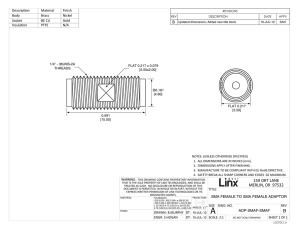

Guidelines for Shape-Memory Device Design Group Project EMSE 120 – Spring Semester 2021 Background: Shape-memory alloys (also called SMA’s) are a special family of “Smart” or “Functional” materials that have the ability to be easily deformed at room temperature and to return to a predetermined shape when heated above a “transformation temperature.” The unique properties of SMA’s, such as Nitanol, have led to their increased usage in a wide range of applications, including as actuators for smart systems in aerospace and automotive applications, in robotics, motors/engines, and biomedical devices such as cardiovascular stents, blood clot filters, etc.. Goal: The goal of this group (comprised of entire class) project is to design and build a device that utilizes the shape-memory alloy Nitanol in various forms (e.g., a loop of wire, wire formed in the shape of a spring) as a the key component to mechanically actuate the device, for example, a “motor” that drives the wheels of a vehicle, or the blades of a fan. Many examples of both of these types of SMA applications are shown on YouTube, in addition to several simple applications shown in class (shaping a word on a metal pegboard). Design Criteria The scope of possible devices can be broad, however, the following basic design criteria apply. 1) The device and its design should be sufficiently complex in terms of its actions and performance. 2) Assume the use of principally a standard 1mm (0.040”) diameter Nitanol wire with a transformation temperature of 45oC, as shown in the figure below (this was the material we purchased and from which successfully produced springs as shown in the YouTube video https://youtu.be/mkWVH8aRXDo using a shapesetting temperature of 500oC for 20 minutes.) 3) All components must be capable of being produced in ThinkBox using the 3D printers, machine shop, etc. 4) The total cost of the device/system exclusive of the SMA should be less than $250.00 Documentation/Reporting Requirements 1. A detailed schematic illustration of the device or system, using AutoDesk Sketchbook or ideally a CAD program, such as AutoDesk TinkerCad. Include illustrations of the device at various stages of operation as appropriate, and how the device operates through SMA activation. Prior to proceeding with CAD design work provide me with a sketch of your proposed design. Also include basic illustrations of auxiliary equipment required to operate the device (e.g., a container of hot water, system for resistance heating a SMA spring). 2. A description of the rationales that support the successful operation of the device and, in turn, any concerns regarding its successful operation. For example, as mentioned in class the forces provided by SMA-actuated components are at a level in which friction between components can be very important to operational efficiency and success. 3. A detailed description of device/system components including material type and information required for 3D printing or machining. Some components may also be purchased but the total cost needs to be below $250.00. 4. A detailed description of the SMA processing, including the shape-setting process, special fixturing, etc. 5. A PowerPoint presentation that includes the information above for presentation in class. Construction of Device The device should be fabricated using Nitanol wire provided in class and materials and fabrication equipment available in ThinkBox. The device will be demonstrated as part of your Powerpoint presentation. YouTube Videos on SMA Devices Nitanol Engine - https://youtu.be/q__7eemjc4U Nitanol Experiments and Devices – Google Rimstar Nitanol Devices and view images General Video on SMA’s - https://youtu.be/wI-qAxKJoSU General Video on SMA’s - https://youtu.be/yR-6_lS9vts SMA Butterfly - https://youtu.be/6lpWri1DOlY