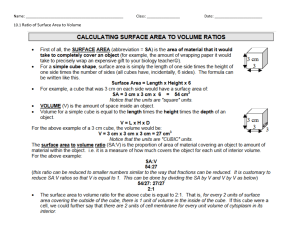

Sarah Clancy MEM 687 HW 6 1. Determine the values of the items listed below which are required to successfully mold 8 plastic enclosures. The dimensions of the enclosure are provided on page 3 and dimensions for the mold layout are provided on page 4. The material is high density polyethylene and the thickness of the enclosure is 0.05in. The primary, secondary, and tertiary runners have trapezoidal crosssections with an internal angle of 20deg between the side and small width. Assume standard vent spacing on runners. For calculation purposes, ignore notches in enclosure. H= (d/2) sqrt(pi*cos(20)) = .859d W= (d/2) sqrt(pi/cos(20)) (1+sin(20)) = 1.227d a) Width and height of tertiary runners. Length = 1in Dbranch= 0.119in Width= 0.146in Height= 0.102in b) Width and height of secondary runners. Length = 4in Dfeed = 1.4*dbranch = 0.167 Width = 1.227 *d = 0.205 Height = .859 *d = 0.143 c) Width and height of the primary runners. Length = 4.25 Dfeed=1.4*dbranch = 0.233 Width = 1.227d = 0.286 Height = .859d = 0.200 d) Gate Dimensions (land, width, and depth) Land = 0.025 Width = 0.125 Depth = 0.03 e) Vent depth, width, land, and spacing on runners and cavity (assume equally spaced) Cavity: Depth = .001, Width = 0.15, Land = 0.045, Spacing = 0.75 Runners: Depth = 0.002, Width = 0.15, Land = 0.045, Spacing = 0.5 Sarah Clancy 2. Calculate the clamping force required to hold the mold closed with an injection pressure of 12,500psi. Use the widths calculated in 1a.,1b., and 1c.as the widths of runners in the parting plane. 3. The location of cavity vents and parting plane relative to the location of the cavity gate(s) is extremely important. They must be positioned such that the air in the cavity is pushed out of the cavity by the advancing polymer flow. If air gets trapped in the cavity it can become superheated and burn the polymer material as well as cause dimensional problems with the final product. Examine section C-C on page 4. The cavity vents are not shown but they are located along the perimeter of the cavity adjacent to the parting plane. What potential problem exists with the gates being located as shown on page 4? What is a better gate location? The polymer will fill from the bottom of the mold to the top, pushing air straight up. With no vents at the top, the air will be trapped. A better gate location may be the center of the mold.