent oxidation in polyolefins both during processing in the melt and during long-term heat aging in the solid phase. These additives also have an influence on the light stability of polypropylene. Hindered phenols function by reaction with peroxy radicals (formed in of the oxidation process) to give hydroperoxides, thus terminating the oxidation chains - Hindered phenols are radical- trapping antioxidants for oxy and especially peroxy radicals: Such compounds are also called chain breaking antioxidants and examples include the hindered phenols and aromatic amines. Combinations of hindered phenols with peroxide decomposers (e.g. phosphites or thioethers) are widely employed and often provide enhanced protection during melt processing or long term heat aging. The chemical structures of some common phenolic antioxidants: phenolic antioxidan - Chemical structure of ethylenebis(oxyethylene)-bis(3-(5-tert-butyl-4-hydroxy-m-tolyl)propionate) phenol phenolic antioxidant - Chemical structure of 2,6-di-tert-butyl4-(4,6-bis(octylthio)-1,3,5-triazine-2-ylamino) 28 Phosphites and Phosphonites - Phosphites and phosphonites are used as melt processing stabilizers in polyolefins, usually in combinations with hindered phenols or hydroxylamines. Phosphite antioxidants function by decomposing peroxides (see green and blue arrow in the picture) and provide protection to adhesives, plastics, and coatings during high-temperature processing but much less so in the solid phase at lower temperatures. The most important preventive mechanism is the hydroperoxide decomposition where the hydroperoxides are transformed into non-radical, nonreactive, and thermally stable products as shown in the reaction schematic below: The chemical structures of some common phosphite antioxidants: trinonylphenol phosphite pentaerythritol diphosphite - Chemical structure of bis-(2,4-di-tbutylphenol) 29 Hindered Amine Light Stabilizers (HALS) - light stabilization of polyolefins. HALS also contributes to the thermal oxidative stability of polyolefins in the solid phase, especially at lower temperatures ( ≤ 120 [℃]) HALS is conveniently classified as: Low- to medium-molecular weight (HALS-1 through HALS-3) or High molecular weight types (HALS-4 and HALS-5). While HALS of all molecular weights is effective as light stabilizers, only the medium and high molecular weight types are effective to improve thermal oxidative stability. hindered amines and their transformation products (i.e. nitroxyl radicals and iminoether or “NOR” derivatives) are capable of stabilizing polyolefins through multiple mechanisms involving the scavenging of free radical and peroxide intermediates in the oxidation process. An important feature differentiating hindered amines from other classes of stabilizers is their ability to act by a regenerative mechanism - single hindered amine is capable of deactivating multiple oxidation chains. However, regeneration mechanism is less efficient in polypropylene than in other polyolefins. Regenerative mechanism for Hindered Amine Light Stabilizers: The chemical structures of some common HALS: Chemical structure of - 1,3,5-triazine-2,4,6- triamine, N,N0 v[1,2-ethane-diyl-bis[[[4,6-bis[butyl- (1,2,6,6-pentamethyl-4piperidinyl)amino]-1,3,5-triazine2-yl]imino]-3,1-propanediyl] bis[N0 ,Nv-dibutyl-N0 ,Nv-bis (1,2,2,6,6-pentamethyl-4piperidinyl)-1,3,5-triazine-2,4, 6-triamine Chemical structure of bis(2,2,6,6-tetramethyl-4-piperidyl) sebacate 30 Hydroxylamines (Distearyl hydroxylamine) – Recently, distearyl hydroxylamine has been commercialized as a new antioxidant (Irgastab FS-042) by Ciba Specialties Inc. Distearyl hydroxylamine is melt processing stabilizers, acts by scavenging free radicals as well as decomposing hydroperoxides: Scavenging of Oxygen-centered Radical by Distearyl Hydroxylamine Scavenging of Carbon-centered Radical by Distearyl Hydroxylamine Distearyl hydroxylamine is basic, so can be used as a radical scavenger in place of a phenol additive with potential antagonism to HALS, and does not color the stabilized material, although amine-type additives are generally not used for polymer materials except for rubbers because of the tendency to color the polymer materials. In addition, not effective to prevent oxidation in the solid phase and must be used in combination with either a hindered amine light stabilizer (HALS) or a hindered phenol. Summary of the function of different families of stabilizer additives: Stabilizer Class Reactivity · Hindered phenols POO Phosphites POOH HALS P· / POO· Hydroxylamines POO· / POOH Thioethers POOH Benzoates POO· UV absorbers hν Primary effect Secondary effect High Temperature Melt Processing Heat Stability (Solid Phase) UV / Light Stability 31 Reduction of Polymer Degradation during Processing: PP is a very useful material for various applications because of its good properties and process ability in largescale production by extrusion, injection molding and casting: Various products can be manufactured from several types of PP, including: a) isotactic b) crystalline PP homopolymers c) random copolymers and d) Impact or heterophasic copolymers PP can be processed in practically all known conversion types for thermoplastic polymers, even if it may require specific selection or adaptation of the selected type or grade. Roughly speaking a positive correlation between the MFR and the processing speed (or, more specifically, the applied shear or extension rate) exists. This implies that the PP types with highest molar mass will be applied in “slow” processes such as compression molding or pipe extrusion, while the grades with lowest molar mass find their use in “fast” processes such as thin-wall injection molding or fiber spinning. Antioxidants are used to prevent or inhibit thermal and/or photooxidation degradation process both during processing, where melting temperatures are experienced by the resin, and during lifetime when exposed to its upper service temperatures and radiations. In order to choose the most effective stabilizer package, it is important to know what temperature range the polymer will be exposed to during processing and application. The effectiveness of antioxidant depends on its concentration in the polymer, which decreases in processing and during long-term use. Morphology of a Melt: Morphology is the type of arrangement of the molecules. Polypropylenes (PP) are crystalline materials. If a piece of PP is melted, the molecules move away from each other and all the crystallites disappear. There is no systematic arrangement of the molecules placing them in a random arrangement. Since they are random, the PP in its melt form is in an amorphous state. The melt of a crystalline polymer is therefore always in an amorphous state. Crystallites are formed because of high molecular attraction and because of the possibility of the chains being unhindered to form the bond. Sometimes just the presence of another molecule or a side chain prevents crystallization. For melt processing, the crystallites must be dissolved and the chains separated from each other in order to reduce the viscosity. It is this basic nature of forming and dissolving of the crystallites that dictates various differences in processing and melt behavior. 32 Extruder Screw Design or Processing Parameters: a) Extruder length and cylinder/screw geometry: During processing of polymers a reduction of degradation is possible via suitable setup of the processing zones and screw design. The aim is to design the melting zone in a way that the polymer granules are processed to allow gentle fusion. In the following mixing zone processing length and energy input should be as high as required, but as low as possible. A higher mass temperature leads to higher degradation compared to a longer residence time*. Therefore, if technically possible, the choice of lower temperatures is favorable with the compromise of having possibly a longer processing zone and longer residence times. The dispersion result and granule homogeneity definitely need to be assessed as there is no decoupling possible of mixing efficacy, thermal stress, and polymer degradation. Residence Time and Maximum Residence Time of a Plastic* - The residence time is the time each particle spends in the extruder, from when it enters the first barrel section until it exits the die. Each screw configuration is associated with a residence time distribution depending on number of parameters. At a given melt temperature, a polymer can be held without degradation only for a finite amount of time. If the polymer is subjected to longer lengths of time, the polymer chains break and start to degrade. This time is defined as the maximum residence time. b) Selection of mixing elements: With a careful selection of gentle mixing elements a compromise can usually be realized ensuring sufficient mixing efficacy and reducing mechanical as well as thermal stress during compounding. Although not necessarily accessible via usual temperature sensors, high shear rates can cause a local overheating of the melt, which can exceed the mean processing temperature by more than 50 °C. Especially the area between mixing elements and their geometry influence this effect. The influence of these temperature spots on polymer degradation depends on thermal sensitivity and stability of the polymer or polymeric compound. In general, selection of gentle mixing elements can reduce damaging influence as long as the mixing result is reached. Distributive mixing elements: Pin mixing section Dulmage mixing section Saxton mixing section Pineapple mixing section c) Screw speed and throughput: Mechanical energy input in the melt is defined via specific energy input. Energy input can be minimized via low screw speed and high throughput resulting in lower energy input per mass and higher filling degree. This may result in higher residence time of the melt within the hot processing zones but allows lower mean mass temperatures in comparison to processing with high screw speed and lower throughput. 33 d) Recipe changes: As polymer degradation is influenced by residence time from melting up to solidifying as well as by possible impurities, a thorough cleaning of the extruder before or after changes to new recipes or compounds is recommended. Long times of heated equipment without screw movement (e. g. overnight) should also be avoided due to accelerated degradation at higher temperatures. Changes of Melt Flow Behavior via Molecular Weight and Flow Modifiers: a) Flow modifiers: In order to improve incorporation of solids into melts their viscosity can be reduced via addition of lowmolecular waxes*. Due to their low melting point they can cause better wetting of added solids and they also lead to a reduction of melt viscosity. These additives allow in many cases a reduction of processing temperatures and as a result also a reduction of thermally induced degradation reactions. Polyolefin waxes* can be introduced into the polymerization process during the preparation of a plastic. Furthermore, they can be added to a polymer before a processing step. Various methods are possible for this: polyolefin waxes can be dusted onto a polymer, compounded in, or introduced into a plastic in a cold or hot powder mixing process. b) Use of different polymer grades (molecular weight): Reduction of melt viscosity during processing can also be achieved via use of polymers with lower average molecular weight (or higher melt flow index, respectively), e. g. via use of easy-flowing injection molding grades as mixing partner. This allows reduction of the temperature profile with similar processing conditions compared to more viscous polymer grades. The following mixing and compounding of lower-viscous grades of the same polymer is unproblematic due to miscibility of polymers with the same chemical structure but different molecular weight. 34 Influence of multiple reprocessing cycles on the rheological and mechanical properties of PP: PP, a material widely used for packaging and containers, causes the biggest portion of plastic waste (22.8% in 2013). Therefore, it has a high potential for recycling. Unlike metals which are easily recoverable and recyclable, plastics wastes increasing day by day and forcing governments to legislate for the limitation of such waste by introducing the concept of isofunctional recycling which means he recycled plastics can be used in same application as pure plastics. Thermoplastics Market Share 2015 (Plastics Europe Market Research Group, 2015): The four key areas of recycling that are used today are primary, secondary, tertiary and quaternary: 1. Primary recycling (called closed-loop Recycling) involves the use of scrap plastics to make products whose performance characteristics are equivalent to the one obtained with virgin products. Usually, injection molding, extrusion, rotational molding, and compression molding represent the mechanical processes that are used. Only thermoplastic polymers can be recycled with this process. 2. In secondary recycling, end-of-life waste products are transformed by mechanical means, and it leads to applications where the demand of properties is lower than that required for the original article; it can be applied to thermoplastics, or slightly cross-linked polymers (e.g., rubbers that are able to decross-link by the combination of heat and high shearing). In this case, before the processing step is done, separation, washing, and preparation of the polymer to produce homogenous end-products with reasonably good properties is required. 3. In tertiary recycling (chemical recycling), polymer wastes are transformed into smaller molecules (Liquids or gases). In the case of polyolefins they are converted into its oil/hydrocarbon component, and into monomers in the case of polyesters and polyamides. These molecules can be used as raw materials for new polymer production. Chemical recycling process includes hydrolysis, pyrolysis, glycolysis, gasification, liquid gas hydrogenation, viscosity breaking, steam or catalytic cracking. 4. Quaternary recycling (incineration) known as EFW (Energy from Waste) - is commonly used when the plastics are mixed and/or heavily contaminated and cannot be economically recycled by another method. It involves burning the material and losing the material properties. Plastic materials are a convenient energy source because of their high calorific value. Incineration results in a volume reduction of 90-99%. 35 The use of polypropylene has highly increased due to its good material properties such as better stiffness, ductility, an acceptable elastic limit and an excellent chemical resistance at a relatively lower price. Due to the longer exposure to high temperatures, intensive shearing and the presence of moisture, reprocessing may give rise to thermal, thermo-oxidative or mechanical degradation that may affect the structure of both the matrix and the fillers and as a consequence the properties of the composites may decrease. Thus, the development of reprocessing operations needs knowledge of their effects on degradation, in order to assure a minimum decrease in property values. Effect of number recycling cycles on PP property: Rheological characterization - MFI value: MFI* value increased linearly with recycling. The viscosity of neat polypropylene melt under standard conditions dropped through reprocessing and kept dropping with increase in recycling times. Lower viscosity of melt usually means that the molecular weight of polymer decreased after recycling. The absence of changes in the chemical structure (ATR test) and the increase in the MFI suggest that chain scission, not oxidation, is the dominant degradation mechanism under the experimental conditions. Change in viscosity with melt flow index (MFI)*, which indicates how much material in grams flows through a small capillary within 10 min. The larger the MFI values, the lower the viscosity. The MFI increases slightly with an increasing number of reprocessing steps. The increase in MFI during this continued reprocessing without refreshing is caused by chain scission degradation due to thermal and mechanical degradation. 36 Continuation of - Effect of number recycling cycles on PP property: Test The Young’s modulus as a function of the number of recycling cycles: The yield stress as a function of the number of recycling cycles: The modulus increased slightly with increase in number of recycling up to 10 cycles, then decreased slightly till 20 cycles. Results for PP recycling and that this could be due to the higher crystallinity of the recycled PP. The flexibility of a plastic depends basically on the ability of its segments to rotate. Crystalline structures hinder such rotations; therefore, a crystalline material is significantly stiffer than the equivalent plastic in its amorphous condition. The difference of yield strain between the 20 cycles and first cycle is no more than 4%, which suggested that there is not much effect of recycling on yield strain. Breaking strain as a function of the number of recycling cycles: Impact resistance as a function of the number of recycling cycles: Elongation at break for polypropylene dropped by almost 50% after 20 cycles which was related to the reduction of the molecular weight with repeated processing cycles Impact resistance of recycled polypropylene reduced which indicated that ductility of polypropylene decreased as a result of molecule chain breaking by shearing during reprocessing. Results Analysis of results 37 Summary: The loss in properties and the financial cost associated with the degradation of polymers leads to a need to understand the processes by which these chemical reactions occur and how to prevent them. As we have seen, degradation can be affected by numerous factors at all stages in a product’s lifetime. Degradation reactions induced during processing can lead to a reduced life cycle time of final parts. In order to reduce degradation processes, processing conditions during extrusion are recommended to be chosen allowing low thermal stress. Therefore, careful engineering and thought must to go into developing polymer products. This is especially important with regards to the processing conditions, the types of stabilizers we use and the expected lifetime of the final product. Recyclability of plastic waste depends on the origin of the waste as well as the sensitivity of the polymer(s) to degradation. In most cases, preconsumer waste (manufacturing scrap) can be reprocessed with little deterioration of properties. The property changes can even be minimized or extended by refreshing the regrind waste with virgin plastic. Although the processing properties such as viscosity are affected, the changes in service-life properties such as mechanical performance are often negligible. Reprocessing of PP gives rise to an overall decrease in the melt viscosity due to degradation. The chemical structure was unaffected by reprocessing. The mechanical properties were affected to a different extent as a consequence of reprocessing. Small strain properties were slightly affected. However, after harsh reprocessing, PP showed a general decrease in break strain in tensile and breaking energy in impact resistance. The main and overall reason for this mechanical response is the chain scission because of the high shear rate and temperature in injection molding. 38 Bibliography: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. Handbook of Plastic Films Structure and Rheology of Molten Polymers - From Structure to Flow Behavior and Back Again Polyolefins - Processing, Structure Development, and Properties Review on Development of Polypropylene Manufacturing Process - Sumitomo Chemical Co., Ltd. Process & Production Technology Center Polymer Chemistry - Properties and Applications Polymer Extrusion (5th Edition) Robust Process Development and Scientific Molding - Theory and Practice (2nd Edition) Plastics Handbook - The Resource for Plastics Engineers (5th Edition) extrusion Dies for Plastics and Rubber - Design and Engineering Computations (3rd Edition) Plastics in Medical Devices - Properties, Requirements, and Applications Thermal Oxidation of Polypropylene Close to Industrial Processing Conditions ARIEL HOFF and SVEN JACOBSSON Additives for Polyolefins - Getting the Most Out of Polypropylene, Polyethylene and TPO (2nd Edition) Mechanisms of photostabilization of polyolefins with N-alkyl(methy1) HALS Institute of Macromolecular Chemistry, Czechoslovak Academy of Sciences 16206 ,Prague 6, Czechoslovakia Antioxidants and Stabilizers PROCEBBIYQ BTABILISATION OF POLYOLEPIYB W.O. Drake, J.R. Pauquet, R.V. Todesco and H. Zweifel Thermal Profile of Polypropylene and Polyethylene. I. A Novel Look at a Traditional Technique The Effect of Reprocessing on Mechanical Properties of Polypropylene CONFERENCE PROCEEDING (2014) Degradation and stability of polymer: A mini review To cite this article: N Sazali et al 2020 IOP Conf. Ser.: Mater. Sci. Eng. 788 012048 Polypropylene Degradation Control during Reactive Extrusion Influence of Multiple Reprocessing Cycles on the Rheological Properties of PP CONFERENCE PROCEEDING By Society of Plastics Engineers(2016) Understanding Plastics Recycling - Economic, Ecological, and Technical Aspects of Plastic Waste Handling 39