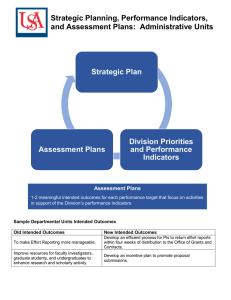

Sustainable Production and Consumption 26 (2021) 455–468 Contents lists available at ScienceDirect Sustainable Production and Consumption journal homepage: www.elsevier.com/locate/spc Review article Nano and micro level circular economy indicators: Assisting decision-makers in circularity assessments Carla Tognato de Oliveira∗, Thales Eduardo Tavares Dantas, Sebastião Roberto Soares Federal University of Santa Catarina (UFSC), Department of Sanitary and Environmental Engineering, Life Cycle Assessment Research Group (CICLOG), Florianopolis, 88040-970, Brazil a r t i c l e i n f o Article history: Received 17 September 2020 Revised 29 November 2020 Accepted 30 November 2020 Available online 2 December 2020 Editor: Prof. Konstantinos Tsagarakis Keywords: Sustainability Circular economy Circularity Indicators Nano level Micro level a b s t r a c t The growing interest for Circular Economy (CE) urged experts to develop assessment metrics regarding the shift from a linear to a circular rationale. As a response, the recent literature has been populated with a plethora of circularity indicators addressing different CE scales: nano (products), micro (companies), meso (industrial symbiosis), and macro (governments). However, simply shifting to circular systems does not necessarily result in favorable alternatives, as trade-offs may occur concerning environmental, economic, or social impacts. In order to assist decision-makers in the processes of choosing the bestsuiting indicator for circularity assessments, this study presents a systematic literature review aiming at nano- and micro-level indicators, which were evaluated according to their relation to the sustainability pillars and life cycle stages (take, make, use, recover). Sixty-one publications were analyzed (44 peerreviewed, 16 from gray literature, 1 dissertation). Fifty-eight indicators were explored (38 nano, 14 micro, 6 directed to both levels). Findings show that the majority of metrics are nano-level environmentallydriven indicators that focus on material and resource recovery strategies. A second expressive group is simultaneously focused on the environmental and economic pillars. Social repercussions are rarely addressed. We argue that the analyzed indicators mainly focus on material and resource recirculation and lack robustness to assess the sustainability performance of circular systems. Future research could analyze the integration of the investigated indicators with consolidated methodologies to overcome the barrier of combining circularity and sustainability performance. © 2020 Institution of Chemical Engineers. Published by Elsevier B.V. All rights reserved. 1. Introduction Abbreviations: APL, assessment of circular economy strategies at the product level; BWPE, bim-based whole-life performance estimator; BCI, building circularity indicators; BPI, end of life best practice indicators; CAM, circularity assessment model; CBA, circular building assessment prototype; CBM-IS, circular business model set of indicators based on sustainability; CC, circularity calculator; CE, circular economy; CEBI, circular economy benefit indicators; CEI, circular economy index; CEIP, circular economy indicator prototype; CEMS, circular economy measurement scale; CE-PCF, evaluation index system of circular economy for pcfs; CET, circular economy toolkit; CEV, circular economic value; CG, circular gap; Check, circularity check; CI, circularity index; CLC, Closed Loop Calculator; CMT, Circularity Measurement Toolkit; CP, Circular Pathfinder; CPI, Circular Economy Performance Indicator; CTI, Circularity Transition Indicators; CYT, Circulytics; eDiM, Ease of Disassembly Metric; EEI, Economic-Environmental Indicators; EER, Economic-Environmental Remanufacturing; EMF, Ellen MacArthur Foundation; EoL, End of Life; EoLi, End of Life Indices; FPI, Environmental Sustainability for Food Packaging Indicators; GRI, Global Resource Indicator; IOBS, Input-Output Balance Sheet; LCA, Life Cycle Assessment; LCSA, Life Cycle Sustainability Assessment; L&C, Longevity and Circularity; MCEM-PLCS, Multi-Criteria Evaluation Method of Product-Level Circularity Strategies; MCI, Material Circularity Indicator; MECI, Material and Energy Circularity Indicator; MESCS, Material Efficiency in Supply Chain Spreadsheets; MI, Mine Site MFA Indicator; MIPS, Material Input Per Service Delivered; MIS, Multidimensional Indicator Set; PCIP, Product Circularity Improvement Program; PCM, Product-Level Circularity Metric; PRISMA, Preferred Reporting Items for Systematic Reviews and meta- The transition from the current linear economic model to a circular economy (CE) is a prominent topic in academic literature, public governance, and the corporate domain (Lindgreen et al., 2020). A CE requires decoupling economic growth from finite resource consumption and extraction (Ghisellini et al., 2016), as well as designing out pollution and seeking better strategies to extract the maximum value from energy and materials inserted into sys- Analyses; PR-MCDT, Product Recovery Multi-Criteria Decision Tool; PRP, PRP Circular e-Procurement Tool; PRDI, Product Recycling Desirability Index; QC, Circularity of Material Quality; RDI, Resource Duration Indicator; REAPro, Resource Efficiency Assessment of Products; RI for CE, Recycling Indices for the CE; RPI, Reuse Potential Indicator; SCI, Sustainable Circular Index; SDGs, Sustainable Development Goals; SIAS, Set of Indicators to Assess Sustainability; SICED, Systems Indicators for Circular Economy Dashboard; S-LCA, Social Life Cycle Assessment; SPI, Sustainability Performance Indicators; WBCSD, World Business Council for Sustainable Development; WCI, Improved Water Circularity Index. ∗ Corresponding author. E-mail addresses: carla.tognato@posgrad.ufsc.br (C.T. de Oliveira), sr.soares@ufsc.br (S.R. Soares). https://doi.org/10.1016/j.spc.2020.11.024 2352-5509/© 2020 Institution of Chemical Engineers. Published by Elsevier B.V. All rights reserved. C.T. de Oliveira, T.E.T. Dantas and S.R. Soares Sustainable Production and Consumption 26 (2021) 455–468 tems (EMF and Granta, 2015). As interest in CE grows, companies need to prepare transition strategies based on information regarding their circular performance and associated risks and opportunities (WBCSD, 2018). To do so, following the emblematic corporative phrase “what gets measured, gets done” (Nuñez-Cacho et al., 2018), businesses need a consistent way to assess their circularity. Companies are using circular metrics to communicate with their customers (Howard et al., 2019; Vanegas et al., 2018). Thus, there is a need for credible and coherent disclosure or reporting of circular initiatives to relevant stakeholders, including customers, investors, regulators, media, suppliers, and non-governmental organizations (WBCSD, 2018). As the resource-centered rationale proposed by CE is rapidly being incorporated by governmental and private strategies (Geissdoerfer et al., 2017), new projects must have clear circular intentions and be accompanied by an assessment of their actual impact to draw the attention of investors and the civil society. Hence, in the context of this ongoing economic model shift, decision-makers are faced with the need to address effectively and measure the outcomes of the transition from linear to circular models (Jabbour et al., 2019), stressing the need for comprehensive indicators at the product and company levels of CE. MACRO Cities and regions MESO Industrial symbiosis MICRO Companies NANO Products Fig. 1. CE levels. 1.2. Nano and micro-level circularity indicators 1.1. Circular economy and circularity indicators This study’s understating of CE levels is primarily based on the division among the macro, meso, and micro circularity levels commonly applied in CE research (Kirchherr et al., 2017). The macro level is the CE development in cities, provinces, or regions. It involves redesigning infrastructural systems, such as clean energy, transportation, the cultural framework, and the social system (Ghisellini et al., 2016). The meso level presents CE strategies to industrial eco-parks or inter-enterprise associations known as industrial symbiosis (Balanay and Halog, 2016). In turn, the micro level is related to the CE progress to consumers, a single company, or a product and its components (Franklin-Johnson et al., 2016). As the micro level has a broad scope, many metrics referred to as micro-level indicators do not cover the complexity of a CE and may lead to different interpretations of what this specific CE level is targeting during circularity assessments (Lindgreen et al., 2020). Therefore, Saidani et al. (2017) introduced a new productcentered term to the CE context, the nano level, which describes “the circularity of products, components, and materials, included in three wider systemic levels, all along the value chain and throughout their entire lifecycle” (Saidani et al., 2017). In parallel, the systemic CE view provided by Huamao and Fengqi (2007) shows that CE levels influence and interact with one another, i.e., the upper levels are based on the lower levels, which, in turn, orient their development. This point of view is graphically exemplified in Fig. 1. Thereby, we adopt the views of Saidani et al. (2017) to deepen the scientific understanding regarding the nano- and micro-level circularity indicators, as these levels offer greater specificity concerning the context in which strategies are applied (Blomsma et al., 2019). As pointed out by Lindgreen et al. (2020), grouping all corporate operations under the same category to assess companylevel circularity may be overly general and extensive. The further division into four circularity levels aims to dissolve the common confusion derived from a far too broad view of the micro level. In this context, the implementation of circularity indicators to the nano level is a way to strictly distinguish the influence of specific products and design options from the overall company circularity. As supported by Huamao and Fengqi (2007) and Saidani et al. (2017), the nano level is intrinsically present in the upper levels. However, by highlighting the circularity degree of products, decision-makers may implement strategies to better attend to specific parts of their production process, which would also benefit the upper circularity levels. As the topic challenged the scientific community, the early phase of CE-related research developed a plethora of concepts trying to define best such a broad idea (Korhonen et al., 2018). This study employs the definition brought by Kirchherr et al. (2017) as a conceptual basis for CE: “an economic system that replaces the ‘end of life’ (EoL) concept with reducing, alternatively reusing, recycling, and recovering materials in production/distribution and consumption processes. It operates at the micro level (products, companies, consumers), meso level (eco-industrial parks), and macro level (city, region, nation) to accomplish sustainable development, thus simultaneously creating environmental quality, economic prosperity, and social equity to the benefit of current and future generations”. This study, however, further distinguishes the CE levels of operation by adding a fourth degree, the nano level, further explored in Section 1.2. Due to the nature of this research, it becomes necessary to define the term indicator. As pointed out by Saidani et al. (2019), indicators are valuable analytical tools applied to simplify information. The main goals of indicator use are related to tracking, monitoring, and measuring the progress and performance of specific systems or processes. Moreover, it is important to stress that these tools may aid the understanding of complex phenomena through both quantitative and qualitative assessments. Parallel terms, such as metric, index, and indices, are hereby understood as synonyms to the term “indicator” and applied within the same context. As this paper addresses assessment methods within the CE context, a clear definition of circularity is essential for a comprehensive understanding of the evaluated metrics. Linder et al. (2017) defined circularity at the product level as “the fraction of a product that comes from a used product”. However, circularity assessments are imperative to the monitoring and improvement of a CE at different scales. Therefore, this study presents a broader definition of the beforementioned concept. We define circularity as the alignment of a material or energy flow, product, processes, or system to a set of CE strategies (redesign, product disassembly, recycling, use of renewable energy, etc.) that meet the general CE goals. Therefore, circularity indicators may be understood as analytical tools focused on measuring the degree of association of a system (or part of one) to practices and strategies applied to develop a CE further. In that sense, higher circularity means that a specific item or system is closer to achieving the goals set by the guiding standards of a CE. 456 C.T. de Oliveira, T.E.T. Dantas and S.R. Soares Sustainable Production and Consumption 26 (2021) 455–468 1.3. Goal and scope of this work Science database, two of the most extensive repositories in the related scientific field. Subsequently, a variation of a semi-structured snowballing approach (Wohlin, 2014) was performed to capture additional and emerging methodologies and indicators presented in reports and gray literature (Lindgreen et al., 2020). Although gray literature may present preliminary and even simplistic findings (Costa et al., 2019), the inclusion of such publications is vital to the objective of this paper since many of the circularity assessment tools are developed as initiatives from business organizations and non-academic institutions (Geissdoerfer et al., 2017; Lindgreen et al., 2020). The literature search and snowballing were carried out until no new interactions (publications showcasing metrics different from those already present in the portfolio) were found. The search led to the identification of 53 peer-reviewed documents, and the snowballing completed the set with the inclusion of 61 publications. Duplicates accounted for 16 excluded publications, with 97 documents remaining. Eight additional papers were excluded based on the information presented in titles, abstracts, and keywords. While recognizing that studies have already been developed to review metrics used to measure circularity assessments, to the best of our knowledge, no recent review has focused on identifying CE indicators considering the division between the nano and micro levels. Therefore, this article builds on previous reviews (Kristensen and Mosgaard, 2020; Lindgreen et al., 2020; Parchomenko et al., 2019; Saidani et al., 2019) and aims to update the list of critically analyzed indicators while still contributing to the indicator selection processes by separating nano- and micro-level circularity indicators. Additionally, to better support sustainability-oriented decision-makers, we innovate by identifying the pillars of sustainability (environmental, economic, and social) and life cycle stages (take, make, use, recover) that each indicator covers. To fill these scientific gaps and achieve the goal of this article, three research questions were drawn up and addressed throughout this study: 1 Why divide circular economy levels further into nano and micro levels? 2 Can the three sustainability pillars be assessed through circularity indicators? 3 What are the life cycle stages covered by the nano- and microlevel indicators analyzed? 2.2. Eligibility The selection of eligible publications was based on a full reading of the remaining articles and their adherence to the search criteria presented in Table 1. A total of 28 publications were ruled out upon full-text reading as they did not fit the purpose and goals of this study. This leads to an initial portfolio of 14 articles remaining from the database search and 47 publications from the semi-structured snowball technique (30 papers are present in peer-reviewed literature, 16 are part of gray literature publications, 1 dissertation). Thus, the final portfolio included 61 publications that addressed nano- and/or micro-level circularity indicators through reviews, case studies, and methodological approaches. The overarching objective of this article is to develop a list of circularity indicators at the nano and micro levels to assist decision-makers in indicator selection processes based on the three dimensions of sustainability and life cycle stages. To do so, this article is organized as follows: Section 2 outlines the research method for the literature review; Section 3 presents the bibliometric and indicator-related results; Section 4 explores the results concerning the three aforementioned research questions; Section 5 closes the study by drawing the research conclusions and future research proposals. 2.3. Content analysis 2. Methodology R The final portfolio was organized through Endnote software and moved to a spreadsheet for further analysis (for the final portfolio, please refer to the Supplementary Material). The portfolio was organized based on bibliometric information (authors, year of publication, title, journal, type of publication) and indicatorrelevant data. The latter occurred through the differentiation of the level of application of the indicators (nano or micro) based on Saidani et al. (2017), the sustainability pillars addressed (environmental, economic, social), and the life cycle stages (take, make, use, recover). The selection of the four life cycle stages applied in the study followed the common division applied in life cycle thinking. The only exception is the lack of a “disposal” stage, since it is outside the scope of the assessed indicators. The stage “Take” refers to the extraction of natural resources from the environment (energy and materials) (Lèbre et al., 2017). Circularity indicators directed toward the “Make” stage focus on the manufacturing process under the CE rationale (Zhang et al., 2020). The “Use” stage hints at the acceptance and behavioral shift of consumers to the circular context (Sadhukhan et al., 2020). Lastly, the life cycle stage “Recover” refers to CE practices promoting waste, materials, and energy recovery after their first use (Prieto-Sandoval et al., 2018). For the analysis regarding the connection of the indicators to the sustainability pillars, all those that strictly involved material and energy flows were considered to address the environmental dimension of sustainability. For an indicator to be considered economic, it had to clearly show an economic nature and purpose (i.e., monetary flows, material costs, etc.). Social indicators were those This study proposes a comprehensive analysis of circularity indicators directed toward resources, products, and companies. Nevertheless, it is important to state that strictly environmental, economic, social, or sustainability indicators are not within the scope of this study. Therefrom, we conducted a systematic literature review based on the Preferred Reporting Items for Systematic Reviews and meta-Analyses (PRISMA) guidelines (Moher et al., 2009), aiming at both peer-reviewed articles and gray literature (i.e., reports, commercial publications, tools present in websites, etc.). The literature review was carried out following a four-step procedure illustrated in Fig. 2. 2.1. Identification and screening Guided by the research questions presented in Section 1.5, a set of keywords encompassing both business- and CE-related terms were selected. The search was conducted through the combination of such keywords using Boolean operators (AND/OR). The search string applied to the scientific databases was: (("compan∗ ") OR ("business∗ ") OR ("entreprise∗ ") OR ("organi?ation∗ ") OR ("micro level")) AND (("circular indicator∗ ") OR ("circular index∗ ") OR ("circular metric∗ ") OR ("circular tool∗ ") OR ("circular economy measur∗ ") OR ("circular economy assess∗ ")) The keyword combination was applied to “title, abstract, and keywords” in the Scopus database and to “topic” in the Web of 457 C.T. de Oliveira, T.E.T. Dantas and S.R. Soares Sustainable Production and Consumption 26 (2021) 455–468 Fig. 2. Literature review procedure as per the PRISMA guidelines (Moher et al., 2009). Table 1 Literature search criteria. Inclusion criteria Exclusion criteria Circular economy-related Nano or micro level Peer-reviewed or gray literature (reports) Tools present in websites Papers that did not present circularity indicators Papers focused on meso and macro levels directed toward common social issues regarding the system operations (i.e., employment, safety, etc.) Once all nano- and micro-level circularity indicators were organized and screed based on the aforementioned criteria, the content was analyzed, and results were qualitatively and quantitatively extracted. The communication of the results follows in the next section. dicators over the years, as well as their geographical distribution (based on the first-author affiliation), type of publication (peerreviewed journals, gray literature, and dissertations), and the distribution of publications per journal. Circularity assessment is not only a matter of interest to academia but also a deep concern of companies and governments (Stahel, 2016). Therefore, it is natural that the development of circularity assessment tools is carried out by non-academic institutions as well. This fact becomes evident in this analysis, as 26% of all publications assessed were issued in reports, online tools, or on the websites of specific institutions (16 publications). However, the majority of the nano- and micro-level indicators gathered were published in peer-reviewed articles (44 publications). Additionally, one dissertation was assessed (Verbene, 2016), accounting for 2% of the total portfolio. The first publication evaluated dates from 2002 (Ritthoff et al., 2002), years before CE became a hot topic within the academic literature (Ghisellini et al., 2016). This publication was accepted by this study’s search criteria because many CE practices and strategies (i.e., recycling, composting, waste-to-energy, etc.) were already developed and vastly explored before being discussed under the CE 3. Results At the end of the literature review procedure illustrated in Fig. 2, the final portfolio was analyzed following the steps explained in Section 2. The results are shown and discussed in this section. The bibliometric results are presented next, followed by the analysis of the several circularity indicators found through the review procedure. 3.1. Bibliometric results The bibliometric analysis was carried out based on the distribution of papers related to nano- and micro-level circularity in458 C.T. de Oliveira, T.E.T. Dantas and S.R. Soares Sustainable Production and Consumption 26 (2021) 455–468 Fig. 3. – Publication distribution over the years. Table 2 Geographical distribution of publications. banner (Korhonen et al., 2018). In contrast, all other publications reviewed in this study present direct links to CE in their texts. The three highest-ranked years according to the number of CE-related articles issued were: 2017 (16 publications), 2018 (12 publications), and 2019 (9 publication). Although only eight papers were released in 2020 so far, it is expected that more papers follow throughout the year, as this analysis only accounts for articles published by the search date (August 2020). To illustrate the emerging development of the topic, the 61 publications with direct links to CE were published according to the chronological distribution shown in Fig. 3. Fig. 3 illustrates the scientific effort to better measure and understand circularity, a concept that has rapidly evolved in the last decade. As mentioned by Saidani et al. (2019), the development of circularity indicators has been strongly addressed by many researchers as an urgent scientific gap, with a plethora of indicators emerging swiftly ranging from the nano to the macro level. As previously stated, the product- and company-level circularity indicators released within this timeframe are assessed in this study and discussed in the further topics. Table 2 shows the geographical distribution of publications according to the first author affiliation. Although intercountry scientific collaboration is a reality in the current interconnected world, this analysis hints at the global trends in CE research. As one may observe in Table 2, most publications addressing nano- and micro-level circularity indicators may be traced to European countries. All gray literature publications have European origin, amplifying the expressive contribution of this region. The five highest-ranked origins of papers analyzed in this review are the United Kingdom, the Netherlands, Germany, France, and Italy. Moreover, the circularity assessment methods seem to be an emerging topic in the Latin American context, represented by publications from Brazil, Ecuador, and Colombia. Other regions (e.g., Asia) are less expressive in terms of the number of articles assessed. Four publications were marked as “n/a” since they represent indicators developed by European Union projects and cannot be traced to a specific country. These findings show the concern and interest of (mainly European) institutions and research bodies from different nations to develop comprehensive circularity indicators to assess and leverage this economic model shift. The 44 peer-reviewed articles analyzed in the study were issued over 15 different journals, the highest-ranked of which were the Journal of Cleaner Production (15 publications), Resources, Con- Country (first author affiliation) Number of publications United Kingdom Netherlands France Germany Italy Belgium Slovenia Spain Sweden United States of America Australia Austria Brazil China Colombia Denmark Ecuador Hungary Poland Portugal Singapore Switzerland n/a 9 7 6 6 5 4 2 2 2 2 1 1 1 1 1 1 1 1 1 1 1 1 4 servation and Recycling (8 publications), digital journal Sustainability (5 publications), and the Journal of Industrial Ecology (3 publications). The International Journal of Production Research and the International Journal of Sustainable Engineering showcased 2 publications each. The nine remaining journals accounted for a single publication analyzed per each (for more information, please refer to the Supplementary Material). It can be noticed that the articles are spread over a variety of engineering and sustainability-related journals. These findings show how circularity indicators have been developed mostly by the scientific niches engaged in the resource efficiency and sustainability agenda, contributing both to general discussions around the quantification of CE-related processes and as an argument in sector-specific topics. 3.2. Circularity indicator analysis A total of 58 nano- and micro-level circularity indicators were assembled through the literature review. Table 3 shows the full list 459 C.T. de Oliveira, T.E.T. Dantas and S.R. Soares Sustainable Production and Consumption 26 (2021) 455–468 Table 3 Nano- and micro-level circularity indicators. # Indicator Circularity level 1 2 Global Resource Indicator (GRI) BIM-based Whole-life Performance Estimator (BWPE) Nano Nano 3 Nano 5 Product Recovery Multi-Criteria Decision Tool (PR-MCDT) Multi-Criteria Evaluation Method of Product-Level Circularity Strategies (MCEM-PLCS) Resource Efficiency Assessment of Products (REAPro) Nano 6 Sustainable Circular Index (SCI) Micro 7 Circular Building Assessment Prototype (CBA) Nano 8 Micro 9 10 Material Efficiency in Supply Chains Spreadsheets (MESCS) Circular Economy Indicator Prototype (CEIP) Circular Gap (CG) 11 Product Circularity Improvement Program (PCIP) Nano Nano and Micro Nano 12 13 C2C Indicators Circularity Index (CI) Nano Nano 14 15 Circular Economy Index (CEI) Circularity Check (Check) 16 Material Circularity Indicator (MCI) 17 Circulytics (CYT) Nano Nano and Micro Nano and Micro Micro 18 Circular Economy Toolkit (CET) Nano 19 EoL indices (EoLi) Nano 20 21 22 Longevity and Circularity (L&C) Circular Economic Value (CEV) Resource Duration Indicator (RDI) Nano Nano Nano 23 Economic-environmental Indicators (EEI) Nano 24 Circularity Measurement Toolkit (CMT) Micro 25 Circularity Assessment Model (CAM) Micro 26 Set of Indicators to Assess Sustainability (SIAS) Micro 27 28 29 Circular Economy Performance Indicator (CPI) Circular Economy Benefit Indicators (CEBI) End of Life Best Practice Indicators (BPI) Nano Nano Nano 30 Closed Loop Calculator (CLC) Nano 31 Mine site MFA Indicator (MI) Micro 32 End-of-Life Index Nano 33 34 35 Evaluation Index System of CE for PCFs (CE-PCF) Product-Level Circularity Metric (PCM) Input-Output Balance Sheet (IOBS) Micro Nano Nano 36 Sustainability Performance Indicators (SPI) Nano 51 Product Recycling Desirability Index (PRDI) Nano 37 38 Multidimensional Indicator Set (MIS) Assessment of Circular Economy Strategies at the Product Level (APL) Circular Economy Measurement Scale (CEMS) Reuse Potential Indicator (RPI) Nano Nano 4 39 40 41 42 Environmental Sustainability of Food Packaging indicators (FPI) Circ(T) Sustainability pillars Environmental and social Environmental and Economic Environmental, Economic, and Social Environmental, Economic, and Social Environmental Nano Environmental, Economic, and Social Environmental and Economic Environmental Life Cycle Stages Authors Full life cycle Full life cycle Adibi et al. (2017) Akanbi et al. (2018) Recover Alamerew and Brissaud (2019) Alamerew et al. (2020) Recover Recover Make, Use, Recover Full life cycle Ardente and Mathieux (2014) Azevedo et al. (2017) BAMB (2020) Make Braun et al. (2018) Full life cycle Full life cycle Cayzer et al. (2017) Circle Economy (2018) Make, Use, Recover Full life cycle Make, Use, Recover Recover Full life cycle Circularity IQ and KPMG (2020) C2C (2014) Cullen (2017) Full life cycle EMF and Granta (2015) Full life cycle EMF (2020) Full life cycle Evans and Bocken (2013) Recover Favi et al. (2017) Use, Recover Make, Use Use, Recover Full life cycle Figge et al. (2018) Fogarassy et al. (2017) FranklinJohnson et al. (2016) Fregonara et al. (2017) Full life cycle Garza-Reyes et al. (2019) Full life cycle Giacomelli et al. (2018) Recover Golinska et al. (2015) Recover Recover Recover Full life cycle Huysman et al. (2017) Huysveld et al. (2019) Jiménez-Rivero and García-Navarro (2016) Kingfisher (2014) Full life cycle Lèbre et al. (2017) Make, Recover Lee et al. (2014) Full life cycle Recover Full life cycle Liang et al. (2018) Linder et al. (2017) Capellini (2017) Recover Mesa et al. (2018) Recover Recover Full life cycle Mohamed Sultan et al. (2017) Nelen et al. (2014) Niero and Kalbar (2019) Make, Recover Recover Nuñez-Cacho et al. (2018) Park & Chertow (2014) Nano Environmental Environmental and Economic Environmental Full life cycle Pauer et al. (2019) Nano Environmental Full life cycle Pauliuk et al. (2017) Environmental Environmental and Economic Environmental and Economic Environmental and Social Environmental Environmental Environmental and Economic Environmental Environmental and Economic Environmental and Economic Environmental and Economic Environmental Environmental Environmental Environmental and Economic Environmental and Economic Environmental and Economic Environmental, Economic, and Social Environmental Environmental Environmental, Economic, and Social Environmental and Economic Environmental and Economic Environmental and Economic Environmental Economic Environmental and Economic Environmental, Economic, and Social Environmental and Economic Environmental Environmental Micro Nano Di Maio and Rem (2015) Ecopreneur (2019) (continued on next page) 460 C.T. de Oliveira, T.E.T. Dantas and S.R. Soares Sustainable Production and Consumption 26 (2021) 455–468 Table 3 (continued) # Indicator Circularity level Sustainability pillars Life Cycle Stages Authors 43 Nano and Micro Nano Environmental, Economic, and Social Environmental Full life cycle Pauliuk (2018) Full life cycle Rendemint (2016) 45 Systems Indicators for Circular Economy Dashboard (SICED) PRP Circular e-Procurement Tool (PRP) and The R ReNtry -module Circular Pathfinder (CP) Micro Make ResCoM (2017) 46 Circularity Calculator (CC) Nano Make, Recover ResCoM (2017) 47 Material Input Per Service Delivered (MIPS) Full life cycle Ritthoff et al. (2002) 48 Full life cycle Rossi et al. (2020) 49 Circular Business Model Set of Indicators based on Sustainability (CBM-IS) Improved Water Circularity Index (WCI) Nano and Micro Nano and Micro Micro Environmental and Economic Environmental and Economic Environmental Make, Recover Sartal et al. (2020) 50 Circularity of Material Quality (QC) Nano Steinmann et al. (2019) 52 Ease of Disassembly Metric (eDiM) Nano Take, Make, Recover Recover 53 Economic-Environmental Remanufacturing (EER) Nano 54 Recycling Indices (RIs) for the CE Nano 55 Expended Zero Waste Practice Model (ZWP) Micro 56 Building Circularity Indicators (BCI) Nano 57 Circularity Transition Indicators (CTI) Micro 58 Material and Energy Circularity Indicators (MECI) Micro 44 Environmental, Economic, and Social Environmental and Economic Environmental Environmental and Economic Environmental and Economic Environmental Environmental, Economic, and Social Environmental and Economic Environmental and Economic Environmental of indicators compiled, along with their respective circularity level, connection to the sustainability pillars, and life cycle stages. As previously stated, we identify circularity indicators as analytical tools focused on measuring the degree of association of a system (or part of one) to practices and strategies applied to develop a CE further. However, the majority of indicators assessed in this study combine different metrics to deliver simplified results. In other terms, they apply a group of methods and calculations to measure a system’s circularity under their premises. From the 58 indicators discussed in the study, only 9 (16%) rely on a single indicator in their procedure. Most of the indicators shown in Table 3 (48 indicators, 84%) depend on a set of analytical tools to deliver their results. For more information on whether a specific indicator presented in the aforementioned table relies on a single indicator or a group thereof, please refer to the Supplementary Material. Recover Make, Recover Make, Use, Recover Make, Use, Recover Full life cycle Take, Make, Recover Vanegas et al. (2018) van Loon and van Wassenhove (2018) Van Schaik and Reuter (2016) Veleva et al. (2017) Verbene (2016) WBCSD (2020) Zore et al. (2018) pillar. The remaining 24 indicators (circa 39%) aim to assess circularity through the lens of a single sustainability dimension. The largest group of assessed indicators, composed by 23 indicators (40% of the portfolio) provide information solely on the environmental aspects of circular systems. One indicator, representing less than 2% of the portfolio, delivered circularity assessments strictly linked to the economic pillar. No circularity indicator showed an exclusive focus on the social impacts of a CE. A total of 24 indicators (41%) had simultaneous links to the economic and environmental pillars. Only two indicators (3.5%) had the purpose of assessing the environmental and social aspects connected to circularity at the same time. The remaining eight indicators (14%) aimed to deliver a circularity assessment guided by the triple bottom line model and covered all the sustainability pillars in their methodologies. If summed up, the environmental pillar is the one that attracts the most attention from scholars and organizations, being present in 57 of the indicators analyzed (98%). The economic pillar follows in second, having been evaluated by 33 indicators (57%). The social dimension, although only considered in combination with other pillars, is shown in 10 circularity indicators (17%). 3.2.1. Levels of circularity According to the findings shown in Table 3, most indicators that fit the search criteria applied in this review were developed to assess product-level circularity. Of the indicators included in the portfolio, 66% are directed toward energy and material flows within the nano level of circularity (38 indicators). Micro-level indicators (i.e., company-level circularity) accounted for 24% of the analyzed metrics (14 indicators). A third cluster constituted of indicators that may be used to assess both nano- and micro-level circularity was established and accounts for 6 indicators (10%). For further information about the indicators analyzed and a summary that assists in identifying the targeted circularity level of each indicator, please refer to the Supplementary Material. 3.2.3. Life cycle stages The explored nano- and micro-level indicators were analyzed according to the life cycle stages they cover. Fig. 5 shows the distribution of indicators per life cycle stage. Out of the 58 indicators, 25 (43%) comprise all stages in their scopes (referred to here as “Full life cycle”). The majority of indicators equipped to deliver full life cycle evaluations (13 indicators, 22%) target product-level circularity. Only 6 metrics (10%) focus on companies. The remaining 6 indicators (10%) connected to this group may be used to examine both the nano and micro levels. The “Take” life cycle stage is the least assessed by the indicators included in the investigated portfolio. Only two indicators (3%), one from each circularity level, partially address this stage. All other 3.2.2. Sustainability pillars The several indicators examined in this study have diverse relations to the pillars of sustainability. Fig. 4 shows how each indicator is connected to particular pillars. Approximately 59% of the portfolio (34 indicators) deliver results linked to more than one 461 C.T. de Oliveira, T.E.T. Dantas and S.R. Soares Sustainable Production and Consumption 26 (2021) 455–468 Fig. 4. Distribution of indicators per pillars of sustainability. indicators that cover the “Take” stage are more holistic methods grouped under “Full life cycle”. A group of 12 indicators targets manufacturing processes and product design (“Make” life cycle stage) along with other life cycle stages (21%). Only 3% of the total portfolio (2 indicators) are exclusively related to the “Make” stage and focus on company-level circularity assessment. No nano level indicator exclusively addressed the “Make” stage. The “Use” stage is directly considered in 8 indicators (14%), among which only 2 are oriented toward the micro level of circularity. All 6 other indicators were developed to assess the “Use” stage of a product along with other life cycle stages. The “Recover” stage, the main characteristic of circular systems related to closed loops and resource recirculation, was the most addressed by the reviewed indicators, of which 17 are strictly dedicated to energy or material recovery strategies (15 nano, 2 micro), accounting for 29% of the total. If the indicators that deal with other life cycle stages combined with recovery strategies are considered, 30 indicators (52%) may be linked to this stage (excluding the Full life cycle indicators). 4.1. Why divide circular economy levels further into nano and micro levels? CE is linked to the efficient use of resources. In this new rationale, systems are designed to circulate resources as much and for as long as possible. When Saidani et al. (2017) coined the term “nano level”, they stated that the micro-level indicators did not encompass the complexity of a CE and the EoL possibilities. Additionally, Rincón-Moreno et al. (2021) point out that the definitions of tools and criteria for product-level circularity measurements are still lacking. This view is also present in the work of Cayzer et al. (2017) and Ghisellini et al. (2016), who note that many of the circularity indicators shown in the literature are mainly directed toward companies, industrial parks, regions, or nations. In contrast, the results illustrated by Fig. 5 point to the growing trend in product-level circularity indicators. However, the conceptual background and common view of a CE still does not fully acknowledge the differences between product-level and companylevel circularity. The findings shown in Section 3.2.1 suggest that the current micro-level views are filled with indicators aimed at the detailed analysis of specific products. Indicators such as PCIP, L&C, and RDI differ considerably from CEMS, MI, SIAS in terms of the inputs needed to perform their assessments. That discrepancy is grounded in the clear distinctions between the scopes investigated. The first group (nano indicators) rely on material and component specificities (Figge et al., 2018; Franklin-Johnson et al., 2016) and deliver results aimed at improving product quality, design, and resource recovery (Mestre and Cooper, 2017; Mohamed Sultan et al., 2017; Steinmann et al., 2019). On the other hand, the second group (company-level circularity indicators) centers on environ- 4. Discussion This section is divided into three sub-sections and aims to answer the research questions introduced in Section 1.3. First, we discussed the distinction between nano and micro-level circularity indicators. Following, we analyzed the links between circularity indicators and the pillars of sustainability. Lastly, we discussed the results regarding the life cycle stages covered by the indicators of the examined portfolio. 462 C.T. de Oliveira, T.E.T. Dantas and S.R. Soares Sustainable Production and Consumption 26 (2021) 455–468 Fig. 5. Distribution of indicators per level and life cycle stage. 463 C.T. de Oliveira, T.E.T. Dantas and S.R. Soares Sustainable Production and Consumption 26 (2021) 455–468 mental benefits and value generation by identifying proactive and preventive waste management strategies (Lèbre et al., 2017) while allowing direct measurements of the importance of a CE for companies (Nuñez-Cacho et al., 2018). This scope difference may be noticed across this study’s portfolio and directly influences the goals, intended public, and result formats of each indicator. Under such circumstances, we argue that the further division between these circularity levels is crucial at the current development pace of CE-related studies. As pointed out by Lindgreen et al. (2020) while reviewing micro-level circularity indicators, grouping all industrial activities under the same umbrella to evaluate their circularity may be overly general and extensive. In this regard, an additional division of the micro level would reduce confusion concerning a far too broad view of company-level circularity, which, under the current concept, embraces all activities and outputs of businesses. This approach not only better portraits the different attention given to products and components (Mestre and Cooper, 2017; Vanegas et al., 2018) by companies (Azevedo et al., 2017; Blomsma et al., 2019) but also enables a more detailed analysis of specific processes that are parts of circular business models. Therefore, by putting product-level circularity under the spotlight, decision-makers may identify the specificities of different goods developed by the same company, which could, for example, highlight the outcomes from strategical and innovative changes to product design (Cayzer et al., 2017; Favi et al., 2017). It is important to stress that these conceptual changes would not exert any changes to micro-level circularity, as the low levels are intrinsically present in the uppers circularity levels (Huamao and Fengqi, 2007). Lastly, this division between nano and micro-level circularity would also assist in an organizational matter by providing stricter partitioning of the abundant circularity indicators. Although it entails a more simplistic outcome from this approach, decisionmakers and scholars could benefit from more direct and intuitive compartmentalization during the indicator selection process, sometimes clouded by the misconceptions regarding the different approaches aimed at circular products and companies. 2016), translated here as the low recurrence of circularity indicators linked to this pillar. The following topics offer a deeper analysis of the interface between circularity indicators and each sustainability pillar. Additionally, the last topic provides insights regarding the indicators equipped to deliver results according to all three sustainability pillars. 4.2.1. Environmental pillar The environmental pillar was covered by the majority of the indicators assessed. It should be noted that our analysis was based on indicators that handle environmental aspects (i.e., materials, components, energy, water, etc.). Hence, indicators that highlight the reinsertion of materials or components into the system were grouped into the environmental pillar. Within these circumstances, we corroborate Corona et al. (2019) by reaffirming that the majority of circularity indicators (i.e., REAPro, MESCS, CEI, CEV, etc.) focus on material recirculation and resource efficiency, not being capable of portraying the complex reality and possible trade-offs of circular systems. The lack of information regarding the calculation processes of certain indicators is also alarming. For example, according to Kristensen and Mosgaard (2020), EOLi does not demonstrate how the environmental impact and amount of emissions from recycling and remanufacturing are considered. Only a few indicators are equipped to demonstrate the actual environmental performance of circular systems (i.e., PR-MCDT, EZWP, APL). Harris et al. (2021) describe this shortcoming as searching for “circularity for circularity’s sake”. In alignment with the aforementioned authors and corroborating Corona et al. (2019) and Linder et al. (2017), we highlight the excessive focus given to resource recirculation in contrast to the assessment of environmental impacts by the circularity indicators. Although material and resource reinsertion may be important inputs for decision-makers involved in circular business models (Manninen et al., 2018), to bridge this gap, we support the use of robust environmental accounting methods for the evaluation of circular systems in parallel with the use of circularity indicators. Examples of advised methodologies are Life Cycle Assessment (LCA) (de Souza Junior et al., 2020), Material Flow Analysis (Haas et al., 2015), and Emergy Analysis (Santagata et al., 2020). 4.2. Can the three pillars of sustainability be assessed through circularity indicators? Indicators are developed to simplify information and provide performance improvement tools (Saidani et al., 2019). Several authors indicate that circular practices and potential loop-closing have to be assessed through a multilateral approach to avoid tradeoffs (Geissdoerfer et al., 2017; Inghels et al., 2019) and ultimately promote the comprehensive understanding of the system repercussions. This claim is also supported by the increasing attention given to the links between a CE and the Sustainable Development Goals (SDGs) (Dantas et al., 2021). Different authors have stipulated sets of main SDGs covered by a CE (Fassio and Tecco, 2019; Rodriguez-Anton et al., 2019; Schroeder et al., 2019). Although the lists of targeted SDGs vary according to each publication, they all point to CE being a valuable strategy to contribute to the SDGs. However, that relation must be supported by quantitative indicators to assist decision-making processes (Elia et al., 2017). Therefore, a deeper understanding of the links between circularity indicators and sustainability pillars is beneficial not only for CE but also for creating assertive pathways towards the SDGs. The findings illustrated by Fig. 4 indicate that the current circularity indicators have a strong relation to environmental aspects, followed by the economic assessments and the societal traits of the analyzed systems. Such results corroborate the view that a CE is driven by markets and governments willing to transition the current economy to a less environmentally impactful yet economically profitable system (Ghosh and Agamuthu, 2018). However, the social side of a CE still receives insufficient attention (Ghisellini et al., 4.2.2. Economic pillar Although mainly considered in combination with the environmental dimension, the economic pillar was the second most covered sustainability pillar. These indicators vastly tackled the resource fluxes in terms of their monetary value. The only indicator strictly related to the economic dimensions of sustainability was PCM. Its authors recommend using the recirculated economic value to total product value ratio as a circularity metric, using value chain costs as estimators (Linder et al., 2017). This procedure may initially aid stakeholders in developing and adjusting the strategies of new circular business models (Ghisellini et al., 2016); however, it still lacks the comprehensiveness needed to assess circular systems (Geissdoerfer et al., 2017). The common combination of economic indicators with environmental and social approaches suggests an alternative to such a limitation. For example, indicators such as EER, eDiM, PRDI, and RPI were developed to translate the economic gains of material recirculation through CE practices like recycling and remanufacturing. On the other hand, CC, EOLi, MI, and other indicators focus on the price of products or the CE strategy applied. Either way, the economic evaluation of circular systems lies at the core of the transition to a CE since businesses unchangeably hold profit as their main goal. Based on our analysis and in alignment with the work of Lindgreen et al. (2020) and Niero and Kalbar (2019), we argue 464 C.T. de Oliveira, T.E.T. Dantas and S.R. Soares Sustainable Production and Consumption 26 (2021) 455–468 that economic analyses are of imperative importance to a CE. However, they do not cover the sustainability performance of the circular system. A superior analysis could provide results based on the integration of economic circularity indicators and methods capable of addressing the environmental and social traits of a system. indicators only partially cover the three sustainability pillars, we recommend that decision-makers analyze the vast list of available circularity indicators carefully and either be mindful of the fragilities of each approach or combine them with other procedures to reach more substantial and detailed results. It is important to underline that each indicator is created to translate information regarding specific circumstances (Patterson et al., 2017). However, since the scope of most of our portfolio was flexible in terms of the industrial sector they could be applied to (for more information, please refer to the Supplementary Material), we build on the views of Niero and Kalbar (2019) and argue that the use of a robust sustainabilitydriven methodology such as the Life Cycle Sustainability Assessment (LCSA), in parallel with circularity indicators based on material recirculation and resource efficiency, would prove to be a more comprehensive strategy. This approach would not only enable full life cycle evaluations but also use LCA to point the environmental impacts of CE strategies, address the societal issues through a refined S-LCA framework, and measure the prices, costs, and further economic repercussions through Life Cycle Costing. Albeit timeconsuming and highly dependent on technical expertise, we believe this method, when combined with circularity indicators, may bring optimized results compared to the procedure followed by the eight indicators in the center of Fig. 4. 4.2.3. Social pillar The social dimension is the least addressed by the indicators in our portfolio. As shown in Fig. 4, no indicator was particularly developed aiming at this pillar. The societal repercussions of circular systems were only addressed in combination with economic and environmental indicators. These results endorse the work by (Lee, 2020), which highlights the scarcity of social performance measurement systems, and the study by PadillaRivera et al. (2020), which states that there is still no consensus on how to analyze the social issues related to circular systems comprehensively. Furthermore, our review also corroborates these authors regarding the most common social aspects analyzed (i.e., employment, health and safety, wage). The clear focus on the economic and environmental features of a CE demonstrates that the developed indicators have not yet reached a consensus regarding the social analysis of circular systems (Blomsma and Brennan, 2017; Kristensen and Mosgaard, 2020). Padilla-Rivera et al. (2020) point to the use of Social Life Cycle Assessment (S-LCA) as a way to bridge this gap. Nevertheless, S-LCA is still in its developing phase, with many methodological difficulties still to be solved by scholars and practitioners (Petti et al., 2018). Thus, while consensus has not yet been found, the inclusion of social aspects in circularity indicators is a welcoming approach to this scientific field. Even if the social pillar is often not the main target, every product system invariably interacts with it (Reinales et al., 2020), and, therefore, it should also be accounted for in assessments concerning systemic shifts such as the ones proposed by a CE. 4.3. What are the life cycle stages covered by the nano- and micro-level indicators analyzed? Based on our portfolio, the majority of indicators highlight the life cycle stage “Recover”, which centers on EoL strategies. Proportionally, nano-level indicators focus more on EoL practices than micro-level indicators, as they aim to facilitate an effective flow of materials while ensuring that their highest value is extracted throughout the extension of product lifetimes (Alamerew and Brissaud, 2019). Against this background, the investigated nano indicators are directed toward recycling, refurbishment, reconditioning, repurposing, reuse, and other circular strategies. However, their main focus is on resource recirculation, whereas not many indicators provide further information regarding the impacts and repercussions of such practices. These findings are in alignment with work by Corona et al. (2019) and Linder et al. (2017), who previously identified the same tendency in groups of circularity indicators. These results also confirm that the concept of nano circularity indicators is not yet well defined (Rincón-Moreno et al., 2021). The nano-level denotation introduced by Saidani et al. (2017) describes it as “the circularity of products, components, and materials […] throughout their entire lifecycle”, hinting at the novelty of this concept. We argue that the division between nano- and micro-level indicators would benefit this scientific area more by further exposing different trends related to products and companies. Nonetheless, our analysis also shows that attention given to product level circularity does not encompass the entire product life cycle, focusing instead on specific life cycle stages. Most micro-level indicators focus on the “Make” life cycle stage. Although companies do not work solely on the production of goods, our results stress the importance given to this part of the supply chains in the making of circularity indicators. As microlevel circularity assessment intrinsically focuses on all stages and procedures of the production processes (Lindgreen et al., 2020), it also entails phases before the physical manufacturing of goods. As a product’s design directly influences the rest of its life cycle (Cayzer et al., 2017; Mestre and Cooper, 2017), we propose that micro-level circularity indicators may be used to analyze and compare the circularity scores of different design options. Therefore, the high frequency of the “Make” life cycle stage in our results rep- 4.2.4. Circularity assessments based on the three sustainability pillars Only eight indicators provided a procedure built over the three sustainability pillars. Despite the initial similarity, the approaches differ considerably. Two indicators are developed based on life cycle and multi-criteria decision tools (PR-MCDT and MCEM-PLCS) and apply indicators related to the impact categories used in LCA. SCI follows the Global Report Initiative indicators. SPI focuses on material flows, reusability, reconfiguration, and functional performance. BPI, CBM-IS, SIAS, ZWP are formed by a group of indicators proposed based on literature reviews, assumptions, and onsite monitoring. These differences illustrate the plurality found in circularity indicators, even in a smaller group of sustainabilityfocused indicators. Some of them were developed to assist in specific sectors (BPI, ZWP), some are holistic enough to support general assessments (PR-MCDT, MCEM-PLCS), and others, as pointed out by Veleva et al. (2017), provide a starting point for companies to develop their industry/company-specific measurement strategies. The variety of approaches and “sub-indicators” found for these indicators point to the divergences found in the crossroads between sustainability and a CE (Geissdoerfer et al., 2017; Rossi et al., 2020). According to the aforementioned arguments, we conclude that the circularity indicators that form our portfolio lack robustness to provide sustainability performance assessments comprehensively. Although a small group of indicators is equipped to analyze all three pillars, they normally focus on specific pillars or are not structured around solid scientific methodologies. Two exceptions may be made: PR-MCDT and MCEM-PLCS (Alamerew et al., 2020; Alamerew and Brissaud, 2019), which are developed through the application of combined LCA and multi-criteria tools, providing strong scientific foundations. Nevertheless, as the vast majority of 465 C.T. de Oliveira, T.E.T. Dantas and S.R. Soares Sustainable Production and Consumption 26 (2021) 455–468 resents a need for more comprehensive indicators to understand the circularity trade-offs that such changes in the design and production phases might result in. For micro-level indicators, EoL strategies (“Recover”) appear in the same number of indicators as life cycle stage “Make”. The indicators include several EoL approaches such as reuse/resell (e.g., Veleva et al., 2017), repair (e.g., Nuñez-Cacho et al., 2018), remanufacture (e.g., Golinska et al., 2015), and recycle (e.g., Giacomelli et al., 2018). We also identified that “Recovery” is a result of waste legislation in several countries. Such legal provisions indicate that companies have shared responsibility for product life cycles (de Oliveira et al., 2019) or even extended the responsibility (Alamerew and Brissaud, 2019), rendering companies responsible for monitoring their post-consumer products. It is also important to stress that waste management hierarchy directives in Europe (European Parliament, 2008), for example, are older than CE action plans (EC, 2015), hinting at the potential use of more indicators in the life cycle stage “Recover” than in “Take” and “Use”. Each indicator was established to consider specific aspects of circular systems or even specific practices, such as eDiM (Venegas et al., 2018) and RPI (Park and Chertow, 2014). By defining proper indicators and assessing manufacturing processes, companies can aim at developing circular products through CE practices (Niero and Kalbar, 2019), redesign goods to favor EoL and closed loops (Favi et al., 2017), or even change perspectives and seek different ways to solve customer needs, such as moving to “Product as a Service” models or digitalizing services (LüdekeFreund et al., 2019). Therefore, for their successful implementation, one has to consider the particularities and disadvantages of each approach. The nano-level indicators are mainly directed toward material recovery and full life cycle strategies. Such findings indicate the focus given by corporations and scholars to practices aiming at closing loops and assessing the impacts of a product’s manufacturing through the life cycle perspective. The micro indicators also show a predisposition to evaluate the overall circularity of a company through this same viewpoint. However, the nano- and micro-level indicators focused on “Take” and “Use” stages are spread throughout other alternatives. For example, only one nano circularity indicator (QC) focuses on the extraction of materials (Take) while still also tacking the "Make" and "Recover" stages. Considering all 58 indicators from the portfolio, our findings show that almost half of them promote the circularity assessment throughout the life cycle (for further information, please refer to the Supplementary Material). These results show the concern of companies and scholars in tracking and evaluating the systemic repercussions of manufacturing processes, which indicates an attempt to move away from a productive-directed rationale towards systematic thinking regarding EoL options and resource employment. This research has valuable implications for companies, policymakers, industry professionals, and academic researchers. We innovate by investigating and discussing nano-level circularity indicators. Therefore, we contribute to corporative circularity assessments by further dividing into nano- and micro-levels, aiming to i) avoid confusion regarding an overly broad view of the microlevel; ii) separate product-level circularity from the overall scores of companies; iii) organize a large number of circularity indicators in a stricter division to aid decision-makers. Our findings show that the division between nano and microlevel indicators ensures that circularity assessments provide a standardized language to simplify the understanding and exchange of information, thus facilitating the transition of companies to the circular rationale. Additionally, we argue the investigated indicators assess sustainability performance superficially, mainly due to their limited scopes. We recommend the use of consolidated methodologies such as LCSA in parallel with circularity indicators proven to deliver context-specific results (e.g., recycling or refurbishment indices, indicators directed to particular sectors) to deliver robust and comprehensive sustainability assessment in the CE context. From a general perspective, results show that most indicators in our portfolio provide “Full life cycle” circularity assessments. Nano-level indicators focus on material and resource recovery strategies such as recycling, refurbishing, reconditioning, repurposing, reusing, etc. In turn, company-level circularity indicators center on manufacturing processes (i.e., design strategies, resource implementation). These findings highlight the general efforts in developing methodologies to quantify the move from a product-oriented perspective to circular systems. The main limitations related to this study concern: i) the lack of a classification of circularity indicator implementation feasibility; ii) the exclusion of structured methodologies (e.g., LCA) as circularity indicators; iii) the sometimes clouded explanations regarding the indicator methodologies (especially from gray literature), which hampered the analysis regarding the sustainability pillars and life cycle stages covered by each indicator assessed. Future research may further investigate the differences between nano- and micro-level circularity indicators based on views presented in this study or review meso– and macro-level circularity indicators. Moreover, future works could also analyze the 58 circularity indicators in parallel with consolidated methodologies (e.g., LCSA, LCA) to overcome barriers regarding combined circularity and sustainability performance assessments. We believe that more empirical research is necessary to examine and compare the circularity indicators from our portfolio, classifying them by implementation practicability and integrating them. Thus, future works could also focus on creating specific frameworks for different sectors with the standardization of indicators and data, through which companies may develop and compare their results and CE strategies. 5. Conclusion The understanding of the CE background is vital for creating a holistic strategy to implement circularity indicators successfully. However, research shows that they often cover large amounts of information, which results in superficial circularity assessments through uncomprehensive indicators. Against this backdrop, the primary aim of this research was to perform a systematic literature review focused on CE indicators. We intended to develop a list of nano- and micro-level CE indicators to assist decision-makers based on the three dimensions of sustainability and the four life cycle stages. To attain this purpose, we distinguished nano- and micro-level circularity indicators, the connection that such indicators have with the sustainability pillars, and the life cycle stages they are inserted in. Declaration of Competing Interest The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. Acknowledgments The authors would like to acknowledge the financial support of the Brazilian Coordination for the Improvement of Higher Education Personnel (CAPES). We also thank the anonymous reviewers for their insightful comments. 466 C.T. de Oliveira, T.E.T. Dantas and S.R. Soares Sustainable Production and Consumption 26 (2021) 455–468 Supplementary materials Ellen Macarthur Foundation (EMF), 2020. Circulytics - measuring circularity. Available at: https://www.ellenmacarthurfoundation.org/resources/apply/ circulytics- measuring- circularity . Acessed in August/2020. European Commission (EC), 2015. Closing the loop–an EU action plan for the circular economy. European Parliament, 2008. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives. Off. J. Eur. Union L 312 (3). Evans, J. and Bocken, N., 2013. Circular economy toolkit. Available at: http://www. circulareconomytoolkit.com/ . Acessed in August/2020. Fassio, F., Tecco, N., 2019. Circular economy for food: a systemic interpretation of 40 case histories in the food system in their relationships with SDGs. Systems 7, 43. doi:10.3390/systems7030043. Favi, C., Germani, M., Luzi, A., Mandolini, M., Marconi, M., 2017. A design for EoL approach and metrics to favour closed-loop scenarios for products. Int. J. Sustainable Eng. 10, 136–146. doi:10.1080/19397038.2016.1270369. Figge, F., Thorpe, A.S., Givry, P., Canning, L., Franklin-Johnson, E., 2018. Longevity and Circularity as Indicators of Eco-Efficient Resource Use in the Circular Economy. Ecol. Econ. 150, 297–306. doi:10.1016/j.ecolecon.2018.04.030. Fogarassy, C., Horvath, B., Kovacs, A., Szoke, L., Takacs-Gyorgy, K., 2017. A circular evaluation tool for sustainable event management—an olympic case study. Acta Polytechnica Hungarica 14, 161–177. Franklin-Johnson, E., Figge, F., Canning, L., 2016. Resource duration as a managerial indicator for Circular Economy performance. J. Clean. Prod. 133, 589–598. doi:10.1016/j.jclepro.2016.05.023. Fregonara, E., Giordano, R., Ferrando, D.G., Pattono, S., 2017. Economicenvironmental indicators to support investment decisions: a focus on the buildings’ end-of-life stage. Buildings 7, 65. doi:10.3390/buildings7030065. Garza-Reyes, J.A., Valls, A.S., Nadeem, S.P., Anosike, A., Kumar, V., 2019. A circularity measurement toolkit for manufacturing SMEs. Int. J. Prod. Res. 57, 7319–7343. doi:10.1080/00207543.2018.1559961. Geissdoerfer, M., Savaget, P., Bocken, N.M.P., Hultink, E.J., 2017. The Circular Economy – A new sustainability paradigm. J. Clean. Prod. 143, 757–768. doi:10.1016/ j.jclepro.2016.12.048. Ghisellini, P., Cialani, C., Ulgiati, S., 2016. A review on circular economy: the expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 114, 11–32. doi:10.1016/j.jclepro.2015.09.007. Ghosh, S.K., Agamuthu, P., 2018. Circular economy: the way forward. Waste Manage. Res. doi:10.1177/0734242X18778444. Giacomelli, J., Kozamernick, D., Lah, P., 2018. Evaluating and monitoring circularity. Macro Regul. Environ. EU Slovenia. Golinska, P., Kosacka, M., Mierzwiak, R., Werner-Lewandowska, K., 2015. Grey Decision Making as a tool for the classification of the sustainability level of remanufacturing companies. J. Clean. Prod. 105, 28–40. doi:10.1016/j.jclepro.2014.11.040. Haas, W., Krausmann, F., Wiedenhofer, D., Heinz, M., 2015. How circular is the global economy?: an assessment of material flows, waste production, and recycling in the european union and the world in 2005. J. Ind. Ecol. 19, 765–777. doi:10.1111/ jiec.12244. Harris, S., Martin, M., Diener, D., 2021. Circularity for circularity’s sake? scoping review of assessment methods for environmental performance in the circular economy. Sustain. Prod. Consump. 26, 172–186. 10.1016/j.spc.2020.09.018. Howard, M., Hopkinson, P., Miemczyk, J., 2019. The regenerative supply chain: a framework for developing circular economy indicators. Int. J. Prod. Res. 57, 7300–7318. doi:10.1080/00207543.2018.1524166. Huamao, X., Fengqi, W., 2007. Circular economy development mode based on systems theory. Chin. J. Popul. Resourc. Environ. 4, 92–96. doi:10.1080/10042857. 2007.10677537. Huysman, S., De Schaepmeester, J., Ragaert, K., Dewulf, J., De Meester, S., 2017. Performance indicators for a circular economy: a case study on post-industrial plastic waste. Resour. Conserv. Recycl. 120, 46–54. doi:10.1016/j.resconrec.2017. 01.013. Huysveld, S., Hubo, S., Ragaert, K., Dewulf, J., 2019. Advancing circular economy benefit indicators and application on open-loop recycling of mixed and contaminated plastic waste fractions. J. Clean. Prod. 211, 1–13. doi:10.1016/j.jclepro.2018. 11.110. Inghels, D., Dullaert, W., Aghezzaf, E.-.H., Heijungs, R., 2019. Towards optimal tradeoffs between material and energy recovery for green waste. Waste Manage. (Oxford) 93, 100–111. doi:10.1016/j.wasman.2019.05.023. Jabbour, C.J.C., Jabbour, A.B.L., de, S., Sarkis, J., Filho, M.G., 2019. Unlocking the circular economy through new business models based on large-scale data: an integrative framework and research agenda. Technol. Forecast. Soc. Change 144, 546–552. doi:10.1016/j.techfore.2017.09.010. Jiménez-Rivero, A., García-Navarro, J., 2016. Indicators to measure the management performance of end-of-life gypsum: from deconstruction to production of recycled gypsum. Waste Biomass Valorization 7, 913–927. doi:10.1007/ s12649- 016- 9561- x. Kirchherr, J., Reike, D., Hekkert, M., 2017. Conceptualizing the circular economy: an analysis of 114 definitions. Resour. Conserv. Recycl. 127, 221–232. doi:10.1016/j. resconrec.2017.09.005. Kingfisher, 2014. The business opportunity of closed loop innovation: closed loop innovation booklet. Korhonen, J., Honkasalo, A., Seppälä, J., 2018. Circular economy: the concept and its limitations. Ecol. Econ. 143, 37–46. doi:10.1016/j.ecolecon.2017.06.041. Kristensen, H.S., Mosgaard, M.A., 2020. A review of micro level indicators for a circular economy – moving away from the three dimensions of sustainability. J. Clean. Prod. 243, 118531. doi:10.1016/j.jclepro.2019.118531. Supplementary material associated with this article can be found, in the online version, at doi:10.1016/j.spc.2020.11.024. References Adibi, N., Lafhaj, Z., Yehya, M., Payet, J., 2017. Global Resource Indicator for life cycle impact assessment: applied in wind turbine case study. J. Clean. Prod. 165, 1517–1528. doi:10.1016/j.jclepro.2017.07.226. Akanbi, L.A., Oyedele, L.O., Akinade, O.O., Ajayi, A.O., Davila Delgado, M., Bilal, M., Bello, S.A., 2018. Salvaging building materials in a circular economy: a BIMbased whole-life performance estimator. Resour. Conserv. Recycl. 129, 175–186. doi:10.1016/j.resconrec.2017.10.026. Alamerew, Y.A., Brissaud, D., 2019. Circular economy assessment tool for end of life product recovery strategies. J. Remanuf. 9, 169–185. doi:10.1007/ s13243- 018- 0064- 8. Alamerew, Y.A., Kambanou, M.L., Sakao, T., Brissaud, D., 2020. A multi-criteria evaluation method of product-level circularity strategies. Sustainability 12. doi:10. 3390/su12125129. Ardente, F., Mathieux, F., 2014. Identification and assessment of product’s measures to improve resource efficiency: the case-study of an Energy using Product. J. Clean. Prod. 83, 126–141. doi:10.1016/j.jclepro.2014.07.058. Azevedo, S.G., Godina, R., Matias, J.C.O., 2017. Proposal of a sustainable circular index for manufacturing companies. Resources 6 (4). doi:10.3390/ resources6040063. Balanay, R., Halog, A., 2016. Charting policy directions for mining’s sustainability with circular economy. Recycling 1, 219–231. doi:10.3390/recycling1020219. Blomsma, F., Brennan, G., 2017. The emergence of circular economy: a new framing around prolonging resource productivity. J. Ind. Ecol. 21 (3), 603–614. doi:10. 1111/jiec.12603. Blomsma, F., Pieroni, M., Kravchenko, M., Pigosso, D.C., Hildenbrand, J., Kristinsdottir, A.R., Kristoffersen, E., Shahbazi, S., Nielsen, K.D., Jönbrink, A.K., Li, J., Wiik, C., McAloone, T.C., 2019. Developing a circular strategies framework for manufacturing companies to support circular economy-oriented innovation. J. Clean. Prod. 241, 118271. doi:10.1016/j.jclepro.2019.118271. Buildings as Material Banks (BAMB), 2020. Circular building assessment prototype. Available at: https://www.bamb2020.eu/post/cba-prototype/ . Accessed in August/2020. Braun, A.T., Kleine-Moellhoff, P., Reichenberger, V., Seiter, S., 2018. Case study analysing potentials to improve material efficiency in manufacturing supply chains, considering circular economy aspects. Sustainability 10. doi:10.3390/ su10030880. Cayzer, S., Griffiths, P., Beghetto, V., 2017. Design of indicators for measuring product performance in the circular economy. Int. J. Sustainable Eng. 10, 289–298. doi:10.1080/19397038.2017.1333543. Circle Economy, 2018. The circularity gap report. Circularity IQ and KPMG, 2020. Circularity IQ: producy circularity improvement program. Available at: https://www.circular-iq.com/ product-circularity-improvement-program/ . Accessed in August/2020. Corona, B., Shen, L., Reike, D., Rosales Carreón, J., Worrell, E., 2019. Towards sustainable development through the circular economy—A review and critical assessment on current circularity metrics. Resour. Conserv. Recycl. 151. doi:10.1016/j. resconrec.2019.104498. Costa, D., Quinteiro, P., Dias, A.C., 2019. A systematic review of life cycle sustainability assessment: current state, methodological challenges, and implementation issues. Sci. Total Environ. 686, 774–787. doi:10.1016/j.scitotenv.2019.05.435. Cradle to Cradle Products Innovation Institute (C2C), 2014. Cradle-to-cradle product certification. Available at: https://www.c2ccertified.org/get-certified/ product-certification . Acessed in August/2020. Cullen, J.M., 2017. Circular economy: theoretical benchmark or perpetual motion machine. J. Ind. Ecol. 21, 483–486. doi:10.1111/jiec.12599. Dantas, T.E.T., de-Souza, E.D., Destro, I.R., Hammes, G., Rodriguez, C.M.T., Soares, S.R., 2021. How the combination of circular economy and industry 4.0 can contribute towards achieving the sustainable development goals. Sustain. Prod. Consump. 26, 213–227. 10.1016/j.spc.2020.10.005. de Souza Junior, H.R.A., Dantas, T.E.T., Zanghelini, G.M., Cherubini, E., Soares, S.R., 2020. Measuring the environmental performance of a circular system: emergy and LCA approach on a recycle polystyrene system. Sci. Total Environ., 138111 doi:10.1016/j.scitotenv.2020.138111. de Oliveira, C.T., Luna, M.M.M., Campos, L.M.S., 2019. Understanding the Brazilian expanded polystyrene supply chain and its reverse logistics towards circular economy. J. Clean. Prod. 235, 562–573. doi:10.1016/j.jclepro.2019.06.319. Di Maio, F.D., Rem, P.C., 2015. A robust indicator for promoting circular economy through recycling. J. Environ. Prot. (Irvine, Calif) 6, 1095–1104. doi:10.4236/jep. 2015.610096. Ecopreneur, 2019. Circularity Check: how circular are the products and services your company puts on the market? Available at: https://ecopreneur.eu/ circularity- check- landing- page/ . Accessed in August/2020. Elia, V., Gnoni, M.G., Tornese, F., 2017. Measuring circular economy strategies through index methods: a critical analysis. J. Clean. Prod. 142, 2741–2751. doi:10.1016/j.jclepro.2016.10.196. Ellen Macarthur Foundation (EMF) and Granta, 2015. Circularity indicators: an approach to measuring circularity. 467 C.T. de Oliveira, T.E.T. Dantas and S.R. Soares Sustainable Production and Consumption 26 (2021) 455–468 Lèbre, É., Corder, G., Golev, A., 2017. The role of the mining industry in a circular economy: a framework for resource management at the mine site level. J. Ind. Ecol. 21, 662–672. doi:10.1111/jiec.12596. Lee, S., 2020. Role of social and solidarity economy in localizing the sustainable development goals. Int. J. Sustainable Dev. World Ecol. 27 (1), 65–71. doi:10. 1080/13504509.2019.1670274. Lee, H.M., Lu, W.F., Song, B., 2014. A framework for assessing product End-Of-Life performance: reviewing the state of the art and proposing an innovative approach using an End-of-Life Index. J. Clean. Prod. 66, 355–371. doi:10.1016/j. jclepro.2013.11.001. Liang, W.-.Z., Zhao, G.-.Y., Hong, C.-.S., 2018. Performance assessment of circular economy for phosphorus chemical firms based on VIKOR-QUALIFLEX method. J. Clean. Prod. 196, 1365–1378. doi:10.1016/j.jclepro.2018.06.147. Linder, M., Sarasini, S., Loon, P.van, 2017. A metric for quantifying product-level circularity. J. Ind. Ecol. 21, 545–558. doi:10.1111/jiec.12552. Lindgreen, E.R., Salomone, R., Reyes, T., 2020. A critical review of academic approaches, methods and tools to assess circular economy at the micro level. Sustainability 12. doi:10.3390/su12124973. Lüdeke-Freund, F., Gold, S., Bocken, N.M.P., 2019. A review and typology of circular economy business model patterns. J. Ind. Ecol. 23, 36–61. doi:10.1111/ jiec.12763. Manninen, K., Koskela, S., Antikainen, R., Bocken, N., Dahlbo, H., Aminoff, A., 2018. Do circular economy business models capture intended environmental value propositions. J. Clean. Prod. 171, 413–422. doi:10.1016/j.jclepro.2017.10.003. Capellini, M., 2014. Measuring the products circularity. Mesa, J., Esparragoza, I., Maury, H., 2018. Developing a set of sustainability indicators for product families based on the circular economy model. J. Clean. Prod. 196, 1429–1442. doi:10.1016/j.jclepro.2018.06.131. Mestre, A., Cooper, T., 2017. Circular product design. a multiple loops life cycle design approach for the circular economy. Design J. 20, S1620–S1635. doi:10.1080/ 14606925.2017.1352686. Mohamed Sultan, A.A., Lou, E., Mativenga, P.T., 2017. What should be recycled: an integrated model for product recycling desirability. J. Clean. Prod. 154, 51–60. doi:10.1016/j.jclepro.2017.03.201. Moher, D., Liberati, A., Tetzlaff, J., Altman, D.G., 2009. Preferred reporting items for systematic reviews and meta-analyses: the PRISMA statement. BMJ 339, b2535. doi:10.1136/bmj.b2535. Nelen, D., Manshoven, S., Peeters, J.R., Vanegas, P., D’Haese, N., Vrancken, K., 2014. A multidimensional indicator set to assess the benefits of WEEE material recycling. J. Clean. Prod. 83, 305–316. doi:10.1016/j.jclepro.2014.06.094. Niero, M., Kalbar, P.P., 2019. Coupling material circularity indicators and life cycle based indicators: a proposal to advance the assessment of circular economy strategies at the product level. Resour. Conserv. Recycl. 140, 305–312. doi:10.1016/j.resconrec.2018.10.002. Nuñez-Cacho, P., Górecki, J., Molina-Moreno, V., Corpas-Iglesias, F.A., 2018. What gets measured, gets done: development of a Circular Economy measurement scale for building industry. Sustainability (Switzerland) 10. doi:10.3390/ su10072340. Padilla-Rivera, A., Russo-Garrido, S., Merveille, N., 2020. Addressing the social aspects of a circular economy: a systematic literature review. Sustainability 12, 7912. doi:10.3390/su12197912. Parchomenko, A., Nelen, D., Gillabel, J., Rechberger, H., 2019. Measuring the circular economy-a multiple correspondence analysis of 63 metrics. J. Clean. Prod. 210, 200–216. doi:10.1016/j.jclepro.2018.10.357. Park, J.Y., Chertow, M.R., 2014. Establishing and testing the “reuse potential” indicator for managing wastes as resources. J. Environ. Manage. 137, 45–53. doi:10. 1016/j.jenvman.2013.11.053. Patterson, M., McDonald, G., Hardy, D., 2017. Is there more in common than we think? convergence of ecological footprinting, emergy analysis, life cycle assessment and other methods of environmental accounting. Ecol. Modell. 362, 19–36. doi:10.1016/j.ecolmodel.2017.07.022. Pauer, E., Wohner, B., Heinrich, V., Tacker, M., 2019. Assessing the environmental sustainability of food packaging: an extended life cycle assessment including packaging-related food losses and waste and circularity assessment. Sustainability 11, 925. doi:10.3390/su11030925. Pauliuk, S., 2018. Critical appraisal of the circular economy standard BS 8001:2017 and a dashboard of quantitative system indicators for its implementation in organizations. Resour. Conserv. Recycl. 129, 81–92. doi:10.1016/j.resconrec.2017.10. 019. Pauliuk, S., Kondo, Y., Nakamura, S., Nakajima, K., 2017. Regional distribution and losses of end-of-life steel throughout multiple product life cycles—Insights from the global multiregional MaTrace model. Resour. Conserv. Recycl. 116, 84–93. doi:10.1016/j.resconrec.2016.09.029. Petti, L., Serreli, M., Di Cesare, S., 2018. Systematic literature review in social life cycle assessment. Int. J. Life Cycle Assess. 23, 422–431. doi:10.1007/ s11367- 016- 1135- 4. Prieto-Sandoval, V., Ormazabal, M., Jaca, C., Viles, E., 2018. Key elements in assessing circular economy implementation in small and medium-sized enterprises. Bus. Strat. Environ. 27, 1525–1534. doi:10.1002/bse.2210. Reinales, D., Zambrana-Vasquez, D., Saez-De-Guinoa, A., 2020. Social life cycle assessment of product value chains under a circular economy approach: a case study in the plastic packaging sector. Sustainability 12, 6671. doi:10.3390/ su12166671. Rendemint, 2016. PRP circular e-procurement. Available at: https://www.rendemint. nl/en/circular- e- procurement- tool . Accessed in August/2020. ResCoM, 2017. Circular Pathfinder: identify promising circular design strategies. Available at: https://www.rescoms.eu/platform- and- tools . Accessed in August/2020. ResCoM, 2017. Circularity Calculator: quickly compare the potential of different circular design strategies. Available at: https://www.rescoms.eu/ platform- and- tools. Accessed in August/2020. Rincón-Moreno, J., Ormazábal, M., Álvarez, M.J., & Jaca, C. 2021. Advancing circular economy performance indicators and their application in Spanish companies. J. Clean. Prod., 279, 123605. 10.1016/j.jclepro.2020.123605. Ritthoff, et al., 2002. Calculating MIPS – Resource productivity of Products and Services. Wuppertal Institute for Climate, Environment and Energy at the Science Centre North Rhine-Westphalia. Rodriguez-Anton, J.M., Rubio-Andrada, L., Celemín-Pedroche, M.S., AlonsoAlmeida, M.D.M., 2019. Analysis of the relations between circular economy and sustainable development goals. Int. J. Sustain. Dev. World Ecol. 26, 708– 720. doi:10.1080/13504509.2019.1666754. Rossi, E., Bertassini, A.C., Ferreira, C.D.S., Neves do Amaral, W.A., Ometto, A.R., 2020. Circular economy indicators for organizations considering sustainability and business models: plastic, textile and electro-electronic cases. J. Clean. Prod. 247. doi:10.1016/j.jclepro.2019.119137. Sadhukhan, J., Dugmore, T.I.J., Matharu, A., Martinez-Hernandez, E., Aburto, J., Rahman, P.K.S.M., Lynch, J., 2020. Perspectives on “game changer” global challenges for sustainable 21st century: plant-based diet, unavoidable food waste biorefining, and circular economy. Sustainability 12. doi:10.3390/su12051976. Saidani, M., Yannou, B., Leroy, Y., Cluzel, F., 2017. How to assess product performance in the circular economy? proposed requirements for the design of a circularity measurement framework. Recycling 2, 6. doi:10.3390/recycling2010 0 06. Saidani, M., Yannou, B., Leroy, Y., Cluzel, F., Kendall, A., 2019. A taxonomy of circular economy indicators. J. Clean. Prod. 207, 542–559. doi:10.1016/j.jclepro.2018.10. 014. Santagata, R., Zucaro, A., Viglia, S., Ripa, M., Tian, X., Ulgiati, S., 2020. Assessing the sustainability of urban eco-systems through Emergy-based circular economy indicators. Ecol. Indic. 109. doi:10.1016/j.ecolind.2019.105859. Sartal, A., Ozcelik, N., Rodríguez, M., 2020. Bringing the circular economy closer to small and medium entreprises: improving water circularity without damaging plant productivity. J. Clean. Prod. 256. doi:10.1016/j.jclepro.2020.120363. Schroeder, P., Anggraeni, K., Weber, U., 2019. The relevance of circular economy practices to the sustainable development goals. J. Ind. Ecol. 23, 77–95. doi:10. 1111/jiec.12732. Stahel, W.R., 2016. The circular economy. Nature News 531, 435. doi:10.1038/ 531435a. Steinmann, Z.J.N., Huijbregts, M.A.J., Reijnders, L., 2019. How to define the quality of materials in a circular economy. Resour. Conserv. Recycl. 141, 362–363. doi:10. 1016/j.resconrec.2018.10.040. van Loon, P., Wassenhove, L.N.V., 2018. Assessing the economic and environmental impact of remanufacturing: a decision support tool for OEM suppliers. Int. J. Prod. Res. 56, 1662–1674. doi:10.1080/00207543.2017.1367107. van Schaik, A., Reuter, M.A., 2016. Recycling indices visualizing the performance of the circular economy. World Metall. Erzmetall. 69 (4), 5–20. Vanegas, P., Peeters, J.R., Cattrysse, D., Tecchio, P., Ardente, F., Mathieux, F., Dewulf, W., Duflou, J.R., 2018. Ease of disassembly of products to support circular economy strategies. Resour. Conserv. Recycl. 135, 323–334. doi:10.1016/j. resconrec.2017.06.022. Veleva, V., Bodkin, G., Todorova, S., 2017. The need for better measurement and employee engagement to advance a circular economy: lessons from Biogen’s “zero waste” journey. J. Clean. Prod. 154, 517–529. doi:10.1016/j.jclepro.2017.03.177. Verbene, J., 2016. Building Circularity indicators: an Approach For Measuring Circularity of a Building. Eindhoven University of Technology, Eindhoven, Netherlands Masters Dissertation. Wohlin, C., 2014. Guidelines for snowballing in systematic literature studies and a replication in software engineering. In: Proceedings of the 18th International Conference on Evaluation and Assessment in Software Engineering, EASE ’14. Association for Computing Machinery, New York, NY, USA, pp. 1–10. doi:10. 1145/2601248.2601268. World Business Council for Sustainable Development (WBCSD), 2018. Circular metric landscape analysis. World Business Council for Sustainable Development (WBCSD), 2020. Circular Transition Indicators V1.0 – metrics for business, by business. Zhang, X., Zhang, L., Fung, K.Y., Bakshi, B.R., Ng, K.M., 2020. Sustainable product design: a life-cycle approach. Chem. Eng. Sci. 217. doi:10.1016/j.ces.2020.115508. Zore, Ž., Čuček, L., Kravanja, Z., 2018. Synthesis of sustainable production systems using an upgraded concept of sustainability profit and circularity. J. Clean. Prod. 201, 1138–1154. doi:10.1016/j.jclepro.2018.07.150. 468