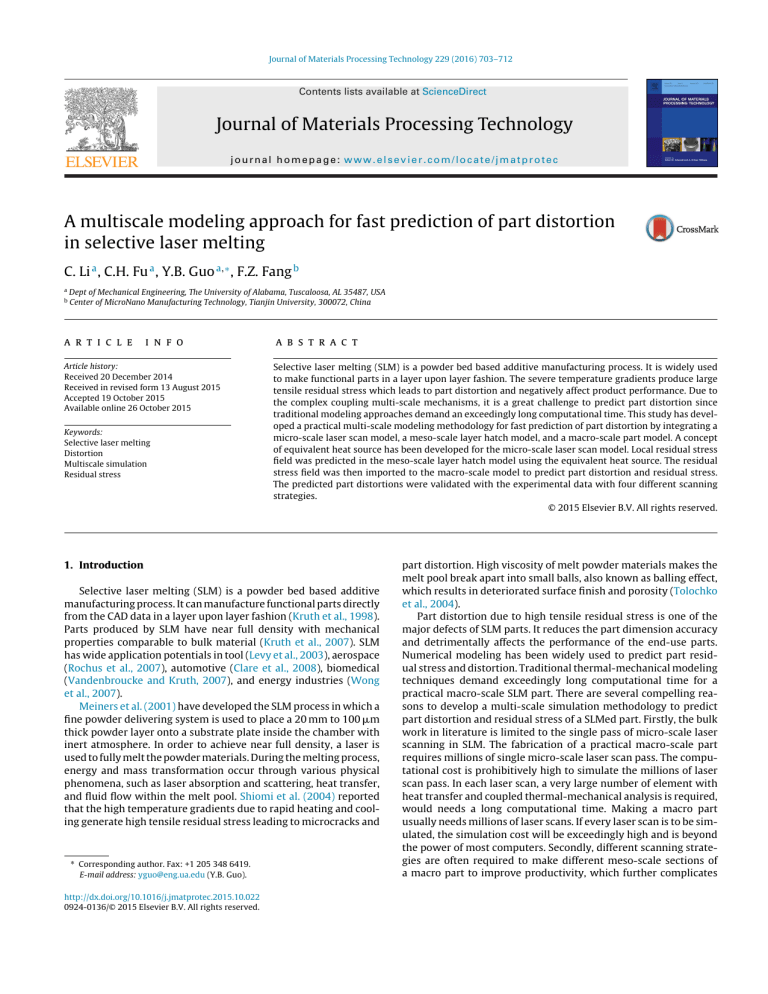

Journal of Materials Processing Technology 229 (2016) 703–712 Contents lists available at ScienceDirect Journal of Materials Processing Technology journal homepage: www.elsevier.com/locate/jmatprotec A multiscale modeling approach for fast prediction of part distortion in selective laser melting C. Li a , C.H. Fu a , Y.B. Guo a,∗ , F.Z. Fang b a b Dept of Mechanical Engineering, The University of Alabama, Tuscaloosa, AL 35487, USA Center of MicroNano Manufacturing Technology, Tianjin University, 300072, China a r t i c l e i n f o Article history: Received 20 December 2014 Received in revised form 13 August 2015 Accepted 19 October 2015 Available online 26 October 2015 Keywords: Selective laser melting Distortion Multiscale simulation Residual stress a b s t r a c t Selective laser melting (SLM) is a powder bed based additive manufacturing process. It is widely used to make functional parts in a layer upon layer fashion. The severe temperature gradients produce large tensile residual stress which leads to part distortion and negatively affect product performance. Due to the complex coupling multi-scale mechanisms, it is a great challenge to predict part distortion since traditional modeling approaches demand an exceedingly long computational time. This study has developed a practical multi-scale modeling methodology for fast prediction of part distortion by integrating a micro-scale laser scan model, a meso-scale layer hatch model, and a macro-scale part model. A concept of equivalent heat source has been developed for the micro-scale laser scan model. Local residual stress field was predicted in the meso-scale layer hatch model using the equivalent heat source. The residual stress field was then imported to the macro-scale model to predict part distortion and residual stress. The predicted part distortions were validated with the experimental data with four different scanning strategies. © 2015 Elsevier B.V. All rights reserved. 1. Introduction Selective laser melting (SLM) is a powder bed based additive manufacturing process. It can manufacture functional parts directly from the CAD data in a layer upon layer fashion (Kruth et al., 1998). Parts produced by SLM have near full density with mechanical properties comparable to bulk material (Kruth et al., 2007). SLM has wide application potentials in tool (Levy et al., 2003), aerospace (Rochus et al., 2007), automotive (Clare et al., 2008), biomedical (Vandenbroucke and Kruth, 2007), and energy industries (Wong et al., 2007). Meiners et al. (2001) have developed the SLM process in which a fine powder delivering system is used to place a 20 mm to 100 m thick powder layer onto a substrate plate inside the chamber with inert atmosphere. In order to achieve near full density, a laser is used to fully melt the powder materials. During the melting process, energy and mass transformation occur through various physical phenomena, such as laser absorption and scattering, heat transfer, and fluid flow within the melt pool. Shiomi et al. (2004) reported that the high temperature gradients due to rapid heating and cooling generate high tensile residual stress leading to microcracks and ∗ Corresponding author. Fax: +1 205 348 6419. E-mail address: yguo@eng.ua.edu (Y.B. Guo). http://dx.doi.org/10.1016/j.jmatprotec.2015.10.022 0924-0136/© 2015 Elsevier B.V. All rights reserved. part distortion. High viscosity of melt powder materials makes the melt pool break apart into small balls, also known as balling effect, which results in deteriorated surface finish and porosity (Tolochko et al., 2004). Part distortion due to high tensile residual stress is one of the major defects of SLM parts. It reduces the part dimension accuracy and detrimentally affects the performance of the end-use parts. Numerical modeling has been widely used to predict part residual stress and distortion. Traditional thermal-mechanical modeling techniques demand exceedingly long computational time for a practical macro-scale SLM part. There are several compelling reasons to develop a multi-scale simulation methodology to predict part distortion and residual stress of a SLMed part. Firstly, the bulk work in literature is limited to the single pass of micro-scale laser scanning in SLM. The fabrication of a practical macro-scale part requires millions of single micro-scale laser scan pass. The computational cost is prohibitively high to simulate the millions of laser scan pass. In each laser scan, a very large number of element with heat transfer and coupled thermal-mechanical analysis is required, would needs a long computational time. Making a macro part usually needs millions of laser scans. If every laser scan is to be simulated, the simulation cost will be exceedingly high and is beyond the power of most computers. Secondly, different scanning strategies are often required to make different meso-scale sections of a macro part to improve productivity, which further complicates 704 C. Li et al. / Journal of Materials Processing Technology 229 (2016) 703–712 Fig. 1. Multi-scale methodology for fast prediction of part distortion and residual stress. this issue. Thirdly, distortion and residual stress are critical structural integrity for a macro-scale SLMed part. Therefore, a novel multi-scale simulation methodology is highly needed to predict part distortion and residual stress with low computational cost. 2. Background on SLM modeling for part distortion A few simulations have been tried to predict residual stress and distortion of SLM parts on a micro-scale or meso-scale level. Li et al. (2004) studied the local thermal stress distribution in the melt pool and its implication on crack formation during laser melting of ceramic materials. Different thermal loads with and without latent heat and fluid flow of the melt pool were used. Aggarangsi and Beuth (2006) studied the residual stress reduction method of a SLMed thin-wall structure. The powder material was locally preheated by a secondary moving heat flux and then melted by a primary moving heat flux. Hodge et al. (2013) studied the thermal and mechanical history of SLM process on a meso-scale (12 layers of powder). A volumetric moving flux was used to melt powder materials. Phase change during the process was considered and a coarse mesh was used to reduce computational time. Dai and Shaw (2004) studied the effect of powder-to-solid transition to investigate the residual stress and distortion of metal and ceramic powders on a small domain. Only two layers were built with a layer thickness of 0.5 mm. It should be noted that the coupled thermal-mechanical analysis for several layers at micrometer level with a fine mesh was very time consuming. Thus, it is not practical to predict distortion of a macro-scale SLM part using this method. Some studies predicted residual stress and part distortion in SLM on a macro-scale. Nickel et al. (2001) applied a constant heat flux to heat an entire scan at same time. Different scanning patterns were considered to predict the residual stress and distortion. Zaeh and Branner (2010) applied a uniform thermal load adjusted from experimental data to heat up 20 powder layers (meso-scale hatching zone) at the same time to predict the temperature and residual stress distribution of a SLMed cantilever. Papadakis et al. (2013) traced the temperature history of one specific point in the melt pool, and then extended this temperature history to one powder layer or multiple layers (hatching zone) to predict shape distortion of a cantilever. These modeling approaches were all based on applying a uniform thermal load to one layer or multiple layers (hatching layer) at one time. However, it should be noted that a uniform thermal load applied on one layer or multiple layers underestimates the steep temperature gradients in a SLM process. Furthermore, scanning strategy plays an important role in temperature distribution, part distortion, and cracks formation in SLM parts (Yasa et al., 2009). However, little has been done to address the pressing problems. Therefore, the objective of this study is to develop a practical multi-scale methodology for fast prediction of distortion and residual stress of a SLMed part by: (a) developing a novel concept of equivalent heat source that includes temperature gradient within one layer in a micro-scale laser scan model; (b) calculating a local residual stress field in a meso-scale hatch model; (c) mapping the residual stress field into a macro-scale part model with four scanning strategies; to predict part distortion and residual stress field. 3. Multi-scale simulation methodology 3.1. Multi-scale modeling procedure In order to develop an efficient method for fast prediction of the distortion and residual stress field of SLM parts with reasonable computational time, a multi-scale finite element model has been developed. The procedures to develop the multi-scale simulation model (Fig. 1) have three parts: • Micro-scale laser scan model (Fig. 2): a moving heat flux was applied on the surface of the powder material to determine an equivalent heat source of a stabilized melt pool; Fig. 2. Micro-scale laser scan model with 3D moving Gaussian heat flux. C. Li et al. / Journal of Materials Processing Technology 229 (2016) 703–712 705 solid material, kr is the thermal conductivity portion of the powder bed due to radiation among particles. 3.2.2. Convection It was stated that heat lost by convection between melt pool and powder bed is significant in powder bed based additive manufacturing process (Dai and Shaw, 2004). Therefore, it is critical to incorporate natural convection between the melt pool and its surrounding powder bed in the simulation. The heat loss due to this convection is determined by qc = hc (T − T0 ) Fig. 3. Dimension and boundary conditions in the meso-scale layer hatch model. (3) where T is melting pool temperature, T0 is the ambient temperature, and hc is the heat transfer coefficient, which is described by hc = Nu kf L (4) where L is the characteristic length of the specimen, kf is the thermal conductivity of fluid, and Nu is the Nusselt number, which is described by ⎡ Nu = ⎤1/6 ⎢ Nu0 + ⎣ Gr Pr /300 1 + 0.5/Pr 9/16 ⎥ 16/9 ⎦ (5) where Gr is the Grashof number and Pr is the Prandtl number. Gr and Pr are given by Eqs. (6) and (7), respectively. Fig. 4. Dimension and boundary conditions in the macro-scale part model. Gr = • Meso-scale layer hatch model (Fig. 3): the equivalent heat source is imported to the meso-scale layer hatch model to obtain a local residual stress field; • Macro-scale part model (Fig. 4): the local residual stress field was mapped to the macro-part model to predict part distortion and residual stress field with four scanning strategies. 3.2. Heat transfer modeling Heat dissipation between the melt pool and the environment is through three mechanisms: conduction into powder bed and the substrate, radiation and convection to the environment. Fig. 3 illustrates the three mechanisms of heat loss applied in the multiscale modeling approach. The methods of heat transfer are detailed as follows. 3.2.1. Conductivity The heat loss through thermal conductivity from melt pool to the powder bed and substrate during a SLM process can be described as: q = −k T (1) where k is the thermal conductivity coefficient, T is the temperature gradient between the two different materials. The effective thermal conductivity of the powder bed k can be described as (Sih and Barlow, 1995): k = kf + 1− 1−ϕ 1−ϕ 1+ 2 1− ϕ kr kf 1 kf ks 1− kf ks ln Pr = s kf −1 kr kf Cp f kf (7) 3.2.3. Radiation Radiation of the powder bed was also considered in this study. Radiation into environment causes heat loss qr , which is determined by qr = T 4 − T04 (8) where is the Stefan-Boltzman constant, T0 is the ambient temperature, and is the emissivity of the powder bed, which is given by = AH H + (1 − AH ) s (9) where AH is the area fraction of the surface that is occupied by the radiation-emitting holes, H is emissivity of the hole, and s is the emissivity of the solid particle. AH and H are defined by Eqs. (10) and (11), respectively. 0.908ϕ2 1.908ϕ2 − 2ϕ + 1 (10) + (6) 2f where g is the gravitational acceleration, f is the fluid density, ˇf is the thermal volumetric expansion (ˇf = 1/Tf , Tf = 0.5 (T + T0 )), is the specific heat of the fluid, and is the viscosity of the melting pool. AH = k gL3 f2 ˇf (T − T0 ) (2) where ϕ is the fractional porosity of the powder bed, kf is the is the thermal conductivity of air, ks is the thermal conductivity of the H = s 2 + 3.082( 1−ϕ ϕ ) s 1 + 3.082( 1−ϕ ϕ ) 2 2 (11) +1 where ϕ is the fractional porosity of the powder bed. 706 C. Li et al. / Journal of Materials Processing Technology 229 (2016) 703–712 Fig. 5. Temperature field on the cross-section of melt pool during the micro-scale laser scan. Table 1 SLM process parameters. Laser power Laser spot diameter Scan speed Scan spacing Layer thickness W 300 m 600 mm/s 50 m 100 m 150 3.3. Simulation conditions 3.3.1. Process parameters The laser source in this study was a continuous Nd:YAG laser with a wavelength of 1.064 m. The process parameters including laser power, laser spot diameter, scan speed, scan spacing, and layer thickness are listed in Table 1. 3.3.2. Material properties This study aims to predict part distortion and compare with the experimental data using lab-made iron-based powders (Kruth et al., 2004). Due to the non-available property of the lab-made Fe-based powder, very similar material properties of steel-based commercial material DirectSteel® from EOS GmbH DirectSteel® was used to approximate the iron-based powders. The comparison between the iron-based powder and DirectSteel® is listed in Table 2. Temperature-independent mechanical and thermal material properties of DirectSteel® are listed in Table 3. The substrate was a steel plate. 3.4. Micro-scale laser scan model In the micro-scale laser single scan model, finite element analysis (FEA) package ABAQUS/Standard was used to conduct a thermal analysis to predict temperature field in the melt pool. The mesh is shown in Fig. 2. The model had two components: powder layer and substrate. The dimensions of the powder layer were 5 mm (length) × 0.6 mm (width) × 0.15 mm(thickness) and the dimensions of the substrate were 5 mm (length) × 0.6 mm (width) × 5 mm (height). The powder layer had a fine mesh with an element size of 50 m (length) × 50 m (width) × 37.5 m (thickness). The heat flux and melt pool are symmetrical with respect to the X-Z plane to reduce the computational time. The initial temperature of powder and substrate was set to room temperature (20 ◦ C). A moving Gaussian heat flux is applied to the top surface of the powder layer as boundary condition. In the micro-scale laser scan model, conductivity dominates the heat transfer process due to the powder’s short (in ms) exposure time to laser, convection and radiation of the non-melting pool were incorporated as the coefficients of convection and radiation for the melting pool are difficult to determine. It is assumed that energy loss of the melt pool through convection Fig. 6. Temperature contour in the cross-section of the melt pool. and radiation is small as the melt pool size is very small, which may require a separate future study. The size of melt pool is affected by process parameters and powder size, however, the average size of a melt pool is expected to vary within a small range under the constant SLM conditions. In this study, a continuum mechanics based finite element method was used to predict the melt pool size. If the unstable melt pool and non-equilibrium physical and chemical metallurgical problems are focused, a separate method such as LBM (Lattice Boltzmann Method) would be used for this purpose, which is beyond the scope of this work. The nodal temperatures on the cross-section of the melt pool were obtained, as shown in Fig. 5. The temperature contour on the cross section of the melt pool is shown in Fig. 6. It was noted that the center of the melt pool has the highest temperature. Moving away from the pool center in both the depth and width directions, the temperature dramatically decreases, which indicates a severe temperature gradient. Based on the fact that repeating laser scanning at same conditions will be performed many times, an equivalent heat input with temperature gradient can be developed from the temperature field and applied to the subsequent meso-scale hatch model to predict local residual stress. Since every point on the cross-section along C. Li et al. / Journal of Materials Processing Technology 229 (2016) 703–712 707 Table 2 Comparison of chemical composition between iron-based powder (Kruth et al., 2004) and DirectSteel® (Rombouts, 2006). Powder material Fe wt.% Ni wt.% Cu wt.% P wt.% Ref. Iron-based powder DirectSteel® Powder 62.66 59.3 ± 0.4 20 29.1 ± 1.4 15 9.6 ± 0.9 2.34 1.5 ± 0.1 (Kruth et al. (2004) Rombouts (2006) Table 3 Material properties of solid DirectSteel® (Eos GmbH, 2004). Elastic modulus Poisson’s ratio Tensile strength Yield strength GPa 15.3 Melting point ◦ C 1330 – 0.41 Coefficient of thermal expansion 10−6 /K 9 MPa 600 Thermal conductivity W/m K 13 MPa 400 Specific heat J/kg K 375 Multiple scans with the fixed scan spacing were performed simultaneously by applying the equivalent heat input on the powder layer. Fig. 7 shows the temperature profile at the top surface of the powder layer. Then, the powder and substrate were cooled down to a uniformly room temperature (around 20 ◦ C). Three cooling mechanisms are incorporated, namely, heat conduction to the substrate, heat convection to the powder bed and surrounding atmosphere, and heat radiation to the surrounding atmosphere. The temperature distribution in the hatch layer before and after cooling is shown in Fig. 8. The temperature history of the top surface of the hatch layer is shown in Fig. 9. Temperature dropped from 4900 ◦ C to 400 ◦ C in less than 0.1 s, which confirms the rapid cooling nature during the SLM process. The predicted residual stress field in the meso-scale hatch model was imported to the subsequent macro-scale part model as a patch unit for predicting part distortion and residual stress. Fig. 7. Temperature profile at the top surface of the hatch layer. the scanning path experiences a similar temperature history, it is reasonable to apply the temperature field of the melt pool crosssection to the whole scan pass. Although the assumption of layer equivalent model for various scan patterns may slightly increase inaccuracy in residual stress prediction, the inaccuracy can be justified by the significantly shortened computational time upon the prediction accuracy is acceptable. In this study, since only one layer was deposited on the substrate in the experiment, there was no previous layer preheating effect. But, there could be a certain heat accumulation between neighboring hatches in the mesoscale hatch model. However, the influence of the heat accumulation between neighboring hatches could be small, which is indicated in another study (Zach, 2010) of SLM process. 3.5. Meso-scale layer hatch model In the meso-scale hatch model, a coupled thermal-mechanical analysis was conducted to predict the local residual stress distribution of the scanned layer. The model dimensions with boundary conditions are shown in Fig. 3. The powder layer had a dimension of 5 mm (length) × 5 mm (width) × 0.15 mm (thickness). Same mesh density and mesh size were used in the powder layer as the scan model. The powder layer was placed on a 5 mm (length) × 5 mm (width) × 1 mm (thickness) substrate with constrained bottom. 3.6. Macro-scale part model In SLM process, melt pool experiences a comparable mechanical history; therefore, it is feasible to fast predict the distortion of a macro-scale part by importing local residual stress field from the meso-scale hatch model. The mesh design of the macro part model is shown in Fig. 6. The dimensions of the powder layer were 35 mm (length) × 15 mm (width) × 0.15 mm (thickness). The powder layer was placed on top of a steel plate that had a dimension of 45 mm (length) × 22 mm (width) × 1 mm (thickness). Within the fine mesh in the powder layer, the element size was 150 m × 150 m × 50 m.Four different scanning strategies (Fig. 10) were studied for the macro part model, namely, (a) horizontal sequential pattern, (b) vertical sequential pattern, (c) successive pattern, and (d) “least” heat influence (LHI) pattern. For the successive and LHI patterns, the scanning area was divided into 21 scan patches (5 mm × 5 mm). The number inside each patch in Fig. 10 represents the hatching order. The successive patches were laser scanned based on scanning sequence, the initial residual stress tensor residual from the mesoscale layer hatch model was applied to each corresponding patch. ⎡ ⎤ S11 S12 S13 residual = ⎣ S21 S22 S23 ⎦ S31 S32 S33 ⎢ ⎥ (12) 708 C. Li et al. / Journal of Materials Processing Technology 229 (2016) 703–712 Fig. 8. Temperature field in hatch layer in the meso-scale layer hatch model ((a): before cooling, (b): after cooling). 4. Model validation and discussions 4.1. Deflection in the layer hatch model Fig. 9. Temperature history of the top surface in the meso-scale layer hatch model. The deflection predicted by the meso-scale hatch model is shown in Fig. 11. At first, the expansion of the heated layer was restricted by the surrounding material during laser scanning; therefore, a compressive stress was generated on the top surface. When the yield stress of the material was reached, plastic bending occurs. As the hatch layer cools down to room temperature, the contraction of the top layer was then constrained by the surrounding material, which leads to tensile residual stress on the top surface. Also, the cooling induced shrinkage shortens the top surface compared to the subsurface, thus, the layer was deflected towards the laser beam. The predicted phenomenon agrees well with the temperature gradient mechanism (Kruth et al., 2004). 4.2. Distortion in the macro-scale part model If there is a rotation of laser scanning vector between two successive patches, the residual stress tensor was applied by using the transformation matrix: ⎡ cos Rz () = ⎣ − sin 0 sin cos 0 0 ⎤ 0⎦ (13) 1 where is the angle of rotation measured from the X-axis with respect to Z axis (Fig. 10c). The residual stress tensor after rotation can be calculated by: residual = Rz () residual Rz () T (14) During the SLM experiment, one iron-based powder layer was deposited on a 1 mm thickness steel plate. However, this is not the scenario of a SLM production, for actual SLM production of metal parts, a substrate with only 1 mm thickness would not be used, instead a much thick substrate will be usually used. Four different scanning strategies were used, then the deflections for different scanning strategies were measured from the bottom surface of the substrate and compared. Since this study is limited to the prediction of the effect of different scanning strategies on distortion and correlation with the experimental data. As one layer was deposited on the substrate, if a thick substrate was used the deflection of the deposited layer would be too small to measure. The use of a thin substrate in the SLM experiment will produce a relative large deflection for easy measurement. The sequential scanning pattern was favored according to the measurement. The normal- C. Li et al. / Journal of Materials Processing Technology 229 (2016) 703–712 709 Fig. 10. Four scanning strategies: (a) horizontal sequential, (b) vertical sequential, (c) successive, and (d) “least” heat influence (LHI). Fig. 11. Deflection in the meso-scale layer hatch model (half-hatch due to symmetric). Fig. 12. Comparison between the predicted distortion and the measured data. ized deflection is defined as the ratio of deflection at each point to the maximum deflection. The normalized distance is defined as the ratio of each point’s distance to the part edge to the part length. The distortion was measured by recording the deflection of measuring points located on the bottom surface of the substrate. 4.2.1. Longitudinal distortion of sequential pattern vs. experimental result The distortion along the longitudinal direction (X) (Fig. 12) was retrieved and compared to the experimental data. Similar bending Fig. 13. Distortion along the longitudinal (X) direction for different scanning strategies. trend and magnitude are observed for both the prediction and the measured data. This trend is attributed to the thermal history of the part during laser scanning. More specifically, the top layer was expanded at first due to the heat input. The plastic strain in the top surface became smaller than the bottom surface after cooling down. Therefore a convex distortion towards the laser source side gradually formed. 710 C. Li et al. / Journal of Materials Processing Technology 229 (2016) 703–712 in longitudinal distortion was observed between the successive pattern and the LHI pattern. The distortion for the successive pattern is only slightly smaller than the LHI pattern. The possible reason for this difference is that a higher temperature gradient exists in the LHI scanning process than that in the successive scanning process. 4.2.3. Crosswise distortions at different scanning strategies Distortions along the crosswise direction (Y) for the four scanning strategies are shown in Fig. 14. It can be found that the horizontal sequential pattern produced the biggest crosswise distortion, while the vertical sequential pattern resulted in the smallest crosswise distortion. For the successive and LHI patterns, almost same crosswise distortions were produced. The predicted distortions along the longitudinal (X) and crosswise (Y) directions for four scanning strategies were consistent with the experimental data (Kruth et al., 2004). Fig. 14. Distortion along the crosswise (Y) direction for different scanning strategies. 4.2.2. Longitudinal distortions at different scanning strategies Distortions along the longitudinal direction (X) for the four scanning strategies are shown in Fig. 13. It can be seen that the horizontal sequential pattern produced the smallest longitudinal distortion, while the vertical sequential pattern resulted in the biggest longitudinal distortion. Moreover, no significant difference 4.3. Residual stress in the micro-scale part model Fig. 15(a) shows the residual stress S11 (longitudinal direction) of the substrate along the depth (Z) direction for four scanning strategies. Within the top layers of the substrate, S11 was compressive. At approximately 0.6 mm, the residual stress transitioned from compressive to tensile. The residual stress is compressive for top layers while it is tensile for the bottom layers, which caused the substrate Fig. 15. Residual stress profiles of substrate (Z direction) for four scanning strategies. Fig. 16. Residual stress contours for four scanning strategies: (a) horizontal sequential, (b) vertical sequential, (c) successive, and (d) LHI. C. Li et al. / Journal of Materials Processing Technology 229 (2016) 703–712 711 Fig. 17. Residual stress profiles on the part top surface. Fig. 18. Residual stress profiles of the part along the depth (Z) direction. bend up.Vertical sequential pattern generated the biggest residual stress along X direction, while the horizontal sequential pattern generates the smallest residual stress. In addition, no significant difference was observed between residual stress generated by the successive and LHI patterns. Fig. 15(b) shows residual stress S22 (crosswise direction) of the substrate along the depth (Z) direction for four scanning strategies. The horizontal sequential pattern generated the biggest residual stress along Y direction, while the vertical sequential pattern generated the smallest residual stress. Also, there is no significant difference between residual stresses generated by successive and LHI patterns. Residual stress contours (von Mises stress, S11 , and S22 ) for the part and the substrate at four scanning strategies are shown in Fig. 16. No compressive residual stress was observed in the part. Residual stress S11 and S22 profiles on the part surface for four scanning strategies along the longitudinal (X) direction are shown in Fig. 17. It can be observed that both horizontal sequential and vertical sequential patterns generated a relatively stable and uniform tensile residual stress in X and Y directions compared to other two scanning patterns. On the top surface of the part, the vertical sequential pattern generated the biggest residual stress in X direction and the smallest residual stress in Y direction. The successive and LHI patterns generated residual stresses along X direction varied from patch to patch, which led to stress oscillation. Fig. 18 shows the residual stress profiles for four scanning strategies along the depth (Z) direction. Both S11 and S22 increased as depth increases for all scanning strategies. Moreover, horizontal sequential pattern generated the smallest longitudinal residual stress (S11 ) and the largest crosswise residual stress (S22 ). This study provides a multiscale method to test the feasibility of part deflection and residual stress by SLM using the regular laser scan patterns. As the melt pool temperature field can be obtained from the micro-scan model, the method can be extended to hatch layers with irregular shapes as long as the nodal set for the uneven length hatch vectors can be created. This versatile approach could be applied to a complex scanning case in SLM. However, it should be pointed out that the study was restricted to a simple enough case for which the scan vectors remain of equal length and would not interfere between physical layers, the layer equivalent model may still capture the residual stress field. However, for a complex SLM part with varying scan vectors not laid in 0-90-0 or 0-0-0 fashion between layers, it would be very difficult for the method to capture the residual stress field as residual stress produced in each physical layer and their interferences between layers will be very complex to predict precisely. 5. Conclusions A multi-scale finite element simulation method has been developed for fast prediction of part distortion of SLMed parts. The predicted distortions in four different scanning strategies were investigated and verified by the experimental data. The key findings are summarized as follows: • A concept of equivalent heat source has been developed for the micro-scale laser scan model and imported to the meso-scale hatch model to predict local residual stress, which can be mapped into the macro-scale part model to predict part distortion. • For the sequential scanning pattern, the smallest deflection occurs along the laser scanning direction. The successive scanning strategy with the LHI pattern is preferred in terms of minimizing part distortion. • Both horizontal and vertical sequential patterns generated a relatively uniform tensile residual stress, while the successive and LHI patterns generated oscillating tensile residual stress in the part. Moreover, residual stresses became more tensile as depth increased in the part for the concerned four scanning strategies. References Aggarangsi, P., Beuth, J.L., 2006. Localized preheating approaches for reducing residual stress in additive manufacturing. In Proc. SFF Symp. 709–720. Clare, A.T., Chalker, P.R., Davies, S., Sutcliffe, C.J., Tsopanos, S., 2008. Selective laser melting of high aspect ratio 3D nickel–titanium structures two way trained for MEMS applications. Int. J. Mech. Mater. Des. 4 (2), 181–187. 712 C. Li et al. / Journal of Materials Processing Technology 229 (2016) 703–712 Dai, K., Shaw, L., 2004. Thermal and mechanical finite element modeling of laser forming from metal and ceramic powders. Acta Mater. 52 (1), 69–80. Eos GmbH, 2004. Direct metal and DirectSteel materials for EOSINT M 250 xtended. Hodge, N., Ferencz, R., Solberg, J., 2013. Implementation of a Thermomechanical Model in Diablo for the Simulation of Selective Laser Melting. Lawrence Livermore National Laboratory (LLNL), Livermore, CA. Kruth, J., Froyen, L., Van Vaerenbergh, J., Mercelis, P., Rombouts, M., Lauwers, B., 2004. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 149 (1), 616–622. Kruth, J., Leu, M., Nakagawa, T., 1998. Progress in additive manufacturing and rapid prototyping. CIRP Ann. Manuf. Technol. 47 (2), 525–540. Kruth, J., Levy, G., Klocke, F., Childs, T., 2007. Consolidation phenomena in laser and powder-bed based layered manufacturing. CIRP Ann. Manuf. Technol. 56 (2), 730–759. Levy, G.N., Schindel, R., Kruth, J., 2003. Rapid manufacturing and rapid tooling with layer manufacturing (LM) technologies, state of the art and future perspectives. CIRP Ann. Manuf. Technol. 52 (2), 589–609. Li, J.F., Li, L., Stott, F.H., 2004. Thermal stresses and their implication on cracking during laser melting of ceramic materials. Acta Mater. 52 (14), 4385–4398. Meiners, W., Wissenbach, K., Gasser, A., 2001. Selective laser sintering at melting temperature. Pat. US, 6,215,093. Nickel, A., Barnett, D., Prinz, F., 2001. Thermal stresses and deposition patterns in layered manufacturing. Mater. Sci. Eng. A 317 (1), 59–64. Papadakis, L., Loizou, A., Risse, J., Bremen, S., 2013. A thermo-mechanical modeling reduction approach for calculating shape distortion in SLM manufacturing for aero engine components. VRAP International Conference, 1–5. Rochus, P., Plesseria, J., Van Elsen, M., Kruth, J., Carrus, R., Dormal, T., 2007. New applications of rapid prototyping and rapid manufacturing (RP/RM) technologies for space instrumentation. Acta Astronaut 61 (1), 352–359. Rombouts, M., 2006. Selective Laser Sintering/Melting of Iron-based Powders. Doctoral Dissertation. Katholieke Universiteit, Leuven. Shiomi, M., Osakada, K., Nakamura, K., Yamashita, T., Abe, F., 2004. Residual stress within metallic model made by selective laser melting process. CIRP Ann. Manuf. Technol. 53 (1), 195–198. Sih, S.S., Barlow, J.W., 1995. The prediction of the thermal conductivity of powders. In Proc. SFF Symp. 397, 40. Tolochko, N.K., Mozzharov, S.E., Yadroitsev, I.A., Laoui, T., Froyen, L., Titov, V.I., Ignatiev, M.B., 2004. Balling processes during selective laser treatment of powders. Rapid Prototyping J. 10 (2), 78–87. Vandenbroucke, B., Kruth, J., 2007. Selective laser melting of biocompatible metals for rapid manufacturing of medical parts. Rapid Prototyping J. 13 (4), 196–203. Wong, M., Tsopanos, S., Sutcliffe, C.J., Owen, I., 2007. Selective laser melting of heat transfer devices. Rapid Prototyping J. 13 (5), 291–297. Yasa, E., Deckers, J., Craeghs, T., Badrossamay, M., Kruth, J., 2009. Investigation on occurrence of elevated edges in selective laser melting. In Proc. SFF Symp. 673–85. Zaeh, M.F., Branner, G., 2010. Investigations on residual stresses and deformations in selective laser melting. Prod. Eng. 4 (1), 35–45.