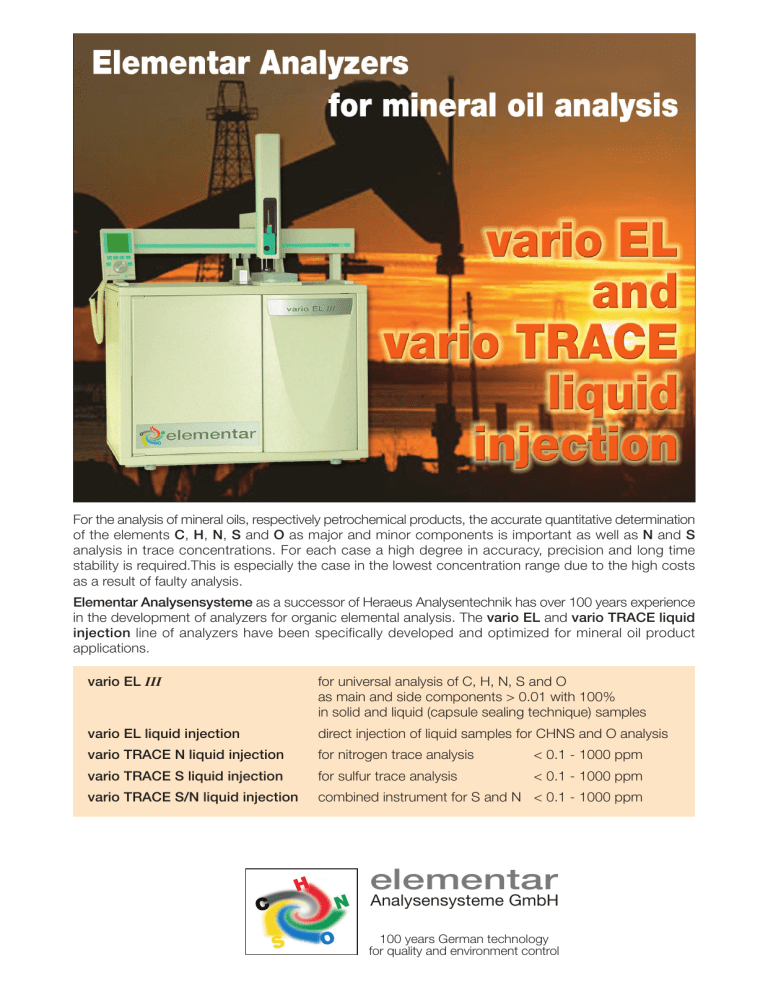

For the analysis of mineral oils, respectively petrochemical products, the accurate quantitative determination of the elements C, H, N, S and O as major and minor components is important as well as N and S analysis in trace concentrations. For each case a high degree in accuracy, precision and long time stability is required.This is especially the case in the lowest concentration range due to the high costs as a result of faulty analysis. Elementar Analysensysteme as a successor of Heraeus Analysentechnik has over 100 years experience in the development of analyzers for organic elemental analysis. The vario EL and vario TRACE liquid injection line of analyzers have been specifically developed and optimized for mineral oil product applications. vario EL III for universal analysis of C, H, N, S and O as main and side components > 0.01 with 100% in solid and liquid (capsule sealing technique) samples vario EL liquid injection direct injection of liquid samples for CHNS and O analysis vario TRACE N liquid injection for nitrogen trace analysis < 0.1 - 1000 ppm vario TRACE S liquid injection for sulfur trace analysis < 0.1 - 1000 ppm vario TRACE S/N liquid injection combined instrument for S and N < 0.1 - 1000 ppm elementar Analysensysteme GmbH 100 years German technology for quality and environment control The basis matters All elemental analyzers by ELEMENTAR for mineral oil products are based on the universal analyzer vario EL III, setting the standards in organic elemental analysis now in the third generation. Hundreds of instruments are in operation worldwide. vario EL III has been enhanced for the special requirements of petrochemical analysis. Common features: ● Very high injection volume up to 80 µl in a few seconds due to highly efficient total combustion results in high detection sensitivity. Injection of gas samples with up to more than 10 ml for TRACE S and N determination. ● PC control and data processing under Windows® including LIMS coupling and implementation in other data networks. ● High stability Long time stability of the multipoint calibration. Long stability of the analyzer allowing maintenance free operation over night. ● Automatic septum-free sample injection for 98 samples for best possible repeatability and saving of precious labor time. Optional heating device for samples with high viscosity. ● Gas separation with "purge and trap" technique serves for large concentration range, detection sensitivity, sample volume from micro to semimacro as well as automatic control of analysis time. ● Compact design, easy installation and handling, cost effective operation 230/110 V, 50/60 Hz, approx. 1800 VA, footprint 780 x 600 mm (basic unit). ● In accordance with the international standards functional diagram vario EL liquid injection CHNS version autosampler 100 µl-syringe reference gas PC He O2 adsorber adsorber adsorber vario EL liquid injection ● For the accurate and precise analysis of major and minor components in the versions CHNS and CHN and O (optional). ● Very large working range of absolute element content by means of purge-and-trap gas components separation and detection with highly stable thermoconductivity detector (TCD). ● Measuring value processing with standardization function for automatic correction of temperature depending density fluctuation of the injection volume. ● The determination of sample specific density is not required ! Relative standard deviation Working range C, H: < 0.2 % rel. (for 10 µl toluene) S: 1-2 % rel. (for approx. 1% content) O: < 1 % rel. (for 10 µl isobutanol) C: H: N: S: O: 0.03 - 20 mg abs. (or 100 %) 0.03 - 3 mg abs. (or 100 %) 0.03 - 2 mg/ or 10 mg abs.(or 100 %) 0.03 - 6 mg abs. (or 100 %) 0.03 - 5 mg abs. (or 100 %) The Trace Analyzers Instruments of the vario EL TRACE line are designed without compromises for highest sensitivity and precision for sulfur and nitrogen in hydrocarbons, gasoline or oil in order to even meet future requirements for environmental protection in terms of lower detection limits. Key for the high performance is the large sample injection volume of up to 40 µl and/or 80 µl of liquid or 10 ml of gas to be injected in a few seconds only. The special design (patent applied for) provides absolutely residue free combustion. The electronic control serves for absolute constant gas stream of the analytes. vario TRACE N liquid injection Analyzer for trace concentrations of nitrogen in mineral oils acc. to ASTM D 4629. Combustion of the injected sample (1-40 µl) at 1150°C in Ar/O2-mixture with optimum NO yield. Injection of 10 ml gaseous samples in a few seconds. After gas drying NO detection with highly sensititve chemiluminescence detection (CLD) with integrated vacuum pump. Working range N: < 0.1 - 1000 ppm Precision at 10 ppm: < 3 % rel. Detection limit: approx. 60 ppb PC autosampler chemiluminescence detector 100 µl-syringe manual gas injection carrier gas supply septumfree injection port MFC drying combustion tube furnace vario TRACE S liquid injection Analyzer for trace concentrations of sulfur in mineral oils acc. to ASTM D 5453 and D 6667. Combustion of the injected sample (1-80 µl) at 1150°C in synthetic air with optimum SO2 yield. Injection of 10 ml gaseous samples. After gas drying collection of the formed SO2 at an adsorption trap. Release of the SO2 by heating of the trap column results in a sharp peak and separation of interfering gases like CO2. SO2 detection by means of a highly sensitive UVfluorescence detector with integrated vacuum pump. Working range S: < 0.1 - 1000 ppm Precision at 10 ppm: < 2 % rel. Detection limit: approx. 10 ppb PC autosampler carrier gas supply UVflourescence detector 100 µl-syringe manual gas injection septumfree injection port MFC SO2 adsorber drying combustion tube furnace MFC PC UVflourescencedetector 100 µl-syringe manual gas injection drying furnace with 2 combustion tubes MFC SO2 adsorber drying manual gas injection carrier gas supply chemiluminescence detector autosampler 2 septumfree injection ports Analyzer for trace concentrations of sulfur and nitrogen in mineral oils acc. to ASTM D 4629, D 5453, D 6667. In one compact instrument 2 complete digestion and detection channels for S and N are integrated. This serves for optimum operation conditions respectively analytical performance of two special instruments in one combination instrument (patent applied for). Injection takes place in sequential mode within a short period of time from one automatic sampler position into two injection ports. Additional manual gas injection possible. Working range S and N: < 0.1 - 1000 ppm Precision at 1 ppm: S < 2 % rel., N < 3 % rel. Detection limit: S approx. 10 ppb, N approx. 60 ppb carrier gas supply vario TRACE S/N liquid injection Performance decides vario elemental analyses for mineral oil analysis Instrument Sample Volume C% H% vario EL CHN liquid injection mineral oil 10 µl 86.59 86.58 86.59 86.54 13.44 13.44 13.44 13.44 vario EL CHNS liquid injection synthetic sample (tme 23200) 10 µl 85.70 85.66 85.67 85.59 10.99 11.05 11.24 11.34 vario EL O mode liquid injection butylacetate 10 µl vario TRACE N liquid injection gasoline 40 µl 1.99 ppm 1.95 ppm 1.94 ppm oil 40 µl 284.1 ppm 282.6 ppm 283.7 ppm decaline toluene based standard 0.15 ppm 80 µl 80 µl 0.097 ± 0.003 ppm 0.145 ± 0.006 ppm gasoline 95 diesel 80 µl 80 µl 14.65 ± 0.19 ppm 29.94 ± 0.38 ppm butane I butane II propane I 10 ml 10 ml 10 ml 0.34 ± 0.015 ppm 0.24 ± 0.015 ppm 0.09 ± 0.01 ppm vario TRACE S liquid injection gas injection S% 1.748 1.754 1.750 1.767 27.55 ± 0.16 % O (theor. 27.55 %) Issue: 7/2003. Subject to alterations. elementar Analysensysteme GmbH Donaustrasse 7 · D-63452 Hanau Telefon: +49 (0) 61 81- 9100- 0 Telefax: +49 (0) 61 81- 910010 Internet: http://www.elementar.de E-mail: info @ elementar.de N% ISO 9001 Nitrogen/Protein-Macro Analyzers · CHNOS Universal Analyzers TOC/TNb-Analyzers for Liquid and Solid Samples Schöniger Digestion units for halogens and other hetero atoms