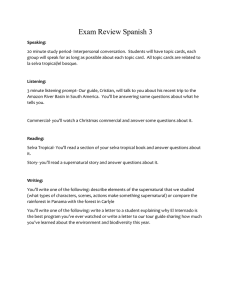

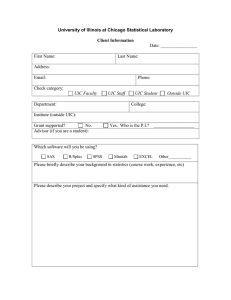

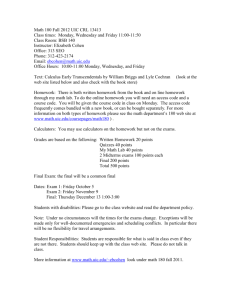

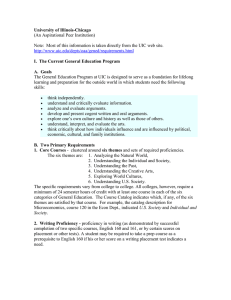

UIC BUSINESS Process Analysis and Little’s Law IDS 532 Instructor: Selva Nadarajah Discussion Plan • • • • • UIC BUSINESS Process analysis notation Guidelines to analyze a process (in-class exercises) Little’s law Measures of utilization Retail and supply chain performance measures related to Little’s law (Text book chapters: 2 & 3) Selva Nadarajah 2 UIC BUSINESS Process View of an Organization • A process is a set of activities that accepts inputs and produces outputs. Inputs Transformation Process Raw material, Customers Outputs Goods, Services Resources Labor & Capital • Why can’t business processes transform inputs into outputs instantaneously? • What stops these processes from creating more supply? Selva Nadarajah 3 UIC BUSINESS Examples of Processes • Call center Automated routing Agent Wait • Iron production Ore Preheater First Iron smelter reactor ……… Briquetting Goods • In general, a process can have multiple inputs and outputs. Selva Nadarajah 4 UIC BUSINESS Basic Performance Metrics Input rate [units/hr] Inventory [units] Flow rate [units/hr] Flow Time [hrs] • Capacity is defined as the maximum possible flow rate. • Cycle time (= 1/flow rate) is the average time between completion of successive units. **This animation is a graphical illustration but not a process flow diagram Selva Nadarajah 5 UIC BUSINESS Fundamentals of Process Flow Notation Activity/Task Buffer Flow Typically not represented graphically Resource **When an activity has a single resource, the term activity and resource are used interchangeably Selva Nadarajah 6 UIC BUSINESS Diploma Production Process • In a fictitious business school named OM, diploma production involves three main steps Stamp “OM MBA” on diploma Verify and stamp name Punch a hole to insert the diploma in a fancy folder • What is the flow unit in this process? diplomas • What is the process flow diagram? OM MBA Selva Nadarajah Name Hole Punch 7 UIC BUSINESS Diploma Production OM MBA Processing rate (dipl/min) 12 Name 7.5 Hole Punch ?? 24 • How much time does “OM MBA” take to process a diploma? 1/12 mins/dipl. = 5 sec/dipl. • In which buffer is there an inventory build up? The one between “OM MBA” and “Name” • What is the rate at which inventory builds up in this process? 4.5 dipl/min • Is this imbalance sustainable? Perhaps for diploma production but not possible for a long time Selva Nadarajah 8 UIC BUSINESS Diploma Production OM MBA Name Hole Punch Processing rate (dipl/min) 12 ?? 7.5 ?? 24 Processing Time (sec/dipl) 5 8 2.5 • Can you guess how to compute the capacity of the entire process? Minimum of activity capacities: 7.5 dipl/min Selva Nadarajah 9 UIC BUSINESS Bottleneck and Process Capacity Bottleneck Bottleneck is the activity with the smallest capacity, that is, this activity determines the process capacity Selva Nadarajah 10 UIC BUSINESS Process Flow Rate Bottleneck Input Capacity constrained Is the process capacity always equal to the process flow rate? No, because the process may be constrained by demand Bottleneck Input Demand constrained Selva Nadarajah 11 Analyzing Processes: Guidelines UIC BUSINESS 1. Setup Select process scope (define the cycle) Define flow unit Draw process flow diagram 2. Rule #1: Break process down to individual activities 3. Rule #2: Work with repetitive cycles in each step 4. Rule #3: Put it back together at the process level Selva Nadarajah 12 Example 1: Diploma Production UIC BUSINESS Base case OM MBA Name Flow Rate 12 dipl./min 7.5 dipl./min 24 dipl./min Cycle Time 5 sec./dipl 8 sec./dipl. 2.5 sec. dipl Hole Punch • What is the bottleneck activity? Name • What is the process capacity? Selva Nadarajah 7.5 dipl./min 13 UIC BUSINESS Unbalanced System • First two stages unbalanced • Scenario1: “OM MBA” works for 30 min, then takes break Processing Rate OM MBA Name 12 dipl./min 7.5 dipl./min • Question: How long can the break last without slowing down the process? • Answer: Cycle = produce for 30 min, break for X min Total time = 30 + X min Total work = 30 min * (12 dipl./min) = 360 diplomas 360/ (30 + X) = 7.5 ⟹ X = 18 min Selva Nadarajah 14 UIC BUSINESS Inventory Buildup • Question: If we do that, what is the average inventory b/w these stages • Answer: Flow Rate OM MBA Name 12 dipl./min 7.5 dipl./min • Flow rate difference between “OM MBA” and “Name” is 4.5 dipl./min Inventory Focus on one cycle: Produce for 30 mins, break for 18 mins time Selva Nadarajah 15 UIC BUSINESS Inventory buildup contd… Inventory time total inventory in a cycle area of triangle 0.5×48×135 135 • Avg. inventory = = = = 48 2 duration of a cycle triangle base • Avg. inventory = Selva Nadarajah maximum inventory 135 = 2 2 16 UIC BUSINESS Resource Downtime • Scenario 2: Every 120 diplomas, the hole punch needs to be emptied. Takes an average of 1 min to empty OM MBA Name Hole Punch Flow Rate 12 dipl./min 7.5 dipl./min Capacity? Cycle Time 5 sec./dipl 8 sec./dipl. Cycle time? • Answer: Cycle: 120 diplomas followed by clean out Total time = 120*2.5 sec + 60 sec = 360 sec = 6 min Total work = 120 diplomas New capacity= 120 dipl. / 6 min. = 20 dipl./min. Selva Nadarajah Hole Punch processing rate is 24 dipl/min and its processing time is 2.5 sec./dipl. 17 UIC BUSINESS Imperfect Yield • Scenario 3: “Name” activity produces defects 3% of the time OM MBA Name Hole Punch Flow Rate 12 dipl./min Capacity? 24 dipl./min Cycle Time 5 sec./dipl. Cycle time? 2.5 sec./dipl. • Answer: Cycle: 100 diplomas attempted Total time = (100 dipl.) * (8 sec./dipl.) = 800 sec = 13.33 min Total work = 97 diplomas Capacity = 97 dipl. / 13.33 min. = 7.28 dipl./min. Selva Nadarajah Name processing rate is 7.5 dipl/min and its processing time is 8 sec./dipl. 18 UIC BUSINESS Little’s Law • Little’s law relates the averages of basic performance metrics over time • I = Inventory = how many flow units are in the process • R = Flow Rate = rate at which flow units leave the process • T = Flow Time = total time a flow unit is in the process • Little’s Law: Inventory = Flow Rate x Flow Time or I=RxT • Practical implication: Given any two metrics the third can be found Selva Nadarajah 19 Insurance Company Example UIC BUSINESS • An insurance company processes 10,000 claims per year. The average processing time is 3 weeks. How many claims are in the system on average? (Assuming 50 weeks in a year) R= 200 claims / week, T = 3 Weeks, I = R x T = 600 claims • Now, the company reduces its processing time by 80%. How many claims are in the system on average? R= 200 claims / week, T = 0.6 Weeks, I = R x T =120 claims Selva Nadarajah 20 Potbelly’s Promise UIC BUSINESS • When you enter Potbelly, you see the overhead sign saying “FAST: 8 minutes through the line max” and you notice that 24 people are waiting (including you). For Potbelly to delivery that promise, how many customers should be leaving the check-out counter every minute? T = 8 min, I = 24 customers, R = I / T = 3 customers / min Selva Nadarajah 21 UIC BUSINESS Utilization • Measure that quantifies actual processing rate relative to how much could be processed if operating at capacity Utilization = Flow rate Capacity • Can be applied to an individual resource, activity, or the entire process • The bottleneck activity has the highest utilization • Utilization is at most 100% but can be less because (?) 1. Demand is less than capacity 2. Input is less than capacity 3. Downtime or setups in the process Selva Nadarajah 22 Illustration of Utilization UIC BUSINESS • There are four steps in the manufacturing process of a stuffed toy: cutting, stuffing, sealing, and packaging. There are two employees each for cutting and stuffing but one each for sealing and packaging. The processing times of cutting, stuffing, sealing, and packaging are 8, 5, 3, and 2 seconds per toy. What is the utilization at the "packaging" resource if demand is unlimited? • • • • • Answer: Capacity of packaging = ½ toys per second. Process capacity = Min(2/8, 2/5, 1/3, 1/2) = ¼ toys per second. Flow rate = Min(Demand, Process capacity) = ¼ toys per second. Why? Utilization = Flow rate/Capacity = 0.25/0.5 = 50%. Selva Nadarajah 23 UIC BUSINESS Implied Utilization • Measures mismatch between what could flow through the resource (demand/work load) and what the resource can provide (capacity) Implied utilization = Demand Capacity • Can be applied to an individual resource, activity, or the entire process • Implied utilization of multiple resources can be greater than 100% Activities with implied utilization greater than 100% are candidates for capacity expansion • The bottleneck activity has the highest implied utilization Selva Nadarajah 24 Illustration of Implied Utilization UIC BUSINESS • There are four steps in the manufacturing process of a stuffed toy: cutting, stuffing, sealing, and packaging. There are two employees each for cutting and stuffing but one each for sealing and packaging. The processing times of cutting, stuffing, sealing, and packaging are 8, 5, 3, and 2 seconds per toy. What is the implied utilization at the "packaging" resource if demand is 1 toy per second? • • • • • Answer: Capacity of packaging = ½ toys per second. Process capacity = Min(2/8, 2/5, 1/3, 1/2) = ¼ toys per second. Implied utilization = Demand/Capacity = 1/0.5 = 200%. What would be implied utilization if demand was unlimited? Selva Nadarajah 25 Retail and Supply Chain Benchmarks UIC BUSINESS • Little’s law can be leveraged to compute two commonly used benchmarks in the retail and supply chain areas 1. Days of supply: Number of days an average item spends in the store (or supply chain) 2. Inventory turns: Number of times a store (or supply chain) turns over its inventory • Low turnover is a sign of low sales and hence excess inventory • High turnover signals strong sales and is typically seen as a positive sign Annual Inventory turns = Selva Nadarajah 365 Days of supply 26 Using Little’s Law to Compute Days of Supply UIC BUSINESS • Consider a retail firm with multiple products • How can inventory be measured? Physical units: Not appropriate Monetary unit: OK • Little’s law with flow unit as the “individual dollar bill” Inventory is expressed in dollars What is the flow rate? Cost of goods sold (COGS) Days of supply (Flow time) = Selva Nadarajah Inventory Flow rate (COGS) 27 UIC BUSINESS Per-unit Inventory Cost • Inventory holding costs are typically substantially higher than financial holding costs Inventory may become obsolete or be perishable Theft Storage costs and overhead Impact on waiting times (discussion in session 5) and quality (discussed in session 6) Per-unit inventory costs = Selva Nadarajah Annual inventory costs Annual inventory turns 28 UIC BUSINESS Walmart Vs Kohls (numbers in millions) Kohl’s Walmart Cost of goods sold (COGS) $ 11,359 $ 307,646 Inventory (Inv) $ 3,036 $ 36,318 2011 Data Calculations Days of supply (Inv/COGS x 360) Inventory turns (COGS/Inv) 97 days 43 days 3.74 turns/yr 8.47 turns/yr • What do these numbers tell us about Kohls and Walmart? Walmart turns over its inventory at a substantially higher rate This is a positive sign for Walmart for reasons already discussed Selva Nadarajah 29 Walmart Vs Kohls UIC BUSINESS • Suppose inventory costs are 20% per year of COGS • Question: What is the per-unit inventory cost? • Answer: Kohl’s: 20%/3.74 = 5.35% Walmart: 20% / 8.47 = 2.36% Selva Nadarajah 30 UIC BUSINESS Net Profit Margin • Source: Stern, NYU Retail segment Net margin % (Jan 2014) Net margin % (Jan 2020) Automotive 2.94 3.55 Building supply 5.56 6.45 Distributors 3.53 4.51 General 2.90 2.44 Grocery and food 0.75 1.44 Internet 3.37 4.57 Special lines 3.88 3.31 • The two percent inventory cost difference between Kohl’s and Walmart in our analysis is significant! Selva Nadarajah 31