Curing Kinetics of the Synthesis of Poly(2-hydroxyethyl

methacrylate) (PHEMA) with Ethylene Glycol

Dimethacrylate (EGDMA) as a Crosslinking Agent

CHEN-WEI HUANG, YI-MING SUN, WEI-FUNG HUANG

Department of Chemical Engineering, Yuan-Ze Institute of Technology, Chung-Li, Taiwan 320, Republic of China

Received 19 August 1996; accepted 3 December 1996

ABSTRACT: An experimental study was carried out to investigate the effect of ethylene

glycol dimethacrylate (EGDMA, as a crosslinking agent) content on the curing kinetics

of the polymerization of 2-hydroxyethyl methacrylate (HEMA), using differential scanning calorimetry (DSC) and Fourier transform infrared spectroscopy (FTIR). EGDMA

may cause a crosslinking-facilitated gel effect which reduces the termination rate of

living free radicals and enhances the overall reaction rate, but it may also induce a

diffusional resistance for the reactants so that some free monomers are trapped and

pendant vinyl groups are prohibited from reaction by the crosslinked structure. At

higher content of EGDMA, the later effect becomes predominant, and the reaction rate

and the final conversion are limited. The exothermic peak of the curing reaction tends

to carry a shoulder and then split into two peaks as the amount of EGDMA is increased,

possibly due to a later reaction of the trapped monomers and pendant vinyls. The heat

of reaction measured by DSC in the scanning mode is 61.2 kJ/mol C|C. The activation

energy (E) of the curing reaction ranges from 56.5 to 78.3 kJ/mol C|C depending on

the EGDMA content and the type of operation. The diffusion-limited reaction rate and

the different thermal history experienced in the nonisothermal and isothermal curing

can result in variations of the results in the activation energy measurement. q 1997

John Wiley & Sons, Inc. J Polym Sci A: Polym Chem 35: 1873–1889, 1997

Keywords: free-radical polymerization; kinetics; hydrogel; thermoset; crosslinking

INTRODUCTION

Hydrogels are crosslinked hydrophilic polymer

materials that can absorb a significant amount of

water while maintaining a distinct three-dimensional structure (insoluble). The preparation of

poly(2-hydroxyethyl methacrylate) (PHEMA)

hydrogels is a subject of great interest, especially

for biomedical and pharmaceutical applications.1–6

Correspondence to: Y.-M. Sun

Contract grant sponsor: National Science Council, Republic

of China; contract grant number: NSC-83-0425-B-155-001M08

Contract grant sponsor: Standard Chemical and Pharmaceutical Co.; contract grant number: NSC-83-0425-B-155-001M08

q 1997 John Wiley & Sons, Inc. CCC 0887-624X/97/101873-17

The hydrogels in a matrix form have been used

as soft contact lenses, 1,6 artificial organ, 2,6 implants, 3 – 4,6 and devices for controlled drug release.5,7 On the other hand, the hydrogels in a

spherical microparticle form (microspheres or

beads) are used in hemoperfusion, 8 enzyme immobilization, 9,10 endovascular occlusion, 11 and

also in controlled drug release.5,12 – 13 They have

the major advantages of good biocompatibility,

moderate degree of swelling in water, and biological inertness.

Several techniques have been used to prepare

these hydrogels: such as bulk polymerization (for

matrix of various shapes), 5,7 suspension polymerization 14,15 (for microspheres), and solution polymerization for a linear polymer then followed by

a crosslinking reaction.16 Many comonomers can

1873

/ 8G42$$0239

05-30-97 07:23:20

polca

W: Poly Chem

1874

HUANG, SUN, AND HUANG

be used to adjust the crosslinking density and hydrophilicity to modify the swelling properties, mechanical strength, and the permeation rate of solutes through the hydrogels. Ethylene glycol dimethacrylate (EGDMA) is a frequently used

comonomer in the preparation of PHEMA hydrogels, 5,17 and it functions as a crosslinking

agent in the thermosetting system. The reaction

kinetics of the thermosetting polymerization,

such as the curing of epoxy resins, 18 – 20 unsaturated polyester resins, 21 – 24 and some multifunctional vinyl or acetylenic systems, 25 – 28 has been

studied by many investigator; however, the manner in which the crosslinking agent influences the

reaction kinetics of PHEMA has seldom been reported. There is a need to better understand the

reaction kinetics during synthesis in order to

properly prepare the PHEMA hydrogels for a critical application.

Since the preparation of PHEMA is a free radical chain growth crosslinking copolymerization of

HEMA and EGDMA, as one may expect, initial

molar ratio of HEMA C|C to EGDMA C|C

bonds, concentrations of initiator and inhibitor,

reaction temperatures, and thermal histories of

curing would affect the reaction kinetics in different ways. It is well known that the gel effect

(Trommsdorff effect) can suppress the termination rate of a free radical polymerization so that

an autoacceleration generally results.29 It was

also reported that the free radical polymerization

was diffusion-controlled and the final conversion

was always incomplete.30,31 The presence of crosslinking structure will further complicate the diffusion behavior of the reactants and free radicals

during reaction. A kinetic expression with consideration of all those factors is essential to interpret

or predict the rate of polymerization at a given

temperature and conversion. However, detailed

mechanism of free radical crosslinking polymerization still remains obscure.28 Even if a kinetic

model based on mechanistic consideration is

available, 24,32 – 34 it is generally tedious in practical

application.

A simple phenomenological model, which took

the autoacceleration characteristics in to account,

was proposed by Kamal and co-workers 21,35 to correlate the kinetic data obtained from differential

scanning calorimetry (DSC) with good reproducibility. The model is expressed as

da

Å ka m (1 0 a ) n

dt

/ 8G42$$0239

05-30-97 07:23:20

(1)

where da /dt is reaction rate, k is rate constant,

and m and n are constants describing the order

of the reaction. The model can fit the bell-shape

reaction rate profiles which are typical for the curing of epoxy or unsaturated polyester resins and

its parameters (k, m, and n) can be determined

from the isothermal DSC results.20 – 24 The activation energy of the polymerization reaction can be

determined from the Arrhenius plot of the logarithm of rate constant (k) and the reciprocal of

the reaction temperature.

In the present study, the isothermal and nonisothermal (scanning mode; temperature raising

at predetermined constant rate) reaction kinetics

were determined by a differential scanning calorimeter (DSC) and the conversion of C|C bonds

were confirmed by a Fourier transform infrared

spectrophotometer (FTIR). The range of isothermal temperatures were selected according to

those commonly applied to decompose the initiator AIBN. The curing kinetics were analyzed according to the rate profiles of heat release recorded by DSC. The isothermal DSC results were

tested with the Kamal model mentioned above to

extract the kinetic parameters. In addition, the

activation energies of the polymerization reactions based on an arbitrary kinetic form36 were

determined from the nonisothermal DSC data

and were compared with those obtained from the

Kamal model. The reaction system mimics a bulk

polymerization with good heat transfer to its environment. The kinetic parameters obtained here

can be used to better correlate and design the

synthesis conditions of PHEMA in either bulk polymerization or suspension polymerization, in

which each monomer droplet of the suspended

phase can be considered to be a mini-bulk polymerization system.

EXPERIMENTAL

Materials

HEMA provided by Chung-Chun Chemical Co.

(Taiwan) as a gift was employed in this study.

There was a small amount of monomethyl ether

of hydroquinone in the monomer as an inhibitor.

EGDMA was purchased from Aldrich Chemical

Co. (USA), and was also inhibited with monomethyl ether of hydroquinone. The monomers designated for kinetic measurements were vacuum

distilled, with small amounts of CuCl, so that hydroquinone could be removed. Azobisisobutyroni-

polca

W: Poly Chem

1875

SYNTHESIS OF PHEMA WITH EGDMA

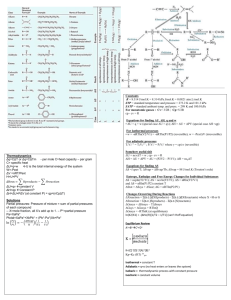

Table I. The Compositions of HEMA, EGDMA, and Initiator (AIBN) in the Samples Prepared in this Study

Weight Ratio of EGDMA/HEMA

Total moles of C|C/g monomer

g AIBN/g monomer

mol AIBN/mol C|C

[AIBN]o,z /[AIBN]o,0/10a

a

0/10

1/9

2/8

3/7

7.69 1 1003

0.002

1.58 1 1003

(1)

7.93 1 1003

0.002

1.54 1 1003

(0.975)

8.17 1 1003

0.002

1.49 1 1003

(0.943)

8.42 1 1003

0.002

1.45 1 1003

(0.918)

z Å Weight ratio of EGDMA/HEMA (0/10, 1/9, 2/8, and 3/7).

trile (AIBN, Aldrich Chemical Co.) was used as

received.

Sample Preparation

The initiator (AIBN) concentration was fixed at

0.2% by weight with respect to the total amount

of monomers. In the sample preparation, HEMA

and EGDMA were weighed separately and mixed

together first at room temperature. The initiator

was added into the monomer solution and the solution was stirred until thoroughly mixed. Then

the solution was degassed by using an ultrasonic

cleaner (NEY, 300) before curing experiments.

Samples with the weight ratio of EGDMA/HEMA

(WR) equals to 0/10, 1/9, 2/8, and 3/10 were prepared (Table I). Although no EGDMA was added

to the sample with WR Å 0/10, the polymerization

still involves slight crosslinking reaction since the

diester EGDMA is always present in the HEMA

as a by-product during the preparation of raw

HEMA, and upon distillation the disproportionation of HEMA 1,37 increases the amount of EGDMA. In addition, some crosslinking of the polymer due to radical chain transfer mechanisms

was suggested.38 The hydrogels prepared in this

manner can be considered as thermosetting systems.

By convention, the addition of initiator was

based on the weight percentage of the monomers

used. To facilitate later discussion, the conversion

of the weight basis into the molar basis are listed

in Table I. It can be seen that the number of moles

of the C|C bonds, including the vinyl groups of

EGDMA and HEMA, per gram of monomers are

shown in row 1 increasing with the weight ratio

of EGDMA/HEMA. If we neglect the density variation of the sample solutions with different weight

ratio of EGDMA/HEMA, the values in row 3

would reflect the magnitudes of molar concentrations for AIBN. It can be seen that with the same

/ 8G42$$0239

05-30-97 07:23:20

weight percentage of AIBN relative to the monomers, the molar concentration, however, would

decrease with increasing molar concentration of

C|C bonds. The numbers in parenthesis shown

in rows 4 represent the relative values of the molar concentrations of AIBN by taking that of the

sample with weight ratio of 0/10 (EGDMA/

HEMA) as unity.

Because the rate of polymerization reaction

may be affected by the concentration of initiator

in the system, it should be corrected by taking this

effect into consideration. The propagation rate of

polymerization, Rp , is proportional to the square

root of the rate of initiation or free radical formation, 29 Ri , i.e.,

Rp Å kp[Mr][M] Å kp[M](Ri /2kt ) 1 / 2

(4)

where kp and kt are the rate constants for propagation and termination, respectively, [M • ] is the total concentration of all the chain radicals, and

[M] is the monomer concentration. The rate of

initiation depends on the initial concentration of

initiator, and

Ri } [AIBN]o

(5)

where [AIBN]o is the initial molar concentration

of initiator AIBN. Since the concentration of initiator is different for the sample with different composition of monomers, the following equation can

be used to correct the reaction rate later on.

Rpm Å Rp ,z /([AIBN]o ,z /[AIBN]o ,0 / 10 ) 1 / 2 ,

z Å 1/9, 2/8, 3/7 (6)

where the subscript z indicates the weight ratio

(WR) of EGDMA/HEMA in the sample and Rpm

is the modified polymerization rate.

polca

W: Poly Chem

1876

HUANG, SUN, AND HUANG

DSC Measurement

A DuPont 910 differential scanning calorimeter

was used to follow the overall reaction rate profiles in a close system form. The instrument was

calibrated with pure indium as standard. All the

reactions were conducted in hermetic aluminum

sample pans to prevent monomer evaporation.

The sample average weight was 6–10 mg. Nitrogen gas was feed at 30 ml/min into the reaction

environment as a purge gas during the reaction.

Profiles of the non-isothermal reaction rate versus

temperature (time) were determined in the scanning mode at raising rate of 5, 10, 15, and 207C/

min from room temperature to 2207C. Profiles of

the isothermal reaction rate versus time were

measured at 60, 70, 80, and 907C. Isothermal DSC

runs were ended when there was no further exotherm and samples were reheated to 2207C in the

scanning mode with a raising rate of 107C/min to

determine the residual reactivity left in the isothermally cured samples. For each testing condition, experiments were run for at least three

times. The total heat of reaction was calculated

from the area under the exothermic peak of a DSC

curve, where the heat release rate (dDHt /dt) was

plotted with time. The rate of heat release measured by DSC can then be directly converted into

the overall reaction rate (da /dt) and fractional

conversion ( a ) as a function of time and the formulae are shown as follows 39 :

1 d DH t

da

Å

dt

DHT dt

aÅ

1

D HT

(2)

* dDdtH dt Å DDHH

t

t

0

t

(3)

T

where DHt is the accumulated heat released before the time t, and DHT is the total heat released

at the end of the reaction. In a nonisothermal

scanning run, DHT equals to the accumulated

heat released from room temperature to 2207C

( DHS ), i.e., DHT Å DHS . In an isothermal run,

DHT may stand for the summation of the isothermal heat release, DHiso , and the residual scanning heat release, DHres , i.e., DHI Å DHiso / DHres

and DHT Å DHI .39 Intuitively, DHI should be the

same as DHS for the same sample if all the vinyl

groups in the system are converted, however, it

is usually not the case. The fractional conversion

( a ) of an isothermal run can be determined by

taking either one as reference. We denote aI and

aS as the conversion calculated based on DHI and

averaged DHS , respectively.

/ 8G42$$0239

05-30-97 07:23:20

Figure 1. Nonisothermal DSC rate profiles at a scanning rate of 57C/min for the curing reaction with various weight ratios of EGDMA/HEMA.

FTIR Measurement

In the present study, a Perkin-Elmer 1725X

Fourier transform infrared spectrophotometer

(FTIR) with a resolution of 4 cm01 in the transmission mode was used to confirm the consumption of C|C bonds in HEMA and EGDMA. The

reaction of HEMA–EGDMA cured in the DSC cell

was stopped by rapidly chilling the sample pan in

liquid nitrogen. The sample was then milled,

mixed with KBr, and pressed into a solid disk of

1 cm diam prior to the IR measurement. In the

analysis of IR spectra, change of the absorbance

of the peak at 1635 cm01 (C|C stretching) was

employed to estimate the conversion of vinyl

groups in the cured samples. The absorbance of

the peak at 1730 cm01 (C|O stretching) was

picked as an internal standard. Two straight lines

connected the points of a spectrum at 1600, 1660,

and 1850 cm01 were taken as the base lines for

peak intensity measurement to correct the extraneous background. The relative intensity for the

peaks 1635 and 1730 cm01 was determined by the

ratio of the intensities of these two peaks with the

base line correction.

RESULTS AND DISCUSSIONS

Reaction Rate Profiles

Figures 1–4 show the non-isothermal DSC profiles of heat release rates (dDHt /dt) for the samples with various weight ratio of EGDMA/HEMA

(WR Å 0/10, 1/9, 2/8, and 3/7) at the raising rate

of 5, 10, 15, and 207C/min, respectively, from room

polca

W: Poly Chem

SYNTHESIS OF PHEMA WITH EGDMA

1877

Figure 2. Nonisothermal DSC rate profiles at a scanning rate of 107C/min for the curing reaction with various weight ratios of EGDMA/HEMA.

Figure 4. Nonisothermal DSC rate profiles at a scanning rate of 207C/min for the curing reaction with various weight ratios of EGDMA/HEMA.

temperature to 2207C. Figures 5–8 show the isothermal DSC rate profiles at several temperatures

(60, 70, 80, and 907C) for the samples with the

weight ratio of 0/10, 1/9, 2/8, and 3/7 (EGDMA/

HEMA), respectively. The rate shown in the figures

is expressed as kJ/mol C|C/s instead of kJ/g

monomer/s, since the number of moles of total

C|C bonds for every gram of monomer with different weight ratio differs from one another, 39 as

shown in Table I. However, the rate profiles shown

in Figures 1–8 were not corrected for the variation

of the molar concentration of the initiator in the

system. The overall reaction rate can be obtained

by dividing the instantaneous heat release rate by

the total heat released according to the eq. (2).

Table II summarizes the calculated results of

nonisothermal reactions including the total heat

of reaction ( DHT or DHS ), temperature at maximum rate (Tp ), fractional conversion at maximum

rate ( ap ), maximum rate (Rp ), and modified maximum rate (Rpm ). Tables III–VI summarizes the

results obtained from the isothermal reaction,

which includes the heat generated in isothermal

cure ( DHiso ), the residual heat ( DHres ) that was

released when the sample was heated to 2207C

from the isothermal temperature at 107C/min

upon completion of the isothermal cure, and the

total heat of cure ( DHI Å DHiso / DHres ). Also

listed in Tables III–VI are the final isothermal

conversions, aI and aS , based on DHI and DHS ,

respectively, induction time (td ), time at maximum rate (tm ), fractional conversion at maximum

Figure 3. Nonisothermal DSC rate profiles at a scanning rate of 157C/min for the curing reaction with various weight ratios of EGDMA/HEMA.

Figure 5. Isothermal DSC rate profiles for the curing

reaction with weight ratio of EGDMA/HEMA Å 0/10:

(

) experimental data, (rrrrr) simulated data.

/ 8G42$$0239

05-30-97 07:23:20

polca

W: Poly Chem

1878

HUANG, SUN, AND HUANG

Figure 6. Isothermal DSC rate profiles for the curing

reaction with weight ratio of EGDMA/HEMA Å 1/9:

(

) experimental data, (rrrrr) simulated data.

Figure 8. Isothermal DSC rate profiles for the curing

reaction with weight ratio of EGDMA/HEMA Å 3/7:

(

) experimental data, (rrrrr) simulated data.

rate ( am , based on DHI ), maximum rate (Rp ), and

modified maximum rate (Rpm ).

Although the isothermal and non-isothermal

operations are different in nature, their thermograms show some similarity in terms of the shape

of rate profiles. It can be seen that the exothermic

peak tends to carry a shoulder and then split into

two peaks in the extreme case, as the weight ratio

of EGDMA/HEMA increases under the same reaction condition. The peak splitting becomes more

pronounced when the reaction temperature is elevated in an isothermal operation or the scanning

rate is lowered in a non-isothermal one. The first

and the major peak is due to the reaction initiated

by the decomposition of AIBN and the propaga-

tion of the free radical polymerization. However,

the difunctional EGDMA may leave the main

chains unreacted vinyl pendant groups, which are

partially reacted because of their limited mobility

toward a free radical. Besides, more unreacted

free monomers may be trapped as the crosslinking

density is higher when higher fraction of EGDMA

is used. When the conversion of the polymerization increases, the density of the polymer matrix

increases, the polymer chains become close to

each other, and those unreacted vinyl groups and

trapped free monomers can line up if sufficient

energy is provided for a local rearrangement. A

zip propagation mechanism could result if a free

radical, which either has survived since the AIBN

initiation step or is produced due to thermal initiation, exists in the vicinity of these unreacted pendant vinyl groups or free monomers.29 A shoulder

or a second exothermic peak appears as a consequence. In an isothermal run, it can only be observed at higher reaction temperature, and a distinct second peak shows up at higher weight ratio

of EGDMA/HEMA. In a nonisothermal run, the

relative height of the second peak to the first one

increases with the weight ratio of EGDMA/

HEMA, but it decreases with the scanning rate.

The effect of the weight ratio has been explained

as above, and the effect of scanning rate needs a

further interpretation. At higher scanning rate, a

reaction system with the same weight ratio can

reach a higher temperature within shorter time

period so that most unreacted vinyl pendant

groups and free monomers will have better chance

to react with a living free radical, which is produced either by the AIBN initiation at beginning of

Figure 7. Isothermal DSC rate profiles for the curing

reaction with weight ratio of EGDMA/HEMA Å 2/8:

(

) experimental data, (rrrrr) simulated data.

/ 8G42$$0239

05-30-97 07:23:20

polca

W: Poly Chem

1879

SYNTHESIS OF PHEMA WITH EGDMA

Table II. Total Heat of Reaction (DHS ), Temperature at Maximum Rate (Tp), Conversion at Maximum Rate

(ap), Maximum Rate (Rp), and Modified Maximum Rate (Rpm) for EGDMA/HEMA Curing Reactions in the

Scanning Mode of DSC Study (Nonisothermal Operation)

Scanning Rate (7C/min)

EGDMA/HEMA Å 0/10

DHS (kJ/mol C|C)

Tp (K)

ap (Tp)

Rp (kJ/mol C|C/s)

Rpm (kJ/mol C|C/s)

EGDMA/HEMA Å 1/9

DHS (kJ/mol C|C)

Tp (K)

ap (Tp)

Rp (kJ/mol C|C/s)

Rpm (kJ/mol C|C/s)

EGDMA/HEMA Å 2/8

DHS (kJ/mol C|C)

Tp (K)

ap (Tp)

Rp (kJ/mol C|C/s)

Rpm (kJ/mol C|C/s)

EGDMA/HEMA Å 3/7

DHS (kJ/mol C|C)

Tp (K)

ap (Tp)

Rp (kJ/mol C|C/s)

Rpm (kJ/mol C|C/s)

5

10

15

20

61.5 { 0.3

378.8 { 0.1

0.52

0.59

0.59

61.3 { 0.2

391.1 { 0.2

0.53

1.02

1.02

61.8 { 0.5

399.0 { 0.1

0.54

1.26

1.26

61.6 { 0.2

405.4 { 0.2

0.54

1.43

1.43

60.8 { 0.2

376.4 { 0.3

0.41

0.76

0.78

60.8 { 0.8

385.4 { 0.7

0.43

1.18

1.21

61.2 { 0.7

393.4 { 0.9

0.40

1.70

1.74

61.4 { 0.9

398.9 { 0.1

0.41

2.03

2.08

61.9 { 0.2

374.2 { 0.1

0.36

0.88

0.93

60.9 { 0.2

383.6 { 0.1

0.37

1.33

1.41

60.8 { 0.2

390.8 { 0.3

0.37

1.94

2.06

60.5 { 0.2

395.6 { 0.4

0.34

2.17

2.30

61.3 { 0.4

370.6 { 0.1

0.32

0.57

0.62

58.7 { 0.2

379.8 { 0.2

0.35

1.10

1.20

57.5 { 0.6

385.9 { 0.2

0.35

1.39

1.52

57.5 { 0.4

391.0 { 0.4

0.35

1.71

1.86

the reaction or by the thermal initiation at the

higher temperature, because they have higher energy to cross the diffusion barrier formed by the

polymer networks. Therefore, the fraction of the remaining unreacted vinyl bonds (including pendant

and free ones) for the later zip reaction is reduced

and the relative height of the second peak to the

first one decreases with increasing scanning rate.

Conversion of Vinyl Bonds by FTIR Measurement

Figure 9 shows a typical FTIR spectra of a curing

system (a) before reaction, (b) after isothermal reaction, and (c) after rescanning. The band near

1730 cm01 , a characteristic band of C|O stretching, was chosen as an internal standard. It is shown

in Figure 9 that the intensity of band near 1635

cm01 , a characteristic band of C|C stretching, decreases after isothermal reaction and decreases

more after rescanning. The spectra confirm that the

vinyl bonds are consumed during the polymerization. The curve (c) in Figure 9 shows that there is

/ 8G42$$0239

05-30-97 07:23:20

still a small peak of C|C band after rescanning

reaction. It indicates that the system has a limited

conversion, there are still some residual C|C

bonds buried inside the network structure despite

the sample experiencing rescanning by DSC.

Figure 10 shows the relative intensities of C|C

band to C|O band for the samples that have been

cured at isothermal temperature. It can be seen

that the relative intensity increases with increasing

weight ratio of EGDMA/HEMA and with decreasing curing temperature. Because the higher the

crosslinking density is, the monomers will have

more difficulty to diffuse to the reactive site of a free

radical and remain unreacted. When the system is

cured at higher temperature, the monomers will

have higher mobility so that they are able to go

through the diffusion barrier and then the number

of the unreacted monomers become minimized.

Heat of Reaction and the Overall Conversion

The heat of reaction was determined from the

area under the peak(s) of a DSC thermogram.

polca

W: Poly Chem

1880

HUANG, SUN, AND HUANG

Table III. Summary of the Kinetic Information Obtained by Isothermal DSC Study for EGDMA/HEMA

Curing Reaction at 607C

Weight Ratio of EGDMA/HEMA

Heats of reaction of the isothermal

run (DHiso ), rescanning after

isothermal run (DHres ), and the

total (DHI ):

DHiso (kJ/mol C|C)

DHres (kJ/mol C|C)

DHI Å DHiso / DHres (kJ/mol C|C)

Total conversion of the isothermal run

based on DHI and averaged DHS

(61.2 kJ/mol C|C):

a1

aS

Induction time td (min)

Time at maximum rate tm (min)

Dt Å tm 0 td (min)

Conversion at max. rate, am

Rp (J/mol C|C/s)

Rpm (J/mol C|C/s)

0/10

1/9

2/8

3/7

51.6 { 1.3

4.7 { 0.1

56.3 { 1.4

48.7 { 1.5

7.2 { 0.1

55.9 { 1.6

42.8 { 0.2

10.0 { 0.2

52.8 { 0.4

42.0 { 1.4

10.8 { 0.2

52.8 { 1.6

0.92

0.84

68 { 10

129 { 2

61 { 12

0.59

39.0

39.0

0.87

0.79

81 { 1

122 { 7

41 { 8

0.55

40.2

41.2

0.81

0.70

128 { 5

167 { 3

39 { 8

0.51

44.4

47.0

0.80

0.69

83 { 2

123 { 1

40 { 3

0.47

47.0

51.2

Consistent results were obtained in the nonisothermal scanning operation ( DHS in Table II).

Except for the cases where the sample is with

EGDMA/HEMA ratio Å 3/7 and scanned at

higher heating rates, all the other cases give an

averaged reaction heat of 61.2 kJ/mol of C|C

with a standard deviation less than 2%. In comparison with the reaction heat of the polymeriza-

Table IV. Summary of the Kinetic Information Obtained by Isothermal DSC Study for EGDMA/HEMA

Curing Reaction at 707C

Weight Ratio of EGDMA/HEMA

Heats of reaction of the isothermal

run (DHiso), rescanning after

isothermal run (DHres), and the

total (DHI ):

DHiso (kJ/mol C|C)

DHres (kJ/mol C|C)

DHI Å DHiso / DHres (kJ/mol C|C)

Total conversion of the isothermal run

based on DHI and averaged DHS

(61.2 kJ/mol C|C):

aI

aS

Induction time td (min)

Time at maximum rate tm (min)

Dt Å tm 0 td (min)

Conversion of max. rate, am

Rp (J/mol C|C/s)

Rpm (J/mol C|C/s)

/ 8G42$$0239

0/10

1/9

2/8

3/7

51.7 { 0.8

4.0 { 0.03

55.7 { 0.9

49.0 { 1.0

4.8 { 0.1

53.8 { 1.1

44.2 { 1.5

7.1 { 0.1

51.3 { 1.6

44.1 { 0.5

8.4 { 0.1

52.4 { 0.6

0.93

0.84

14.6 { 1.6

41.5 { 0.5

27 { 2

0.53

72.1

72.1

0.91

0.80

11.4 { 0.5

28.6 { 1.3

17 { 2

0.47

88.8

91.1

0.86

0.72

28.0 { 0.8

44.0 { 1.1

16 { 2

0.45

74.6

79.1

0.84

0.72

20.5 { 1.1

38.1 { 1.0

17 { 1.1

0.44

84.6

92.1

05-30-97 07:23:20

polca

W: Poly Chem

SYNTHESIS OF PHEMA WITH EGDMA

1881

Table V. Summary of the Kinetic Information Obtained by Isothermal DSC Study for EGDMA/HEMA

Curing Reaction at 807C

Weight Ratio of EGDMA/HEMA

Heats of reaction of the isothermal

run (DHiso), rescanning after

isothermal run (DHres ), and the

total (DHI ):

DHiso (kJ/mol C|C)

DHres (kJ/mol C|C)

DHI Å DHiso / DHres (kJ/mol C|C)

Total conversion of the isothermal run

based on DHI and averaged DHS

(61.2 kJ/mol C|C):

aI

aS

Induction time td (min)

Time at maximum rate tm (min)

Dt Å tm 0 td (min)

Conversion at max. rate, am

Rp (J/mol C|C/s)

Rpm (J/mol C|C/s)

0/10

1/9

2/8

3/7

54.7 { 0.4

2.2 { 0.1

56.9 { 0.5

53.2 { 0.5

2.8 { 0.2

56.0 { 0.7

48.8 { 0.01

4.5 { 0.1

53.2 { 0.1

48.2 { 0.6

6.0 { 0.3

54.2 { 0.9

0.96

0.89

2.0 { 0.3

13.7 { 0.0

11.7 { 0.3

0.43

97.7

97.7

0.95

0.87

2.2 { 0.1

10.3 { 1.1

8.1 { 1.2

0.40

111.5

114.3

0.92

0.80

2.5 { 0.3

9.6 { 0.2

7.1 { 0.5

0.32

104.2

110.5

0.89

0.79

2.3 { 0.4

9.2 { 0.7

6.9 { 1.1

0.26

100.5

109.5

tion of methyl methacrylate, 56.5–61.0 kJ/mol

measured by DSC, 28 the obtained result shows a

good agreement among the monomers of similar

kind. The reaction heat was lowered in the pre-

viously mentioned exceptional cases (WR Å 3/7),

probably due to limited conversion of the pendant

vinyl groups or buried monomers in a highly

crosslinked network. If we consider 61.2 kJ/mol

Table VI. Summary of the Kinetic Information Obtained by Isothermal DSC Study for EGDMA/HEMA

Curing Reaction at 907C

Weight Ratio of EGDMA/HEMA

Heats of reaction of the isothermal

run (DHiso), rescanning after

isothermal run (DHres), and the

total (DHI ):

DHiso (kJ/mol C|C)

DHres (kJ/mol C|C)

DHI Å DHiso / DHres (kJ/mol C|C)

Total conversion of the isothermal run

based on DHI and averaged DHS

(61.2 kJ/mol C|C):

aI

aS

Induction time td (min)

Time at maximum rate tm (min)

Dt Å tm 0 td (min)

Conversion at max. rate, am

Rp (J/mol C|C/s)

Rpm (J/mol C|C/s)

/ 8G42$$0239

0/10

1/9

2/8

3/7

56.6 { 0.4

1.3 { 0.01

57.9 { 0.4

54.5 { 0.4

1.4 { 0.04

56.0 { 0.4

52.1 { 0.1

2.6 { 0.1

54.7 { 0.2

50.6 { 0.4

3.6 { 0.1

54.2 { 0.5

0.98

0.92

0.88 { 0.01

5.1 { 0.1

4.2 { 0.1

0.41

211.5

211.5

0.97

0.89

0.87 { 0.02

2.8 { 0.1

1.9 { 0.1

0.34

380.5

390.3

0.95

0.85

0.89 { 0.01

2.3 { 0.1

1.4 { 0.1

0.26

336.2

356.5

0.93

0.83

0.93 { 0.03

2.4 { 0.1

1.5 { 0.1

0.25

289.5

315.3

05-30-97 07:23:20

polca

W: Poly Chem

1882

HUANG, SUN, AND HUANG

Figure 9. FT-IR spectra of sample with EGDMA/HEMA Å 3/7: (a) before reaction,

(b) after isothermal curing at 907C, and (c) after rescanning to 2207C.

Figure 10. (a) Relative intensity of C|C band to

C|O band in IR spectra for samples with different

weight percentage of EGDMA cured at 707C (h), (b)

Relative intensity of C|C band to C|O band in IR

spectra for samples with EGDMA/HEMA Å 3/7 cured

at different temperature ( n).

/ 8G42$$0239

05-30-97 07:23:20

as the reaction heat of all the reactable vinyl

groups in the system, then we can estimate that

those unreacted fraction of all the vinyl groups

may be up to 6% for the sample with EGDMA/

HEMA ratio Å 3 / 7 scanned at rate of 15 or

207C/min.

The reaction heat measured in an isothermal

run gives DHiso , the heat released during the rescanning to 2207C gives the residual reaction

heat DHres , and the sum of them gives DHI in

the Tables III – VI. The conversion in an isothermal run can be calculated based on DHI or DHS .

The estimated conversion ( aI or aS ) is always far

less than unity in the experimental conditions of

this study; therefore, there are a great number

of residual vinyl groups in the system, either in

form of unreacted free monomers or pendants.

Unreacted monomers can be easily extracted by

a good swelling agent. Nevertheless, a highly

crosslinked hydrogel may have a large number

of unreacted vinyl pendants if the curing reaction

is carried out at temperature similar to the range

of this study. One should be careful in using

these crosslinked gel for biomedical application

if the existence of unsaturated vinyl groups is

polca

W: Poly Chem

SYNTHESIS OF PHEMA WITH EGDMA

restricted. On the other hand, those unreacted

vinyl pendants can provide sites for grafting the

parent polymer with a second polymer for further

modification or a bioactive compound for controlled release.

There are two kinds of conversion in an isothermal run, aI and aS , calculated based on DHI and

DHS , respectively. By definition, aS is the isothermal conversion of all the reactable vinyl double

bonds in the system, and aI may represent the

apparent isothermal conversion of the vinyl bonds

which can be converted in this particular full operation (isothermal curing r rescanning). Because

all the initiators were completely consumed during the isothermal run and unreacted vinyl

groups were less reactive as they were buried between chains of formed polymer networks, further

scanning to a higher temperature is not effective

enough to react all the remaining vinyl groups so

that DHI is always lower than the DHS and thus

aI ú aS .

The isothermal conversion ( aI or aS ) decreases

with increasing EGDMA ratio but increases with

increasing reaction temperature. The free radical

polymerization is diffusion-controlled and the final conversion is always incomplete.30,31 Although

the formation of crosslinking structure reduces

the termination rate of free radicals, it also reduces the diffusion of reactants at later stage of

the reaction so the final conversion is limited.

Higher EGDMA ratio will give higher crosslinking density so the final conversion is lower. At

higher reaction temperature, reactants will have

higher energy to break the diffusion limitation so

the conversion is higher.

Effect of the EGDMA Content in the

Nonisothermal DSC Study

Both the temperature at maximum reaction rate,

Tp , and the conversion at maximum reaction rate,

ap , decrease with increasing weight ratio of EGDMA/HEMA as shown in Table II. It is wellknown that, for the diffusion-controlled free radical polymerization, the apparent termination rate

constant kt decreases much fast than the propagation rate constant kp does as the reaction goes on.

The reaction follows an autocatalytic kinetics and

will reach a maximum rate in the middle of the

reaction, and the so-called gel effect takes place.29

In the dynamic scanning study, the conversion at

the maximum point ( ap ) is relatively independent

of the scanning rate.36 The presence of a crosslinking agent further facilitates the gel effect because

/ 8G42$$0239

05-30-97 07:23:20

1883

Figure 11. The modified maximum reaction rate of

the first peak, Rpm , as a function of the weight percentage of EGDMA in a nonisothermal run. Scanning rate:

(l) 57C/min, (j) 107C/min, (l) 157C/min, (m) 207C/

min.

the crosslinked network creates a greater diffusional limitation for the termination of active free

radicals. The on-set of the gel effect will occur at

a lower conversion and lower temperature in a

consequence. The samples with higher EGDMA

content will let the diffusion-controlled propagation reaction begin at earlier time of the curing.

It is suggested that the generated crosslinking

structure plays a significant role in determining

the commencement of this liquid to solid transition at the gel point.

The maximum reaction rate is also affected by

the presence of a divinyl crosslinking agent. After

the correction for the variation of Ri by using WR

Å 0/10 as the basis (row 4 in Table I), the modified maximum reaction rate at peak, Rpm , is plotted with the weight percentage of EGDMA in the

Figure 11. The maximum reaction rate initially

increases with increasing EGDMA content up to

the point of 20% and then decreases as the EGDMA content further increases. It indicates that

the overall reaction rate is initially enhanced by

the crosslinking facilitated gel effect and then retarded due to limited mobility of unreacted monomers or pendants in a highly crosslinked structure. Therefore, more and more unreacted vinyl

groups (including pendant and free ones) are left

in the network so that a second peak, as we have

discussed previously, appears in the rate profile

at later time and higher temperature and becomes

more distinct with increasing EGDMA content. It

polca

W: Poly Chem

1884

HUANG, SUN, AND HUANG

can be seen from Figures 1–4 that the increasing

order of Rp for the second peak is that WR Å 1/9

õ 2/8 õ 3/7.

Effect of the EGDMA Content in the Isothermal

DSC Study

The degree of crosslinking density also affects the

isothermal reaction as it does in the nonisothermal operation due to the same reason. At any

curing temperature, aI or aS and DHiso decrease

with increasing weight ratio of EGDMA/HEMA

(Tables III–VI). The diffusional limitation

brought by the increasing degree of crosslinking

structure can leave more residual vinyl groups in

the network so the isothermal conversion and the

accompanying heat released will be reduced. The

overall conversion for the samples with the same

EGDMA content is elevated at higher reaction

temperature because both the monomers and

polymer network will have higher energy to relax

the limitation of diffusion.

The orders of the induction time (td ) and the

time at maximum rate (tm ) at any reaction temperature do not show any explicit dependence on

the EGDMA content, but the difference between

them ( Dt Å tm 0 td ) shows a regular pattern as

it is largely reduced to a similar value, which is

independent of the weight ratio, with the presence

of EGDMA (Tables III–VI). The reason for this

behavior is not clear at this moment, but it may

be also related to the diffusional limitation

brought by the presence of a crosslinked structure

and the suppressed termination of free radicals.

Crosslinking can restrict the relative movement of macromolecular chains in a polymer. In

a consequence, gelation in a polymerizing medium

can occur at a lower conversion. The conversion

at maximum reaction rate ( am ) decreases with

increasing weight ratio of EGDMA/HEMA at any

isothermal reaction temperature (Tables III–VI).

On the other hand, a higher curing temperature

will largely enhance the reaction rate, and the

propagation of the polymerization may become

diffusion limited at lower degree of gelation.

Therefore, the conversion at maximum reaction

rate ( am ) for the samples with the same EGDMA

content decreases with increasing reaction temperature.

The effect of EGDMA content on the modified

maximum rate Rpm is a complicated matter and

the effect also depends on the reaction temperature. There are two opposite effects which determine the reaction rate. The crosslinking facili-

/ 8G42$$0239

05-30-97 07:23:20

Figure 12. The modified maximum reaction rate of

the first peak, Rpm , as a function of the weight percentage of EGDMA in an isothermal run. Reaction temperature: ( l) 607C, (j) 707C, (l) 807C, (m) 907C.

tated gel effect can enhance the reaction rate due

to reduced termination reaction, and a highly

crosslinked structure will decrease the reaction

rate due to limited mobility of unreacted monomers or pendants. At 607C, the exothermic peaks

for all the samples of different EGDMA contents

are bell-shape without any sign of a shoulder or

second peak (Figures 5–8). The modified maximum rate Rpm increases monotonically as the EGDMA content increases (Fig. 12). Probably the

reaction rate is only enhanced by the crosslinking

facilitated gel effect and the formation of crosslinked structure is not ample enough, due to the

lower conversion at this temperature, to retard

the diffusion of reactants to the active sites of

living radicals. At 707C, the shape of the exothermic peaks for the samples of different EGDMA

contents are not consistently the same (Figures

5–8), and the dependence of the modified maximum rate Rpm on EGDMA content is not distinct

(Fig. 12). At 80 and 907C, the exothermic peak

tends to carry a shoulder and then split to two

peaks as the EGDMA content increases (Figs. 5–

8). The modified maximum rate Rpm first increases as the EGDMA content changed from 0 to

10% (wt.) then decreases as the EGDMA content

further increases (Fig. 12). The reaction rate may

first be enhanced by the gel effect then be retarded

by the slow diffusion of reactants. When the EGDMA content is higher than 10% (wt.), the reduction of the maximum reaction rate in the first

polca

W: Poly Chem

SYNTHESIS OF PHEMA WITH EGDMA

peak results in the formation of a second minor

peak in the rate profile. The second minor peak

becomes more distinct with increasing EGDMA

content (Figs. 5–8).

Kinetic Models and Activation Energies

The free radical polymerization of monovinyl

(HEMA) and divinly (EGDMA) monomers is

thermosetting and autoaccelerated so that it can

be described by eq. (1). The rate constant (k) follows the Arrhenius equation:

k Å A exp(0E/RT )

(7)

ln k Å ln A 0 E/RT

(8)

where A is pre-exponential factor, E is activation

energy, R is gas constant, and T is absolute curing

temperature. To a good approximation, the isothermal curing of a free radical polymerization

can be assumed to be a second order reaction.21–23

Mathematically, this is expressed as

m/nÅ2

(9)

Substituting eq. (9) into eq. (1) and rearranging

the equation, 23 one can obtain

ln

F

da /dt

a2

G

Å ln k / n ln

F

10a

a

G

(10)

Applying this equation to the isothermal rate data

of each run, we can obtain the rate constant k and

corresponding reaction orders. The results are

shown in Table VII. It was found that the reaction

orders changed with temperature, so the averaged

values of them were calculated. The activation

energy of the reaction for each formulation was

determined by eq. (8) in an Arrhenius plot. The

results along with the pre-exponential factor and

the square of the linear regression coefficient are

given in Table VIII. Simulated rate profiles by

using eq. (1) with the averaged m and n in Table

VII and the Arrhenius parameters in Table VIII

are plotted accompanying the experimental rate

profiles in Figures 5–8. Because the first-order

differential equation of eq. (1) needs an initial

condition to start the integration, an nonzero initial conversion ( a ) has to be defined at the td (induction time) for each run, otherwise the calculated reaction rate will be zero all the time. The

initial conversions were arbitrarily chosen as

/ 8G42$$0239

05-30-97 07:23:20

1885

0.001, 0.0015, 0.005, and 0.02 for reaction temperatures of 60, 70, 80, and 907C, respectively, and

they were the same for samples of different compositions. Variation of the initial conversion will

shift the predicted tm (time at maximum rate) to

a different time, but it does not affect the shape

and the maximum rate of the predicted profile for

each run (Fig. 13). Fairly good agreement, at

least in the same order of magnitude, between the

simulated and the experimental rate profiles can

be observed. Some deviation between them are

unavoidable due to the limitation of the model,

and other poor predicted results can be explained

by the large standard deviations of the averaged

reaction orders and the less satisfactory values of

the square of regression coefficients in fitting eqs.

(8) and (10). Nevertheless, the analysis demonstrates that the simple autoaccelerated kinetic

model can roughly follow the process of the curing

reaction but the model cannot describe the nonideal shapes (shoulder or the second peak) of the

experimental rate profiles and predict the induction time (td ), the time at maximum rate (tm ), or

the difference between them ( Dt) for each run.

On the other hand, the nonisothermal DSC

data can give the activation energy of the polymerization reaction without assuming an exact

rate expression in prior provided that the conversion at maximum rate ( ap ) is independent of heating rate ( f ). Based on the work of Ozawa 40,41 and

Doyle, 42,43 a simple relationship between activation energy, heating rate, and temperature at

maximum rate (Tp ) is given as 36 :

EÉ

0R d ln f

1.052 d(1/Tp )

(11)

where R is the gas constant. The activation energy

is for the rate constant of an arbitrary kinetic

form36 :

da

Å k f (a )

dt

(12)

where f ( a ) is an empirical function representing

the conversion-dependent part of the rate expression. By plotting ln f vs. (1/Tp ), the activation

energy (E) can be determined from the slope. The

results are shown in Table IX.

The effect of the EGDMA content on the activation energies obtained from the isothermal and

non-isothermal studies was not consistent (Table

VIII and IX). In the nonisothermal curing, the

polca

W: Poly Chem

1886

HUANG, SUN, AND HUANG

Table VII. Rate Constants (k), Reaction Orders (m and n), and the Square of Regression Coefficient (r 2) for the

EGDMA/HEMA Curing Reaction at Different Isothermal Temperature

Isothermal

Temperature

(7C)

k

(s01)

m

r2

n

EGDMA/HEMA Å 0/10

60

70

80

90

average

2.41

4.28

7.57

1.32

{

{

{

{

0.04

0.06

0.58

0.03

1

1

1

1

1003

1003

1003

1002

1.20

1.08

0.96

0.87

1.03

{

{

{

{

{

0.05

0.00

0.03

0.01

0.12

0.80

0.92

1.04

1.13

0.97

{

{

{

{

{

0.05

0.00

0.03

0.01

0.12

0.989

0.987

0.986

0.987

{

{

{

{

0.001

0.001

0.003

0.002

0.97

1.05

1.11

1.32

1.11

{

{

{

{

{

0.01

0.04

0.05

0.02

0.13

0.982

0.988

0.996

0.994

{

{

{

{

0.001

0.001

0.003

0.001

1.00

1.07

1.19

1.44

1.17

{

{

{

{

{

0.05

0.02

0.04

0.01

0.17

0.980

0.985

0.997

0.989

{

{

{

{

0.005

0.012

0.001

0.000

1.04

1.06

1.21

1.40

1.18

{

{

{

{

{

0.02

0.00

0.02

0.04

0.14

0.986

0.986

0.996

0.989

{

{

{

{

0.011

0.002

0.001

0.003

EGDMA/HEMA Å 1/9

60

70

80

90

average

2.47

5.30

8.59

1.89

{

{

{

{

0.02

0.28

0.50

0.13

1

1

1

1

1003

1003

1003

1002

1.03

0.95

0.89

0.68

0.89

{

{

{

{

{

0.01

0.04

0.05

0.02

0.13

EGDMA/HEMA Å 2/8

60

70

80

90

average

2.89

5.43

7.44

1.70

{

{

{

{

0.09

0.38

0.09

0.17

1

1

1

1

1003

1003

1003

1002

1

1

1

1

03

1.00

0.93

0.81

0.56

0.83

{

{

{

{

{

0.05

0.02

0.04

0.01

0.17

EGDMA/HEMA Å 3/7

60

70

80

90

average

2.67

5.60

7.65

1.57

{

{

{

{

0.06

0.13

0.19

0.10

10

1003

1003

1002

activation energy increased as the EGDMA content increased. In the isothermal curing, the activation energy increased first as the EGDMA content increased from 0 to 10% (WR Å 0/10 to 1/

9), and then dropped to a similar lower value

as the amount of EGDMA further increased. The

results of nonisothermal curing suggest that the

0.96

0.94

0.79

0.60

0.82

{

{

{

{

{

0.02

0.00

0.02

0.04

0.14

presence of a crosslinking agent facilitates the gel

effect so that the reaction becomes more sensitive

to temperature and the activation energy increases. In the isothermal curing, the results of

samples with lower EGDMA content (WR Å 0/10

and 1/9) also agreed with this suggestion. The

increment of the activation energy was about the

Table VIII. Arrhenius Parameters for the Rate Constant Based on eq. (1): Activation Energy (E),

Pre-exponential Factor (A), and the Square of Linear Regression Coefficient (r 2) of the Analysis

EGDMA/HEMA

E (kJ/mol C|C)

A (s01)

r2

/ 8G42$$0239

0/10

1/9

2/8

3/7

57.2

2.09 1 106

0.9997

66.2

5.99 1 107

0.991

56.5

2.04 1 106

0.969

56.6

2.05 1 106

0.978

05-30-97 07:23:20

polca

W: Poly Chem

SYNTHESIS OF PHEMA WITH EGDMA

Figure 13. Effect of the initial conversion on the simulated heat release profile for a sample of EGDMA/

HEMA Å 1/9 cured at 607C. Curves from left to right:

initial conversion Å 1 1 10 02 , 1 1 10 03 , 1 1 10 04 , 1

1 10 05 , and 1 1 10 07 , respectively, while the induction

time td is assumed to be 0 min.

same as the weight ratio changed from 0/10 to 1/

9 in both of the isothermal and non-isothermal

operations. However, the results of samples with

higher EGDMA content (WR Å 2/8 and 3/7) disagreed with it.

The disagreement is caused by the highly crosslinked network structure, which limits the mobility of reactants toward living free radicals. In an

isothermal curing, the rate data were used for the

determination of reaction rate constant [eq. (11)].

However, the rate is limited by the diffusion-controlled propagation step in the highly crosslinked

structure as we discussed previously. The rate

constants obtained in the cases of WR Å 2/8 and

3/7 were smaller than those obtained in the case

of WR Å 1/9 at 80 and 907C (Table VII). In a

consequence, the activation energies obtained in

the former two cases were smaller than the one

1887

obtained in the later one. Furthermore, the activation energies obtained in the former two cases

might not be adequate because the regression coefficients was not good enough (r 2 õ 0.98). The

reaction may encounter different level of diffusion

limitation at different isothermal reaction temperature in these two cases. On the contrary, the

calculation of activation energy from non-isothermal data only requires the peak temperature and

heating rate, and it is performed under a criteria

that the conversion at the peak is the same for

different heating rate. The same conversion guarantees that the level of diffusion limitation of

monomers is the same when the activation energy

is determined. High quality linear regression was

obtained in all the cases with various EGDMA/

HEMA ratio as the square of the regression coefficient was higher than 0.99.

The activation energy is determined by a combination effect of the intrinsic chemical reaction

rate and the mass transfer resistance of reacting

species in the system. The activation energies for

the cases of WR Å 0/10 and 1/9 measured in nonisothermal curing is about 10% higher than those

obtained in isothermal curing. These results are

similar to the results reported by Prime 19 who

studied the curing kinetics of epoxy resins by

DSC. The unknown kinetic form in eq. 12 may be

different from that in eq. (1) possibly due to a

different level of diffusional resistance in these

two types of curing operations. The diffusion of

reactants within the system may become the rate

limiting step as the reaction temperature goes

higher. All the temperatures at maximum rate

were higher than 957C in a nonisothermal operation, and the curing temperature was between 60

and 907C in an isothermal operation. The diffusion limitation may not be the same for the same

sample at different reaction temperature; therefore, difference in the results of activation energy

is observed due to the different thermal history

experienced in each curing operation.

Table IX. Arrhenius Parameters for the Rate Constant Based on eq. (12): Activation Energy (E) and the

Square of Linear Regression Coefficient (r 2) of the Analysis

EGDMA/HEMA

E (kJ/mol C|C)

r2

/ 8G42$$0239

0/10

1/9

2/8

3/7

63.6

0.9993

72.4

0.991

75.3

0.997

78.3

0.998

05-30-97 07:23:20

polca

W: Poly Chem

1888

HUANG, SUN, AND HUANG

CONCLUSIONS

The effect of EGDMA content on the curing kinetics of the synthesis of PHEMA hydrogels has been

studied by DSC over the entire conversion range

and FTIR for the cured product. The presence of

EGDMA may promote the reaction rate initially

due to a crosslinking-facilitated gel effect but may

retard the diffusion of reactants and leave unreacted vinyl groups (trapped free monomers or

pendants) within the system at later stage. The

exothermic peaks in the rate profiles of the curing

tend to carry a shoulder and then split into two

peaks as the amount of EGDMA increases. Slower

heating rate in the nonisothermal curing and

higher reaction temperature in the isothermal

curing will promote the formation of two distinct

peaks. The reaction of those trapped free monomers and pendant vinyl groups on the main chain,

possibly due to a zip propagation mechanism, is

responsible for the formation of the shoulder or

second peak in the rate profiles. The heat of reaction measured by DSC in the scanning mode is

61.2 kJ/mol C|C, which is almost independent

of the heating rate, and it shifts to a lower value

only when the weight ratio of EGDMA/HEMA is

3/7 due to limited final conversion. The heat released of a sample cured in an isothermal run is

always lower than that in a non-isothermal scanning run indicates that the reaction is never complete during an isothermal curing at temperature

of 907C or less. Both the DSC and FTIR measurements demonstrate that the conversion ( aI or aS )

of vinyl groups decreases as the weight ratio of

EGDMA/HEMA increases and the reaction temperature decreases in an isothermal run. The temperature at maximum rate (Tp ) and the conversion at maximum rate ( ap ) in a nonisothermal

curing and the conversion at maximum rate ( am )

in a isothermal curing decrease with increasing

EGDMA content due to the crosslinking facilitated gel effect. In the nonisothermal curing and

the isothermal curing at higher temperature (80

and 907C), the maximum rate (Rp or Rpm ) can be

enhanced first due to the same facilitated gel effect and then be reduced due to the diffusional

limitation generated by the crosslinking structure

as the amount of EGDMA increases. In an isothermal run, the induction time (td ) and the time at

maximum rate (tm ) do not show any regular pattern with the weight ratio of EGDMA, but the

difference between them ( Dt Å tm 0 td ) reduces

to a relatively constant value with the presence

of EGDMA. The Kamal model can generally follow

/ 8G42$$0239

05-30-97 07:23:20

the isothermal curing reaction; however, it cannot

predict the time events (td , tm , and Dt) and describe the nonideal rate profiles in detail. As the

content of EGDMA increases from 0 to 30%, the

activation energy (E) of the curing reaction in the

non-isothermal operation increases monotonically

from 63.6 to 78.3 kJ/mol C|C, and that in the

isothermal operation changes from 57.2 (WR Å 0/

10) to 66.2 (WR Å 1/9) kJ/mol C|C and drops

to about 56.5 kJ/mol C|C (WR Å 2/8 or 3/7).

Diffusion-controlled reaction rate may cause a deviation in activation energy measurement in the

isothermal curing of the sample with WR Å 2/8

or 3/7. The different thermal history experienced

in the isothermal and nonisothermal curing can

cause a discrepancy in the values of the activation

energy measured in these two operations. This

study provides us with ample information about

the kinetic behaviors of the PHEMA synthesis either qualitatively or quantitatively, which will be

useful for the design of a fabrication process for

the production of hydrogels in many different

forms for biomedical applications. Although this

study avoids thorough analyses of the microgel

formation, 28,44 mechanistic kinetic modeling, 24,32–34

and quantifying the diffusion limitation, 32,45 it

will benefit the future studies of those subjects.

This work was supported by a joint research grant

NSC-83-0425-B-155-001-M08 from the National Science Council of the Republic of China and the Standard

Chemical and Pharmaceutical Co.

REFERENCES AND NOTES

1. O. Wichterle, in Encyclopedia of Polymer Science

and Technology, Vol. 15, H. F. Mark, N. G. Gaylord,

and N. M. Bikales, Eds., Interscience, New York,

1971, p. 273.

2. B. D. Ratner and A. S. Hoffman, in Hydrogels for

Medical and Related Applications, J. D. Andrade,

Ed., ACS Symposium Series 31, American Chemical Society, Washington, DC, 1976, p. 1.

3. N. A. Peppas, Ed., Hydrogels in Medicine and Pharmacy, Vols. I–III, CRC Press, Boca Raton, FL,

1986–1987.

4. V. Kudela, in Encyclopedia of Polymer Science and

Engineering, Vol. 7, 2nd ed., H. F. Mark, N. M. Bikales, C. G. Overberger, G. Menges, and J. I.

Kroschwitz (eds.), Wiley, New York, 1987, p. 783.

5. S. H. Gehrke and P. I. Lee, in Specialized Drug

Delivery Systems, Manufacturing and Production

Technology, P. Tyle, Ed., Dekker, New York, 1989,

p. 333.

polca

W: Poly Chem

SYNTHESIS OF PHEMA WITH EGDMA

6. J.-P. Montheard, M. Chatzopoulos, and D. Chappard, J. M. S.-Rev. Macromol. Chem. Phys., C32,

1 (1992).

7. N. R. Vyavahare, M. G. Kulkarni, and R. A. Mashelkar, J. Membrane Sci., 54, 205 (1990).

8. P. J. Skelly and B. J. Tighe, Polym. Commun., 20,

1051 (1979).

9. M. Chang, M. Colvin, and A. J. Rembaum, J.

Polym. Sci. Polym. Lett. Ed., 24, 603 (1986).

10. A. Denizli, A. Y. Rad, and E. Piskin, J. Chromatography, B: Biomedical Appl., 668, 13 (1995).

11. D. Horak, F. Svec, J. Kalal, K. Gumargalieva, A.

Adamyan, N. Skuba, M. Titova, and N. Trostenyuk,

Biomaterials, 7, 188 (1986).

12. P. I. Lee and C.-J. Kim, J. Controlled Rel., 16, 229

(1991).

13. I. Orienti, V. Bertasi, and V. Zecchi, J. Controlled

Rel., 22, 159 (1992).

14. K. F. Mueller, S. J. Heiber, and W. L. Plankl, U.S.

Pat. 4,224,427 (1980).

15. A. B. Scranton, A. G. Mikos, L. C. Scranton, and

N. A. Peppas, J. Appl. Polym. Sci., 40, 997 (1990).

16. A. G. Andreopoulos, J. Appl. Polym. Sci., 45, 1005

(1992).

17. Y.-M. Sun and J.-N. Chang, J. Polym. Res., 2, 71

(1995).

18. K. Horie, H. Hiura, M. Sawada, I. Mita, and H.

Kambe, J. Polym. Sci. A-1, 8, 1357 (1970).

19. B. Prime, Polym. Eng. Sci., 13, 365 (1973).

20. M. R. Keenan, J. Appl. Polym. Sci., 33, 1725

(1987).

21. M. R. Kamal and S. Sourour, Polym. Eng. Sci., 13,

59 (1973).

22. K.-W. Lem and C. D. Han, Polym. Eng. Sci., 24,

175 (1984).

23. P. W. K. Lam, Polym. Composites, 8, 427 (1987).

24. Y. J. Huang, J. D. Fan, and L. J. Lee, Polym. Eng.

Sci., 30, 684 (1990).

25. P. E. Willard, Polym. Eng. Sci., 12, 120 (1972).

/ 8G42$$0239

05-30-97 07:23:20

1889

26. A. Thakur, A. K. Banthia, and B. R. Maiti, J. Appl.

Polym. Sci., 58, 959 (1995).

27. S. B. Sastri, J. P. Armistead, and T. M. Keller, Polymer, 36, 1449 (1995).

28. Y. Y. Chiu and L. J. Lee, J. Polym. Sci. Part A:

Polym. Chem., 33, 257 (1995).

29. G. Odian, Principles of Polymerization, 3rd ed., Wiley, New York, 1991, chapter 3, p. 198.

30. K. Horie, I. Mita, and H. J. Kambe, J. Polym. Sci.

A-1, 7, 2561 (1969).

31. K. Horie, I. Mita, and H. J. Kambe, J. Polym. Sci.

A-1, 8, 2839 (1970).

32. G. L. Batch and C. W. Macosko, J. Appl. Polym.

Sci., 44, 1711 (1992).

33. J. F. Stevenson, Polym. Eng. Sci., 26, 746 (1986).

34. H. Ng and I. Manas-Zloczower, Polym. Eng. Sci.,

29, 1097 (1989).

35. M. R. Kamal, S. Sourour, and M. E. Ryan, SPE

ANTEC Tech. Papers, 19, 187 (1973).

36. B. R. Prime, in Thermal Characterization of Polymeric Materials, E. A. Turi, Ed., Academic, New

York, 1981, chapter 5, p. 435.

37. E. H. Schacht, in Recent Advances in Drug Delivery

Systems, J. M. Anderson and S. W. Kim, Eds., Plenum, New York, 1984, p. 259.

38. D. E. Gregonis, C. M. Chen, and J. D. Andrade, in

Hydrogels for Medical and Related Applications,

J. D. Andrade, Ed., ACS Symposium Series 31,

American Chemical Society, Washington, DC,

1976, p. 88.

39. Y. J. Huang and C. J. Chen, J. Appl. Polym. Sci.,

46, 1573 (1992).

40. T. Ozawa, Bull. Chem. Soc. Jpn., 38, 1881 (1965).

41. T. Ozawa, J. Therm. Anal., 2, 301 (1970).

42. C. D. Doyle, J. Appl. Polym. Sci., 5, 285 (1961).

43. C. D. Doyle, J. Appl. Polym. Sci., 6, 639 (1961).

44. Y. Y. Chiu and L. J. Lee, J. Polym. Sci. Part A:

Polym. Chem., 33, 269 (1995).

45. Y. J. Huang and L. J. Lee, AIChE J., 31, 1585

(1985).

polca

W: Poly Chem