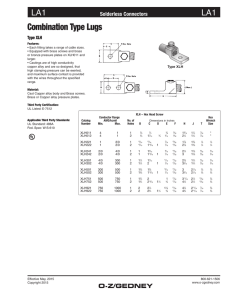

ABSTRACT After 8 months of Commissioning, a series of leaks were observed under Contract C2015-80 – Renewal of pipeline at Riche-En-Eau, Grand Bel Air and Ville Noire. Upon investigation, the ferrules were found to leak. The quantity and type of leaks rendered everyone perplex. This paper through some research works attempts to explain the leaks. Firstly, it should be noted that the Ferrules supplied is made up of an alloy of Copper: CW615N with chemical composition CuZn39Pb3Sn while our bidding document specifies Gunmetal (as per BS 1400-LG2) and Ductile Iron. The existence of Ductile Iron Ferrules is doubtful. Gunmetal is another alloy of Copper:CC491K and chemical composition CuSn5Pb5Zn5. CW615N contains 39% zinc as compared to 5% in CC491K which is Gunmetal. Beyond the threshold of 15% Zinc, the alloy is prone to - Stress Cracking Corrosion and - Dezincification. Both thrive in certain environments. FERRULE ALERT Workmanship cannot be overlooked. Over-tightening leads to excessive stresses in the threads and contributes to the occurrence of stress corrosion cracking failures. Colleagues are invited to give their views and for discussion. This ferrule problem is very real, their replacement should not be considered as the only solution. Equipped with the right knowledge, proper care and precautions, these ferrule failures can be avoided. A.Baldan (T.O) Jan 2020 C2015-80 – RENEWAL OF PIPELINE FROM RICHE EN EAU TO GRAND BEL AIR & VILLE NOIRE July 2019 PART 1 REPORT ON LEAKS (SADDLES AND FERRULES) CONTRACT FEATURES: Contract Price Contractor Commencement Date Duration Scheduled Completion Revised Completion Mobilisation on Site Excavation Starts DI 100 Excavation Starts DI 200 Connection Ch 00 REE Res. Testing Starts Rs 119 844 021.00 (excl. vat) Sotravic Limitee 27-Sep-2017 20 Months 26-May-2019 17-Jun-2019 30-10-17 26-02-18 Grand Bel Air 07-03-18 CH OO Stretch A 19-06-18 Ch 00 - Ruisseau Delices on both DI 300 from Cluny and Tapping Starts 17-04-18 18-05-18 19-06-18 09-07-18 21-06-18 Laterals DI 100 Main DI 200 Laterals DI 100 Laterals DI 150 Main DI 200 Shifting Starts 27-08-18 Jauferally St – Grand Bel Air PRV Set 17-09-18 4.8 / 2.0 bar Commission GBA 18-09-18 Final Lat Connections 25-09-18 01-10-18 End V-Noire to Mahebourg - PE 160 at Bridge Start Petit Bel Air - PE 160 FULL COMMISSIONNING 11-10-18 Last Connection to NHDC Ville Noire No of HH 1033 111 HH at Debarcadere shifted on this System. Previously supplied from Ruisseau Delices. Taking Over 21-11-18 Permanent Reinst- Asphalt 19-02-19 Cite Ville Noire Start RDA Reinstatement End 25-06-19 District Council - 11-06-19 Appearance of Ferrule Leaks 25-04-19 Leak Detection Exercise Sept – Oct 2019 Ferrule Replacement 07-10-19 (Full Fledged) Shifting started on August 2018 and leakages started to appear on 25 April 2019. Therefore, the pipeline run for 8 months until the first sign of leaks appears. Upon repairs, cracks were found on the ferrules where water spurts out in jets. This continuous action eventually eroded the ferrule and even the adaptor. The following pictures illustrate the leaks: ORIGIN OF FERRULES: Contractor Sotravic supplied the ferrules for this Contract. The manufacturer is Ningbo Bestway M&E Co Ltd. From China. Note: ‘’NB’’ is embossed at the Top of the Ferrule. The following documents were submitted. 1.0 2.0 3.0 4.0 5.0 Certificate of Registration/ISO certification Manufacturer Authorisation Statement of Origin Product Catalogue Project References (Local) 5.1 Supply and Replacement of Mains in John Kennedy DMA (NRW), contract CPB/20/2014 5.2 Supply and Replacement of Mains in Curepipe & Lislet Goeffroy DMAs (NRW) The above 2 projects were under progress at Bid Submission. FREQUENCY OF LEAKS Leaks on Ferrule 10 9 9 8 8 7 6 5 4 4 4 4 3 3 2 3 2 3 2 2 2 1 4 3 3 2 1 4 2 2 2 1 1 23-07-19 19-07-19 17-07-19 11-07-19 04-07-19 26-06-19 21-06-19 20-06-19 19-06-19 12-06-19 17-06-19 07-06-19 04-06-19 31-05-19 30-05-19 28-05-19 24-05-19 22-05-19 20-05-19 17-05-19 13-05-19 10-05-19 25-04-19 0 Leaks started to appear after 8 months that the ferrules have been put into service The above graph illustrates the no. of leaks/repairs on the corresponding dates for the period April to July 2019 A very small drop is observed in the Trendline. ACTION TAKEN: Since the occurrence of leaks, PMO is liaising closely with Ops as well as the Contractor. Once the complaints are received, same is immediately communicated to the Contractor who promptly organize for the repairs. Contractor has already used All of the ferrules supplied under the Contract. So as not to delay reparation works, ferrules were taken from Contract C2016-34 – Renewal of Pipeline in Magnien. (60 Ferrules were therefore transferred) These 60 ferrules will be deducted from Contractor’s claim. Contractor was informed that no more ferrules would be obtained from Plaine Magnien site and that he would have to supply his own for future repairs. Consequently, the upcoming repairs were done using ferrules supplied by Contractor Sotravic for their Riviere du Rempart Contract. 1- A Site visit was effected on the 31st May 2019 where Mr Soocheta – EE PMO and Mr Bundhoo CWO OPS were present to assess the leaks de-visu. 2- A meeting was convened on the 10th June at St Paul to discuss the issue of leakage on ferrules. 3- It is known that after commissioning the pressure at end of Grand Bel Air and at the end of the pipeline at Ville Noire was around 4 to 5 bar. 4- Furthermore, a plan showing the location of leaks has been produced. The leaks are more prominent at end of Grand Bel Air and end of Pipeline in Ville Noire where the recorded pressure at commissioning were 4 to 5 bar. Another pressure monitoring carried out on Thursday 25th July 2019, the pressure has subsided to 2.5bar. Further pressure readings have to be taken during the night where pressure builds up where demand is lowest. C2015-80 – RENEWAL OF PIPELINE FROM RICHE EN EAU TO GRAND BEL AIR & VILLE NOIRE Nov 2019 PART 2 REPORT ON LEAKS (SADDLES AND FERRULES) LEAK DETECTION EXERCISE. From the meeting of 10 June 2019, the Contractor mentioned that he would submit a report after some investigation works. Meanwhile, the leaks kept on cropping and the Contractor attended to the repairs promptly. A Leak Detection exercise was carried out on the newly laid pipeline from the 25 Sept 2019 to the 08 Oct 2019. RC Mamad from Ops South arranged and monitored the exercise. Contractor was represented by one of his Foreman, Mr Kamlesh Seebah. As for the PMO, myself, TO Baldan was present. A summary of the qty of possible Leaks detected per Agglomeration is given in the following table: ROADS AREA Grand Bel Air Cite Ville Noire Fresonge Fabien Debarcadere LEAKS DETECTED 65 11 56 3 16 151 L/m 9045 It is worth to be noted that 70/151 probable leaks were detected on the RDA Classified road. On the 06 August 2019, samples of the leaked ferruled were handed over to the Mauritius Standard Bureau (MSB) for analysis in terms of their Chemical Composition. MSB does not have the accreditation to test for copper and its alloys and they sent it to South Africa for the Tests. NOM 10 October 2019. Based on the Leak Detection Exercise and previous repairs, it was found that 30% of the ferrules are defective and therefore ALL THE FERRULES SHOULD BE REPLACED. The Contractor requested to the CWA to supply him the ferrules which he will bear the costs. Ferrule supplied by La Cure StoresCompression Type. The Copper insert is pushed inside the PE 20mm. Ferrule supplied by Contractor Note: It is supplied with a Brass Adaptor to connect the PE 20mm externally FINDINGS DURING REPAIRS WORKS. From the Leak Detection Exercise, 151 leak spots were identified. We should appreciate that one leak spot may include several tapings, hence several ferrules. During Excavation works, up to now, Leaks have been found at the Leaking Spots (69 spots). This represent 100% successful detection and credits goes to the Detection Team. TYPE OF LEAKS ENCOUNTERED. PIC 1 PIC 2 PIC 3 Fully holed Crack in Brass Adaptor Hairline Crack Sookye Rd, Ch 14 The above RHS picture (PIC 3) shows a hairline crack which was undetected during the Leak Detection Exercise. However, it was weeping. With time, the hairline will erode the ferrule into a wider and wider gap. (PIC 1) PIC 2 shows a hairline crack in the Brass Adaptor. The above scenario justifies the decision to change All the ferrules, as in some point in time, they will start to leak if the cracks have already been formed. SUMMARY OF FERRULE REPLACEMENT UP TO DEC 2019. Contract C2015-80 - Renewal of Pipeline at Riche En Eau Grand Bel Air and Ville Noire SUMMARY of Replaced Ferrules From 25-04-19 25-09-19 27-09-19 16-10-19 25-10-19 31-10-19 15-11-19 25-11-19 05-12-19 09-12-19 To 24-09-19 15-10-19 24-10-19 30-10-19 14-11-19 22-11-19 04-12-19 06-12-19 17-12-19 Total Remaining 12-01-20 Nonleaking Leaking District Council 9 104 27 85 28 71 40 41 26 66 68 71 15 105 64 86 17 40 73 86 33 114 103 80 29 76 393 570 55.18 % 594 PIT 113 95 156 44 175 104 127 43 106 963 1033 70 Replaced before Leak Detection Leak detection starts Replaced after leak Detection Replaced after leak Detection Replaced after leak Detection Replaced after leak Detection Replaced after leak Detection Replaced after leak Detection Replaced after leak Detection Replaced after leak Detection Total Replaced Asphalted RDA PIT Asphalted 27 27 17 17 22 11 18 22 11 18 95 95 Total Qty of Ferrules Total 550* POTABLE WATER RECOVERED TILL DECEMBER 2019 FOLLOWING FERRULE REPLACEMENT 15-Oct-2019 4395 m3/d 26-Dec-2019 2909m3/d TECHNICAL SPECIFICATION OF SUPPLIED FERRULES. The supplied Ferrules are from NINGBO BESTWAY M&E CO LTD, China. (ANNEX 1) As per the Bid Submission, they meet the requirements of ISO9001:2008. 9001:2008 is the standard that outlines the requirements an organization must maintain in their quality system for ISO 9001:2008 certification. The technical aspects mention a Brass/Bronze construction ferrule for an HDPE Outlet. Contractor informed that these ferrules have been used at 1.0 Supply and Replacement of Mains in John Kennedy DMA (NRW), contract CPB/20/2014 2.0 Supply and Replacement of Mains in Curepipe & Lislet Goeffroy DMAs (NRW) Both are CWA Projects. MISSING USEFUL INFORMATION From the submission, the following important data cannot be found: 1.0 2.0 3.0 4.0 Working Pressure Temperature Type of Ferrule (Push fit or Compression) Material percentage composition as per which Standard / BS/ISO Grade of material. Installation Instructions. Resistance to Corrosion. 5.0 6.0 CWA’s REQUIREMENT. As per our document Contract C2015-80, pg 325, APPENDIX TO SPECIFICATIONS: 4.0 CLAUSE 2.22: DUCTILE IRON PIPES, FLANGES AND FITTINGS For Swivel Ferrules to be supplied, both Gunmetal (as per BS 1400-LG2) and Ductile Iron (BS EN 545/ ISO 2531: 2000), will be accepted under this Contract. Also, it should be noted that our item in the Supply BOQ is as follows: 2.16 SWIVEL FERRULE (PRISECOCK) NIL 0 2.16.1 BRASS SWIVEL FERRULE TO ACCOMMODATE TRANSITION COUPLER 20 MM HDPE/BRASS WITH MALE THREAD UNIT 900 CAUSE OF LEAKAGES. From the above background information, 2 avenues will be explored to investigate the most plausible cause of the Leaks. 1.0 - Material Supplied (Ferrule) in terms of its composition and Characteristics. 2.0 - Workmanship and Method of Installation. 1.0 MATERIAL SUPPLIED CHARACTERISTICS. (FERRULE) IN TERMS OF ITS COMPOSITION AND As per CWA Specs, the ferrule material should be Gunmetal or Ductile Iron. Ductile Iron Swivel ferrules are not available. ALLOYS OF COPPER/BRASS/BRONZE?? Copper is frequently used in alloys with tin, zinc, nickel etc., To put it simply, Brass is a Copper-Zinc alloy in which Zinc is the Main Alloying element. Bronze is a Copper-Tin alloy in which Tin is the Main Alloying agent. Effects of alloying elements Lead The addition most commonly made to brasses to modify their properties is lead, up to 3% of which may be added to alpha-beta brasses to provide free-machining properties. The lead does not form a solid solution with the copper and zinc but is present as a dispersed discontinuous phase distributed throughout the alloy. It has no effect on corrosion resistance. Lead is not added to wrought alpha brasses since, in the absence of sufficient beta phase, it gives rise to cracking during hot working. Tin 1% tin is included in the composition of Admiralty brass CW706R (CZ111) and Naval brass CZ112 (nearest CW712R). As their names indicate, these brasses were developed originally for seawater service, the tin being added to provide improved corrosion resistance. http://herzmediaserver.com/data/01_product_data/06_broschure/eng/herz-brass-versus-bronze-inmaterial-selection.pdf 1.1 GUNMETAL (BS 1400-LG2) – As per our Contract Document https://en.wikipedia.org/wiki/Gunmetal Gun metal, also known as red brass in the United States, is a type of bronze – an alloy of copper, tin, and zinc. Proportions vary but 88% copper, 8–10% tin, and 2–4% zinc is an approximation. Originally used chiefly for making guns, it has largely been replaced by steel. Gunmetal, which casts and machines well and is resistant to corrosion from steam and salt water,[1] is used to make steam and hydraulic castings, valves, gears, statues, and various small objects, such as buttons. It has a tensile strength of 221 to 310 MPa, a specific gravity of 8.7, a Brinell hardness of 65 to 74, and a melting point of around 1,000 degrees Celsius. Chemical Composition – CuSn5Pb5Zn5 and Alloy designation (UK) CC491K BS1400 is the old BS Standard and has been replaced by BS EN 1982:2008 It is about Copper Alloy ingots and Copper Alloy and High conductivity copper castings The UNS (Unified Numbering System) designation (US) is C83600 1.2 SUPPLIED FERRULES On the other side, as per the Laboratory (Scrooby’s- South Africa) results, the ferrules supplied have chemical composition – CuZn39Pb3Sn and Alloy designation (UK) CW615N The supplied ferrules do not have any BS Standards but it has an EN 12165: 1998 which is about Copper and copper alloys. Wrought and unwrought forging stock There is no UNS designation for CW615N. The nearest one is for CW613N is C48500 for CuZn39Pb2Sn and CW614N is C38500 for CuZn39Pb3 https://books.google.mu/books?id=sxkPJzmkhnUC&pg=PA29&lpg=PA29&dq=CW615N&source=bl&ots=AKwu4bkx l0&sig=ACfU3U0In1Sdbz5a_wfor9s6GgAylvxSGQ&hl=en&sa=X&ved=2ahUKEwibyc__PXmAhUEu3EKHTjVBPM4ChDoATACegQICBAB#v=onepage&q=CW615N&f=false 1.3 ALLOY DESIGNATION SYSTEM. 1.4 CHEMICAL COMPOSITION COMPARISON Contractor sent samples of the defective ferrules used under the C2015-80 Contract as well as other ferrules from different sources for chemical analysis to Scrooby’s Laboratory Service CC South Africa. Contractor also performed tests on ferrules supplied from STR and METEX. Most of ferrules in use are normally supplied by these 2 suppliers. Ferrules obtained from La Cure Stores mostly are from them. The tests consist of analyzing the % Composition in Mass of the different elements found in the ferrules. PMO also sent the defective ferrules for investigation to the MSB. It is worth to note that MSB does not have the accreditation to perform Tests on Brass Materials. Therefore, MSB sent our ferrules to one of their partners in South Africa. The results are still pending. 1.41 MAJOR FINDINGS IN THE CHEMICAL ANALYSIS As per the Test carried out by the Contractor, the % of the constituents’ present in the supplied ferrules are within the range set in EN 12165. However, as mentioned earlier, the ferrules should meet the requirements set in BS1400 – LG2 as per CWA Bid Document. As per BS 1400, Gun Metals LG2, CC491K, has a much higher copper content than that of the supplied CW615N ferrule. 84-86% as compared to 57-59% The remaining main elements of Gunmetal, LG2, i.e. Tin, Lead and Zinc are evenly present in the range of 5-6%, whereas in CW615N, Tin represents 0.2-0.5% and Lead is 2.5-3.5%. Moreover, the supplied CW615N has a much higher % of Zinc (39 %) as compared to the 5% in Gunmetal. CONTRACT: CWA/C2015/80 - RENEWAL OF PIPE LINE FROM RICHE EN EAU TO GRAND BEL AIR AND VILLE NOIR Further to testing of ferrules carried out by Sotravic Ltd and the CWA, the table below describes their chemical composition with respect to establised standards. Elements (%) Standards/Samples REMARKS Copper, Cu Tin, Sn Zinc, Zn Lead, Pb BS 1400 : 1985 (As per Contract) 84 - 86 4-6 4-6 4-6 EN 12165 (CUZN39Pb3Sn – CW615N) 57.0 – 59.0 0.20 – 0.50 Remainder 2.50 – 3.50 A1 57.3 0.67 38.7 2.27 A3 57.8 0.86 37.0 2.76 Roche Bois B1 57.6 0.67 38.5 2.26 (IN USE) B3 60.0 0.89 35.3 2.66 C1 57.4 0.72 37.8 2.50 C3 59.6 1.27 34.8 2.63 Riche En Eau D1 57.6 0.70 37.8 2.28 (IN USE) D3 56.9 0.96 37.9 2.76 Riche En Eau E1 56.9 1.04 37.9 2.77 (DAMAGED) E3 59.0 1.05 35.7 2.67 STR F1 58.4 0.73 37.0 2.07 G1 57.7 0.85 37.0 2.69 G3 57.9 0.87 37.1 2.62 Roche Bois (NEW) Riche En Eau (NEW) METEX Results of Test effected by CWA PENDING Compiled by EE Jeetoo 1.41 SIGNIFICANCE OF A HIGH ZINC CONTENT IN THE COPPER ALLOY BRASS. There are numerous different types of brass specified by EN (European Norm) Standards. Their composition varies depending upon the properties required for a particular application. Brasses are classified in a variety of ways, including by their mechanical properties, crystal structure, zinc content, and color. The main constituent of Brass is Zinc, but the latter’s proportion itself is usually modified to improve a specific characteristic, such as strength, workability or Resistance to a particular type of Corrosion. The type of Brass manufactured is determined by the copper to Zinc proportion by weight (%) Brass types Class Proportion by weight (%) Copper Notes Zinc Alpha brasses > 65 < 35 Alpha brasses are malleable, can be worked cold, and are used in pressing, forging, or similar applications. They contain only one phase, with face-centered cubic crystal structure. With their high proportion of copper, these brasses have a more golden hue than others Alpha-beta brasses 55–65 35–45 Also called duplex brasses, these are suited for hot working. They contain both α and β' phases; the β'-phase is body-centered cubic and is harder and stronger than α. Alpha-beta brasses are usually worked hot. The higher proportion of zinc means these brasses are brighter than alpha brasses. Beta brasses[citation 50–55 45–50 Beta brasses can only be worked hot, and are harder, stronger, and suitable for casting. The high zinc-low copper content means these are some of the brightest and least-golden of the common brasses. Gamma brasses 33–39 61–67 There are also Ag-Zn and Au-Zn gamma brasses, Ag 30–50%, Au 41%.[27] White brass < 50 > 50 These are too brittle for general use. The term may also refer to certain types of nickel silver alloys as well as Cu-Zn-Sn alloys with high proportions (typically 40%+) of tin and/or zinc, as well as predominantly zinc casting alloys with copper additives. These have virtually no yellow coloring at all, and instead have a much more silvery appearance. needed] https://en.wikipedia.org/wiki/Brass 1.42 ALPHA-BETA BRASSES (Double Phase or Duplex) Based upon the composition of CW615N, we are concerned with Alpha-Beta Brasses. Alpha-Beta Brass is cheaper than single phase brass because of the larger amount of zinc used in it. At the same time, it’s more prone to corrosion. Still, the chemical composition leads to greater strength and hardness. Therefore, double phase brass is suitable for hot forming and casting. Extrusion, stamping and die-casting are usable methods with that type of metal. . 1.5 CORROSION IN BRASSES. Pure Copper is a noble metal and resists well to corrosion. But the alloys depending on their composition are at the mercy of corrosion. In the presence of some reagents certain alloys suffer from 1.0 Hydrogen embrittlement or Stress Corrosion Cracking and 2.0 Dezincification. 1.51 STRESS CORROSION CRACKING- SCC Corrosion cracking most commonly occurs in brass that is exposed to ammonia or amines. Brasses containing more than 15% Zn are the most susceptible. Copper and most copper alloys that either do not contain zinc or are low in zinc content generally are not susceptible to SCC. Because SCC requires both tensile stress and a specific chemical species to be present at the same time, removal of either the stress or the chemical species can prevent cracking. Annealing or stress relieving after forming alleviates SCC by relieving residual stresses. Stress relieving is effective only if the parts are not subsequently bent or strained in service; such operations reintroduce stresses and resensitize the parts to SCC. Copper and Copper Alloys Edited by J. R. Davis Davis & Associates Prepared under the direction of the ASM International Handbook Committee SCC is commonly referred to as season cracking. In the case of copper alloy fittings, it is manifested by the appearance of intergranular cracking, usually (but not always) disposed along the longitudinal axis of the component. It is due to four essential factors: • Residual Stress in the Fitting • A Stress Cracking Agent ; Ammonia Derivatives ( http://www.conexbanninger.com/) • Moisture • An Alkaline Environment HERZ Armaturen GmbH , Richard-Strauss-Str. 22, A-1230 Vienna Failed ½ in. brass ball valve from HVAC system. Valve split at male internal threads https://www.valvemagazine.com/webonly/categories/technical-topics/5283-forensic-engineeringtracks-valve-failures.html Broken Ferrule at Soochit Store, Ville Noire (20-01-2020). This is a probable case of SCC. This ferrule was issued by La Cure Stores Better resistance to SCC is possible if Brasses of Low Zinc are used. Avoiding high stresses during the manufacturing, assembling and operation phase will also help, As for operation, the following example is most relevant to our case: 1.51.1 USE OF PTFE AND OVERTIGHTENING On site, when undertaking connection and assembly works with small fittings, PTFE Tape (Teflon), is used at the joints and the plumber tighten the fittings TIGHTLY. In doing so, a high level of stresses is introduced which may induce SCC. When PTFE tape is used to seal the thread, it is all too easy to overtighten such joints to a point where a very high circumferential hoop stress is generated in the female member. There have been many examples of subsequent longitudinal stress corrosion cracking of the valve ends as a result of contact with quite low concentrations of ammonia in service. SITE PHOTOGRAPHS SHOWING PROBABLE STRESS CORROSION CRACKING- SCC FROM SITE C2015-80 1.52 DEZINCIFICATION. Dezincification is the leaching out of Zinc from brass. It can cause (meringue) build-up and pipe blockage, fitting bursts, lead contamination events and pitting failure. Dezincification can occur as a uniform or localized process, with or without meringue build-up. While resistant brasses have been developed and are available for use in potable water systems, it has become commonplace to use alloys susceptible to dezincification due to their low cost. It is accepted that high chloride, low hardness and low alkalinity waters are especially prone to dezincification. Zhang Y. Dezincification and Brass Lead Leaching in Premise Plumbing Systems: Effects of Alloy, Physical Conditions and Water Chemistry. [Thesis]. Blacksburg: Virginia Polytechnic Institute and State University; 2009. There are also health concerns due to links between dezincification and increased lead contamination of potable water from brass (Triantafillou and Edwards 2007) (D. E. Kimbrough 2007) (D. Kimbrough 2001). Preventing and Treating the Dezincification of Brass – Canadian Conservation Institute (CCI) Notes 9/13 https://www.canada.ca/en/conservation-institute/services/conservation-preservationpublications/canadian-conservation-institute-notes/dezincification-brass.html Brass containing less than 15 wt% zinc resists dezincification, but brass with more than 15 wt% zinc is susceptible to the phenomenon. Duplex brass is even more prone to dezincification than alpha brass (Scott 2002). The first sign of dezincification of brass is a change in colour, from the yellow typically found in brass to the salmon pink of pure copper metal. The pink colour may then turn reddish and then brown if the surface copper corrodes to form cuprite. More severe dezincification produces a porous, weak metal, which is mainly copper (Dinnappa and Mayanna 1987). Severe dezincification of brass plumbing fixtures can perforate the brass and cause leaks. Larry Muller. The Basics of Dezincification - Director, Metallurgy and Technical Services Chase Brass and Copper Company, LLC. Montpelier, OH; 201 Not all brasses are prone to Dezincification. Up to 15% of Zinc, the material is safe from Dezincification. At ≤ 35% zinc, some additives and/or thermal treatments can prevent this corrosion. Dezincification can be prevented by adding inhibitors like, 0.2% of Arsenic, Antimony and Phosphorous. Adding 0.25%-2% of Tin, Nickel and Aluminum also help. However, if the material contains > than 35%, the inhibitors cannot offer full protection. Here, we recall that the supplied ferrule which is alloy CW615N has a 39 % of Zinc as tested by Scrooby’s Laboratory Service CC - South Africa and the results submitted by the Contractor. 1.53 WATER CONDITIONS FOR DEZINCIFICATION. Water Conditions High O2 & CO2, stagnant or slow-moving water Slightly acid water & low salt content Soft water, low pH, low mineral content Waters high in chloride ions Neutral / alkaline waters, high salt, ≥ room temperature Type of Dezincification LAYER - Progression is Slow and along a broad front. PLUG - Progression is faster and Localised To summarize dezincification, 1. Dezincification is the selective loss of zinc from brass. 2. It’s an electrochemical reaction between zinc and some chemicals found in water. 3. It results in a weak spongy copper layer at the water contact surface 4. It can progress through the part causing leaks 5. It can cause blockage of the water path if it forms a “meringue” deposit 6. The loss of the wall’s cross section can cause mechanical failure by straight-forward fracture or increased vulnerability to stress corrosion cracking (SCC) Photographs of Dezincification https://www.festoolownersgroup.com/hom e-improvement-other-projects/thedezincification-of-brass-a-lesson-learned/ 1.54 DEZINCIFICATION RESISTANT BRASS Standard Brass is widely used in the water industry. However, in certain conditions, when exposed to certain pH values and Chlorides, they can suffer from dezincification. The solution to this problem is a dezincification resistant alloy - DZR brass. This material is the ideal choice when aggressive conditions prevail. https://www.ldmbrass.com/en/product/4-0-0/4-39/dzr.htm EN12165 also mentions the above at Clause (5c) when ordering. SITE PHOTOGRAPHS SHOWING PROBABLE DEZINCIFICATION FROM SITE C2015-80. Totally Crumbled parts of a defective ferrules from Site C2015-80 – July 2019 – This may be a consequence of Dezincification. 3.0 FURTHER READING Zhang Y. Dezincification and Brass Lead Leaching in Premise Plumbing Systems: Effects of Alloy, Physical Conditions and Water Chemistry. [Thesis]. Blacksburg: Virginia Polytechnic Institute and State University; 2009. Clement Cartier, Identification et traitements des principales sources de plomb en eau potable - Département des génies civil, géologique et des mines école polytechnique de montréal thèse présentée en vue de l’obtention du diplôme de philosophiae doctor (génie civil) - UNIVERSITÉ DE MONTRÉAL - JUIN 2012 Moustafa Said Seleet , Electrochemistry of stress corrosion cracking of brass, Iowa State University, 1986 https://www.valvemagazine.com/web-only/categories/technical-topics/5283-forensic-engineeringtracks-valve-failures.html Water Journal – Australian Water and Wastewater Association – April 1993 Aalco – The UK’s largest independent multi-metals stockholder. BS1400 Copper Alloy ingots and Copper Alloy and High conductivity copper castings EN12165 Copper and copper alloys. Wrought and unwrought forging stock Ps : You must have noted that the workmanship aspect has not been fully scrutinized. This will be for another paper after consulting more experienced colleagues. Stress Corrosion Cracking, Dezincification or a Lethal combination of Both. adjeiB Jan 2020