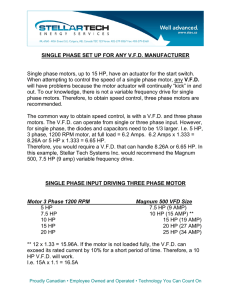

Electrical Panel Selection Prepared in collaboration with: M/s. Power Engineering, Plot No. 552, Industrial Area, Phase- IX, Mohali Contact Person: Sh. B.S. Verma, 9417233527 Typical Power System Types of Power Connections • • • • LT < 50KW. HT > 50KW. Independent feeders 11KV. High Voltage Transmission/ Distribution is Preferred because of Low losses & Reduced size of Conductors during transmission. • The power is transmitted at high voltage and low current. • The heat generated during transmission is proportional to current transmission. Selection of Circuit Breaker Power (KW/KVA/HP) Rated Current. System Voltage Breaking Capacity Making Capacity Category A or B Suitability to site Condition (Indian Condition) Maintenance Definitions Effect of harmonics Calculation Formulas System for HT/ LT connection • • • • • • HVPN Supply GO Switch HT Metering VCB Transformer LT Panel ( Power control centre, Power factor panel, AMF) • Distribution Panel • Sub Distribution panel Selection Of GO Switch Gang Operated Switch Comprises of :- Lightning Arresters, GO (gang operated) switch, Drop off Fuse(DO), Plate Earthings two Nos. for LA (lightening arrestor) & GO switch. Selected at 11KV Only. Selection of CT & PT • CT (Current Transformer /5A) Selected as per the full load current of Transformer. • PT ( Potential Transformer) As per the system Voltage.(11Kv/220v/110v/24V)AC • Calculation of HT Current for CT KVA/11KV/1.732 • Example:- Transformer rating ( HT current for CT/PT selection) 500Kva/11KV/1.732 = 26.24 • Tri vector Meter selected as per HT Current. VCB Panel • Vacuum Circuit Breaker • For Switching carrying Normal Current and Breaking abnormal current at High Voltage. • 630A ( Short circuit current) and Above. • Over Load, Short Circuit & E/F protections. • Measurement of current, Voltage etc. Transformer • 11KV( input)/433V ( Output) • Selection of Transformer as per Total load. • Buckle relay and winding temperature for safety of Transfer. These help to trip VCB. • Silica gel to check moisture content. If blue- Ok, If white or light pink- replace it. LT Panels PCC--- Power Control Center. MCC- Motor Control Center. AMF- Auto Mains Failure Panel APFC- Automatic Power Factor Correction Distribution Panels. STARTER FOR THREE PHASE INDUCTION MOTOR Starting is a process in which a motor’s rotor is brought from zero speed to rated speed. The force to rotate in angular movement is called Torque. Direct On Line Starters used upto 10 HP Star Delta Starters o o o o Manual Star Delta Starters ( not used) Automatic Start Delta Starters Soft Starters VFD Starter Panel for Induction Motors 1. 2. 3. 4. 5. 6. Contactors + Over Load + MCCB / MPCB Motor Protection Relay On delay Timer + Capacitor Duty Contactor + Capacitors Under Voltage & Over Voltage Relay Hour Meter Time Switch Components To Be used In Starters DOL– MPCB-1No,Contactor- 1No, Push Button 2Nos. On Indication 1 No., single phase preventer 1 No Up to 10HP, Star Delta Starter– MCCB 1no, Contactors 3nos,MPR1no, star-delta Timer 1No, Ammeter with CT 1 No, Push Button 2no, on Indication 1no., single phase preventer 1 No. Soft Starter- MCCB 1 No, Semiconductor fuses 3 Nos., Line Contactor 1 No, Soft Starter 1 No. ( with built in bye-pass contactor & soft starter selected as per duty or application), Push Button 2 Nos. VFD- MCCB 1 No, Semiconductor fuses 3 Nos, VFD1 No. Push Button 2 Nos. Input/ Out put Chokes. REDUCTION IN KVA DEMAND DUE TO POWER FACTOR LOAD - 900 KW EXISTING P.F. (COS Ø 1)- 0.6 DESIRED P.F. (COS Ø2) - 0.92 COS Ø. = KVA = kW kVA kW cos Ø. KVA 1 = 900 / 0.6 = 1500 KVA2 = 900 / 0.92 = 978 Ø. KW Reduction in KVA 1500 - 978 = 522 REDUCTION IN LINE CURRENT KVA1 - 1500 KVA = KVA2 - 978 I = I1 = Reduction in Current 2087 - 1361 = 726 I2 √3 V I 1000 KVA x 1000 √3 x 415 1500 x 1000 √3 x 415 = 2087 Amp = 978 x 1000 √3 x 415 = 1361 Amp Selection of Capacitor • Configuration of capacitors 1. Individual Compensation 2. Group Compensation 3. Central Compensation • KVAR required ( Capacitor) = KVA X √(1- PF(E)²) - KVA X √(1- PF(T)²) Existing Power factor from HVPN= PF(E) i.e. 0.6 to 0.75 Target Power factor for system = PF(T) i.e. 0.99 Advantage of Soft Starter It starts the motor rotor from zero to designed speed thereby reducing initial load on system. The star Delta starts generally starts with jerk i.e. 30 % of designed speed. Soft starters are preferred at high heads. Direct on Line START Line Contactor Overload % VOLTS 100 80 60 40 20 0 Run Start TIME Run Contactor START Line Contactor Resistors Primary Resistance Overload % VOLTS 100 80 60 40 20 0 Run Start TIME Autotransformer Star Point Contactor START Transformer Contactor % VOLTS 100 80 60 40 20 0 Line Contactor Overload Run Start TIME START Star Point Contactor Star Delta Delta Contactor % VOLTS 100 80 60 40 20 0 Line Contactor Overload Run Start TIME Soft Starting START % VOLTS 100 80 60 40 20 0 Run Start TIME EBG – Electrical Standard Products Basics of AC Drives • Frequency controls Motor IMSspeed 2 Product Familiarisation • Supply Voltage controls Motor Torque • Supply Voltage is varied in proportion to supply frequency so as to keep torque constant LARSEN & TOUBRO LIMITED. GOOD TERMINATION PRACTICE DO’s AND DON’Ts TERMINATION WITH BUSBAR/LINK DON’T DO DON’T DO DON’T DO DON’T DO TERMINATION WITH LUGS DON’T DO DON’T DO DON’T DO DON’T DO MCB (Miniature Circuit Breaker), • Rated current not more than 63 A, Thermal or thermal-magnetic operation. MCCB (Moulded Case Circuit Breaker) • Rated current above 32 A upto 630 A, Trip current may be adjustable, Thermal or thermal-magnetic operation. Air Circuit Breaker • Rated current from 800 A upto 6,000 A, • Trip characteristics often fully adjustable including configurable trip thresholds and delays. • Usually electronically controlled—some models are microprocessor controlled. • Often used for main power distribution in large industrial plant, where the breakers are arranged in draw-out enclosures for ease of maintenance. MCB Selection • Overload which is intended to prevent the accidental overloading of the cable in a no fault situation. The speed of the MCB tripping will vary with the degree of the overload. This is usually achieved by the use of a thermal device in the MCB. • The second characteristic is the magnetic fault protection, which is intended to operate when the fault reaches a predetermined level and to trip the MCB within one tenth of a second. The level of this magnetic trip gives the MCB its type characteristic as follows: Type Tripping Current Operating Time Type B ( Domestic) Type C ( Industrial) Type D ( Capacitor) 3 To 5 time full load current 5 To 10 times full load current 10 To 20 times full load current 0.04 To 13 Sec 0.04 To 5 Sec 0.04 To 3 Sec Fuse and MCB characteristics • The fuse and the MCB, even though their nominal currents are similar, have very different properties. • For example, For 32Amp MCB and 30 Amp Fuse, to be sure of tripping in 0.1 seconds, the MCB requires a current of 128 amps, while the fuse requires 300 amps. • The fuse clearly requires more current to blow it in that time, but notice how much bigger both these currents are than the ’30 amps’ marked current rating. • Fuse require replacement after blowing but MCB only switched on. ACB ACB Cable Selection • • • • • • Armoured Cables ( For Out door, under ground) Unarmoured Cables ( for indoor but open in cable trays) Submersible cables Size of Cable ( as per load) Insulation on cable ( PVC, XLPE) Core 3 ( where neutral not required) or 3 ½ cable ( where neutral required) • 3 core cable in HT, Motor, capacitor • 3 ½ Core in light load, Insulation over cable • Poly Vinyl Chloride • Cross-Linked Polyethylene (XLPE)- Less deformation below 100°C, Lower in cost, Lower dissipation factor, Lower dielectric constant, Higher dielectric strength Physically tougher, More resistant to chemicals, More oil resistant Colour Code for Cables Single Phase System Live Red Neutral Black Ground Green Three phase System Red, Yellow, Blue Black Green EARTHING BY EARTHING (OR GROUNDING), WE MEAN MAKING A PHYSICAL AND ELECTRICAL CONNECTION TO THE GENERAL MASS OF EARTH. TYPES OF EARTHING • • • • SYSTEM EARTHING EQUIPMENT EARTHING LIGHTNING PROTECTION EARTHING STATIC EARTHING SYSTEM EARTHING SYSTEM EARTHING IS THE EARTHING ASSOCIATED WITH THE CURRENT CARRYING CONDUCTOR (USUALLY THE NEUTRAL POINT OF THE TRANSFORMER OR GENERATOR) AND IS NORMALLY ESSENTIAL FOR THE SECURITY OF THE SYSTEM. (This is covered by IS 3043:1987 – Code of Practice for Earthing) EQUIPMENT EARTHING EQUIPMENT EARTHING IS THE EARTHING ASSOCIATED WITH NON CURRENT CARRYING METAL WORK AND IS ESSENTIAL TO THE SAFETY OF HUMAN LIFE, ANIMALS & PROPERTY. (This is covered by IS 3043:1987 – Code of Practice for Earthing) LIGHTNING PROTECTION EARTHING LIGHTNING PROTECTION EARTHING IS CONCERNED WITH THE CONDUCTION OF CURRENT DISCHARGES IN ATMOSPHERE ORIGINATING IN CLOUD FORMATIONS TO EARTH AND IS ESSENTIAL FOR THE PROTECTION OF BUILDINGS, TRANSMISSION LINES AND ELECTRICAL EQUIPMENT. (This is covered by IS 2309:1989 – Protection of buildings and allied structures against lightning – Code of Practice) SYSTEM EARTHING WHY ? GREATER SERVICE CONTINUITY REDUCTION IN OCCURRENCES OF MULTIPLE FAULTS TO GROUND FEWER ARCING FAULT BURNDOWNS EASIER LOCATION OF FAULTS GREATER SAFETY POSSIBLE SAVING IN COST EQUIPMENT EARTHING WHY ? 1. FREEDOM FROM DANGEROUS ELECTRIC SHOCK HAZARDS 2. REDUCTION IN FIRE HAZARDS 3. PRESERVATION OF SYSTEM PERFORMANCE REDUCTION IN SHOCK HAZARDS CASE 1 : NO EQUIPMENT EARTHING LOAD SOURCE V SYSTEM EARTHING REDUCTION IN SHOCK HAZARDS CASE 3 : EQUIPMENT EARTHING WITH PE CONDUCTOR LOAD SOURCE V SYSTEM EARTHING EQUIPMENT EARTHING Difference between Pipe and Plate Earthing • • • • Plate earthing costly but reliable. Plate earhing is more efficient. Less maintenance cost. Easy to maintain resistance value. Standard Pipe & Plate Type Earthing Design for the 11 Kv. Kv. System Equipments, Distribution Transformer Centers,, L.T. Distribution System Equipments Centers • Design Details : 1. Earthing Pit : Size 1000 X 1000 X 1800 mm Depth.M.S. / C.I. Plate : 500 X 500 X 8 mm Thick. 2. Electrode Assembly : 40 mm Ø GI / CI Perforated pipe duly fitted or welded with base plate and 50 X 6 mm flat termination taken on top for equipment earthing as shown in drawing. Standard Pipe & Plate Type Earthing Design for the 11 Kv. System Equipments, Distribution Transformer Centers, L.T. Distribution System Equipments 4. Mixture - I : Homogeneous mixture of black soft soil 0.3 CMT. approx. 5. Mixture - II : Homogeneous mixture of common salt 25 Kgs. + wood charcoal pieces 25 Kgs. + Black soft soil 1 CMT. Approx. 6. Crushed Rock pieces Gravel Size 50 X 35 mm 0.1 CMT. Approx. 7. Arrangement for earthing lead terminations from equipment body, and connection for main earthing Grid. Typical arrangement for Pipe electrode earthing pit (Bore Type) • Design Details : 1. 75 mm thick RCC Cover. 2. 300 mm Ø 6000 mm deep (Approx. 20 ft.) bore in the earth. 3. 65 mm Ø 6000 mm long (Approx 20 ft.) G.I. pipe electrode. Forged at the top up to 75 mm length and 12 mm hole provided for taking earthing connection. 4. A homogeneous mixture of 50 kgs. wooden coal pieces + 50 kgs. common salt 5. Water pouring purpose at the time of routine maintenance No. of earthing Required • • • • • • Equipment GO Switch HT metering panel Transformer LT Panel Electric Motor Pipe 1 1 1 Plate 2 1 2 2 - HP of Motor HP of Motor= QH/4500/efficiency Q= Discharge in LPM H= Head of pump in meters Efficiency varies from 65% to 85% Motor Start Theory ME00107A Type of Insulation and Enclosures for electric motors • Insulation Class of winding wire Class Y- 90°C, Class A- 105°C, Class E- 120°C, Class B- 130°C, Class H- 180°C To be used as application. • Enclosures Screen Protected, screen protected drip proof, Splash proof, Totally enclosed fan cooled, Totally enclosed and separately air cooled, totally enclosed air circuit motor, direct ventilated motor Detail of TRANSFORMER and its Accessories 1 2 3 Descripition of Transformer KVA of Transformer KW of TR. at P.F -0.8 Full load current of TR. Details of accessories to run the transformer 4 Size of cable 3-core H.T.side ( Aluminium ) in mm2 5 Size of cable 3 1/2 core L.T. side(Aluminium ) in mm2 Metering panel with C.T./P.T 6 unit Trivector meter as per TR. 7 rating HT VCB/SF-6 panel with HT 8 metering As per TR. Rating. G.O.switch with all 9 accessories I/C D.O.fuse , lighting arrestor and stay wire set, earthing etc. HT current of TR.- on HT side 10 (Amp.) 11 Impedance % Capocitor for TR (KVAR) only 12 for TR losses Capacity 100 75 150 150 125 200 200 175 250 250 200 347 35 35 35 35 1x185 sqmm 1x240 sqmm 1x240 sqmm 2X185 sqmm 15/5 A/110 V 15/5 A/110 V 15/5 A/110 V 15/5 A/110 V 15/5 A/110 V 15/5 A/110 V 15/5 A/110 V 15/5 A/110 V NA NA NA NA Required Required Required Required 5.24 4 7.88 4 10.5 4.75 13.33 4.75 4 5 7 10 1 2 3 Descripition of Transformer KVA of Transformer KW of TR. at P.F -0.8 Full load current of TR. Capacity 315 252 433 Details of accessories to run the transformer 4 Size of cable 3-core H.T.side ( Aluminium ) in mm2 35 5 Size of cable 3 1/2 core L.T. side(Aluminium ) in mm2 2X240 sqmm Metering panel with C.T./P.T 6 unit 20/5 A/110 V Trivector meter as per TR. 7 rating 20/5 A/110 V HT VCB/SF-6 panel with HT 8 metering As per TR. Rating. Required G.O.switch with all 9 accessories I/C D.O.fuse , lighting arrestor and stay wire set, earthing etc. Required HT current of TR.- on HT side 10 (Amp.) 16.8 11 Impedance % 4.75 Capocitor for TR (KVAR) only 12 for TR losses 12.5 400 320 530 500 400 687 630 604 866 50 50 50 2X240 sqmm 3X240 sqmm 3X240 sqmm 25/5 A/110 V 30/5 A/110 V 50/5 A/110 V 25/5 A/110 V 30/5 A/110 V 50/5 A/110 V Required Required Required Required Required Required 21.33 4.75 26.66 4.75 40.26 5 20 25 30 Descripition of Transformer 1 KVA of Transformer 2 KW of TR. at P.F -0.8 3 Full load current of TR. Details of accessories to run the transformer 4 Size of cable 3-core H.T.side ( Aluminium ) in mm2 800 640 1100 1000 800 1375 Capacity 1250 1000 1718 1600 1280 2199 2000 1600 2740 70 70 95 125 125 Bus duct 1200 Bus duct 1600 Bus duct 2000 Bus duct 2500 Bus duct 4000 A A A A A 5 Size of cable 3 1/2 core L.T. side(Aluminium ) in 3X400 sqmm 4X400 sqmm N/A N/A N/A mm2 Metering panel with C.T./P.T 6 unit 50/5 A/110 V 60/5 A/110 V 70/5 A/110 V 100/5 A/110 V 125/5 A/110 V Trivector meter as per TR. 7 rating 50/5 A/110 V 60/5 A/110 V 70/5 A/110 V 100/5 A/110 V 125/5 A/110 V HT VCB/SF-6 panel with 8 HT metering As per TR. Rating. Required Required Required Required Required G.O.switch with all 9 accessories I/C D.O.fuse , lighting arrestor and stay wire set, earthing etc. Required Required Required Required Required HT current of TR.- on HT 10 side (Amp.) 42.66 53.33 66.66 85.33 106.66 11 Impedance % 5 5 5 6.25 6.25 Capocitor for TR (KVAR) 12 only for TR losses 35 50 50 75 100 NOTE :a) HT VCB / SF-6 as incomer of Transformer on HT side ( and required as per Electricity Board norms ) b) CT ratio 50/25/5 A ( if load vary from 25 amp. To 50 amp after expansion on HT side of Transformer c) CT ratio - 30/30/5 amp. ( separate for metering and separate for protection.) d) Calculation of HT current of Transformer = Kva / 11 kv / 1.73. e) PT- 110 /220 volt AC.( as per requirement ) Detail of D.G.Sets with details 1 KVA 5 7.5 10 15 15 20 25 30 30 40 50 2 KW 4 6 8 12 12 16 20 24 24 32 40 3 62.5 62.5 50 50 AMPS 6.95 10.4 13.9 20.8 20.8 27.8 34.75 41.7 41.7 55.6 69.5 86.9 86.9 4 BHP 7 10 12 18.7 1 KVA 100 125 160 2 KW 80 100 128 3 AMPS 139 4 BHP 127 173.7 222.4 154 205 19 65 76 83 75 82.5 60 66 104 114.6 105 105 28 32 38 43 50.5 180 200 250 320 380 437 500 625 750 1000 144 160 200 256 304 350 400 500 600 800 250 278 348 445 528 608 614 868.8 1043 1390 231 255 306 380 450 530 614 750 890 1180 Detail of DIRECT ON LINE ( DOL ) starter with all type of possible accessories S.No. 1 2 3 4 5 6 7 8 9 10 11 DESCREPTION OF MOTOR HP-3Phase 415 V AC 0.5 0.75 1 KW of Motor 0.37 0.55 0.75 Full load current of Motor in amp. 1.2 1.6 1.8 EQUIPMENT TO START THE MOTOR BELOW FOR EACH MOTOR MPCB as incomer. In amp. MPCB MPCB MPCB 1-1.6 A 1-1.6 A 1.6-2.5 A Contactor rating in amp. 1x9 amp 1x9 amp 1x9 amp Single phase preventor 415 v AC. A/P/R A/P/R A/P/R Control MCB SP.( single pole ) 6 amp SP 6 amp SP 6 amp SP Push Botton ( START & STOP ) 1 NO+1 NC 2-Nos 2-Nos 2-Nos On Indication ( LED 220 V AC ) 1-Nos 1-Nos 1-Nos Cable for supply side 3 1/2 core COPPER 1.5 sq mm 1.5 sq mm 1.5 sq mm Cable for Motor side 3-core COPPER. 1.5 sq mm 1.5 sq mm 1.5 sq mm 1.5 1.1 2.6 MPCB 2.5-4 A 1x9 amp A/P/R 6 amp SP 2-Nos 1-Nos 1.5 sq mm 1.5 sq mm Detail of DIRECT ON LINE ( DOL ) starter with all type of possible accessories S.No DESCREPTION OF . MOTOR 1 HP-3Phase 415 V AC 2 3 5 7.5 2 KW of Motor 1.5 2.25 3.75 5.5 3 Full load current of Motor in amp. 3.5 5 7.5 11 EQUIPMENT TO START THE MOTOR BELOW FOR EACH MOTOR 4 MPCB as incomer. In amp. MPCB MPCB MPCB MPCB 2.5-4 A 4-6.3 A 6-10 A 9-15 A 5 Contactor rating in amp. 1x9 amp 1x9 amp 1x12 amp 1x18 amp 6 Single phase preventor 415 v AC. A/P/R A/P/R A/P/R A/P/R 7 Control MCB SP.( single pole ) 6 amp SP 6 amp SP 6 amp SP 6 amp SP 8 Push Botton ( START & STOP ) 1 NO+1 NC 2-Nos 2-Nos 2-Nos 2-Nos 9 On Indication ( LED 220 V AC ) 1-Nos 1-Nos 1-Nos 1-Nos 10 Cable for supply side 3 1/2 core COPPER 2.5 sq mm 2.5 sq mm 2.5 sq mm 4 sq mm 11 Cable for Motor side 3core COPPER. 2.5 sq mm 2.5 sq mm 2.5 sq mm 4 sq mm Single phase preventor 415 v AC = A/P/R ( AS PER REQUIRMENT ) 10 7.5 14 MPCB 9-15 A 1x25 amp A/P/R 6 amp SP 2-Nos 1-Nos 4 sq mm 4 sq mm Detail of STAR/DELTA starter with all type of possible accessories DESCREPTION OF S.No. MOTOR 1 HP-3Phase 415 V AC 15 20 25 2 KW of Motor 11 15 18.5 Full load Line current of 3 Motor in amp. 21 28 35 Phase current of Motor in 4 amp. 12 16 20 EQUIPMENT TO START THE MOTOR BELOW FOR EACH MOTOR MPCB/MCCB as incomer. 5 In amp. MPCB MPCB MCCB 19-25 A 24-32 A 63 A 6 Contactor rating in amp. 3x25 amp 3x32 amp 3x32 amp 7 Motor protection relay -MPR Not-req Not-req MPR ( 2.5-5 A ) 8 Timers 0-60 sec 0-60 sec 0-60 sec Single phase preventor 415 9 v AC. A/P/R A/P/R A/P/R 10 Control MCB SP. 6 amp SP 6 amp SP 6 amp SP 11 Amp. Meter 0-50 amp 0-50 amp 0-50 amp 12 CT,s ( -/5 amp ) 50/5 amp 50/5 amp 50/5 amp Cable for supply side 3 1/2 13 core ALUMINIUM 10 sq mm 10 sq mm 16 sq mm Cable for Motor side 3-core 14 ALUMINIUM. 2x6 sq mm 2x6 sq mm 2x10 sq mm 30 22 35 26 40 47 23 27 MCCB 100 A 3x40 amp MPR ( 2.5-5 A ) 0-60 sec MCCB 100 A 3x40 amp MPR ( 2.5-5 A ) 0-60 sec A/P/R 6 amp SP 0-50 amp 50/5 amp A/P/R 6 amp SP 0-75 amp 75/5 amp 16 sq mm 25 sq mm 2x10 sq mm 2x16 sq mm Detail of STAR/DELTA starter with all type of possible accessories DESCREPTION OF S.No. MOTOR 1 HP-3Phase 415 V AC 2 KW of Motor Full load line current of 3 Motor in amp. Phase current of Motor in 4 amp. 5 6 7 8 9 10 11 12 13 14 40 30 50 37 60 45 75 56 90 67.5 55 66 80 100 120 30 35 45 57 69 MCCB 160 A 3x80 amp MPR ( 2.5-5 A ) 0-60 sec MCCB 200 A 3x110amp MPR ( 2.5-5 A ) 0-60 sec A/P/R 6 amp SP 0-150 amp 150/5 amp A/P/R 6 amp SP 0-150 amp 150/5 amp 70 sq mm 70 sq mm 2x25 sq mm 2x50 sq mm EQUIPMENT TO START THE MOTOR BELOW FOR EACH MOTOR MPCB/MCCB as incomer. In amp. MCCB MCCB MCCB 100 A 100 A 125 A Contactor rating in amp. 3x40 amp 3x50 amp 3x70 amp Motor protection relay -MPR MPR MPR MPR ( 2.5-5 A ) ( 2.5-5 A ) ( 2.5-5 A ) Timers 0-60 sec 0-60 sec 0-60 sec Single phase preventor 415 v AC. A/P/R A/P/R A/P/R Control MCB SP. 6 amp SP 6 amp SP 6 amp SP Amp. Meter 0-75 amp 0-100 amp 0-100 amp CT,s ( -/5 amp ) 75/5 amp 100/5 amp 100/5 amp Cable for supply side 3 1/2 core ALUMINIUM 25 sq mm 35 sq mm 50 sq mm Cable for Motor side 3-core ALUMINIUM. 2x16 sq mm 2x16 sq mm 2x25 sq mm Detail of STAR/DELTA starter with all type of possible accessories DISCREPTION OF S.No. MOTOR 1 HP-3Phase 415 V AC 100 125 150 175 2 KW of Motor 75 90 112 132 Full load line current 3 of Motor in amp. 135 165 200 230 Phase current of Motor 4 in amp. 78 95 115 133 EQUIPMENT TO START THE MOTOR BELOW FOR EACH MOTOR MPCB/MCCB as 5 incomer. In amp. MCCB MCCB MCCB MCCB 250 A 250 A 400 A 400 A 6 Contactor rating in amp. 3x110amp 3x140amp 3x140amp 3x200amp Motor protection relay 7 MPR MPR MPR MPR MPR ( 2.5-5 A ) ( 2.5-5 A ) ( 2.5-5 A ) ( 2.5-5 A ) 8 Timers 0-60 sec 0-60 sec 0-60 sec 0-60 sec Single phase preventor 9 415 v AC. A/P/R A/P/R A/P/R A/P/R 10 Control MCB SP. 6 amp SP 6 amp SP 6 amp SP 6 amp SP 11 Amp. Meter 0-150 amp 0-250 amp 0-250 amp 0-250 amp 12 CT,s ( -/5 amp ) 150/5 amp 250/5 amp 250/5 amp 250/5 amp Cable for supply side 3 13 1/2 core ALUMINIUM 95 sq mm 120 sq mm 240 sq mm 240 sq mm Cable for Motor side 32x50 sq 2x70 sq 14 core ALUMINIUM. mm mm 2x95 sq mm 2x95 sq mm 200 150 250 187 275 323 159 185 MCCB 400 A 3x200amp MCCB 630A 3x265amp MPR ( 2.5-5 A ) 0-60 sec MPR ( 2.5-5 A ) 0-60 sec A/P/R 6 amp SP 0-400 amp 400/5 amp 2x120 sq mm 2x120 sq mm A/P/R 6 amp SP 0-400 amp 400/5 amp 2x150 sq mm 2x185 sq mm IMPORTANT - ALL THE POWER CONNECTION OF STARTER IN SIDE THE PANEL WITH SOLID BUS BARS 50 HP AND ABOVE. VIDEO ON STAR - DELTA STARTER 500 160KVA Power of the transformer 250KVA KVA 48.0 KA =Icc downstream the transformer 400KVA 630KVA Maine line (Alu or Copper) 800KVA a=alu (cu by default) a Lenght 5 m Cross section 800 mm² 1000KVA 1250KVA 1600KVA 45.3KA 2000KVA 2500KVA Secundary level (Alu or Copper) a=alu (cu by default) Lenght Cross section third level (Alu or Copper) a=alu (cu by default) Lenght Cross section a 10 240 33.1 m mm² KA 20 1.5 m mm² Icc3 = 0.75 KA Icc1 = 0.60 KA Thank You