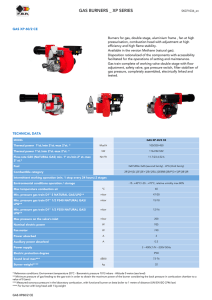

© BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY 1 We Deliver Energy Efficiency SPRAY CHARACTERISTICS AND COMBUSTION PERFORMANCE OF INDUSTRIAL BURNERS Spray Delivery and Combustion Systems Supplier for Industrial Applications Industrial Furnace Burners | Dust Suppression | Spray and Combustion Testing © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY 2 WEBINAR SESSION 1: INTRODUCTION TO COMBUSTION AND FURNACE BURNERS MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 3 Mr. Arindam Ghatak Founder and Managing Director IIT Kharagpur (BTech in Mechanical Engineering) The Ohio State University at Columbus (MS in Mechanical Engineering) 14+ years exp. incl. 10 years in upstream oil and gas industry in Houston, Texas Mechanical system design, project management © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY 4 AGENDA FOR SESSION 1 § Fundamentals of Combustion § Boiler and Burner Efficiency § Combustion Mechanisms § Furnace Burner Types § Flame Types and Characteristics MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 5 FUNDAMENTALS OF COMBUSTION SOLID FUELS GASIFICATION BY PYROLYSIS GASEOUS FUELS LIQUID FUELS GASIFICATION BY VAPORISATION MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 6 TYPES OF COMBUSTION STOICHIOMETRIC COMBUSTION (IDEAL SCENARIO, Φ = 1, λ = 1) INCOMPLETE COMBUSTION (RICH F/A MIXTURE, Φ > 1, λ < 1) Fuel-Air Equivalence Ratio, Air-Fuel Equivalence Ratio, λ = AFR / AFRst = 1/Φ COMPLETE COMBUSTION (LEAN F/A MIXTURE, Φ < 1, λ > 1) = FAR / FARst © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY 7 AIR / FUEL RATIO CxHy + a (O2 + 3.76 N2) -> x CO2 + y/2 H2O + 3.76a N2 a = x + y/4 Air-Fuel Stoichiometric Ratio, AFRst = a (32 + 3.76 x 28) / (12x + y) Air-Fuel Ratio, AFR = (1 + e) x AFRst where e = % Excess Combustion Air CxHy + a(1+e) (O2 + 3.76 N2) -> x CO2 + y/2 H2O + ae O2 + a(1+e)(3.76) N2 % Excess O2 by Volume in Flue Gas (Wet Basis) = ae / (x + y/2 + ae + 3.76a(1+e)) % Excess O2 by Volume in Flue Gas (Dry Basis) = ae / (x + ae + 3.76a(1+e)) § Therefore, using Emission Analyzer, % O2 in the flue gas can be measured to determine % excess combustion air MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 8 STOICHIOMETRIC AIR / FUEL RATIO Fuel Stoichiometric AFR (AFRst) AFRactual if Excess Air = 10% % Excess O2 (Dry Basis) in Exhaust Ethane (C2H6) 16.0 17.6 2.1% Diesel (C12H23) 14.6 16.1 2.0% Furnace Oil (C20H42 ~ C70H142) 14.7 ~ 14.8 16.2 ~ 16.3 2.0% © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY 9 BOILER LIFECYCLE COST § Installation of cutting edge equipment (CAPEX) and maintenance costs minimal, but impact energy cost enormously © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY 10 BURNER AND BOILER EFFICIENCY § Thermal efficiency determination methodology given in BS845-1:1987 A. More the excess combustion air, lower the boiler efficiency B. More the unburnt or incompletely burnt fuel, lower the combustion and boiler efficiency C. Higher the fuel and combustion air temperatures, higher the combustion efficiency D. Lower the stack temperature, higher the boiler efficiency (Net Stack Temperature = Stack Temperature – Combustion Air Temperature) © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY 11 MINIMIZE STACK TEMPERATURE REDUCE SCALING AND SOOT LOSSES § Every rise of 6°C in boiler feed water § Every milimeter thickness of soot coating temperature through waste heat recovery would offer about 1% fuel savings § For every reduction in flue gas temperature by 22°C for heat recovery, fuel savings of about 1% can be achieved Source: https://www.slideshare.net/MagdyAly2/5-energy-efficiency-opportunities-in-boilers increases the stack temperature by 55°C § A deposit of 3mm of soot can cause an increase in fuel consumption by 2.5% § A 1mm thick scale (deposit) on the water side could increase fuel consumption by 5% to 8% MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 12 MINIMIZE HEAT LOSS FROM BOILER INSULATION § Expected saving of up to 5% of fuel consumption to the boiler § Running boiler with deteriorated thermal insulation will lead to high fuel consumption and high thermal losses Source: https://www.slideshare.net/MagdyAly2/5-energy-efficiency-opportunities-in-boilers © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY 13 REDUCE EXCESS AIR AVOID INCOMPLETE COMBUSTION § To minimize escape of heat through flue gases, § Incomplete combustion can arise from reduce excess air to reach 2 – 3% O2 at the flue gas § Every 1% reduction in excess O2 increases boiler efficiency by 1% Source: https://www.slideshare.net/MagdyAly2/5-energy-efficiency-opportunities-in-boilers shortage of air or poor distribution of fuel © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY 14 MECHANISMS OF LIQUID FUEL SPRAY COMBUSTION © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY 15 MECHANISMS OF LIQUID FUEL SPRAY COMBUSTION § Smaller the spray droplets, faster is the combustion § Better the fuel-air mixing, more uniform and efficient is the combustion Source: Chiu and Croke (1981) MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 16 MECHANISMS OF GASEOUS FUEL COMBUSTION Nozzle Mix Burner: Flames from co-flow burner; fuel is supplied through core pipe and oxidizer through the annular region Premix Burner: Atmospheric partially aerated burner Source: Combustion technology: essentials of flames and burners © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY 17 BURNER TYPES AND CONSTRUCTION On the basis of fuel, four main types of burners are in common use: On the Basis of Construction, two main types of burner in common use: § Gaseous Fuel Burner § Monobloc burners § Liquid Fuel Burner § Dualbloc burners § Solid Fuel Burner § Dual / Combination Fuel Burner Source: ISH MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 18 GASEOUS FUEL BURNER NOZZLE MIX GAS BURNER PREMIXED GAS BURNER LOW NOX STAGED AIR NOZZLE MIX GAS BURNER Source: API RP 535:2014 MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 19 LIQUID FUEL BURNER Nozzle Assembly Fuel Pipe Atomizing Air Pipe Combustion Air Pipe Fuel Supply Line Interface © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY 20 DUAL / COMBINATION FUEL BURNER OIL AND GAS COMBINATION BURNER LOW NOX STAGED AIR COMBINATION BURNER Source: API RP 535:2014 MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 21 FURNACE BURNER SETUP Accessories Include: § Air compressor for atomizing air (optional) Furnace Wall Compressor (Atomizing Air) § Steam generator for atomizing steam (optional) Fuel Pump § Centrifugal fan for combustion air § Heat exchanger (recuperator) for flue gas heat recovery Fuel Tank Bricks Furnace Burner Air Heater (Recuperator) Centrifugal Fan (Combustion Air) Conveyor Belt § Fuel pump and heated (optional) storage tank MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 22 BURNER FLAME TYPES Source: https://www.ispatguru.com/burners-and-flames-in-industrial-furnaces/ Flame Type A Feather shaped flame with no swirl Flame Type F Long luminous and lazy flame C Ball shaped with substantial swirl G Long luminous flame with a ‘fire hose’ appearance E Flat Flame H Flame with high velocity and low swirl MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 23 BURNER FLAME CHARACTERISTICS § Flame dimensions (length and diameter) are governed by heating requirement § More the fuel flow rate (burner power output), longer will be the flame (~2.5m/MW for low NOx burners) § More the fuel-air mixture swirl, smaller the flame length, larger the flame diameter § Faster the combustion, smaller the flame dimensions, higher the flame temperature, more the chances of NOx generation § Staged air low NOx burners have larger flame dimensions TURBULENT FLAMES Source: Combustion technology: essentials of flames and burners LAMINAR FLAMES © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY 24 ASSIGNMENT If a fuel droplet of diameter, D, is atomized into droplets of diameter, D/4, then find the following: § How many droplets has this large droplet broken down into ? Ans: 64 § What is the ratio of the new cumulative surface area to the surface area of the large droplet ? Ans: 4 MISSION: HELP INDUSTRIES ACHIEVE ENERGY AND ENVIRONMENTAL SUSTAINABILITY VISION: MAKE INDIA THE MOST ENERGY EFFICIENT COUNTRY GLOBALLY © BNG SPRAY SOLUTIONS PRIVATE LIMITED, 2020 25 THANK YOU contactus@bngspraysolutions.com | +91 91139 97209 | +91 94871 52586 | http://bngspraysolutions.com #69/2, N.R.Nivas (Behind KK Bakery), Raghavendra Temple Road, Sharadamba Nagar, Jalahalli, Bengaluru 560013 Karnataka, India REGISTRATION NO CIN DIPP No KBITS No GSTIN 115962 U29309KA2018PTC115962 29309 KBITS/SK-REGN/2018-19/943 29AAHCB9798C1Z3